roof RENAULT TWINGO 2009 2.G Panelwork Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 209

Page 5 of 209

Contents

Rear end panel: General

descr iption 44A-24

Rear end panel: Description 44A-25

45A TOP OF BODY

Roof: General description 45A-1

Roof: Description 45A-2

Roof front section:

Description 45A-6

Roof rear section:

Description 45A-7

Roof front cross member:

General description 45A-8

Roof centre cross member:

General description 45A-9

Roof rear cross member:

General description 45A-10

47A SIDE OPENING ELEMENTS

Front side door: Removal -

Refitting 47A-1

Front side door: Stripping -

rebuilding 47A-3

Front side door: Adjustment 47A-5

Fuel filler flap co ver:

Removal - Refitting 47A-8

48A NON-SIDE OPENING ELEMENTS

Bonnet: Removal - Refitting 48A-1

Bonnet: Stripping -

Rebuilding 48A-3

Bonnet: Adjustment 48A-4

Tailgate: Removal - Refitting 48A-6 44A REAR UPPER STRUCTURETailgate: Stripping -

Rebuilding 48A-8

Tailgate: Adjustment 48A-10 48A NON-SIDE OPENING ELEMENTS

Page 16 of 209

40A-11

GENERAL INFORMATION

Hollow section inserts: Precautions for the repair

40A

The expanding inserts ensure that the vehicle cavities

are sealed and soundproofed. They react to the tempe-

rature when the bodywork is immersed in the catapho-

retic bath at the factory. These conditions cannot be

reproduced on the bodywork.

As inserts are not recoverable, always replace expan-

ding inserts.

The inserts supplied by the Parts Department are

identical to the original parts.

To obtain the same sealing and soundproofing proper-

ties, carry out the following operations:

-clean the bonding surfaces with heptane,

-if necessary, block the holes in the insert using pieces

cut from a soundproofing pad.

-apply a bead of preformed trim sealing mastic around

and inside the insert holes,

-fit the insert by compressing the mastic.

In some cases, it is possible to replace the accessible

part of the insert only, which must be cut out of the re-

placement part.WARNING

Do not refit the part after compressing the bead.

When EGW welding, protect the inserts from spat-

ter and heat dispersion.

For example, use a heat shield.

Page 22 of 209

40A-17

GENERAL INFORMATION

Vehicle structure, side section: Description

40A

SIDE STRUCTURE

120919

No. Description Classification Type Thickness

(mm)

(1) Roof drip moulding lining (see MR 400)HLE1.3

(2) Normal roof front cross member (see 45A, Top of body, Roof

front cross member: General

description, page 45A-8) Mild

steel1

(3) Roof rear cross member (see 45A, Top of body, Roof

rear cross member: General

description, page 45A-10) HLE1.2

(4) Sill pane stiffener (see 41C, Side lower structure, Sill panel stiffener: Des-

cription, page 41C-15)

(5) Sill panel reinforcement (see 41C, Side lower structure, Sill panel reinforce-

ment: Description, page 41C-13)

(6) A-pillar reinforcement (see 43A, Side upper structure, A-pillar reinforcement:

Description, page 43A-6)

(7) Sill panel closure panel (see 41C, Side lower structure, Sill panel closure panel:

Description, page 41C-10)

Page 23 of 209

40A-18

GENERAL INFORMATION

Vehicle structure, side section: Description

40A

(8) B-pillar reinforcement (see 43A, Side upper structure, B-pillar reinforcement:

Description, page 43A-10)

(9) Windscreen pillar lining (see Windscreen pillar lining: Description)

(10) A-pillar (see 43A, Side upper structure, A-pillar: Description,

page 43A-2)

(11) Roof centre cross member (see Roof centre cross member: Description)

(12) Front section of roof (see 45A, To p of body, Roof front section: Description,

page 45A-6)

(13) Sill panel (see 41C, Side lower structure, Sill panel: Description,

page 41C-5)

(14) Roof (see 45A, Top of body, Roof: Description, page 45A-2)

(15) Upper body (see 43A, Side upper structure, Upper body: Descrip-

tion, page 43A-17)

(16) Rear section of roof (see 45A, Top of body, Roof rear section: Description,

page 45A-7) No. Description Classification Type Thickness

(mm)

Page 154 of 209

43A-17

SIDE UPPER STRUCTURE

Upper body: Description

43A

To replace this part, also order the A-pillar insert (A) .

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART IN POSITION

Complete replacement

Section B

125414

121004

No. Description Type Thic-

kness

(mm)

(1) Body side Mild

steel0.75

(2) Roof bar moun-

ting reinforce-

mentMild

steel1.5

121001

121002

Page 157 of 209

44A-2

REAR UPPER STRUCTURE

Rear wing panel: Description

C44

44A

the options for replacing this part are as follows:

-partial replacement,

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART IN POSITION

1 - Partial replacement

125413

121006

No. Description Type Thickness

(1) Body side Mild

steel0.75

(2) Roof bar moun-

ting reinforce-

mentMild

steel1.5

121008

Page 172 of 209

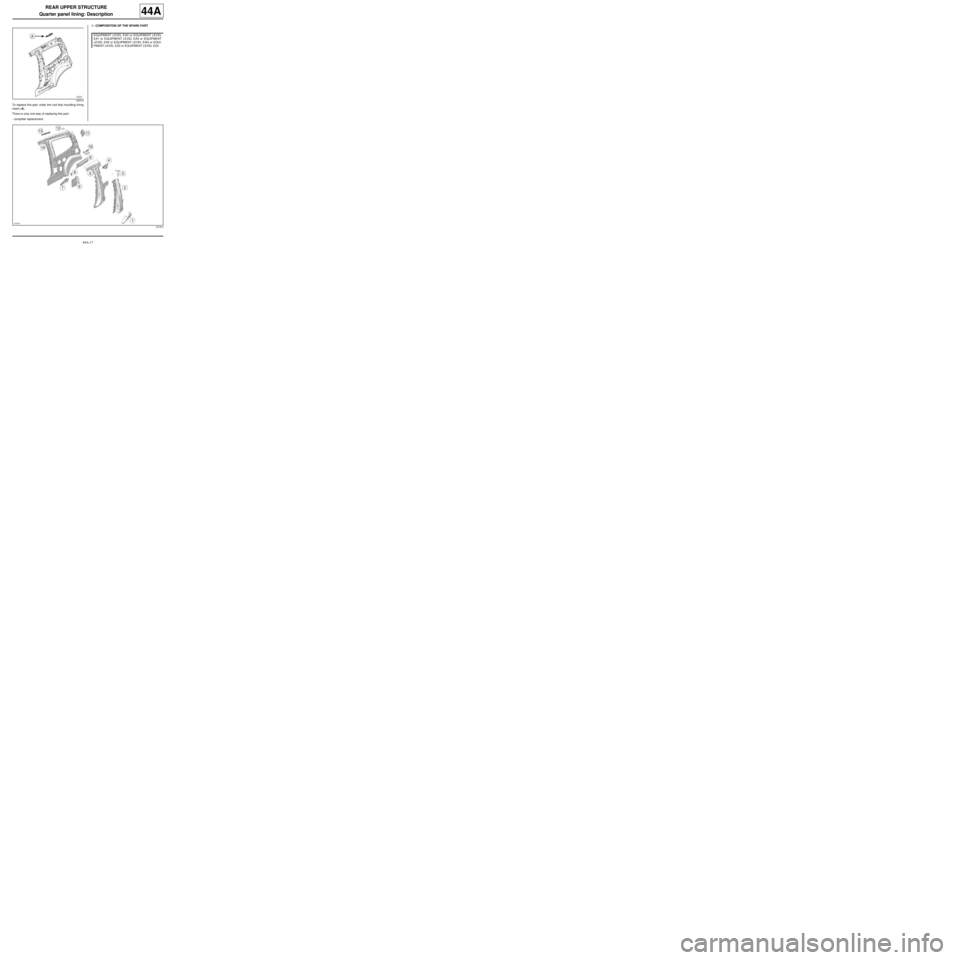

44A-17

REAR UPPER STRUCTURE

Quarter panel lining: Description

44A

To replace this part, order the roof drip moulding lining

insert (A) .

There is only one way of replacing this part:

-complete replacement.I - COMPOSITION OF THE SPARE PART

125416

EQUIPMENT LEVEL EA0 or EQUIPMENT LEVEL

EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT

LEVEL EA5 or EQUIPMENT LEVEL EAG or EQUI-

PMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

121913

Page 182 of 209

45A-1

TOP OF BODY

Roof: General description

45A

DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; its only function is that of a roof.

The special feature of the roof is that it is laser welded

to the body sides.

For vehicles fitted with a sunroof, the roof only has a

front section and a rear section.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400). Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

121044

Page 183 of 209

45A-2

TOP OF BODY

Roof: Description

45A

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART FITTED

1 - Dismantling

a - Cutting

Cut 1 cm from the weld (see MR 400, Basic instruc-

tions for structural bodywork repair, 40A, General

information, Cutting tool for a structural compo-

nent: Use).

Remove the damaged part.

b - Grinding

Weaken the weld without removing it, using a straight

grinder fitted with a cutting disc.

Remove the remaining metal strips. Special tooling required

Car. 1786Levelling tool for bodywork

seal

Equipment required

safety strap(s)

121044

No. Description Type Thic-

kness

(mm)

(1) Roof Mild

steel0.75

120099

121622

Page 184 of 209

45A-3

TOP OF BODY

Roof: Description

45A

Level off the weld residue (see MR 400, Basic instruc-

tions for structural bodywork repair, 40A, General

information, Tool for levelling off weld residue:

Use).

2 - Preparation before assembly

a - Positioning and adjustment

Position the spare part, adjust it and fit it using locking

pliers (see MR 400, Basic instructions for structural

bodywork repair, 40A, General information, Tool

for adjusting and supporting a structural compo-

nent: Use).

If necessary, reassemble the adjacent components

and check the panel gaps.

b - Marking and identifying the joints

Mark the optimum position of the roof with masking

tape between the spare part and the body side (2) .

Remove the replacement part.

c - Preparing the mating faces on the spare part

Gently sand the internal mating faces on the bonding

zones of the spare part with P320 dry sand paper or a

red abrasive pad, without removing the protection.

Prepare the rest of the replacement part according to

the joint type.

d - Preparing the mating faces on the vehicle

Gently sand the internal mating face bonding zones on

the vehicle with P320 dry sand paper or a red abrasive

pad, without removing the protection.

Prepare the rest of the vehicle according to the joint ty-

pe.e - Apply the protection before assembly

Apply the spare part and vehicle protection before as-

sembly (see MR 400, Basic instructions for structu-

ral bodywork repair, 40A, General information, Pre-

assembly anticorrosion protection product: Use).

3 - Assembly

a - Application of the bonding products

Degrease the bonding zones on the replacement part

and the vehicle using heptane.

Apply a cement bead of M.J. Pro to the roof cross

members (3) .

Apply a bead of HIGH PERFORMANCE STRUCTU-

RAL ADHESIVE to the entire internal mating face on

the body side (see MR 400, Basic instructions for

structural bodywork repair, 40A, General informa-

tion, Connection by rigid bonding: Description).

121623

121626

120077