ECU RENAULT TWINGO 2009 2.G Panelwork Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 209

Page 32 of 209

40A-27

GENERAL INFORMATION

Structural components to be positioned on the repair bench: Description40A

V - FRONT SHOCK ABSORBER UPPER MOUNTING

The jig supports the underneath of the shock absorber

cup and is centred on the hole (14) of the shock absor-

ber cup.

The jig is used to replace:

-a wheel arch,

-a front half unit.

The jig is also used in straightening.VI - ENGINE MOUNTING

The jig rests on the engine mounting and is centred on

engine mounting securing holes (15) .

The jig is used with the subframe removed for the re-

placement of:

-a front half unit.

-the engine mounting.

VII - FRONT IMPACT CROSS MEMBER MOUNTING

The jig rests vertically against the front end lower cross

member mounting unit, it is centred in the mounting ho-

les (16) .

The jig is used to replace:

-the radiator cross member mounting,

-the front side member completely or partially,.

121753

IMPORTANT

This point contributes to ensuring the front axle

geometry. This point aligns the subframe of the

front axle in relation to the body. This point has a

direct influence on all of the front axle angles.

121753

121754

Page 72 of 209

41B-8

CENTRE LOWER STRUCTURE

Front cross member under front seat: General description41B

DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; its function is to secure the front

section of the front seat and to stiffen the bodywork in

the event of a side impact.Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading this general information, check that

there are no special notes associated with this vehi-

cle. These special notes will be specified if applica-

ble in other parts of this subsection dealing with the

par t.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

110507

Page 93 of 209

41D-2

REAR LOWER STRUCTURE

Rear floor: Description

41D

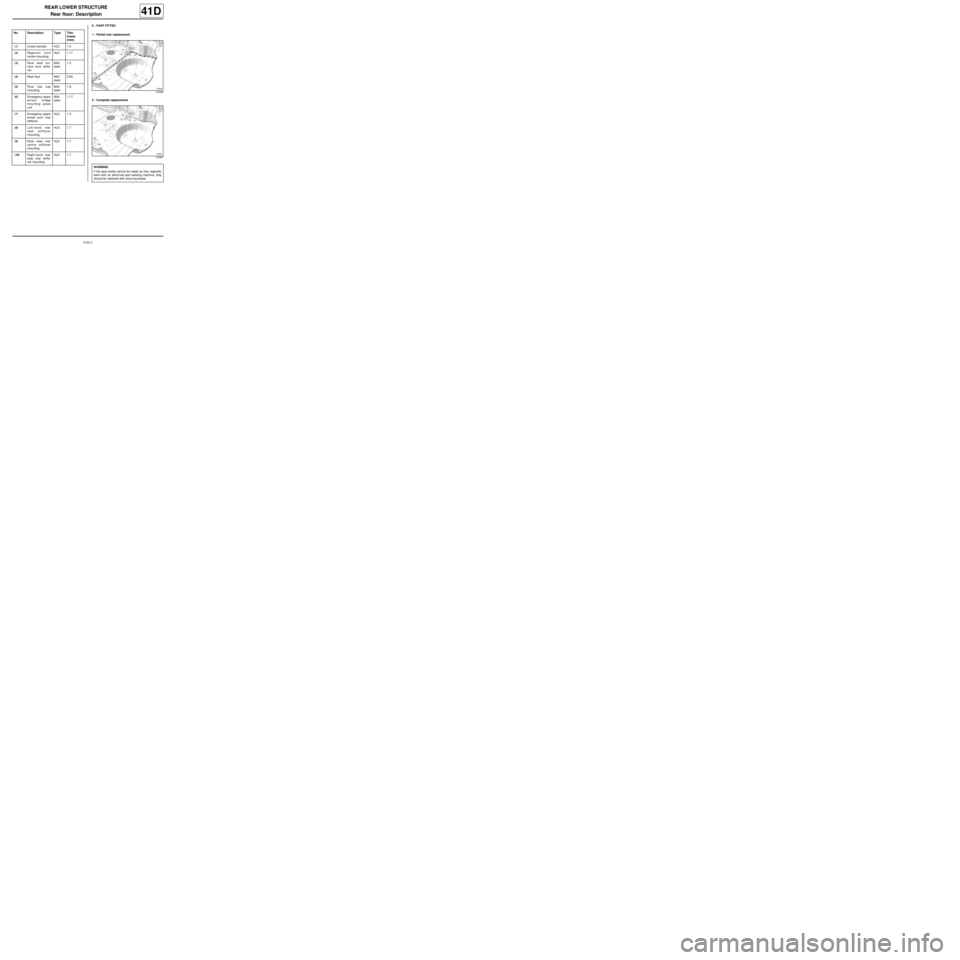

II - PART FITTED

1 - Partial rear replacement

2 - Complete replacement No. Description Type Thic-

kness

(mm)

(1) Cross member HLE 1.5

(2) Reservoir front

centre mountingHLE 1.17

(3) Rear seat run-

ners front stiffe-

nerMild

steel1.2

(4) Rear floor Mild

steel0.65

(5) Rear tow eye

mountingMild

steel1.8

(6) Emergency spare

wheel bridge

mounting piece

unitMild

steel1.17

(7) Emergency spare

wheel arch rear

stiffenerHLE 1.5

(8) Left-hand rear

seat stiffener

mountingHLE 1.7

(9) Rear seat rear

centre stiffener

mountingHLE 1.7

(10) Right-hand rear

seat rear stiffe-

ner mountingHLE 1.7

120988

120987

WARNING

If the spot welds cannot be made as they originally

were with an electrical spot welding machine, they

should be replaced with securing beads.

Page 127 of 209

42A-18

FRONT UPPER STRUCTURE

Upper reinforcement of scuttle side panel: General description42A

DESIGN OF THE STRUCTURAL COMPONENT

This type of part secures the bonnet hinge mounting

and the front wing upper mounting support.Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

121053

Page 186 of 209

45A-5

TOP OF BODY

Roof: Description

45A

Hold the spare part with locking pliers (at the front and

rear cross members) and the safety strap(s) to posi-

tion it securely according to the markings made earlier

(5) (see MR 400, Basic instructions for structural

bodywork repair, 40A, General information, Tools

for adjusting and supporting a structural compo-

nent: Use).

Let the adhesive dry for 10 hours at an ambient tem-

perature or for 2 hours at 60˚C.

c - Making the other joints

Make the rest of the replacement part joints.

4 - Finishing after assembly

Applying finishing product

Prime the side bonding areas.Apply a finishing seal, type M. J. Pro to the side bon-

ding areas.

Scrape off the surplus of bonding before it dries using

the (Car. 1786).

121630

Note:

To fit the safety straps without removing the quarter

panel windows, use 3 safety straps.

121631