BMW 540i 1998 E39 Workshop Manual

Manufacturer: BMW, Model Year: 1998, Model line: 540i, Model: BMW 540i 1998 E39Pages: 1002

Page 551 of 1002

Downloaded from www.Manualslib.com manuals search engine

- Raise and safely support vehicle

WARNING-

Make sure the car is stable and well supporied at all times.

Use a professional automotive /iff orjack stands designed for

the

ournose. A floor jack is not adeouate suooort.

- If necessary, remove transmission splash shield.

- Disconnect fluid line from slave cylinder on lefl side of trans-

mission. Place pan under hose to catch dripping fluid.

4 Working underneath transmission, remove slave cylinder

mounting nuts (arrow) from clutch housing and remove

cylinder.

- Installation is reverse of removal, noting the following:

Check for wear on slave cylinder. Any wear except on tip is

caused by misalignment of clutch components.

Lightly coat

pushrod tip with molybdenum disulfide grease

(MolyltoteIB Longterm or equivalent).

. During installation be sure pushrod tip engages recess in

clutch release lever.

Fill fluid reservoir with clean fluid.

. Bleed clutch hydraulics as described earlier.

Tightening

toraues - -.

Clutch slave cylinder to transmission 22 Nm (16 R-lb)

Fluid line to slave cylinder 17 Nm (13 ft-lb)

The transmission must be removed from the engine to access

the clutch mechanical components. It is recommended that

the clutch disc, pressure plate and release bearing be re-

placed during a clutch overhaul.

Besure tocheck the bottom of the bellhousing foroil. If engine

oil is found, check for a faulty rear crankshaft main oil seal.

See

119 Lubrication for rear main seal replacement.

Clutch variations

Two versions of the clutch are used:

1997 528i (6 cylinder) uses traditional clutch components.

All

540i (V-8) and 1998 and later 6 cylinder models from

use a self-adjusting clutch (SAC).

Page 552 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-1 0

Clutch

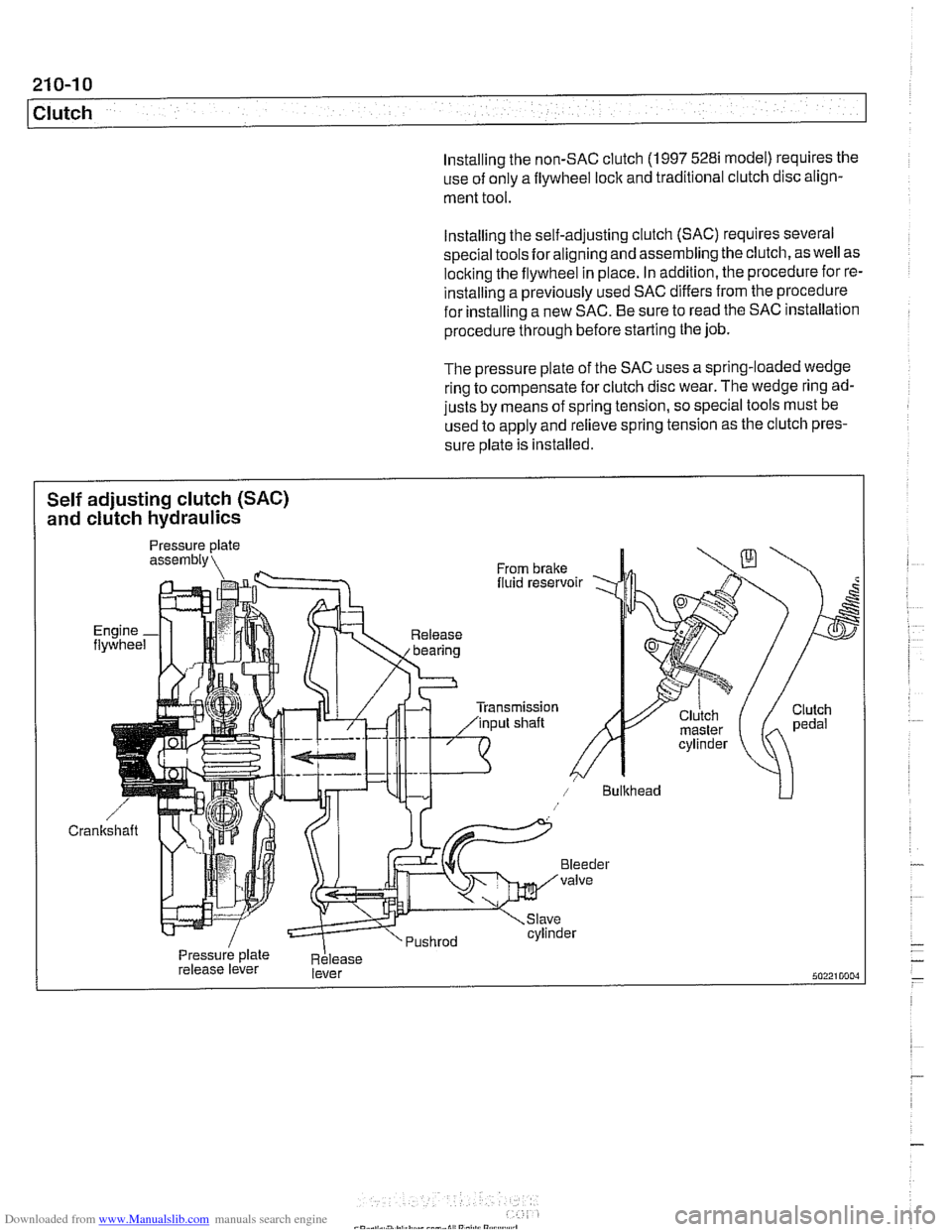

Installing the non-SAC clutch (1 997 5281 model) requires the

use of only a flywheel lock and traditional clutch disc align-

ment tool.

Installing the self-adjusting clutch (SAC) requires several

special tools for aligning and assembling the clutch, as well as

locking the flywheel in place. In addition, the procedure for re-

installing a previously used SAC differs from the procedure

for installing

a new SAC. Be sure to read the SAC installation

procedure through before starting the job.

The pressure plate of the SAC uses a spring-loaded wedge

rino to cornoensate for clutch disc wear. The wedge ring

ad-

;u$s by means of spr'ng tenson, so specal toolsh~st be

used to

appy and relieve spring tension as the c utch pres-

sure plate is installed.

Self adjusting clutch (SAC)

and clutch hydraulics

Page 553 of 1002

Downloaded from www.Manualslib.com manuals search engine

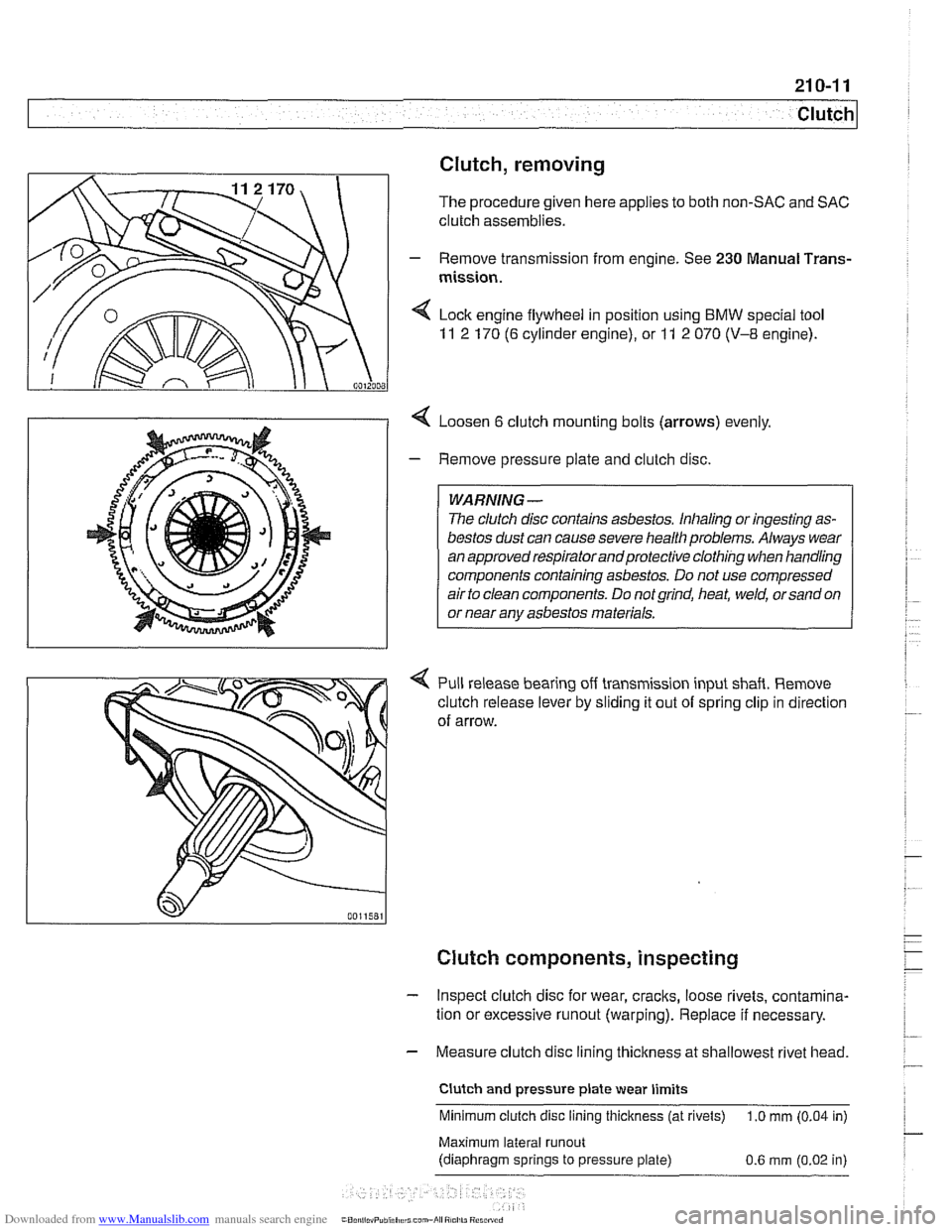

Clutch, removing

The procedure given here applies to both non-SAC and SAC

clutch assemblies.

- Remove transmission from engine. See 230 Manual Trans-

mission.

4 Loosen 6 clutch mounting bolts (arrows) evenly

- Remove pressure plate and clutch disc.

WARNING-

The clutch disc contains asbestos. Inhaling or ingesting as-

bestos dust can cause severe health problems. Always wear

an approved respiratorandprotective clothing when handling

components containing asbestos. Do not use compressed

air to clean components. Do not

grind, heat, weld, or sand on

or near anv asbestos materials.

Pull release bearing off transmission input shaft. Remove

clutch release lever by sliding it out of spring clip in direction

of arrow.

Clutch components, inspecting

- Inspect clutch disc for wear, cracks, loose rivets, contamina-

tion or excessive

runout (warping). Replace if necessary.

- Measure clutch disc lining thickness at shallowest rivet head. 7

Clutch and pressure plate wear limits

Minimum clutch disc lining thickness (at rivets)

1.0

mm (0.04 in) - Maxtmum lateral runout

(d~aphragm sprtngs to pressure plate) 0 6 mm (0 02 in)

Page 554 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-1 2

Clutch

Release bearing

Release

bearin

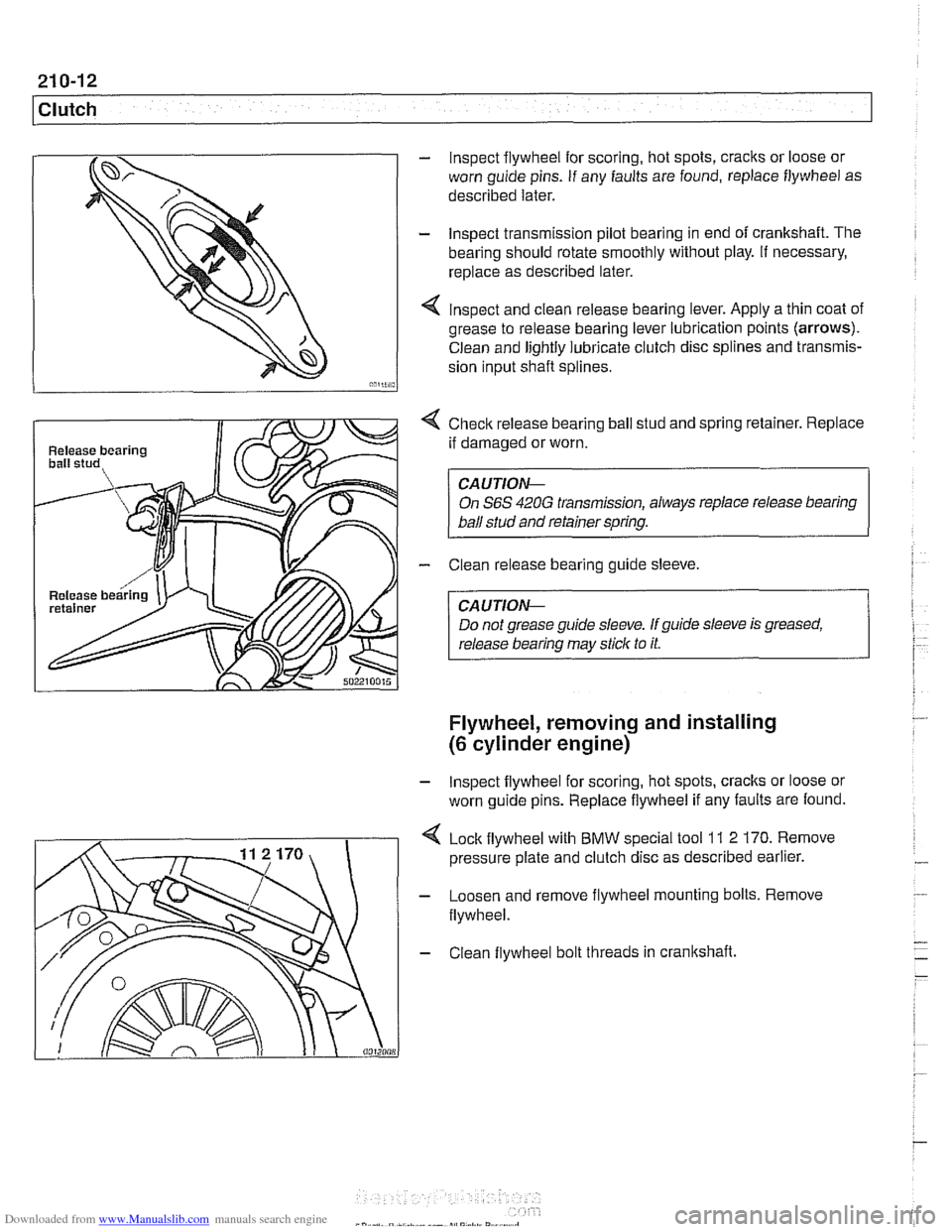

- lnspect flywheel for scoring, hot spots, cracks or loose or

worn guide pins. If any faults are found, replace flywheel as

described later.

- lnspect transmission pilot bearing in end of crankshaft. The

bearing should rotate smoothly without play. If necessary,

replace as described later.

4 lnspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points (arrows).

Clean and lightly lubricate clutch disc splines and transmis-

sion input

shaft splines.

4 Checlc release bearing ball stud and spring retainer. Replace

if damaged or worn.

CAUTION--

On S6S 420G transmission, always replace release bearing

ball stud and retainer spring.

- Clean release bearing guide sleeve.

CA U TIOG

Do not grease guide sleeve. If guide sleeve is greased,

release bearing may stick to it.

Flywheel, removing and installing

(6 cylinder engine)

- lnspect flywheel for scoring, hot spots, cracks or loose or

worn guide pins. Replace flywheel if any faults are found.

Lock flywheel with BMW special tool

11 2 170. Remove

pressure plate and clutch disc as described earlier.

- Loosen and remove flywheel mounting bolts. Remove

flywheel.

- Clean flywheel bolt threads in crankshaft.

Page 555 of 1002

Downloaded from www.Manualslib.com manuals search engine

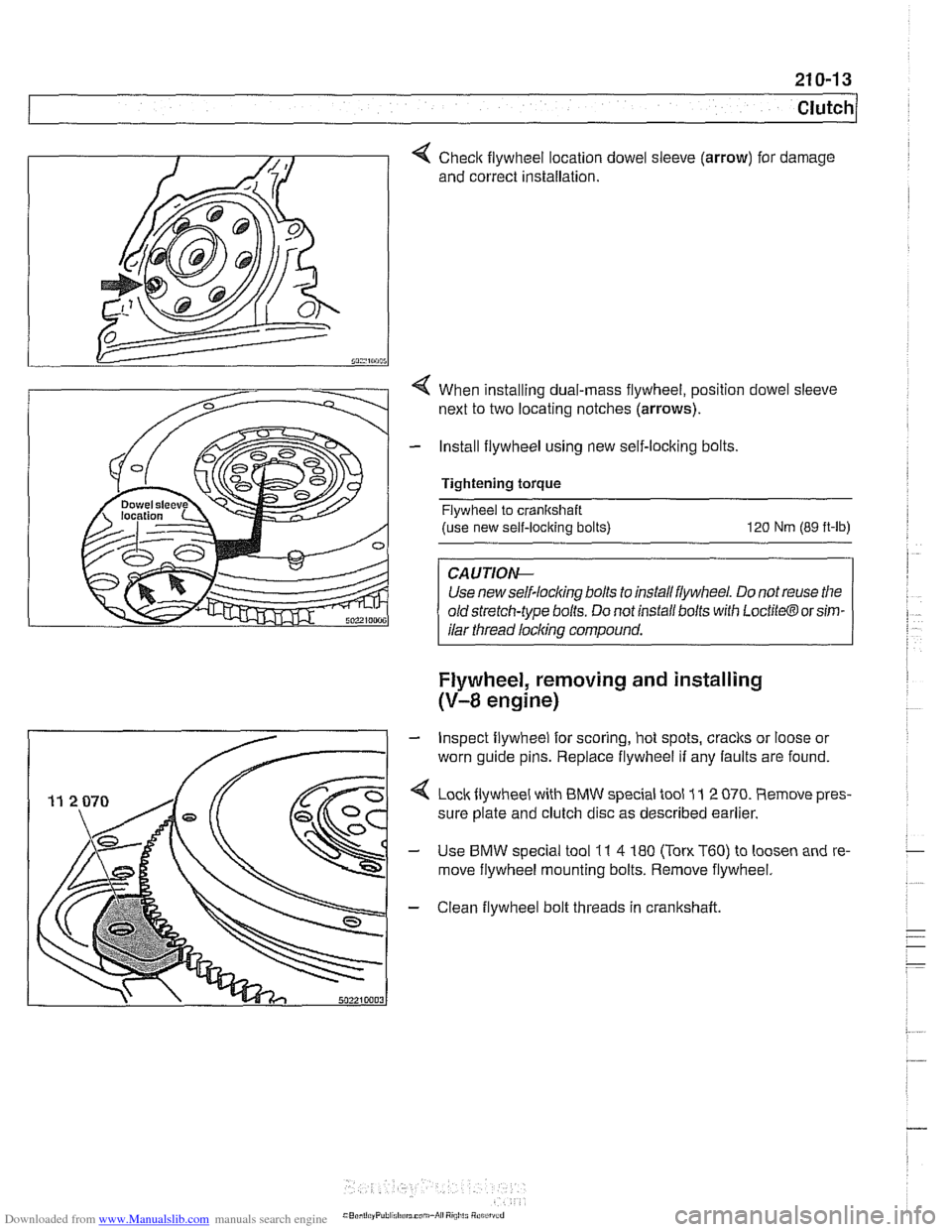

Checlc flywheel location dowel

and correct installation. sleeve (arrow) for

damage

4 When installing dual-mass flywheel, position dowel sleeve

next to two locating notches

(arrows).

- Install flywheel using new self-locking bolts,

Tightening torque Flywheel to cranltshaft

(use new self-locking bolts)

120 Nm (89 ft-lb)

Use new self-lock~ng bolls lo rnslall llylvheel Do not reuse llle

old slrelch-lype bolls Do nor rnsrall bolls wrlh Loct~lo@ or srm-

I ilar thread licking compound. 1

Flywheel, removing and installing

(V-8 engine)

- Inspect flywheel for scoring, hot spots, cracks or loose or

worn guide pins. Replace flywheel if any faults are found.

4 Loclcflywheel with BMW special tool 11 2 070. Remove pres-

sure plate and clutch disc as described earlier.

- Use BMW special tool 11 4 180 (Ton. T60) to loosen and re-

move flywheel mounting bolts. Remove flywheel.

- Clean flywheel bolt threads in crankshaft

Page 556 of 1002

Downloaded from www.Manualslib.com manuals search engine

210-1 4

1 Clutch

Dowel sleeve I

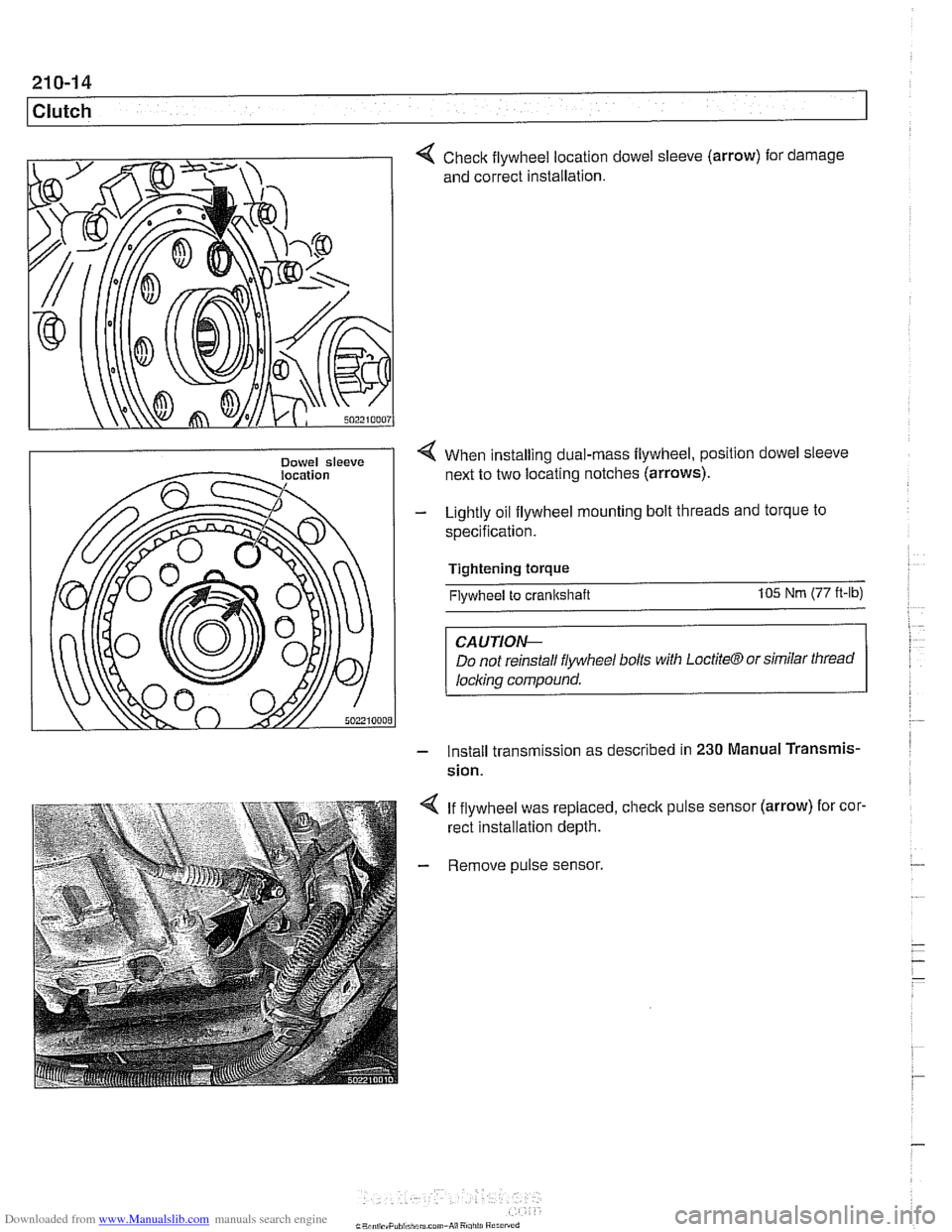

Check flywheel location

and correct installation. dowel sleeve

(arrow)

for . damage

< When installing dual-rnass flywheel, position dowel sleeve

next to two locating notches (arrows).

- Lightly oil flywheel mounting bolt threads and torque to

specification.

Tightening torque

Flywheel to crankshaft 105 Nm (77 ft-lb)

CAUTIOI\C

Do not reinstall flywheel bolls with LoctiteCTJ or similar thread

locl~ing compound.

- Install transm~ssion as descr~bed in 230 Manual Transmis-

sion.

4 If flywheel was replaced, check pulse sensor (arrow) for cor.

rect installation depth.

- Remove pulse sensor.

Page 557 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-1 5

Clutch

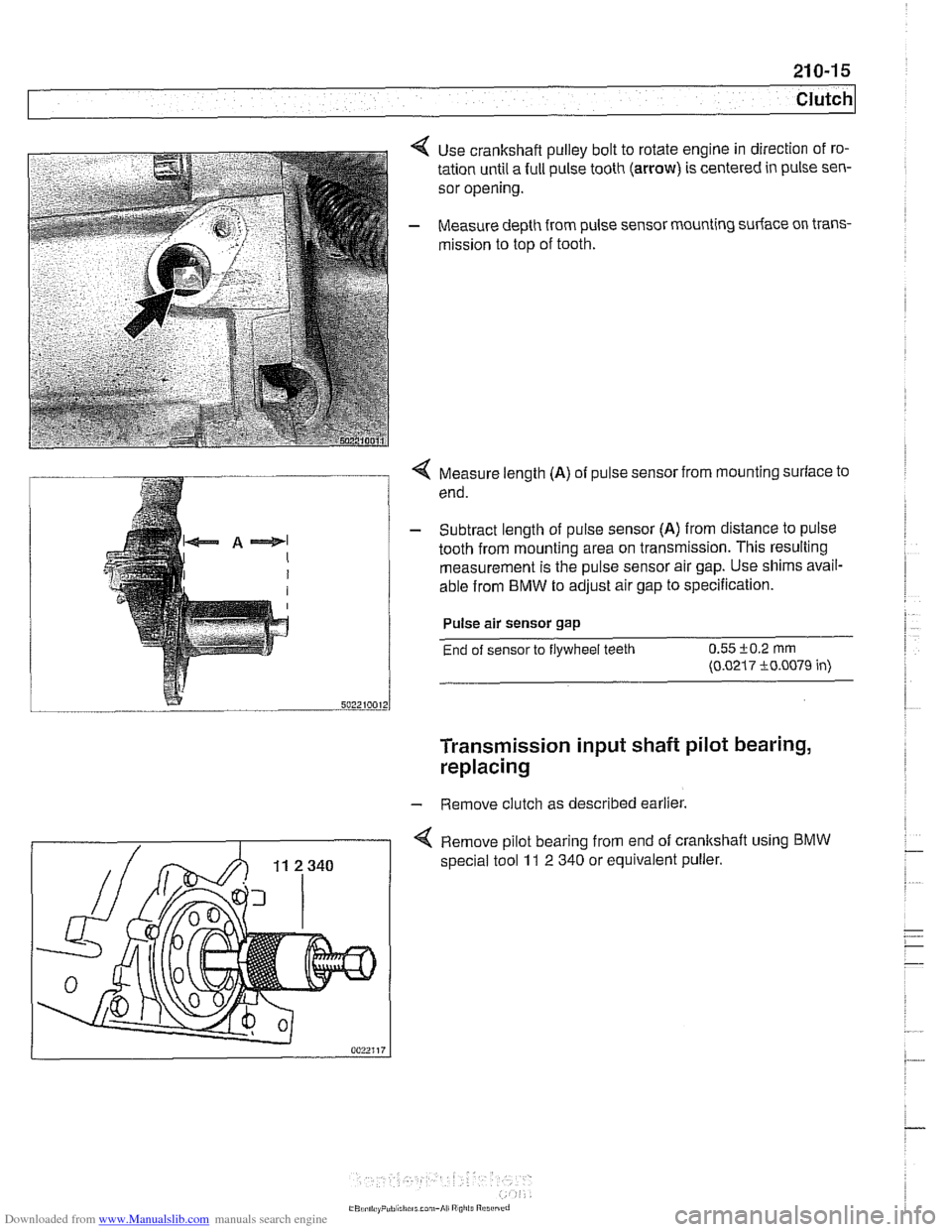

Use crankshaft pulley bolt to rotate engine in direction of ro-

tation until a full pulse tooth

(arrow) is centered in pulse sen-

sor opening.

Measure depth from pulse sensor mounting surface on trans-

mission to top of tooth.

Q Measure length (A) of pulse sensor from mounting surface to

end.

- Subtract length of pulse sensor (A) from distance to pulse

tooth from mounting area on transmission. This resulting

measurement is the pulse sensor air gap. Use shims avail-

able from

BMW to adjust air gap to specification.

Pulse air sensor gap

End of sensor to flywheel teeth 0.55 i-0.2 rnrn

(0.0217 i0.0079 in)

Transmission input shaft pilot bearing,

replacing

- Remove clutch as described earlier.

4 Remove pilot bearing from end of crankshaft using BMW

special tool 11 2 340 or equivalent puller.

Page 558 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-1 6

Clutch

4 Press new bearing into place using BMW special tool

11 2 350 or equivalent driver.

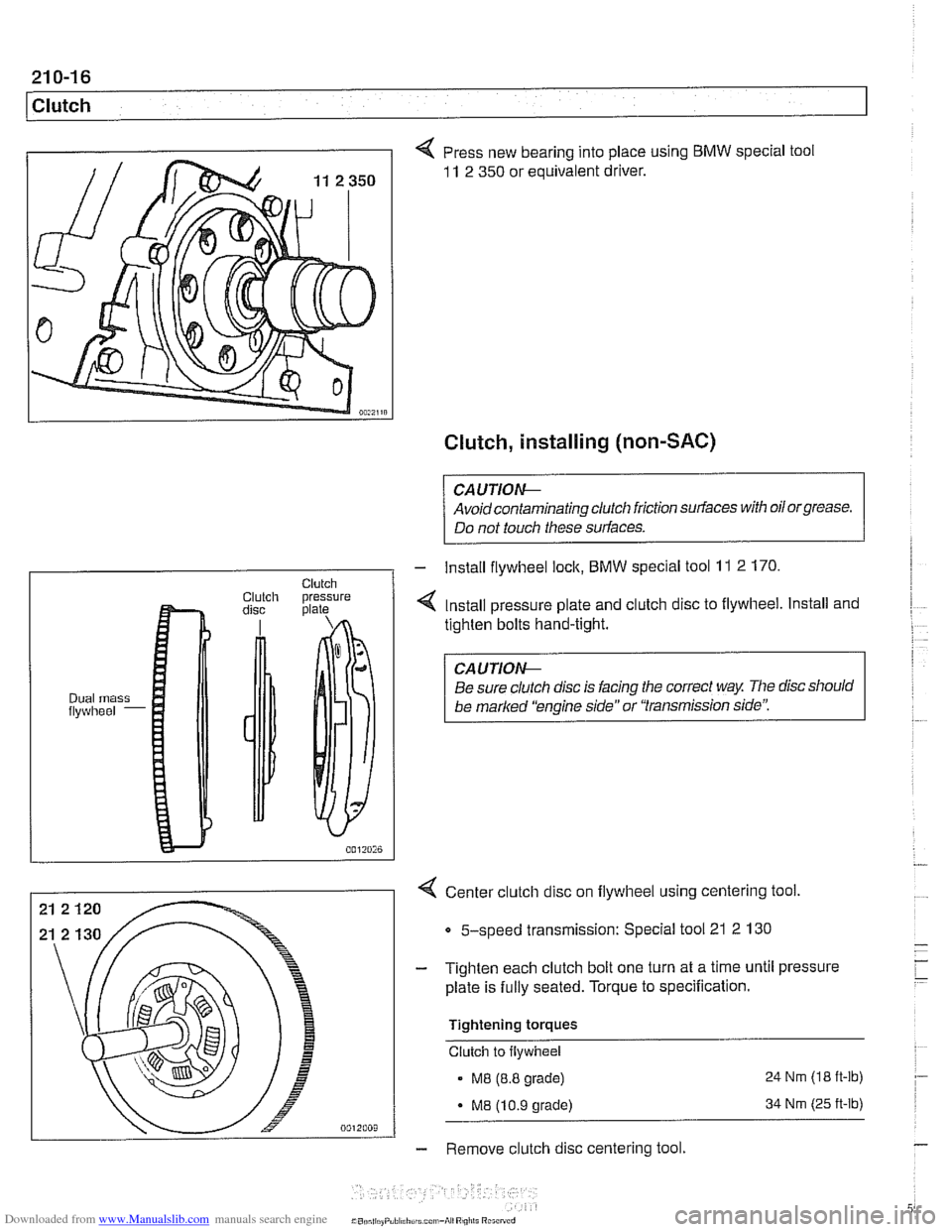

Clutch, installing (non-SAC)

CAUTIOG

Avoidcontaminating clutch friction surfaces with oilorgrease.

Do not touch these surfaces.

4 Center clutch disc on flywheel using centering tool

Clutch Clutch pressure disc plate

Dual mass flywheel -

5-speed transmission: Special tool 21 2 130

- Install flywheel lock, BMW special tool 11 2 170.

4 Install pressure plate and clutch disc to flywheel. Install and

tighten bolts hand-tight.

CAUTIOG

Be sure clutch disc is facing the correct way The disc should

be

marked 'kngine side" or "transmission side':

- Tighten each clutch bolt one turn at a time until pressure

plate is fully seated. Torque to specification.

Tightening torques

Clutch to flywheel

. M8 (8.8 grade) 24 Nrn (18

ft-lb)

- M8 (10.9 grade) 34 Nrn (25 ft-lb)

- Remove clutch disc centering tool.

Page 559 of 1002

Downloaded from www.Manualslib.com manuals search engine

Clutch

- Remove flywheel locking tool

4 Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. Install re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

CAUTION-

Do not grease release bearing guide sleeve. If guide sleeve

is greased, release bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- Install transmission. See 230 Manual Transmission

.

Transmission to engine

MB (Torx) 22 Nm (16 fl-lb)

MlO(Torx) 43 Nm (32 fl-lb)

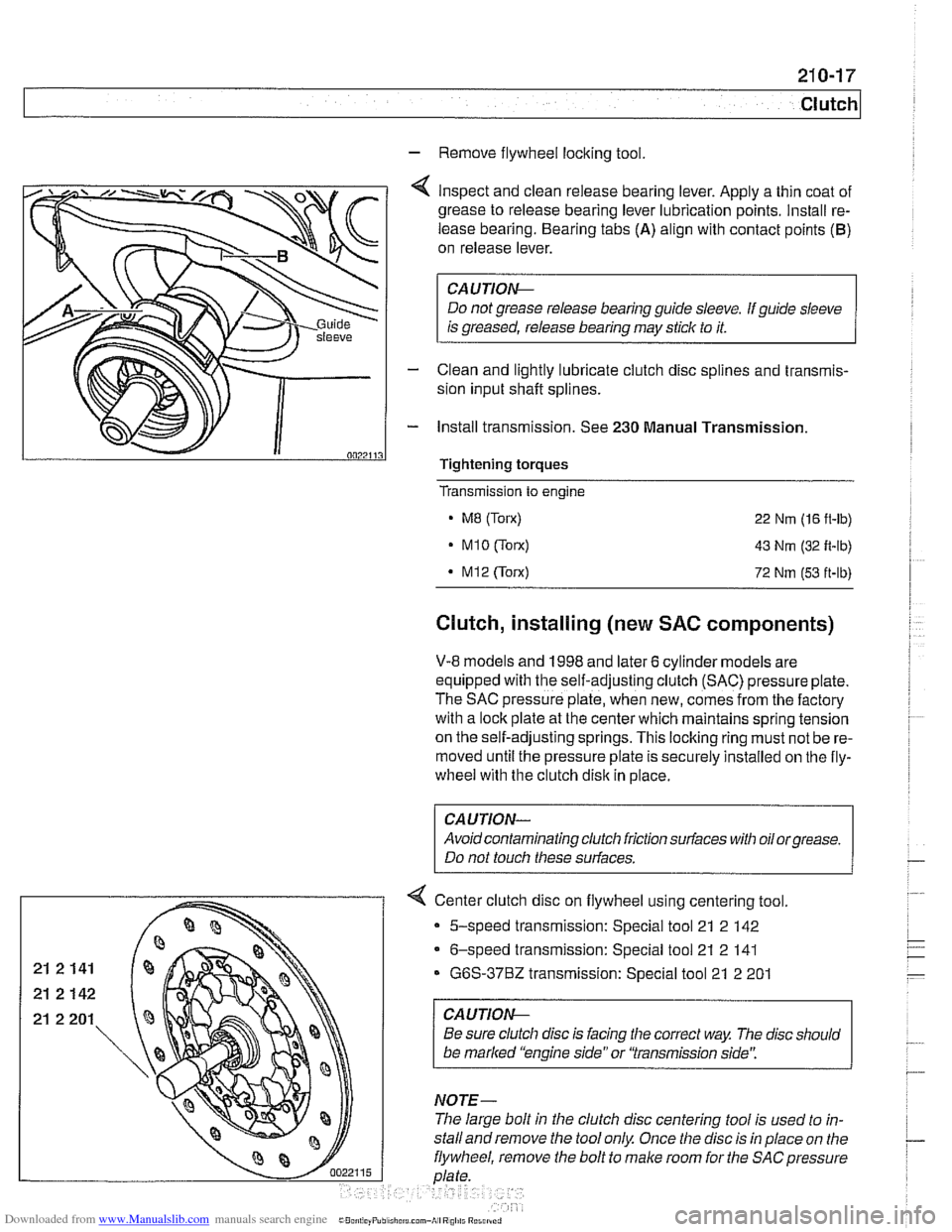

Clutch, installing (new SAC components)

V-8 models and 1998 and later 6 cylinder models are

equipped with the self-adjusting clutch (SAC) pressure plate.

The SAC pressure plate, when new, comes from the factory

with a lock plate at the center which maintains spring tension

on the self-adjusting springs. This

loclting ring must not be re-

moved until the pressure plate is securely installed on tlie fly-

wheel with the clutch disk in place.

CAUTION-

Avoidcontaminating clutch friction surfaces with oilorgrease.

Do not touch these surfaces.

< Center clutch disc on flywheel using centering tool.

5-speed transmission: Special tool 21 2

142

- 6-speed transmission: Special tool 21 2 141

G6S-3782 transmission: Special tool 21 2 201

CAUTION-

Be sure clutch disc is facing the correct way The disc should

be marked "engine side" or "transmission side':

The large bolt in the clutch disc centering tool is used to

in-

stalland remove the tool only. Once the disc is in place on the

eel, remove the bolt to male room for tlie

SACpressure

Page 560 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-1 8

Clutch

- lnstall flywheel lock, special tool 11 2 170 (6 cylinder model)

or

11 2 070 (V-8 model).

- Install SAC pressure plate on dowel pins at flywheel. lnstall

clutch mounting bolts and tighten each one turn at a time until

pressure plate is fully seated. Torque to specification.

Tightening torques Clutch to flywheel

- M8 (8.8 grade)

MB 110.9 orade)

24 Nm (1 8 it-lb)

34 Nm (25

ft-lb)

Use 14 mm Allen wrench to unscrew (clocltwise or counter-

clockwise) lock plate in center of pressure plate.

NOTE-

The spring lockplate may make snapping noises while being

unscrewed.

Using large bolt, pull out clutch centering tool

Remove flywheel locking tool

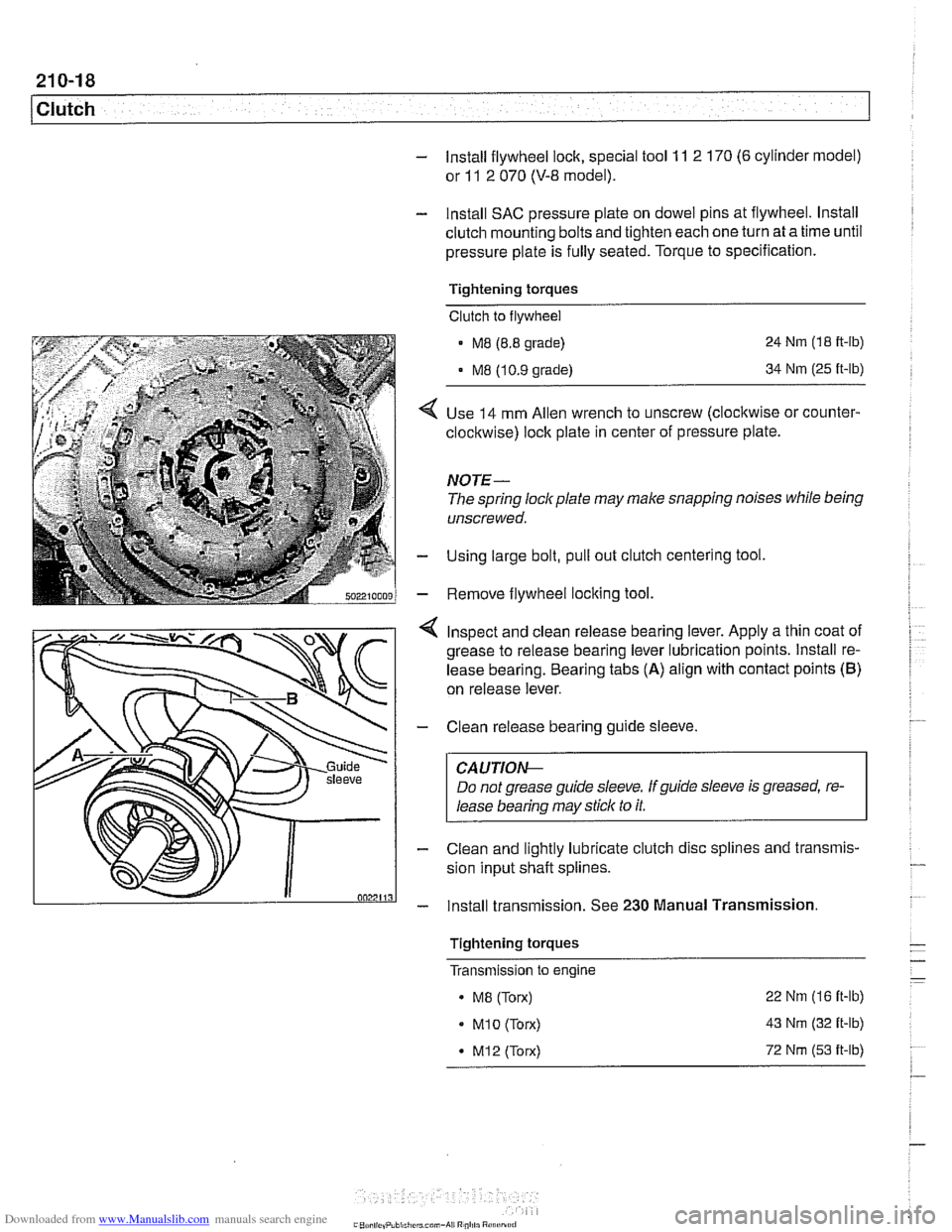

4 Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. lnstall re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

- Clean release bearing guide sleeve.

CAUTIOG

Do not grease guide sleeve. Ifguide sleeve is greased, re-

lease bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- lnstall transmission. See 230 Manual Transmission.

Tightening torques

- - - Transmlsslon to engine -

. MB (Torx) 22

Nm (16 it-lb)

MI0 (Torx) 43 Nm (32 it-lb)

* M12 (Torx) 72 Nm (53 it-lb)

.-