section 5 ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 203 of 421

mxm^^^?

Electrics

Airbag System

Airbag DM Fault Code 14

Primary crash sensor circuit short to ground

Airbag DM Fault Code 21

Safing sensor insecure mounting.

Normal Operation

The diagnostic module measuresthevoltage at pins

1

-2 and

1

-6. The normal voltage at these pins is 10

volts (±1 volt) with the ignition on, and battery

voltage with the ignition off.

If the voltage at the airbag diagnostic module

connector pins

1

-2 or

1

-6 drops below 5 volts, fault

code 14 will be generated and the airbag warning

lamp will be switched on. When generating a code

14 the diagnostic module also generates a signal to

blow its own internal thermal fuse. This action

disables the airbag deployment circuit. The airbag

diagnostic module fuse is non-repairable and the

module must be replaced after removing the short

circuit. If the voltage at pins 1-2 and 1-6 returns to

normal,

fault code 51 (blown thermal fuse) will be

logged.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of

this

section when

working on the airbag system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4)

2.

Disconnect the airbag diagnostic module and

remove the plastic wedge from plug

1

(slate).

Note:

The

plastic wedge contains a shorting bar which

would

short

together pins

1-3

(gnd),

1-11

and 1-2 when

the plug is disconnected.

3 Measure the continuity to ground at the following

pins on the diagnostic module harness connector:

1-2 RH crash sensor monitor

1-11 LH crash sensor feed

1

-6 LH crash sensor monitor

1-12 RH crash sensor feed

If no short circuit is detected, go to step 4.

If a short circuit

is

detected, disconnect the relevant

crash sensorandrepeatthecontinuity measurement

to isolate the circuit fault. Service the wiring or

replace the crash sensor as necessary. Refit the

plastic wedge to the diagnostic module connector.

Fit a new airbag diagnostic module and rearm the

airbags (6.4.21.4).

Normal Operation

The diagnostic module measures the resistance

between pins

1

-10 (safing sensor case ground) and

1-3 (monitor reference ground) at the diagnostic

module connector. If the resistance is greater than

2Q

a

fault code

21

will be generated and the airbag

warning lamp will be switched on.

Note:

a

good ground connection is vital.

The

wire from

pin

1-1

is riveted to the safing

sensor case

and the

case

must

be securely

grounded to the vehicle

body.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic connector and check for

continuity from pin 1-3 to chassis ground.

If continuity is good, go to step 3.

If the resistance reading is 2Q or more, service the

diagnostic module ground circuit to pin 1-3 as

necessary. Confirm a good ground path between

pins 1-10 and 1-3.Clearthecode21 and rearm the

airbags (6.4.21.4).

Check for continuity between pins

1

-10 and chassis

ground at the safing sensor.

If the resistance is above 2Q, check for continuity

from the safing sensor connector pin 5 to chassis

ground.

Also check the safing sensor mounting for

corrosion,

dirt or loose fixings. Service the wiring

and/or clean and secure the sensor mounting as

necessary, if a satisfactory ground is not achieved,

replace the safing sensor.

Make

a

final continuity test from diagnostic module

connector pin

1

-3 to

1

-10 to ensure a satisfactory

ground

path.

Reconnect the diagnostic module.

Clear the code

21.

Rearm the airbags (6.4.21.4).

September 1996 6-87

Page 204 of 421

Electrics

Airbag System [D:B3-2?

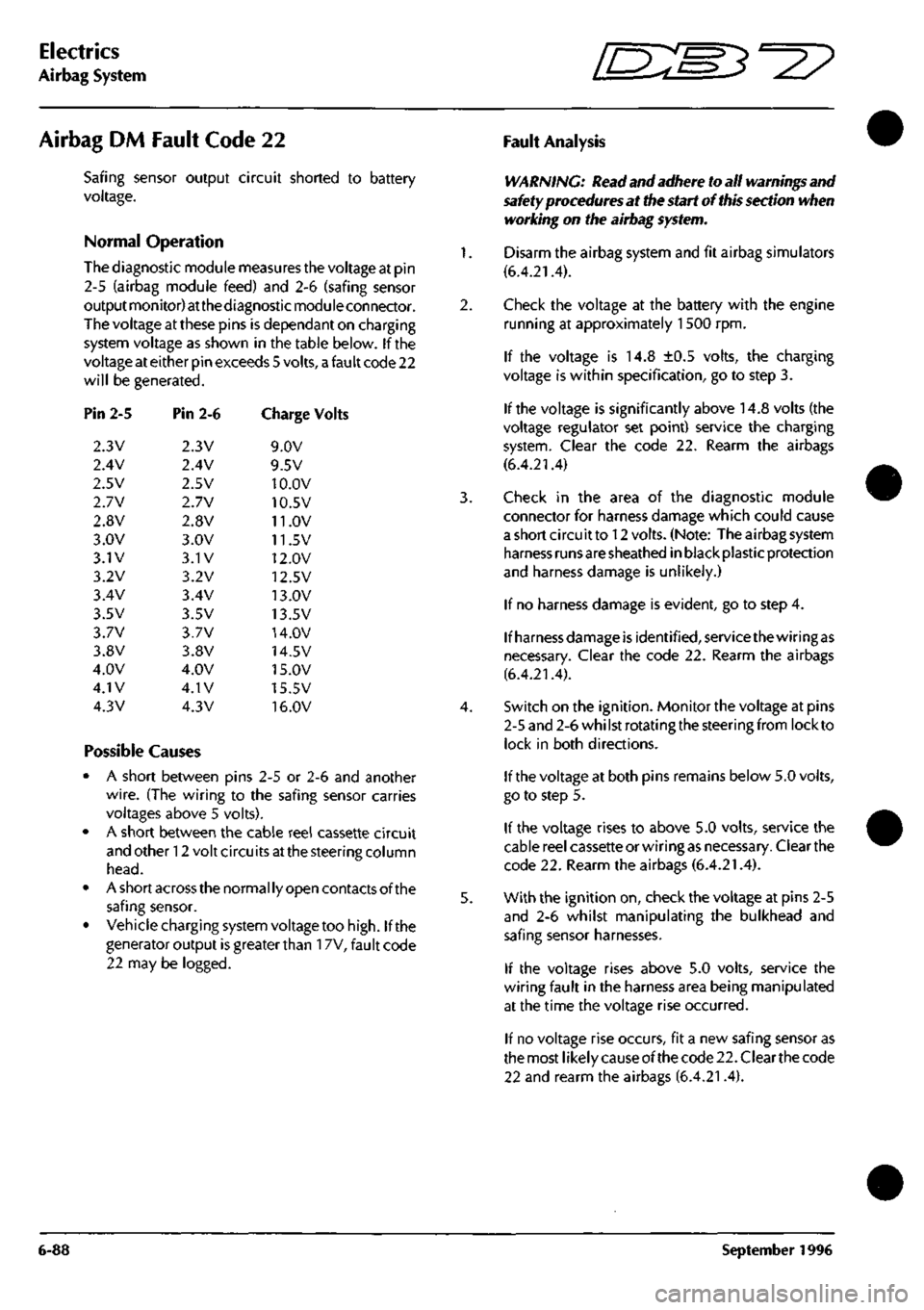

Airbag DM Fault Code 22

Safing sensor output circuit shorted to battery

voltage.

Normal Operation

The diagnostic module measures the voltage at pin

2-5 (airbag module feed) and 2-5 (safing sensor

output monitor) at thediagnosticmoduleconnector.

The voltage at these pins is dependant on charging

system voltage as shown in the table below. If the

voltage at either pin exceeds 5 volts,

a

fault code 22

will be generated.

in 2-5

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4 V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2 V

3.4 V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Charge Volts

9.0V

9.5V

10.0V

10.5V

11.0V

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

Possible Causes

• A short between pins 2-5 or 2-6 and another

wire.

(The wiring to the safing sensor carries

voltages above 5 volts).

• A short between the cable reel cassette circuit

and other 12 volt circu its at the steering column

head.

• A short across the normal ly open contacts of the

safmg sensor.

• Vehiclechargingsystem voltage too

high.

If the

generator output is greater than 17V, fault code

22 may be logged.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Check the voltage at the battery with the engine

running at approximately 1500 rpm.

If the voltage is 14.8 ±0.5 volts, the charging

voltage is within specification, go to step 3.

If the voltage is significantly above 14.8 volts (the

voltage regulator set point) service the charging

system.

Clear the code 22. Rearm the airbags

(6.4.21.4)

Check in the area of the diagnostic module

connector for harness damage which could cause

a short circu it to 12 volts. (Note: The airbag system

harness runs are sheathed in black plastic protection

and harness damage is unlikely.)

If no harness damage is evident, go to step 4.

If harness damage is identified, service the wiring as

necessary. Clear the code 22. Rearm the airbags

(6.4.21.4).

Switch on the ignition. Monitor the voltage at pins

2-5 and 2-6 whilst rotatingthe steering from lock to

lock in both directions.

If the voltage at both pins remains below 5.0 volts,

go to step 5.

If the voltage rises to above 5.0 volts, service the

cable reel cassette or wiring as necessary. Clear the

code 22. Rearm the airbags (6.4.21.4).

With the ignition on, check the voltage at pins 2-5

and 2-6 whilst manipulating the bulkhead and

safing sensor harnesses.

If the voltage rises above 5.0 volts, service the

wiring fault in the harness area being manipulated

at the time the voltage rise occurred.

If no voltage rise occurs, fit a new safing sensor as

the most likely cause of the code 22. Clear the code

22 and rearm the airbags (6.4.21.4).

6-88 September 1996

Page 205 of 421

>^ '—-y ^ Electrics

-^ ^ ^ Airbag System

Airbag DM Fault Code 23

Safing sensor input- battery feed/return open circuit.

Normal Operation

The diagnostic module measures the voltage on

diagnostic module pin

1

-9 at all times. The voltage

can be as high as 25 volts when the backup power

supply is fully charged.

Pin

1

-9 is connected to pin 2-11 inside the safing

sensor and the voltage on both these pins shou

Id

be

the same. If the voltage on pin 2-11 fails below the

voltage on pin

1

-9, a code 23 is generated.

Possible Causes

• Open circuit in the wiring to diagnostic module

pin 1-9.

• Open circuit in the wiring to diagnostic module

pin2-n.

Fault Analysis

WARNING: Read and adhere to all

warnings

and

safety procedures at the start of

this

section when

working on the airbag

system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Disconnect the diagnostic connector and thesafing

sensor connector. Check for continuity from DM

pi n 1

-9 to safing sensor harness connector

pi n

7 and

from DMpin 1-11 to

safing

sensor harness connector

pin 6.

If the continuity of both leads is good, go to step 3.

If a continuity fault is detected, repair the wiring as

necessary. Reconnect ail components. Clear the

code 23. Rearm the airbags (6.4.21.4).

3. Check the continuity between pins 6 and 7 of the

safing sensor.

If the continuity is good, replace the diagnostic

module. Rearm the airbags (6.4.21.4).

If a continuity fault is detected, replace the safing

sensor. Reset the code 23. Rearm the airbags

(6.4.21.4).

September 1996 6-89

Page 206 of 421

Electrics

Airbag System =2?

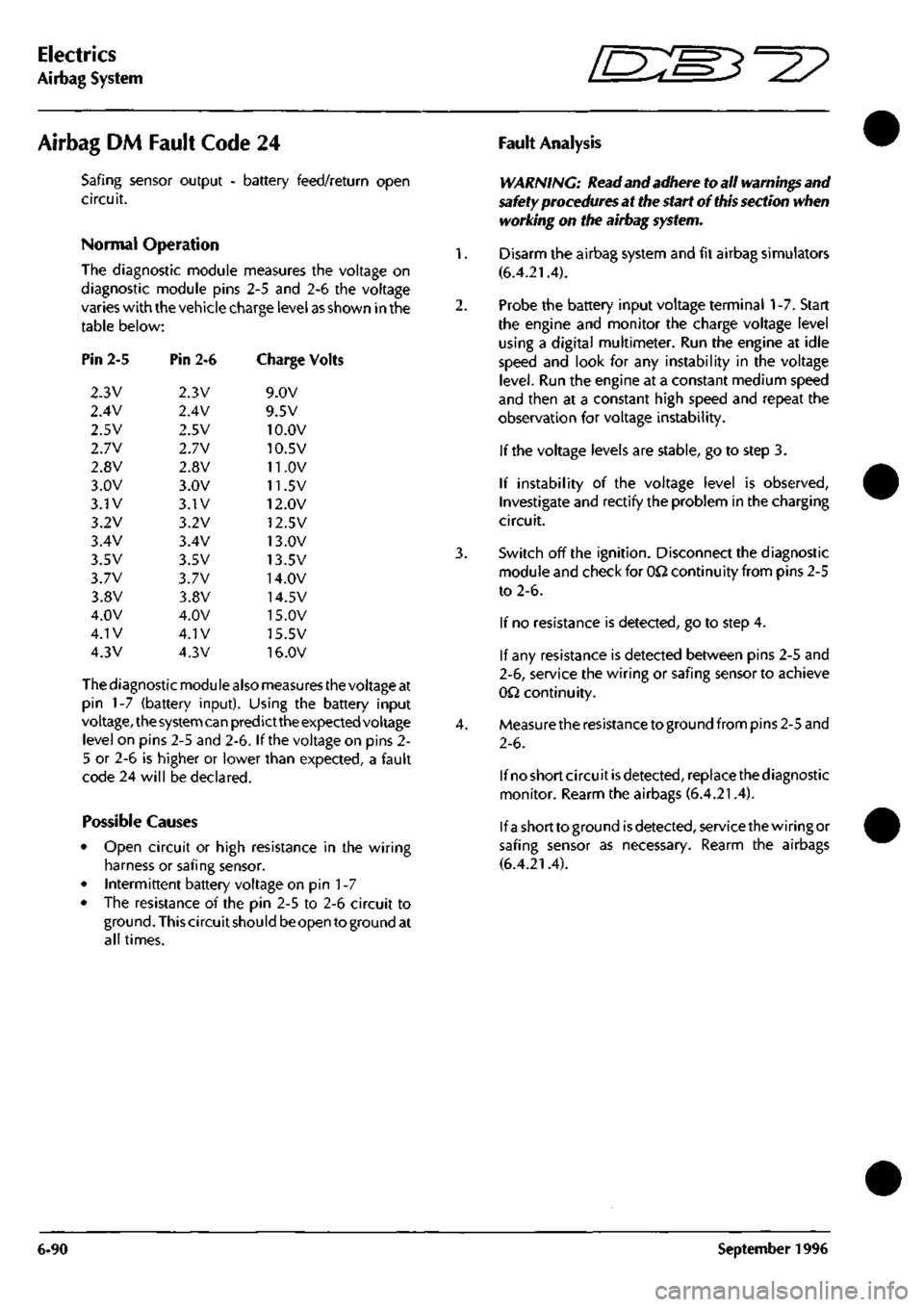

Airbag DM Fault Code 24

Safing sensor output - battery feed/return open

circuit.

Normal Operation

The diagnostic module measures the voltage on

diagnostic module pins 2-5 and 2-6 the voltage

varies with the vehicle charge level

as

shown in the

table below:

in 2-5

2.3V

2.4 V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Cliarge Volts

9.0V

9.5V

10.0V

10.5V

11.0V

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

The diagnostic module also measures the voltage at

pin 1-7 (battery input). Using the battery input

voltage, the system can predict the expected voltage

level on pins 2-5 and 2-6. If the voltage on pins 2-

5 or 2-6 is higher or lower than expected, a fault

code 24 will be declared.

Possible Causes

• Open circuit or high resistance in the wiring

harness or safing sensor.

• Intermittent battery voltage on pin 1-7

• The resistance of the pin 2-5 to 2-6 circuit to

ground.

This circuit should be open to ground at

all times.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of

this

section when

working on the airbag system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

2.

Probe the battery input voltage terminal

1

-7. Start

the engine and monitor the charge voltage level

using a digital multimeter. Run the engine at idle

speed and look for any instability in the voltage

level.

Run the engine at a constant medium speed

and then at a constant high speed and repeat the

observation for voltage instability.

If the voltage levels are stable, go to step 3.

If instability of the voltage level is observed,

Investigate and rectify the problem in the charging

circuit.

3. Switch off the ignition. Disconnect the diagnostic

module and check for OQ continuity from pins 2-5

to 2-6.

If no resistance is detected, go to step 4.

If any resistance is detected between pins 2-5 and

2-6,

service the wiring or safing sensor to achieve

Ofi continuity.

4.

Measure the resistance to ground from pins 2-5 and

2-6.

If no short circuit is detected, replace the diagnostic

monitor. Rearm the airbags (6.4.21.4).

If

a

short to grou

nd

is detected, service the wiring or

safing sensor as necessary. Rearm the airbags

(6.4.21.4).

6-90 September 1996

Page 221 of 421

^^

Electrics

Seat Belt Pretensioner

Diagnostic Trouble Codes

050A Pretensioner squib leak to battery positive

050B Pretensioner squib leak to ground

050C Pretensioner squib high resistance

050D Pretensioner squib low resistance

0D13 Capacitor voltage error

0D14 Capacitor capacitance

0D09 Energy reserve sv^^itch

0D1

E

Energy shutdown switch

050E Seatbelt pretensioner switch error

0109 Accelerometer function

01OA Acceleration out of range

01 OB

Accelerometer offset

0209 Safing sensor error

030A Temperature sensor error

060C Warning lamp short circuit

060D Warning lamp open circuit

060E Warning lamp driver error

OAOC Analogue voltage error

0A09 Communications error

090A EEPROM not programmed

0909 EEPROM checksum

OAOA External watchdog error

OAOB External watchdog time out

020A Safing sensor not closed

090C RAM check error

Seat Beit Pretensioner Diagnostics

WARNING: To avoid the possibility of personal

injury caused by accidental deployment of the

pretensioner, disconnect the vehicle battery and

iva/f at least 10 minutes for all voltages to fully

discharge before working on the pretensioner

system. This covers the possibility of the normal

capacitor discharge circuits being inoperative and

failing to discharge the capacitor when instructed

to do

so.

WARNING: Do not make any electrical

measurements on the pretensioner

squib.

Electrical

measurement devices

can

induce sufficient voltage

to cause unintentional firing of the pretensioner

assembly

050 A Pretensioner Squib Leak to Battery

Positive

050A will be logged if the resistance of the

pretensioner squib feed or return line to a positive

potential falls below

1

k£2.

Procedure

1.

Read the warnings given at the start of this

pretensioner diagnostics section.

2.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050A code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

3. Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

4.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting

link which short circuits

the

squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic cheater to remove the short

circuit

between pins 11 and 12 before continuing with fault

diagnosis.

i"o

o o b 6 o ooooooooo'

I

ooo

Inserr cheater here

September 1996 6-105

Page 222 of 421

Electrics

Seat Belt Pretensioner 5^^?

Switch on the ignition and check for a positive

potential on the squib feed or return lines at the two

pins of the squib harness connector (activating

circuits in the rearward harness in turn may assist in

identifyingthe voltage

source).

Ifa positive potential

is detected, switch off and repair the circuit fault.

If no short circuit is detected in the rearward

harness, go to step 6.

With the ignition switched off and the pretensioner

squib disconnected, check the squib harness for

physical damage.

If any damage is detected, replace the complete

pretensioner squib assembly.

If no damage is detected, the fault is possibly in the

pretensioner control module. Replace the control

module.

Remove the cheater from the control module

connector.

'o o 0080 000000000' 000 ™ ^^ ^^^

ir Insert cheater here

Reconnect all components. Switch on the ignition

and test the vehicle to ensure that the problem is

resolved.

050B Pretensioner

Squib

Leakto Ground

050B will be logged if the resistance of the

pretensioner squib feed or return line to ground

falls below

Ikfi.

Procedure

1.

Read the warnings given at the start of this

pretensioner diagnostics section.

2.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050B code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

3. Switch offthe ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

4.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting link which

short

circuits

the squib lines together

when the connector is displaced. Carefully insert a

suitable non-metallic cheater to remove the

short circuit

between pins 11 and 12 before continuing with fault

diagnosis.

'o

o 00 8 o 000000000' 000

Insert cheater here

Check for a short circuit to vehicle ground on the

squib feed or return lines at the two pins of the squib

harness connector. If a short circuit is detected,

switch off and repair the circuit fault.

If no short circuit is detected in the rearward

harness, go to step 6.

With the ignition switched off and the pretensioner

squib disconnected, check the squib harness for

physical damage.

If any damage is detected, replace the complete

pretensioner squib assembly.

If no damage is detected, the fault is possibly in the

pretensioner control module. Replace the control

module.

Remove the cheater from the control module

connector. Reconnect all components. Switch on

the ignition and test the vehicle to ensure that the

problem is resolved.

6-106 September 1996

Page 223 of 421

D=27

Electrics

Seat Belt Pretensioner

050C Pretensioner Squib High Resistance 050D Pretensioner squib low resistance

050C will be logged if the resistance of the

pretensioner squib circuit rises above 4.5 ±0.5C2

050D will be logged if the resistance of the

pretensioner squib circuit falls below 1.4 ±0.4Q

Procedure

Read the warnings given at the start of this

pretensioner diagnostics section.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 050C code is logged and note if the fault is

shown as internnittent. Note any other codes in the

DTC log and then clear ail codes.

Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

Disconnect the pretensioner squib connector at the

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

3.

Procedure

Read the warnings given at the start of this

pretensioner diagnostics section.

Connect the PDU to the lower diagnostic socket

and accessthe pretensioner control module. Verify

that an 050D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes.

Switch off the ignition and wait at least 10 minutes

for the pretensioner squib firing capacitors to fully

discharge before continuing with this procedure.

Disconnect the pretensioner squib connector atthe

rearward harness. Disconnect the pretensioner

control module and temporarily cheat the squib

shorting link.

Note: The control module harness connector has a

shorting link which

short

circuits the squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic

cheater to

remove

the short

circuit

between pins 11 and 12 before continuing with fault

diagnosis.

.j^ 'o o ob bo oooooooo

O O O

iV ^3 ^3 ^3 ^3 ^3 ^

lU Insert cheater here

Check the continuity of the squib feed and return

lines.

If any significant resistance is measured,

service the wiring as necessary.

Also check the condition of the connector pins for

damage or lack of tension and service

as

necessary.

If the circuit resistance is acceptable and the

connector pins are good, go to step 6.

If any defects are identified and serviced, go to step

7.

If the checks in step 4 are good, the high circuit

resistance must be in the pretensioner squib or in

thecontrol module. Replace the pretensioner squib

and reconnect all components.

Clearall logged DTCs from the pretensioner control

module and then test the vehicle.

If the 050C code is logged again, replace the

control module.

Note: The control module harness connector has a

shorting link which

short

circuits the squib

lines together

when the connector is displaced. Carefully insert a

suitable non-metallic

cheater to remove the

short circuit

between pins 11 and 12 before continuing with fault

diagnosis.

Insert cheater here

Check the continuity from the squib feed line to the

squib return line. With the shorting link cheated,

the resistance should be more than lOkQ. If the

resistance is less than 10kQ, service the wiring as

necessary.

Also check the connector pins for any damage

which could cause an unintentional short circuit.

If the checks in step 5 are good, the low circuit

resistance must be in the pretensioner squib or in

thecontrol module. Replace the pretensioner squib

and reconnect all components.

Clearall logged DTCs from the pretensioner control

module and then test the vehicle.

If the 050D code is logged again, replace the

control module.

September 1996 6-107

Page 224 of 421

Electrics

Seat Belt Pretensioner ^?

060C Warning Lamp Short Circuit

060C will be logged if the nnonitor current flow

through the SRS/Airbag warning lamp is excessive.

The warning lamp circuit is normally at 12 volts and

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

If either control module connector is displaced and

the ignition is switched on, the warning lamp will

be illuminated via the ground shorting link between

pins!

and 2 ofthe pretensioner controller connector

or pins 4 and 5 of the airbag controller connector,

both control modules must be checked for the

appropriate DTC to isolate which circuit is at fault.

Procedure

1.

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060C code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

If fault code 060C is not logged, go to the diagnostics

section of the airbag system.

2.

Check the security of the pretensioner control

module connector.

If the connector is secure, go to step 3.

If the connector isdisplaced,resecu re theconnector.

Clear all logged DTCs and retest the vehicle to

ensure that the problem is resolved.

3. Access the SRS/Airbag warning lamp and check the

lamp resistance.

If the resistance is approximately

120£2,

the lamp is

good.

Refit the lamp and go to step 4.

If the resistance of the lamp is significantly less than

approximately 120^, fit a new lamp and refit the

instrument panel. Clear the logged DTCs from the

pretensioner control module and retest the vehicle

to ensure that the problem is resolved.

4.

If the checks in step 3 are good, the low circuit

resistance must be in the instrument pack or in the

control module. Replace the pretensioner control

module and reconnect all components.

6. Switch on the ignition and then test the vehicle.

If the 060C code is logged again, replace the

instrument pack.

060D Warning lamp open circuit

060D will be logged if the monitor current flow

through the SRS/Airbag warning lamp is below the

normal monitor level.

The warning lampcircuit is normally at 12 voltsand

is switched to ground by the airbag control module

or by the pretensioner control module when one of

these control modules detects a fault.

Procedure

Connect the PDU to the lower diagnostic socket

and access the pretensioner control module. Verify

that an 060D code is logged and note if the fault is

shown as intermittent. Note any other codes in the

DTC log and then clear all codes. Go to step 2.

lffaultcode060D is not

logged,

gotothediagnostics

section of the airbag system.

Switch off the ignition. Access the SRS/Airbag

warning lamp and check the lamp resistance. The

resistance should be approximately 120Q.

If the resistance is 120i2, go to step 3.

If the lamp resistance is significantly lower than

120^2,

replace the lamp. Retest the vehicle to

ensure that the problem is resolved.

Wait 10 minutes after switching off the ignition to

ensure that the pretensioner firing capacitors have

fully discharged.

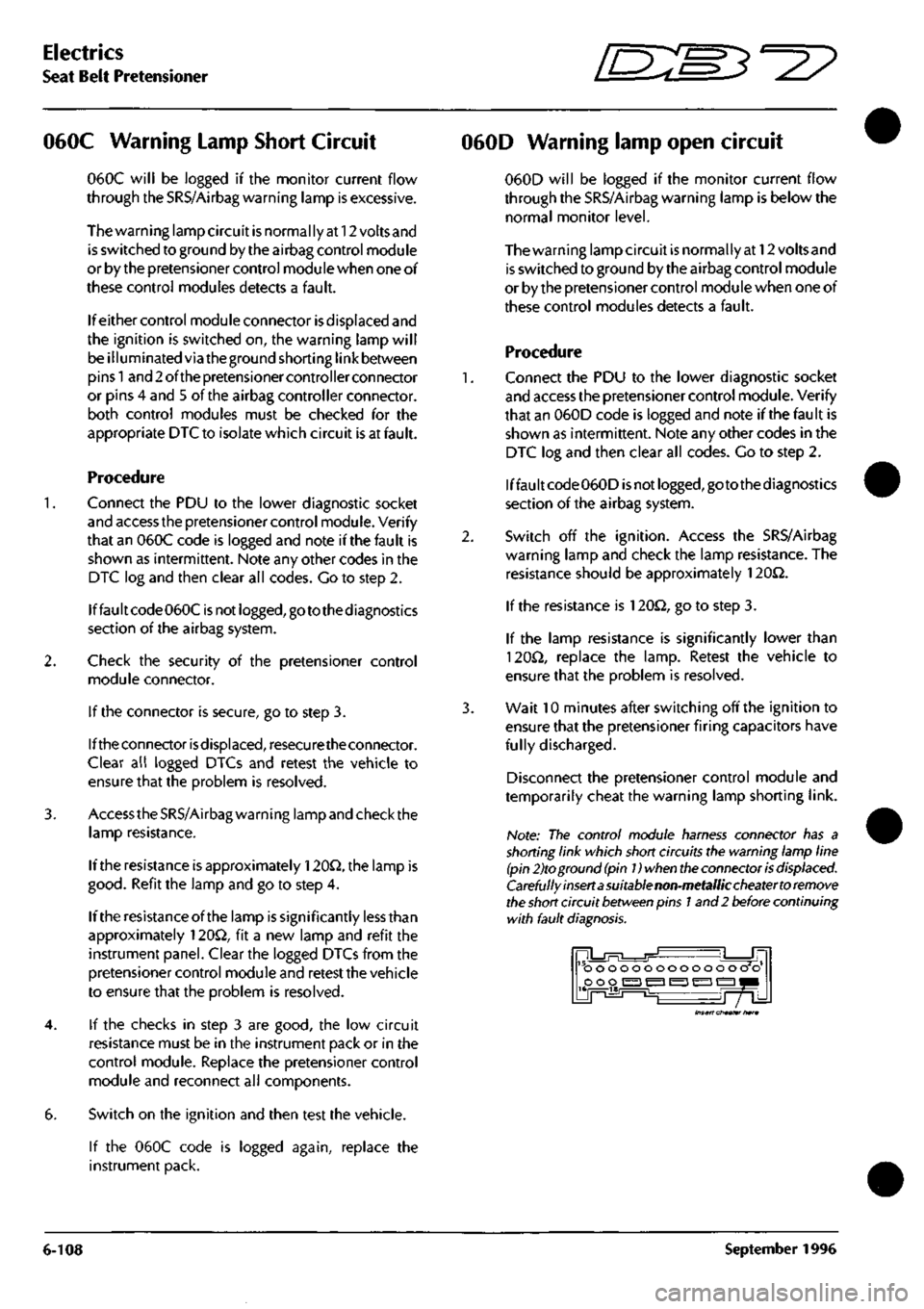

Disconnect the pretensioner control module and

temporarily cheat the warning lamp shorting link.

Note: The control module harness connector has a

shorting link which short circuits the warning lamp line

(pin 2)to ground

(pin

Dwhen

the

connector

is

displaced.

Carefully insert a suitable non-metallic cheater to remove

the

short

circuit

between

pins

1

and 2 before continuing

with fault

diagnosis.

ooooooooooooo o o poo

i^i

^ ^ ^ 1^1

Insert cheater hare

6-108

September

1996

Page 230 of 421

Body and Trim //-->> ^izz^^ ' ^ ^

Body Repair ' —^^ '-^ >^-/

Body Repair

Introduction

This section contains information for the body repair and rectification of the vehicle. Wherever possible the vehicle

must be returned to its original manufactured condition. Following repair the vehicle must be fully checked and, if

necessary, the braking system and steering must be fully reset.

Health and Safety

Ensure that the correct working practices are established before beginning work.

Observe that the correct working practices are followed whether they be legislative or common sense.

Be aware of the potential risks of using materials used in the manufacture and repair of vehicles and take the

appropriate precautions.

Warning: Make sure that the working practices for the air conditioning

system

are followed: do not vent the refrigerant

directly into the atmosphere and always use the approved recovery/recycle /recharge equipment, always wear

suitable protective garments to prevent injury to the eyes and the skin.

Potential Risks

Paint

If the organic solvents, contained in paints, are inhaled for any length of time damage can be caused to the liver,

kidneys, respiratory tract and the digestive system.

Prolonged exposure to isocyanates can cause lung sensitisation and asthma-like symtoms can develop with

subsequent re-exposure to even low concentrations.

Solvent inhilation can cause dizziness or loss of consciousness.

Inhilation of spray dust and sanding debris can cause lung damage.

Paint activatorsand additives will damage the eyesor can cause dermatitis if allowed to splash and come into contact

with these areas. Peroxide and acid catalysts can cause burns.

Applied heat

There is considerable risk of damage to the eyes and skin when welding or flame cutting.

Fire is a serious danger as many materials and fluids in the vehicle are inflammable.

Toxic and dangerous fumes can be liberated when the following are subjected to heat; expanded foam, corrosion

protection,

adhesive and sealing compounds,

trim,

seat material and paints that contain isocyanates.

When heated to

a

temperature of 300°C, polyu rethane based compounds can

1

iberate small quantities of isocyanate.

Many types of nitrogen containing chemicals may be liberated as breakdown products, these chemicals can

contain isocyanates, oxides of nitrogen and hydrogen cyanide.

Potentially toxic or asphyxiant fumes and gases are produced by welding, for example; zinc oxide with zinc coated

panels and ozone gas from the MIC process.

Metal repair

There is considerable risk of damage to the eyes, ears and skin when metal cutting, forming and dressing is being

carried out.

Soldering may be hazardous because of heat generated fumes and skin contact with the materials.

7-2 May 1996

Page 231 of 421

^"^

Body and Trim

Body Repair

Precautions

Paint

Ensure that there is efficient ventilation at all times. Paint spraying should be confined to spray booths.

Anyone with a history asthma should not be engaged in any process which involves the use of isocyanates.

Any operator working inside a spray booth where isocyanates are present must use air-fed breathing equipment.

Supplied air to the visor should be fed at the recommended pressure and filtered to remove oil, water and fumes.

Operators involved in handling, mixing or spraying should wear protective clothing, gloves and goggles to avoid

skin and eye contact. A Paticle mask or canister typr respirator should be worn when sanding.

Applied heat

When welding, flame cutting or brazing and so on, goggles, a mask or fume extractor and flameproof protective

clothing should be used always.

It is especially important when working with polyurethane compounds to use air-fed breathing equipment.

Ensure that at all times the appropriate fire fighting equipment isavailableand that personnel are trained in its use.

Metal repair

Wear appropriate eye and hand protection when sanding, drilling, cutting, chiselling, flatting or welding. Wear a

face mask or air-fed visor when sanding or flatting either body solder or

fillers.

When a soldering operation has been

completed,

remove swarf from the work area and wash your hands thoroughly.

General Repair Notes

The following precautions should be noted before any work is carried out:

• disconnect the vehicle battery ground

lead,

taking note of the reconnection procedures

• Make sure that you have read and understood the safety related procedures in this section.

Caution:

Electric arc

welding must not

be

used on the

vehicle as the high

voltages produced by

this process

will

cause

irreparable

damage

to the electrical control and

microprocessor

systems.

All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel

removal or replacement.

Welding and Gas Process Special Notes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated

metal.

The flanges of panels, which are to be welded together, must be clean, corrosion free and treated as

appropriate with either weld-through or inter-weld sealer.

The resistance spot welding equ ipment used in vehicle repair does not always produce

a

weld of

equ

ivalent strength

to that produced in manufacturing. This means that a single row of spot welds should be spaced on a pitch of 19-

25 mm, which will usually result in more spot welds than found in the original factory joint.

Use a resistance spot weld cutter to remove resistance spot welds. Where a new joint is to be MIC welded, cut the

old resistance spot welds from the panel that is to be retained; the resulting holes are then used for plug welding.

Suitable holes may be drilled or punched as follows:

• 8.0 mm for sections up to 1.5 mm thickness

• 10.0 mm for thicker sections.

Always refer to the welding equipment manufacturers diagrams and tables for the relevant procedure.

May 1996 7-3