differential AUDI A4 1999 B5 / 1.G 01V Transmission Drive Pinion And Ring Gear Adjust Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A4, Model: AUDI A4 1999 B5 / 1.GPages: 38, PDF Size: 0.52 MB

Page 5 of 38

39-169

Gear set, adjustment sequence

If drive pinion and gear ring have to be adjusted,

the following sequence is recommended for

maximum efficiency:

1.) Determine total shim thickness "Stot"for S1 +

S2 for the specified pre-tension of tapered

roller bearings for differential.

2.) Determine total shim thickness "S3" so that

the drive pinion is installed in the same

location as on the test machine during

production.

3.) Distribute total shim thickness Stotal S1 +

S2, so that the specified backlash between

ring gear and drive pinion is maintained.

Note:

Overview of components and adjustment shims

page 39

-171

.

Pa

ge 5 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 6 of 38

39-170

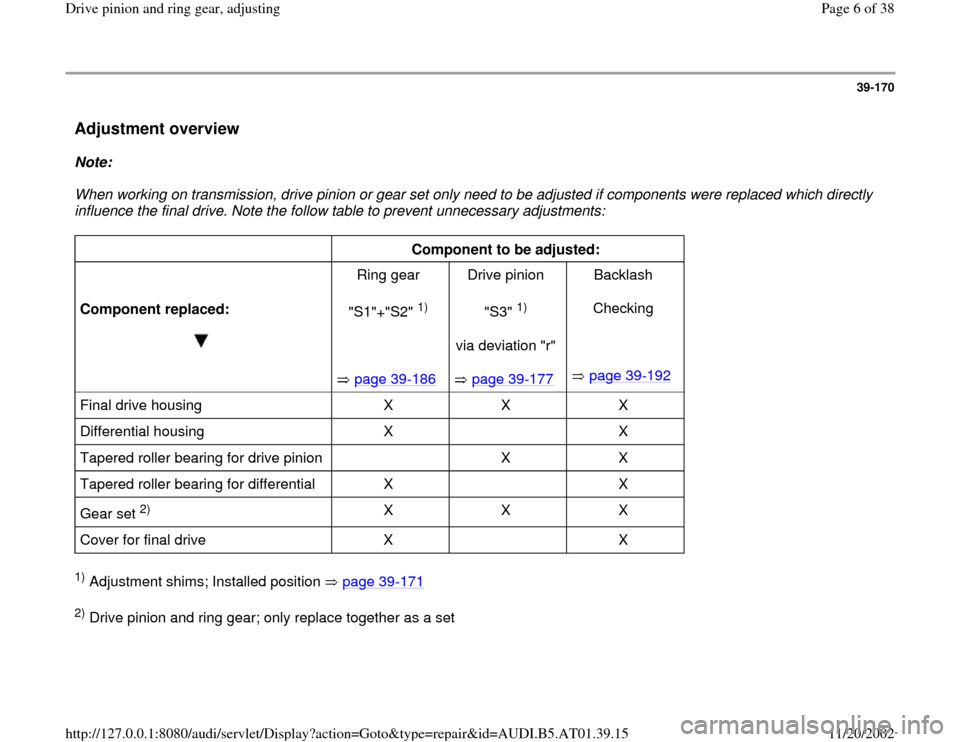

Adjustment overview

Note:

When working on transmission, drive pinion or gear set only need to be adjusted if components were replaced which directly

influence the final drive. Note the follow table to prevent unnecessary adjustments:

Component to be adjusted:

Component replaced:

Ring gear

"S1"+"S2"

1)

page 39

-186

Drive pinion

"S3"

1)

via deviation "r"

page 39-177

Backlash

Checking

page 39

-192

Final drive housing X X X

Differential housing X X

Tapered roller bearing for drive pinion X X

Tapered roller bearing for differential X X

Gear set

2)

X X X

Cover for final drive X X

1) Adjustment shims; Installed position page 39

-171

2) Drive pinion and ring gear; only replace together as a set

Pa

ge 6 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 7 of 38

39-171

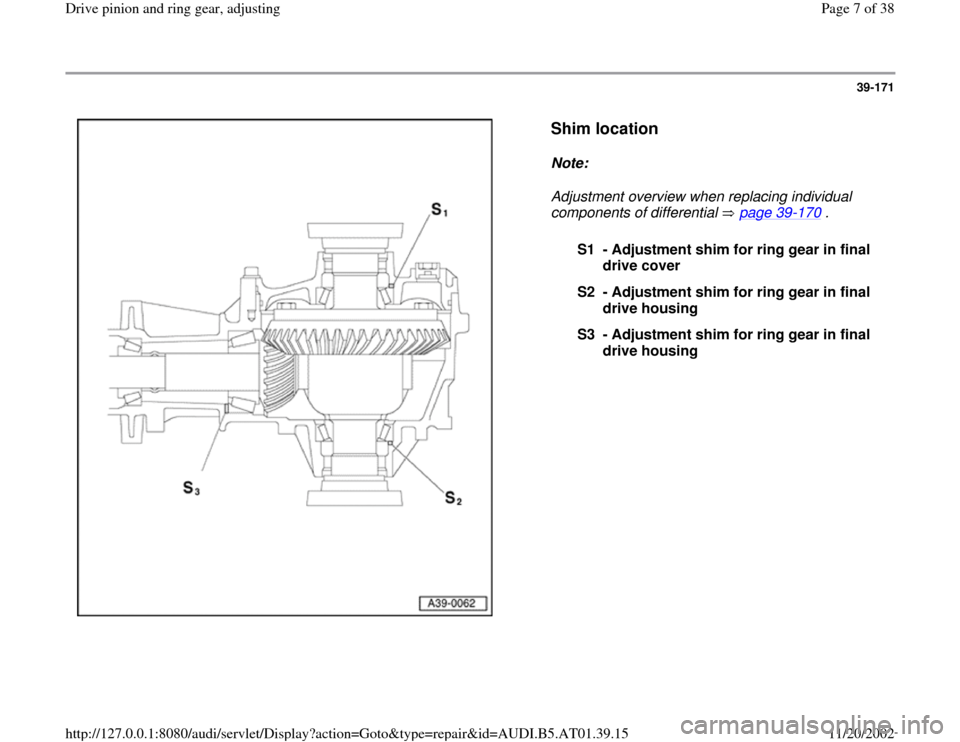

Shim location

Note:

Adjustment overview when replacing individual

components of differential page 39

-170

.

S1 - Adjustment shim for ring gear in final

drive cover

S2 - Adjustment shim for ring gear in final

drive housing

S3 - Adjustment shim for ring gear in final

drive housing

Pa

ge 7 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 18 of 38

39-181

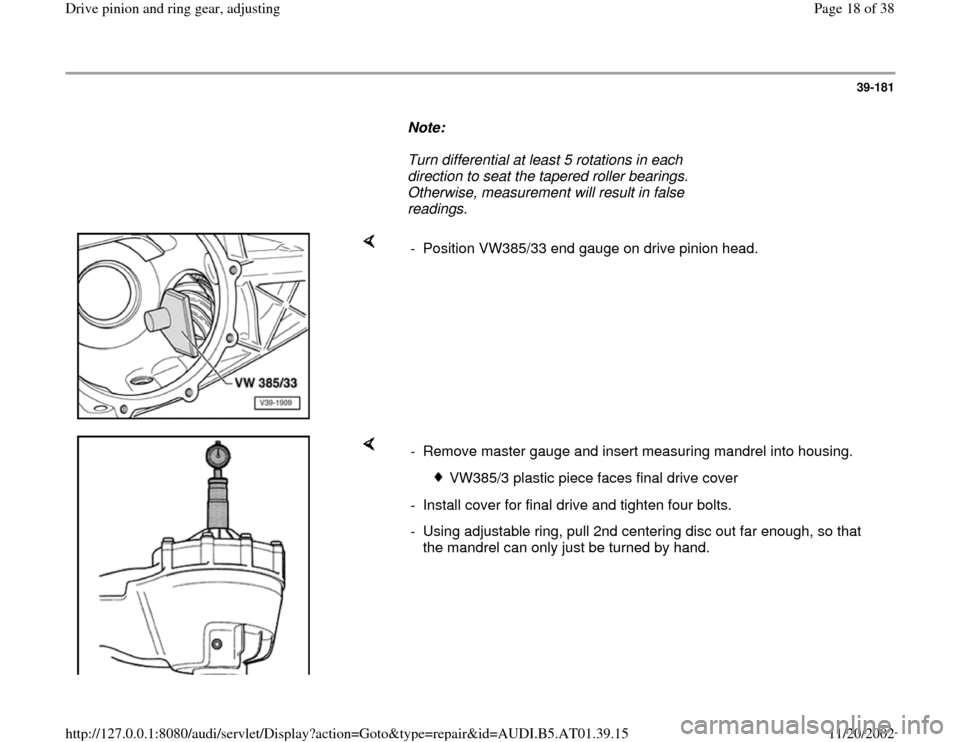

Note:

Turn differential at least 5 rotations in each

direction to seat the tapered roller bearings.

Otherwise, measurement will result in false

readings.

- Position VW385/33 end gauge on drive pinion head.

- Remove master gauge and insert measuring mandrel into housing.

VW385/3 plastic piece faces final drive cover

- Install cover for final drive and tighten four bolts.

- Using adjustable ring, pull 2nd centering disc out far enough, so that

the mandrel can only just be turned by hand.

Pa

ge 18 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 24 of 38

39-186

Ring gear, adjusting

(Adjusting differential)

Procedures after which the ring gear must be

adjusted Adjustment overview page 39

-

170

.

Notes:

Tapered roller bearings for differential are low-

friction bearings. Therefore friction torque can

only be used for check measurement in a

limited way. A correct adjustment is only

possible by determining the total thickness

"Sges".

Do not grease new tapered roller bearings

additionally for friction torque measurement.

The bearings are already greased with a

special oil from the factory.

Total shim thickness "Stotal" for adjustment

shims "S1" + "S2", determining

(adjust preload of tapered roller bearing for

differential)

Drive pinion removed or ring gear detached

from differential housing

Pa

ge 24 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 25 of 38

- Pry out drive flange seal using tire iron.

- Remove tapered roller bearings for differential

and remove adjustment shims page 39

-136

.

Pa

ge 25 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 26 of 38

39-187

- Press tapered roller bearing outer race for left

side of differential housing (housing side)

together with shim "S2" into differential housing

Page 39

-144

. Use a shim "S2*" with a 1.00

mm thickness for measurement purposes (1

shims with 0.80 and 1 with 0.20 mm).

Note:

All measurements are performed with shim S2

with 1.00 mm thickness. The shim will be

indicated by "S2*" in the following procedures.

After determining backlash, S2* is replaced by

final shim S2.

- Press in tapered roller bearing outer race for

right side (cover side) of differential without

adjustment shims to stop Fig. 8

, page 39

-

136

.

- Insert differential in housing. Ring gear is on the

right side (cover side).

- Install cover and tighten bolts to 25 Nm.

- Install VW521/4 locking sleeve and 521/8 sleeve press tool into

differential housing on housing side.

- Rotate cover side of differential housing upward.

Pa

ge 26 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 27 of 38

39-188

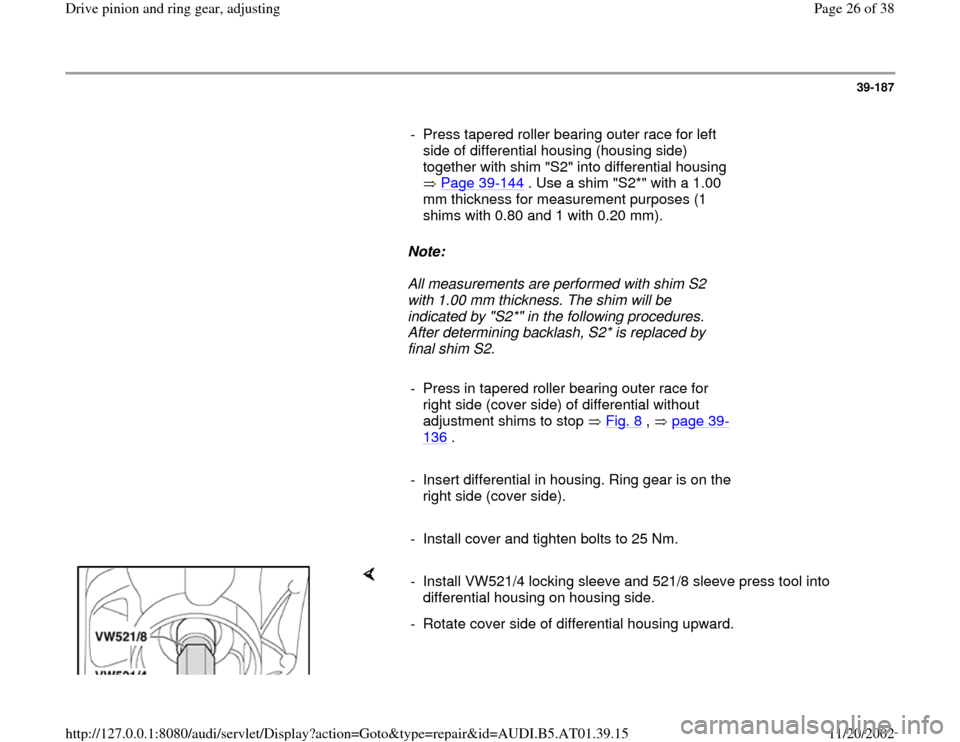

- Turn differential 5 rotations in each direction to

seat the tapered roller bearing.

- Place VW385/17 magnetic plate onto

differential.

- Install measuring tools.

A - Dial gauge extension approx. 30 mm long

B - Hex bolt M8 x 45

- Set dial gauge extension onto center of VW 385/17 magnetic plate.

- Set dial indicator (3 mm measuring range) to 0 with 2 mm preload.

Note:

If measurement is repeated, differential must first be rotated 5 complete

revolutions in both directions again to seat tapered roller bearing. - Lift the differential without turning it, read play on dial indicator and

note.

Measured value in the following example: 0.50 mm

Pa

ge 27 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 30 of 38

39-191

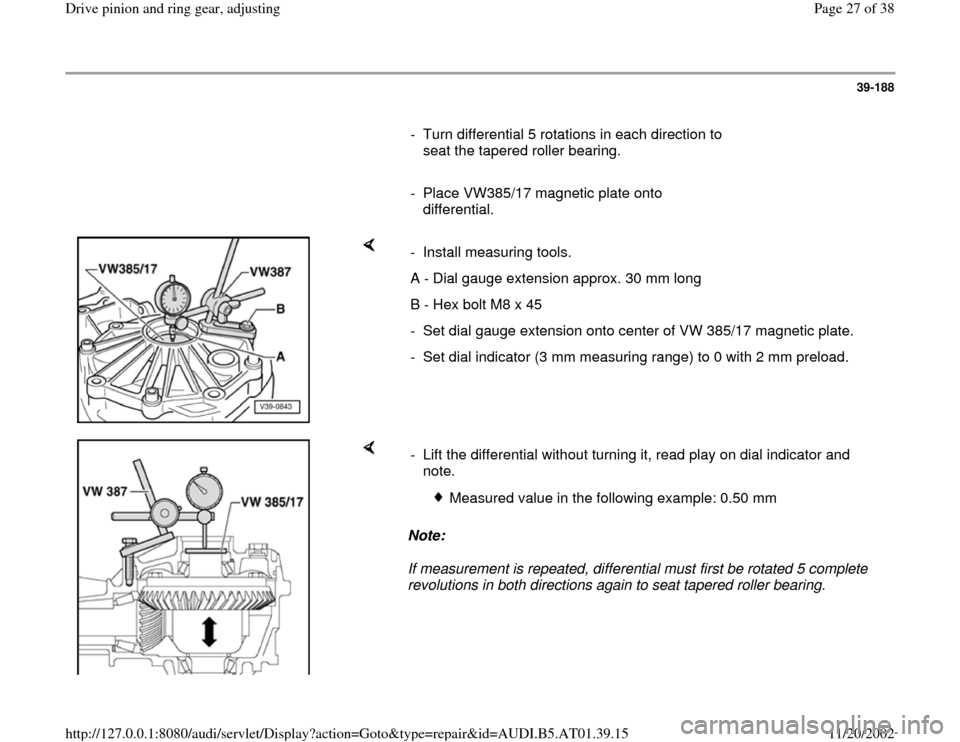

Measuring friction torque (check

measurement)

Drive pinion removed

Differential installed with shims "S1*" and

"S2*"

Friction torque specified values: 1) have been run in at least 50 km

Notes: - Position torque gauge 0 to 600 Ncm -A- on differential.

- Read friction torque.New bearings

Run-in bearings

1)

150 to 300 Ncm 30 to 60 Ncm

Tapered roller bearings for differential are low-friction bearings.

Therefore friction torque can only be used for check measurement in a

limited way. A correct adjustment is only possible by determining the

total thickness "Sges". Do not grease new tapered roller bearings additionally for friction

torque measurement. The bearings are already greased with a special

oil from the factory. For a new adjustment of the gear set, the drive pinion adjustment

Pa

ge 30 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

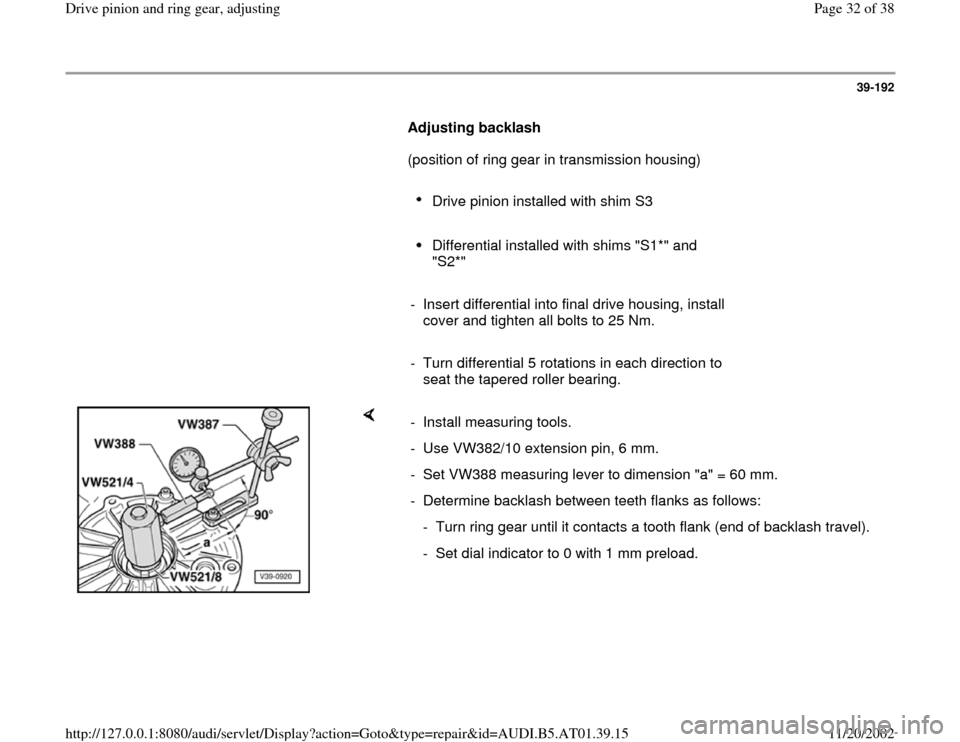

Page 32 of 38

39-192

Adjusting backlash

(position of ring gear in transmission housing)

Drive pinion installed with shim S3

Differential installed with shims "S1*" and

"S2*"

- Insert differential into final drive housing, install

cover and tighten all bolts to 25 Nm.

- Turn differential 5 rotations in each direction to

seat the tapered roller bearing.

- Install measuring tools.

- Use VW382/10 extension pin, 6 mm.

- Set VW388 measuring lever to dimension "a" = 60 mm.

- Determine backlash between teeth flanks as follows:

- Turn ring gear until it contacts a tooth flank (end of backlash travel).

- Set dial indicator to 0 with 1 mm preload.

Pa

ge 32 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15