change time CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 396 of 659

CLUTCH AND TRANSMISSIONS 7-37

LI.

- LI Range can be selected at any vehicle speed,

and the transmission will shift to second gear

and remain in second until vehicle speed is re-

duced to approximately 40 MPH, .depending on

axle ratio. LI Range position prevents the trans-

mission from shifting out of first gear.

It is very important that any communication concerning

the Turbo Hydra-Matic always contain the transmission

serial number and that all transmission parts returned

to Chevrolet Motor Division always be tagged with the

transmission serial number.

MAINTENANCE AND ADJUSTMENTS

TRANSMISSION FLUID

Transmission fluid level should be checked with trans-

mission warm and selector lever in "P" Park position,

every time engine oil level is checked or as specified in

Section 0 when engine oil is changed.

CAUTION: Since the Turbo Hydra-Matic trans-

mission is very sensitive to oil level, special

precautions should be taken when checking the

oil level, to insure against an overfifE

Transmission fluid should be changed as specified in

Section 0.

FLUID LEVEL INDICATOR

The fluid level indicator is located in the filler pipe at

the right rear corner of the engine. To bring the fluid

level from the add mark to the full mark add 1 pint.

Fluid level should be to the full mark with transmission

at normal operating temperature. With cold fluid the

level should be at the add mark or slightly below.

SHIFT CONTROL LINKAGE ADJUSTMENT

Adjust linkage as shown below and in Figure 2.

1.

The shift tube and lever assembly must be free in the

mast jacket See Section 9 for alignment of steering

column assembly if necessary.

2.

To check for proper shift linkage adjustment, lift the

transmission selector lever towards the steering

wheel. Allow the selector lever to be positioned in

drive (D) by the transmission detent.

NOTE: Do not use the indicator pointer as a

reference to position the selector lever. When

performing linkage adjustment, pointer is ad-

justed last.

3.

Release the selector lever. The lever should be in-

hibited from engaging low range unless the lever is

lifted.

4.

Lift the selector lever towards the steering wheel,

and allow the lever to be positioned in neutral (N) by

the transmission detent.

5.

Release the selector lever. The lever should now be

inhibited from engaging reverse range unless the

lever is lifted.

6. A properly adjusted linkage will prevent the selector

lever from moving beyond both the neutral detent,

and the drive detent unless the lever is lifted to pass

over the mechanical stop in the steering column.

See schematic diagram.

7.

In the event that an adjustment is required, place the

selector lever in drive (D) position as determined by

the transmission detent. See Steps 2 and 3.

8. Loosen the adjustment swivel at the cross-shaft, and

rotate the transmission lever so that it contacts the

drive stop in the steering column.

9. Tighten the swivel and recheck the adjustment. See

Steps 2 and 6. -

l(h Readjust indicator needle if necessary to agree with

the transmission detent" positions. See Section 9.

11.

Readjust neutral safety switch if necessary to pro-

vide the correct relationship to the transmission de-

tent positions. See Section 12.

12.

When properly adjusted the following conditions must

be met by manual operation of the steering column

shift lever:

a. From reverse to drive position travel, the trans-

mission detent feel must be noted and related to

indicated position on dial.

b.

When in drive and reverse positions, pull lever

rearward (towards steering wheel) and then re-

lease. It must drop back into position with no

restrictions.

NEUTRAL SAFETY SWITCH ADJUSTMENT

The neutral safety switch must be adjusted so that the

car will start in the park or neutral position, but will not

start in the other positions. For replacement refer to

Section 12 of this Manual.

DRAINING AND REFILLING TRANSMISSION

Drain oil immediately after operation before it has had

an opportunity to cool.

To drain oil proceed as follows:

1.

Remove bottom pan attaching screws, pan, and gas-

ket.

2.

Remove oil strainer. Remove "O" ring seal from

pick-up pipe and discard.

3.

Discard strainer if dirty.

4.

Install new "O" ring seal on pick-up pipe and install

strainer and pipe assembly.

5.

Thoroughly clean bottom pan.

6.. Affix new gasket to bottom pan with petroleum jelly.

7.

Install bottom pan with attaching screws and torque

to specifications;

8. If only the pan has been removed, pour approximately

7-1/2 pints of fluid into the transmission. If the

valve body has also been removed use 9-1/2 pints.

After a complete overhaul approximately 19 pints

are required. Be sure container, spout, or funnel is

clean.

9. Start engine and let idle (carburetor off fast idle

step).

Place selector lever in P position and apply

hand brake.

10.

With transmission warm (approximately 150°F), add

fluid to bring level to full mark on indicator.

CAUTION: Do not overfill. Foaming will re-

sult.

CHEVROLET CHASSIS SERVICE MANUAL

Page 475 of 659

STEERING 9-35

Fig.

66—Power Steering Diagnosis

shown in Figure 66. Gauge must be between shut-

off valve and pump. Open shut-off valve,

b.

Remove filler cap from pump reservoir and check

fluid level. Fill pump reservoir to full mark on

dip stick. Start engine and, holding steering

wheel against stop, check connections at Tool

J-5176 for leakage. Bleed system as outlined

under Maintenance and Adjustments. Insert ther-

mometer (Tool J-5421) in reservoir filler open-

ing. Move steering wheel from stop to stop

several times until thermometer indicates that

hydraulic fluid in reservoir has reached tempera-

ture of 150° to 170°F.

CAUTION: To prevent scrubbing flat spots on

tires,

do not turn steering wheel more than five

times without rolling car to change tire-to-floor

contact area.

c. Hold steering wheel against a stop momentarily

and read pressure gauge. If the maximum pres-

sure is below specifications, a faulty hydraulic

circuit is indicated. To determine which part is

faulty, proceed with test number two.

Test Number Two—Oil Circuit Closed

a. Slowly turn shut-off valve on J-5176 to closed

position and read pressure indicated on gauge.

Quickly reopen valve to avoid pump damage, if

indicated pressure is less than specification,

pump output is below requirement and pump may

be considered faulty. If pressure indicated is

within specifications, it may be safely assumed

that the external hoses, connections, valve and

adapter or steering gear is at fault.

NOTE:

If pump proves faulty in test number

two,

test should be repeated after pump is re-

paired and installed in vehicle. This will provide

a means of checking the repairs made to the

pump and the condition of the steering gear or

valve and adapter which may also be faulty.

COMPONENT REPLACEMENT AND REPAIRS

POWER STEERING PUMP

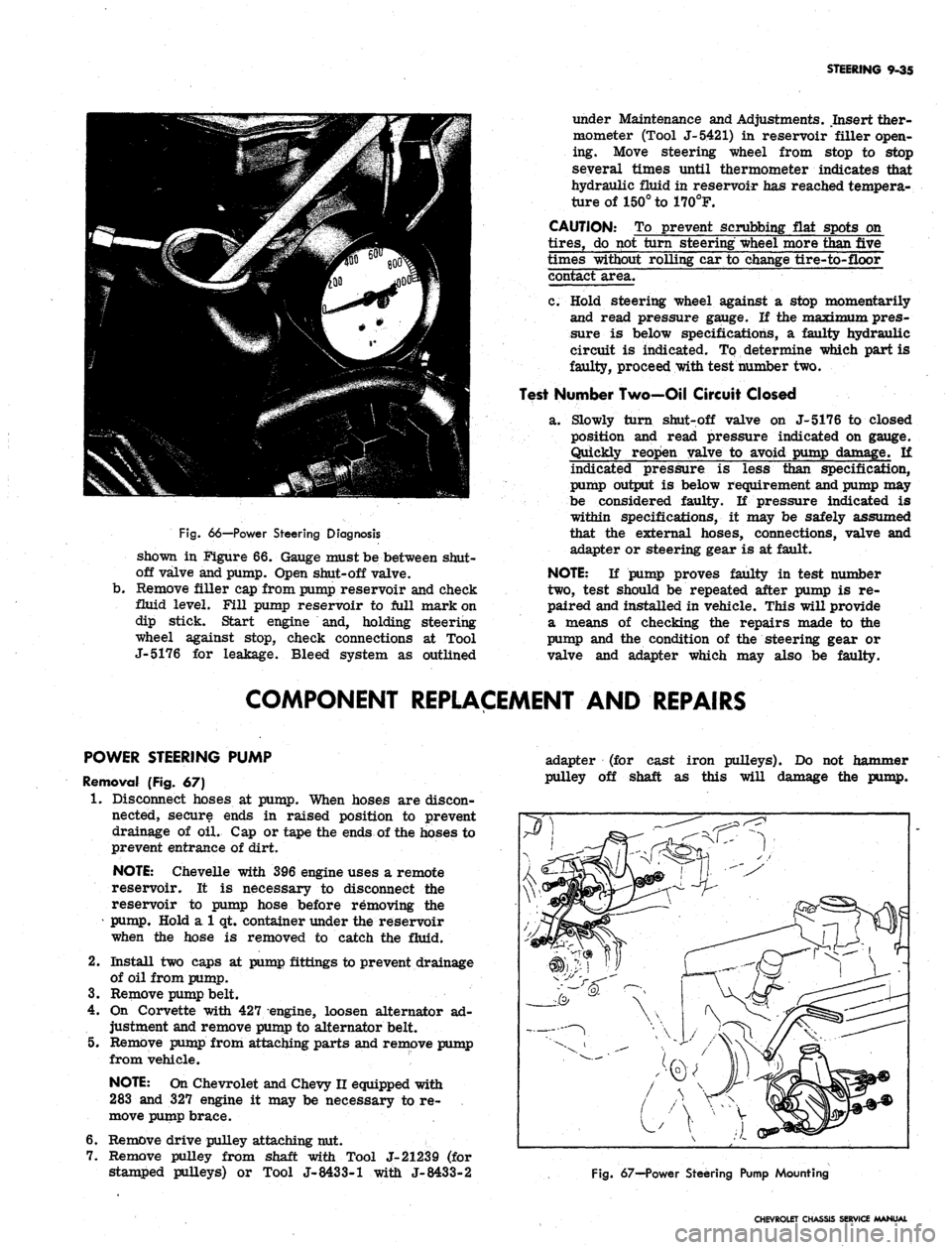

Removal (Fig. 67)

1.

Disconnect hoses at pump. When hoses are discon-

nected, secure ends in raised position to prevent

drainage of oil. Cap or tape the ends of the hoses to

prevent entrance of dirt.

NOTE:

Chevelle with 396 engine uses a remote

reservoir. It is necessary to disconnect the

reservoir to pump hose before removing the

pump.

Hold a 1 qt. container under the reservoir

when the hose is removed to catch the fluid.

2.

Install two caps at pump fittings to prevent drainage

of oil from pump.

3.

Remove pump belt.

4.

On Corvette with 427 engine, loosen alternator ad-

justment and remove pump to alternator belt.

5. Remove pump from attaching parts and remove pump

from vehicle.

NOTE:

On Chevrolet and Chevy II equipped with

283 and 327 engine it may be necessary to re-

move pump brace.

6. Remove drive pulley attaching nut.

7. Remove pulley from shaft with Tool J-21239 (for

stamped pulleys) or Tool J-8433-1 with J-8433-2

adapter (for cast iron pulleys). Do not hammer

pulley off shaft as this will damage the pump.

Fig.

67—Power Steering Pump Mounting

CHEVROLET CHASSIS SERVICE MANUAL

Page 484 of 659

WHEELS AND TIRES 10-4

the road and it slips, grinding off the tread on the inside

half of the tire at an excessive rate. This type of tire

shows much the same appearance of tread wear as tire

wear caused by negative camber.

Second, the transfer of weight may also over-load the

outside tires so much that they are laterally distorted

resulting in excessive wear on the outside half of the

tire producing a type of wear like that caused by ex-

cessive positive camber.

Cornering wear can be most easily distinguished from

abnormal camber wear by the rounding of the outside

shoulder or edge of the tire and by the roughening of the

tread surface which denotes abrasion.

Cornering wear often produces a fin or raised portion

along the inside edge of each row in the tread pattern.

In some cases this fin is almost as pronounced as a

toe-in fin, and in others, it tapers into a row of tread

blocks to such an extent that the tire has a definite step

wear appearance.

The only remedy for cornering wear is proper in-

struction of owners.

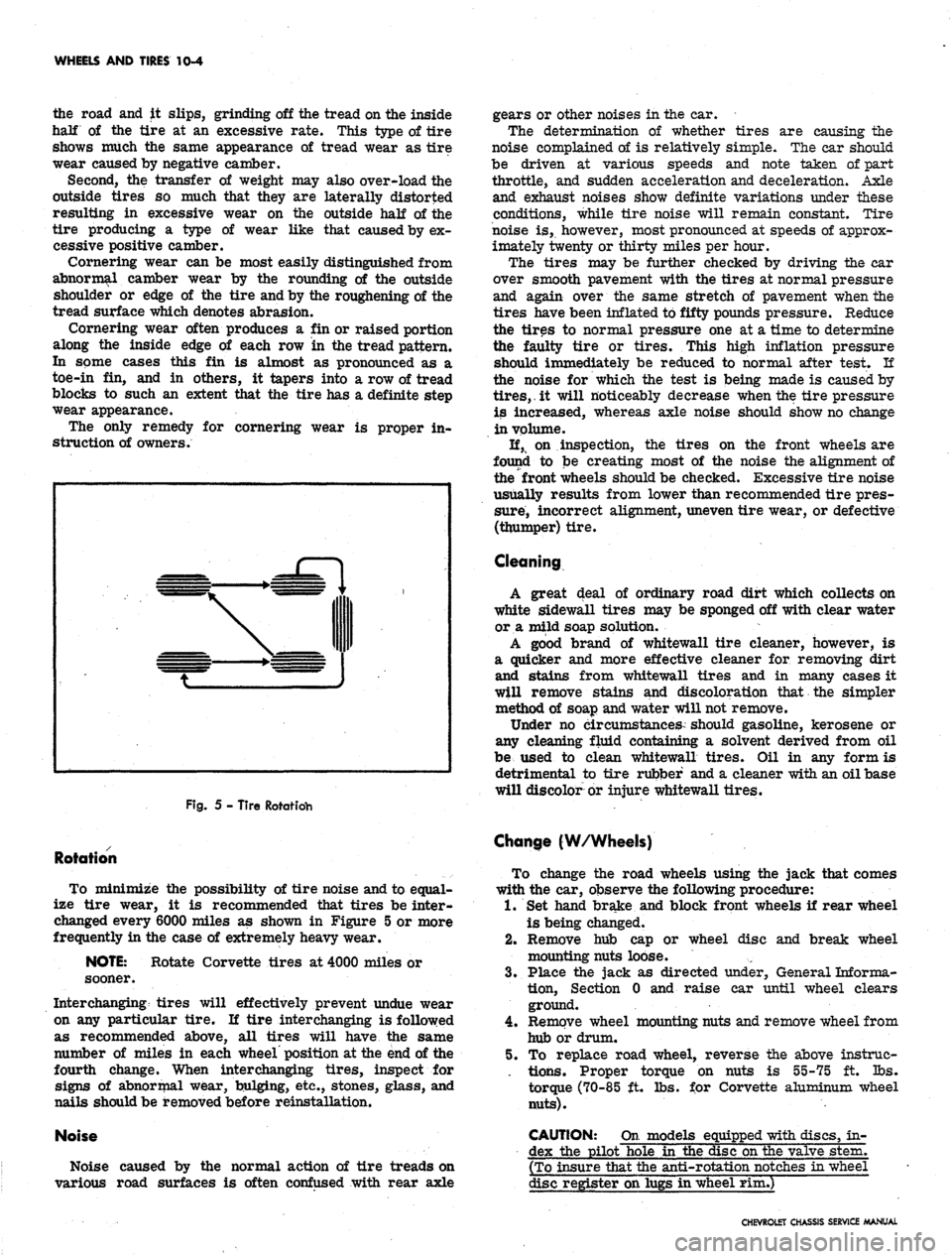

Fig.

5 - Tire Rotatidh

Rotation

To minimize the possibility of tire noise and to equal-

ize tire wear, it is recommended that tires be inter-

changed every 6000 miles as shown in Figure 5 or more

frequently in the case of extremely heavy wear.

NOTE:

Rotate Corvette tires at 4000 miles or

sooner.

Interchanging tires will effectively prevent undue wear

on any particular tire. II tire interchanging is followed

as recommended above, all tires will have the same

number of miles in each wheel position at the end of the

fourth change. When interchanging tires, inspect for

signs of abnormal wear, bulging, etc., stones, glass, and

nails should be removed before reinstallation.

Noise

Noise caused by the normal action of tire treads on

various road surfaces is often confused with rear axle

gears or other noises in the car.

The determination of whether tires are causing the

noise complained of is relatively simple. The car should

be driven at various speeds and note taken of part

throttle, and sudden acceleration and deceleration. Axle

and exhaust noises show definite variations under these

conditions, while tire noise will remain constant. Tire

noise is, however, most pronounced at speeds of approx-

imately twenty or thirty miles per hour.

The tires may be further checked by driving the ear

over smooth pavement with the tires at normal pressure

and again over the same stretch of pavement when the

tires have been inflated to fifty pounds pressure. Reduce

the tires to normal pressure one at a time to determine

the faulty tire or tires. This high inflation pressure

should immediately be reduced to normal after test. If

the noise for which the test is being made is caused by

tires,.

it will noticeably decrease when the tire pressure

is increased, whereas axle noise should show no change

in volume.

If, on inspection, the tires on the front wheels are

found to be creating most of the noise the alignment of

the front wheels should be checked. Excessive tire noise

usually results from lower than recommended tire pres-

sure, incorrect alignment, uneven tire wear, or defective

(thumper) tire.

Cleaning

A great deal of ordinary road dirt which collects on

white sidewall tires may be sponged off with clear water

or a mild soap solution.

A good brand of whitewall tire cleaner, however, is

a quicker and more effective cleaner for removing dirt

and stains from whitewall tires and in many cases it

will remove stains and discoloration that the simpler

method of soap and water will not remove.

Under no circumstances should gasoline, kerosene or

any cleaning fluid containing a solvent derived from oil

be used to clean whitewall tires. Oil in any form is

detrimental to tire rubber and a cleaner with an oil base

will discolor or injure whitewall tires.

Change (W/Wheels)

To change the road wheels using the jack that comes

with the car, observe the following procedure:

1.

Set hand brake and block front wheels if rear wheel

is being changed.

2.

Remove hub cap or wheel disc and break wheel

mounting nuts loose.

3.

Place the jack as directed tinder, General Informa-

tion,

Section 0 and raise car until wheel clears

ground.

4.

Remove wheel mounting nuts and remove wheel from

hub or drum.

5. To replace road wheel, reverse the above instrue-

. tions. Proper torque on nuts is 55-75 ft. lbs.

torque (70-85 ft. lbs. for Corvette aluminum wheel

nuts).

CAUTION: On models equipped with discs, in-

dex the pilot hole in the disc on the valve stem.

(To insure that the anti-rotation notches in wheel

disc register on lugs in wheel rim.)

CHEVROLET CHASSIS SERVICE MANUAL

Page 513 of 659

SECTION 12

ELECTRICAL-BODY AND CHASSIS

CONTENTS

OF

THIS

SECTION

Page

Page

System 12-1

Instruments and Gauges 12-21

Directional Signal 12r40

Windshield Wipers and Washers 12-44

Wiring Diagrams 12-56

Special Tools 12-60

LIGHTING SYSTEM

INDEX

Page

General Description

!2-i

Maintenance and Adjustments

•.................. 12-2

Headlamp Adjustment......................

12-3

Headlamp Panel Travel Adjustment.

12-5

Service Operations.

. . .. 12-5

Front Lighting

12-5

Headlamp

. 12_5

Parking Lamp

12-5

Fender Lamp

. 12_^

Headlamp Panel

12-8

Headlamp Panel Motor

^2-9

Rear Lighting

l2-10

Tail, Stop and Directional Lamps

12-10

Page

Backing Lamps

12-14

License Plate Lamp

12-14

Automatic Transmission Quadrant Lamp

12-14

Seat Separator Console Lamps

. 12-15

Lighting Switch

. . 12-15

Wiper Switch.

12-15

Stoplight Switch

12-15

Dimmer Switch

12-15

Backing Lamp Switches

12-15

Neutral Safety Switches

12-17

Parking Brake Alarm Switch

................. 12-19

Instrument Panel Compartment Lamp/Switch

12-19

Cirgarette Lighter

12-19

GENERAL DESCRIPTION

.

The lighting system includes: the main lighting switch,

stop light, dimmer, and backing lamp switches, head-

lamps, parking lamps, stop, tail and directional lamps,

instrument illumination and indicator lamps, and the

necessary wiring to complete the various circuits. A

fuse panel provides convenient power take offs and fuse

clips for the appropriate circuits (fig. 1).

Chevrolet and Chevelle headlamp installation is all

new in that the headlamps are located in the radiator

support with adjusting screws and springs. Eliminating

the need for having separate headlamp housings. Chev-

rolet and Chevelle headlamp retainers and springs are

interchangeable.

Chevy n headlamp housings are new because of revised

front end styling and Corvette front end lighting is basi-

cally carryover.

Front fender lamps have been added as an option for

Chevrolet models and as standard equipment on Caprice

series.

Camaro models use single headlamps and the Rally

Sport model headlamps are covered by a retractable

section of the grille when lamps are not used. The sec-

tion of the grille covering the headlamps folds back when

lights are required; the headlamps are stationary. The

covering is retracted by a small electric motor mounted

to the headlamp housing. The headlamps are automat-

ically uncovered when the headlight switch is pulled "ON"

for illumination. If at any time the electrical circuit

becomes inoperative, the lamps can be uncovered manu-

ally. The ignition switch must be

"ON"

in order to close

the headlamp doors.

Parking lamp for Chevelle and Chevrolet models are

new due to revised front end sheet metal and bumper

styling. Parking lamps are located in the bumper on

Chevrolet, Chevelle and Chevy n models

Camaro parking lamps are located in the radiator

grille except for the Rally Sport models on which the

parking lamps are in the valance panel. For styling

reasons, the lens is white and an amber glass bulb is

used. All Camaro parking lamps require a separate

ground wire to assure a good ground contact because of

the plastic grille and painted contact surfaces.

The Chevrolet tail, stop, and directional lamps are in

one housing with a three section lens design on Impala

and Caprice sedans. The center lens for Impala series

is the back-up lamp. The center lens on the Caprice is

a tail lamp with the back-up lamps being located in the

rear bumper. Chevrolet station wagons have three indi-

vidual housings with three lenses, the center lamp being

the back-up. Biscayne and Bel-Air sedans have a single

housing and lens for tail, stop, and directional lamp with

a similarly constructed back-up lamp inboard and adja-

cent to it.

Chevelle tail, stop, and directional lamps are a single

lens design that follows through with the rear fender

styling. The back-up lamp is located in r.ear bumper.

Camaro models except Rally Sport have tail lamps

with integral back-up lamps mounted inboard of the rear

fenders between the trunk opening and bumper. The

Rally Sport model has dual tail lamps in the rear housing

and valance mounted back-up lamps.

Corvette, Chevy n, and Corvair tail and directional

signal lights are carryover. The Corvette has new back-

up lamps center mounted above the license plate opening.

CHEVROLET CHASSIS SERVICE

Page 520 of 659

ELECTRICAL-BODY AND CHASSIS 12-8

is inserted through radiator support opening.

Remove two screws retaining lamp assembly to

lower sheet metal.

Remove three screws retaining lamp assembly to

lender.

To replace lamp assembly, reverse removal proce-

dure and check operation of the unit.

is aligned with flat on pivot shaft. Install stop lock

bolt and torque bolt to 45-60 in, lbs. Make sure that

side-to-side panel alignment is not changed when in-

stalling and tightening the stop.

CAUTION: Do not exceed specified torque

when tightening stop lock bolt.

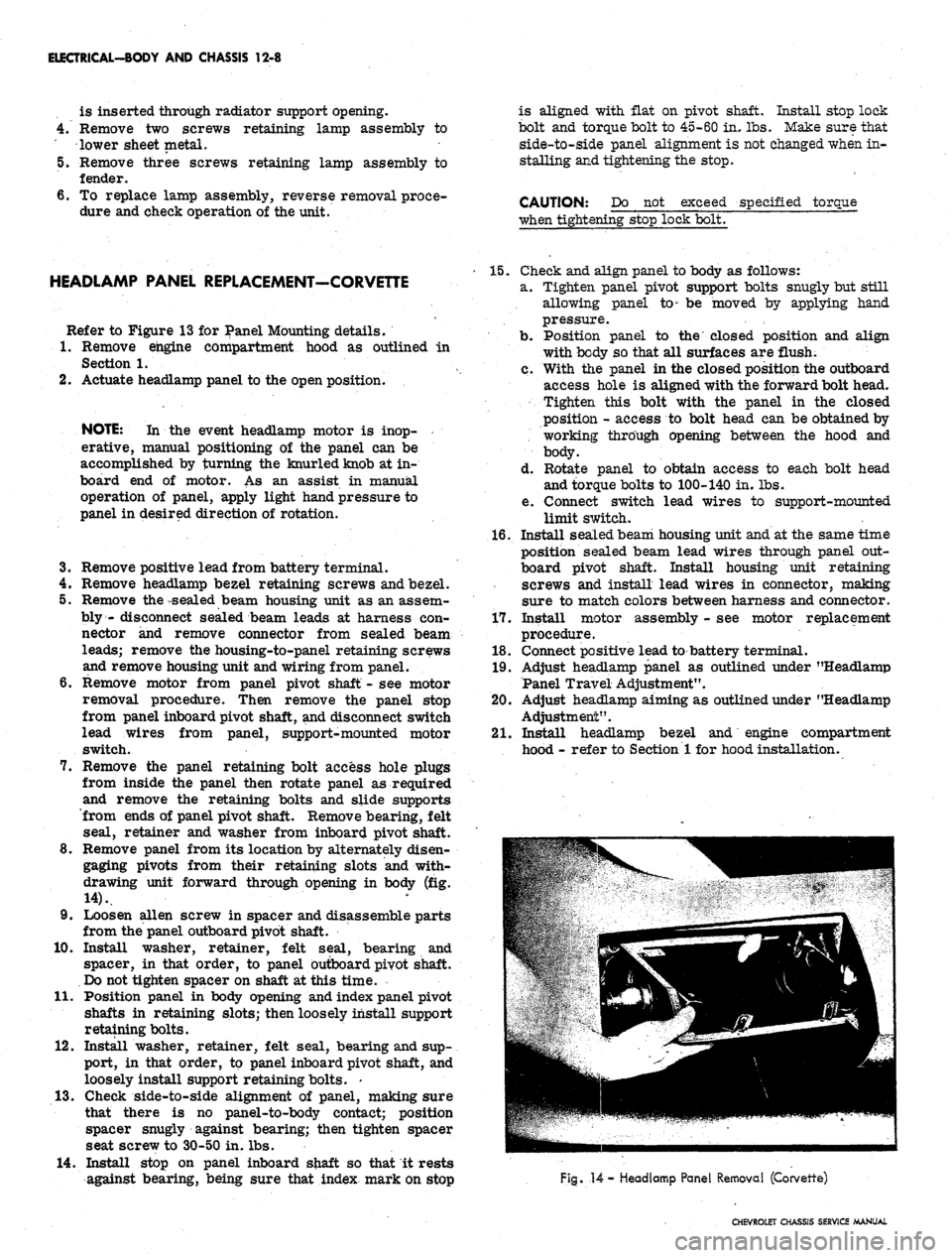

HEADLAMP PANEL REPLACEMENT-CORVETTE

Refer to Figure 13 for Panel Mounting details.

1.

Remove engine compartment hood as outlined in

Section 1.

2.

Actuate headlamp panel to the open position.

NOTE:

In the event headlamp motor is inop-

erative, manual positioning of the panel can be

accomplished by turning the knurled knob at in-

board end of motor. As an assist in manual

operation of panel, apply light hand pressure to

panel in desired direction of rotation.

3.

Remove positive lead from battery terminal.

4.

Remove headlamp bezel retaining screws and bezel.

5. Remove the sealed beam housing unit as an assem-

bly - disconnect sealed beam leads at harness con-

nector and remove connector from sealed beam

leads;

remove the housing-to-panel retaining screws

and remove housing unit and wiring from panel.

6. Remove motor from panel pivot shaft - see motor

removal procedure. Then remove the panel stop

from panel inboard pivot shaft, and disconnect switch

lead wires from panel, support-mounted motor

switch.

7. Remove the panel retaining bolt access hole plugs

from inside the panel then rotate panel as required

and remove the retaining bolts and slide supports

from ends of panel pivot shaft. Remove bearing, felt

seal, retainer and washer from inboard pivot shaft.

8. Remove panel from its location by alternately disen-

gaging pivots from their retaining slots and with-

drawing unit forward through opening in body (fig.

14).

9. Loosen alien screw in spacer and disassemble parts

from the panel outboard pivot shaft.

10.

Install washer, retainer, felt seal, bearing and

spacer, in that order, to panel outboard pivot shaft.

Do not tighten spacer on shaft at this time.

11.

Position panel in body opening and index panel pivot

shafts in retaining slots; then loosely install support

retaining bolts.

12.

Install washer, retainer, felt seal, bearing and sup-

port, in that order, to panel inboard pivot shaft, and

loosely install support retaining bolts. -

13.

Check side-to-side alignment of panel, making sure

that there is no panel-to-body contact; position

spacer snugly against bearing; then tighten spacer

seat screw to 30-50 in. lbs.

14.

Install stop on panel inboard shaft so that it rests

against bearing, being sure that index mark on stop

15.

Check and align panel to body as follows:

a. Tighten panel pivot support bolts snugly but still

allowing panel to" be moved by applying hand

pressure.

b.

Position panel to the closed position and align

with body so that all surfaces are flush.

c. With the panel in the closed position the outboard

access hole is aligned with the forward bolt head.

Tighten this bolt with the panel in the closed

position - access to bolt head can be obtained by

working through opening between the hood and

body.

d. Rotate panel to obtain access to each bolt head

and torque bolts to 100-140 in. lbs.

e. Connect switch lead wires to support-mounted

limit switch.

16.

Install seaLed beam housing unit and at the same time

position sealed beam lead wires through panel out-

board pivot shaft. Install housing unit retaining

screws and install lead wires in connector, making

sure to match colors between harness and connector.

17.

Install motor assembly - see motor replacement

procedure.

18.

Connect positive lead to battery terminal.

19.

Adjust headlamp panel as outlined under "Headlamp

Panel Travel Adjustment".

20.

Adjust headlamp aiming as outlined under "Headlamp

Adjustment".

21.

Install headlamp bezel and engine compartment

hood - refer to Section 1 for hood installation.

Fig.

14

- Headlamp Panel Removal (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 620 of 659

ACCESSORIES 15-11

12 VOLTS D.C.

ELECTRIC BRAKE

RELEASE

IGNITION

SWITCH

ENGINE

VACUUM

TRANSDUCER

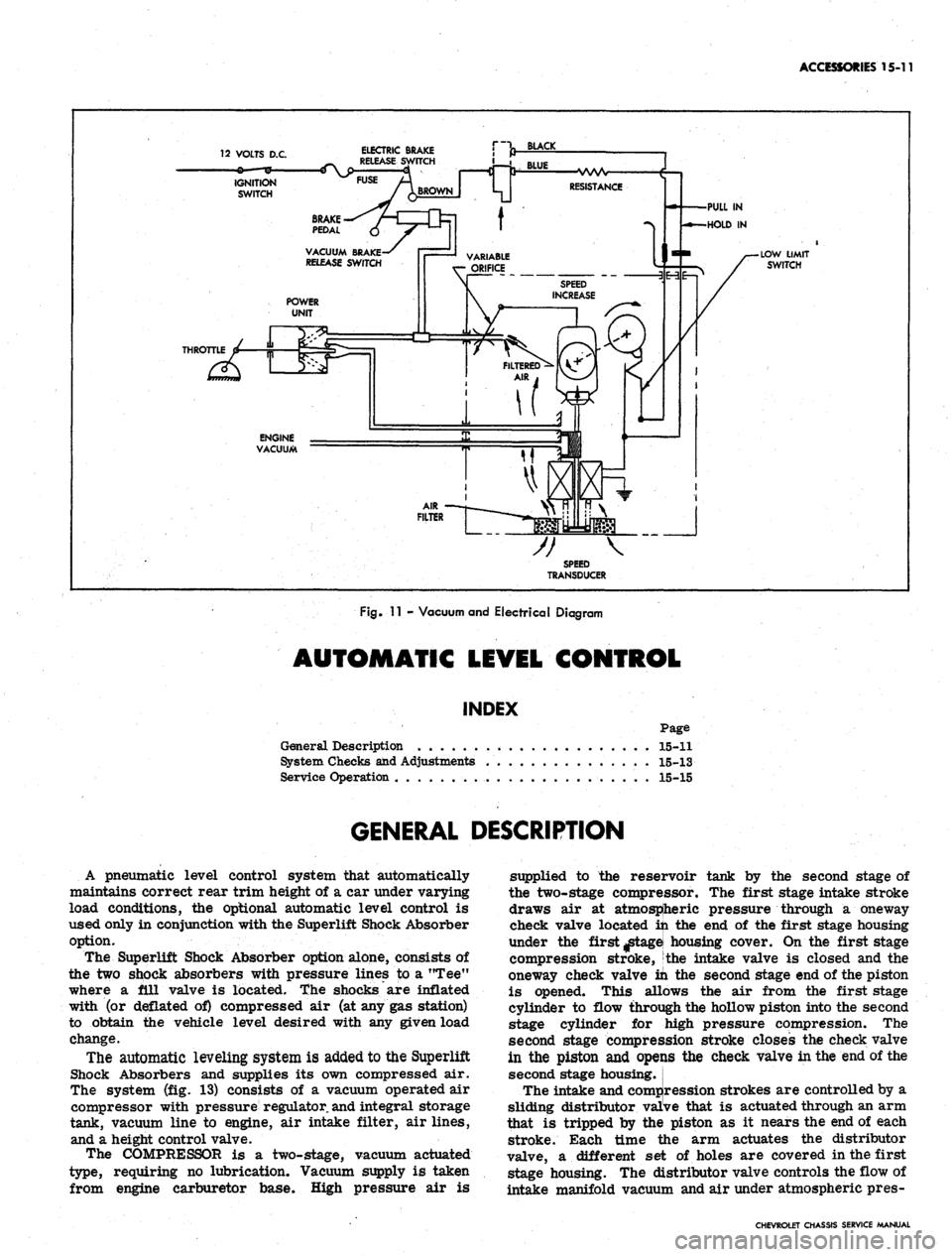

Fig.

11 - Vacuum and Electrical Diagram

AUTOMATIC LEVEL CONTROL

INDEX

Page

General Description . . 15-11

System Checks and Adjustments 15-13

Service Operation . 15-15

GENERAL DESCRIPTION

A pneumatic level control system that automatically

maintains correct rear trim height of a car under varying

load conditions, the optional automatic level control is

used only in conjunction with the Superlift Shock Absorber

option.

The Superlift Shock Absorber option alone, consists of

the two shock absorbers with pressure lines to a "Tee"

where a ill valve is located, the shocks are inflated

with (or deflated of) compressed air (at any gas station)

to obtain the vehicle level desired with any given load

change.

The automatic leveling system is added to the Superlift

Shock Absorbers and supplies its own compressed air.

The system (fig. 13) consists of a vacuum operated air

compressor with pressure regulator,

and

integral storage

tank, vacuum line to engine, air intake filter, air lines,

and a height control valve.

The COMPRESSOR is a two-stage, vacuum actuated

type, requiring no lubrication. Vacuum supply is taken

from engine carburetor base. High pressure air is

supplied to the reservoir tank by the second stage of

the two-stage compressor. The first stage intake stroke

draws air at atmospheric pressure through a oneway

check valve located in the end of the first stage housing

under the first ^tagei housing cover. On the first stage

compression stroke, the intake valve is closed and the

oneway check valve in the second stage end of the piston

is opened. This allows the air from the first stage

cylinder to flow through the hollow piston into the second

stage cylinder for jhigh pressure compression. The

second stage compression stroke closes the check valve

in the piston and opeijis the check valve in the end of the

second stage housing.

The intake and compression strokes are controlled by a

sliding distributor valive that is actuated through an arm

that is tripped by the piston as it nears the end of each

stroke. Each time the arm actuates the distributor

valve, a different set of holes are covered in the first

stage housing. The distributor valve controls the flow of

intake manifold vacuum and air under atmospheric pres-

CHEVROLET CHASSIS SERVICE MANUAL

Page 621 of 659

ACCESSORIES 15-12

VACUUM

(WIT

P

VACUUM Llh

, AIR SUPPt

LINES

t

SUPERLIFT F

SHOCK ABSO

OPERATED AIR COMPRESSOR

H STORAGE TANK AND

RESSURE REGULATORJV

\A

4E FROM ENG«NE^"^

/ \-HEIGHT CONTROL

•^-Z n VALVE (WITH TIME

^*

EAR II

RBERS

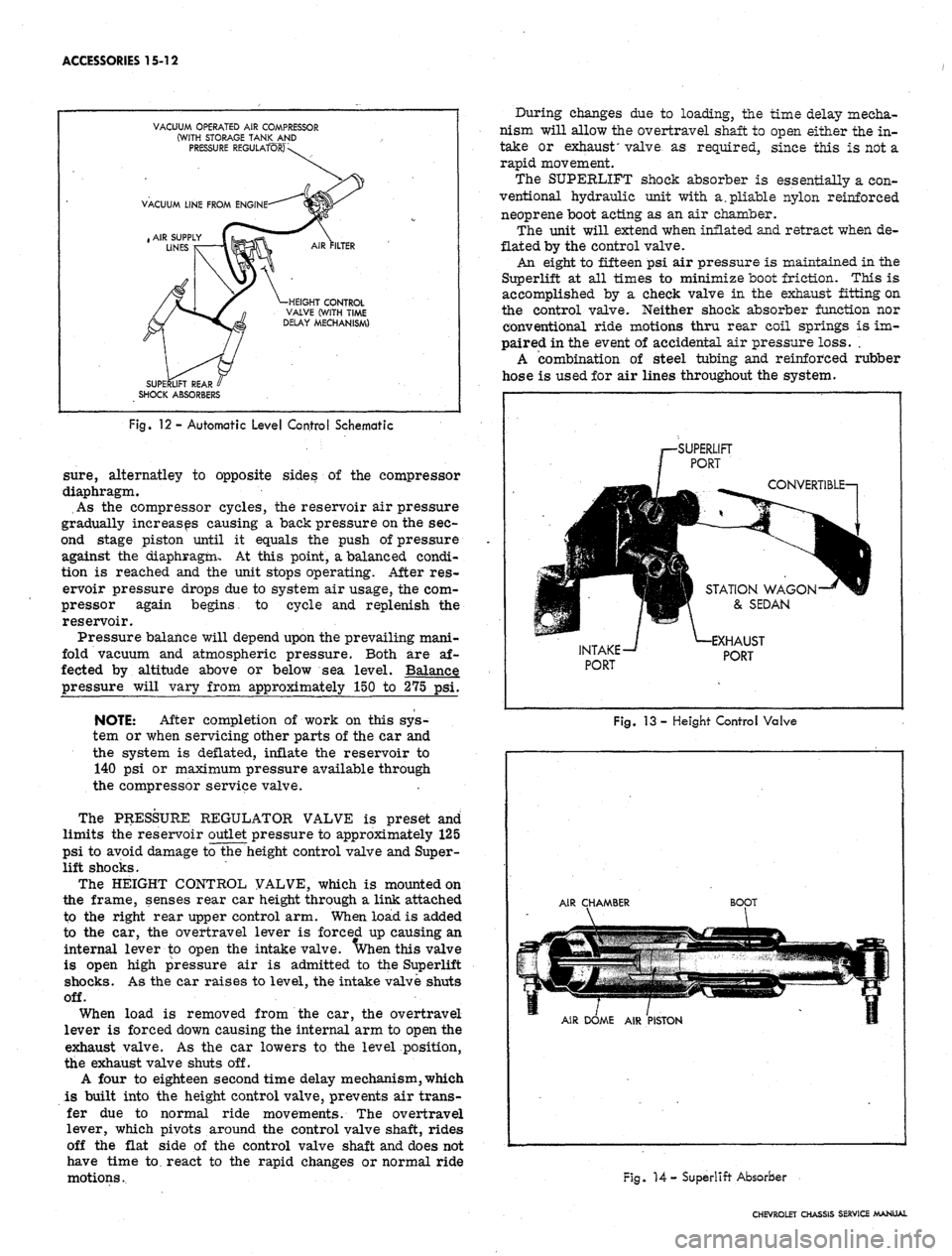

Fig.

12 - Automatic Level Control Schematic

sure,

alternatley to opposite sides of the compressor

diaphragm.

As the compressor cycles, the reservoir air pressure

gradually increases causing a back pressure on the sec-

ond stage piston until it equals the push of pressure

against the diaphragm- At this point, a balanced condi-

tion is reached and the unit stops operating. After res-

ervoir pressure drops due to system air usage, the com-

pressor again begins to cycle and replenish the

reservoir.

Pressure balance will depend upon the prevailing mani-

fold vacuum and atmospheric pressure. Both are af-

fected by altitude above or below sea level. Balance

pressure will vary from approximately 150 to 275 psi.

NOTE: After completion of work on this sys-

tem or when servicing other parts of the car and

the system is deflated, inflate the reservoir to

140 psi or maximum pressure available through

the compressor service valve.

The PRESSURE REGULATOR VALVE is preset and

limits the reservoir outlet pressure to approximately 125

psi to avoid damage to the height control valve and Super-

lift shocks.

The HEIGHT CONTROL VALVE, which is mounted on

the frame, senses rear car height through a link attached

to the right rear upper control arm. When load is added

to the car, the overtravel lever is forced up causing an

internal lever to open the intake valve, when this valve

is open high pressure air is admitted to the Superlift

shocks. As the car raises to level, the intake valve shuts

off.

When load is removed from the car, the overtravel

lever is forced down causing the internal arm to open the

exhaust valve. As the car lowers to the level position,

the exhaust valve shuts off.

A four to eighteen second time delay mechanism, which

is built into the height control valve, prevents air trans-

fer due to normal ride movements. The overtravel

lever, which pivots around the control valve shaft, rides

off the flat side of the control valve shaft and does not

have time to. react to the rapid changes or normal ride

motions.

During changes due to loading, the time delay mecha-

nism will allow the overtravel shaft to open either the in-

take or exhaust' valve as required, since this is not a

rapid movement.

The SUPERLIFT shock absorber is essentially a con-

ventional hydraulic unit with a. pliable nylon reinforced

neoprene boot acting as an air chamber.

The unit will extend when inflated and retract when de-

flated by the control valve.

An eight to fifteen psi air pressure is maintained in the

Superlift at all times to minimize boot friction- This is

accomplished by a check valve in the exhaust fitting on

the control valve. Neither shock absorber function nor

conventional ride motions thru rear coil springs is im-

paired in the event of accidental air pressure loss. .

A combination of steel tubing and reinforced rubber

hose is used for air lines throughout the system.

-SUPERLIFT

PORT

STATION WAGON

& SEDAN

INTAKE

PORT

HAUST

PORT

Fig. 13 - Height Control Valve

AIR CHAMBER

BOOT

AIR DOME AIR PISTON

Fig. 14- Superlift Absorber

CHEVROLET CHASSIS SERVICE MANUAL