bolt pattern DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 111 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

3 - 30 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 113 of 2627

ADJUSTMENTS

Ring gear and pinion are supplied as a matched

sets. Identifying numbers for the ring gear and pin-

ion are painted onto the pinion gear shaft and the

side of the ring gear. A plus (+) number, minus (±)

number or zero (0) along with the gear set sequence

number (01 to 99) is on each gear. This first number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

marked with a (0). The next two numbers are the

sequence number of the gear set. The standard depth

provides the best teeth contact pattern.

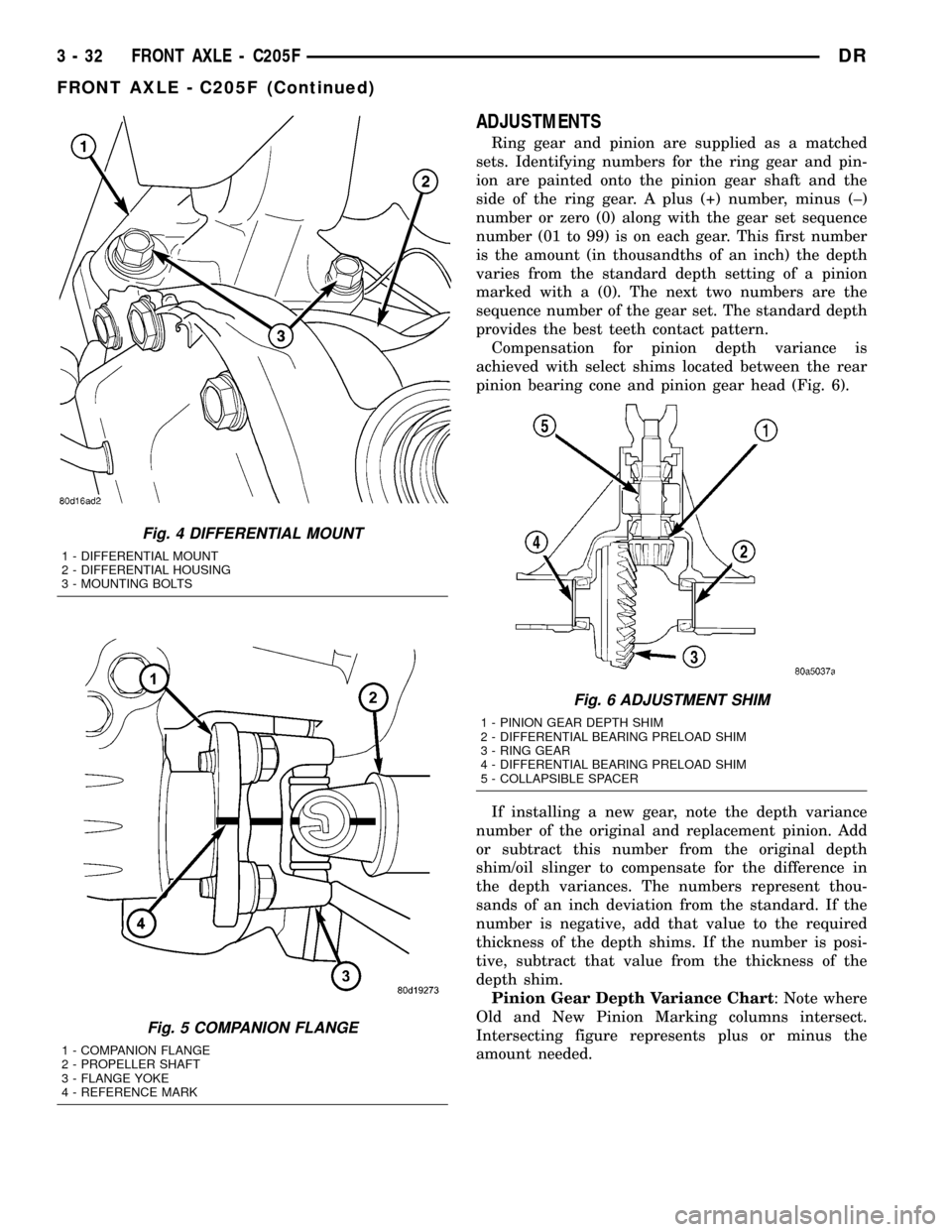

Compensation for pinion depth variance is

achieved with select shims located between the rear

pinion bearing cone and pinion gear head (Fig. 6).

If installing a new gear, note the depth variance

number of the original and replacement pinion. Add

or subtract this number from the original depth

shim/oil slinger to compensate for the difference in

the depth variances. The numbers represent thou-

sands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shims. If the number is posi-

tive, subtract that value from the thickness of the

depth shim.

Pinion Gear Depth Variance Chart: Note where

Old and New Pinion Marking columns intersect.

Intersecting figure represents plus or minus the

amount needed.

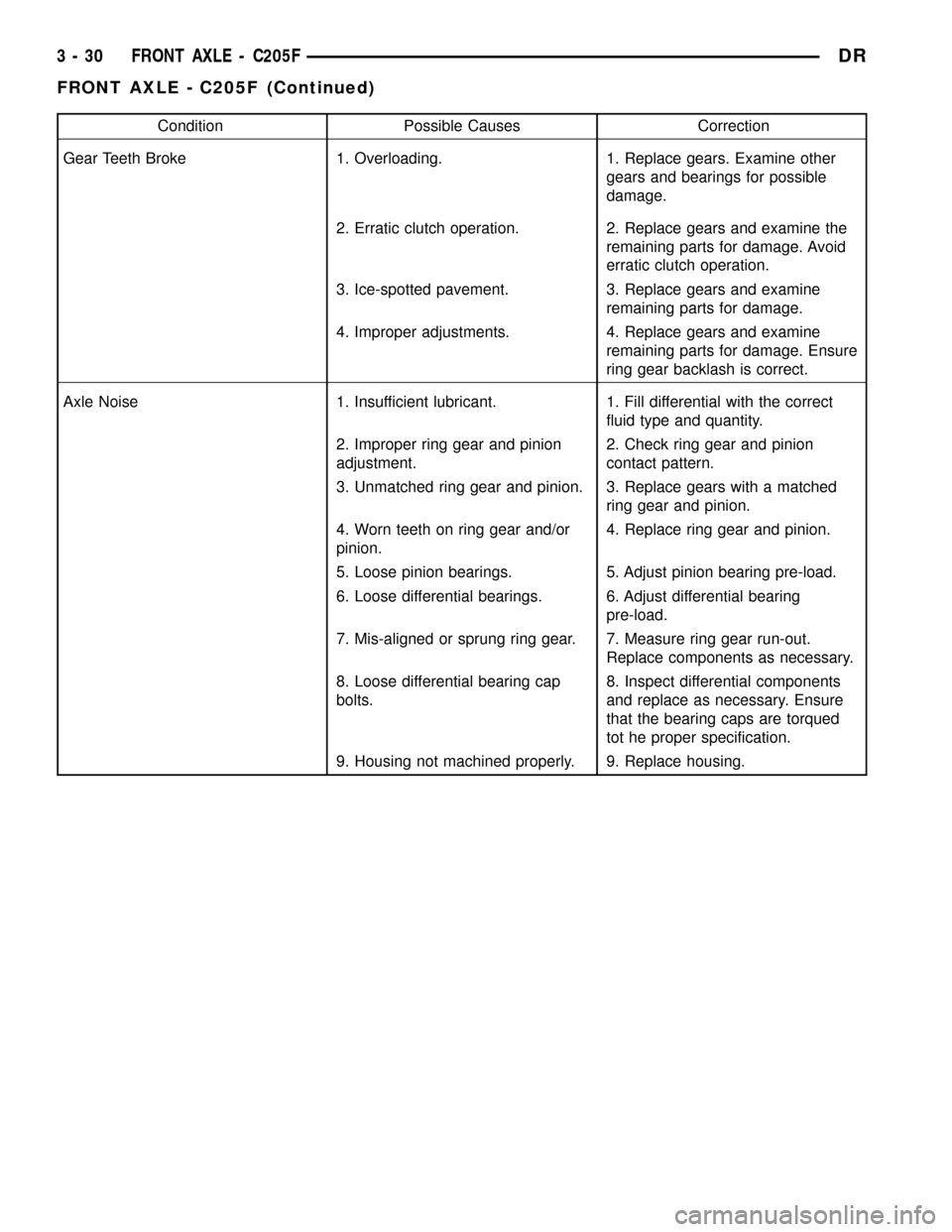

Fig. 4 DIFFERENTIAL MOUNT

1 - DIFFERENTIAL MOUNT

2 - DIFFERENTIAL HOUSING

3 - MOUNTING BOLTS

Fig. 5 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

Fig. 6 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

3 - 32 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 118 of 2627

(23) Subtract 0.05 mm (0.002 in.) from the dial

indicator reading to compensate for backlash between

ring and pinion gears. Add the resulting measure-

ment to the thickness of the single dummy shim.

This is the thickness of shim required to achieve

proper backlash.

(24) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

housing.

(25) Rotate dial indicator out of the way on pilot

stud.

(26) Remove differential case, dummy bearings

and dummy shim from the housing.

(27) Install new side bearing cones and cups on

differential case.

(28) Install Spreader W-129-B and Adapter Plates

8142-A on the housing and spread open enough to

receive differential case.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(29) Place the side bearing shims in the differen-

tial housing against the housing shoulder.

(30) Install the differential case in the housing.

(31) Rotate the differential case several times to

seat the side bearings.

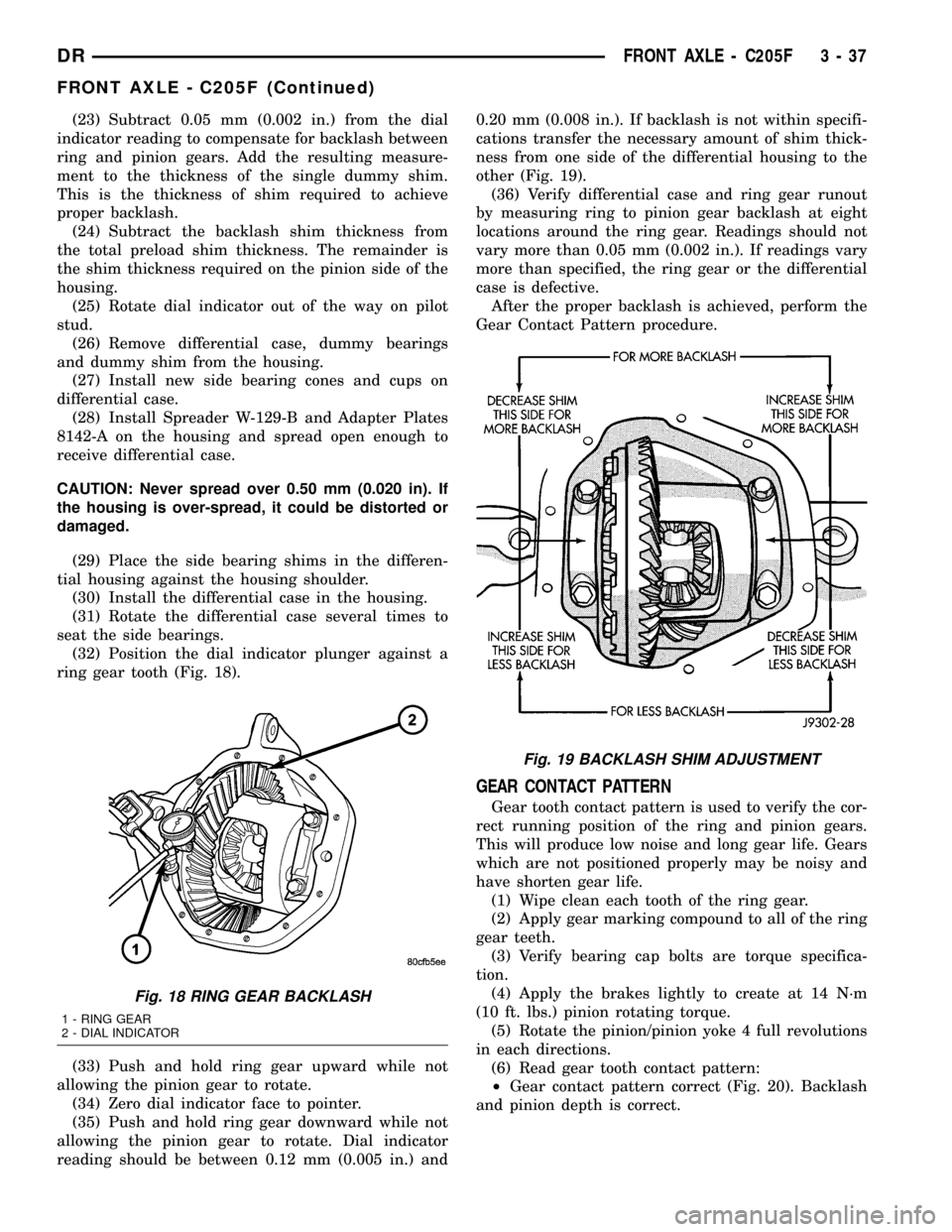

(32) Position the dial indicator plunger against a

ring gear tooth (Fig. 18).

(33) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(34) Zero dial indicator face to pointer.

(35) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.12 mm (0.005 in.) and0.20 mm (0.008 in.). If backlash is not within specifi-

cations transfer the necessary amount of shim thick-

ness from one side of the differential housing to the

other (Fig. 19).

(36) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform the

Gear Contact Pattern procedure.

GEAR CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply the brakes lightly to create at 14 N´m

(10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern correct (Fig. 20). Backlash

and pinion depth is correct.

Fig. 18 RING GEAR BACKLASH

1 - RING GEAR

2 - DIAL INDICATOR

Fig. 19 BACKLASH SHIM ADJUSTMENT

DRFRONT AXLE - C205F 3 - 37

FRONT AXLE - C205F (Continued)

Page 129 of 2627

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are replaced, Refer to adjustments for

Differential Bearing Preload and Gear Backlash pro-

cedures.

(1) Install Spreader W-129-B with the Adapter

Plates 8142-A and install the safety holddown

clamps. Tighten the tool turnbuckle finger-tight.

(2) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load indicator plunger against the

opposite side of the housing and zero the indicator.

(3) Spread housing and measure the distance with

the dial indicator.

CAUTION: Never spread housing over 0.50 mm

(0.020 in). Failure to heed caution may result in

damage.

(4) Remove dial indicator.

(5) Install differential case in the housing. Ensure

differential bearing cups remain in position on the

bearings and the differential preload shims are

seated in the housing. Tap differential case to ensure

bearings cups are seated in the housing.

(6) Install bearing caps to their original locations

and loosely install cap bolts.

(7) Remove housing spreader.

(8) Tighten the bearing cap bolts to 61 N´m (45 ft.

lbs.).

(9) Install axle shafts.

(10) Apply a bead of orange Mopar Axle RTV seal-

ant or equivalent to the housing cover.

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied. Failure to heed caution may result in dam-

age.

(11) Install cover and tighten bolts in a criss-cross

pattern to 22 N´m (15 ft. lbs.).

(12) Fill differential with lubricant.

DIFFERENTIAL CASE

BEARINGS

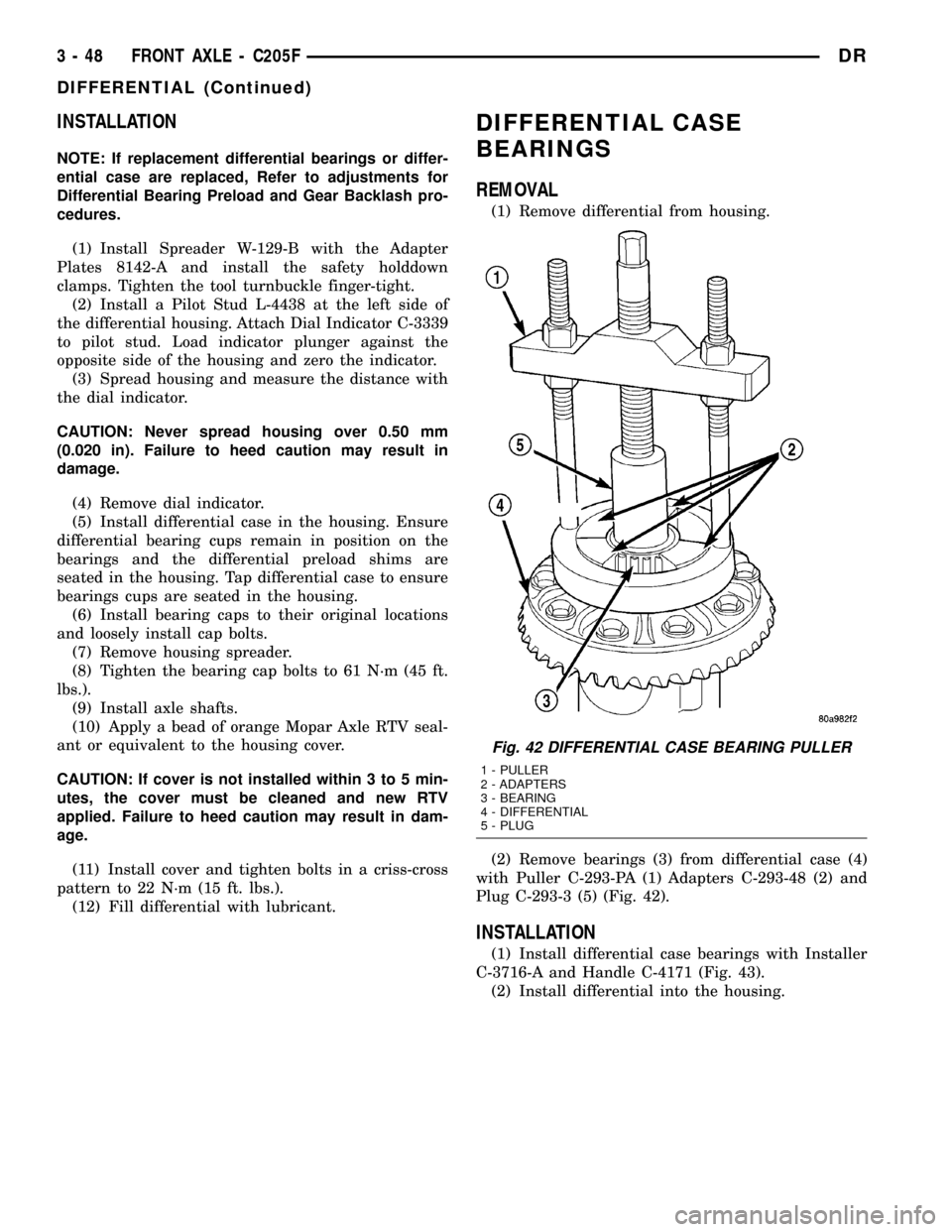

REMOVAL

(1) Remove differential from housing.

(2) Remove bearings (3) from differential case (4)

with Puller C-293-PA (1) Adapters C-293-48 (2) and

Plug C-293-3 (5) (Fig. 42).

INSTALLATION

(1) Install differential case bearings with Installer

C-3716-A and Handle C-4171 (Fig. 43).

(2) Install differential into the housing.

Fig. 42 DIFFERENTIAL CASE BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

3 - 48 FRONT AXLE - C205FDR

DIFFERENTIAL (Continued)

Page 134 of 2627

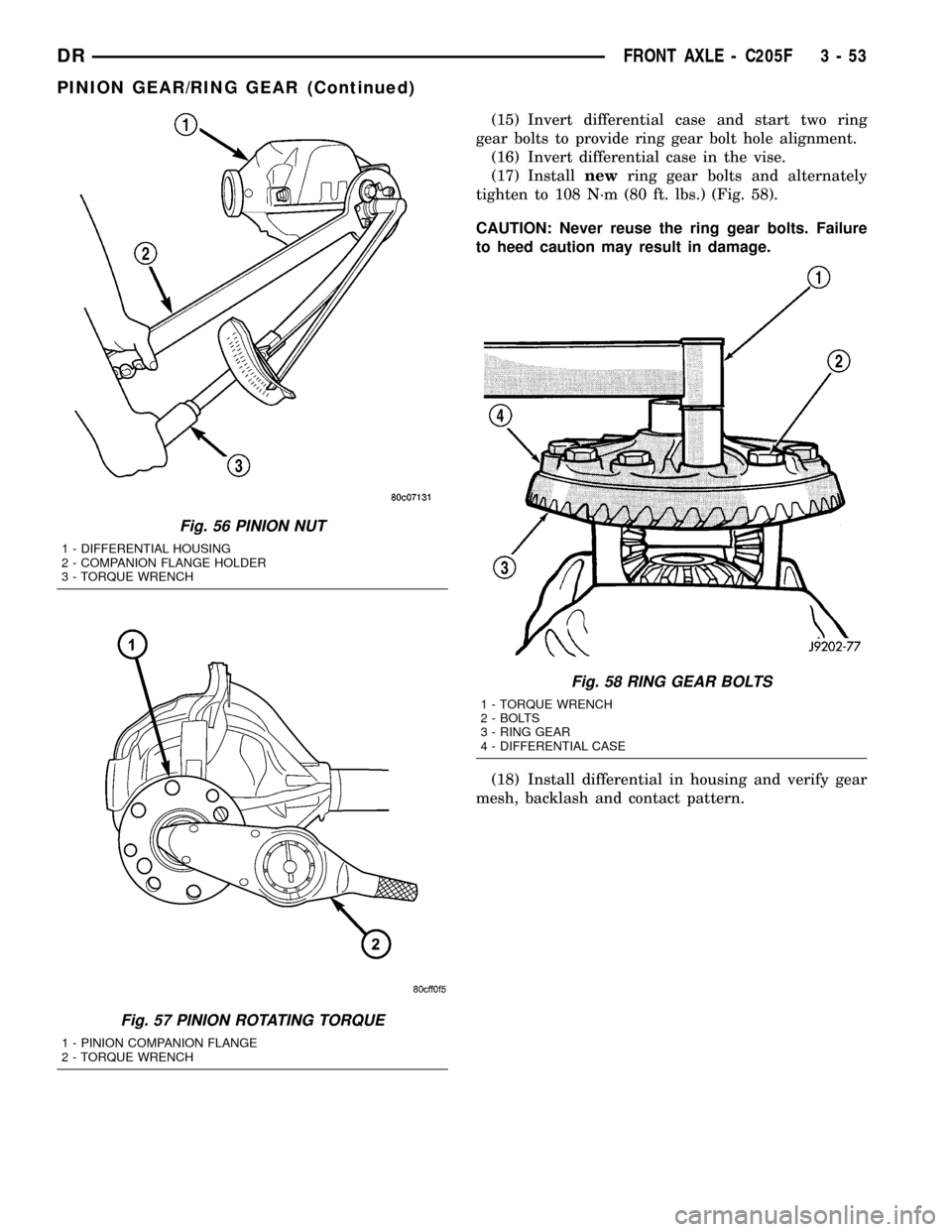

(15) Invert differential case and start two ring

gear bolts to provide ring gear bolt hole alignment.

(16) Invert differential case in the vise.

(17) Installnewring gear bolts and alternately

tighten to 108 N´m (80 ft. lbs.) (Fig. 58).

CAUTION: Never reuse the ring gear bolts. Failure

to heed caution may result in damage.

(18) Install differential in housing and verify gear

mesh, backlash and contact pattern.

Fig. 56 PINION NUT

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

Fig. 57 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

Fig. 58 RING GEAR BOLTS

1 - TORQUE WRENCH

2 - BOLTS

3 - RING GEAR

4 - DIFFERENTIAL CASE

DRFRONT AXLE - C205F 3 - 53

PINION GEAR/RING GEAR (Continued)

Page 138 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

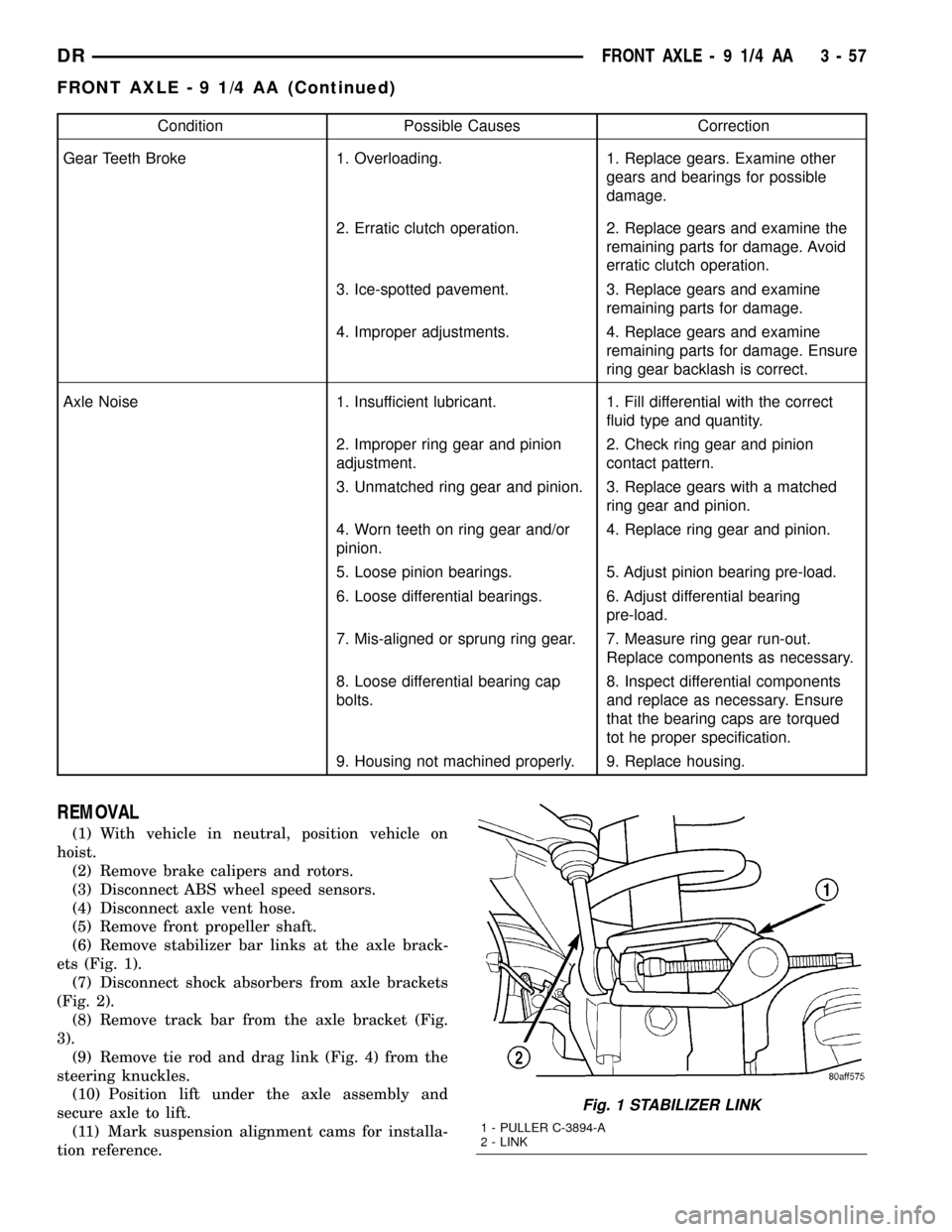

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove brake calipers and rotors.

(3) Disconnect ABS wheel speed sensors.

(4) Disconnect axle vent hose.

(5) Remove front propeller shaft.

(6) Remove stabilizer bar links at the axle brack-

ets (Fig. 1).

(7) Disconnect shock absorbers from axle brackets

(Fig. 2).

(8) Remove track bar from the axle bracket (Fig.

3).

(9) Remove tie rod and drag link (Fig. 4) from the

steering knuckles.

(10) Position lift under the axle assembly and

secure axle to lift.

(11) Mark suspension alignment cams for installa-

tion reference.

Fig. 1 STABILIZER LINK

1 - PULLER C-3894-A

2 - LINK

DRFRONT AXLE - 9 1/4 AA 3 - 57

FRONT AXLE - 9 1/4 AA (Continued)

Page 141 of 2627

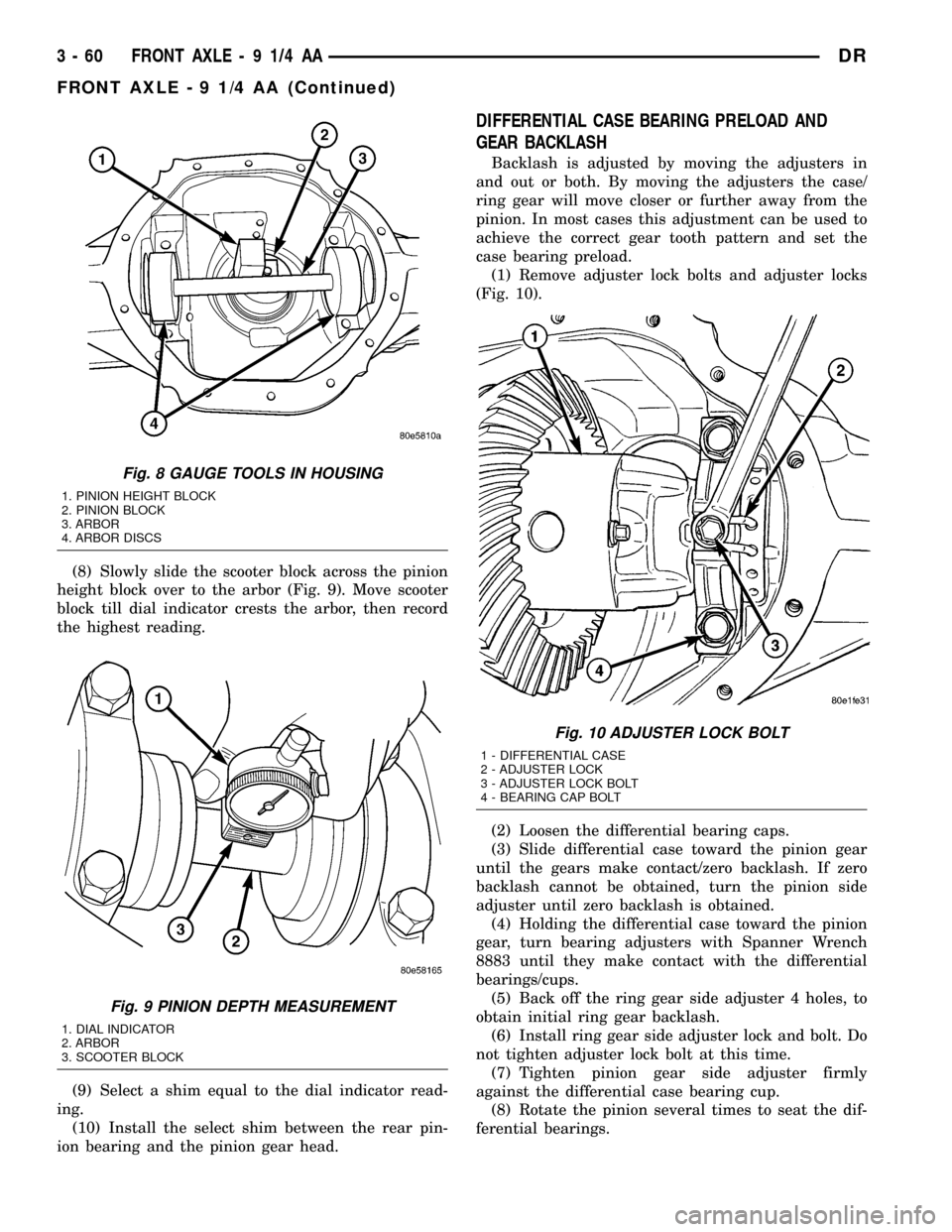

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move scooter

block till dial indicator crests the arbor, then record

the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 10).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the dif-

ferential bearings.

Fig. 8 GAUGE TOOLS IN HOUSING

1. PINION HEIGHT BLOCK

2. PINION BLOCK

3. ARBOR

4. ARBOR DISCS

Fig. 9 PINION DEPTH MEASUREMENT

1. DIAL INDICATOR

2. ARBOR

3. SCOOTER BLOCK

Fig. 10 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 60 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 142 of 2627

(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(12) Tighten bearing cap bolts to 85 N´m (63 ft.

lbs.).

(13) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.).

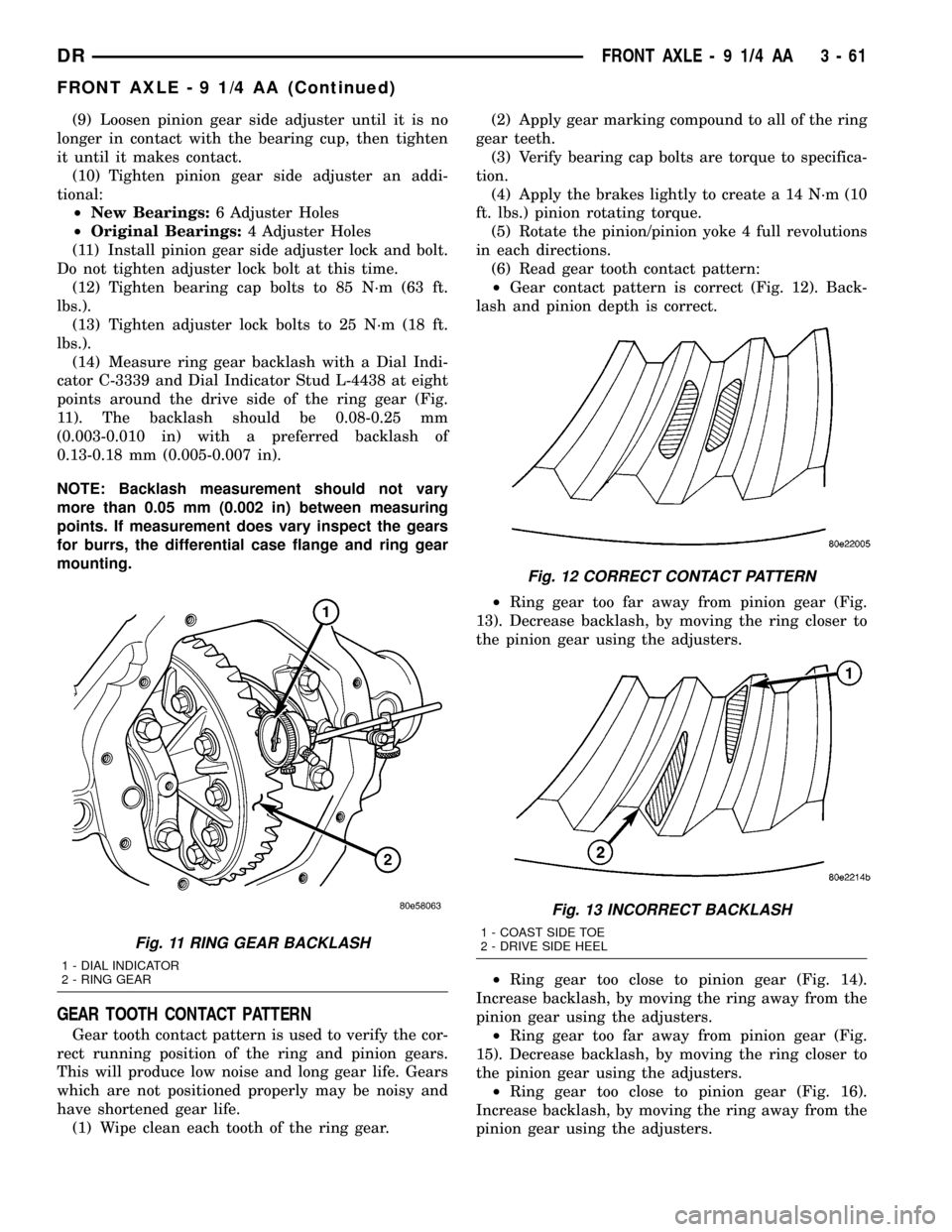

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig.

11). The backlash should be 0.08-0.25 mm

(0.003-0.010 in) with a preferred backlash of

0.13-0.18 mm (0.005-0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

mounting.

GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shortened gear life.

(1) Wipe clean each tooth of the ring gear.(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque to specifica-

tion.

(4) Apply the brakes lightly to create a 14 N´m (10

ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern is correct (Fig. 12). Back-

lash and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

13). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 14).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

²Ring gear too far away from pinion gear (Fig.

15). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 16).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

Fig. 11 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 12 CORRECT CONTACT PATTERN

Fig. 13 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

DRFRONT AXLE - 9 1/4 AA 3 - 61

FRONT AXLE - 9 1/4 AA (Continued)

Page 155 of 2627

(4) Align hole in the pinion gears with hole in the

differential case.

(5) Install pinion shaft.

(6) Installnewpinion shaft lock bolt and tighten

to 52 N´m (38 ft. lbs.).

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

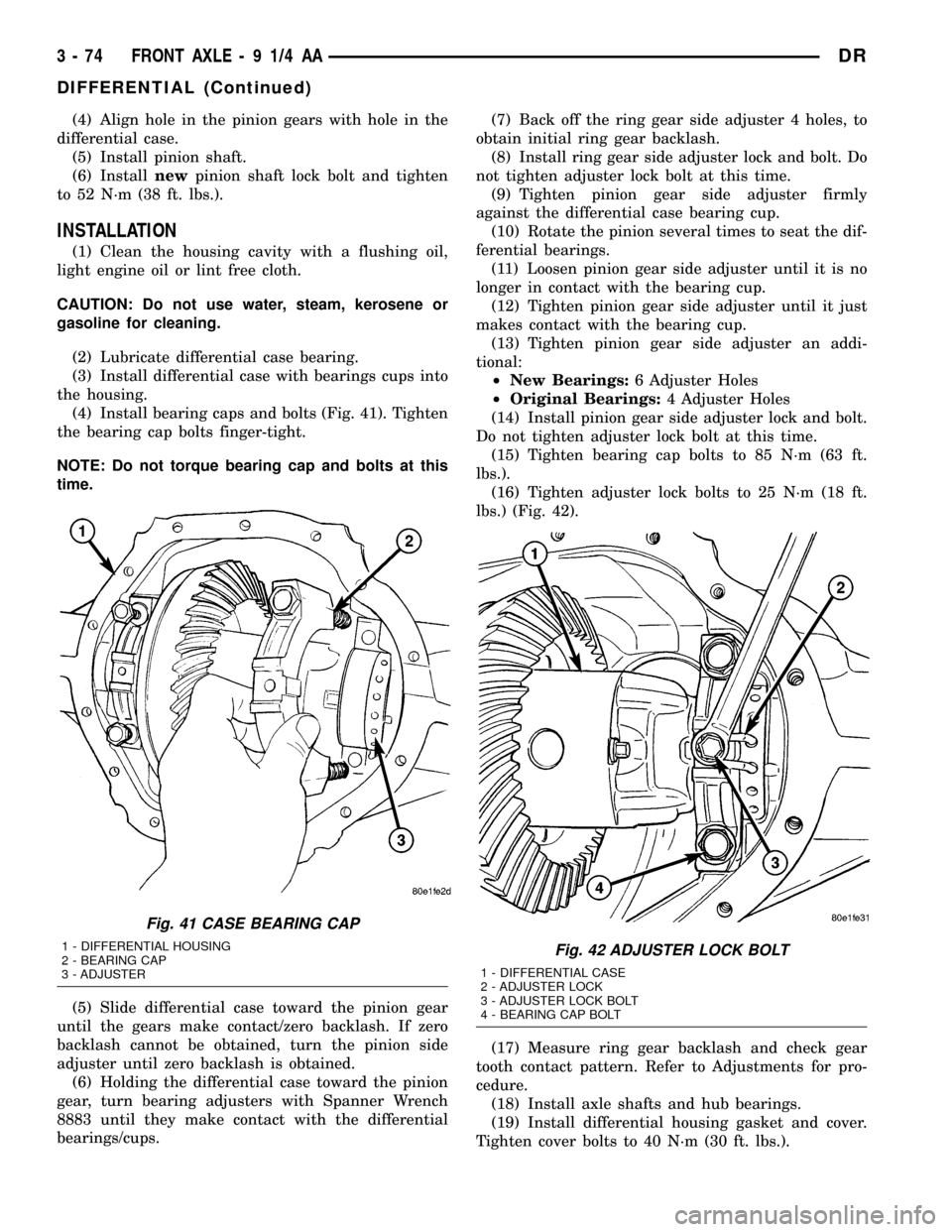

(4) Install bearing caps and bolts (Fig. 41). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 85 N´m (63 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 42).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts and hub bearings.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

Fig. 41 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTERFig. 42 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 74 FRONT AXLE - 9 1/4 AADR

DIFFERENTIAL (Continued)

Page 160 of 2627

(8) Installnewpinion seal (Fig. 56) with Installer

8882 and Handle C-4171.

(9) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(10) Hold pinion and lightly tap the pinion flange

onto the pinion shaft, until a few threads are show-

ing.

(11) Install pinion flange washer andnewpinion

nut.

(12) Hold pinion flange with Flange Wrench 8979

and tighten pinion nut until end play is taken up.

(13) Rotate pinion several times to seat bearings.

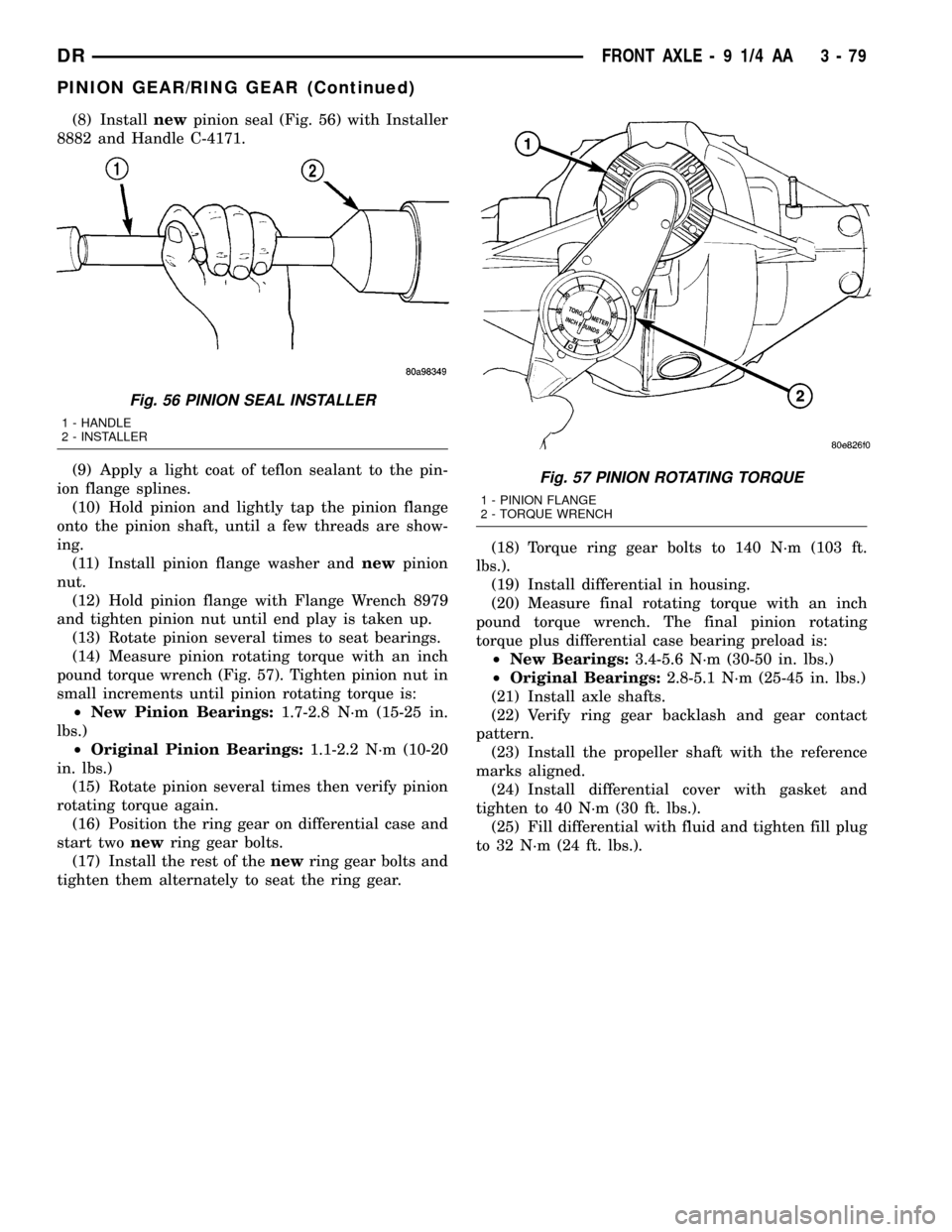

(14) Measure pinion rotating torque with an inch

pound torque wrench (Fig. 57). Tighten pinion nut in

small increments until pinion rotating torque is:

²New Pinion Bearings:1.7-2.8 N´m (15-25 in.

lbs.)

²Original Pinion Bearings:1.1-2.2 N´m (10-20

in. lbs.)

(15) Rotate pinion several times then verify pinion

rotating torque again.

(16) Position the ring gear on differential case and

start twonewring gear bolts.

(17) Install the rest of thenewring gear bolts and

tighten them alternately to seat the ring gear.(18) Torque ring gear bolts to 140 N´m (103 ft.

lbs.).

(19) Install differential in housing.

(20) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)

²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(21) Install axle shafts.

(22) Verify ring gear backlash and gear contact

pattern.

(23) Install the propeller shaft with the reference

marks aligned.

(24) Install differential cover with gasket and

tighten to 40 N´m (30 ft. lbs.).

(25) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

Fig. 56 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 57 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

DRFRONT AXLE - 9 1/4 AA 3 - 79

PINION GEAR/RING GEAR (Continued)