engine AUDI S3 2010 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2010, Model line: S3, Model: AUDI S3 2010Pages: 320, PDF Size: 75.34 MB

Page 288 of 320

IIII.___E_ m_ e_r -=g :...e_ n _ c-=y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

& WARN ING (continued )

• Before you check anything in the engine compartment , always

read and heed all WARNINGS=>

page 215, "Engine compa rt m ent" .

0 Note

• Applying a higher voltage booster battery wil l cause expensive

damage to sensitive electronic components, such as contro l units,

relays, rad io, etc.

• There must be no electrical contact between the vehicles as

otherwise current cou ld already star t to flow as soon as th e positive

(+ ) termina ls are connected .

• Improperly connected jumper cab les can cause substantia l

damage to the electrica l system of the vehic le.

[ i ] Tips

• The disc harged battery must be p ro per ly connected to the

ve hicle's elec trica l system .•

General information of starting

assistance

P lease observe tha t the p rocedure described below for conn ecti ng

jumper cab les is intended to provide a jump start for your vehicle.

M ake sure that the connected c la mp s have s ufficien t metal cont act.

& WARNING

Improper handling of the jumper cables can lead to an explosion

of the battery and severe inju ries . To reduce the r isk of injury, note

the following:

& WARNING (continued )

• The sections of the terminal clamps that are not insulated

must not touch each other. In addition , the cable clamped to the

battery's positive terminal must not come in contact with electri

cally connected parts of the vehicle -danger of short circuit!

• Route the jumper cable so that it cannot catch in any rotating

part s in the engine compartment .

• Do not bend over the batteries -danger of chemical burns!

• The battery cell locking screws must be t ightened securely .

• Keep ignition sources (open flame, burning cigarettes, etc .)

away from the batteries -danger of explosion!

• Do not clamp the minus cable to parts of the fuel system or the

brake lines .

0 Note

If you provide start assistance for others with your vehicle, you

s h ould not c lamp t he min us ca ble(-) to t he negat ive ter min al o f the

discharged battery=> fig. 196

© but to a solid meta l part screwed

f ir m ly to the eng ine bloc k, or to the engi ne b loc k it sel f. In ca se of a n

inadequately v entilated battery of the veh ic le receiving power, there

i s a danger of expl osio n due to deto nating gas !•

Page 289 of 320

______________________________________________ E_ m_ e_r .;::g ;...e _ n_ c __,c. y_ s_it _u_ a_ ti_o _ n_ s _ __._

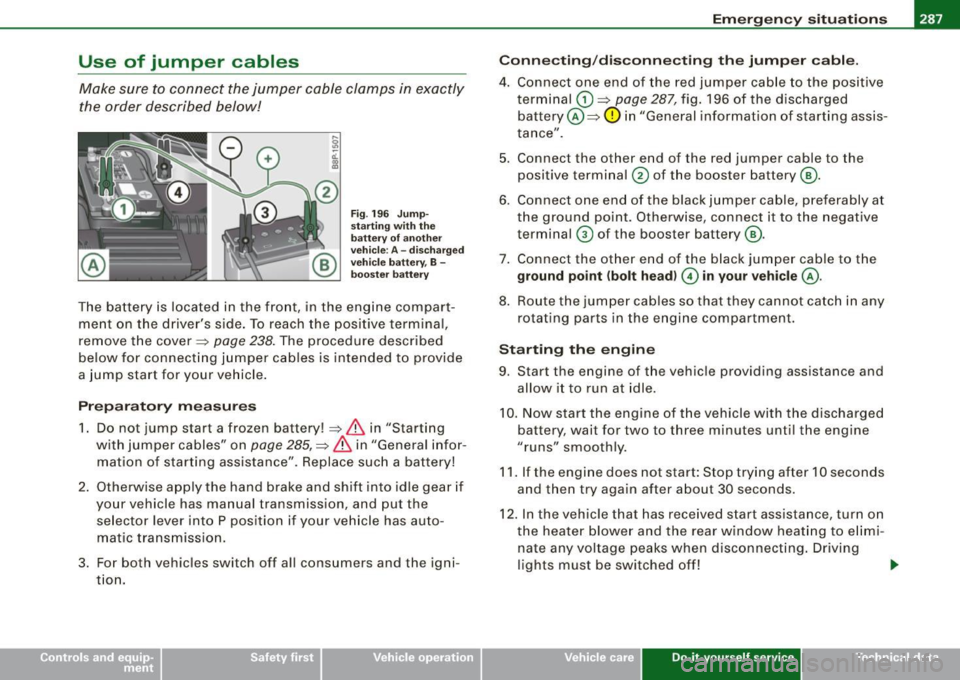

Use of jumper cables

Make sure to connect the jumper cable clamps in exactly

the order described below!

Fig . 196 Jump

starting with the

battery of another

vehicle : A -discharged

vehicle battery , B -

booster battery

The battery is located in the front, in the engine compart

ment on the driver's side. To reach the positive terminal,

remove the cover=>

page 238. The procedure described

below for connecting jumper cables is intended to provide

a jump start for your vehicle.

Preparatory measures

1. Do not jump start a frozen battery ! => & in "Sta rting

with jumper cables" on

page 285, => & in "General infor

mation of starting assistance" . Replace such a battery!

2. Otherwise apply the hand brake and shift into idle gear if

your vehicle has manual transmiss ion, and put the

selector lever into P position if your vehicle has auto

matic transmission.

3. For both veh ic les switch o ff a ll co nsumers and the igni

tion.

Connecting/disconnecting the jumper cable.

4. Connect one end of the red jumper cable to the positive

terminal

(D => page 287, fig . 196 of the discharged

battery @=> (Din "General information of starting assis

tance".

5. Connect the other end o f the red jumper cable to the

positive terminal

@ of th e boost er battery ®·

6. Connect one end of the black jumper cable, preferably at the ground point. Otherwise, connect it to the negat ive

terminal

0 of the booster battery ®·

7. Connect the other end of the black jumper cable to the

ground point (bolt head) © in your vehicle @.

8. Route the jumper cables so that they cannot catch in any

rotating parts in the engine compartment.

Starting the engine

9. Start the engine of the veh icle providing ass istance and

allow it to run at idle.

10. Now start the engine of the vehicle with the discharged

battery , wait for two to three minutes unt il the eng ine

" runs " smoothly.

11. If the engine does not start: Stop t rying after 10 seconds

and then try again after about 30 seconds.

12. In the vehicle that has received start assistance, turn on the heater blower and the rear window heating to elimi

nate any voltage peaks when disconnecting. Driving lights must be switched off! .,

Vehicle care Do-it-yourself service irechnical data

Page 290 of 320

11111.___E_ m _ e _r-==g :...e_ n_ c...:y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

13. Disconnect the cable while the engine is running exactly

in

reverse order to that described in~ page 287,

11Connecting/disconnecting the jumper cable.11

• When

doing so, make sure that the cable cannot contact rotating engine parts.

14. Turn the heater blower and the rear window heating off again.

The battery is vented to the outside to prevent gases from entering

the vehicle interior.

Make sure that the jumper clamps are well connected with their

metal ports in full contact with the battery terminals .

& WARNING

To avoid serious personal injury and damage to the vehicle, heed

all warnings and instructions of the jumper cable manufacturer. If

in doubt, call for road service.

• Jumper cables must be long enough so that the vehicles do not

touch .

• When connecting jumper cables, make sure that they cannot

get caught in any moving parts in the engine compartment.

• Before you check anything in the engine compartment, always

read and heed all WARNINGS =>

page 215, "Engine compartment" .

0 Note

Improperly connected jumper cables can damage or destroy the

generator.

• Do not use the battery negative terminal for jump starting or a

malfunction could occur in the vehicle electrical system.

• Always connect POSITIVE(+) to POSITIVE(+), and NEGATIVE( -) to

NEGATIVE (-l terminal. •

Check that all screw plugs on the battery cells are screwed in

firmly. If not, tighten plugs prior to connecting clamp on negative battery terminal.

• Please note that the procedure for connecting a jumper cable as

described above applies specifically to the case of your vehicle

being jump started. When you are giving a jump start to another

vehicle, do

not connect the minus(-) cable to the minus 1-l terminal

on the discharged battery@=>

page 287, fig. 196. Instead, securely

connect the minus(-) cable to either a massive metal component

that is firmly bolted to the engine block or to the engine block itself.

If the battery that is being charged does not vent to the outside,

escaping battery gas could ignite and explode! •

Emergency towing with commercial

tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by commercial tow truck

operators who know how to operate their equipment safely.

• Never tow your Audi, towing will cause damage to the engine

and transmission.

• Never wrap the safety chains or winch cables around the brake

lines.

• To prevent unnecessary damage, your Audi must be transported

with a car carrier (flat bed truck).

• To load the vehicle on to the flat bed, use the towing loop found

in the vehicle tools and attach to the front or rear anchorage

=>

page 289 and => page 289 . .,_

Page 293 of 320

________________________________________________ E_ m_ e_r .::g :...e_ n _ c_,y'-- s_ i_t _u _a_ t_ i_o _n_ s _---J_

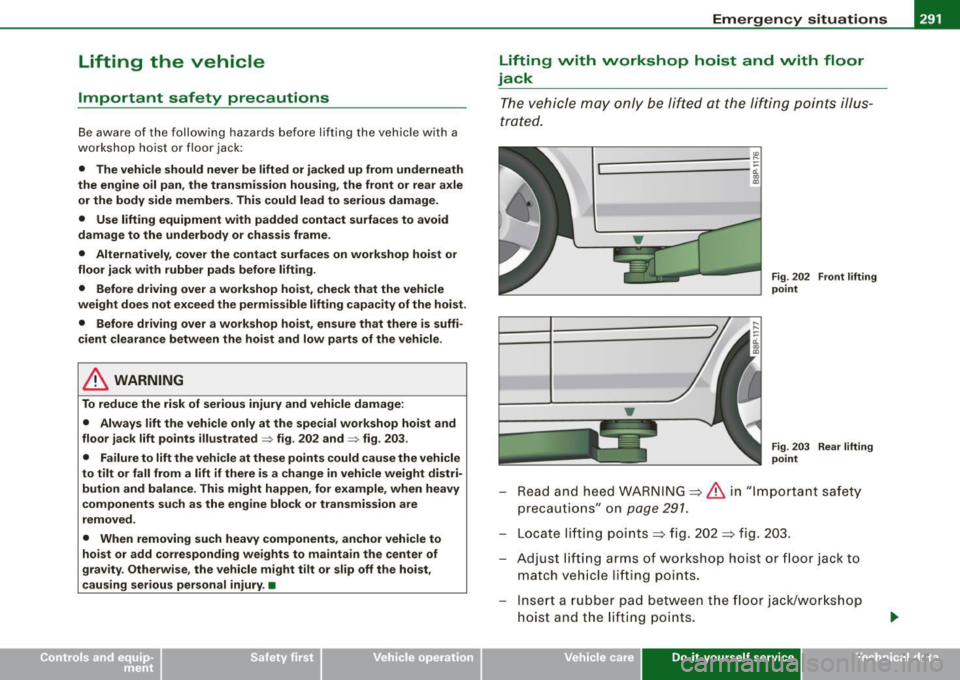

Lifting the vehicle

Important safety precautions

Be aware of the following hazards before lifting the vehicle with a

workshop hoist or floor jack:

• The vehicle should never be lifted or jacked up from underneath

the engine oil pan, the transmission housing, the front or rear axle

or the body side members. This could lead to serious damage.

• Use lifting equipment with padded contact surfaces to avoid

damage to the underbody or chassis frame.

• Alternatively, cover the contact surfaces on workshop hoist or

floor jack with rubber pads before lifting .

• Before driving over a workshop hoist, check that the vehicle

weight does not exceed the permissible lifting capacity of the hoist .

• Before driving over a workshop hoist, ensure that there is suffi

cient clearance between the hoist and low parts of the vehicle .

& WARNING

To reduce the risk of serious injury and vehicle damage:

• Always lift the vehicle only at the special workshop hoist and

floor jack lift points illustrated

=> fig. 202 and => fig. 203 .

• Failure to lift the vehicle at these points could cause the vehicle

to tilt or fall from a lift if there is a change in vehicle weight distri

bution and balance. This might happen, for example, when heavy

components such as the engine block or transmission are

removed .

• When removing such heavy components, anchor vehicle to

hoist or add corresponding weights to maintain the center of

gravity . Otherwise , the vehicle might tilt or slip off the hoist,

causing serious personal injury. •

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting points illus

trated.

.... L===========::::==:: ~ 0:.

Fig . 202 Front lifting

point

Fig . 203 Rear lifting

point

Read and heed WARNING ~ & in "Important safety

precautions " on

page 291.

Locate lifting points~ fig. 202 ~ fig. 203.

Adjust lift ing arms of workshop hoist or floor jack to

match vehicle lifting points.

Inse rt a rubber pad between the floo r jack/workshop

hoist and the lifting poin ts.

Vehicle care Do-it-yourself service irechnical data

Page 294 of 320

lllffl.___E_ m _ e _r-==g :...e_ n_ c...:y _ s_ i_t _u _a _t_ i_o _n_ s _______________________________________________ _

If you mu st lift your veh icle with a floor jack to work underneath , be

sure the vehicle is safely supported on stands intended for this

purpose .

Front lifting point

T he lifting point is located on the floor pan reinforcement about at

t he same leve l as t he jac k mou nti ng poi nt=>

pag e 291, fig. 202 . Do

not lift the vehicle at the vertical sill reinforcement .

Rear lifting point

T he lifting point is located on the vertical reinforcement of the lower

sill for the o n board jack=>

page 291, fi g. 203 .

Lifting with vehicle jack

Refe r to=> page 274.

0 Note

• Be aware of the fo llo wi ng po ints before l ifting t he ve hicle :

- The vehicle should never be lifted or jacked up from under

neath the engine oil pan , the transmission housing , the front or

rear axle or the body side members . This could lead to serious

damage.

- To avoid damage to the underbody or chassis frame , a rubber

pad must be inserted between the floor jack and the lift points .

- Before driving over a workshop hoist, check that the vehi cle

weight does not exceed the permissible lifting capacity of the

hoist .

- Before driving over a workshop hoist , ensure that there is

sufficient clearance between the hoist and low parts of the

vehicle. •

Page 296 of 320

___ G_ e_ n_ e_r_ a _ l_ in_ f_ o _r_m _ a_ t_ i_ o _ n __________________________________________________ _

General information

Explanation of technical data

Some of the technical data listed in this manual requires

further explanation.

The technical data for your vehicle is listed in the charts starting on

~ page 296. This section provides general information, notes and

restrictions which apply to this data. •

Vehicle identification

The key data are given on the vehicle identification

number (VIN) plate and the vehicle data sticker.

Fig. 204 Vehicle Identi

fication Number (VIN)

plate: location on

driver's side dash

panel Fig

. 205 The vehicle

identification label -

inside the luggage

compartment

The Vehicle Identification Number (VIN)

is located on the driver's side so that it is visible from the outside

through the windshield -see ~ fig. 204.

The vehicle identification label

is located in the luggage compartment in the spare wheel well.

The label ~ fig. 205 shows the following vehicle data:

© Production control no.

0 Vehicle identification no.

© Type code number

© Type designation/engine output in Kilowatts

© Engine and transmission code letter

© Paint no./lnterior

0 Optional equipment no.'s

Vehicle data 2 to 7 are also found in your Warranty

& Maintenance

booklet .

The safety compliance sticker

is your assurance that your new vehicle complies with all applicable

Federal Motor Vehicle Safety Standards which were in effect at the

time the vehicle was manufactured. You can find this sticker on the ._

Page 298 of 320

___ D_ a_ ta ______________________________________________________ _

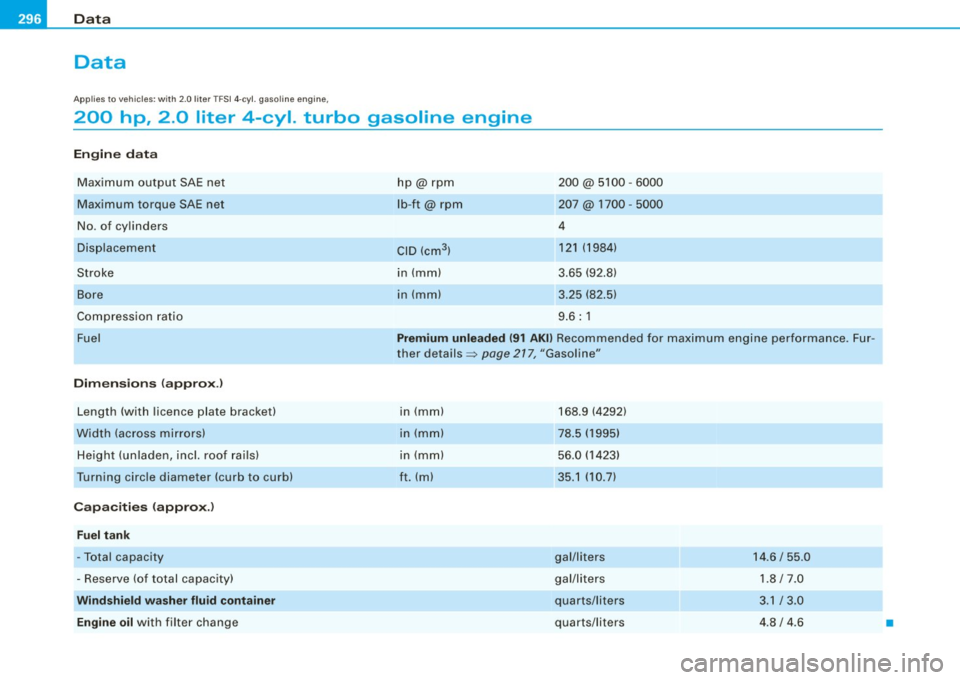

Data

Applies to vehi cles: with 2.0 lite r TFS I 4-cyl. g asoline eng ine ,

200 hp, 2.0 liter 4-cyl. turbo gasoline engine

Engin e data

Maximum output SAE net

Maximum torque SAE net

No. of cy linders

Disp lacement

Stroke

Bore

Compression ratio

Fuel

D im ensio ns (a pprox.)

Length (with licence plate bracket)

Width (across mirrors)

Height (unladen, incl. roof rails)

Turning circle diameter (curb to cu rb)

Ca pacitie s (a pprox.)

F u el t ank

-Total capacity

- Reserve (of total capacity)

W ind shi eld was her fluid cont ain er

Engine oil

with filter change hp@rpm

lb

-ft@ rpm

CID (cm

3 )

in (mm)

in (mm)

200@ 5100 -6000

207 @ 1700 -5000

4 121 (1984)

3.65 (92.8)

3 .25 (82 .5)

9 .6 : 1

Premium unleaded (91 AKI) Recommended for maximum engine performance . Fur

ther det ails =:>

page 277, "Gasol ine"

in (mm)

in (mm)

in (mm)

ft. (ml

168.9 (4292)

78 .5 (1995)

56.0 (1423)

35.1 (10.7)

gal/liters

gal/liters

quarts/liters

quarts/liters 14 .6 / 55.0

1 .8/7.0

3 .1 / 3 .0

4 .8 / 4.6

•

Page 299 of 320

___________________________________________________ D_a_ t_ a __ !II

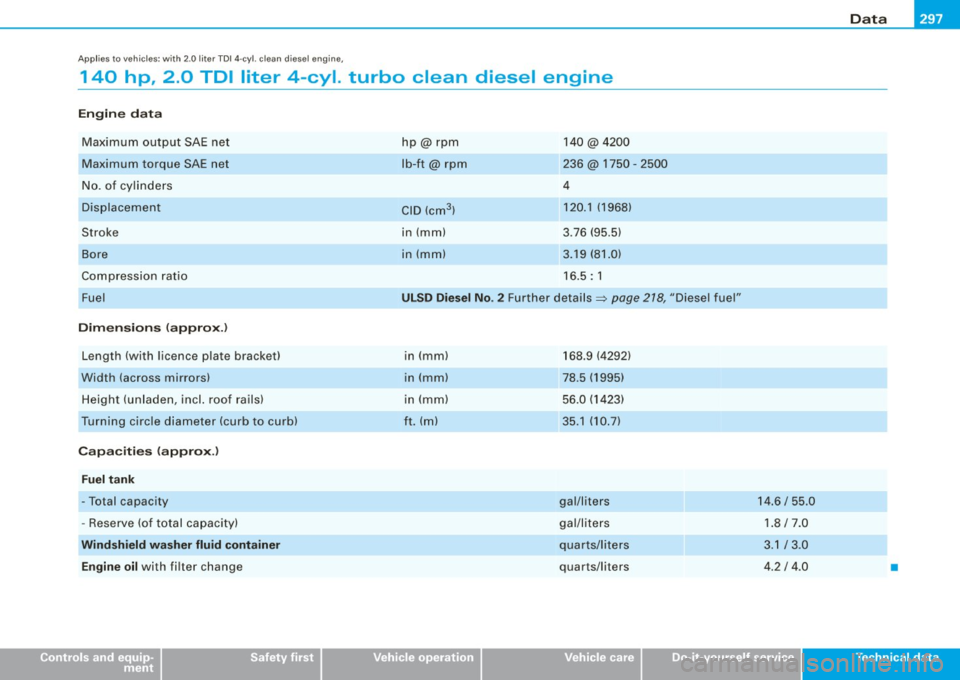

A pp lies to veh ic les : w it h 2 .0 liter TDI 4 -cyl. c le an di esel e ngin e,

140 hp , 2 .0 TOI liter 4-cyl. turbo clean diesel engine

Engine data

Maximum output SAE net

Maximum torque SAE net

N o. o f cy linders

Displacement

Stroke

Bore

Co mpression ratio

Fuel

Dimensions (approx .)

Length (with licence p late bracket)

Width (across mirrors) H eight (unla den, incl. roof ra ils)

Turning circle diameter (curb to curb)

Capacities (approx .)

Fuel tank

-Total capacity

- Reserve (of t otal capacity)

Wind shield wa sher fluid container

Engine oil

with filter change

Controls and equip ment Safety first

hp@rpm

lb-ft@ rpm

CID (cm

3

)

in (mm)

in (mm)

14 0 @4200

236 @ 1750 · 2500

4

120.1 (1968)

3 .76 (95 .5)

3.19 (81 .0)

16. 5: 1

ULSD Diesel No . 2 Further details=> page 218, "Diesel fue l"

in (mm)

in (mm)

in ( mm)

ft. (ml

Vehicle operation

168.9 (4292)

78.5 (1995) 56.0 (14 23)

35.1 (10.7)

gal/liters

gal/li te rs

quarts/liters

quarts/liters

Vehicle care

14.6 / 55.0 1.8/7.0

3.1 / 3_0

4.2 I 4 .0

Do-it-yourself service

•

T ec hn ica l da ta

Page 300 of 320

___ C_ o_n_ s_ u_m _ e_ r_ ln_ f_ o _r _m _ a_ t_ i_o _n ______________________________________________ _

Consumer Information

Warranty coverages

Your A udi i s cov ered b y the follo wing war ra nt ies:

• New Vehicle Limited Warranty

• Limited Warranty Against Corrosion Perforation

• Emissions Control System Warranty

• Emissions Performance Warranty

• California Emissions Control Warranty (USA vehicles only)

• California Emissions Performance Warranty (USA vehicles only)

Detailed information rega rding your warranties can be found in

your

W arr ant y & Maint ena nce Booklet .•

Operating your vehicle outside the

U .S.A. or Canada

Government regulations in the United States and Canada require

that automobiles meet specific em ission regulations and safety

standards. Therefore, vehic les bui lt for the U.S .A. and Canada differ

from vehicles sold in other countries .

If you plan to take your vehic le outside the continental limits of the

United States or Canada, there is the possibility that

• unleaded fue ls for vehicles with catalyt ic converter may not be

available;

• f uel may have a considerably lower octane rating . Improper fuel

may cause engine damage;

• service may be inadequate due to lack of proper service facilities,

tools or testing equipment;

• replacement parts may not be readi ly available . •

Navigation systems for vehicles built for the U.S.A . and Canada

wil l not necessarily work in Europe, and may not work in other coun

tries outside of North Amer ica.

Audi c annot be responsib le for me ch an ical damage that could

result from inadequate fuel , serv ice or parts availability .

0 Note

Audi cannot be responsible fo r mechanica l damage that could

result from inadequate fuel, service or parts avai lability .•

Audi Service Repair Manuals and

Literature

Audi Official Factory Service Manuals are published as soon as

possible af ter model introduction . Service manua ls are available

from:

Audi Te ch n ic al Liter ature Ordering Center

Ca ll toll -free:

Tel. :

1 (800) 544-802 1

(from 8:00 AM to 8:00 PM, EST, Mon day t hrough Friday)

or access their website

www .audi .dd sltd .com on the Internet to

order repair manuals and other Audi literature .•

Page 301 of 320

Consumer Information I'll _________________________________ __::..::....:...:...::...:.:..:....:....:.:;__ _____ _

Maintenance

General

Your vehicle has been designed to help keep maintenance require

ments to a minimum.

However, a certain amount of regular maintenance is still necessary

to assure your vehicle's safety, economy and reliability.

For detailed vehicle maintenance consult your Warranty

& Mainte

nance booklet.

Under difficult operating conditions, for example at extremely low

outside temperatures, in very dusty regions, when towing a trailer

very frequently, etc., some service work should be performed

between the intervals specified. This applies particularly to:

• oil changes, and

• cleaning or replacing the air filter.

ci> For the sake of the environment

By regularly maintaining your vehicle, you help make sure that emis

sion standards are maintained, thus minimizing adverse effects on

the environment. •

Important considerations for you and your

vehicle

The increasing use of electronics, sophisticated fuel injection and

emission control systems, and the generally increasing technical

complexity of today's automobiles, have steadily reduced the scope

of maintenance and repairs which can be carried out by vehicle

owners.

Also, safety and environmental concerns place very strict

limits on the nature of repairs and adjustments to engine and trans

mission parts which an owner can perform.

Controls and equip

ment Safety first Vehicle operation

Maintenance, adjustments and repairs usually require special tools,

testing devices and other equipment available to specially trained

workshop personnel in order to assure proper performance, reli ability and safety of the vehicle and its many systems.

Improper maintenance, adjustments and repairs can impair the

operation and reliability of your vehicle and even void your vehicle

warranty. Therefore, proof of servicing in accordance with the main tenance schedule may be a condition for upholding a possible

warranty claim made within the warranty period.

Above all, operational safety can be adversely affected, creating unnecessary risks for you and your passengers.

If in doubt about any servicing, have it done by your authorized Audi

dealer or any other properly equipped and qualified workshop. We

strongly urge you to give your authorized Audi dealer the opportu

nity to perform all scheduled maintenance and necessary repairs.

Your dealer has the facilities, original parts and trained specialists

to keep your vehicle running properly .

Performing limited maintenance yourself

The following pages describe a limited number of procedures which

can be performed on your vehicle with ordinary tools, should the

need arise and trained personnel be unavailable. Before performing

any of these procedures, always thoroughly read all of the appli

cable text and carefully follow the instructions given. Always rigor

ously observe the

WARNINGS provided.

Before you check anything in the engine compartment, always read

and heed all WARNINGS=>

& and=> & in "Working in the engine

compartment" on

page 224.

& WARNING

• Serious personal injury may occur as a result of improperly

performed maintenance, adjustments or repairs.

Vehicle care Do-it-yourself service Tec hn ica l da ta