oil KIA FORTE 2018 Service Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: FORTE, Model: KIA FORTE 2018Pages: 584, PDF Size: 15.14 MB

Page 496 of 584

Maintenance

34

7

If it is near or at L, add enough oil to

bring the level to F. Do not overfill.

Use a funnel to help prevent oil

from being spilled on engine com-

ponents.

Use only the specified engine oil. (Refer to “Recommended lubricantsand capacities” in section 8.)Changing the engine oil and

filter

Have engine oil and filter changed by

an authorized Kia dealer according

to the Maintenance Schedule at the

beginning of this chapter.

WARNING

Used engine oil may cause irri-

tation or cancer of the skin if

left in contact with the skin for

prolonged periods of time.

Always protect your skin by

washing your hands thoroughly

with soap and warm water as

soon as possible after handling

used oil.

OYDM076084

Page 500 of 584

Maintenance

38

7

BRAKE/CLUTCH (IF EQUIPPED) FLUID

Checking the brake/clutch*

fluid level

Check the fluid level in the reservoir

periodically. The fluid level should be

between MAX and MIN marks on the

side of the reservoir.

Before removing the reservoir cap

and adding brake/clutch* fluid, clean

the area around the reservoir cap

thoroughly to prevent brake/clutch*

fluid contamination.

* if equipped If the level is low, add fluid to the

MAX level. The level will fall with

accumulated mileage. This is a nor-

mal condition associated with the

wear of the brake linings and/or

clutch disc (if equipped). If the fluid

level is excessively low, have the

brake/clutch* system checked by an

authorized Kia dealer.

Use only the specified brake/clutch*

fluid. (Refer to “Recommended lubri-cants and capacities” in chapter 8.)

Never mix different types of fluid.

In the event the brake/clutch* system

requires frequent additions of fluid,

the vehicle should be inspected by

an authorized Kia dealer.

When changing and adding

brake/clutch* fluid, handle it carefully.

Do not let it come in contact with

your eyes. If brake/clutch* fluid

should come in contact with your

eyes, immediately flush them with a

large quantity of fresh tap water.

Have your eyes examined by a doc-

tor as soon as possible.

Brake/clutch* fluid, which has been

exposed to open air for an extended

time should never be used as its

quality cannot be guaranteed. It

should be disposed of properly.

CAUTION - Brake/clutch fluid

Do not allow brake/clutch* fluidto contact the vehicle's bodypaint, as paint damage willresult.

CAUTION - Proper fluid

Only use brake/clutch fluid inbrake/clutch system. Smallamounts of improper fluids(such as engine oil) can causedamage to the brake/clutch sys-tem.

OYD076024L

Page 511 of 584

749

Maintenance

When recharging the battery,

observe the following precautions:

The battery must be removed fromthe vehicle and placed in an area

with good ventilation.

Watch the battery during charging, and stop or reduce the charging

rate if the battery cells begin

gassing (boiling) violently or if the

temperature of the electrolyte of

any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

Before performing maintenance or recharging the battery, turn off all

accessories and stop the engine.

The negative battery cable must be removed first and installed last

when the battery is disconnected.Reset items

Items should be reset after the bat-

tery has been discharged or the bat-

tery has been disconnected.

Auto down window (See chapter 4)

Sunroof (See chapter 4)

Trip computer (See chapter 4)

Climate control system (See chapter 4)

Clock (See chapter 4)

Audio (See chapter 4)

Page 521 of 584

759

Maintenance

Temperature -A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. Grades B and A

represent higher levels of perform-

ance on the laboratory test wheel

than the minimum required by law.Tire terminology and definitions

Air Pressure:

The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

pounds per square inch (psi) or kilo-

pascal (kPa).

Accessory Weight: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic

transaxle, power seats, and air con-

ditioning.

Aspect Ratio: The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire: A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure:

The amount of

air pressure in a tire, measured in

pounds per square inch (psi) or kilo-

pascals (kPa) before a tire has built

up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight

Rating for the Front Axle.

GAWR RR: Gross Axle Weight

Rating for the Rear axle.

Page 526 of 584

Maintenance

64

7

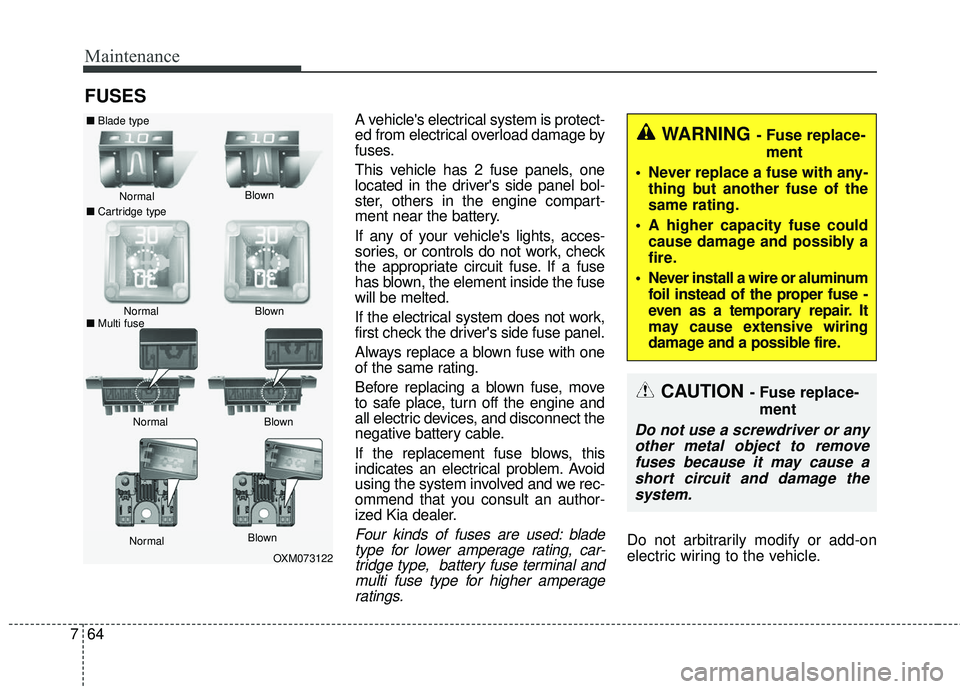

FUSES

A vehicle's electrical system is protect-

ed from electrical overload damage by

fuses.

This vehicle has 2 fuse panels, one

located in the driver's side panel bol-

ster, others in the engine compart-

ment near the battery.

If any of your vehicle's lights, acces-

sories, or controls do not work, check

the appropriate circuit fuse. If a fuse

has blown, the element inside the fuse

will be melted.

If the electrical system does not work,

first check the driver's side fuse panel.

Always replace a blown fuse with one

of the same rating.

Before replacing a blown fuse, move

to safe place, turn off the engine and

all electric devices, and disconnect the

negative battery cable.

If the replacement fuse blows, this

indicates an electrical problem. Avoid

using the system involved and we rec-

ommend that you consult an author-

ized Kia dealer.

Four kinds of fuses are used: blade

type for lower amperage rating, car-tridge type, battery fuse terminal andmulti fuse type for higher amperageratings.Do not arbitrarily modify or add-on

electric wiring to the vehicle.

WARNING - Fuse replace-

ment

Never replace a fuse with any- thing but another fuse of the

same rating.

A higher capacity fuse could cause damage and possibly a

fire.

Never install a wire or aluminum foil instead of the proper fuse -

even as a temporary repair. It

may cause extensive wiring

damage and a possible fire.

CAUTION - Fuse replace-

ment

Do not use a screwdriver or anyother metal object to removefuses because it may cause ashort circuit and damage thesystem.

OXM073122

Normal

Normal

■

Blade type

■ Cartridge type

■ Multi fuse Blown

Blown

Normal Blown

Normal Blown

Page 539 of 584

777

Maintenance

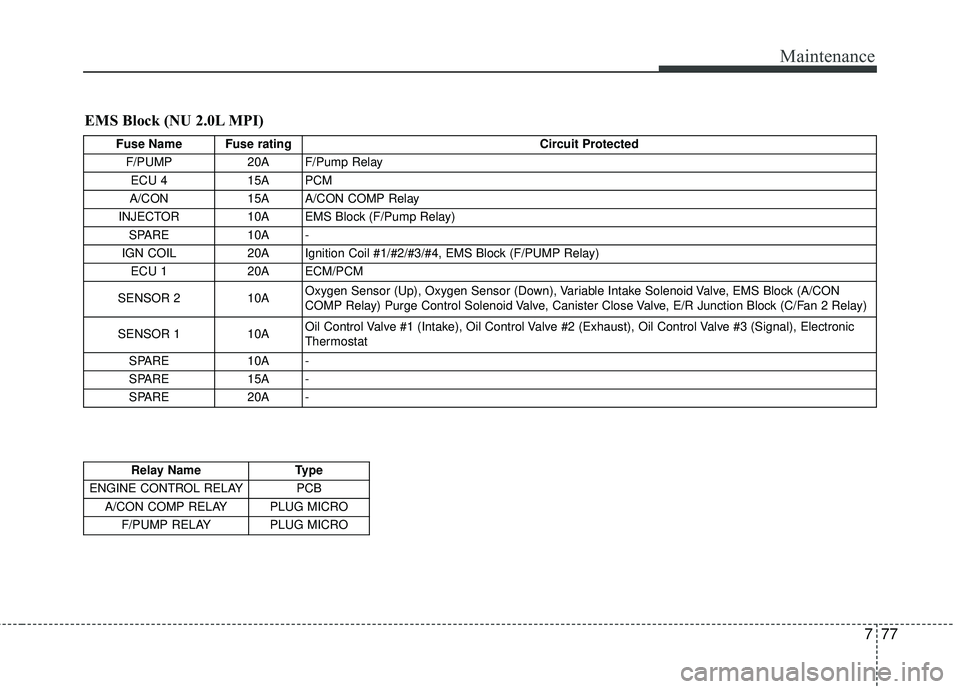

EMS Block (NU 2.0L MPI)

Fuse Name Fuse ratingCircuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

SPARE 10A -

IGN COIL 20A Ignition Coil #1/#2/#3/#4, EMS Block (F/PUMP Relay)

ECU 1 20A ECM/PCM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay) Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)

SENSOR 1 10A Oil Control Valve #1 (Intake), Oil Control Valve #2 (Exhaust), Oil Control Valve #3 (Signal), Electronic

Thermostat

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PLUG MICRO F/PUMP RELAY PLUG MICRO

Page 540 of 584

Maintenance

78

7

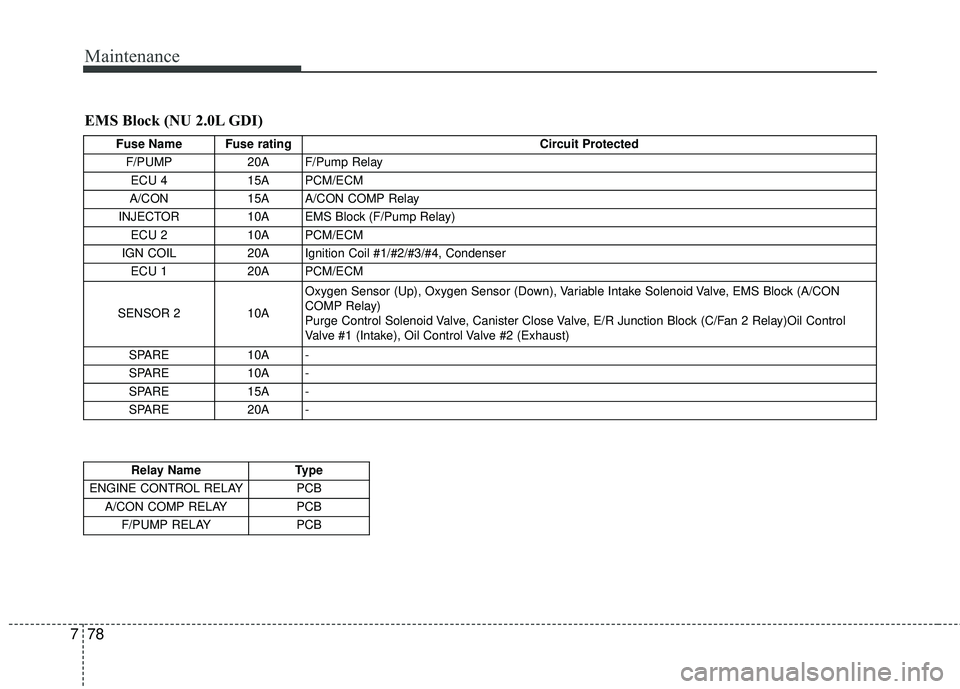

EMS Block (NU 2.0L GDI)

Fuse Name Fuse rating Circuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM/ECM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

ECU 2 10A PCM/ECM

IGN COIL 20A Ignition Coil #1/#2/#3/#4, Condenser

ECU 1 20A PCM/ECM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay)

Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)Oil Control

Valve #1 (Intake), Oil Control Valve #2 (Exhaust)

SPARE 10A -

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PCB

F/PUMP RELAY PCB

Page 541 of 584

779

Maintenance

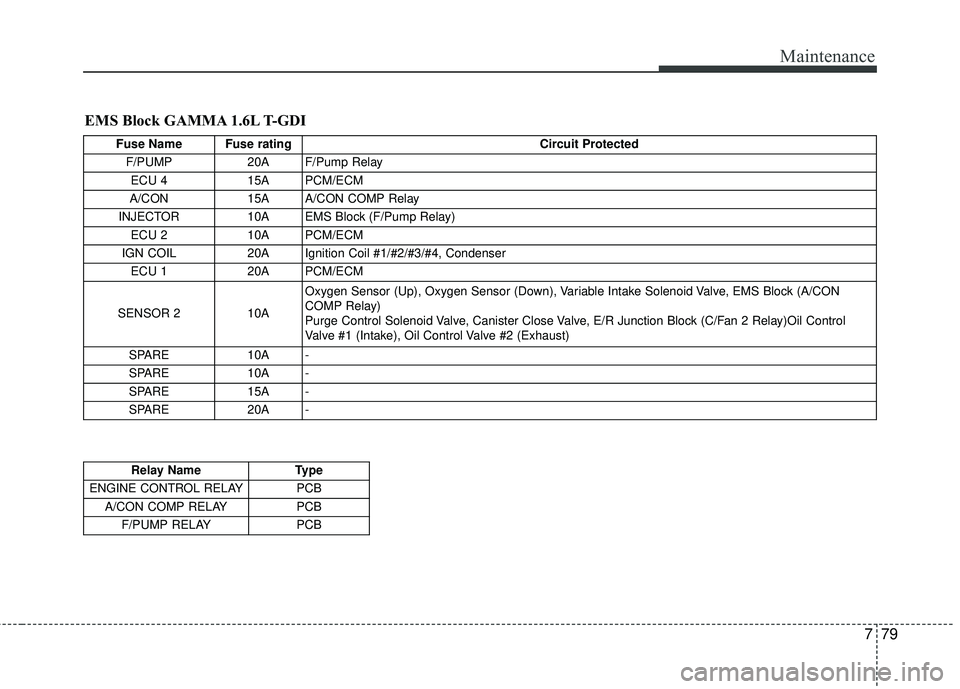

EMS Block GAMMA 1.6L T-GDI

Fuse Name Fuse ratingCircuit Protected

F/PUMP 20A F/Pump Relay

ECU 4 15A PCM/ECM

A/CON 15A A/CON COMP Relay

INJECTOR 10A EMS Block (F/Pump Relay)

ECU 2 10A PCM/ECM

IGN COIL 20A Ignition Coil #1/#2/#3/#4, Condenser

ECU 1 20A PCM/ECM

SENSOR 2 10A Oxygen Sensor (Up), Oxygen Sensor (Down), Variable Intake Solenoid Valve, EMS Block (A/CON

COMP Relay)

Purge Control Solenoid Valve, Canister Close Valve, E/R Junction Block (C/Fan 2 Relay)Oil Control

Valve #1 (Intake), Oil Control Valve #2 (Exhaust)

SPARE 10A -

SPARE 10A -

SPARE 15A -

SPARE 20A -

Relay Name Type

ENGINE CONTROL RELAY PCB A/CON COMP RELAY PCB

F/PUMP RELAY PCB

Page 543 of 584

781

Maintenance

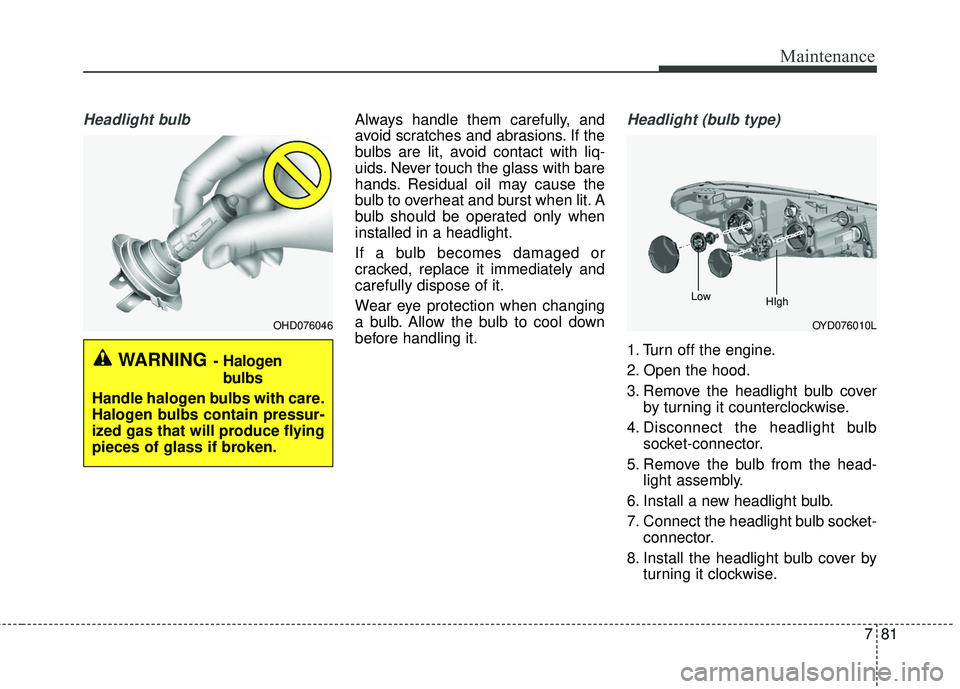

Headlight bulbAlways handle them carefully, and

avoid scratches and abrasions. If the

bulbs are lit, avoid contact with liq-

uids. Never touch the glass with bare

hands. Residual oil may cause the

bulb to overheat and burst when lit. A

bulb should be operated only when

installed in a headlight.

If a bulb becomes damaged or

cracked, replace it immediately and

carefully dispose of it.

Wear eye protection when changing

a bulb. Allow the bulb to cool down

before handling it.Headlight (bulb type)

1. Turn off the engine.

2. Open the hood.

3. Remove the headlight bulb coverby turning it counterclockwise.

4. Disconnect the headlight bulb socket-connector.

5. Remove the bulb from the head- light assembly.

6. Install a new headlight bulb.

7. Connect the headlight bulb socket- connector.

8. Install the headlight bulb cover by turning it clockwise.

OHD076046

WARNING- Halogen

bulbs

Handle halogen bulbs with care.

Halogen bulbs contain pressur-

ized gas that will produce flying

pieces of glass if broken.

OYD076010L

Low

HIgh

Page 552 of 584

Maintenance

90

7

1. Open the tailgate.

2. Gently remove the center cover of

the rear tailgate trim.

3. Disconnect the electrical connector. 4. Loosen the retaining nuts and

remove the spoiler. 5. Remove the high mounted stop

lamp assembly (A) after loosening

the nuts and washer nozzle (B).

6. Reinstall a new lamp assembly in the reverse order of removal.

OYDDMC3072

OYDDMC3074

OYDDMC3073OYDDMC3071

B

A