wheel RENAULT TWINGO 2009 2.G Panelwork Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 209

Page 4 of 209

Contents

Front wing upper mounting

support: Removal - Refi tting 42A-7

Front end panel: General

descr iption 42A-8

Front end panel: Removal -

Refitting 42A-9

Headlight carrier panel:

Removal - Refitting 42A-11

Front upper cross member:

General description 42A-12

Front upper cross member:

Removal - Refitting 42A-13

Scuttle side panel: General

descr iption 42A-14

Scuttle side panel:

Description 42A-16

Upper reinforcement of

scuttle side panel: General

descr iption 42A-18

Upper reinforcement of

scuttle side panel:

Description 42A-19

Front wheel arch: General

descr iption 42A-21

Front wheel arch: Description 42A-22

Front wheel arch, front

section: General description 42A-25

Dashboard cross member:

Removal - Refitting 42A-26

Windscreen aperture lower

cross member closure panel:

Description 42A-28

43A SIDE UPPER STRUCTURE

A-pillar : General description 43A-1

A-pillar : Description 43A-2

A-pillar reinforcement:

General description 43A-5 42A FRONT UPPER STRUCTUREA-pillar reinforcement:

Description 43A-6

Windscreen pillar lining:

General description 43A-8

B-pillar reinforcement:

General description 43A-9

B-pillar reinforcement:

Description 43A-10

Body side: General

descr iption 43A-12

Body side: Description 43A-13

Upper body: General

descr iption 43A-15

Upper body: Description 43A-17

44A REAR UPPER STRUCTURE

Rear wing panel: General

descr iption 44A-1

Rear wing panel: Description 44A-2

Rear lights mounting:

General description 44A-5

Rear lights mounting:

Description 44A-6

Outer rear wheel arch:

General description 44A-8

Outer rear wheel arch:

Description 44A-10

Inner rear wheel arch:

General description 44A-13

Inner rear wheel arch:

Description 44A-14

Quar ter panel lining: General

descr iption 44A-16

Quar ter panel lining:

Description 44A-17

Rear end panel assembly:

Description 44A-22 43A SIDE UPPER STRUCTURE

Page 21 of 209

40A-16

GENERAL INFORMATION

Vehicle structure, front section: Description

40A

(9) Engine stand (see 41A, Front lower structure, Engine stand: Descrip-

tion, page 41A-21)

(10) Front left-hand wheel arch (see 42A, Front upper structure, Front wheel arch: Des-

cription, page 42A-22)

(11) Front half unit (see 41A, Front lower structure, Front half unit: Des-

cription, page 41A-24)

(12) Front right-hand wheel arch (see 42A, Front upper structure, Front wheel arch: Des-

cription, page 42A-22)

(13) Front wheel arch, front section (see 42A, Front upper structure, Front wheel arch: Des-

cription, page 42A-22) No. Description Classification Type Thickness

(mm)

Page 26 of 209

40A-21

GENERAL INFORMATION

Vehicle structure, rear section: Description

40A

REAR STRUCTURE

120917

No. Description Classification Type Thickness

(mm)

(1) Quarter panel rear upper stiffener (see MR 400)HLE1

(2) Rear end panel lining (see 44A, Rear upper structure,

Rear end panel assembly: Des-

cription, page 44A-22) Mild

steel0.95

(3) Rear wing panel (see 44A, Rear upper structure, Rear wing panel: Des-

cription, page 44A-2)

(4) Outer rear wheel arch (see 44A, Rear upper structure, Outer rear wheel arch:

Description, page 44A-10)

(5) Rear side member (see 41D, Rear lower structure, Rear side member:

Description, page 41D-8)

(6) Rear side member assembly (see 41D, Rear lower structure, Rear side member

assembly: Description, page 41D-5)

(7) Rear floor (see 41D, Rear lower structure, Rear floor: Description,

page 41D-1)

(8) Inner wheel arch (see 44A, Rear upper structure, Inner rear wheel arch:

Description, page 44A-14)

Page 30 of 209

40A-25

GENERAL INFORMATION

Structural components to be positioned on the repair bench: Description40A

I - PARTS REQUIRING THE USE OF A BODY JIG

BENCH

(1) Front wheel arch

(2) Front half-unit

(3) Engine mounting

(4) Subframe left-hand front mounting

(5) Front side member front section

(6) Rear side member rear section

(7) Rear side member

(8) Rear side member assembly

(9) Rear floor centre cross member

(10) Inner rear wheel archII - FRONT SUBFRAME REAR MOUNTING

121751

121747

Page 32 of 209

40A-27

GENERAL INFORMATION

Structural components to be positioned on the repair bench: Description40A

V - FRONT SHOCK ABSORBER UPPER MOUNTING

The jig supports the underneath of the shock absorber

cup and is centred on the hole (14) of the shock absor-

ber cup.

The jig is used to replace:

-a wheel arch,

-a front half unit.

The jig is also used in straightening.VI - ENGINE MOUNTING

The jig rests on the engine mounting and is centred on

engine mounting securing holes (15) .

The jig is used with the subframe removed for the re-

placement of:

-a front half unit.

-the engine mounting.

VII - FRONT IMPACT CROSS MEMBER MOUNTING

The jig rests vertically against the front end lower cross

member mounting unit, it is centred in the mounting ho-

les (16) .

The jig is used to replace:

-the radiator cross member mounting,

-the front side member completely or partially,.

121753

IMPORTANT

This point contributes to ensuring the front axle

geometry. This point aligns the subframe of the

front axle in relation to the body. This point has a

direct influence on all of the front axle angles.

121753

121754

Page 33 of 209

40A-28

GENERAL INFORMATION

Structural components to be positioned on the repair bench: Description40A

VIII - REAR SIDE MEMBER END

The jig rests under the rear side member and is cen-

tred in hole (17) .

The jig should be used with the mechanical compo-

nents in place to realign a rear side member.

The jig is used with the mechanical components remo-

ved, under the same conditions, to replace the comple-

te rear side member.

IX - INNER REAR WHEEL ARCH

The jig supports the underneath of the rear shock ab-

sorber cup and is centred on hole (18) .The jig is used when replacing the rear wheel arch.

121748

121749

Page 62 of 209

41A-23

FRONT LOWER STRUCTURE

Front half unit: General description

41A

DESIGN OF THE STRUCTURAL COMPONENT

The special feature of this type of part is that it combi-

nes the functions of front side member, front wheel

arch, centre floor front side cross member and front

end side cross member, and is made up of several pa-

nels of different types and thicknesses.IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400.

109546

Page 63 of 209

41A-24

FRONT LOWER STRUCTURE

Front half unit: Description

C44

41A

Right-hand side

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PART

Left sideRight-hand side

125411

IMPORTANT

Use a repair bench to ensure the positioning of the

points and the geometr y of the axle assemblies.

120631

No. Description Type Thic-

kness

(mm)

(1) Front side mem-

ber closure panelHEL1.4

(2) S ide member,

front sectionHEL1.5

(3) Wheel arch Mild

steel1.2

(4) Cup height adjus-

terMild

steel1.3

120630

No. Description Type Thic-

kness

(mm)

(5) S ide member,

front sectionHEL/

Mild

steel1.5

(6) Front side mem-

ber closure panelHEL1.4

(7) Wheel arch Mild

steel1.2

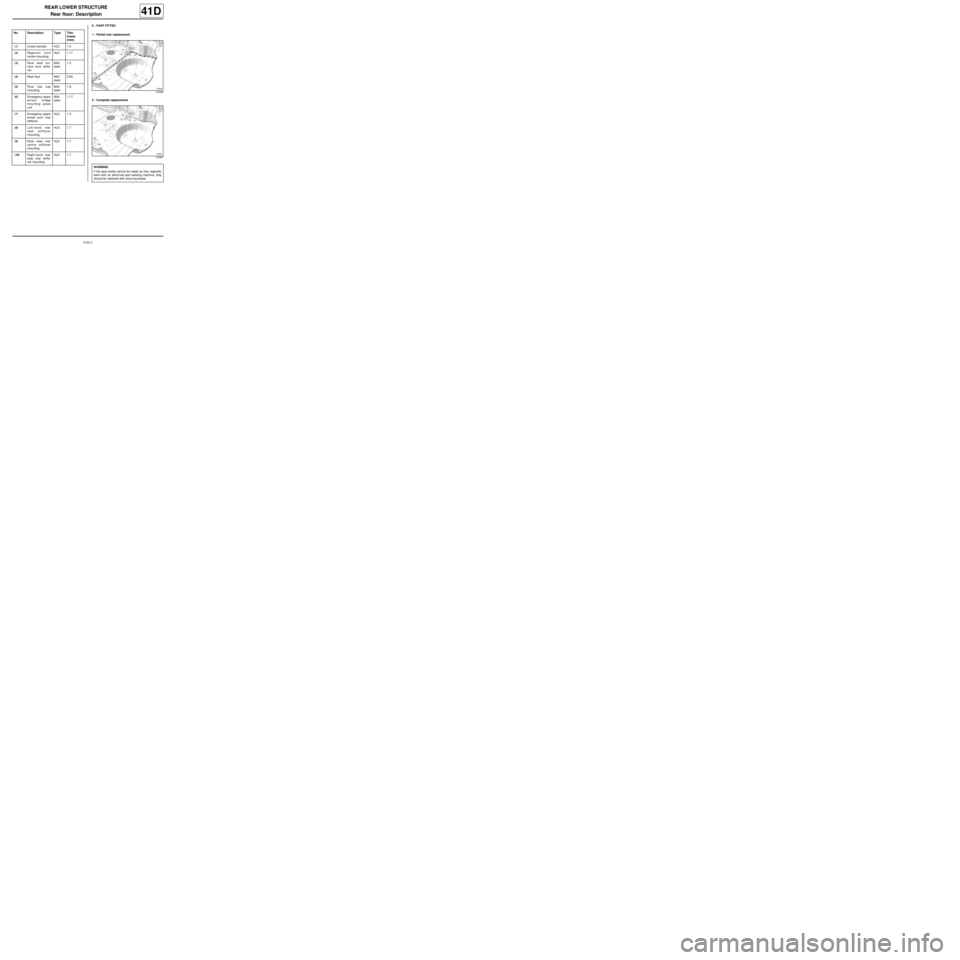

Page 93 of 209

41D-2

REAR LOWER STRUCTURE

Rear floor: Description

41D

II - PART FITTED

1 - Partial rear replacement

2 - Complete replacement No. Description Type Thic-

kness

(mm)

(1) Cross member HLE 1.5

(2) Reservoir front

centre mountingHLE 1.17

(3) Rear seat run-

ners front stiffe-

nerMild

steel1.2

(4) Rear floor Mild

steel0.65

(5) Rear tow eye

mountingMild

steel1.8

(6) Emergency spare

wheel bridge

mounting piece

unitMild

steel1.17

(7) Emergency spare

wheel arch rear

stiffenerHLE 1.5

(8) Left-hand rear

seat stiffener

mountingHLE 1.7

(9) Rear seat rear

centre stiffener

mountingHLE 1.7

(10) Right-hand rear

seat rear stiffe-

ner mountingHLE 1.7

120988

120987

WARNING

If the spot welds cannot be made as they originally

were with an electrical spot welding machine, they

should be replaced with securing beads.

Page 110 of 209

42A-1

FRONT UPPER STRUCTURE

Front wing: General description

42A

I - DESIGN OF THE STRUCTURAL COMPONENT

This type of front wing has the following characteristics:

-plastic wing (NORYL),

-wing bolted to its upper mounting bracket.

II - REMOVAL - REFITTING

To remove or replace the front wing, remove:

-the front wheel arch liner,

-the front bumper,

-the headlight,-the windscreen lower trim piece.

III - ADJUSTMENT

Two main areas of adjustment may be identified:

-the adjustment of the rear area,

-the adjustment of the front area

1 - Adjustment of the rear area: Note:

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

112606

Note:

In all cases of removal of a component without its

replacement with a new one, mark the position of

the mountings before removing the mountings to

avoid adjustments during refitting.

Note:

The front wing is the penultimate removable compo-

nent to be fitted to the vehicle body in the factory.

For final adjustment, correctly position all the other

components including the bumper and the headli-

ghts for them to be correctly positioned.

112042