BMW 540i 1998 E39 Workshop Manual

Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 541 of 1002

Downloaded from www.Manualslib.com manuals search engine

Different automatic transmissions are used, depending on

model and model year

and/orproduction date. All of the auto-

matic transmissions are electrohydraulically controlled with

five forward speeds. Automatic transmission applications are

given in the table below.

Automatic transmission applications Model Year Engine Transmission

526 from 911 999 M52 TU ASS 360R

5251 from 312001 M54 ASS 3252

5301 to 312001 M54 ASS 390R

530i from 312001 M54 ASS 3252

540i

from 111 997 M62 TU ASS 4402

Automatic transmission identification metal ID plate is mount-

ed to body of transmission.

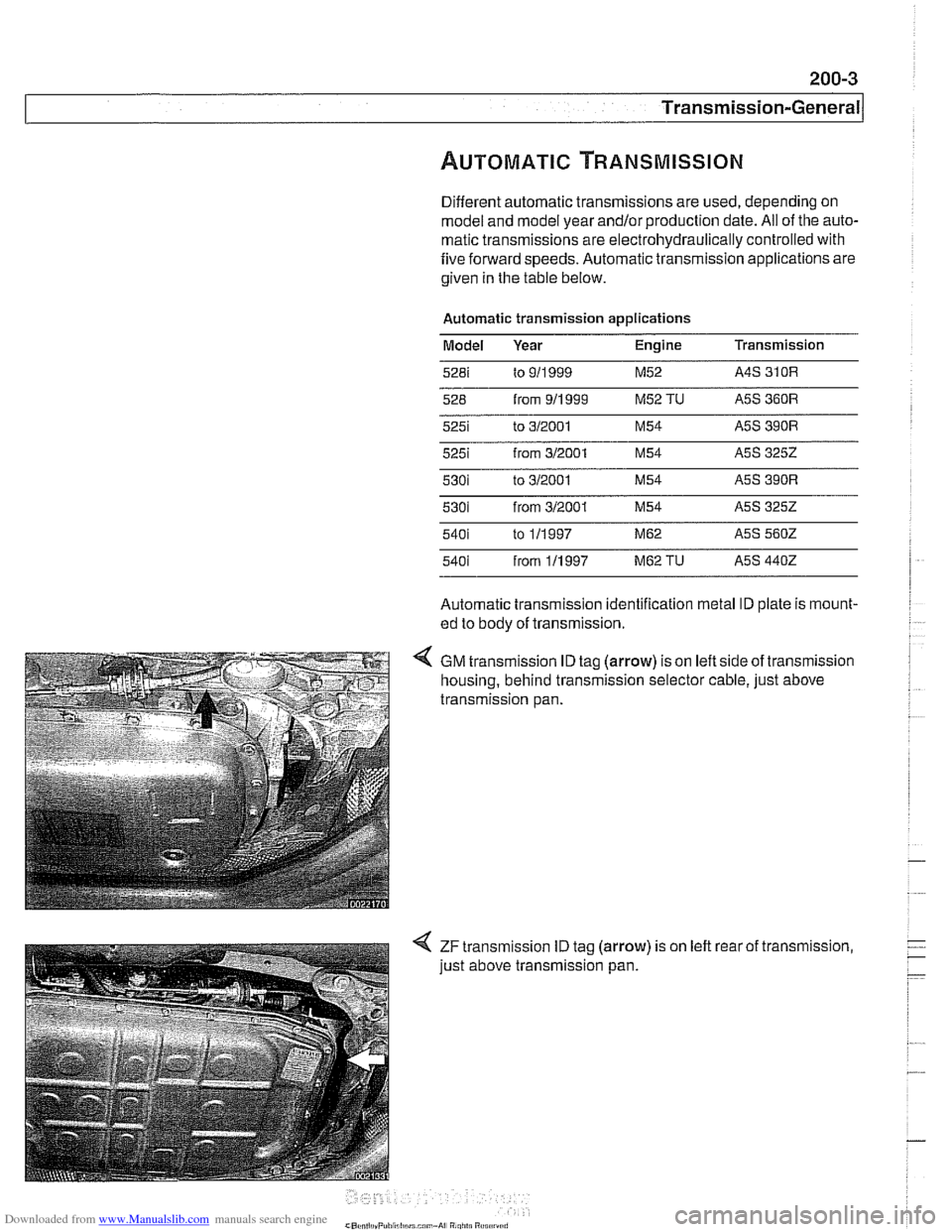

4 GM transmission ID tag (arrow) is on left side of transmission

housing, behind transmission selector cable, just above

transmission pan.

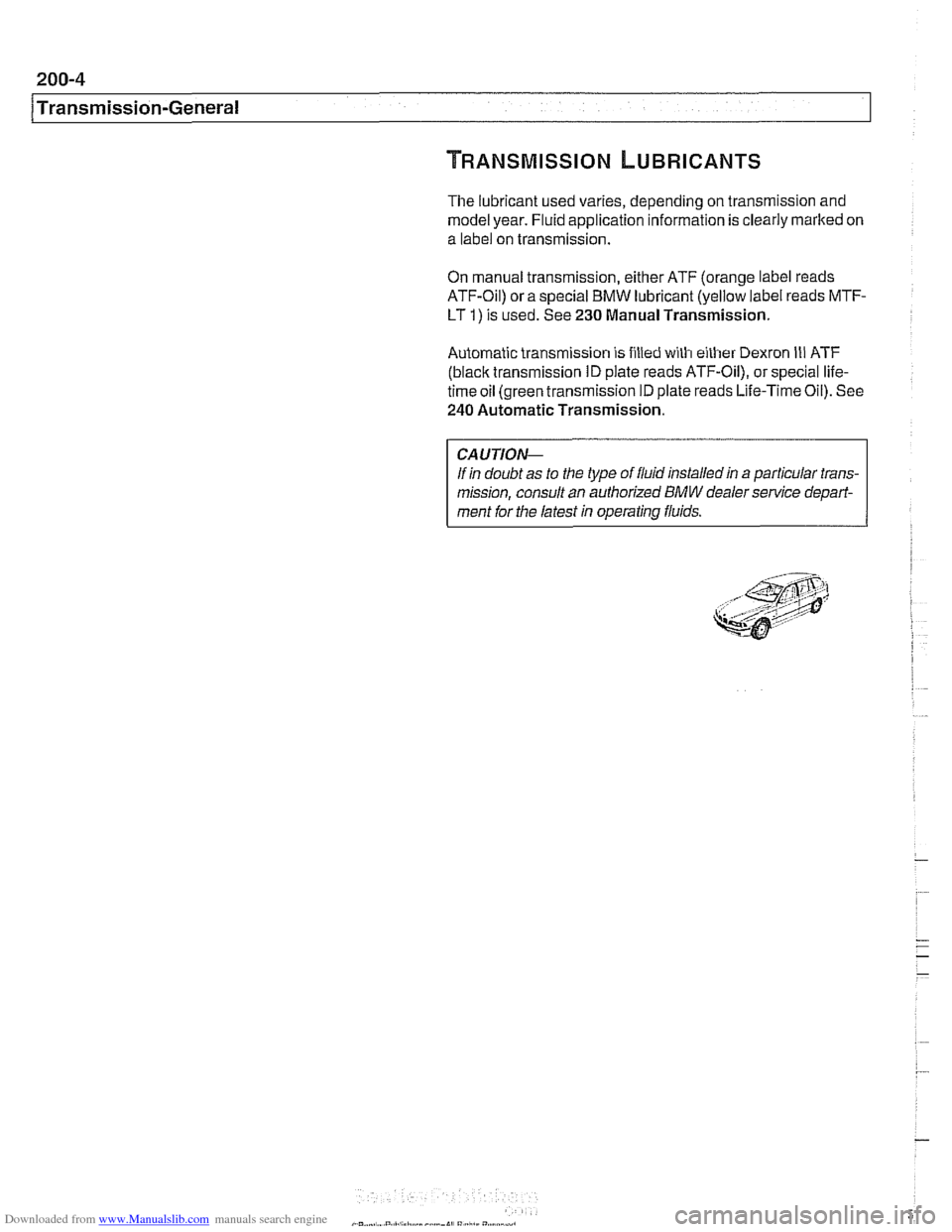

< ZF transmission ID tag (arrow) is on left rear of transmission,

just above transmission pan.

Page 542 of 1002

Downloaded from www.Manualslib.com manuals search engine

The lubricant used varies, depending on transmission and

model year. Fluid application information is clearly marked on

a label on transmission.

On manual transmission, either ATF (orange label reads

ATF-Oil) or a special BMW lubricant (yellow label reads MTF-

LT

I) is used. See 230 Manual Transmission.

Automatic transmission is filled with either Dexron

Ill ATF

(black transmission ID plate reads ATF-Oil), or special life-

time oil (green transmission ID plate reads Life-Time Oil). See

240 Automatic Transmission.

CAUTION--

If in doubt as to the type of fluid installed in a particular trans-

mission, consult an authorized

BMW dealer service depari-

ment for the latest in operating fluids.

Page 543 of 1002

Downloaded from www.Manualslib.com manuals search engine

210 Clutch

........................... General .21 0.2

........................ Special tools .21 0.2

Clutch Hydraulics ................. .21 0.4

Clutch hydraulic system.

bleeding and flushing

................. .21 0.4

Clutch master cylinder. replacing

........ .21 0.6

Clutch slave cylinder. replacing ......... .21 0.8 Flywheel. removing

and installing

................... (6 cylinder engine) 210-12

Flywheel. removing and installing

(V-8 engine) ....................... 21 0-1 3

Transmission pilot bearing. replacing .... 210-1 5

Clutch. installing (non-SAC components) . 210-1 6

Clutch. installing (new SAC components)

. 21 0-17

Clutch.

install in^ (used SAC components) 210-19

Clutch Mechanical ................. .21 0.9 self-adjusting crutch (SAC). breaking in : . 210-21

..................... Clutch variations .21 0.9

................... Clutch. removing .21 0.1 1

Clutch components. inspecting

........ .21 0.1 1

Page 544 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Clutch

This repair group covers replacement of clutch mechanical

and hydraulic components.

BMW 5 Series models with manual transmission use a single

disc hydraulically actuated clutch.

Twoversions of the clutch

are used:

1997

5281 (6 cylinder) uses traditional clutch components.

All 540i (V-8) and 1998 and later

6 cylinder models use a

self-adjusting clutch (SAC).

NOTE-

See 200 Transmission-General for transmission applica-

tion information.

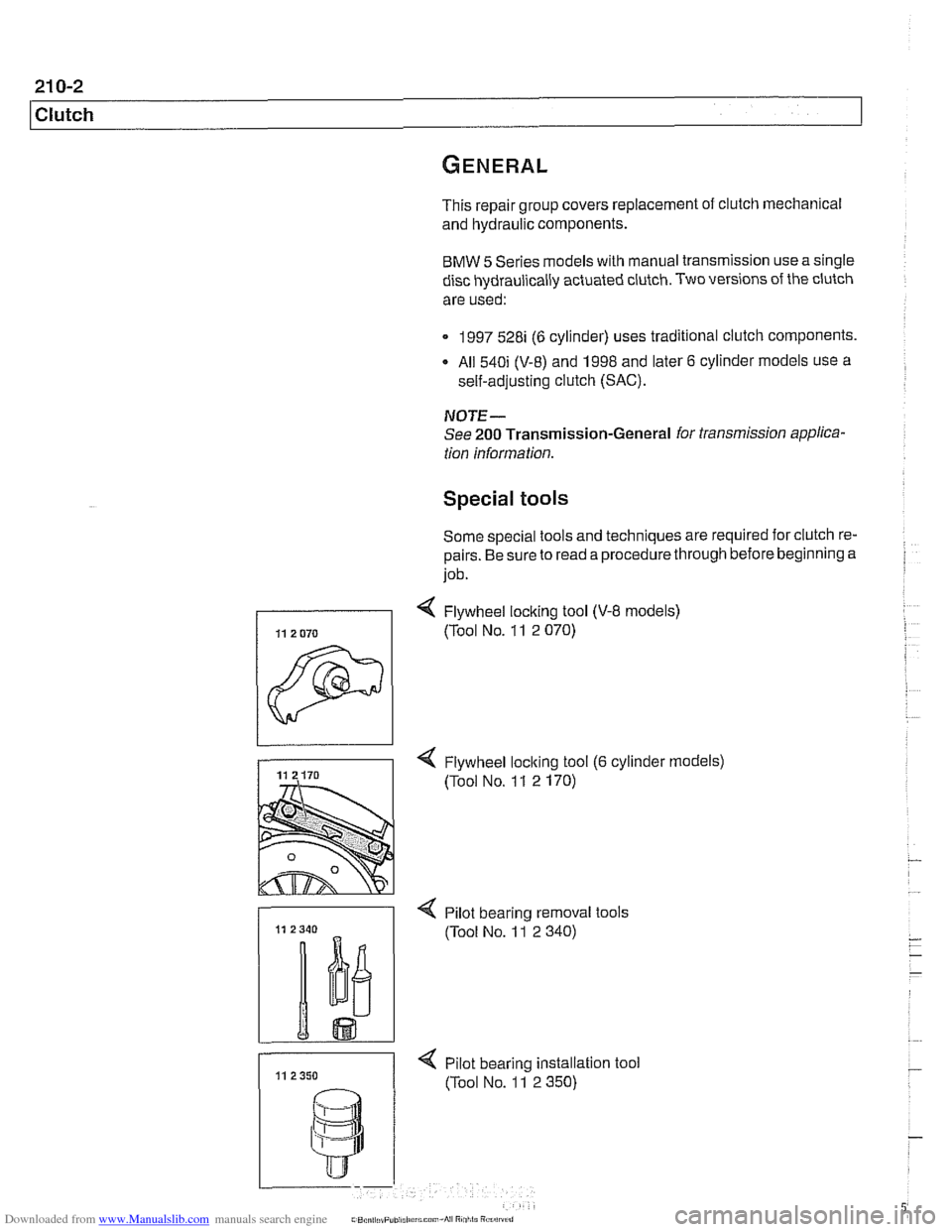

Special tools

Some special tools and techniques are required for clutch re-

pairs. Be sure to read a procedure through before beginning a

job.

< Flywheel loclting tool (V-8 models)

1 (Tool NO. 11 2 070)

-

4 Flywheel loclting tool (6 cylinder models)

(Tool No. 1 1 2 170)

- < Pilot bearino removal tools

11 11 2350 < pilot bearing instaation

(Tool No. 11 2 350) tool

Page 545 of 1002

Downloaded from www.Manualslib.com manuals search engine

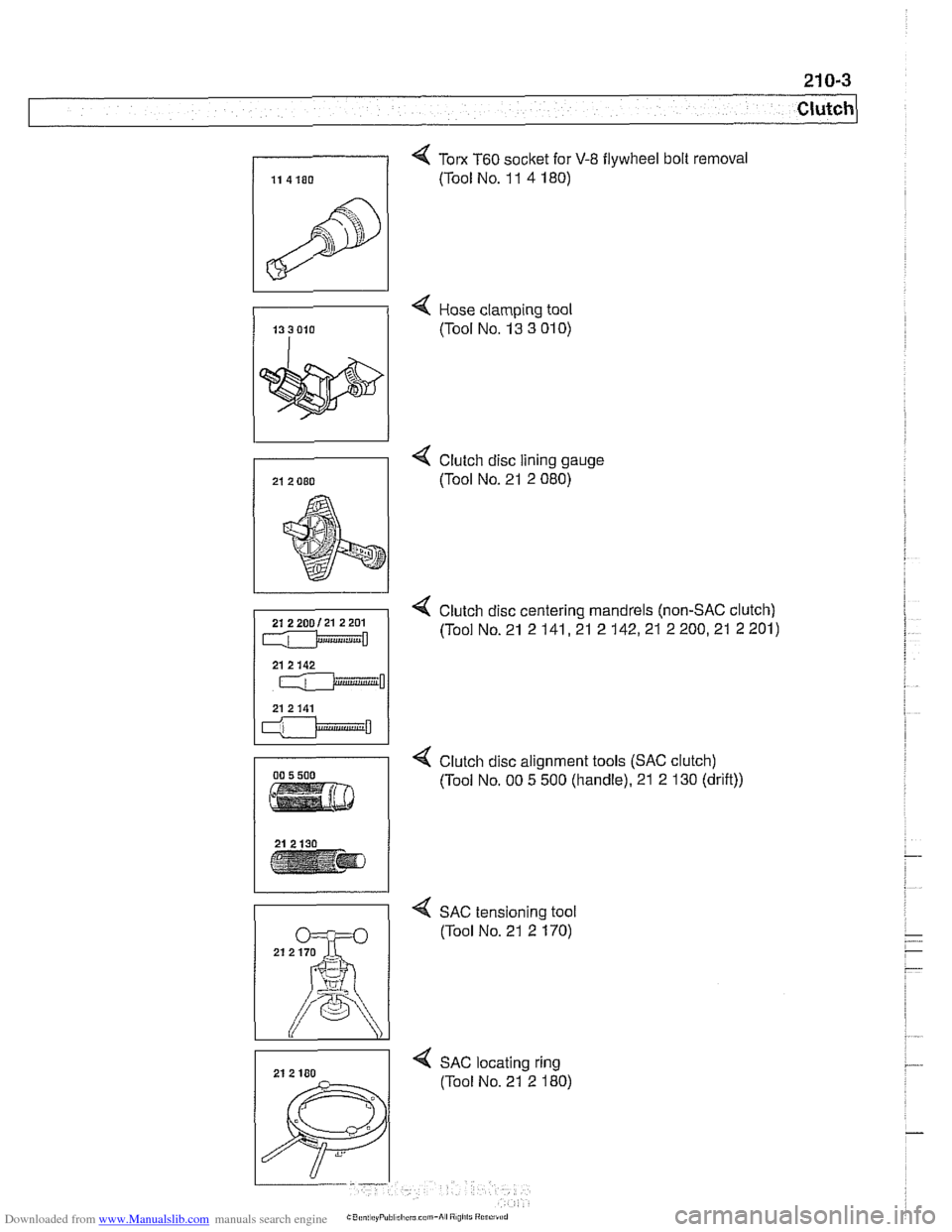

4 Tom T60 socket for V-8 flywheel bolt removal

(Tool No. 1 1 4 180)

4 Hose clamping tool

(Tool No. 13 3

01 0)

4 Clutch disc lining gauge

(Tool No. 21 2 080)

4 Clutch disc centering mandrels (non-SAC clutch)

(Tool No. 21 2

141,21 2 142,21 2 200,21 2 201)

4 Clutch disc alignment tools (SAC clutch)

(Tool No. 00 5 500 (handle). 21 2 130 (drift))

4 SAC tensioning tool

(Tool No. 21 2 170)

4 SAC locating ring

(Tool No. 21 2 180)

Page 546 of 1002

Downloaded from www.Manualslib.com manuals search engine

Tool for bleeding clutch hydraulics (Tool No. 21 5 030)

21 5 030 I

The clutch is hydraulically actuated by the master and slave

cylinders. With the self-adjusting clutch

(SAC), clutch disc

wear is automatically taken up through the self-adjusting

pressure plate springs, making pedal feel consistent through-

out the life of the clutch.

A soft or spongy feel to the clutch pedal, long pedal free-play,

or grinding noises

from the gears while shifting can all indi-

cate problems with the clutch hydraulics. In these circum-

stances it is best to

star? with a clutch fluid flush, followed, if

necessary, by replacement of the hydraulic parts.

NOTE-

The clutch hydraulic system shares the fluid reservoir and flu-

id with the brake hydraulic system.

Clutch hydraulic system,

bleeding and flushing

If the clutchlbralte fluid is murky or muddy, or has not been

changed within the last two years, flush the system and

change the fluid. Flushing the old fluid from the clutch lines is

done using a bralte system pressure bleeder.

- Remove brake fluid reservoir cap. Using a clean syringe, re-

move brake fluid from reservoir. Refill reservoir with clean

DOT

4 bralte fluid.

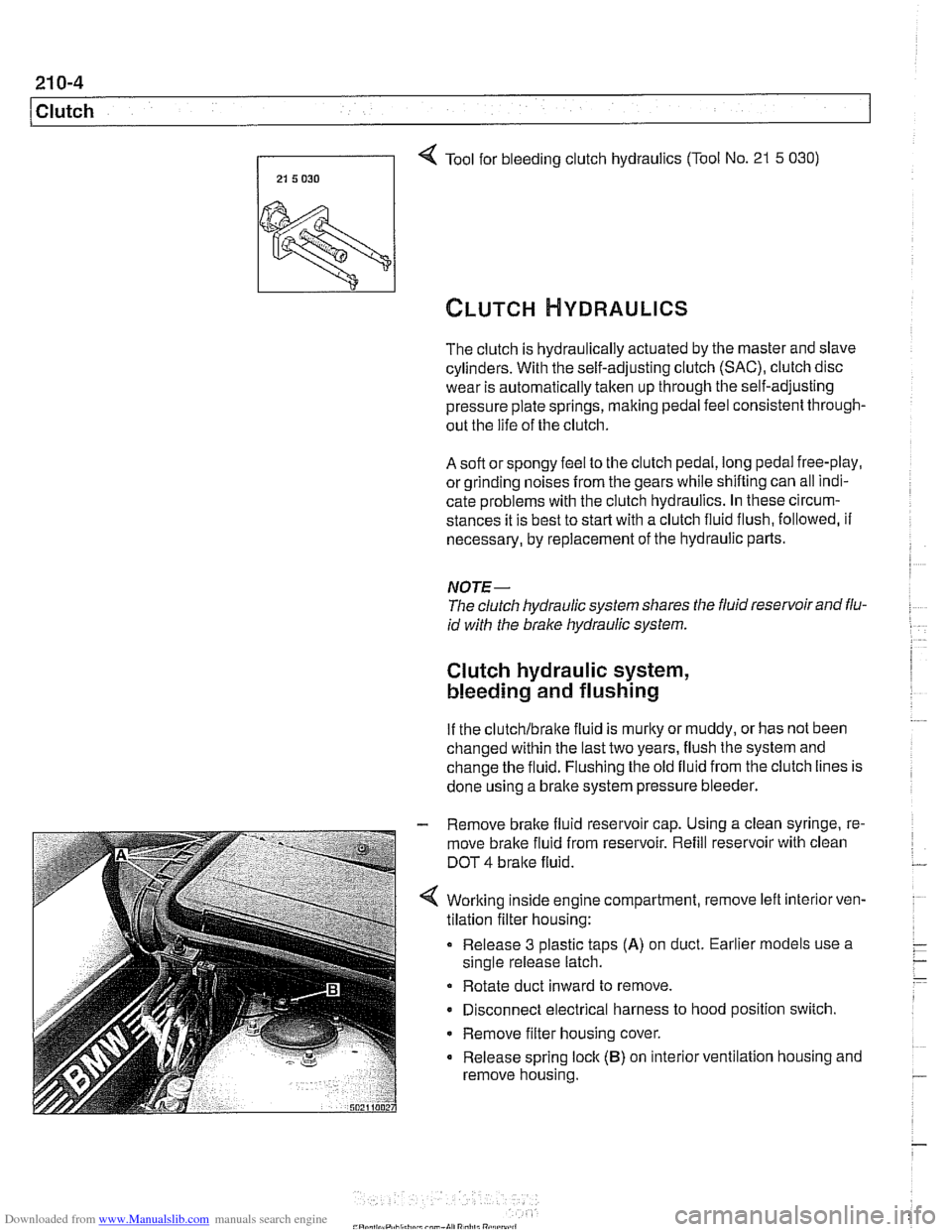

Worlting inside engine compartment, remove left

interiorven-

tilation filter housing:

Release 3 plastic taps

(A) on duct. Earlier models use a

single release latch.

Rotate duct inward to remove.

Disconnect electrical harness to hood position switch.

Remove filter housing cover.

Release spring lock

(B) on interior ventilation housing and

remove housing.

Page 547 of 1002

Downloaded from www.Manualslib.com manuals search engine

Anach pressure brake bleeder to fluid reservoir and pump

bleeder a few times to pressurize hydraulic fluid system.

CAUTION-

* Do not exceed 2 bar (29 psi) pressure at the fluid resenfoil

when bleeding or flushing the hydraulic system.

Brake fluid is poisonous, highly corrosive and danger-

ous to the environment. Wear safety glasses and

rub-

bergloves when working with brake fluid. Do not siphon

brale fluid with your mouth. Immediately clean away

any fluid spilled on painted surfaces and wash with wa-

ter, as brale fluid will remove paint.

Always use new brake fluid from a fresh, unopened

container.

Brake fluid will absorb moisture from the air.

This can lead to corrosion problems in the clutch and

brake hydraulic systems, ;nd will also lower the brake

fluid boiling point. Dispose of brale fluid properly.

- Raise and safely support vehicle.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjackstands designed for

the purpose. A floor

iack is not adequate support.

- If necessary, remove transmission splash shield.

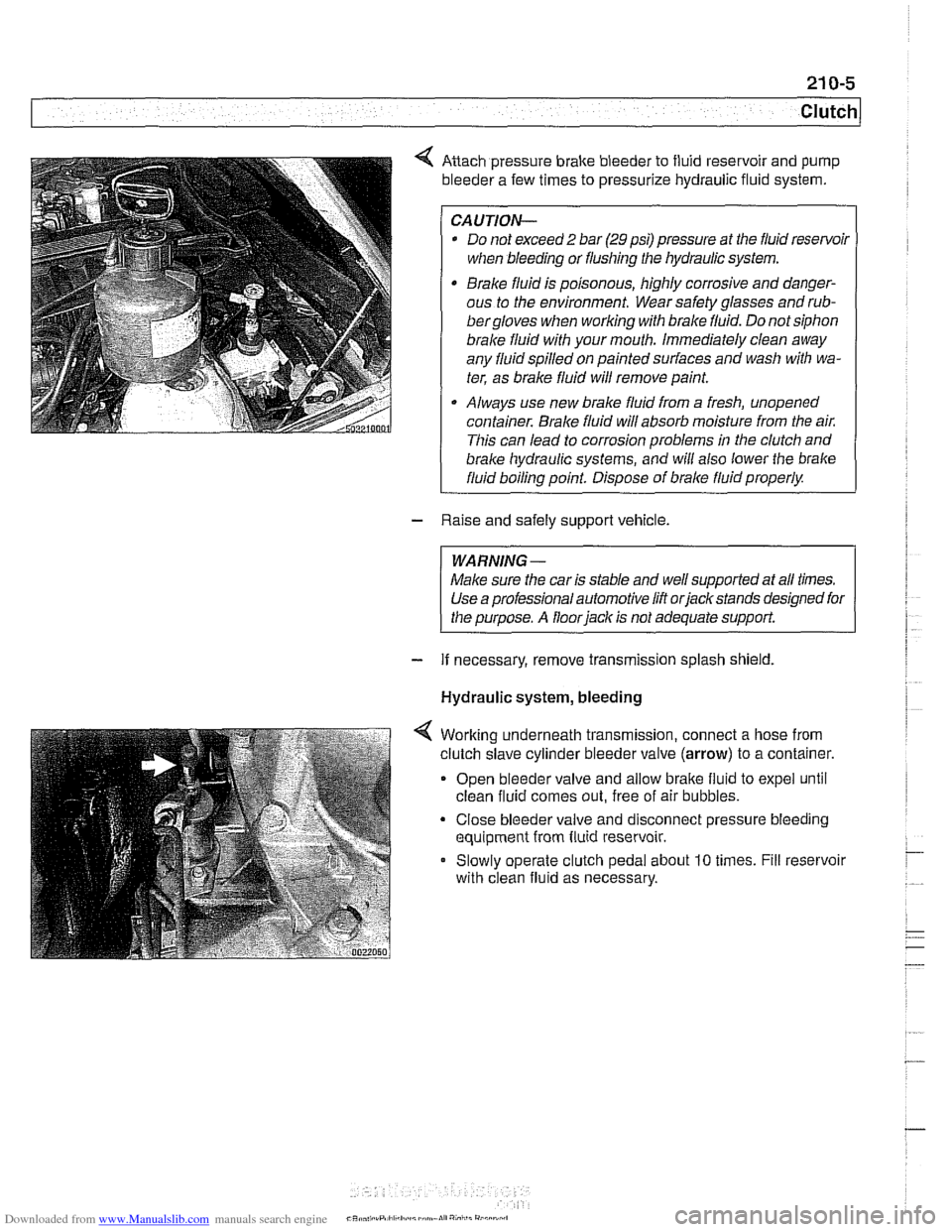

Hydraulic system, bleeding

Worlting underneath transmission, connect a hose from

clutch slave cylinder bleeder valve

(arrow) to a container.

Open bleeder valve and allow bralte fluid to expel until

clean fluid comes out, free of air bubbles.

Close bleeder valve and disconnect pressure bleeding

equipment from fluid reservoir.

Slowly operate clutch pedal about

10 times. Fill reservoir

with clean fluid as necessary.

CR* .,,, .rP,ll,h.:I,,~,~mn.lI","i,,i"

Page 548 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-6

1 Clutch

Hydraulic system, bleeding

(using

BMW special tool 21 5 030)

4 Working underneath transmission, remove slave cylinder

mounting nuts (arrow) from clutch housing and remove

cylinder. Leave fluid line attached.

4 Use BMW special tool 21 5 030 to press slave cylinder push-

rod completely into slave cylinder.

Hold slave cylinder so that bleeder valve is at highest point.

Open bleeder valve and allow brake fluid to expel until

clean fluid comes out, free of air bubbles.

* Close bleeder valve and disconnect pressure bleeding

equipment from fluid reservoir.

Slowly unscrew and detach special tool 21

5 030 from

slave cylinder.

CAUTION-

Do not remove tool if hydraulic system is pressurized.

- Reinstall slave cylinder.

Tightening torque Slave cylinder to transmission case

22 Nm (1 6 ft-lb)

- Slowly operate clutch pedal about 10 times. Fill reservoir with

clean fluid as necessary.

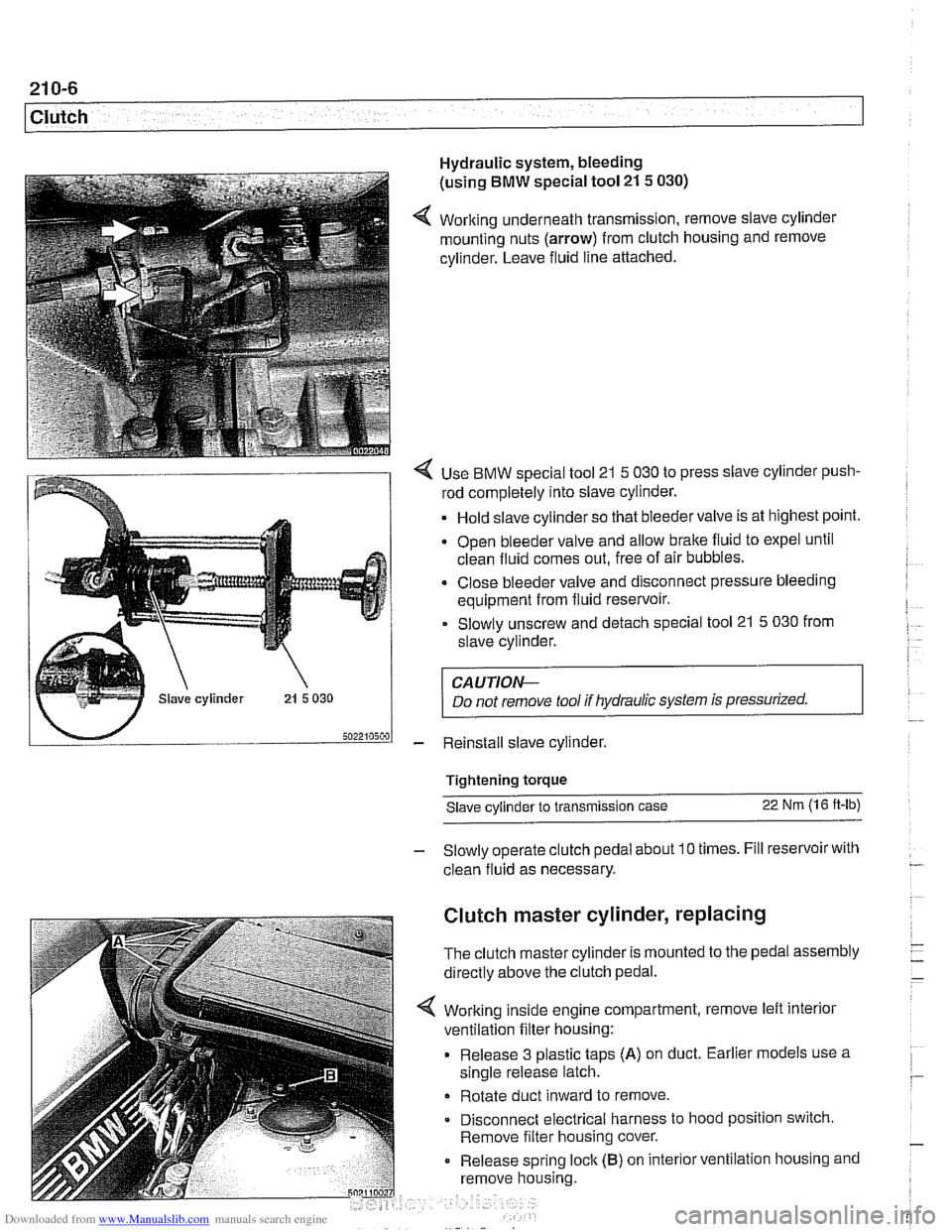

Clutch master cylinder, replacing

The clutch master cylinder is mounted to the pedal assembly

directly above the clutch pedal.

Working inside engine compartment, remove left interior

ventilation filter housing:

Release 3 plastic taps

(A) on duct. Earlier models use a

single release latch.

Rotate duct inward to remove

Disconnect electrical harness to hood position switch.

Remove filter housing cover.

Release spring

loclc (B) on interior ventilation housing and

remove housing.

Page 549 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-7

Clutch

- Remove brake fluid reservoir cap. Using a clean syringe.

remove brake fluid from reservoir to below level of clutch

hydraulic supply hose.

- Detach clutch hydraulic supply hose from brake fluid reser-

voir. Plug reservoir outlet and hose.

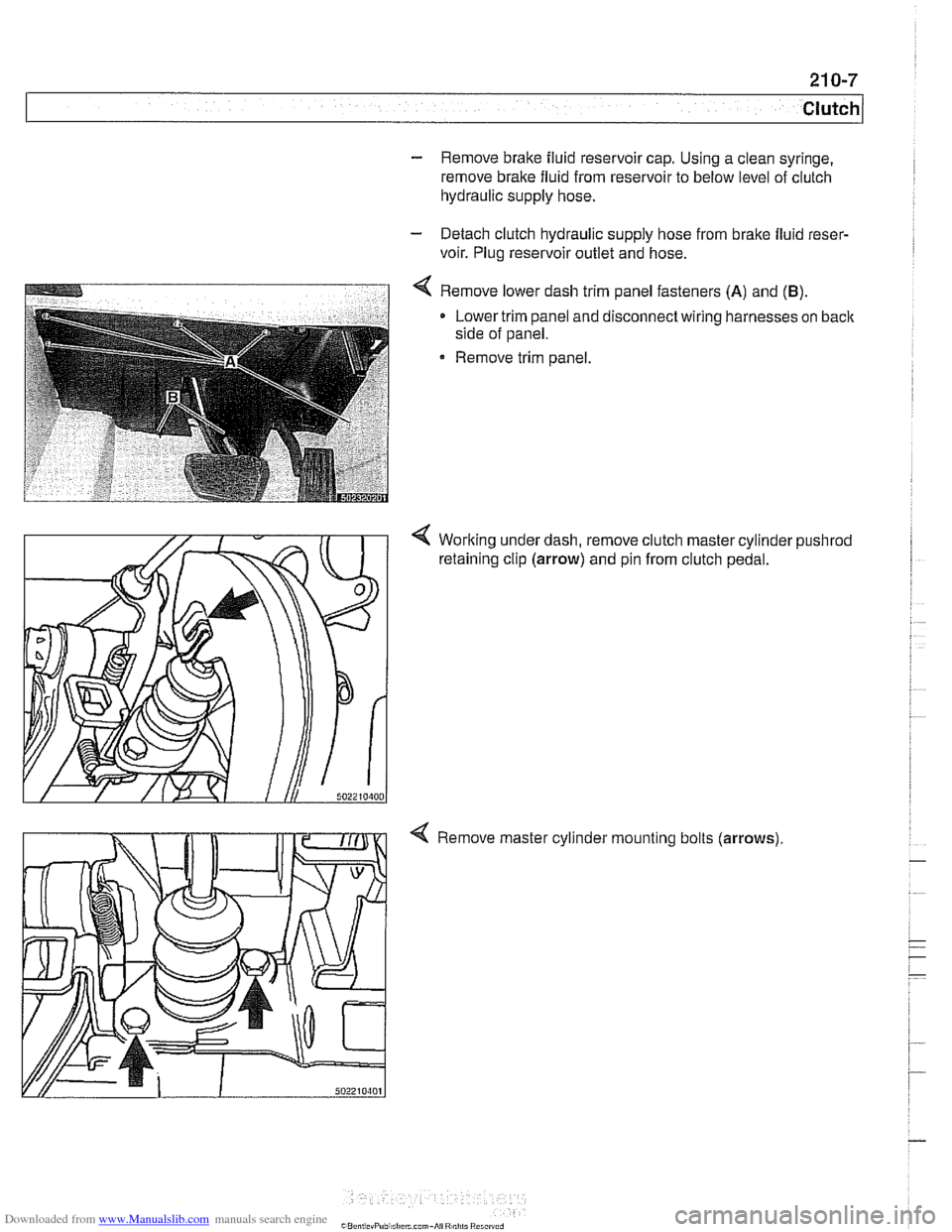

4 Remove lower dash trim panel fasteners (A) and (B).

Lower trim panel and disconnect wiring harnesses on back

side of panel.

Remove trim panel.

4 Working under dash, remove clutch master cylinder pushrod

retaining clip (arrow) and pin from clutch pedal.

4 Remove master cylinder mounting bolts (arrows)

Page 550 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-8

Clutch

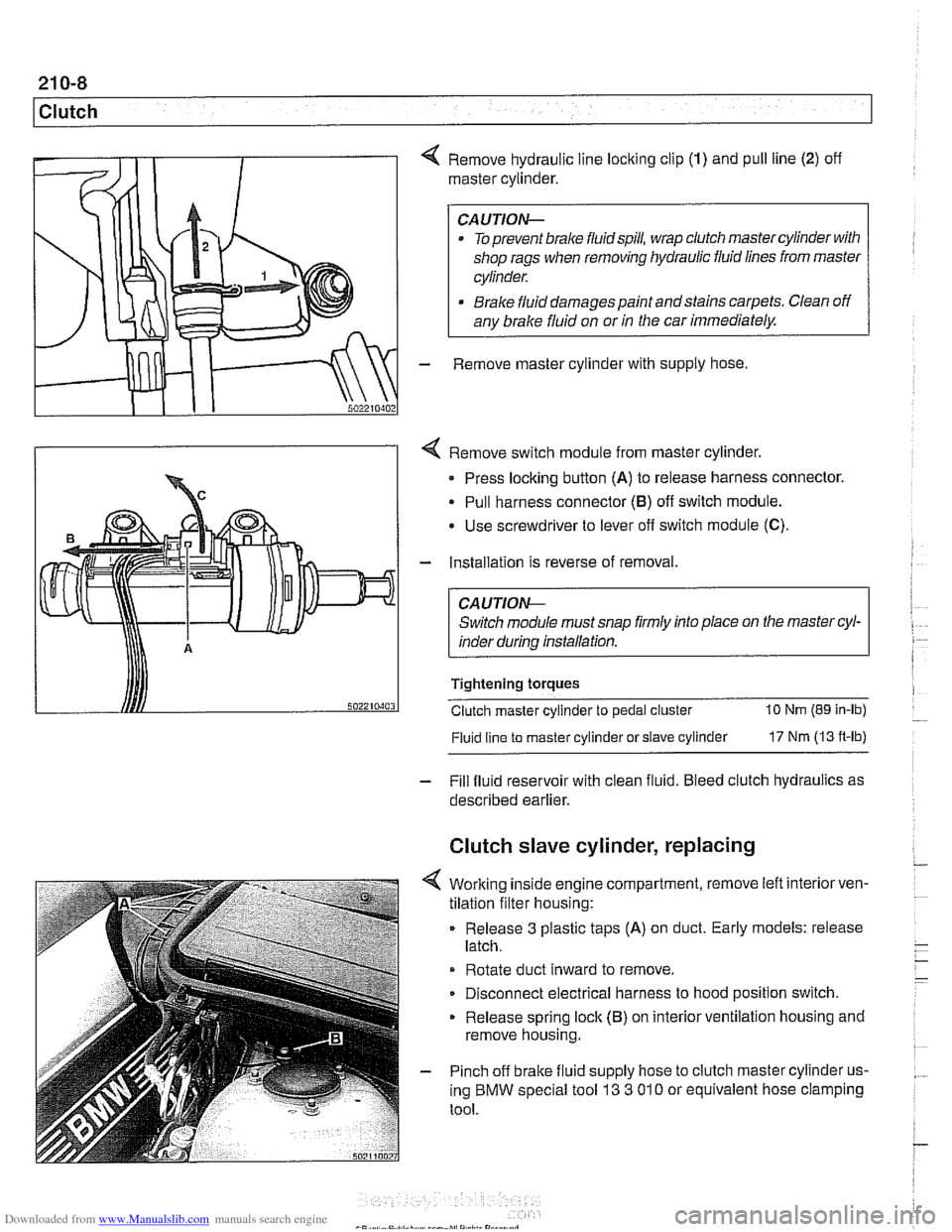

4 Remove hydraulic line locking clip (1) and pull line (2) off

master cylinder.

CAUTION-

. To prevent brake fluidspill, wrap clutch master cylinder with

shop rags when removing hydraulic fluid lines from master

cylinder.

* Brake fluid damages paint andstains carpets. Clean off

any brake fluid on or

in the car immediately.

- Remove master cylinder with supply hose

4 Remove switch module from master cylinder.

Press locking button

(A) to release harness connector.

Pull harness connector

(8) off switch module.

Use screwdriver to lever

off switch module (C).

- Installation is reverse of removal.

CA UTlON-

Switch module must snap firmly into place on the master cyl-

inder during installation.

Tightening torques

Clutch master cylinder to pedal cluster

10 Nm (89 in-lb)

Fluid line

to master cylinder or slave cylinder 17 Nm (13 ft-lb)

- Fill fluid reservoir with clean fluid. Bleed clutch hydraulics as

described earlier.

Clutch slave cylinder, replacing

4 Working inside engine compartment, remove left interiorven-

tilation filter housing:

Release

3 plastic taps (A) on duct. Early models: release

latch.

Rotate duct inward to remove.

Disconnect electrical harness to hood position switch.

Release spring lock (B) on interior ventilation housing and

remove housing.

- Pinch off brake fluid supply hose to clutch master cylinder us-

ing BMW special tool

13 3 01 0 or equivalent hose clamping

tool.