diagram CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 334 of 659

ENGINE-ELECTRICAL 6Y-9

63 AMP 1

MODELS ONLY'

BATTERY FUSIBLE

LINK

HORN

FUSIBLE LINK'

TRANSISTOR

FUSIBLE LINK'

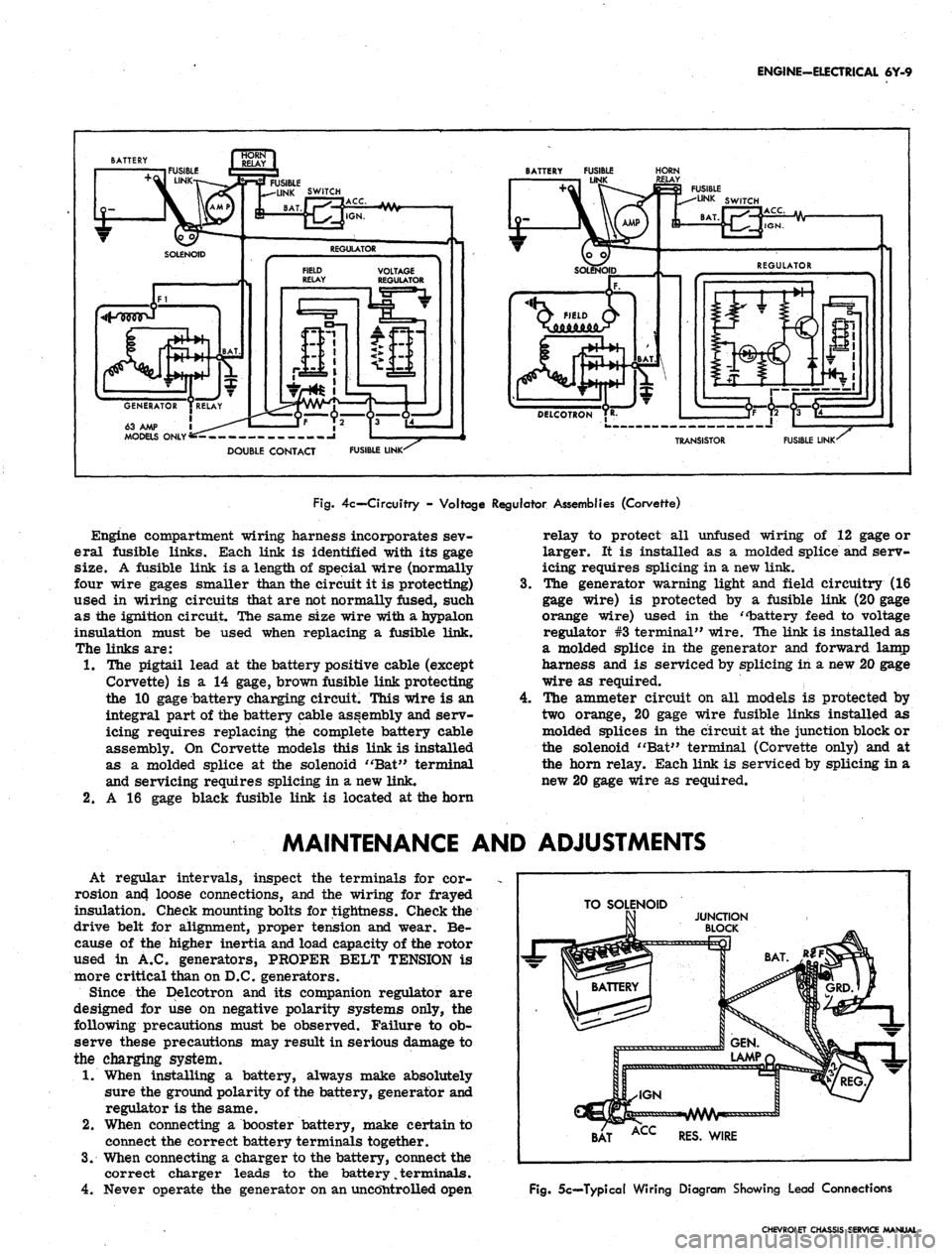

Fig.

4c— Circuitry - Voltage Regulator Assemblies (Corvette)

Engine compartment wiring harness incorporates sev-

eral fusible links. Each link is identified with its gage

size. A fusible link is a length of special wire (normally

four wire gages smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a hypalon

insulation must be used when replacing a fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gage, brown fusible link protecting

the 10 gage battery charging circuit. This wire is an

integral part of the battery cable assembly and serv-

icing requires replacing the complete battery cable

assembly. On Corvette models this link is installed

as a molded splice at the solenoid "Bat" terminal

and servicing requires splicing in a new link.

2.

A 16 gage black fusible link is located at the horn

4.

relay to protect all unfused wiring of 12 gage or

larger. It is installed as a molded splice and serv-

icing requires splicing in a new link.

The generator warning light and field circuitry (16

gage wire) is protected by a fusible link (20 gage

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed as

a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gage

wire as required.

The ammeter circuit on all models is protected by

two orange, 20 gage wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at

the horn relay. Each link is serviced by splicing in a

new 20 gage wire as required.

MAINTENANCE AND ADJUSTMENTS

At regular intervals, inspect the terminals for cor-

rosion an4 loose connections, and the wiring for frayed

insulation. Check mounting bolts for tightness. Check the

drive belt for alignment, proper tension and wear. Be-

cause of the higher inertia and load capacity of the rotor

used in A.C. generators, PROPER BELT TENSION is

more critical than on D.C. generators.

Since the Delcotron and its companion regulator are

designed for use on negative polarity systems only, the

following precautions must be observed. Failure to ob-

serve these precautions may result in serious damage to

the charging system.

1.

When installing a battery, always make absolutely

sure the ground polarity of the battery, generator and

regulator is the same.

2.

When connecting a booster battery, make certain to

connect the correct battery terminals together.

3.

When connecting a charger to the battery, connect the

correct charger leads to the battery

%

terminals.

4.

Never operate the generator on an uncontrolled open

TO SOLENOID

BAT ACC RES. WIRE

Fig.

5c—Typical Wiring Diagram Showing Lead Connections

CHEVROLET CHASSIS SERVICE MANUAL

Page 358 of 659

ENGINE-ELECTRICAL 6Y-33

O

V-8 ENGINE

STARTING MOTOR

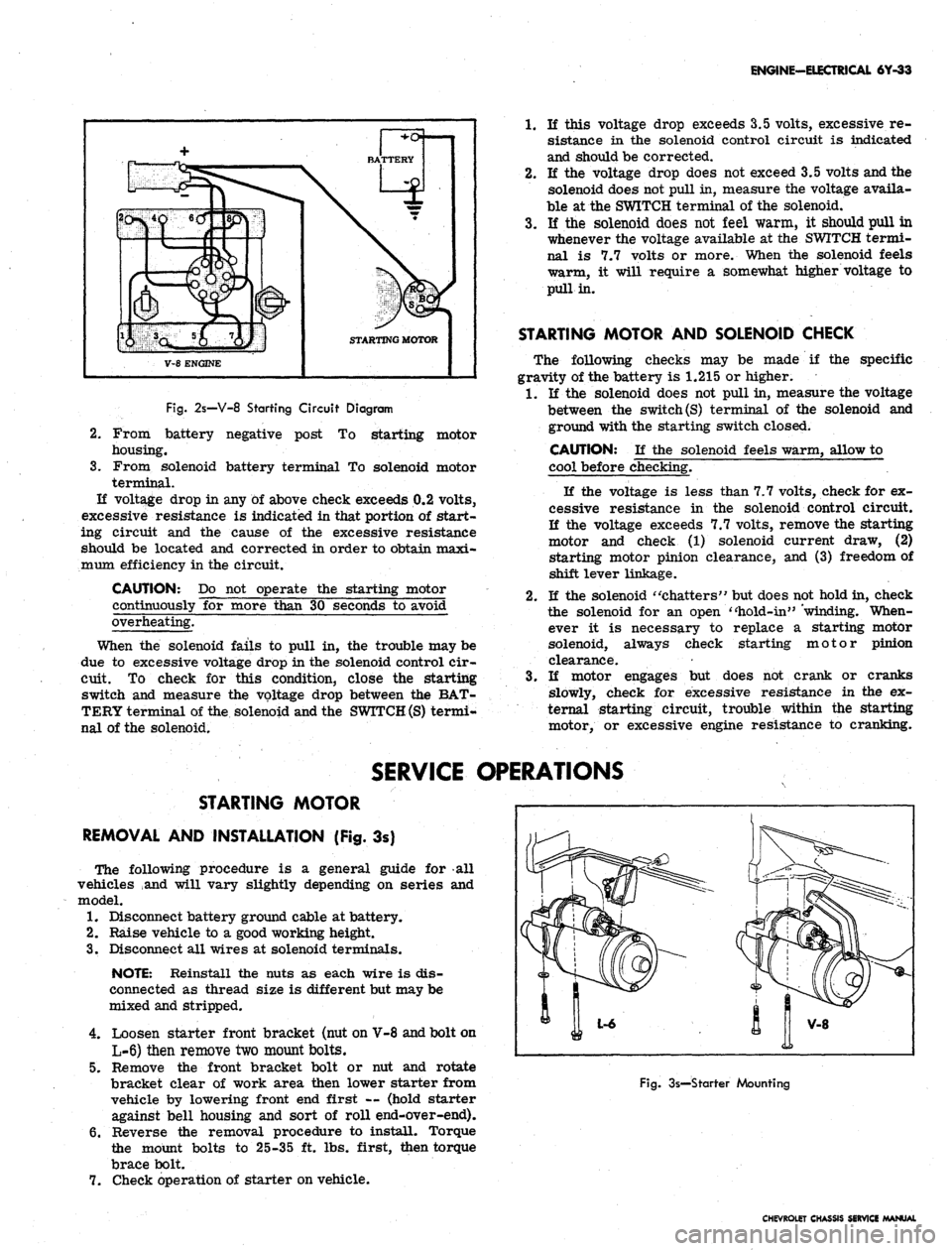

Fig.

2s—V-8 Starting Circuit Diagram

2.

3.

From battery negative post

To

starting motor

housing.

From solenoid battery terminal

To

solenoid motor

terminal.

If voltage drop

in

any

of

above check exceeds 0.2 volts,

excessive resistance

is

indicated in that portion

of

start-

ing circuit

and the

cause

of the

excessive resistance

should

be

located

and

corrected

in

order to obtain maxi-

mum efficiency in the circuit.

CAUTION:

Do not

operate

the

starting motor

continuously

for

more than

30

seconds

to

avoid

overheating.

When

the

solenoid fails

to

pull

in, the

trouble may be

due

to

excessive voltage drop in the solenoid control cir-

cuit.

To

check

for

this condition, close

the

starting

switch

and

measure

the

voltage drop between

the

BAT-

TERY terminal of the solenoid and the

SWITCH (S)

termi-

nal

of

the solenoid.

1.

If

this voltage drop exceeds 3.5 volts, excessive

re-

sistance

in the

solenoid control circuit

is

indicated

and should be corrected.

2.

If the

voltage drop does not exceed 3.5 volts and the

solenoid does not pull in, measure the voltage availa-

ble

at

the SWITCH terminal

of

the solenoid.

3.

If the

solenoid does

not

feel warm,

it

should pull

in

whenever the voltage available

at

the SWITCH termi-

nal

is 7.7

volts

or

more. When

the

solenoid feels

warm,

it

will require

a

somewhat higher voltage

to

pull in.

STARTING MOTOR AND SOLENOID CHECK

The following checks

may be

made

if the

specific

gravity of the battery

is

1.215

or

higher.

1.

If the

solenoid does

not

pull in, measure the voltage

between

the

switch

(S)

terminal

of the

solenoid

and

ground with the starting switch closed.

CAUTION:

If the

solenoid feels warm, allow

to

cool before checking.

If

the

voltage

is

less than 7.7 volts, check for ex-

cessive resistance

in the

solenoid control circuit.

If

the

voltage exceeds 7.7 volts, remove the starting

motor

and

check

(1)

solenoid current draw,

(2)

starting motor pinion clearance,

and (3)

freedom of

shift lever linkage.

2.

If

the solenoid "chatters" but does not hold in, check

the solenoid

for an

open "hold-in" 'winding. When-

ever

it is

necessary

to

replace

a

starting motor

solenoid, always check starting motor pinion

clearance.

3.

If

motor engages

but

does

not

crank

or

cranks

slowly, check

for

excessive resistance

in the ex-

ternal starting circuit, trouble within

the

starting

motor,

or

excessive engine resistance

to

cranking.

SERVICE OPERATIONS

STARTING MOTOR

REMOVAL AND INSTALLATION (Fig.

3s)

The following procedure

is a

general guide

for all

vehicles

and

will vary slightly depending

on

series

and

model.

1.

Disconnect battery ground cable at battery.

2.

Raise vehicle

to a

good working height.

3.

Disconnect all wires

at

solenoid terminals.

NOTE: Reinstall

the

nuts

as

each wire

is

dis-

connected

as

thread size

is

different but may be

mixed and stripped.

4.

Loosen starter front bracket (nut on V-8 and bolt on

L-6) then remove two mount bolts.

5.

Remove

the

front bracket bolt

or nut and

rotate

bracket clear

of

work area then lower starter from

vehicle

by

lowering front end first

—

(hold starter

against bell housing

and

sort

of

roll end-over-end).

6. Reverse

the

removal procedure

to

install. Torque

the mount bolts

to

25-35

ft.

lbs. first, then torque

brace bolt.

7.

Check operation

of

starter on vehicle.

Fig.

3s—Starter Mounting

CHEVROLET CHASSIS SERVICE MANUAL

Page 372 of 659

CLUTCH AND TRANSMISSIONS 7-13

PULL-IN

WINDING

li

HOLD-IN

WINDING

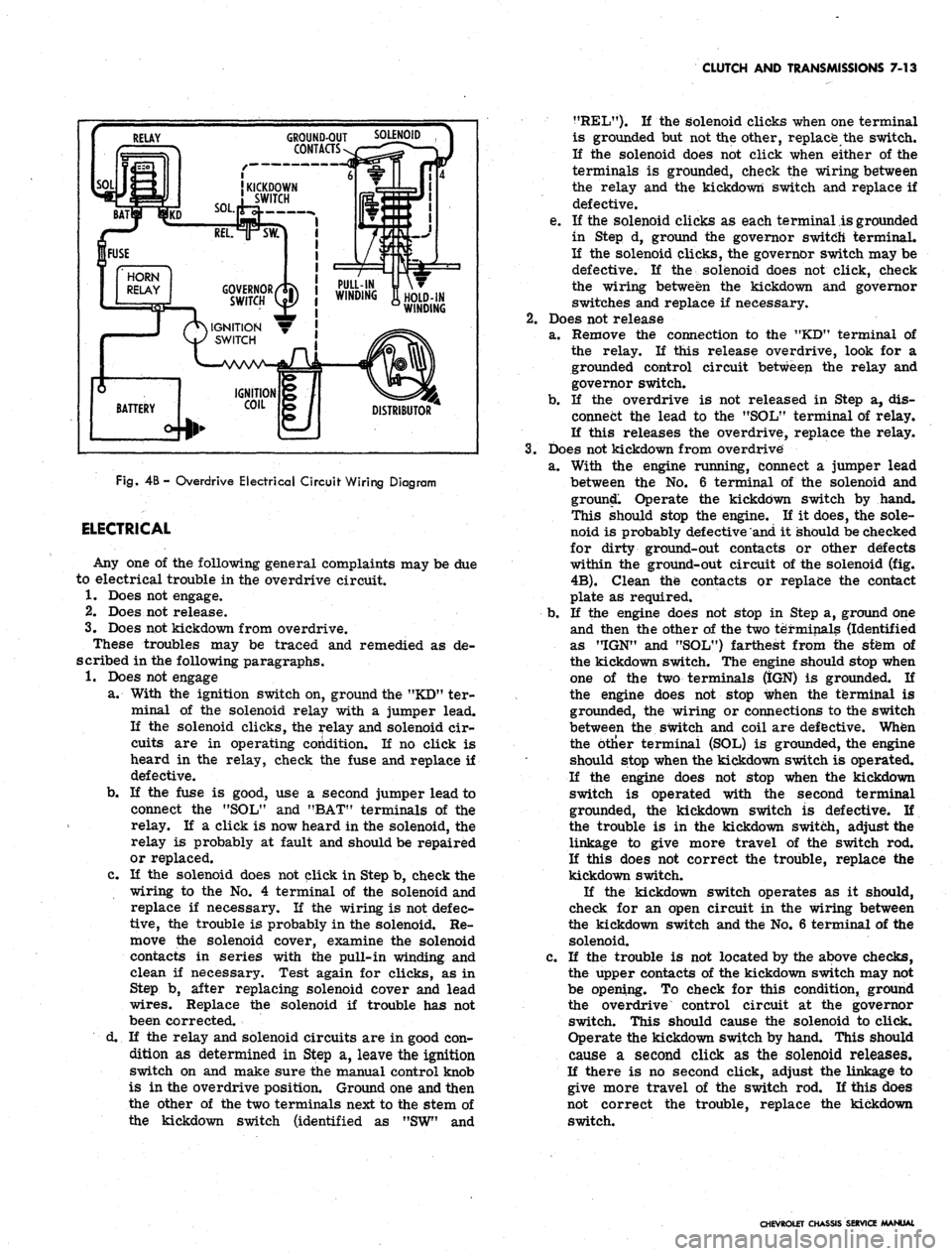

Fig.

4B -

Overdrive Electrical Circuit Wiring Diagram

ELECTRICAL

Any one of the following general complaints may be due

to electrical trouble in the overdrive circuit.

1.

Does not engage.

2.

Does not release.

3.

Does not kickdown from overdrive.

These troubles may be traced and remedied as de-

scribed in the following paragraphs.

1.

Does not engage

a. With the ignition switch on, ground the "KD" ter-

minal of the solenoid relay with a jumper lead.

If the solenoid clicks, the relay and solenoid cir-

cuits are in operating condition. If no click is

heard in the relay, check the fuse and replace if

defective.

b.

If the fuse is good, use a second jumper lead to

connect the "SOL" and "BAT" terminals of the

relay. If a click is now heard in the solenoid, the

relay is probably at fault and should be repaired

or replaced.

c. If the solenoid does not click in Step b, check the

wiring to the No. 4 terminal of the solenoid and

replace if necessary. If the wiring is not defec-

tive,

the trouble is probably in the solenoid. Re-

move the solenoid cover, examine the solenoid

contacts in series with the pull-in winding and

clean if necessary. Test again for clicks, as in

Step b, after replacing solenoid cover and lead

wires.

Replace the solenoid if trouble has not

been corrected.

d. If the relay and solenoid circuits are in good con-

dition as determined in Step a, leave the ignition

switch on and make sure the manual control knob

is in the overdrive position. Ground one and then

the other of the two terminals next to the stem of

the kickdown switch (identified as "SW" and

?fREL"). K the solenoid clicks when one terminal

is grounded but not the other, replace the switch.

If the solenoid does not click when either of the

terminals is grounded, check the wiring between

the relay and the kickdown switch and replace if

defective.

e. If the solenoid clicks as each terminal is grounded

in Step d, ground the governor switch terminal.

If the solenoid clicks, the governor switch may be

defective. If the solenoid does not click, check

the wiring between the kickdown and governor

switches and replace if necessary.

2.

Does not release

a. Remove the connection to the "KD" terminal of

the relay. If this release overdrive, look for a

grounded control circuit between the relay and

governor switch.

b.

If the overdrive is not released in Step a, dis-

connect the lead to the "SOL" terminal of relay.

If this releases the overdrive, replace the relay.

3.

Does not kickdown from overdrive

a. With the engine running, connect a jumper lead

between the No. 6 terminal of the solenoid and

ground. Operate the kickdown switch by hand.

This should stop the engine. If it does, the sole-

noid is probably defective and it should be checked

for dirty ground-out contacts or other defects

within the ground-out circuit of the solenoid (fig.

4B).

Clean the contacts or replace the contact

plate as required.

b.

If the engine does not stop in Step a, ground one

and then the other of the two terminals (Identified

as "IGN" and "SOL") farthest from the sfem of

the kickdown switch. The engine should stop when

one of the two terminals (IGN) is grounded. If

the engine does not stop when the terminal is

grounded, the wiring or connections to the switch

between the switch and coil are defective. When

the btlier terminal (SOL) is grounded, the engine

should stop when the kickdown switch is operated.

If the engine does not stop when the kickdown

switch is operated with the second terminal

grounded, the kickdown switch is defective. If

the trouble is in the kickdown switch, adjust the

linkage to give more travel of the switch rod.

If this does not correct the trouble, replace the

kickdown switch.

If the kickdown switch operates as it should,

check for an open circuit in the wiring between

the kickdown switch and the No. 6 terminal of the

solenoid.

c. If the trouble is not located by the above checks,

the upper contacts of the kickdown switch may not

be opening. To check for this condition, ground

the overdrive control circuit at the governor

switch. This should cause the solenoid to click.

Operate the kickdown switch by hand. This should

cause a second click as the solenoid releases.

If there is no second click, adjust the linkage to

give more travel of the switch rod. If this does

not correct the trouble, replace the kickdown

switch.

CHEVROLET CHASSIS SERVICE MANUAL

Page 396 of 659

CLUTCH AND TRANSMISSIONS 7-37

LI.

- LI Range can be selected at any vehicle speed,

and the transmission will shift to second gear

and remain in second until vehicle speed is re-

duced to approximately 40 MPH, .depending on

axle ratio. LI Range position prevents the trans-

mission from shifting out of first gear.

It is very important that any communication concerning

the Turbo Hydra-Matic always contain the transmission

serial number and that all transmission parts returned

to Chevrolet Motor Division always be tagged with the

transmission serial number.

MAINTENANCE AND ADJUSTMENTS

TRANSMISSION FLUID

Transmission fluid level should be checked with trans-

mission warm and selector lever in "P" Park position,

every time engine oil level is checked or as specified in

Section 0 when engine oil is changed.

CAUTION: Since the Turbo Hydra-Matic trans-

mission is very sensitive to oil level, special

precautions should be taken when checking the

oil level, to insure against an overfifE

Transmission fluid should be changed as specified in

Section 0.

FLUID LEVEL INDICATOR

The fluid level indicator is located in the filler pipe at

the right rear corner of the engine. To bring the fluid

level from the add mark to the full mark add 1 pint.

Fluid level should be to the full mark with transmission

at normal operating temperature. With cold fluid the

level should be at the add mark or slightly below.

SHIFT CONTROL LINKAGE ADJUSTMENT

Adjust linkage as shown below and in Figure 2.

1.

The shift tube and lever assembly must be free in the

mast jacket See Section 9 for alignment of steering

column assembly if necessary.

2.

To check for proper shift linkage adjustment, lift the

transmission selector lever towards the steering

wheel. Allow the selector lever to be positioned in

drive (D) by the transmission detent.

NOTE: Do not use the indicator pointer as a

reference to position the selector lever. When

performing linkage adjustment, pointer is ad-

justed last.

3.

Release the selector lever. The lever should be in-

hibited from engaging low range unless the lever is

lifted.

4.

Lift the selector lever towards the steering wheel,

and allow the lever to be positioned in neutral (N) by

the transmission detent.

5.

Release the selector lever. The lever should now be

inhibited from engaging reverse range unless the

lever is lifted.

6. A properly adjusted linkage will prevent the selector

lever from moving beyond both the neutral detent,

and the drive detent unless the lever is lifted to pass

over the mechanical stop in the steering column.

See schematic diagram.

7.

In the event that an adjustment is required, place the

selector lever in drive (D) position as determined by

the transmission detent. See Steps 2 and 3.

8. Loosen the adjustment swivel at the cross-shaft, and

rotate the transmission lever so that it contacts the

drive stop in the steering column.

9. Tighten the swivel and recheck the adjustment. See

Steps 2 and 6. -

l(h Readjust indicator needle if necessary to agree with

the transmission detent" positions. See Section 9.

11.

Readjust neutral safety switch if necessary to pro-

vide the correct relationship to the transmission de-

tent positions. See Section 12.

12.

When properly adjusted the following conditions must

be met by manual operation of the steering column

shift lever:

a. From reverse to drive position travel, the trans-

mission detent feel must be noted and related to

indicated position on dial.

b.

When in drive and reverse positions, pull lever

rearward (towards steering wheel) and then re-

lease. It must drop back into position with no

restrictions.

NEUTRAL SAFETY SWITCH ADJUSTMENT

The neutral safety switch must be adjusted so that the

car will start in the park or neutral position, but will not

start in the other positions. For replacement refer to

Section 12 of this Manual.

DRAINING AND REFILLING TRANSMISSION

Drain oil immediately after operation before it has had

an opportunity to cool.

To drain oil proceed as follows:

1.

Remove bottom pan attaching screws, pan, and gas-

ket.

2.

Remove oil strainer. Remove "O" ring seal from

pick-up pipe and discard.

3.

Discard strainer if dirty.

4.

Install new "O" ring seal on pick-up pipe and install

strainer and pipe assembly.

5.

Thoroughly clean bottom pan.

6.. Affix new gasket to bottom pan with petroleum jelly.

7.

Install bottom pan with attaching screws and torque

to specifications;

8. If only the pan has been removed, pour approximately

7-1/2 pints of fluid into the transmission. If the

valve body has also been removed use 9-1/2 pints.

After a complete overhaul approximately 19 pints

are required. Be sure container, spout, or funnel is

clean.

9. Start engine and let idle (carburetor off fast idle

step).

Place selector lever in P position and apply

hand brake.

10.

With transmission warm (approximately 150°F), add

fluid to bring level to full mark on indicator.

CAUTION: Do not overfill. Foaming will re-

sult.

CHEVROLET CHASSIS SERVICE MANUAL

Page 513 of 659

SECTION 12

ELECTRICAL-BODY AND CHASSIS

CONTENTS

OF

THIS

SECTION

Page

Page

System 12-1

Instruments and Gauges 12-21

Directional Signal 12r40

Windshield Wipers and Washers 12-44

Wiring Diagrams 12-56

Special Tools 12-60

LIGHTING SYSTEM

INDEX

Page

General Description

!2-i

Maintenance and Adjustments

•.................. 12-2

Headlamp Adjustment......................

12-3

Headlamp Panel Travel Adjustment.

12-5

Service Operations.

. . .. 12-5

Front Lighting

12-5

Headlamp

. 12_5

Parking Lamp

12-5

Fender Lamp

. 12_^

Headlamp Panel

12-8

Headlamp Panel Motor

^2-9

Rear Lighting

l2-10

Tail, Stop and Directional Lamps

12-10

Page

Backing Lamps

12-14

License Plate Lamp

12-14

Automatic Transmission Quadrant Lamp

12-14

Seat Separator Console Lamps

. 12-15

Lighting Switch

. . 12-15

Wiper Switch.

12-15

Stoplight Switch

12-15

Dimmer Switch

12-15

Backing Lamp Switches

12-15

Neutral Safety Switches

12-17

Parking Brake Alarm Switch

................. 12-19

Instrument Panel Compartment Lamp/Switch

12-19

Cirgarette Lighter

12-19

GENERAL DESCRIPTION

.

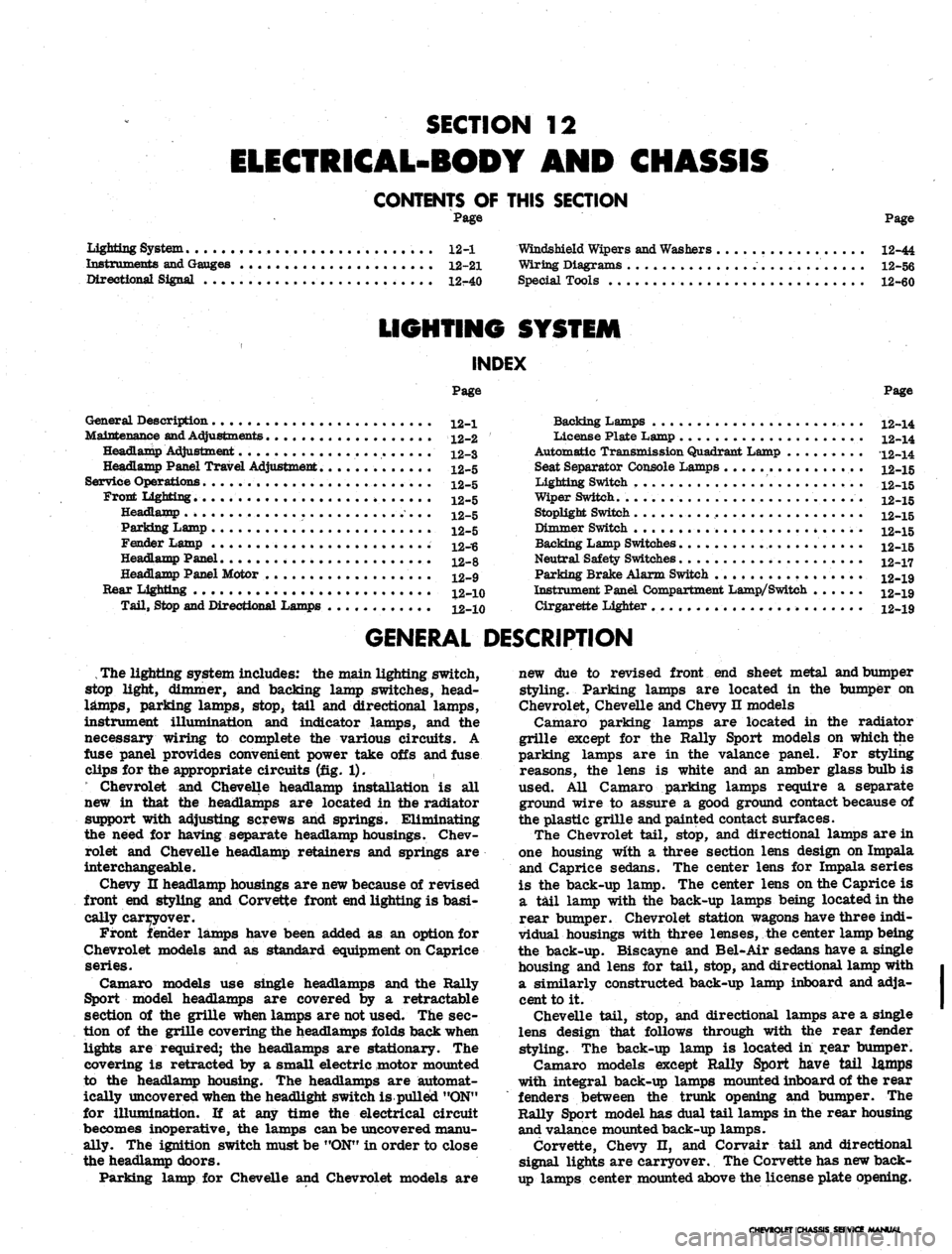

The lighting system includes: the main lighting switch,

stop light, dimmer, and backing lamp switches, head-

lamps, parking lamps, stop, tail and directional lamps,

instrument illumination and indicator lamps, and the

necessary wiring to complete the various circuits. A

fuse panel provides convenient power take offs and fuse

clips for the appropriate circuits (fig. 1).

Chevrolet and Chevelle headlamp installation is all

new in that the headlamps are located in the radiator

support with adjusting screws and springs. Eliminating

the need for having separate headlamp housings. Chev-

rolet and Chevelle headlamp retainers and springs are

interchangeable.

Chevy n headlamp housings are new because of revised

front end styling and Corvette front end lighting is basi-

cally carryover.

Front fender lamps have been added as an option for

Chevrolet models and as standard equipment on Caprice

series.

Camaro models use single headlamps and the Rally

Sport model headlamps are covered by a retractable

section of the grille when lamps are not used. The sec-

tion of the grille covering the headlamps folds back when

lights are required; the headlamps are stationary. The

covering is retracted by a small electric motor mounted

to the headlamp housing. The headlamps are automat-

ically uncovered when the headlight switch is pulled "ON"

for illumination. If at any time the electrical circuit

becomes inoperative, the lamps can be uncovered manu-

ally. The ignition switch must be

"ON"

in order to close

the headlamp doors.

Parking lamp for Chevelle and Chevrolet models are

new due to revised front end sheet metal and bumper

styling. Parking lamps are located in the bumper on

Chevrolet, Chevelle and Chevy n models

Camaro parking lamps are located in the radiator

grille except for the Rally Sport models on which the

parking lamps are in the valance panel. For styling

reasons, the lens is white and an amber glass bulb is

used. All Camaro parking lamps require a separate

ground wire to assure a good ground contact because of

the plastic grille and painted contact surfaces.

The Chevrolet tail, stop, and directional lamps are in

one housing with a three section lens design on Impala

and Caprice sedans. The center lens for Impala series

is the back-up lamp. The center lens on the Caprice is

a tail lamp with the back-up lamps being located in the

rear bumper. Chevrolet station wagons have three indi-

vidual housings with three lenses, the center lamp being

the back-up. Biscayne and Bel-Air sedans have a single

housing and lens for tail, stop, and directional lamp with

a similarly constructed back-up lamp inboard and adja-

cent to it.

Chevelle tail, stop, and directional lamps are a single

lens design that follows through with the rear fender

styling. The back-up lamp is located in r.ear bumper.

Camaro models except Rally Sport have tail lamps

with integral back-up lamps mounted inboard of the rear

fenders between the trunk opening and bumper. The

Rally Sport model has dual tail lamps in the rear housing

and valance mounted back-up lamps.

Corvette, Chevy n, and Corvair tail and directional

signal lights are carryover. The Corvette has new back-

up lamps center mounted above the license plate opening.

CHEVROLET CHASSIS SERVICE

Page 514 of 659

ELECTRICAL-BODY AND CHASSIS 12-2

FJg.

1 - Fuse Panel Assembly

All power window and tailgate circuits require the igni-

tion switch to be "ON" to open or close the windows un-

like past model designs which were operated independ-

ently of the ignition switch.

The windshield wiper and washer switch is new in that

washer button in the center of the knob has been deleted

and its function will be accomplished by pushing the knob.

A set screw is used to retain the knob to the shaft.

In addition to fuses, the wiring harness incorporates

fusible links to protect the wiring. Links are used rather

than a fuse in wiring circuits that are not normally fused,

such as the ignition circuit. Fusible links in the Chevro-

let wiring are four gauge sizes smaller than the cable it

is designed to protect. The links are marked on the

insulation with wire gauge size because of the heavy insu-

lation which makes the link appear a heavier gauge than it

actually is.

Engine compartment wiring harness incorporate sev-

eral fusible links. Each link is identified with its gauge

size.

A fusible link is a length of special wire (normally

four wire gauges smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a spe-

cial hypalon insulation must be used when replacing a

fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gauge, brown fusible link protecting

the 10 gange battery charging circuit. This wire is

an integral part of the battery cable assembly and

servicing requires replacing the complete battery

cable assembly. On Corvette models this link is

installed as a molded splice at the solenoid "Bat"

terminal and servicing requires splicing in a new

link.

2.

A 16 gauge black fusible link is located at horn relay

to protect all unfused wiring of 12 gauge or larger.

It is a serviceable piece with an in-line connector

and is not integral with the wiring harness.

3.

The generator warning light and field circuitry (16

gauge wire) is protected by a fusible link (20 gauge

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed

as a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gauge

wire as required.

4.

The ammeter circuit on all models is protected by

two orange, 20 gauge wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at the

horn relay. Each link is serviced by splicing in a

new 20 gauge wire as required.

The wiring harnesses use a standarized. color code

common to all Chevrolet vehicles. Under the color code,

the color of the wire designates a particular circuit. The

harness title indicates the type of harness, single of mul-

tiple wire, and also describe the location of the harness.

The body harness is a flat, solid wire assembly and is

routed through the vehicle near the center of the body.

Composite wiring diagrams (figs. 104 thru 124) are in-

cluded at the end of this section.

MAINTENANCE AND ADJUSTMENTS

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head-

lamps are properly adjusted. Loose or corroded con-

nections may cause a discharged battery, difficult start-

ing, dim lights, and possible damage to generator and

regulator. Wire harnesses must be replaced if insulation

becomes burned, cracked, or deteriorated. Whenever it

is necessary to splice a wire or repair one that is bro-

ken, always use solder to bond the splice. Always use

rosin flux solder on electrical connections. Use insulat-

ing tape to cover all splices or bare wires.

When replacing wires, it is important that the correct

size be used. Never replace a wire with one of a smaller

size.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

CHEVROLET CHASSIS SERVICE MANUAL

Page 515 of 659

ELECTRICAL-BODY AND CHASSIS 12-3

Fig.

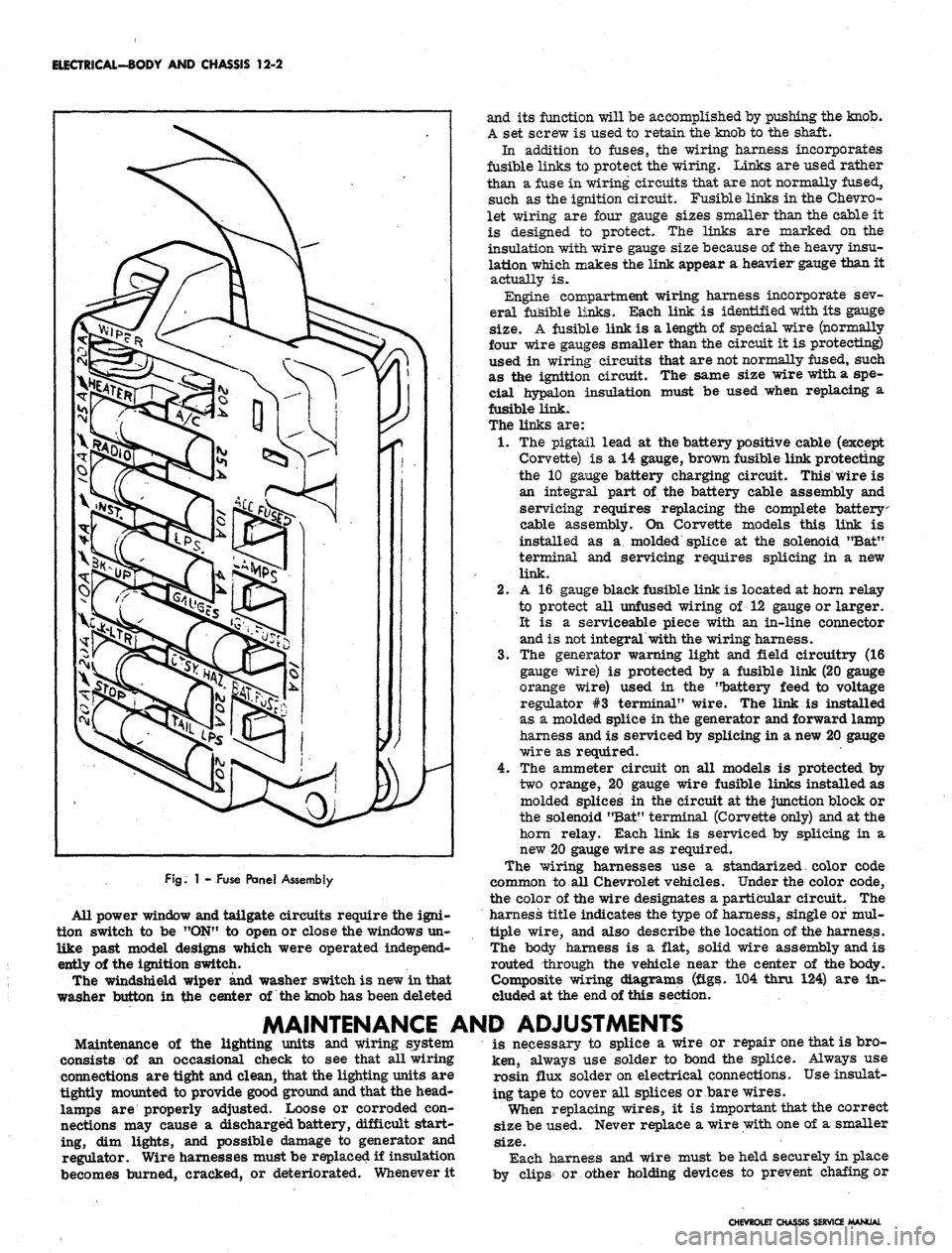

2 - T-3 Safety Aimer

wearing away the insulation due to vibration.

By referring to the wiring diagrams, circuits may be

tested for continuous circuit or shorts with a conventional

test lamp or low reading volt meter.

HEADLAMP ADJUSTMENT-

T-3 HEADLAMPS

CAUTION: Check and tighten radiator support

grille retaining bolts prior to attempting head-

lamp aiming. Distorted grille or supports in

this area will hinder proper aiming of head-

lamps. On Corvette models make sure head-

lamp panel is adjusted properly - refer to

"Headlamp Panel Travel Adjustment".

When aiming headlamps, vehicle should be filled to ca-

pacity with gas, oil, and water but no load. Tires should

be uniformly inflated to recommended pressure.

the T-3 Safety Aimer-Type B (fig. 2), is used for the

headlamp aiming description that follows. An adapter is

required with the Type B T-3 Aimer when adjusting the 7

inch headlamp used on the Chevy n vehicle.

1.

Drive vehicle onto selected aiming area. Bounce

vehicle several times and allow to settle.

2.

Remove headlamp bezels.

3.

Mount the T-3 Aimers on either the No. 1 or No. 2

pair of headlamps so that "the points of the headlamps

engage the smooth inner ring of the aimers.

HORIZONTAL

AIMING

SCREW

STRING OVER

"2R" ON AIMER ARM

Fig.

4—-Headlamp Horizontal Adjustment

NOTE:

In the dual headlamp installation, the

inboard unit is designated No. 1 and the outboard

unit is designated No. 2.

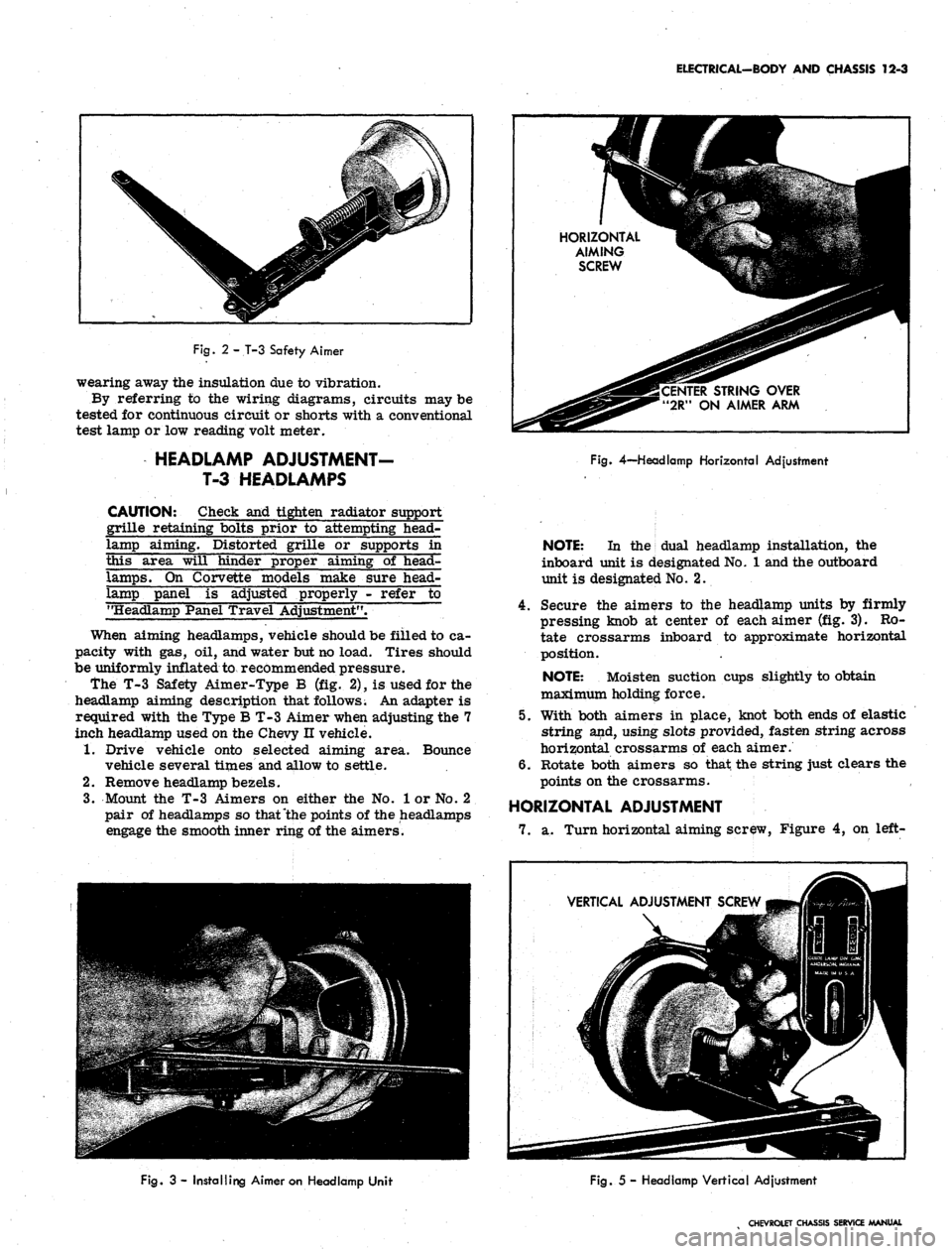

4.

Secure the aimers to the headlamp units by firmly

pressing knob at center of each aimer (fig. 3). Ro-

tate crossarms inboard to approximate horizontal

position.

NOTE:

Moisten suction cups slightly to obtain

maximum holding force.

5. With both aimers in place, knot both ends of elastic

string and, using slots provided, fasten string across

horizontal crossarms of each aimer.

6. Rotate both aimers so that the string just clears the

points on the crossarms.

HORIZONTAL ADJUSTMENT

7. a. Turn horizontal aiming screw, Figure 4, on left-

VERTICAL ADJUSTMENT SCREW

Fig.

3 - Installing Aimer on Headlamp Unit

Fig.

5 - Headlamp Vertical Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 617 of 659

ACCESSORIES

15-8

BROWN

BRAKE

SWITCH

+12V *

BLACK

CONNECTOR

AT FUSE BLOCK

CRUISE POSITION

BUTTON RELEASED

ENGAGE POSITION

BUTTON PARTIALLY DEPRESSED^ N. ENOAOi SWITCH

TRIM POSITION N. N. I

BUHON FULLY DEPRESSED. \ ^

BROWN

BLUE

ENGAGE SWITCH

CONFIGURATION

BLACK

BLUE

REGULATOR

- SOLENOID COIL

(5 a RESISTANCE)

9 BLACK

BLUE

REGULATOR

Fig.

10 - Wiring Diagram

Replacement

1.

Insert the switch into the turn signal knob, push the

retaining ring firmly against the switch, and push the

operating button onto the switch plunger. " .

SERVO

Service

—

H the Servo unit is found to be defective, re-

placement is required. Note the condition of the hoses

and replace any which are cracked or deteriorated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 620 of 659

ACCESSORIES 15-11

12 VOLTS D.C.

ELECTRIC BRAKE

RELEASE

IGNITION

SWITCH

ENGINE

VACUUM

TRANSDUCER

Fig.

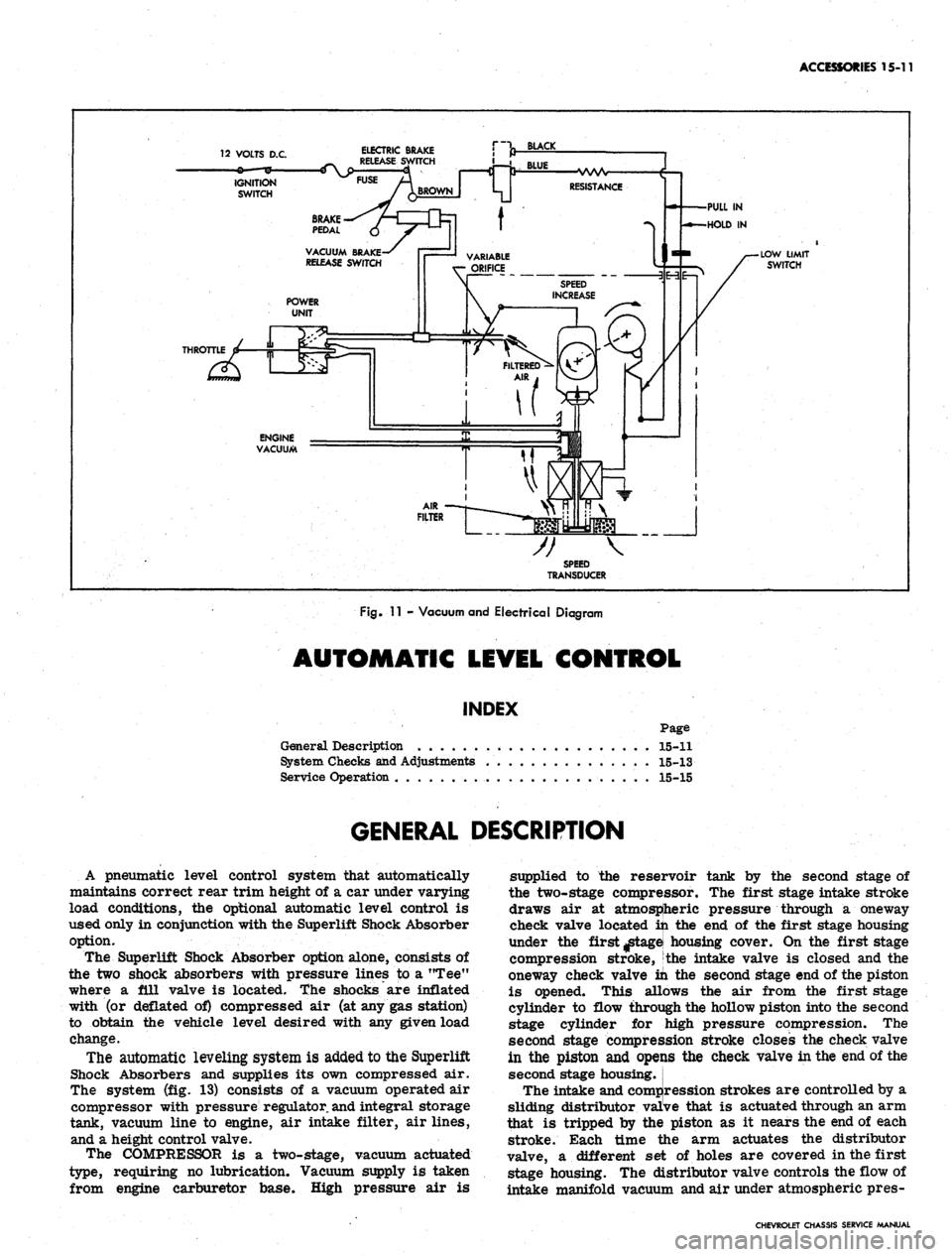

11 - Vacuum and Electrical Diagram

AUTOMATIC LEVEL CONTROL

INDEX

Page

General Description . . 15-11

System Checks and Adjustments 15-13

Service Operation . 15-15

GENERAL DESCRIPTION

A pneumatic level control system that automatically

maintains correct rear trim height of a car under varying

load conditions, the optional automatic level control is

used only in conjunction with the Superlift Shock Absorber

option.

The Superlift Shock Absorber option alone, consists of

the two shock absorbers with pressure lines to a "Tee"

where a ill valve is located, the shocks are inflated

with (or deflated of) compressed air (at any gas station)

to obtain the vehicle level desired with any given load

change.

The automatic leveling system is added to the Superlift

Shock Absorbers and supplies its own compressed air.

The system (fig. 13) consists of a vacuum operated air

compressor with pressure regulator,

and

integral storage

tank, vacuum line to engine, air intake filter, air lines,

and a height control valve.

The COMPRESSOR is a two-stage, vacuum actuated

type, requiring no lubrication. Vacuum supply is taken

from engine carburetor base. High pressure air is

supplied to the reservoir tank by the second stage of

the two-stage compressor. The first stage intake stroke

draws air at atmospheric pressure through a oneway

check valve located in the end of the first stage housing

under the first ^tagei housing cover. On the first stage

compression stroke, the intake valve is closed and the

oneway check valve in the second stage end of the piston

is opened. This allows the air from the first stage

cylinder to flow through the hollow piston into the second

stage cylinder for jhigh pressure compression. The

second stage compression stroke closes the check valve

in the piston and opeijis the check valve in the end of the

second stage housing.

The intake and compression strokes are controlled by a

sliding distributor valive that is actuated through an arm

that is tripped by the piston as it nears the end of each

stroke. Each time the arm actuates the distributor

valve, a different set of holes are covered in the first

stage housing. The distributor valve controls the flow of

intake manifold vacuum and air under atmospheric pres-

CHEVROLET CHASSIS SERVICE MANUAL