brake pads CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1396 of 1903

Downloaded from www.Manualslib.com manuals search engine BRAKES

12

CONTENTSpage

Base Brakes ........................................................................\

. 12-1

Antilock Brakes ..................................................................... 12-34

Parking Brake ...................................................................... 12-79

BASE BRAKES

GENERAL INFORMATION12-2

Description 12-2

Operation 12-3

Specifications 12-4

Special Tools 12-5

Electrical Schematics 12-6

DIAGNOSIS & TESTING12-7

Diagnostic Help 12-7

Brake Noise 12-7

Braking Concerns 12-8

ON-VEHICLE SERVICE12-9

Brake Bleeding 12-9

Brake Bleeding Information 12-9

Brake Bleeding Procedure 12-9

Manual Brake Bleeding 12-9

Pressure Brake Bleeding 12-10

Master Cylinder - LHD 12-11

Description 12-11

Operation 12-11

Removal & Installation 12-11

Master Cylinder - RHD 12-12

Description 12-12

Operation 12-13

Removal & Installation 12-13

Power Brake Booster - LHD 12-14

Description 12-14

Operation 12-14

Removal & Installation 12-14

Power Brake Booster - RHD 12-16

Description 12-16

Operation 12-16

Removal & Installation 12-16Front Brake Caliper

12-18

Description 12-18

Operation 12-18

Removal & Installation 12-19

Rear Brake Caliper 12-19

Description 12-19

Operation 12-20

Removal & Installation 12-20

Front Brake Rotor 12-21

Removal & Installation 12-21

Inspection 12-21

Rear Brake Rotor 12-22

Removal & Installation 12-22

Inspection 12-22

Rear Brake Backing Plate 12-23

Removal & Installation 12-23

Front Brake Pads 12-24

Removal & Installation 12-24

Inspection 12-25

Rear Brake Pads 12-25

Removal & Installation 12-25

Inspection 12-26

UNIT REPAIR12-27

Front Brake Caliper 12-27

Disassemble 12-27

Inspection 12-28

Assemble 12-28

Rear Brake Caliper 12-30

Disassemble 12-30

Inspection 12-31

Assemble 12-32

12

12–1Chery Automobile Co., Ltd.

Page 1397 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

Base Brakes

The base brake system consists of the following components:

•Brake pedal

• Power brake booster

• Master cylinder

• Brake tubes and hoses

• Disc brakes (front)

• Disc brakes (rear)

• Parking brake

• Parking brake shoes (rear)

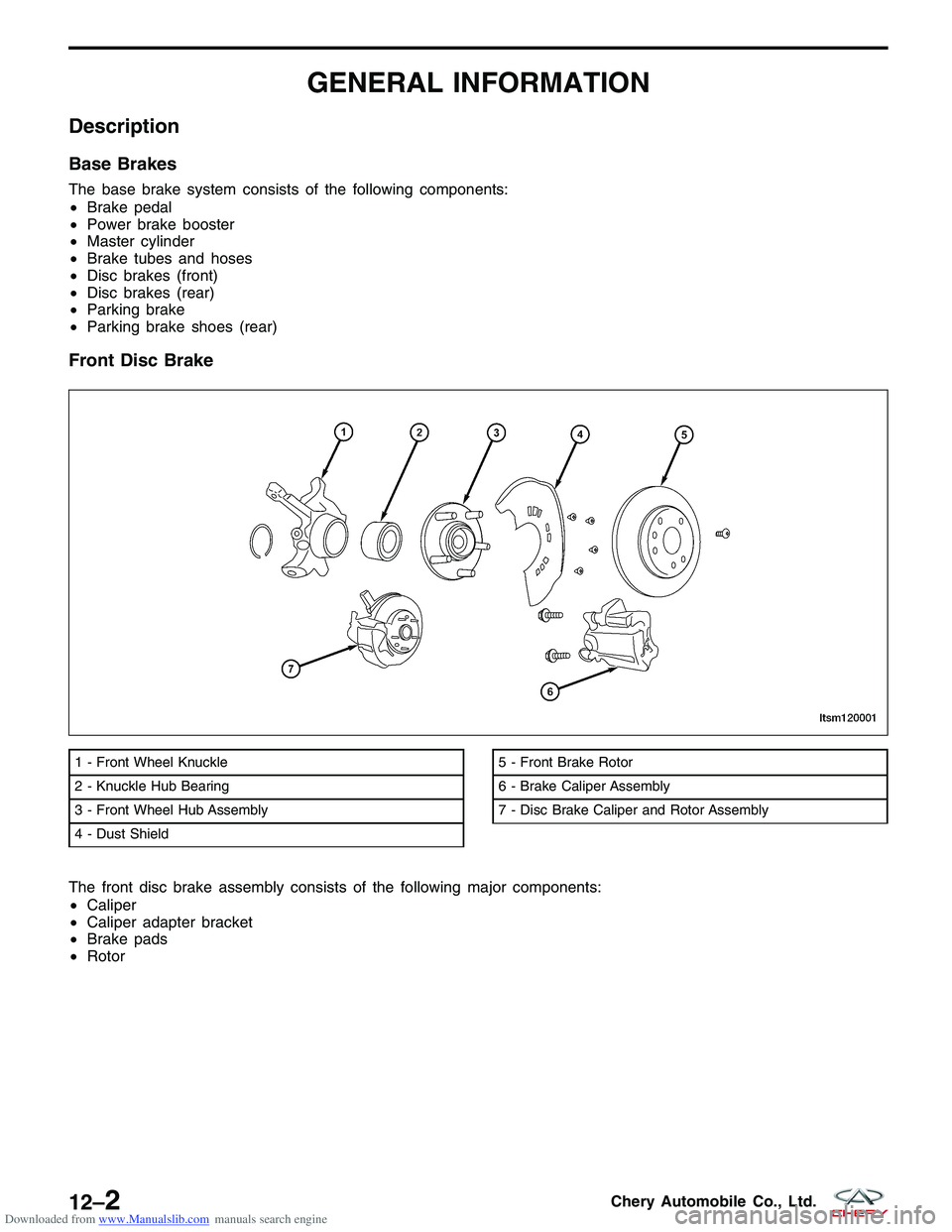

Front Disc Brake

The front disc brake assembly consists of the following major components:

•Caliper

• Caliper adapter bracket

• Brake pads

• Rotor

1 - Front Wheel Knuckle

2 - Knuckle Hub Bearing

3 - Front Wheel Hub Assembly

4 - Dust Shield5 - Front Brake Rotor

6 - Brake Caliper Assembly

7 - Disc Brake Caliper and Rotor Assembly

LTSM120001

12–2Chery Automobile Co., Ltd.

Page 1398 of 1903

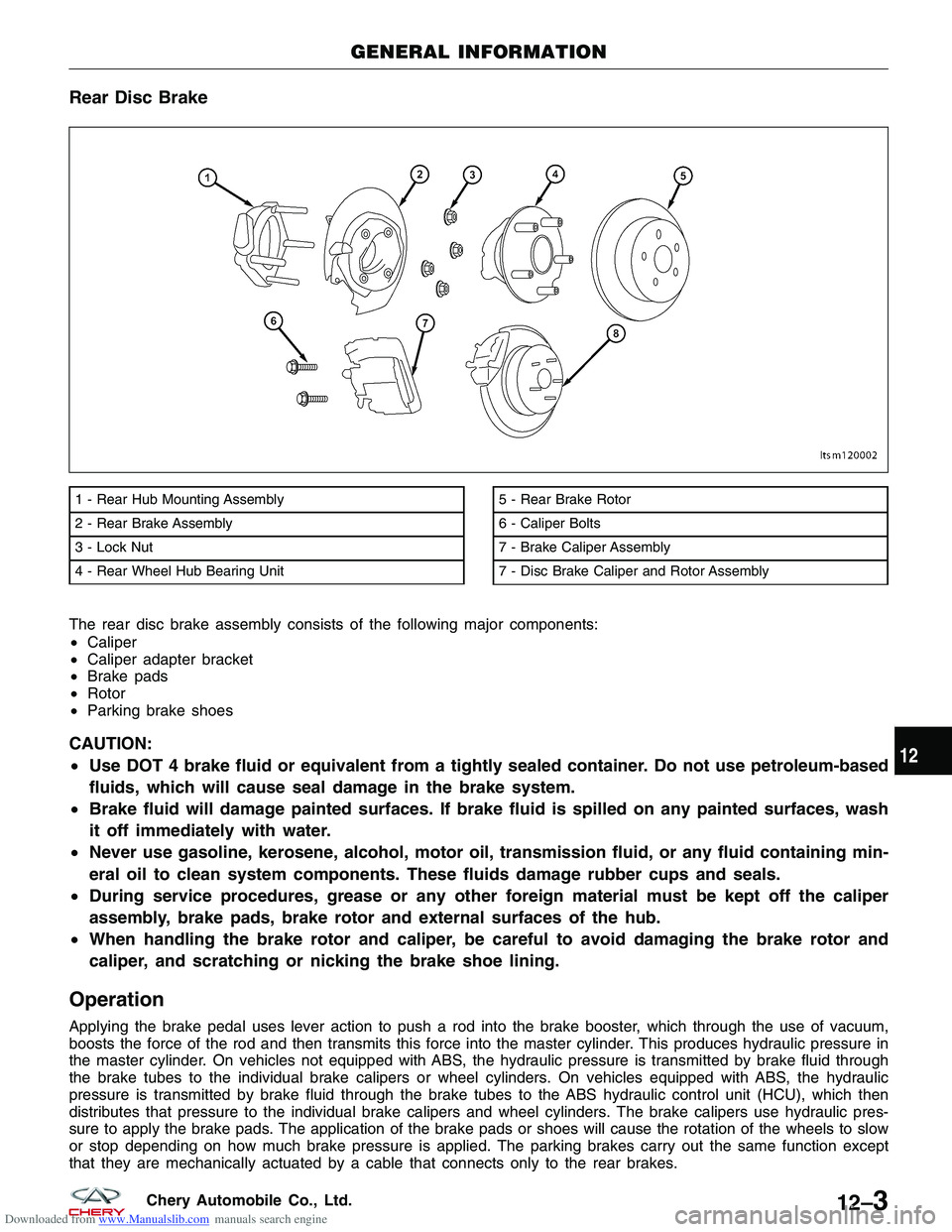

Downloaded from www.Manualslib.com manuals search engine Rear Disc Brake

The rear disc brake assembly consists of the following major components:

•Caliper

• Caliper adapter bracket

• Brake pads

• Rotor

• Parking brake shoes

CAUTION:

•Use DOT 4 brake fluid or equivalent from a tightly sealed container. Do not use petroleum-based

fluids, which will cause seal damage in the brake system.

• Brake fluid will damage painted surfaces. If brake fluid is spilled on any painted surfaces, wash

it off immediately with water.

• Never use gasoline, kerosene, alcohol, motor oil, transmission fluid, or any fluid containing min-

eral oil to clean system components. These fluids damage rubber cups and seals.

• During service procedures, grease or any other foreign material must be kept off the caliper

assembly, brake pads, brake rotor and external surfaces of the hub.

• When handling the brake rotor and caliper, be careful to avoid damaging the brake rotor and

caliper, and scratching or nicking the brake shoe lining.

Operation

Applying the brake pedal uses lever action to push a rod into the brake booster, which through the use of vacuum,

boosts the force of the rod and then transmits this force into the master cylinder. This produces hydraulic pressure in

the master cylinder. On vehicles not equipped with ABS, the hydraulic pressure is transmitted by brake fluid through

the brake tubes to the individual brake calipers or wheel cylinders. On vehicles equipped with ABS, the hydraulic

pressure is transmitted by brake fluid through the brake tubes to the ABS hydraulic control unit (HCU), which then

distributes that pressure to the individual brake calipers and wheel cylinders. The brake calipers use hydraulic pres-

sure to apply the brake pads. The application of the brake pads or shoes will cause the rotation of the wheels to slow

or stop depending on how much brake pressure is applied. The parking brakes carry out the same function except

that they are mechanically actuated by a cable that connects only to the rear brakes.

1 - Rear Hub Mounting Assembly

2 - Rear Brake Assembly

3 - Lock Nut

4 - Rear Wheel Hub Bearing Unit5 - Rear Brake Rotor

6 - Caliper Bolts

7 - Brake Caliper Assembly

7 - Disc Brake Caliper and Rotor Assembly

GENERAL INFORMATION

LTSM120002

12

12–3Chery Automobile Co., Ltd.

Page 1402 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Diagnostic Help

Brake diagnosis involves determining if the concern is related to a mechanical, hydraulic, electrical or vacuum oper-

ated component.

NOTE :

The brake reservoir fluid level will decrease in proportion to normal lining wear.

NOTE :

Brake fluid tends to darken over time. This is normal and should not be mistaken for contamination.

Preliminary Brake Check:

•Check the condition of the tires and wheels. Damaged wheels and worn, damaged or under inflated tires can

cause a pull, shudder, vibration and a condition similar to brake grab.

• If a complaint was based on noise while braking, check the suspension components. Jounce the front and the

rear of vehicle and listen for anything that might be caused by a loose, worn or damaged suspension or steer-

ing component.

• Inspect the brake fluid level and condition.

1. If the fluid level is abnormally low, look for any evidence of leaks at the calipers, brake lines, master cyl-

inder and at the Antilock Brake System (ABS) Hydraulic Control Unit (HCU).

2. If the fluid appears to be contaminated, drain a sample to examine.

• The system will have to be flushed if the fluid is separated into layers, or contains a substance other than

brake fluid. The system seals, cups, hoses, master cylinder and HCU will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

• Check the parking brake operation. Verify free movement and full release of the cables and the lever. Also note

if the vehicle was being operated with the parking brake partially applied.

• Check the brake pedal operation. Verify that the pedal does not bind and has adequate free play. If the pedal

lacks free play, check the pedal and the power booster for looseness or for a binding condition. DO NOT road

test the vehicle until the condition is located and corrected.

• Check the vacuum booster check valve and vacuum supply hose.

• If the preliminary checks appear to be OK, road test the vehicle.

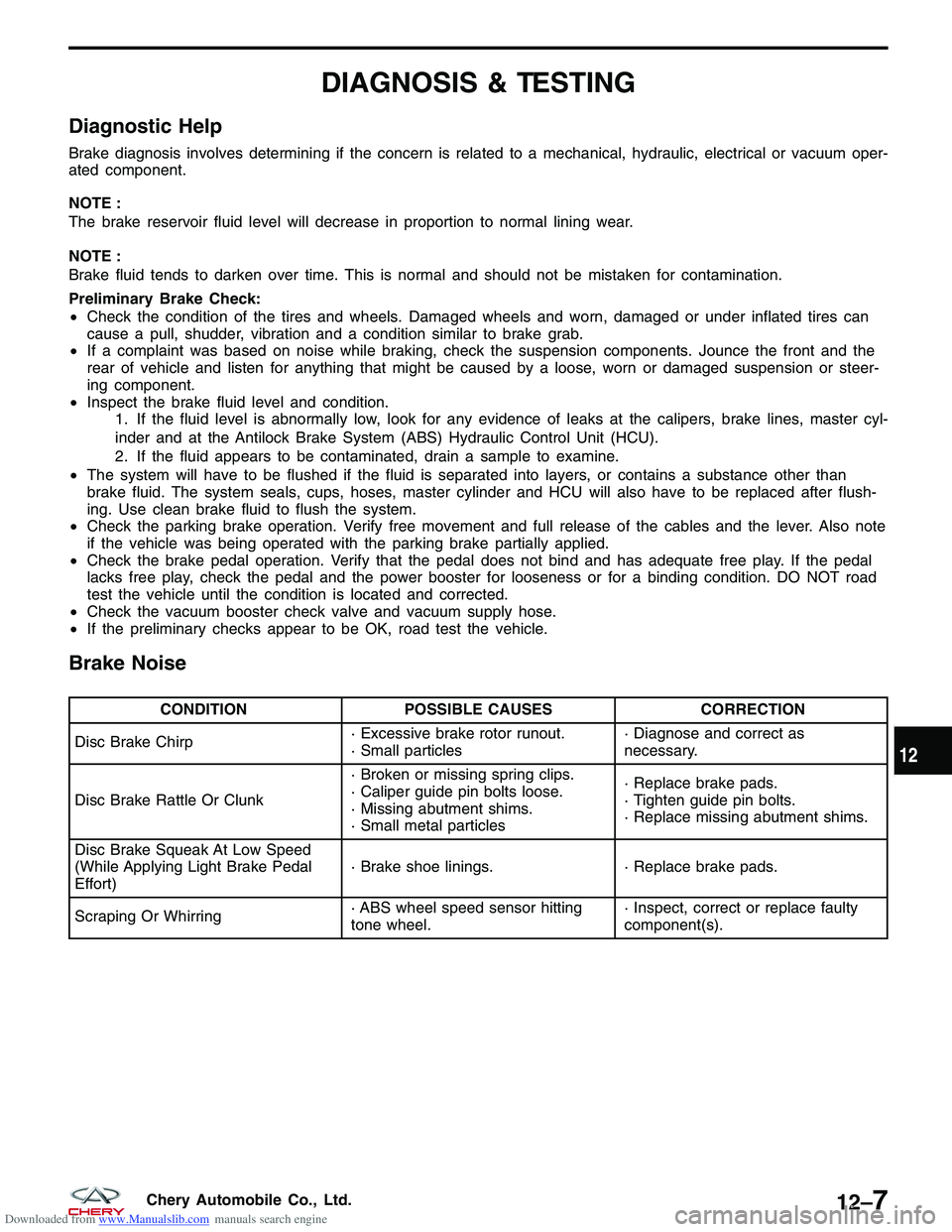

Brake Noise

CONDITION POSSIBLE CAUSES CORRECTION

Disc Brake Chirp · Excessive brake rotor runout.

· Small particles· Diagnose and correct as

necessary.

Disc Brake Rattle Or Clunk · Broken or missing spring clips.

· Caliper guide pin bolts loose.

· Missing abutment shims.

· Small metal particles· Replace brake pads.

· Tighten guide pin bolts.

· Replace missing abutment shims.

Disc Brake Squeak At Low Speed

(While Applying Light Brake Pedal

Effort) · Brake shoe linings.

· Replace brake pads.

Scraping Or Whirring · ABS wheel speed sensor hitting

tone wheel.· Inspect, correct or replace faulty

component(s).

12

12–7Chery Automobile Co., Ltd.

Page 1403 of 1903

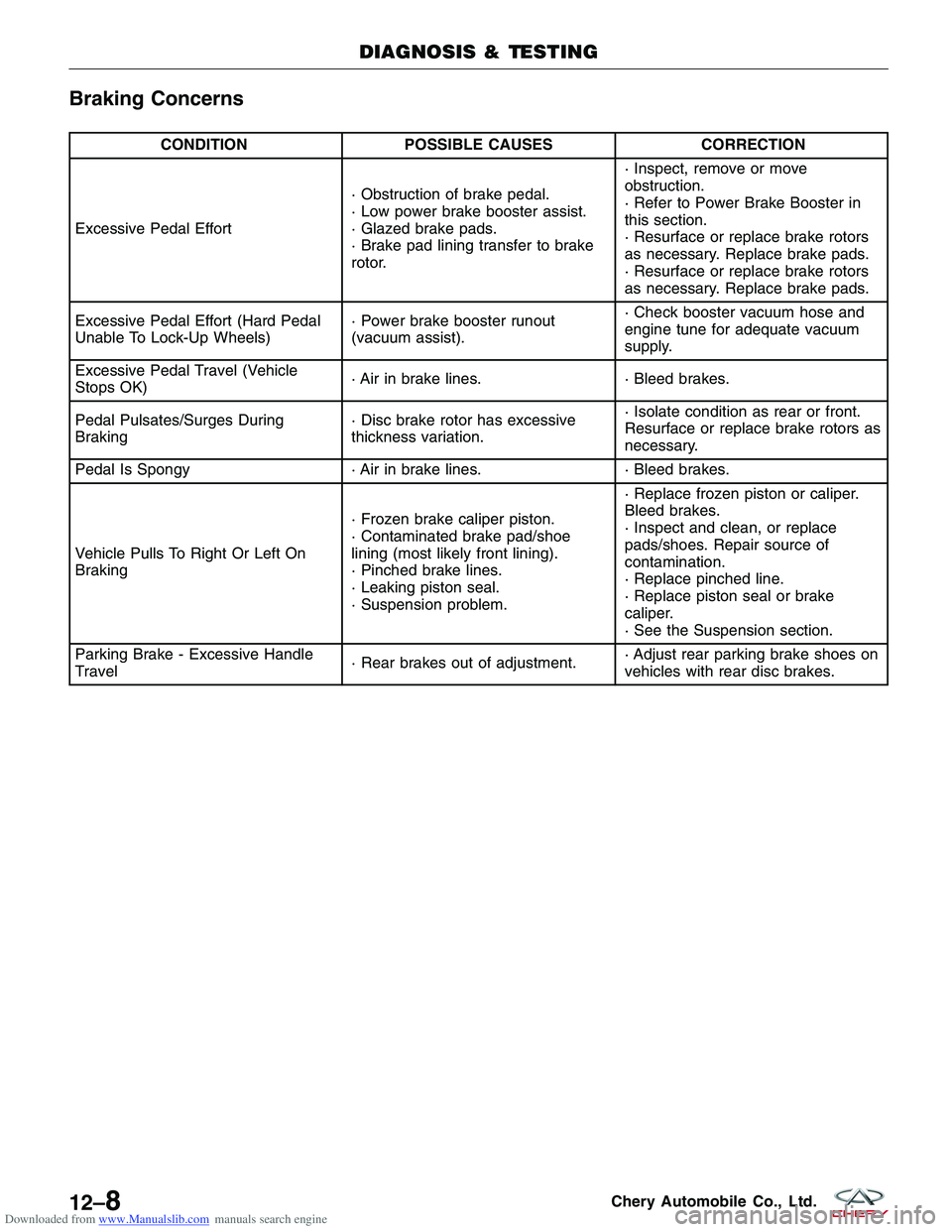

Downloaded from www.Manualslib.com manuals search engine Braking Concerns

CONDITIONPOSSIBLE CAUSES CORRECTION

Excessive Pedal Effort · Obstruction of brake pedal.

· Low power brake booster assist.

· Glazed brake pads.

· Brake pad lining transfer to brake

rotor.· Inspect, remove or move

obstruction.

· Refer to Power Brake Booster in

this section.

· Resurface or replace brake rotors

as necessary. Replace brake pads.

· Resurface or replace brake rotors

as necessary. Replace brake pads.

Excessive Pedal Effort (Hard Pedal

Unable To Lock-Up Wheels) · Power brake booster runout

(vacuum assist).· Check booster vacuum hose and

engine tune for adequate vacuum

supply.

Excessive Pedal Travel (Vehicle

Stops OK) · Air in brake lines.

· Bleed brakes.

Pedal Pulsates/Surges During

Braking · Disc brake rotor has excessive

thickness variation.· Isolate condition as rear or front.

Resurface or replace brake rotors as

necessary.

Pedal Is Spongy · Air in brake lines.· Bleed brakes.

Vehicle Pulls To Right Or Left On

Braking · Frozen brake caliper piston.

· Contaminated brake pad/shoe

lining (most likely front lining).

· Pinched brake lines.

· Leaking piston seal.

· Suspension problem.· Replace frozen piston or caliper.

Bleed brakes.

· Inspect and clean, or replace

pads/shoes. Repair source of

contamination.

· Replace pinched line.

· Replace piston seal or brake

caliper.

· See the Suspension section.

Parking Brake - Excessive Handle

Travel · Rear brakes out of adjustment.· Adjust rear parking brake shoes on

vehicles with rear disc brakes.

DIAGNOSIS & TESTING

12–8Chery Automobile Co., Ltd.

Page 1416 of 1903

Downloaded from www.Manualslib.com manuals search engine Front Brake Rotor

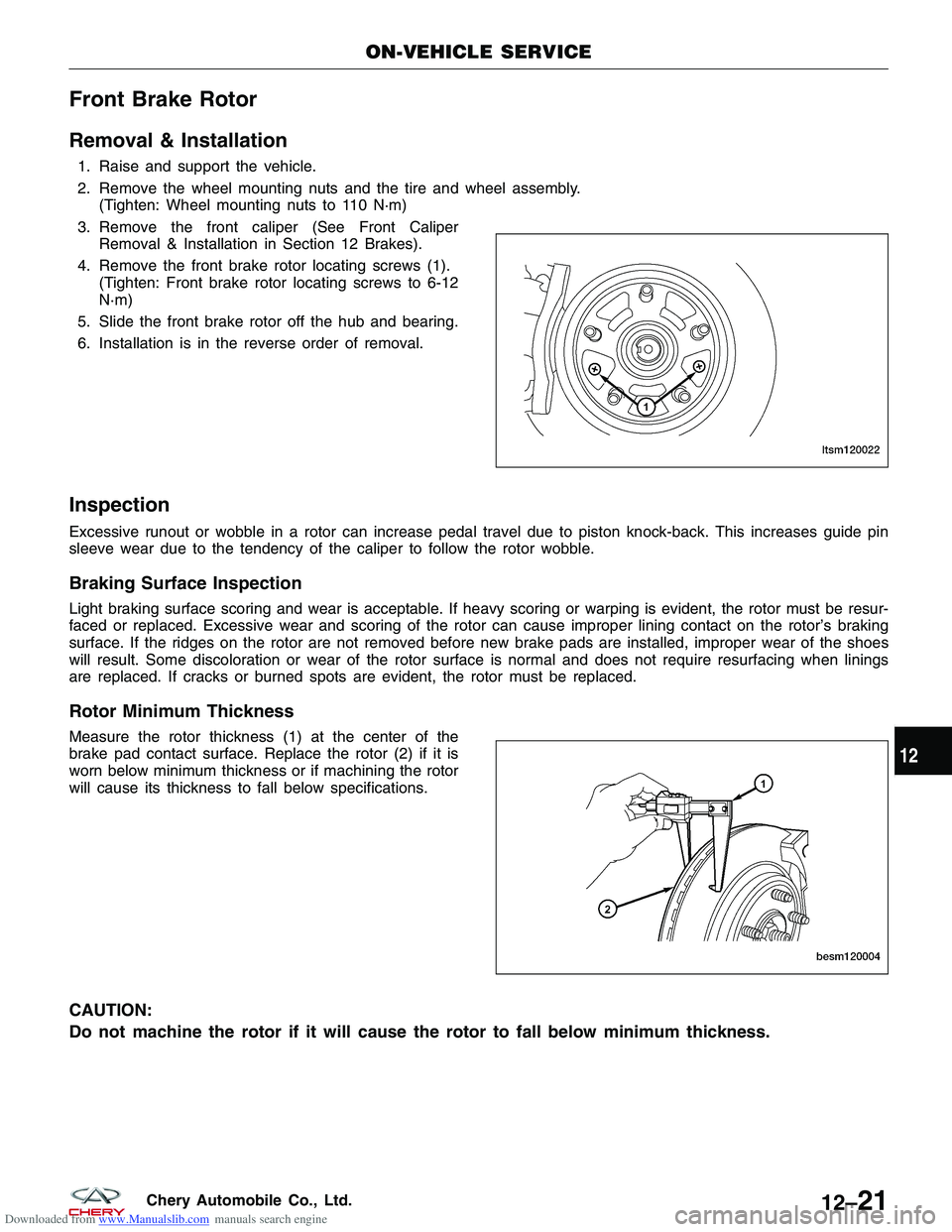

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Remove the front caliper (See Front Caliper Removal & Installation in Section 12 Brakes).

4. Remove the front brake rotor locating screws (1). (Tighten: Front brake rotor locating screws to 6-12

N·m)

5. Slide the front brake rotor off the hub and bearing.

6. Installation is in the reverse order of removal.

Inspection

Excessive runout or wobble in a rotor can increase pedal travel due to piston knock-back. This increases guide pin

sleeve wear due to the tendency of the caliper to follow the rotor wobble.

Braking Surface Inspection

Light braking surface scoring and wear is acceptable. If heavy scoring or warping is evident, the rotor must be resur-

faced or replaced. Excessive wear and scoring of the rotor can cause improper lining contact on the rotor’s braking

surface. If the ridges on the rotor are not removed before new brake pads are installed, improper wear of the shoes

will result. Some discoloration or wear of the rotor surface is normal and does not require resurfacing when linings

are replaced. If cracks or burned spots are evident, the rotor must be replaced.

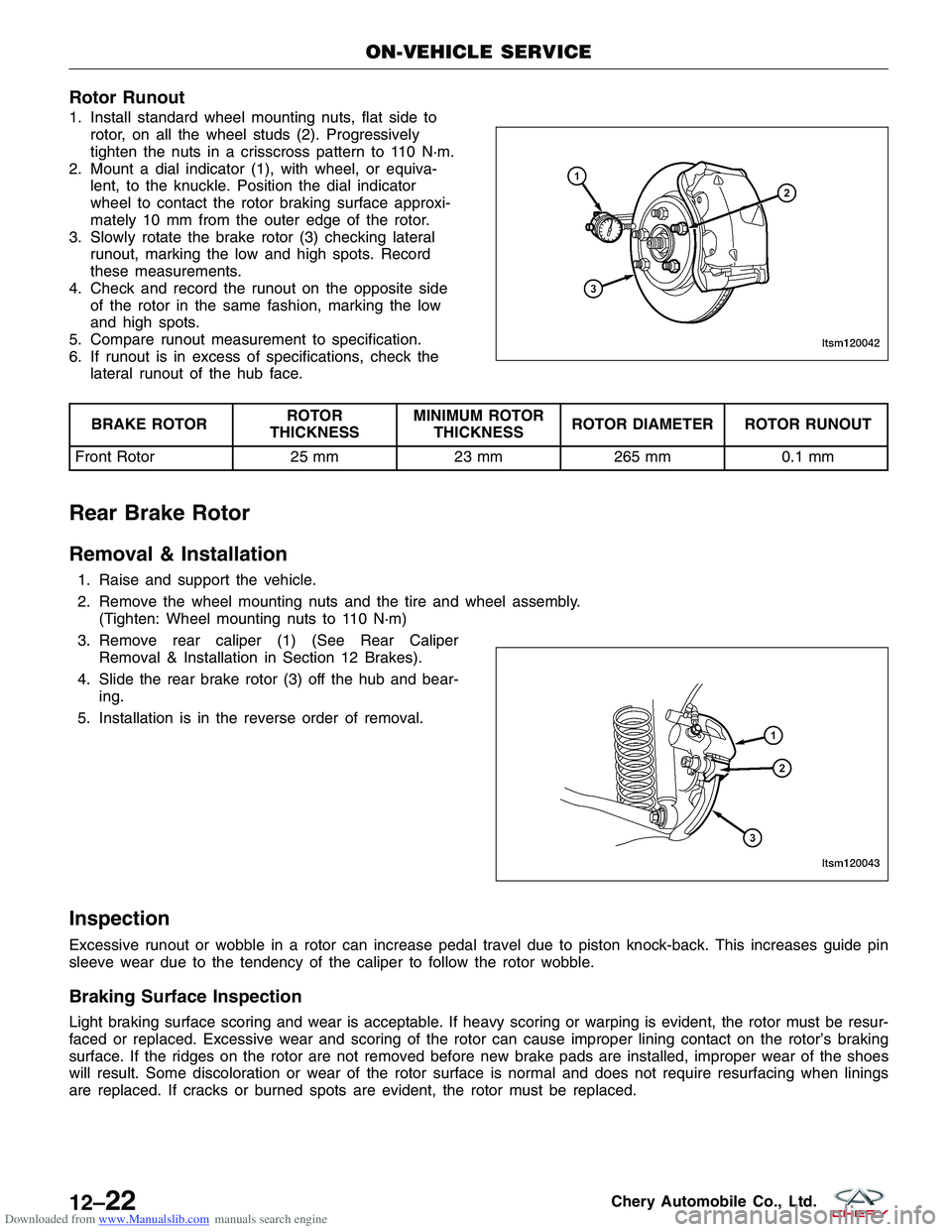

Rotor Minimum Thickness

Measure the rotor thickness (1) at the center of the

brake pad contact surface. Replace the rotor (2) if it is

worn below minimum thickness or if machining the rotor

will cause its thickness to fall below specifications.

CAUTION:

Do not machine the rotor if it will cause the rotor to fall below minimum thickness.

ON-VEHICLE SERVICE

LTSM120022

BESM120004

12

12–21Chery Automobile Co., Ltd.

Page 1417 of 1903

Downloaded from www.Manualslib.com manuals search engine Rotor Runout

1. Install standard wheel mounting nuts, flat side torotor, on all the wheel studs (2). Progressively

tighten the nuts in a crisscross pattern to 110 N·m.

2. Mount a dial indicator (1), with wheel, or equiva- lent, to the knuckle. Position the dial indicator

wheel to contact the rotor braking surface approxi-

mately 10 mm from the outer edge of the rotor.

3. Slowly rotate the brake rotor (3) checking lateral runout, marking the low and high spots. Record

these measurements.

4. Check and record the runout on the opposite side of the rotor in the same fashion, marking the low

and high spots.

5. Compare runout measurement to specification.

6. If runout is in excess of specifications, check the lateral runout of the hub face.

BRAKE ROTOR ROTOR

THICKNESS MINIMUM ROTOR

THICKNESS ROTOR DIAMETER ROTOR RUNOUT

Front Rotor 25 mm23 mm265 mm 0.1 mm

Rear Brake Rotor

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.

(Tighten: Wheel mounting nuts to 110 N·m)

3. Remove rear caliper (1) (See Rear Caliper Removal & Installation in Section 12 Brakes).

4. Slide the rear brake rotor (3) off the hub and bear- ing.

5. Installation is in the reverse order of removal.

Inspection

Excessive runout or wobble in a rotor can increase pedal travel due to piston knock-back. This increases guide pin

sleeve wear due to the tendency of the caliper to follow the rotor wobble.

Braking Surface Inspection

Light braking surface scoring and wear is acceptable. If heavy scoring or warping is evident, the rotor must be resur-

faced or replaced. Excessive wear and scoring of the rotor can cause improper lining contact on the rotor’s braking

surface. If the ridges on the rotor are not removed before new brake pads are installed, improper wear of the shoes

will result. Some discoloration or wear of the rotor surface is normal and does not require resurfacing when linings

are replaced. If cracks or burned spots are evident, the rotor must be replaced.

ON-VEHICLE SERVICE

LTSM120042

LTSM120043

12–22Chery Automobile Co., Ltd.

Page 1419 of 1903

Downloaded from www.Manualslib.com manuals search engine 3. Remove the rear brake caliper (See Rear BrakeCaliper Removal & Installation in Section 12

Brake).

4. Remove the rear brake rotor (See Rear Brake Rotor Removal & Installation in Section 12 Brake).

5. Remove the rear hub and bearing (See Rear Hub And Bearing Removal & Installation in Section 09

Driveline & Axle).

6. Remove the four bolts (1) that mount the rear brake backing plate to the trailing link.

(Tighten: Rear brake backing plate bolts to 20 N·m)

7. Remove the rear brake backing plate assembly.

8. Installation is in the reverse order of removal.

Front Brake Pads

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly. (Tighten: Wheel mounting nuts to 110 N·m)

NOTE :

In some cases, it may be necessary to retract the cal-

iper piston in its bore a small amount in order to pro-

vide sufficient clearance between the pads and the

rotor. 3. Remove the front caliper guide pin bolts (1) and (3).

(Tighten: Front caliper guide pin bolts to 23 N·m)

4. Remove the disc brake caliper (2) from the disc brake adapter bracket and hang it out of the way

using wire. Use care not to over extend the brake

hose when doing this.

5. Remove the inboard brake pad from the caliper adapter bracket.

6. Remove the outboard brake pad from the caliper by prying the brake pad retaining clip over the raised area on the caliper. Slide the brake pad off of the brake caliper.

7. Installation is in the reverse order of removal.

Installation Notes:

• Before installing brake pads, completely retract the caliper piston back into the bore of the caliper.

ON-VEHICLE SERVICE

LTSM120024

BESM120034

BESM120031

12–24Chery Automobile Co., Ltd.

Page 1420 of 1903

Downloaded from www.Manualslib.com manuals search engine •After installation and before moving the vehicle, pump the brake pedal several times to set the pads to the

brake rotor.

• Check and adjust the brake fluid level in the reservoir as necessary.

• Road test the vehicle and make several stops to wear off any foreign material on the brakes and to seat the

brake pads.

• After installation and before moving the vehicle, pump the brake pedal several times to set the pads to the

brake rotor.

Inspection

Visually inspect brake pads for uneven lining wear. Also inspect for excessive lining deterioration. Check the clear-

ance between the tips of the wear indicators (if equipped) on the pads and the brake rotors. If a visual inspection

does not adequately determine the condition of the lining, a physical check will be necessary. To check the amount

of lining wear, remove the disc brake pads from the vehicle. Measure the brake pad minimum thickness. Brake pads

must be replaced when usable material on a brake pad lining measured at its thinnest point measures one millimeter

or less. Replace both disc brake pads (inboard and outboard) at each caliper. It is also necessary to replace the pads

on the opposite side of the vehicle as well as the pads failing inspection to maintain proper braking characteristics.

If the brake pad assemblies do not require replacement, be sure to reinstall the brake pads in the original position

from which they were removed.

Rear Brake Pads

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.

(Tighten: Wheel mounting nuts to 110 N·m)

NOTE :

In some cases, it may be necessary to retract the caliper piston in its bore a small amount in order to provide suf-

ficient clearance between the pads and the rotor. 3. Remove the lower rear caliper guide pin bolt (2). (Tighten: Rear caliper guide pin bolt to 23 N·m)

CAUTION: When moving rear brake caliper

upward, use extreme care not to damage or

overextend the flex hose.

4. Rotate the caliper (1) upward hinging off the upper guide pin bolt. Rotate the caliper upward just

enough to allow brake pad removal.

5. Slide the rear brake pads off of the brake caliper adapter.

ON-VEHICLE SERVICE

LTSM120044

LTSM120018

12

12–25Chery Automobile Co., Ltd.

Page 1421 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection

Visually inspect brake pads for uneven lining wear. Also inspect for excessive lining deterioration. Check the clear-

ance between the tips of the wear indicators (if equipped) on the pads and the brake rotors. If a visual inspection

does not adequately determine the condition of the lining, a physical check will be necessary. To check the amount

of lining wear, remove the disc brake pads from the vehicle. Measure the brake pad minimum thickness. Brake pads

must be replaced when usable material on a brake pad lining measured at its thinnest point measures one millimeter

or less. Replace both disc brake pads (inboard and outboard) at each caliper. It is also necessary to replace the pads

on the opposite side of the vehicle as well as the pads failing inspection to maintain proper braking characteristics.

If the brake pad assemblies do not require replacement, be sure to reinstall the brake pads in the original position

from which they were removed.

ON-VEHICLE SERVICE

12–26Chery Automobile Co., Ltd.