light AUDI S4 2008 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 277 of 342

Wheels and tyres275

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Furthermore, this could cause damage to your vehicle and

possibly also result in an accident.

Note

•

If you cannot continue driving even with run flat tyres please

obtain professional assistance.

•

You should obtain professional assistance if you are in any doubt

regarding the rims and tyres for your vehicle.

Applies to vehicles: with run flat tyresDriving with run flat tyres

Please remember that the vehicle's handling will be

impaired.Driving a vehicle with a deflat ed tyre, or with insufficient

tyre pressure, is an abnormal situation. However, since the

handling of a vehicle equipped with run flat tyres is only

slightly impaired, it is important to remember that you are

driving with a deflated tyre. If you have to make use of the

run flat system please remember the following points:

– The Electronic Stabilisation Program (ESP) must be switched on.

–Do not exceed 80km/h ⇒.

– Anticipate the traffic situation well in advance.

– Be careful when accelerating.

– Avoid unnecessary braking and steering manoeuvres.

– Reduce speed in good time before corners and potential hazards.

Please refer to ⇒page 274, “ When is it no longer possible to

continue driving with the help of the run flat tyres?”

Effects on handling when dr iving with defective tyres

If one of the front tyres is defective , your vehicle will tend to pull

slightly towards that side and braking performance will be

impaired.

A defective rear tyre will also make the vehicle pull slightly to one

side, and the braking response will again be slightly impaired.

These effects will be most noticeable when driving in a corner.

WARNING

•

When using the run flat system the changes in vehicle handling

will be noticeable when braking, in corners and during fast accel-

eration.

•

The maximum permitted speed of 80 km/h is subject to road

and weather conditions. Always observe the relevant rules and

regulations. Run flat tyres allow you to continue your journey in

the event of a loss of tyre pressu re. However, the driver remains

responsible for the safety of the vehicle and for restoring the

correct tyre pressure and having defective parts replaced

⇒ page 276 . For these reasons you should always adjust your

driving to suit the circumstances.Caution

We recommend that you drive with great care when making use of

the run flat system. Avoid abrupt manoeuvres.

WARNING (continued)

document_0900452a81b1b9de.book Seite 275 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

0

•

Page 289 of 342

Self-help287

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Check whether a repair is possible using the Tyre

Mobility System ⇒page 285.

– Ensure that all passengers leave the vehicle and move

away from the danger area ⇒.

– Take the tyre sealant can and the electric compressor out

of the luggage compartment ⇒page 283.

– Fix the sticker “max. 80 km/h”, which is included with the tyre sealant can, onto the instrument cluster where the

driver will see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it will go. This will automatically pierce the foil

sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve insert tool to unscrew the valve insert ⇒page 286,

fig. 270.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back into the tyre valve. Inflating the tyre

– Screw the filling hose of th

e electric compressor onto the

tyre valve and plug the connector into the cigarette

lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pres- sure shown on the pressure gauge.

– If the tyre pressure remains lower than the value speci- fied above drive the vehicle approx. 10 metres forwards

or backwards, so that the sealant can spread evenly in

the tyre. If the pressure is still lower than the specifica-

tion the tyre is too badly damaged and cannot be

repaired using the tyre sealant.

Final checks

– After about 10 minutes stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly damaged. Do not drive on. You should obtain profes-

sional assistance.

WARNING

•

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

•

Make sure your passengers wait in a safe place (for instance

behind the roadside crash barrier).

•

Please observe the manufacturers' safety notes on the

compressor and the instructions supplied with the tyre sealant

can.

•

If it was not possible to build up a tyre pressure of 2.0 bar

within 6 minutes this means that the tyre is too badly damaged.

Do not drive on.

document_0900452a81b1b9de.book Seite 287 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

Page 290 of 342

Self-help

288•

Seek professional assistance if th e repair of a tyre puncture is

not possible with the sealing compound.

•

If tyre pressure is less than 1.3 bar after driving about 10

minutes, the tyre is too badly damaged. Do not drive on. You

should obtain professional assistance.Caution

Take special care if you have to repair a tyre on a gradient.

Note

•

Do not use the compressor for longer than 6 minutes at a time,

as it could overheat. When the compressor has cooled down, you

can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off

like foil.

•

After carrying out a tyre repair remember to buy a new tyre

sealant can at a qualified workshop. This will ensure that the Tyre

Mobility System is operative again.

•

Please observe the relevant regulations.

Changing a wheelPreparations

Some preparations are necessary before changing a

wheel.– If you have a flat tyre, stop the car well away from moving traffic. Choose a location that is as level as possible.– All passengers should

leave the car. They should wait in

a safe place (for instance behind the roadside crash

barrier).

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).

– When towing a trailer: unhitch the trailer from your vehicle.

– Take the tools ⇒ page 283 and the spare wheel*

⇒ page 284 out of the luggage compartment.

WARNING

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel oppo-

site the wheel being changed by placing a stone or similar object

under it to prevent the vehicle from rolling away.

Note

Please observe the relevant regulations.How to change a wheel

Change the wheel as described below.–Pull off the hub cap . Also refer to ⇒page 289, “Hub

caps”.

WARNING (continued)

document_0900452a81b1b9de.book Seite 288 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

0 [I)

-+

I&

+-

0

•

•

Page 292 of 342

Self-help

290

Loosening

–Fit the box spanner as far as it will go over the wheel bolt

5).

– Grip the box spanner as close to the end as possible and

turn the wheel bolts about one turn anti-clockwise

⇒ page 289, fig. 272 -arrow-.

Tightening

– Fit the box spanner as far as it will go over the wheel bolt5).

– Grip the box spanner as close to the end as possible and

tighten the bolt firmly by turning clockwise.

WARNING

To avoid accidents, the wheel bolts should only be loosened

slightly (about one turn) before ra ising the vehicle with the jack*.

Note

•

Do not use the hexagonal socket in the screwdriver handle to

loosen or tighten the wheel bolts.

•

If the wheel bolt is very tight, it may be possible to loosen it by

pushing down the end of the spanner carefully with your foot. Hold

on to the car for support and take care not to slip.

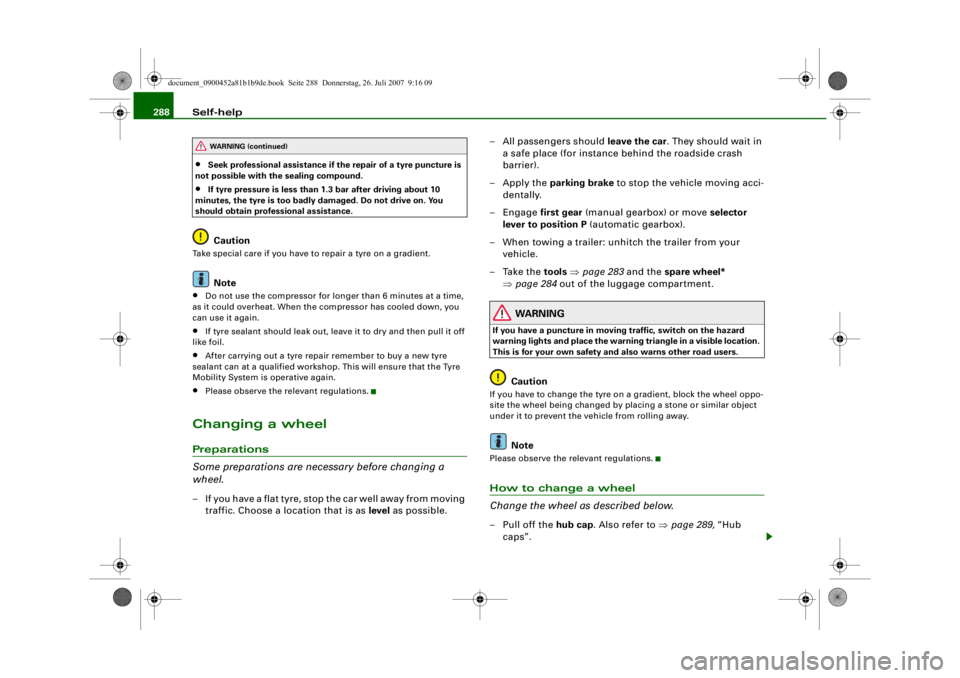

Raising the vehicle

The vehicle must be raised with the jack* to remove the

wheel.Each jacking point is marked by a recess underneath the

vehicle ⇒fig. 273.

– Place the jack ⇒page 283 underneath the jacking point

closest to the wheel being changed. Make sure the base

plate is flat on the ground.

– Wind up the jack by the knob until the claw of the jack completely surrounds the seam on your vehicle

⇒ fig. 274.

5)An adapter is required to unscrew or tighten the anti-theft wheel bolts*

⇒page 292 .

Fig. 273 Changing a

wheel: Jacking pointsFig. 274 Changing a

wheel: Jack

AA

AB

AC

document_0900452a81b1b9de.book Seite 290 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

[I)

+-

•

Page 294 of 342

Self-help

292

– Screw in the mounting pin (provided in the vehicle's tool

kit) by hand in place of the wheel bolt ⇒page 291,

fig. 276.

– Then unscrew the other wheel bolts as described above.

– Take off the wheel. The mounting pin stays where it is.

Putting on the spare wheel

– Put on the spare wheel, using the mounting pin to guide it into place.

– Screw in the wheel bolts and tighten them lightly using

the hexagonal opening in the screwdriver handle.

– Then unscrew the mounting pin and tighten the remaining wheel bolt lightly.

– Carry out the steps required after you have changed the wheel ⇒page 289, “After changing a wheel”.The wheel bolts should be clean and turn easily. Before putting on

the spare wheel, inspect the condition of the wheel and hub

mounting surfaces. These surfaces must be clean before mounting

the wheel.

The wheel bolts are easier to remove from the wheel rim if you use

the hexagonal socket in the screwdriver handle. The reversible

screwdriver blade should be removed as a precautionary measure

when the tool is used for this purpose.

Note the direction of rotation when putting on a tyre with direc-

tional tread pattern ⇒page 292 .

Note

Do not use the hexagonal socket in the screwdriver handle to loosen

or tighten the wheel bolts.

Tyres with directional tread pattern

Tyres with directional tread pattern must be mounted so

that they rotate in the correct direction.A directional tread pattern is identified by arrows on the sidewall

pointing in the forward running direction. Always note the direction

of rotation indicated when mounting the wheel. This is important so

that these tyres can give maximum grip and avoid excessive noise,

tread wear and aquaplaning.

Drive carefully should you ever have a puncture and have to mount

the spare wheel so it rotates in the wrong direction. This is because

the tyre will not give optimum performance. Bear this in mind

particularly when driving on wet roads.

To benefit from the advantages of tyres with this type of tread

pattern, the defective tyre should be replaced and refitted as soon

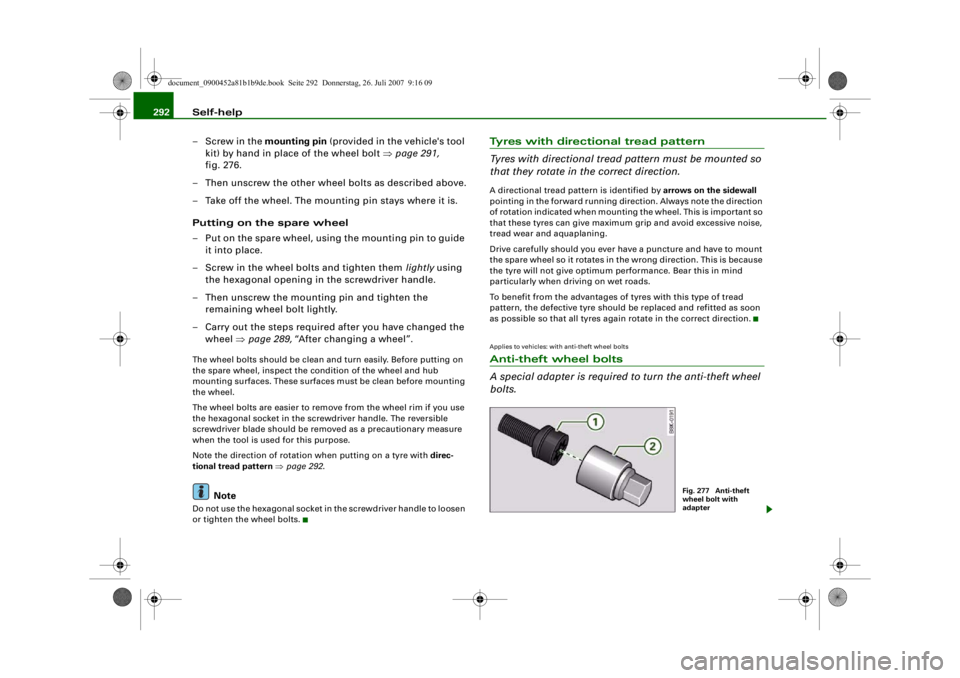

as possible so that all tyres agai n rotate in the correct direction.Applies to vehicles: with anti-theft wheel boltsAnti-theft wheel bolts

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 277 Anti-theft

wheel bolt with

adapter

document_0900452a81b1b9de.book Seite 292 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

[I)

•

Page 297 of 342

Self-help295

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

terminal must not touch metal parts of the vehicle: this can cause

short circuiting.

•

Do not bend over the batteries – risk of acid burns.

•

The screw plugs on the battery ce

lls must be screwed in firmly.

•

Keep sparks, flame and lighted cigarettes away from batteries:

the gases given off can cause an explosion.

•

If jump-starting another vehicle, position the jump leads in

such a way that they cannot come into contact with any moving

parts in the engine compart ment of the other vehicle.Caution

Please note that the above method of connecting the leads is meant

for jump-starting your vehicle. If jump-starting another vehicle, you

should not connect the negative lead (–) to the negative terminal of

the discharged battery, but directly to the engine block or a solid

metal part bolted to the engine bl ock. If the battery of the other

vehicle does not have a gas vent, there is a risk that a mixture of

oxygen and hydrogen gas can accumulate and cause an

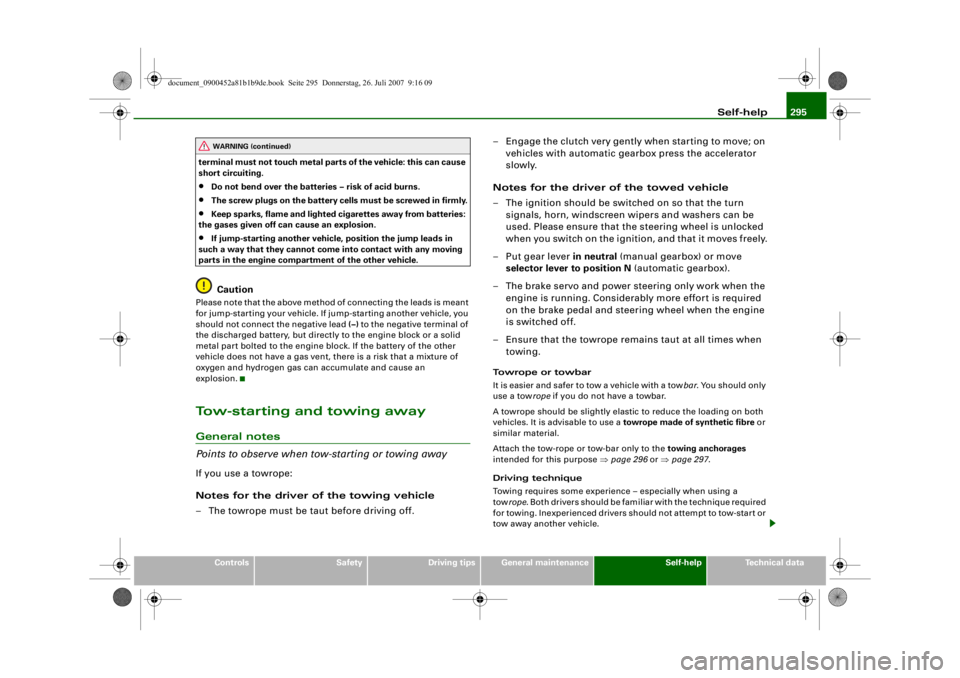

explosion.Tow-starting and towing awayGeneral notes

Points to observe when tow-starting or towing awayIf you use a towrope:

Notes for the driver of the towing vehicle

– The towrope must be taut before driving off. – Engage the clutch very gently when starting to move; on

vehicles with automatic gearbox press the accelerator

slowly.

Notes for the driver of the towed vehicle

– The ignition should be switched on so that the turn signals, horn, windscreen wipers and washers can be

used. Please ensure that the steering wheel is unlocked

when you switch on the ignition, and that it moves freely.

–Put gear lever in neutral (manual gearbox) or move

selector lever to position N (automatic gearbox).

– The brake servo and power steering only work when the engine is running. Considerably more effort is required

on the brake pedal and steering wheel when the engine

is switched off.

– Ensure that the towrope remains taut at all times when towing.

Towrope or towbar

It is easier and safer to tow a vehicle with a tow bar. You should only

use a tow rope if you do not have a towbar.

A towrope should be slightly elasti c to reduce the loading on both

vehicles. It is advisable to use a towrope made of synthetic fibre or

similar material.

Attach the tow-rope or tow-bar only to the towing anchorages

intended for this purpose ⇒page 296 or ⇒page 297 .

Driving technique

Towing requires some experience – especially when using a

tow rope . Both drivers should be familiar with the technique required

for towing. Inexperienced drivers sh ould not attempt to tow-start or

tow away another vehicle.

WARNING (continued)

document_0900452a81b1b9de.book Seite 295 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

CD

-+ +-

•

Page 298 of 342

Self-help

296Do not pull too hard with the towi ng vehicle and take care to avoid

jerking the towrope. When towing on a loose surface there is always

a risk of overloading and damaging the anchorage points.

Caution

If there is no oil in the gearbox or no lubricant in the automatic

transmission the car may only be towed with the driven wheels

lifted clear of the road, or transported on a special car transporter

or trailer.

Note

•

Note the regulations concerning towing.

•

The hazard warning lights of bo th vehicles must normally be

switched on. However, observe an y regulations to the contrary.

•

Make sure that the towrope is not twisted, as otherwise the front

towline anchorage on your vehicle could work itself loose.

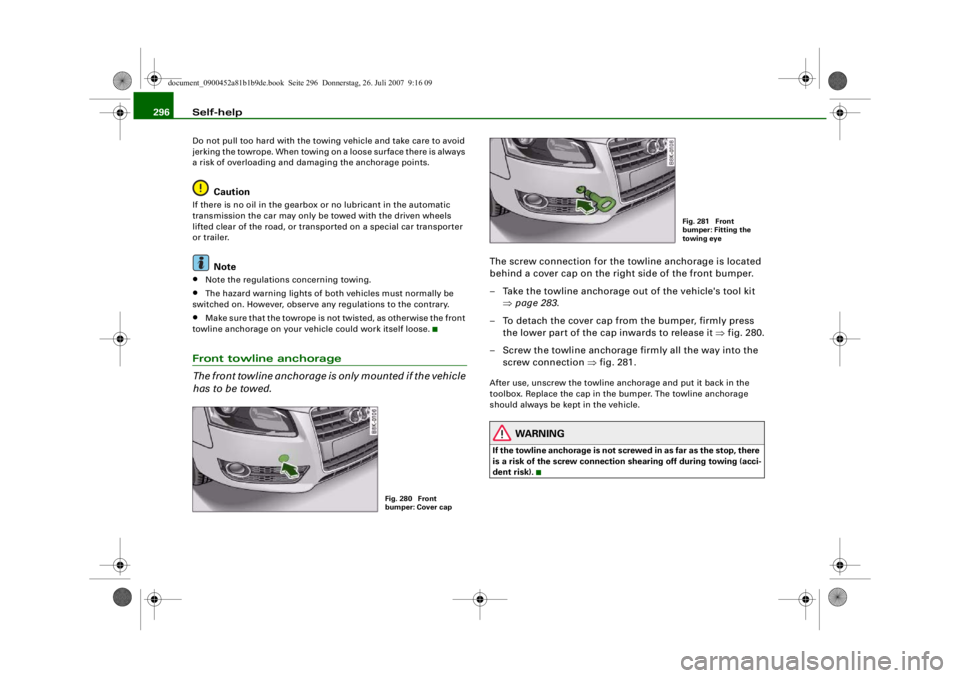

Front towline anchorage

The front towline anchorage is only mounted if the vehicle

has to be towed.

The screw connection for the towline anchorage is located

behind a cover cap on the right side of the front bumper.

– Take the towline anchorage ou t of the vehicle's tool kit

⇒ page 283 .

– To detach the cover cap from the bumper, firmly press the lower part of the cap inwards to release it ⇒fig. 280.

– Screw the towline anchorage firmly all the way into the screw connection ⇒fig. 281.After use, unscrew the towline anchorage and put it back in the

toolbox. Replace the cap in th e bumper. The towline anchorage

should always be kept in the vehicle.

WARNING

If the towline anchorage is not scre wed in as far as the stop, there

is a risk of the screw connection shearing off during towing (acci-

dent risk).

Fig. 280 Front

bumper: Cover cap

Fig. 281 Front

bumper: Fitting the

towing eye

document_0900452a81b1b9de.book Seite 296 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

0 [I]

-+

•

+-

Page 303 of 342

Fuses and bulbs301

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

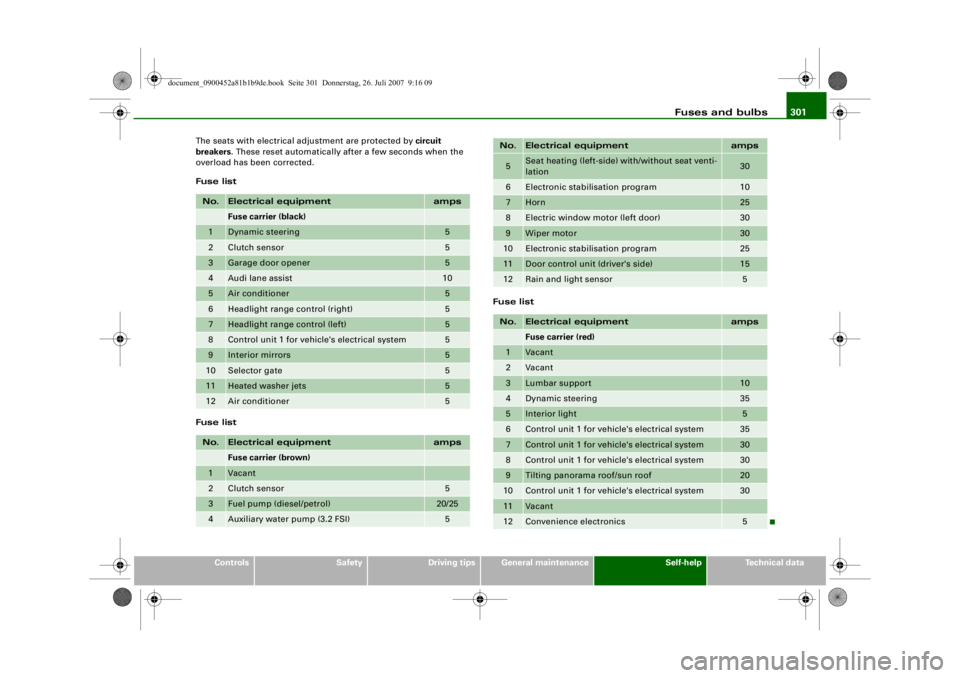

The seats with electrical adjustment are protected by circuit

breakers

. These reset automatically after a few seconds when the

overload has been corrected.

Fuse list

Fuse list Fuse list

No.

Electrical equipment

amps

Fuse carrier (black)

1

Dynamic steering

5

2

Clutch sensor

5

3

Garage door opener

5

4

Audi lane assist

10

5

Air conditioner

5

6

Headlight range control (right)

5

7

Headlight range control (left)

5

8

Control unit 1 for vehicle's electrical system

5

9

Interior mirrors

5

10

Selector gate

5

11

Heated washer jets

5

12

Air conditioner

5

No.

Electrical equipment

amps

Fuse carrier (brown)

1

Vacant

2

Clutch sensor

5

3

Fuel pump (diesel/petrol)

20/25

4

Auxiliary water pump (3.2 FSI)

5

5

Seat heating (left-side) with/without seat venti-

lation

30

6

Electronic stab

ilisation program

10

7

Horn

25

8

Electric window motor (left door)

30

9

Wiper motor

30

10

Electronic stabilisation program

25

11

Door control unit (driver's side)

15

12

Rain and light sensor

5

No.

Electrical equipment

amps

Fuse carrier (red)

1

Vacant

2

Vacant

3

Lumbar support

10

4

Dynamic steering

35

5

Interior light

5

6

Control unit 1 for vehicle's electrical system

35

7

Control unit 1 for vehicle's electrical system

30

8

Control unit 1 for vehicle's electrical system

30

9

Tilting panorama roof/sun roof

20

10

Control unit 1 for vehicle's electrical system

30

11

Vacant

12

Convenience electronics

5

No.

Electrical equipment

amps

document_0900452a81b1b9de.book Seite 301 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

1111

-

-

1111

--

1111

-

-

1111

-

-+

1111

--

+-

1111

--

1111

--

-

1111

-

-

1111

--

1111

--

•

~

Page 304 of 342

Fuses and bulbs

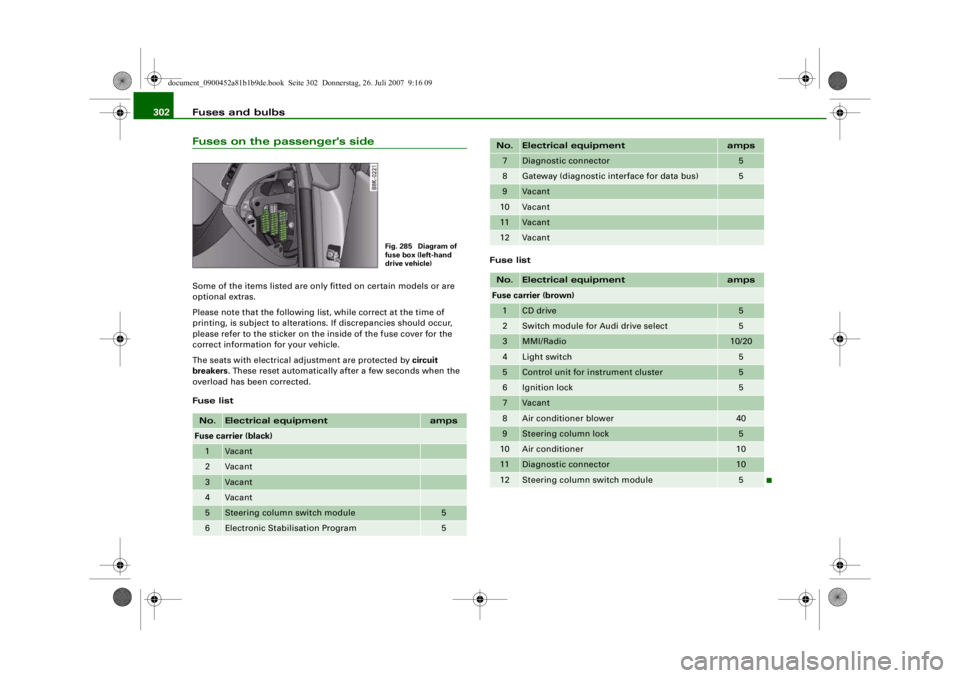

302Fuses on the passenger's sideSome of the items listed are only fitted on certain models or are

optional extras.

Please note that the following li st, while correct at the time of

printing, is subject to alterations. If discrepancies should occur,

please refer to the sticker on the inside of the fuse cover for the

correct information for your vehicle.

The seats with electrical adjustment are protected by circuit

breakers . These reset automatically after a few seconds when the

overload has been corrected.

Fuse list Fuse listNo.

Electrical equipment

amps

Fuse carrier (black)1

Vacant

2

Vacant

3

Vacant

4

Vacant

5

Steering column switch module

5

6

Electronic Stabilisation Program

5

Fig. 285 Diagram of

fuse box (left-hand

drive vehicle)

7

Diagnostic connector

5

8

Gateway (diagnostic in

terface for data bus)

5

9

Vacant

10

Vacant

11

Vacant

12

Vacant

No.

Electrical equipment

amps

Fuse carrier (brown)1

CD drive

5

2

Switch module for Audi drive select

5

3

MMI/Radio

10/20

4

Light switch

5

5

Control unit for instrument cluster

5

6

Ignition lock

5

7

Vacant

8

Air conditioner blower

40

9

Steering column lock

5

10

Air conditioner

10

11

Diagnostic connector

10

12

Steering column switch module

5

No.

Electrical equipment

amps

document_0900452a81b1b9de.book Seite 302 Donnerstag, 26. Juli 2007 9:16 09

-+ ~

--11-

..

-

..

-

..

-

..

-

..

..

..

..

..

..

..

..

..

..

..

--4 -

-

-

T

-

-

-

-

-

+-

-

-

-

-

-

•

4-

---r

Page 306 of 342

Fuses and bulbs

304BulbsChanging bulbs

Changing bulbs requires a certain degree of practical

skill.You can change the following bulbs for exterior lights yourself:•

Halogen headlights: Bulb for dipped headlights

•

Halogen headlights: Bulb for main beam headlights

•

Bulb for fog light

•

Bulbs for rear lights in boot lid

•

Bulbs for rear lights in side panel

•

Bulbs for number plate light

The following bulbs should only be changed by a qualified work-

shop :

•

Halogen headlights: Bulb for turn signals

•

Halogen headlights: Bulb for side lights

•

Xenon headlights*: Bulb for turn signals

•

Xenon headlights*: Light source for daytime running

lights/parki ng lights

•

Bulb for headlights: Bi-xenon lights ⇒

•

Light source for turn signal in exterior mirror housing

•

Light source for high-level brake light

As a rule, you require a certain degree of practical skill to change

defective bulbs. This applies in particular to those bulbs which are

only accessible from the engine compartment.

If in doubt, we recommend that you have defective bulbs changed

by a qualified workshop or qualified mechanic.

If you do decide to change bulbs in the engine compartment your-

self, be aware of the safety risks involved ⇒page 255 ⇒ .

Types of bulbs

You must only replace a bulb with a bulb of the same type. Informa-

tion regarding e.g. the wattage can be found on the base of the

bulb.

4

Cigarette lighter

15

5

Parking aid

5

6

Phone pre-installation without handsfree sys-

tem (VDA interface)

5

7

Control unit for adap tive cruise control

15

8

Vacant

9

EPB switch (electro-mechanical parking brake)

5

10

Lane change assist feature

5

11

Seat heating, rear

5

12

Airbag

5

No.

Electrical equipment

amps

Front bulb (12 V)

Vers io n

Dipped-beam headlights (halogen)

55 W (H7)

Main beam headlights (halogen)

55 W (H7)

Front fog lights

55 W (H7)

Rear bulb (12 V)

Vers io n

Brake lights / tail lights

P 21 W

Turn signals (rear)

P 21 W

Reversing lights

W 16 W

Rear fog light

H 21 W

Number plate lights

5 W

document_0900452a81b1b9de.book Seite 304 Donnerstag, 26. Juli 2007 9:16 09

--4 -

1111

-

T

1111

-

6

1111

-

1111

-

1111

-

•

6

-+ +-