radio CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 355 of 659

ENGINE-ELECTRICAL-6Y-30

Fig.

2 li—Removing Ignition Switch Nut

4.

Remove heater and/or A/C control panel assembly

retaining screws and push panel assembly from

console.

NOTE: If interference between control panel

and radio is encountered, loosen radio retaining

nuts.

5.

Remove radio control knobs, bezels and retaining

nuts.

6. Disconnect radio wiring harness and antenna lead-in.

7.

Remove radio rear brace attaching screw and re-

move radio from vehicle.

Fig.

231—Switch and Connector Unplugged

8. Remove ignition switch bezel nut using Tool J-7607

and push switch rearward from panel opening.

9. Disconnect wiring connector from rear of switch.

10.

To install, reverse removal procedure.

SPARK PLUGS

CLEANING AND REGAPPING

Clean the spark plugs thoroughly, using an abrasive-

type cleaner. If the porcelains are badly glazed or

blistered, the spark plugs should be replaced. All spark

plugs must be of the same make and number or heat

range. Use a round feeler gauge to adjust the spark plug

gap to specifications (fig. 24i).

Fig.

22i—Unlocking Ignition Switch Connector

Fig.

241—Setting Sfxirk Plug Gap

CHEVROLET CHASSIS SERVICE MANUAL

Page 491 of 659

CHASSIS SHEET METAL 11-4

FENDERS

Fenders are adjustable with shims at the cowl and

rocker panel. To add or remove shims, loosen bolts at

shim locations (fig. 7) and carefully apply force with pry

bar to provide clearance for shim removal or installa-

tion.

SHEET METAL ADJUSTMENTS

For proper operation of doors and hood, and for pre-

sentable appearance, adjust front sheet metal to the tol-

erances shown in Figures

4-

and 5.

COMPONENT PART REPLACEMENT

NOTE: When replacing sheet metal compo-

nents on Chevrolet or Chevelle, note position and

attachment of all seals and dust shielding and

replace as necessary.

BATTERY TRAY

Removal

1.

Disconnect battery cables.

2.

Remove screw retaining battery hold down clamp and

remove battery from vehicle.

3.

Remove screws retaining battery tray to fender skirt

and radiator support.

4.

On Chevrolet, remove headlamp bezel and remove

screw retaining tray to radiator support.

5.

Remove battery tray from vehicle.

Installation

Reverse removal procedure.

RADIATOR SUPPORT

Removal

1.

Remove front bumper (Section 14).

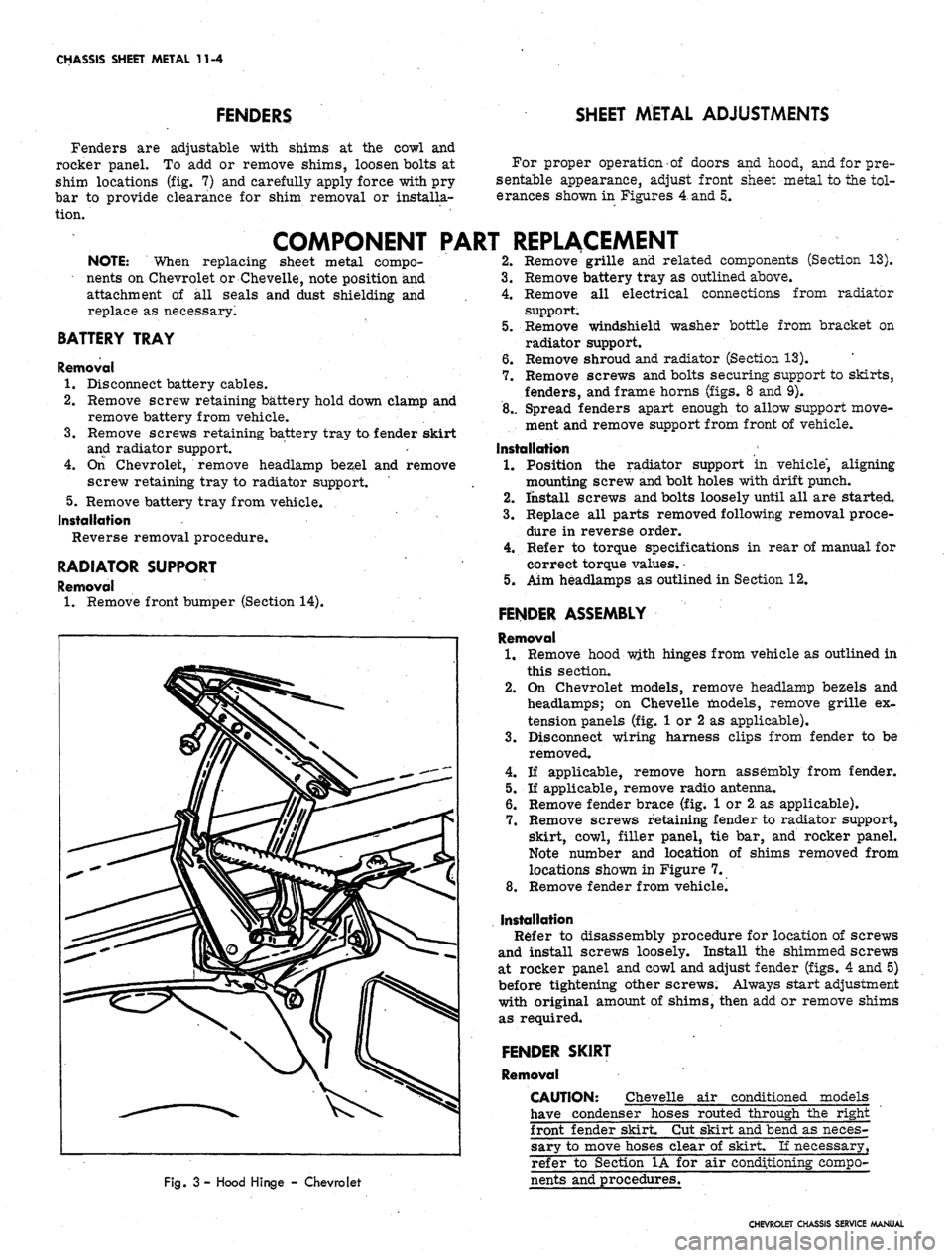

Fig.

3 - Hood Hinge - Chevrolet

2.

Remove grille and related components (Section 13).

3.

Remove battery tray as outlined above.

4.

Remove all electrical connections from radiator

support.

5.

Remove windshield washer bottle from bracket on

radiator support.

6. Remove shroud and radiator (Section 13).

7.

Remove screws and bolts securing support to skirts,

fenders, and frame horns (figs. 8 and 9).

8.. Spread fenders apart enough to allow support move-

ment and remove support from front of vehicle.

Installation

1.

Position the radiator support in vehicle", aligning

mounting screw and bolt holes with drift punch.

2.

install screws and bolts loosely until all are started.

3.

Replace all parts removed following removal proce-

dure in reverse order.

4.

Refer to torque specifications in rear of manual for

correct torque values.

•

5.

Aim headlamps as outlined in Section 12.

FENDER ASSEMBLY

Removal

1.

Remove hood with hinges from vehicle as outlined in

this section.

2.

On Chevrolet models, remove headlamp bezels and

headlamps; on Chevelle models, remove grille ex-

tension panels (fig. 1 or 2 as applicable).

3.

Disconnect wiring harness clips from fender to be

removed.

4.

If applicable, remove horn assembly from fender.

5.

If applicable, remove radio antenna.

6. Remove fender brace (fig. 1 or 2 as applicable).

7.

Remove screws retaining fender to radiator support,

skirt, cowl, filler panel, tie bar, and rocker panel.

Note number and location of shims removed from

locations shown in Figure 7.

8. Remove fender from vehicle.

Installation

Refer to disassembly procedure for location of screws

and install screws loosely. Install the shimmed screws

at rocker panel and cowl and adjust fender (figs. 4 and 5)

before tightening other screws. Always start adjustment

with original amount of shims, then add or remove shims

as required.

FENDER SKIRT

Removal

CAUTION: Chevelle air conditioned models

have condenser hoses routed through the right

front fender skirt. Cut skirt and bend as neces-

sary to move hoses clear of skirt. If necessary,

refer to Section 1A for air conditioning compo-

nents and procedures.

CHEVROLET CHASSIS SERVICE MANUAL

Page 533 of 659

ELECTRICAL-BODY AND CHASSIS 12-21

2.

Remove ash tray, retainer attaching screws and

retainer.

3.

Remove Air Conditioning distributor

duct'

retaining

screws and duct.

4.

Remove heater and/or Air Conditioning control panel

assembly retaining screws and push panel assembly

from console.

NOTE:

If interference between control panel

and radio is encountered, loosen radio retaining

nuts.

5. Remove radio control knobs, bezels and retaining

nuts.

6. Disconnect radio wiring harness and antenna lead-in.

7. Remove radio rear brace attaching screw and re-

move ra(Jio from vehicle.

8. Remove ignition switch bezel nut using Tool J-7607

and push switch rearward.

9. Disconnect cigarette wiring connector.

10.

Remove cigarette lighter retainer and lighter as-

sembly from console.

11.

To install, reverse removal procedure.

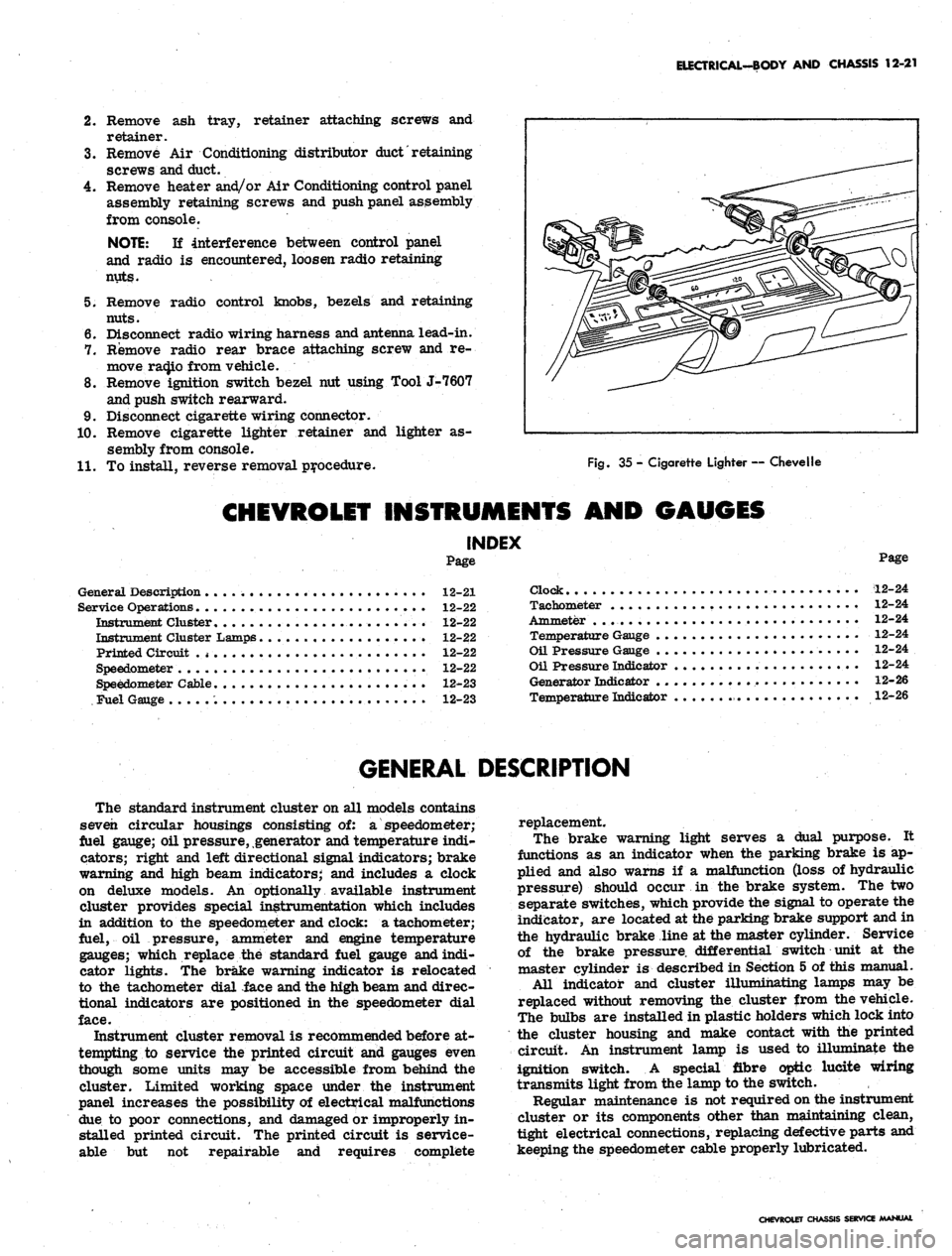

Fig.

35 - Cigarette Lighter — Chevelle

CHEVROLET INSTRUMENTS AND GAUGES

INDEX

Page

General Description 12-21

Service Operations 12-22

Instrument Cluster........................ 12-22

Instrument Cluster Lamps 12-22

Printed Circuit .

* •

12-22

Speedometer 12-22

Speedometer Cable 12-23

Fuel Gauge 12-23

Page

Clock 12-24

Tachometer 12-24

Ammeter . . 12-24

Temperature Gauge 12-24

Oil Pressure Gauge 12-24

Oil Pressure Indicator 12-24

Generator Indicator 12-26

Temperature Indicator 12-26

GENERAL DESCRIPTION

The standard instrument cluster on all models contains

seven circular housings consisting of: a speedometer;

fuel gauge; oil pressure, generator and temperature indi-

cators; right and left directional signal indicators; brake

warning and high beam indicators; and includes a clock

on deluxe models. An optionally available instrument

cluster provides special instrumentation which includes

in addition to the speedometer and clock: a tachometer;

fuel, oil pressure, ammeter and engine temperature

gauges; which replace the standard fuel gauge and indi-

cator lights. The brake warning indicator is relocated

to the tachometer dial face and the high beam and direc-

tional indicators are positioned in the speedometer dial

face.

Instrument cluster removal is recommended before at-

tempting to service the printed circuit and gauges even

though some units may be accessible from behind the

cluster. Limited working space under the instrument

panel increases the possibility of electrical malfunctions

due to poor connections, and damaged or improperly in-

stalled printed circuit. The printed circuit is service-

able but not repairable and requires complete

replacement.

The brake warning light serves a dual purpose. It

functions as an indicator when the parking brake is ap-

plied and also warns if a malfunction (loss of hydraulic

pressure) should occur in the brake system. The two

separate switches, which provide the signal to operate the

indicator, are located at the parking brake support and in

the hydraulic brake line at the master cylinder. Service

of the brake pressure, differential switch unit at the

master cylinder is described in Section 5 of this manual.

All indicator and cluster illumihating lamps may be

replaced without removing the cluster from the vehicle.

The bulbs are installed in plastic holders which lock into

the cluster housing and make contact with the printed

circuit. An instrument lamp is used to illuminate the

ignition switch. A special fibre optic lucite wiring

transmits light from the lamp to the switch.

Regular maintenance is not required on the instrument

cluster or its components other than maintaining clean,

tight electrical connections, replacing defective parts and

keeping the speedometer cable properly lubricated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 538 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-26

•

Low oil

pressure

• High engine temperature

• Defective wiring

or

switch

connector from sender

in block above starter

on

and

at

left front

of

distributor

on V-8

Sending Unit Replacement

1.

Disconnect wiring harness

unit terminal (located

L-6 engines

engines).

2.

Remove sender unit using Tool J-21757

or 12

point

socket, replace with

new

unit

and

check operation.

GENERATOR INDICATOR

1.

Ignition

on,

Engine

not

Running

and

Telltale Light

Off.

• Indicator bulb burned out, replace bulb.

• Open circuit

or

loose connection

in the

telltale

light circuit.

2.

telltale Light Stays

on

after Engine

is

Started.

If indicator light does

not go out at

engine idle

speed, refer

to

Charging Systems under Engine

Electrical, Section

6Y.

TEMPERATURE (COOLING SYSTEM) INDICATOR

The temperature indicator circuit consists

of two re-

motely located units, indicator gauge

and

engine sender

unit.

The

indicator gauge, located

in the

instrument

panel, consists

of a

red light which will indicate

an

over-

heated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system

to a

level below unit.

2.

Remove sender unit (located

in the

inlet manifold

near water pump housing

on V-8

engines and

in the

cylinder head near

an

exhaust port

oh L-6

engines)

and replace with new unit.

3.

Refill cooling system

and

check operation

of

unit.

CHEVELLE INSTRUMENTS AND GAUGES

INDEX

Page

General Description

* *

i2-26

Service Operations

12-26

Instrument Panel

12-26

Instrument Cluster.

12-26

Fuel Gauge and/or Ammeter

12-27

Clock,

i 12-27

Speedometer

12-27

Page

Speedometer Cable

.

. 12-27

Temperature Gauge

12-29

Oil Pressure Gauge

12-29

Indicator Lights.

. 12-29

Oil Pressure Indicator

12-29

Generator Indicator

. . 12-29

• Temperature Indicator

12-29

GENERAL DESCRIPTION

The Chevelle instrument cluster assembly consists

of:

a speedometer;

a

fuel gauge;

a

generator,

an

engine

tem-

perature and an

oil

pressure indicator lamp, and includes

a clock

on

deluxe models.

On

super sport models,

am-

meter, coolant temperature

and oil

pressure gauges

re-

place

the

appropriate indicator lights. Except

for the

speedometer,

all of the

indicator lamps, instruments

and

gauges

of

these clusters may

be

serviced without remov-

ing

the

instrument cluster assembly from

the

vehicle.

In addition

to the

instrument indicator lamps,

a

brake

warning lamp

is

included

in the

cluster

as

standard

equipment.

The

indicator

is

connected

to the

parking

brake

and

brake pressure differential switches

and

serves

a

dual function.

It

lights when the parking brake

is applied

and

also when

the

brake pedal

is

applied,

if a

malfunction should occur

in the

brake system

due to a

loss

of

hydraulic pressure. Servicing

of the

hydraulic

pressure differential switch

is

covered

in

Section

5 of

this manual.

Regular maintenance

is not

required on the instrument

cjLuster

or its

components other than maintaining dean

and tight electrical connections, replacing defective parts

and keeping

the

speedometer cable properly lubricated.

SERVICE OPERATIONS

INSTRUMENT PANEL ASSEMBLY

INSTRUMENT CLUSTER (Figs.

41

thru

44)

Removal

1.

Disconnect battery ground cable.

2.

Remove steering coupling bolt and disconnect steer-

ing shaft from coupling.

3.

Loosen mast jacket lower clamp.

4.

Remove

air

conditioning center distributor duct

(if

so equipped).

5. Remove radio rear support bracket screw.

6. Remove mast jacket upper support clamp and retain-

ing bolts from lower support (refer

to

Section

9,

Steering).

CAUTION: Cover mast jacket

and

parl

brake handle with

a

suitable material

to

prevc

scratching.

7.

Disconnect speedometer cable

at

rear

of

cluster

housing

and

speed warning control knob

at

panel

(if

so equipped).

8. Remove instrument panel retaining screws (nine

upper and five lower).

.

9. Working under the console remove four lower retain-

ing screws from instrument cluster housing.

10.

Pull instrument panel assembly from console and

lay

forward on mast jacket.

11.

Disconnect wiring harness, cluster lamps and wiring

CHEVROLET CHASSIS SERVICE MANUAL

Page 539 of 659

ELECTRICAL-BODY AND CHASSIS 12-27

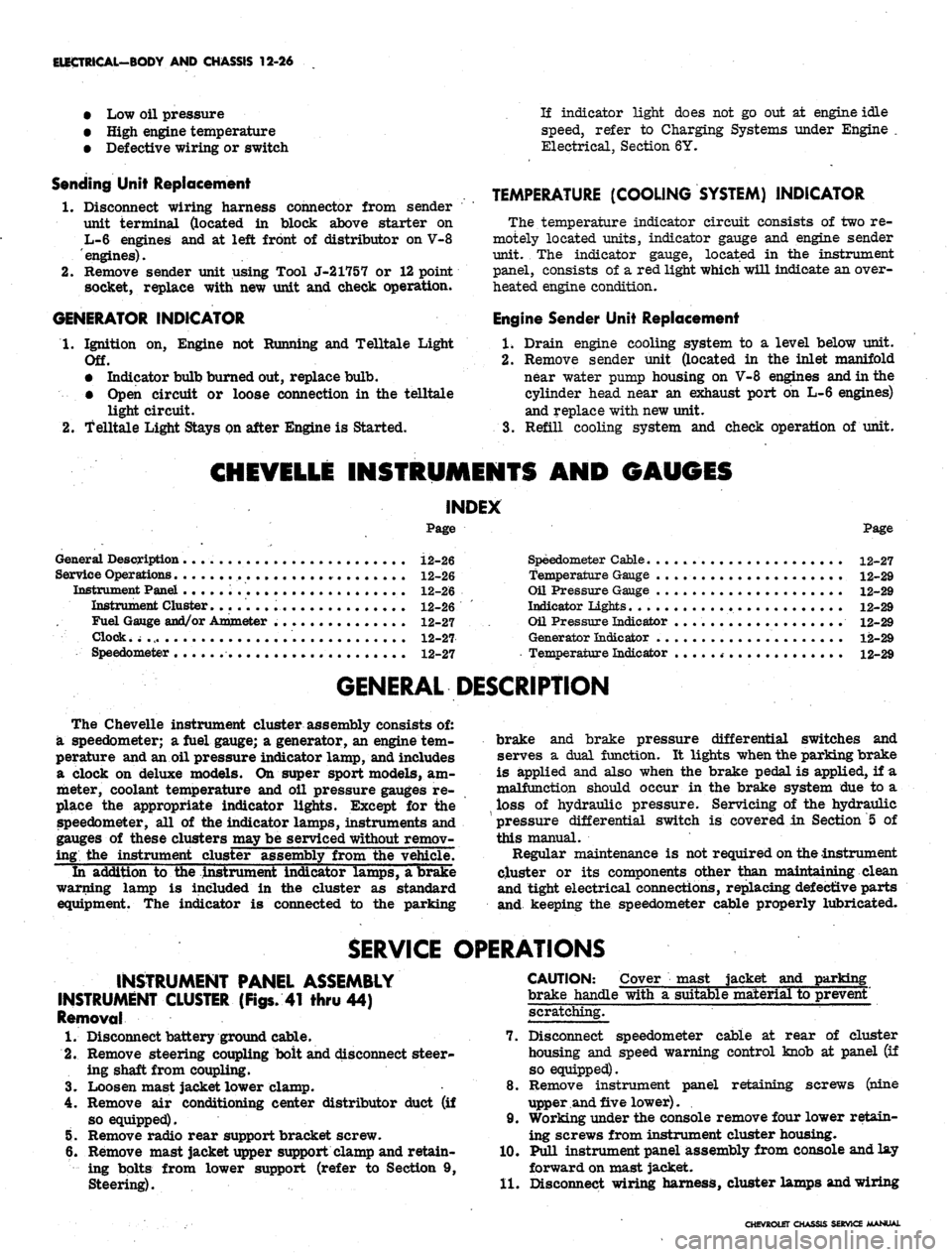

Fig.

41 - Instrument Panel Installation — Chevelle

terminals from rear of cluster assembly (figs. 43

and 44).

12.

Remove four screws retaining upper section of dus-

ter housing to panel and remove cluster from the in-

strument panel and to a suitable working area for

necessary service (fig. 42).

Installation

1.

Position cluster assembly to rear of panel and install

four upper retaining screws.

2.

Connect cluster lamps, wiring connectors and wiring

harness assembly to the cluster assembly.

3.

Position instrument panel assembly into console

(hold panel at center and install center screws) and

install upper and lower retaining screws.

NOTE:

At this point temporarily reconnect

battery and check operation of cluster.

4.

Working under the console, install four lower screws

retaining lower section of cluster cover to rear of

panel.

5. Install radio brace screw at rear of radio.

6. Connect speedometer cable to speedometer and speed

warning device control knob.

7. Install A/C distributor duct and connect A/C hoses to

duct (if so equipped).

8. Install mast jacket upper support clamp.

9. Position steering shaft in the steering coupling and

install retaining bolt.

10.

Tighten mast jacket lower clamp (refer to Steering,

Section 9 for spring tension adjustment).

11.

Connect battery ground cable.

FUEL GAUGE AND/OR AMMETER

REPLACEMENT

1.

Disconnect battery ground cable.

2.

On air conditioned models, disconnect hose and re-

move air outlet from panel.

3.

Disconnect wiring connectors and cluster lamps from

rear of gauge assembly.

4.

Remove mounting plate retaining screws (3) and re-

move fuel gauge from rear of cluster housing.

5. Remove terminal nuts (3) securing gauge to template

and replace gauge.

6. To install, reverse the removal procedure.

CLOCK REPLACEMENT

1.

Disconnect battery ground cable.

2.

Remove clock set shaft knob retaining nut and knob.

3.

Disconnect wiring connector at clock terminal and

cluster lamp from clock housing. On A/C models,

disconnect hose from air distributor duct.

4.

Remove two screws retaining clock housing to

cluster cover and remove clock.

5. To install, reverse removal procedure.

SPEEDOMETER REPLACEMENT

1.

Disconnect battery ground cable.

2.

Remove instrument cluster assembly as previously

outlined in this section.

3.

Remove screws (8) attaching cover to rear of cluster

housing.

4.

Remove two screws attaching speedometer assembly

to cluster cover and carefully remove speedometer

head.

NOTE:

Servicing of the speedometer assembly

should be performed by an authorized

AC

speed-

ometer service station.

5. To install, reverse removal procedure.

SPEEDOMETER CABLE

Replacement or Lubrication

1.

Disconnect the speedometer cable from the speedom-

eter head. Remove the old cable by pulling it out

from speedometer

, end

of conduit.

NOTE:

If old cable is broken it may be neces-

sary to remove lower piece from transmission

end of conduit.

2.

Lubricate the lower 3/4 of cable with speedometer

cable lubricant and push the cable into the conduit.

Connect the upper end to the speedometer head and

road test vehicle for proper speedometer operation.

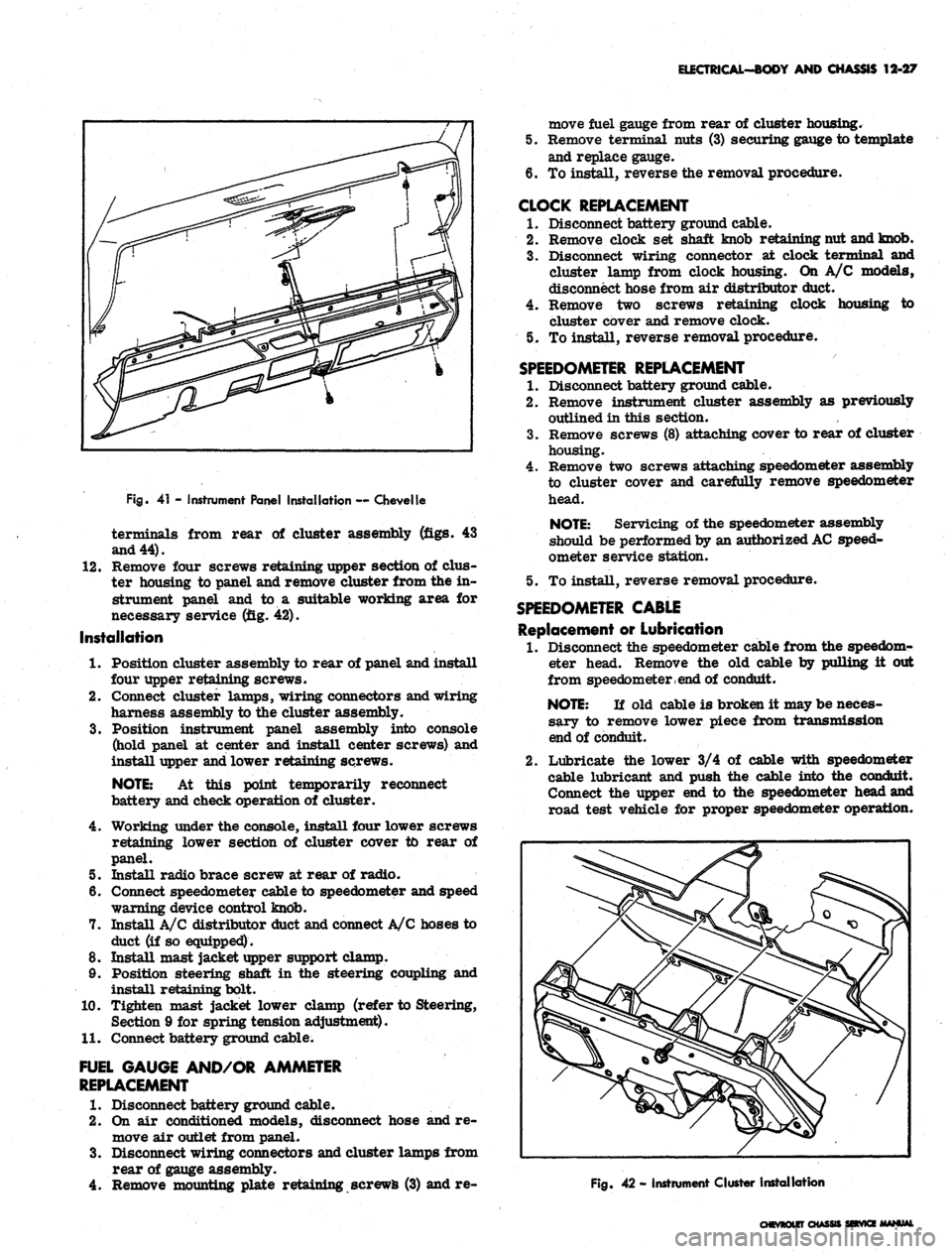

Fig.

42 - Instrument Cluster Installation

CHEVROLET CHASSIS SEtVKE MANUAL

Page 575 of 659

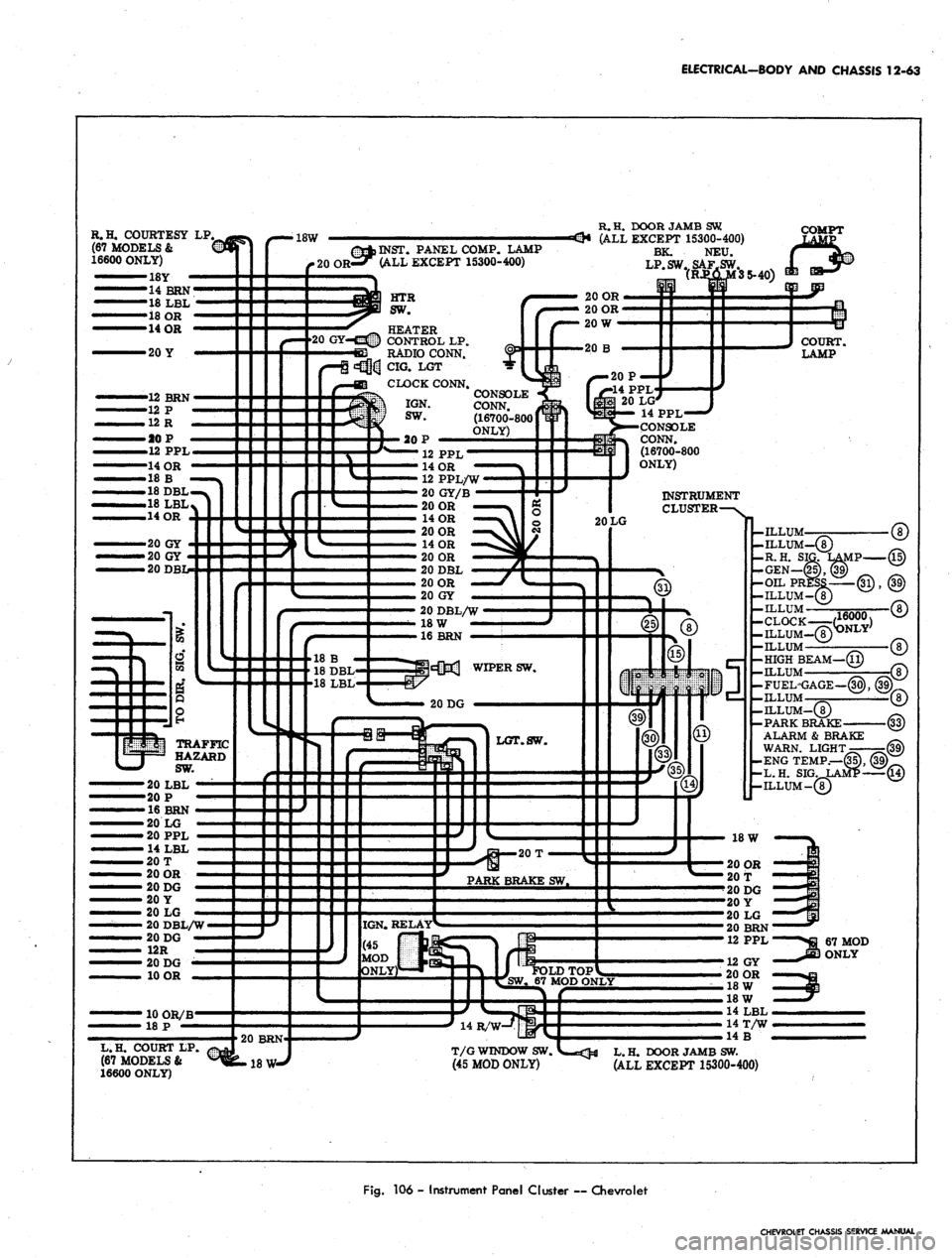

ELECTRICAL-BODY AND CHASSIS 12-63

R.H. COURTESY

LP,

(67 MODELS &

16600 ONLY)

•18Y

R. H. DOOR JAMB

SW

(ALL EXCEPT 15300-400)

BK.

NEU.

LP.SW.SAF.SW.

(RJ»JD^

20 OR

20 OR

COMPT

(U*INST. PANEL COMP. LAMP

R-i3r

(ALL EXCEPT 15300-400)

14BRN

18

LBL

18 OR

14 OR

HEATER

CONTROL

LP.

RADIO CONN.

CIG.

LGT

20

P —

4

PPL

20

LG'

14 PPL—

NSOLE

CONN.

(16700-800

ONLY)

CONSOLE

CONN.

(16700-800

ONLY)

12

PPL

14 OR

12 PPL/W

20

GY/B

20 OR

14 OR

20 OR

14 OR

20 OR

20DBL

20 OR

20

GY

INSTRUMENT

CLUSTER

-ILLUM

-ILLUM

-R.H.

S

-GEN

-OILP

-ILLUM

-ILLUM

20 GY

20 GY

20DBI

20DBL/W

18

W

16BRN

-CLOCK-—:(i??T0°)

-ILLUM

^™LY

18

B

18

DBL

18

LBL

-HIGH BEAM—(11

-ILLUM

-

FUEL-GAGE —{30

-ILLUM

-ILLUM-^

-PARK BRAKE

ALARM & BRAKE

WARN. LIGHT

-ENG TEMP.—(35),

(39

-L.H.

SIG.

LAMP—(14

-ILLUM

-

TRAFFIC

HAZARD

SW.

20

LBL

20

P

16BRN

20

LG

20

PPL

14

LBL

20

T

20 OR

20 DG

20 OR

20

t

20 DG

20

Y

20

LG

20

BRN

12

PPL

PARK BRAKE

SW.

20 DBL/W

20 DG

12R

20 DG

10 OR

12

GY

20 OR

18

W

18

W

14

LBL

14T/W

14

B

SW.

67

MOD ONLY

L.H. COURT

LP.

(67 MODELS

&

16600 ONLY)

18 W-'

T/G WINDOW

SW.

(45 MOD ONLY)

DOOR JAMB

SW.

(ALL EXCEPT 15300-400)

Fig.

106 - Instrument Panel Cluster ~ Chevrolet

CHEVROLET CHASSIS SERVICE MANUAL

Page 580 of 659

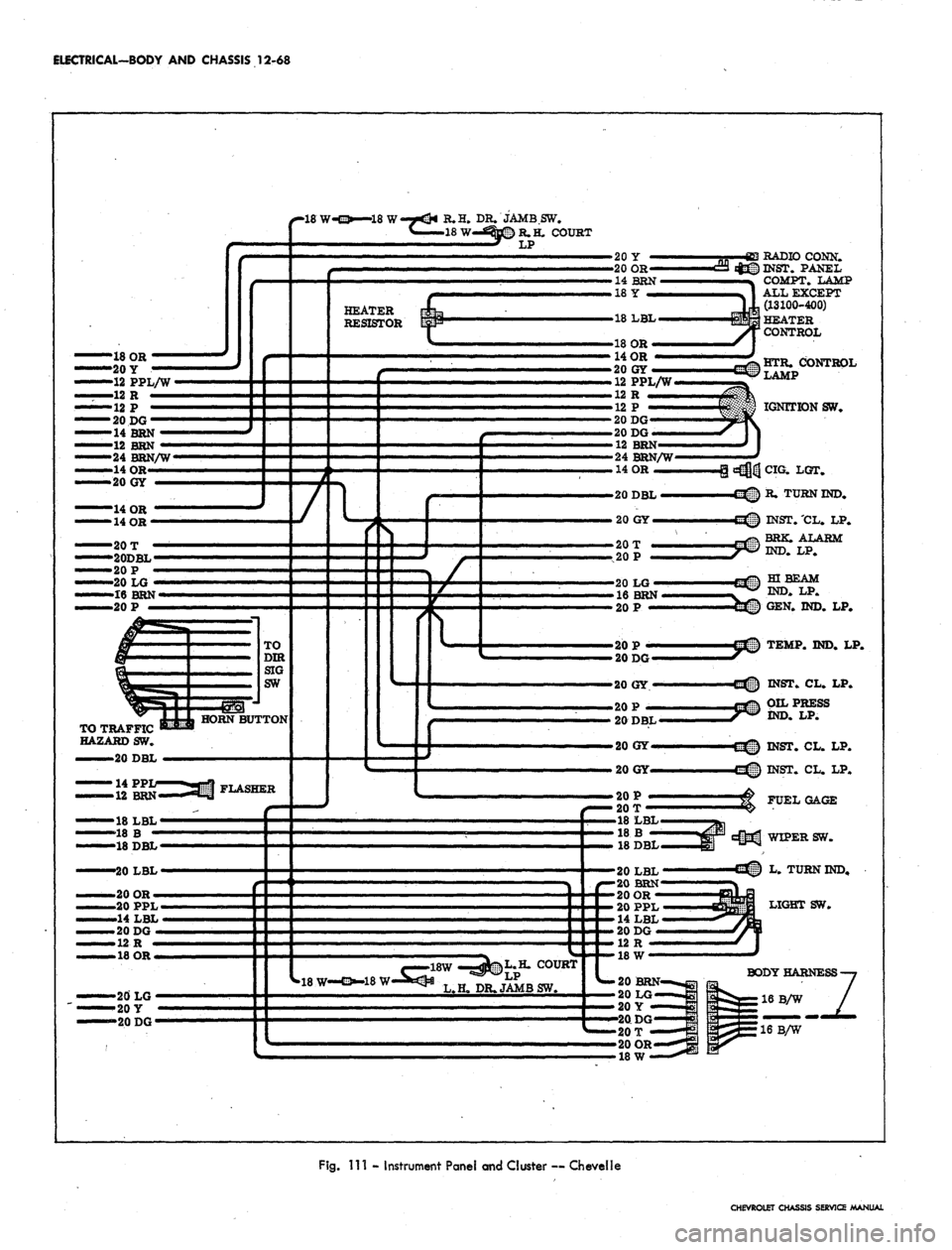

ELECTRICAL-BODY AND CHASSIS 12-68

-7«3« R.H. DR. JAMB.SW.

C_18W-^{|>R.H. COURT

es RADIO CONN.

c5£ siHp INST. PANEL

COMPT. LAMP

ALL EXCEPT

(13100-400)

HEATER

CONTROL

HTR. CONTROL

LAMP

IGNITION SW.

LGT.

R. TURN IND.

INST.'CL. LP.

HEATER

RESISTOR

18 OR

20 Y

12 PPL/W

12 R

12 P

20 DG

14BRN

12 BRN

24 BRN/W

14

OR

20 GY

12 PPL/W

12 R

12 P

24 BRN/W

14

OR

BRK. ALARM

IND.

HI BEAM

IND.

LP.

GEN. IND. LP.

TEMP. IND. LP

INST* CL. LP.

OIL PRESS

IND.

LP.

HORN BUTTON

TO TRAFFIC

HAZARD SW.

20DBL

INST. CL. LP.

INST. CL. LP.

18 LBL

18 B

18DBL

r—20

BRN

20 OR

20

OR

20 PPL

4 LBL

20 DG

12 R

18 OR

BODY HARNESS

18 W—O-18W

^-20 BRN

20 LG

20 Y

20 DG

L.H. DR. JAMB SW.

20 LG

20 Y

20 DG

Fig.

Ill - Instrument Panel and Cluster — CheveNe

CHEVROLET CHASSIS SERVICE MANUAL

Page 588 of 659

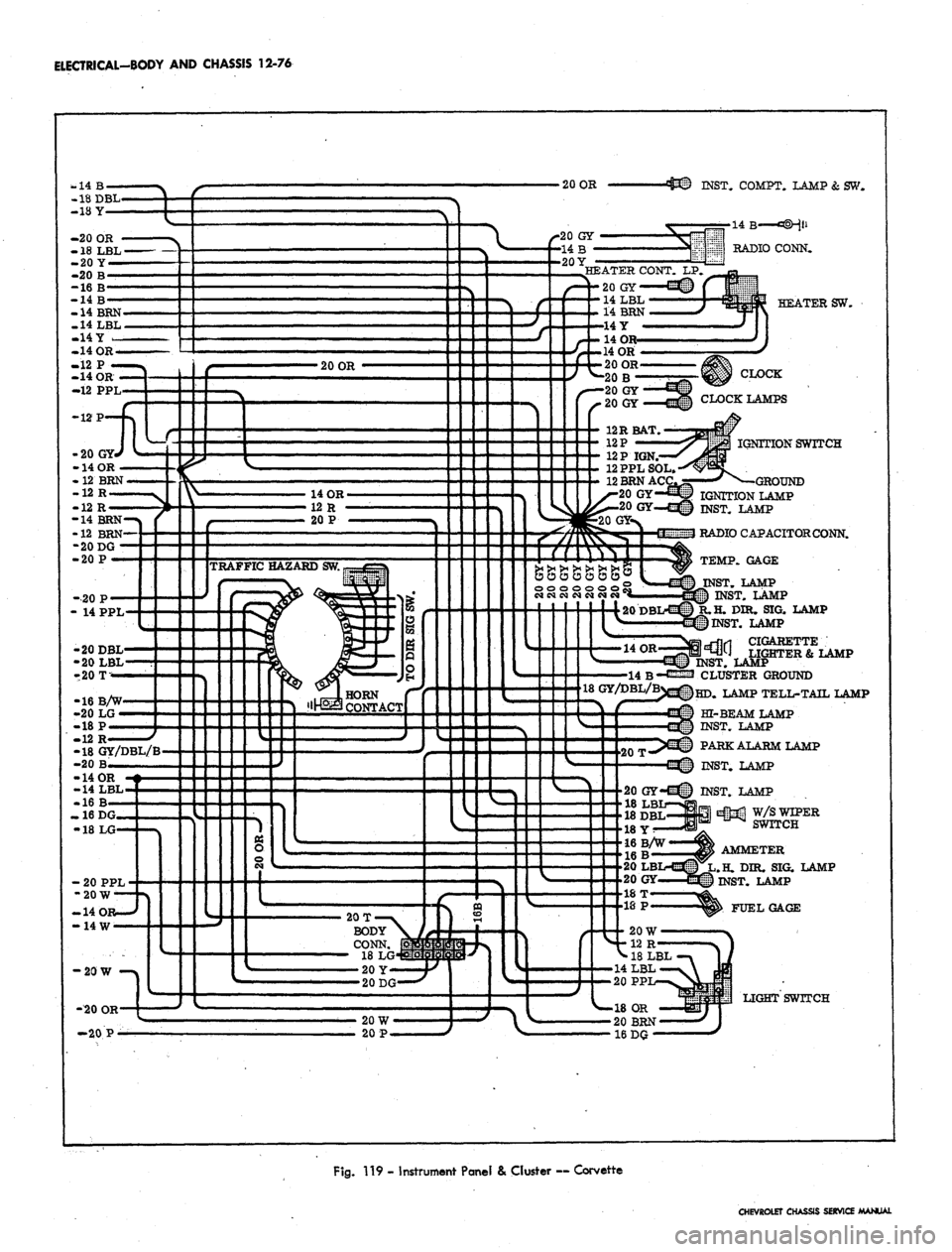

ELECTRICAL-BODY AND CHASSIS 12-76

20 OR

•431 INST. COMPT. LAMP&SW.

14 B

«3@H}U

EMM RADIO CONN.

HEATER SW.

-12 PPL

CLOCK

CLOCK LAMPS

HEATER CONT. LP.

20 GY

14LBL

14 BRN

14 Y

14 o:

14

OR

20 OR

20 B

12 R BAT.

12 P

12 P IGN.

12 PPL SOL.

12BRNAC

20 GY

GY

20 GY

14 OR

12 BRN

12 R

12 R

14 BRN-*

12 BRN—

20 DG

TRAFFIC HAZARD SW.

666SSSB

20DBL

20LBL

20 T

HORN

CONTACT

16B/W

20 LG

18 P

12 R

18 GY/DBL/B

20 B

14

OR

14 LBL

16 B

20

W

12 R

^

18

LBL

14 LBL

20 PP

18 OR

20 BRN

16

DG

IGNTTION SWITCH

GROUND

IGNITION LAMP

INST. LAMP

RADIO CAPACITOR CONN.

TEMP. GAGE

INST. LAMP

INST. LAMP

H. DIR. SIG. LAMP

INST. LAMP

CIGARETTE

SI

"MW LIGHTER & LAMP

INST. LAMP

CLUSTER GROUND

LAMP TELL-TALX LAMP

HI-BEAM LAMP

INST. LAMP

PARK ALARM LAMP

INST. LAMP

W/S WIPER

SWITCH

AMMETER

H. DIR. SIG. LAMP

INST. LAMP

FUEL GAGE

LIGHT SWITCH

-20 P

Fig.

119 - Instrument Panel & Cluster ~ Corvette

CHEVROLET CHASSIS SERVICE MANUAL

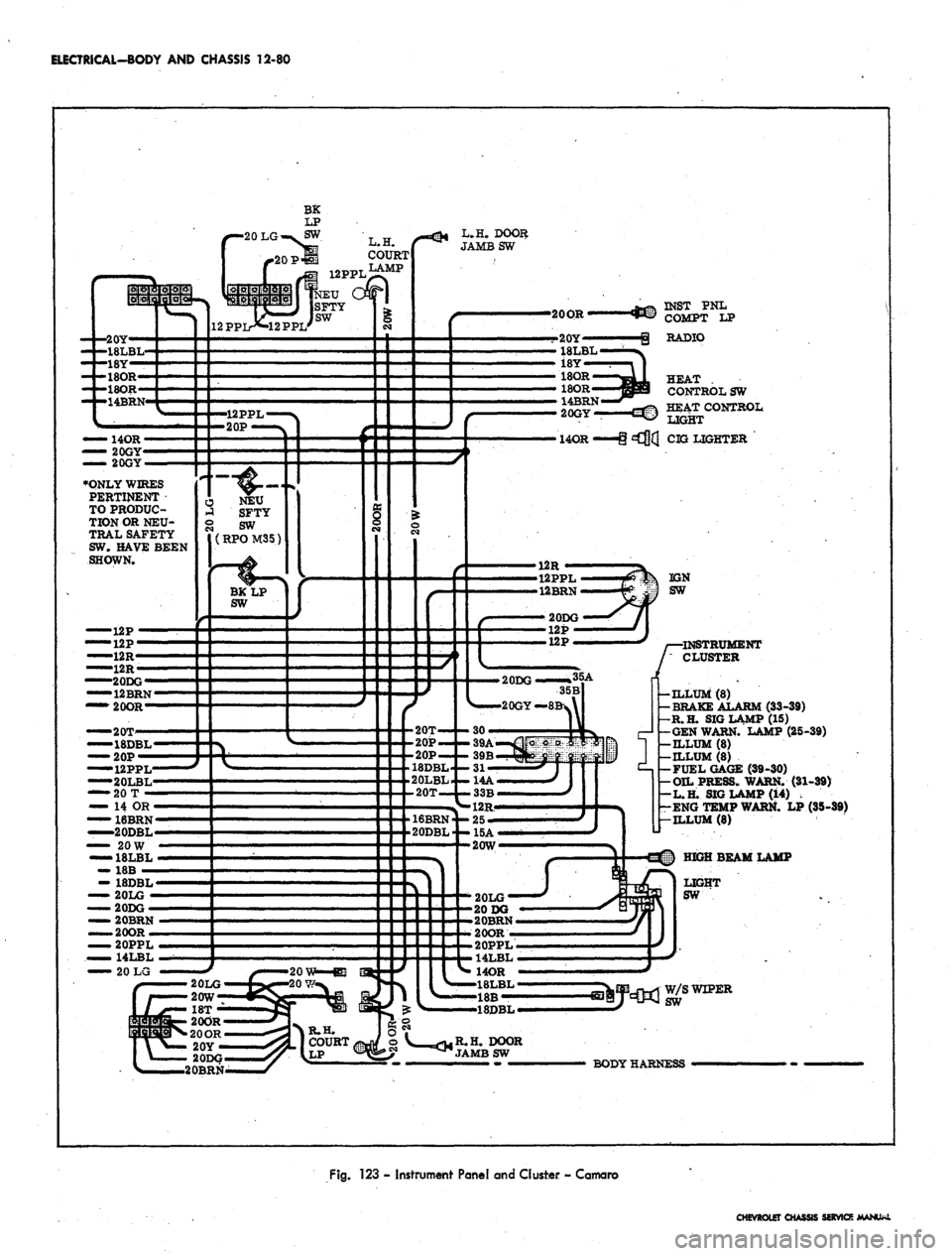

Page 592 of 659

ELECTRICAL-BODY AND CHASSIS 12-80

L.H. DOOR

JAMBSW

— —20Y

20QR

«

«t5§ COMPT LP

RADIO

HEAT .

CONTROL SW

HEAT CONTROL

LIGHT

CJG LIGHTER

14OR

20GY

20GY

•ONLY WIRES

PERTINENT

TO PRODUC-

TION OR NEU-

TRAL SAFETY

HAVE BEEN

SHOWN.

20T—

20P —

20P —

18DBL

20LBL

20T

12PPL

20LBL

20 T

14 OR

16BRN

20DBL

20 W

18LBI

18DBL

20LG

20DG

20 DG

20BRN

20OR

20PPL

14LBL

14OR

48LBL

18B

18DBL

R.H. DOOR

JAMBSW

•INSTRUMENT

CLUSTER

ILLUM <8)

BRAKE ALARM (33-39)

R.H. SIGLAMP(15)

GEN WARN. LAMP (25-39)

ILLUM (8)

ILLUM (8)

FUEL GAGE (39-30)

OIL PRESS. WARN. (31-39)

L.H. SIGLAMP (14) .

ENG TEMP WARN. LP (35-39)

ILLUM (8)

HIGH BEAM LAMP

LIGHT

SW "

W/S WIPER

SW

BODY HARNESS

Fig.

123 - Instrument Panel and Cluster - Camaro

CHEVROLET CHASSIS SERVICE MANUAL

Page 653 of 659

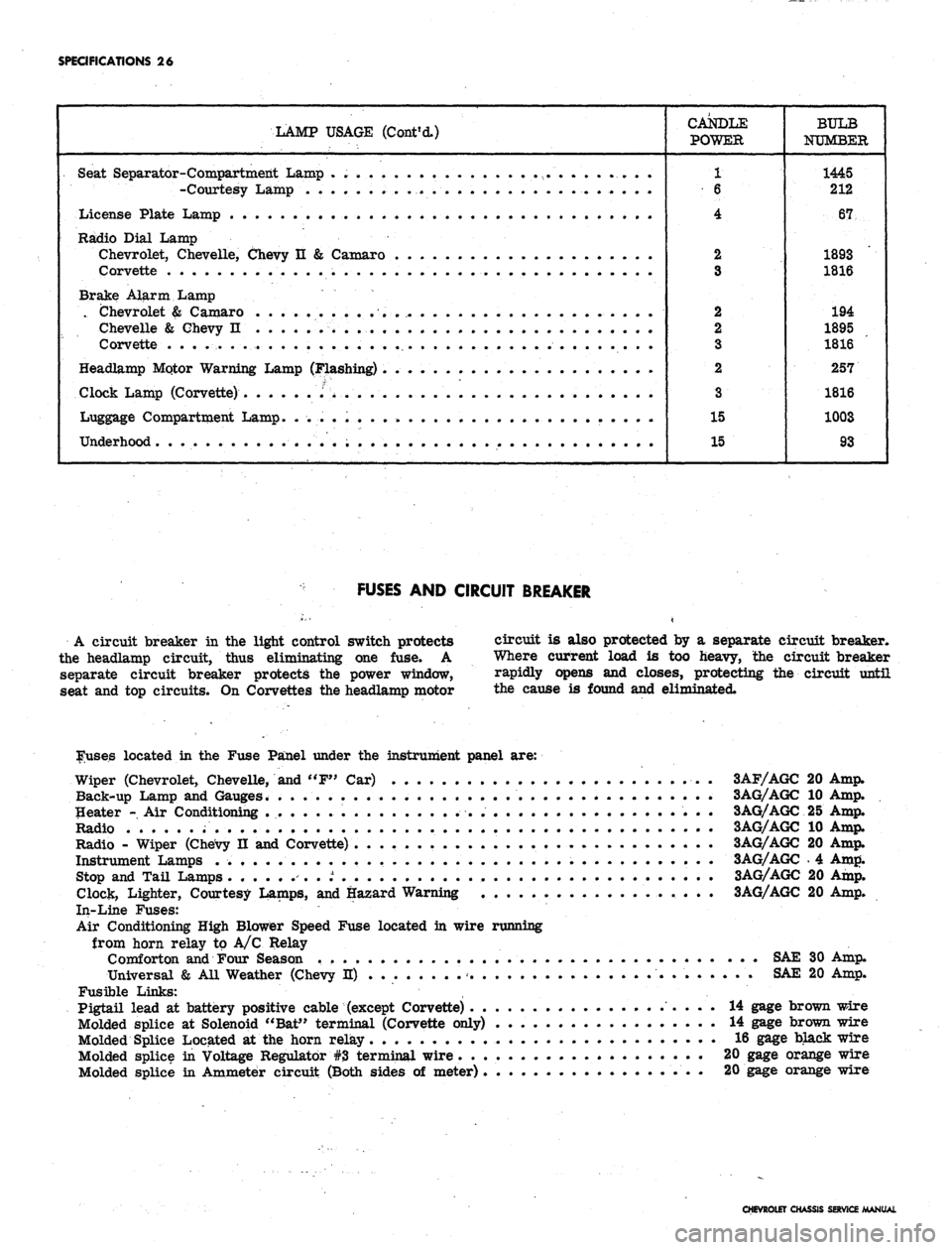

SPECIFICATIONS 26

LAMP USAGE (Cont'd.)

CANDLE

POWER

1

6

4

2

3

2

2

3

2

3

15

15

BULB

NUMBER

1445

212

67

1893

1816

194

1895

1816

257

1816

1003

93

Seat Separator-Compartment Lamp . . . . .

-Courtesy Lamp •

License Plate Lamp . .

Radio Dial Lamp

Chevrolet, Chevelle, Chevy n & Camaro

Corvette

Brake Alarm Lamp

. Chevrolet & Camaro . . .... . .

Chevelle & Chevy n . . . . .'. ;v . . . .

Corvette . . . . . . . .

Headlamp Mqtor Warning Lamp (Flashing) .

Clock Lamp (Corvette) .''> ....

Luggage Compartment Lamp. . ... . . . •

Underhood

FUSES AND CIRCUIT BREAKER

A circuit breaker in the light control switch protects

the headlamp circuit, thus eliminating one fuse. A

separate circuit breaker protects the power window,

seat and top circuits. On Corvettes the headlamp motor

circuit is also protected by a separate circuit breaker.

Where current load is too heavy, the circuit breaker

rapidly opens and closes, protecting the circuit until

the cause is found and eliminated.

louses located in the Fuse Panel under the instrument panel are:

Wiper (Chevrolet, Chevelle, and "F" Car) 3AF/AGC 20 Amp.

Back-up Lamp and Gauges. . . 3AG/AGC 10 Amp.

Heater - Air Conditioning 3AG/AGC 25 Amp.

Radio 3AG/AGC 10 Amp.

Radio - Wiper (Chevy II and Corvette) 3AG/AGC 20 Amp.

Instrument Lamps 3AG/AGC . 4 Amp.

Stop and Tail Lamps ........ t 3AG/AGC 20 Amp.

Clock, Lighter, Courtesy Lamps, and Hazard Warning 3AG/AGC 20 Amp.

In-Line Fuses:

Air Conditioning High Blower Speed Fuse located in wire running

from horn relay to A/C Relay

Comforton and Four Season SAE 30 Amp.

Universal & All Weather (Chevy H) SAE 20 Amp.

Fusible Links: ,

Pigtail lead at battery positive cable (except Corvette) 14 gage brown wire

Molded splice at Solenoid "Bat" terminal (Corvette only) 14 gage brown wire

Molded Splice Located at the horn relay 16 gage black wire

Molded splice in Voltage Regulator #3 terminal wire 20 gage orange wire

Molded splice in Ammeter circuit (Both sides of meter) 20 gage orange wire

CHEVROLET CHASSIS SERVICE MANUAL