air bleeding CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 252 of 2438

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ASSEMBLY/ACCUMULATOR PRIOR PERFORM-

ING THIS OPERATION. MAY RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO PAINTED SURFACES

OF THE VEHICLE.

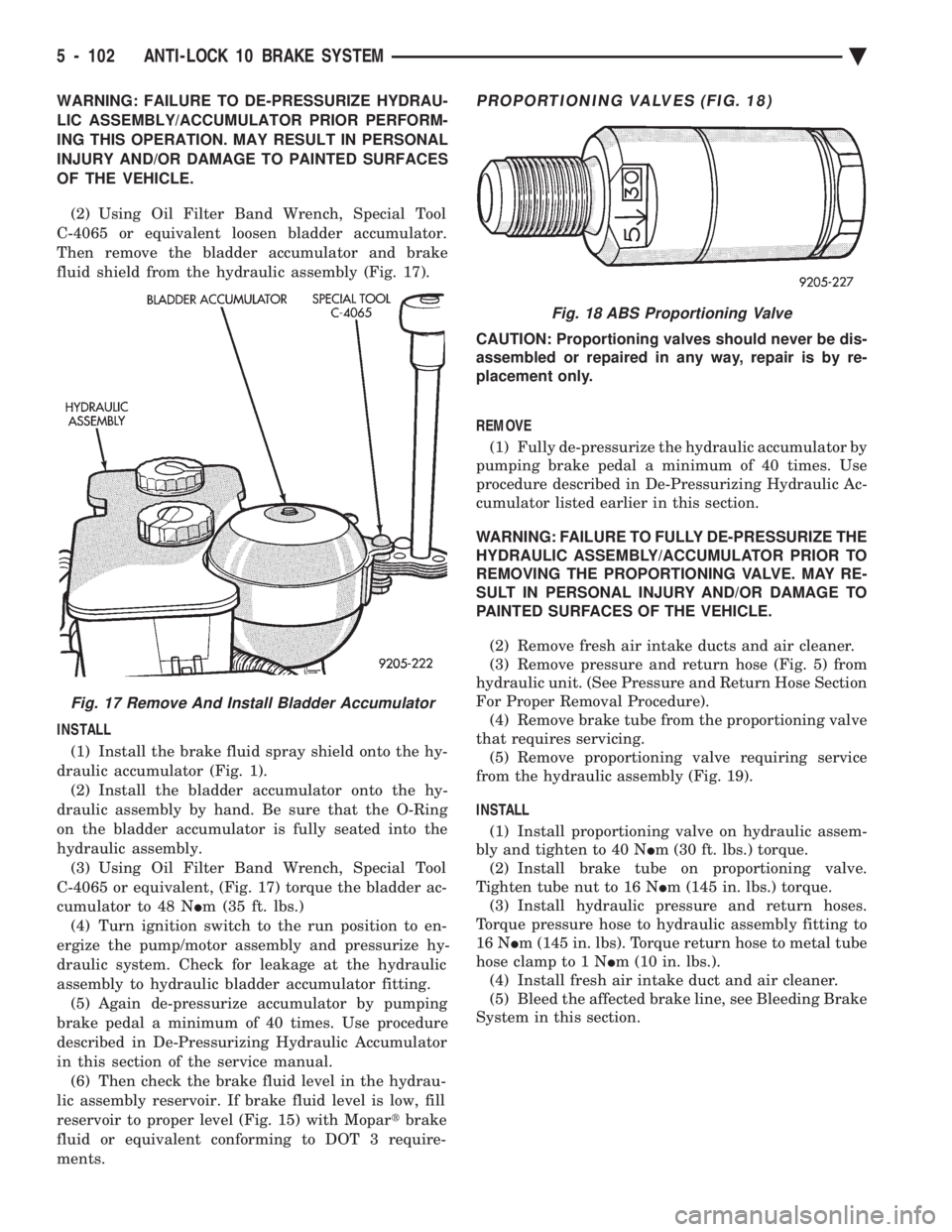

(2) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent loosen bladder accumulator.

Then remove the bladder accumulator and brake

fluid shield from the hydraulic assembly (Fig. 17).

INSTALL

(1) Install the brake fluid spray shield onto the hy-

draulic accumulator (Fig. 1). (2) Install the bladder accumulator onto the hy-

draulic assembly by hand. Be sure that the O-Ring

on the bladder accumulator is fully seated into the

hydraulic assembly. (3) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent, (Fig. 17) torque the bladder ac-

cumulator to 48 N Im (35 ft. lbs.)

(4) Turn ignition switch to the run position to en-

ergize the pump/motor assembly and pressurize hy-

draulic system. Check for leakage at the hydraulic

assembly to hydraulic bladder accumulator fitting. (5) Again de-pressurize accumulator by pumping

brake pedal a minimum of 40 times. Use procedure

described in De-Pressurizing Hydraulic Accumulator

in this section of the service manual. (6) Then check the brake fluid level in the hydrau-

lic assembly reservoir. If brake fluid level is low, fill

reservoir to proper level (Fig. 15) with Mopar tbrake

fluid or equivalent conforming to DOT 3 require-

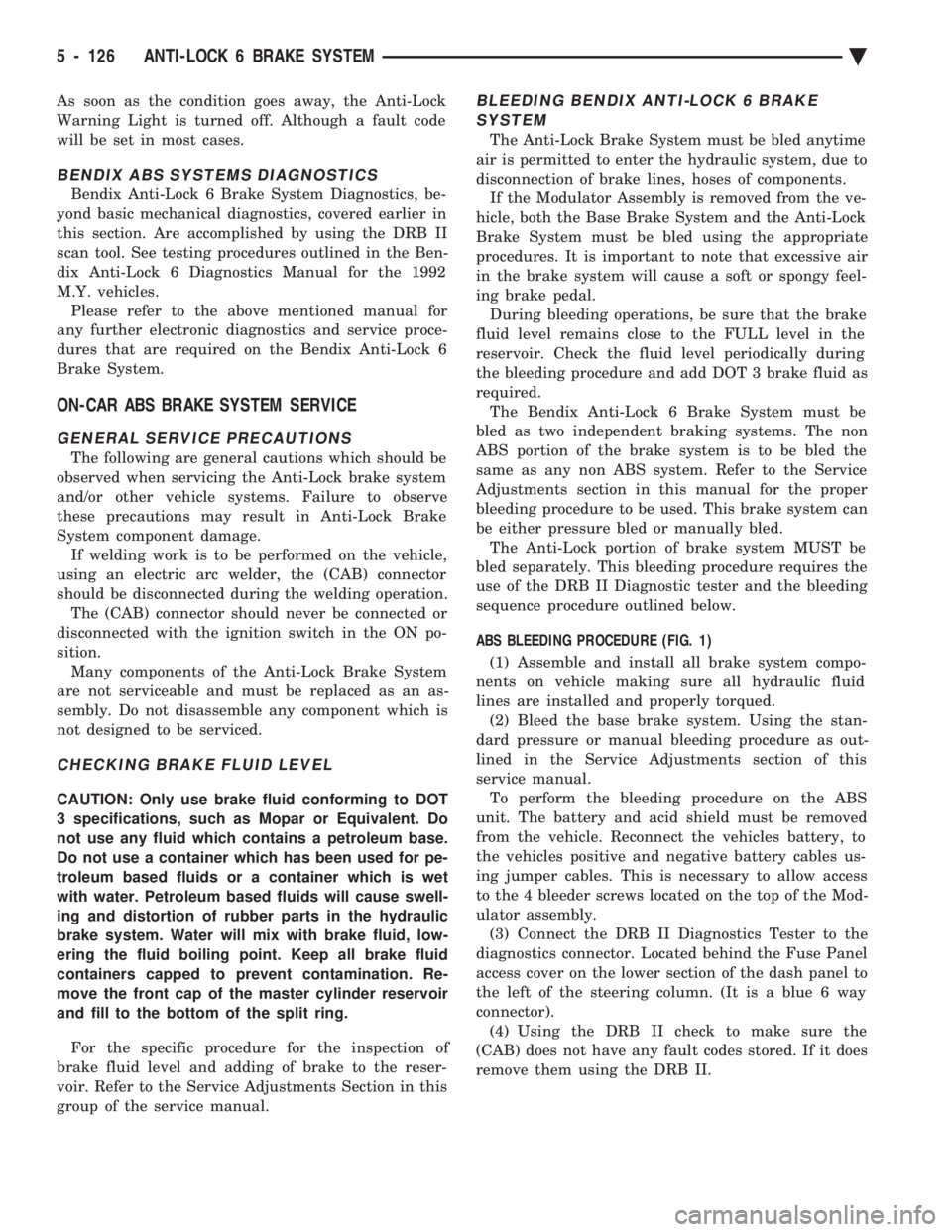

ments.PROPORTIONING VALVES (FIG. 18)

CAUTION: Proportioning valves should never be dis-

assembled or repaired in any way, repair is by re-

placement only.

REMOVE (1) Fully de-pressurize the hydraulic accumulator by

pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO FULLY DE-PRESSURIZE THE

HYDRAULIC ASSEMBLY/ACCUMULATOR PRIOR TO

REMOVING THE PROPORTIONING VALVE. MAY RE-

SULT IN PERSONAL INJURY AND/OR DAMAGE TO

PAINTED SURFACES OF THE VEHICLE.

(2) Remove fresh air intake ducts and air cleaner.

(3) Remove pressure and return hose (Fig. 5) from

hydraulic unit. (See Pressure and Return Hose Section

For Proper Removal Procedure). (4) Remove brake tube from the proportioning valve

that requires servicing. (5) Remove proportioning valve requiring service

from the hydraulic assembly (Fig. 19).

INSTALL (1) Install proportioning valve on hydraulic assem-

bly and tighten to 40 N Im (30 ft. lbs.) torque.

(2) Install brake tube on proportioning valve.

Tighten tube nut to 16 N Im (145 in. lbs.) torque.

(3) Install hydraulic pressure and return hoses.

Torque pressure hose to hydraulic assembly fitting to

16 N Im (145 in. lbs). Torque return hose to metal tube

hose clamp to 1 N Im (10 in. lbs.).

(4) Install fresh air intake duct and air cleaner.

(5) Bleed the affected brake line, see Bleeding Brake

System in this section.

Fig. 17 Remove And Install Bladder Accumulator

Fig. 18 ABS Proportioning Valve

5 - 102 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 276 of 2438

As soon as the condition goes away, the Anti-Lock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ABS SYSTEMS DIAGNOSTICS

Bendix Anti-Lock 6 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section. Are accomplished by using the DRB II

scan tool. See testing procedures outlined in the Ben-

dix Anti-Lock 6 Diagnostics Manual for the 1992

M.Y. vehicles. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Anti-Lock 6

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Anti-Lock brake system

and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock Brake

System component damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) connector should never be connected or

disconnected with the ignition switch in the ON po-

sition. Many components of the Anti-Lock Brake System

are not serviceable and must be replaced as an as-

sembly. Do not disassemble any component which is

not designed to be serviced.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the fluid boiling point. Keep all brake fluid

containers capped to prevent contamination. Re-

move the front cap of the master cylinder reservoir

and fill to the bottom of the split ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

BLEEDING BENDIX ANTI-LOCK 6 BRAKE SYSTEM

The Anti-Lock Brake System must be bled anytime

air is permitted to enter the hydraulic system, due to

disconnection of brake lines, hoses of components. If the Modulator Assembly is removed from the ve-

hicle, both the Base Brake System and the Anti-Lock

Brake System must be bled using the appropriate

procedures. It is important to note that excessive air

in the brake system will cause a soft or spongy feel-

ing brake pedal. During bleeding operations, be sure that the brake

fluid level remains close to the FULL level in the

reservoir. Check the fluid level periodically during

the bleeding procedure and add DOT 3 brake fluid as

required. The Bendix Anti-Lock 6 Brake System must be

bled as two independent braking systems. The non

ABS portion of the brake system is to be bled the

same as any non ABS system. Refer to the Service

Adjustments section in this manual for the proper

bleeding procedure to be used. This brake system can

be either pressure bled or manually bled. The Anti-Lock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB II Diagnostic tester and the bleeding

sequence procedure outlined below.

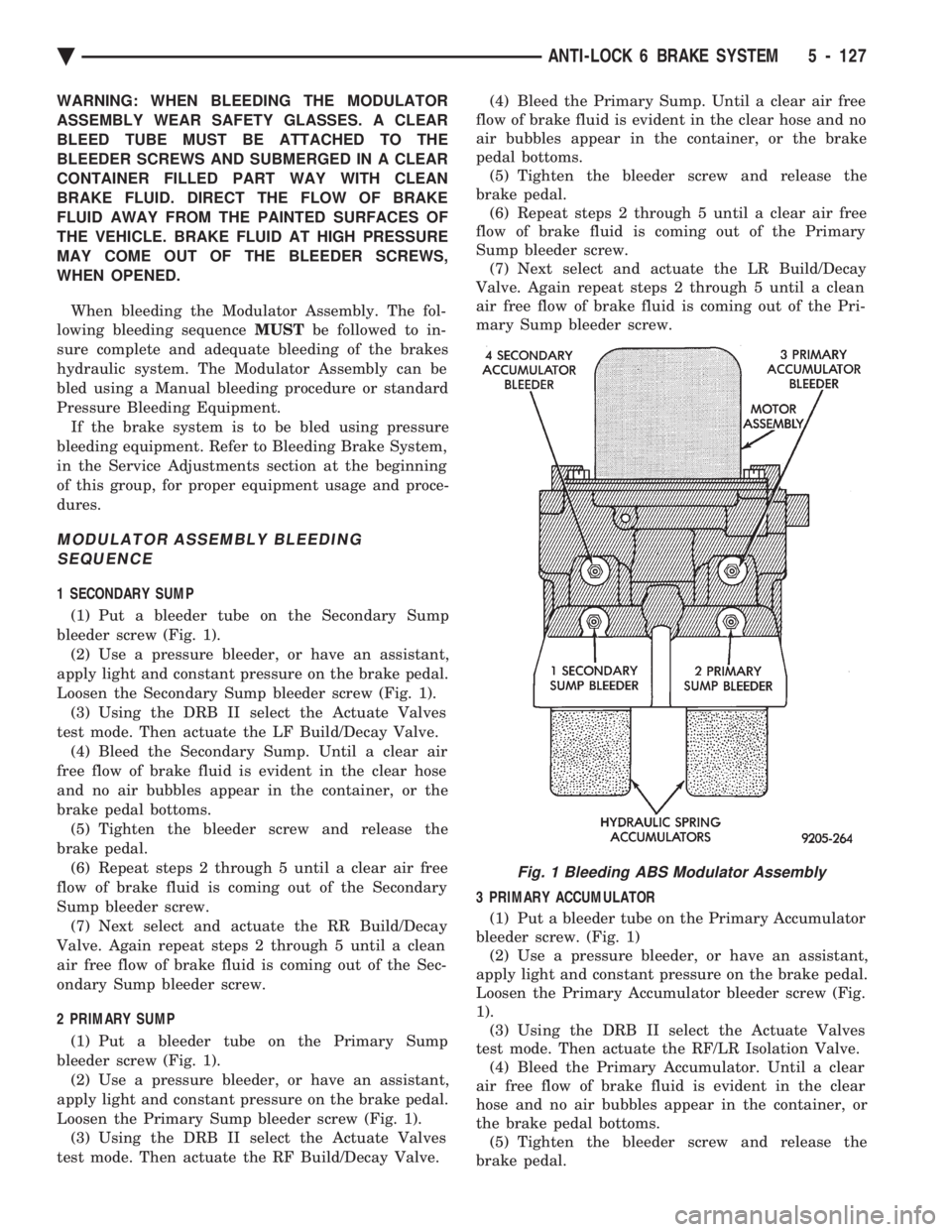

ABS BLEEDING PROCEDURE (FIG. 1)

(1) Assemble and install all brake system compo-

nents on vehicle making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system. Using the stan-

dard pressure or manual bleeding procedure as out-

lined in the Service Adjustments section of this

service manual. To perform the bleeding procedure on the ABS

unit. The battery and acid shield must be removed

from the vehicle. Reconnect the vehicles battery, to

the vehicles positive and negative battery cables us-

ing jumper cables. This is necessary to allow access

to the 4 bleeder screws located on the top of the Mod-

ulator assembly. (3) Connect the DRB II Diagnostics Tester to the

diagnostics connector. Located behind the Fuse Panel

access cover on the lower section of the dash panel to

the left of the steering column. (It is a blue 6 way

connector). (4) Using the DRB II check to make sure the

(CAB) does not have any fault codes stored. If it does

remove them using the DRB II.

5 - 126 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 277 of 2438

WARNING: WHEN BLEEDING THE MODULATOR

ASSEMBLY WEAR SAFETY GLASSES. A CLEAR

BLEED TUBE MUST BE ATTACHED TO THE

BLEEDER SCREWS AND SUBMERGED IN A CLEAR

CONTAINER FILLED PART WAY WITH CLEAN

BRAKE FLUID. DIRECT THE FLOW OF BRAKE

FLUID AWAY FROM THE PAINTED SURFACES OF

THE VEHICLE. BRAKE FLUID AT HIGH PRESSURE

MAY COME OUT OF THE BLEEDER SCREWS,

WHEN OPENED.

When bleeding the Modulator Assembly. The fol-

lowing bleeding sequence MUSTbe followed to in-

sure complete and adequate bleeding of the brakes

hydraulic system. The Modulator Assembly can be

bled using a Manual bleeding procedure or standard

Pressure Bleeding Equipment. If the brake system is to be bled using pressure

bleeding equipment. Refer to Bleeding Brake System,

in the Service Adjustments section at the beginning

of this group, for proper equipment usage and proce-

dures.

MODULATOR ASSEMBLY BLEEDING SEQUENCE

1 SECONDARY SUMP

(1) Put a bleeder tube on the Secondary Sump

bleeder screw (Fig. 1). (2) Use a pressure bleeder, or have an assistant,

apply light and constant pressure on the brake pedal.

Loosen the Secondary Sump bleeder screw (Fig. 1). (3) Using the DRB II select the Actuate Valves

test mode. Then actuate the LF Build/Decay Valve. (4) Bleed the Secondary Sump. Until a clear air

free flow of brake fluid is evident in the clear hose

and no air bubbles appear in the container, or the

brake pedal bottoms. (5) Tighten the bleeder screw and release the

brake pedal. (6) Repeat steps 2 through 5 until a clear air free

flow of brake fluid is coming out of the Secondary

Sump bleeder screw. (7) Next select and actuate the RR Build/Decay

Valve. Again repeat steps 2 through 5 until a clean

air free flow of brake fluid is coming out of the Sec-

ondary Sump bleeder screw.

2 PRIMARY SUMP

(1) Put a bleeder tube on the Primary Sump

bleeder screw (Fig. 1). (2) Use a pressure bleeder, or have an assistant,

apply light and constant pressure on the brake pedal.

Loosen the Primary Sump bleeder screw (Fig. 1). (3) Using the DRB II select the Actuate Valves

test mode. Then actuate the RF Build/Decay Valve. (4) Bleed the Primary Sump. Until a clear air free

flow of brake fluid is evident in the clear hose and no

air bubbles appear in the container, or the brake

pedal bottoms. (5) Tighten the bleeder screw and release the

brake pedal. (6) Repeat steps 2 through 5 until a clear air free

flow of brake fluid is coming out of the Primary

Sump bleeder screw. (7) Next select and actuate the LR Build/Decay

Valve. Again repeat steps 2 through 5 until a clean

air free flow of brake fluid is coming out of the Pri-

mary Sump bleeder screw.

3 PRIMARY ACCUMULATOR

(1) Put a bleeder tube on the Primary Accumulator

bleeder screw. (Fig. 1) (2) Use a pressure bleeder, or have an assistant,

apply light and constant pressure on the brake pedal.

Loosen the Primary Accumulator bleeder screw (Fig.

1). (3) Using the DRB II select the Actuate Valves

test mode. Then actuate the RF/LR Isolation Valve. (4) Bleed the Primary Accumulator. Until a clear

air free flow of brake fluid is evident in the clear

hose and no air bubbles appear in the container, or

the brake pedal bottoms. (5) Tighten the bleeder screw and release the

brake pedal.

Fig. 1 Bleeding ABS Modulator Assembly

Ä ANTI-LOCK 6 BRAKE SYSTEM 5 - 127

Page 289 of 2438

SERVICE ADJUSTMENTS INDEX

page page

Bleeding Bendix Antilock 4 Brake System ....... 3

Master Cylinder Fluid Level .................. 3 Testing for Fluid Contamination

............... 4

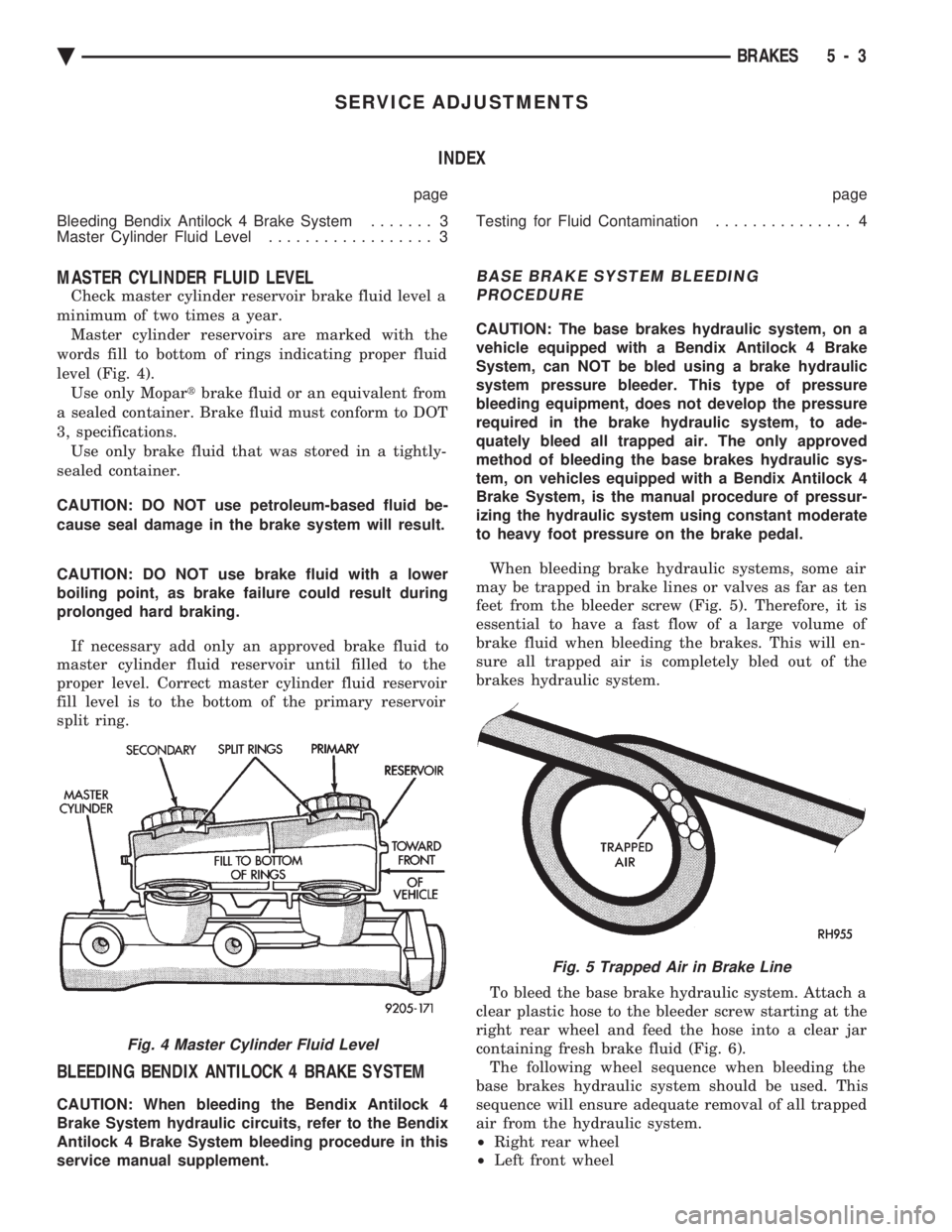

MASTER CYLINDER FLUID LEVEL

Check master cylinder reservoir brake fluid level a

minimum of two times a year. Master cylinder reservoirs are marked with the

words fill to bottom of rings indicating proper fluid

level (Fig. 4). Use only Mopar tbrake fluid or an equivalent from

a sealed container. Brake fluid must conform to DOT

3, specifications. Use only brake fluid that was stored in a tightly-

sealed container.

CAUTION: DO NOT use petroleum-based fluid be-

cause seal damage in the brake system will result.

CAUTION: DO NOT use brake fluid with a lower

boiling point, as brake failure could result during

prolonged hard braking.

If necessary add only an approved brake fluid to

master cylinder fluid reservoir until filled to the

proper level. Correct master cylinder fluid reservoir

fill level is to the bottom of the primary reservoir

split ring.

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM

CAUTION: When bleeding the Bendix Antilock 4

Brake System hydraulic circuits, refer to the Bendix

Antilock 4 Brake System bleeding procedure in this

service manual supplement.

BASE BRAKE SYSTEM BLEEDING PROCEDURE

CAUTION: The base brakes hydraulic system, on a

vehicle equipped with a Bendix Antilock 4 Brake

System, can NOT be bled using a brake hydraulic

system pressure bleeder. This type of pressure

bleeding equipment, does not develop the pressure

required in the brake hydraulic system, to ade-

quately bleed all trapped air. The only approved

method of bleeding the base brakes hydraulic sys-

tem, on vehicles equipped with a Bendix Antilock 4

Brake System, is the manual procedure of pressur-

izing the hydraulic system using constant moderate

to heavy foot pressure on the brake pedal.

When bleeding brake hydraulic systems, some air

may be trapped in brake lines or valves as far as ten

feet from the bleeder screw (Fig. 5). Therefore, it is

essential to have a fast flow of a large volume of

brake fluid when bleeding the brakes. This will en-

sure all trapped air is completely bled out of the

brakes hydraulic system.

To bleed the base brake hydraulic system. Attach a

clear plastic hose to the bleeder screw starting at the

right rear wheel and feed the hose into a clear jar

containing fresh brake fluid (Fig. 6). The following wheel sequence when bleeding the

base brakes hydraulic system should be used. This

sequence will ensure adequate removal of all trapped

air from the hydraulic system.

² Right rear wheel

² Left front wheel

Fig. 4 Master Cylinder Fluid Level

Fig. 5 Trapped Air in Brake Line

Ä BRAKES 5 - 3

Page 297 of 2438

The instrument panel bulb can be checked each

time the ignition switch is turned to the start posi-

tion or the parking brake is set.

HYDRAULIC SYSTEM SERVICE PROCEDURES

BRAKE WARNING SYSTEM

CHECKING BRAKE WARNING SWITCH UNIT

The Red Brake Warning light will come on when the

parking brake is applied with the ignition key turned

ON. The same light will also illuminate should one of

the two service brake hydraulic systems fail.

CAUTION:Make sure air does not enter the hydraulic

system during this test procedure. See bleeding with-

out a pressure bleeder at the beginning of this section

for master cylinder fluid level checking procedures.

To test the service brake warning system lamp.

Raise vehicle on a hoist and open a wheel cylinder

bleeder while a helper depresses the brake pedal and

observes the warning light.

If light fails to come on, inspect for a burned out bulb,

disconnected socket, or a broken or disconnected wire at

the switch. If the bulb is not burned out and the wire

continuity is not interrupted. Check the service brake

warning switch operation with a test lamp between the

switch terminal and a known good ground. Be sure to

fill master cylinder and bleed brake system after correc-

tion has been made, if necessary.

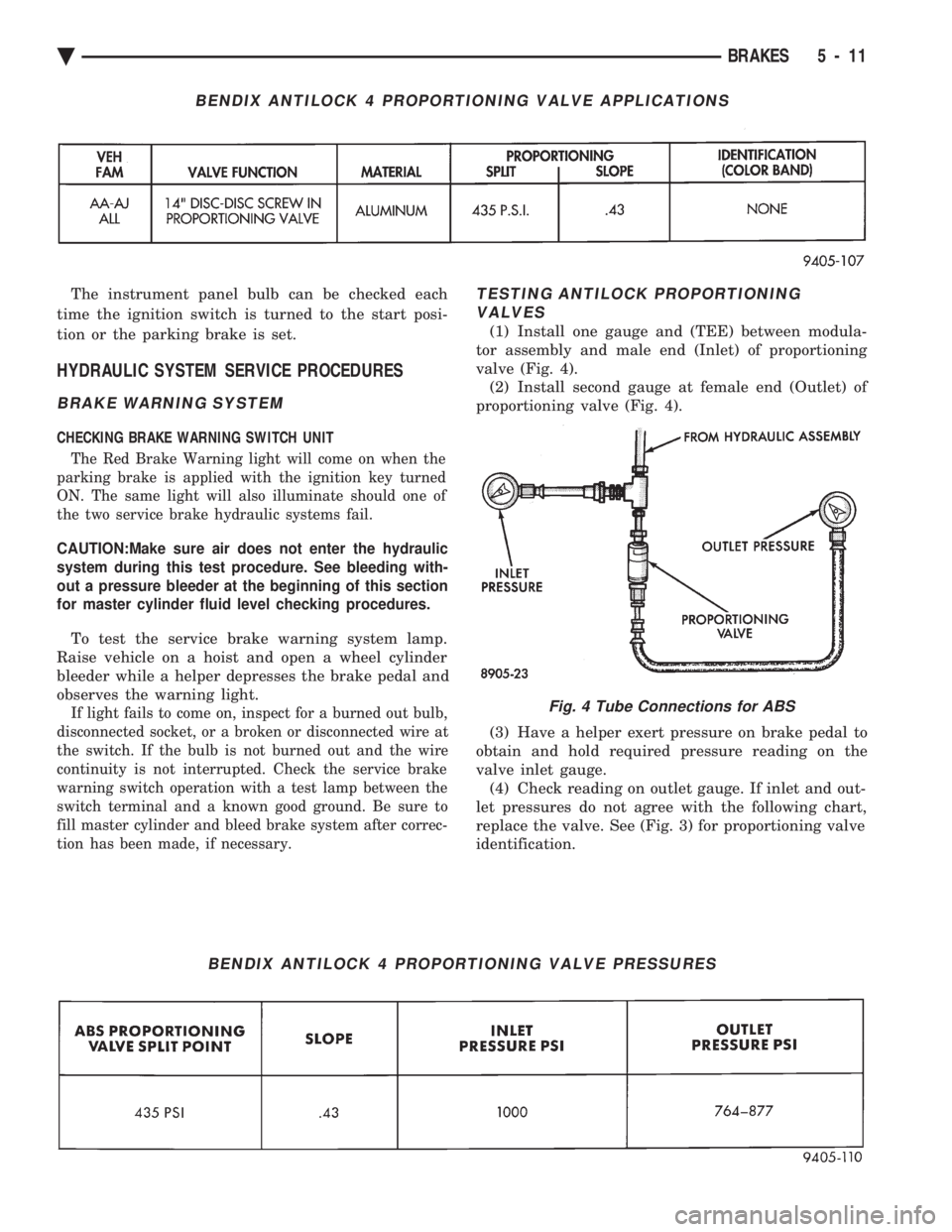

TESTING ANTILOCK PROPORTIONING VALVES

(1) Install one gauge and (TEE) between modula-

tor assembly and male end (Inlet) of proportioning

valve (Fig. 4). (2) Install second gauge at female end (Outlet) of

proportioning valve (Fig. 4).

(3) Have a helper exert pressure on brake pedal to

obtain and hold required pressure reading on the

valve inlet gauge. (4) Check reading on outlet gauge. If inlet and out-

let pressures do not agree with the following chart,

replace the valve. See (Fig. 3) for proportioning valve

identification.

BENDIX ANTILOCK 4 PROPORTIONING VALVE APPLICATIONS

BENDIX ANTILOCK 4 PROPORTIONING VALVE PRESSURES

Fig. 4 Tube Connections for ABS

Ä BRAKES 5 - 11

Page 311 of 2438

LATCHING VERSUS NON-LATCHING ABS FAULTS

Some faults detected by the CAB are latching; the

fault is latched and ABS is disabled until the igni-

tion switch is reset. Thus ABS is disabled even if the

original fault has disappeared. Other faults are non-

latching; any warning lights that are turned on, are

only turned on as long as the fault condition exists.

As soon as the condition goes away, the Antilock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ANTILOCK 4 BRAKE SYSTEM DIAGNOSTICS

Bendix Antilock 4 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section, are accomplished by using the DRB scan

tool. See testing procedures outlined in the 1994 Ben-

dix Antilock 4 Diagnostics Manual. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Antilock 4

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Bendix Antilock 4

Brake System and other vehicle electronic systems.

Failure to observe these precautions may result in

Antilock Brake System component damage. If welding work is to be performed on a vehicle us-

ing an electric arc welder, disconnect the 60 way wir-

ing harness connector from the CAB, prior to

performing the welding operation. The wiring harness connector should never be con-

nected or disconnected from the CAB with the igni-

tion key in the ON or Run position. (3) Most components making up the assemblies of

the Bendix Antilock 4 Brake System can not be ser-

viced separately from those assemblies. This will re-

quire replacement of the complete assembly for the

servicing of these components. Do not disassemble

any component from an assembly which is desig-

nated as non-serviceable.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the boiling point of the brake fluid, possibly causing brake fluid to boil resulting in brake fade.

Keep all brake fluid containers capped to prevent

contamination. Remove the front cap of the master

cylinder reservoir and fill to the bottom of the split

ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

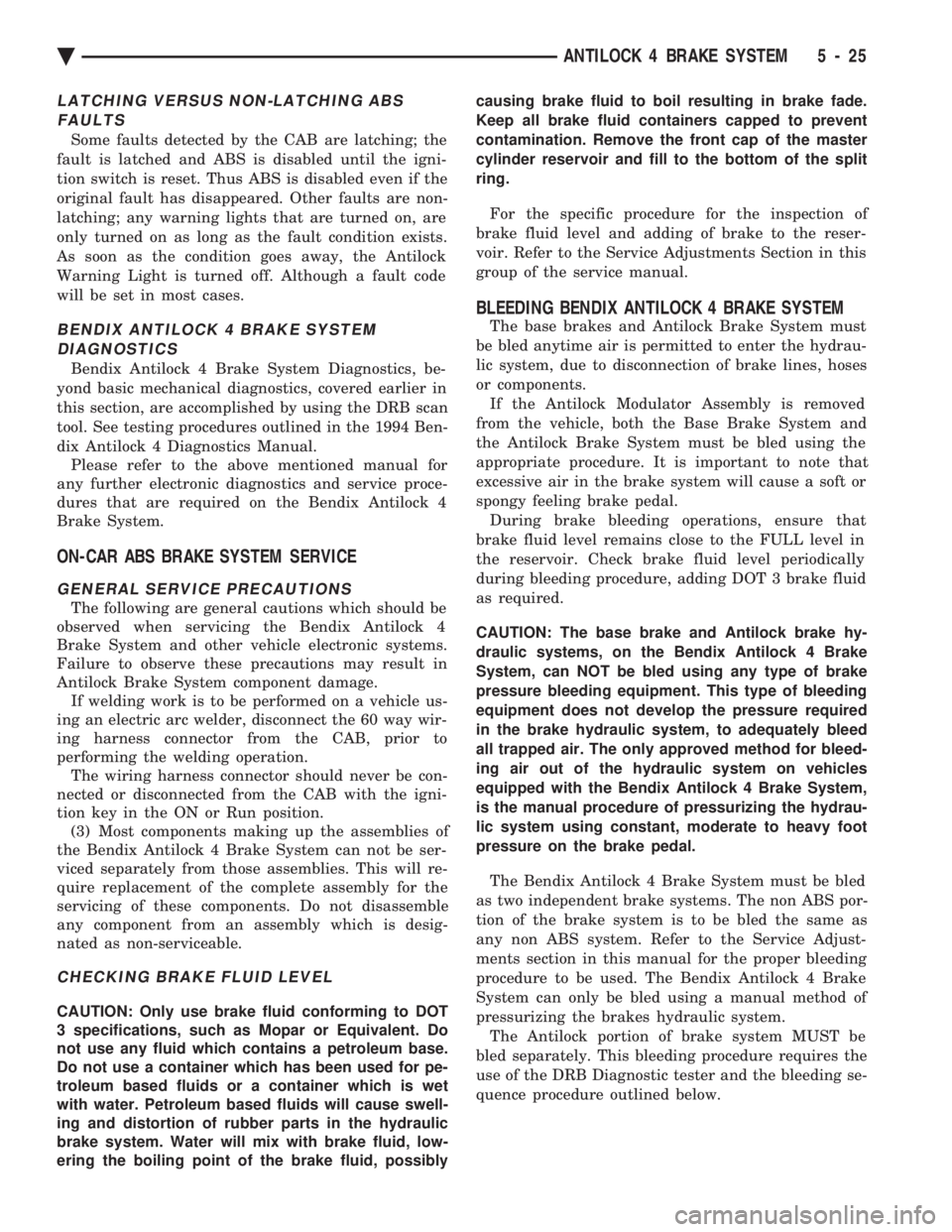

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM

The base brakes and Antilock Brake System must

be bled anytime air is permitted to enter the hydrau-

lic system, due to disconnection of brake lines, hoses

or components. If the Antilock Modulator Assembly is removed

from the vehicle, both the Base Brake System and

the Antilock Brake System must be bled using the

appropriate procedure. It is important to note that

excessive air in the brake system will cause a soft or

spongy feeling brake pedal. During brake bleeding operations, ensure that

brake fluid level remains close to the FULL level in

the reservoir. Check brake fluid level periodically

during bleeding procedure, adding DOT 3 brake fluid

as required.

CAUTION: The base brake and Antilock brake hy-

draulic systems, on the Bendix Antilock 4 Brake

System, can NOT be bled using any type of brake

pressure bleeding equipment. This type of bleeding

equipment does not develop the pressure required

in the brake hydraulic system, to adequately bleed

all trapped air. The only approved method for bleed-

ing air out of the hydraulic system on vehicles

equipped with the Bendix Antilock 4 Brake System,

is the manual procedure of pressurizing the hydrau-

lic system using constant, moderate to heavy foot

pressure on the brake pedal.

The Bendix Antilock 4 Brake System must be bled

as two independent brake systems. The non ABS por-

tion of the brake system is to be bled the same as

any non ABS system. Refer to the Service Adjust-

ments section in this manual for the proper bleeding

procedure to be used. The Bendix Antilock 4 Brake

System can only be bled using a manual method of

pressurizing the brakes hydraulic system. The Antilock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB Diagnostic tester and the bleeding se-

quence procedure outlined below.

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 25

Page 312 of 2438

BENDIX ANTILOCK 4 MODULATOR ASSEMBLY BLEEDING PROCEDURE

(1) Assemble and install all brake system compo-

nents on the vehicle, making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system, using ONLYthe

bleeding procedure outlined in the Service Adjust-

ments section of this service manual supplement. To perform the bleeding procedure on the ABS modu-

lator assembly, the battery, battery tray and acid shield

must be removed from vehicle. Then reconnect the

vehicle's battery to vehicle's battery cables, using

ONLY approved battery jumper cables. (3) Connect the DRB Diagnostics Tester to the vehi-

cle's diagnostics connector. The vehicle diagnostic con-

nector is located behind the fuse panel access cover on

the lower section of the dash panel left of the steering

column. The diagnostic connector is a blue 6 way

connector. (4) Using the DRB check to make sure the CAB does

not have any stored fault codes. If it does, remove them

using the DRB.

WARNING: WHEN BLEEDING THE MODULATOR AS-

SEMBLY WEAR SAFETY GLASSES. A CLEAR BLEED

TUBE MUST BE ATTACHED TO THE MODULATOR

BLEED SCREWS AND SUBMERGED IN A CLEAR

CONTAINER FILLED PART WAY WITH FRESH CLEAN

BRAKE FLUID. DIRECT THE FLOW OF BRAKE FLUID

AWAY FROM THE PAINTED SURFACES OF THE VE-

HICLE. BRAKE FLUID AT HIGH PRESSURE MAY

COME OUT OF THE BLEEDER SCREWS, WHEN

OPENED.

When bleeding Antilock modulator assembly, the

following bleeding sequence MUSTbe followed to

insure a complete bleeding of all air from the Antilock

brake, and base brake hydraulic systems. The modu-

lator assembly can ONLY be bled using a manual

bleeding procedure to pressurize the hydraulic

system.

MODULATOR ASSEMBLY CIRCUIT BLEEDING PROCEDURE AND SEQUENCE

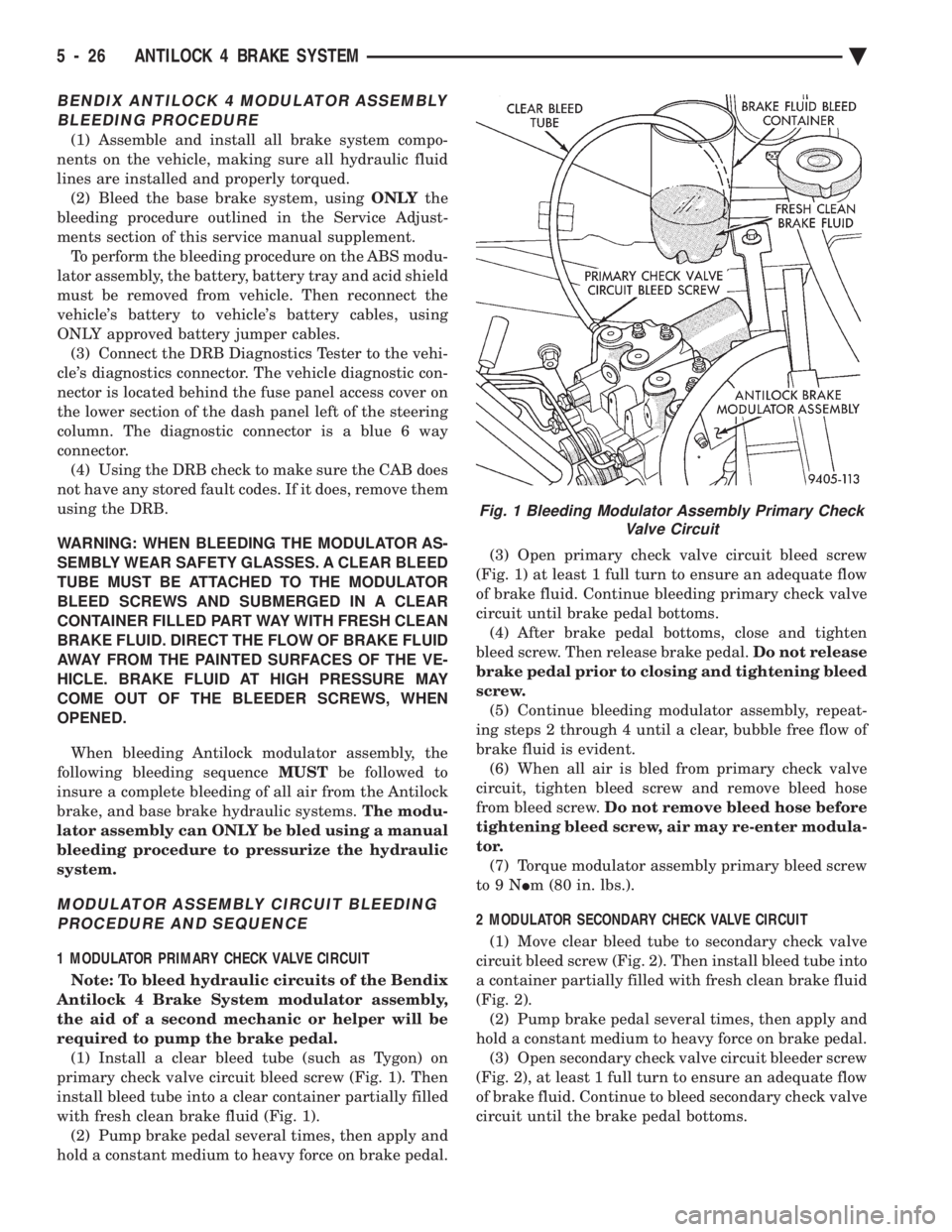

1 MODULATOR PRIMARY CHECK VALVE CIRCUIT

Note: To bleed hydraulic circuits of the Bendix

Antilock 4 Brake System modulator assembly,

the aid of a second mechanic or helper will be

required to pump the brake pedal. (1) Install a clear bleed tube (such as Tygon) on

primary check valve circuit bleed screw (Fig. 1). Then

install bleed tube into a clear container partially filled

with fresh clean brake fluid (Fig. 1). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open primary check valve circuit bleed screw

(Fig. 1) at least 1 full turn to ensure an adequate flow

of brake fluid. Continue bleeding primary check valve

circuit until brake pedal bottoms. (4) After brake pedal bottoms, close and tighten

bleed screw. Then release brake pedal. Do not release

brake pedal prior to closing and tightening bleed

screw. (5) Continue bleeding modulator assembly, repeat-

ing steps 2 through 4 until a clear, bubble free flow of

brake fluid is evident. (6) When all air is bled from primary check valve

circuit, tighten bleed screw and remove bleed hose

from bleed screw. Do not remove bleed hose before

tightening bleed screw, air may re-enter modula-

tor. (7) Torque modulator assembly primary bleed screw

to9N Im (80 in. lbs.).

2 MODULATOR SECONDARY CHECK VALVE CIRCUIT (1) Move clear bleed tube to secondary check valve

circuit bleed screw (Fig. 2). Then install bleed tube into

a container partially filled with fresh clean brake fluid

(Fig. 2). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open secondary check valve circuit bleeder screw

(Fig. 2), at least 1 full turn to ensure an adequate flow

of brake fluid. Continue to bleed secondary check valve

circuit until the brake pedal bottoms.

Fig. 1 Bleeding Modulator Assembly Primary Check Valve Circuit

5 - 26 ANTILOCK 4 BRAKE SYSTEM Ä

Page 313 of 2438

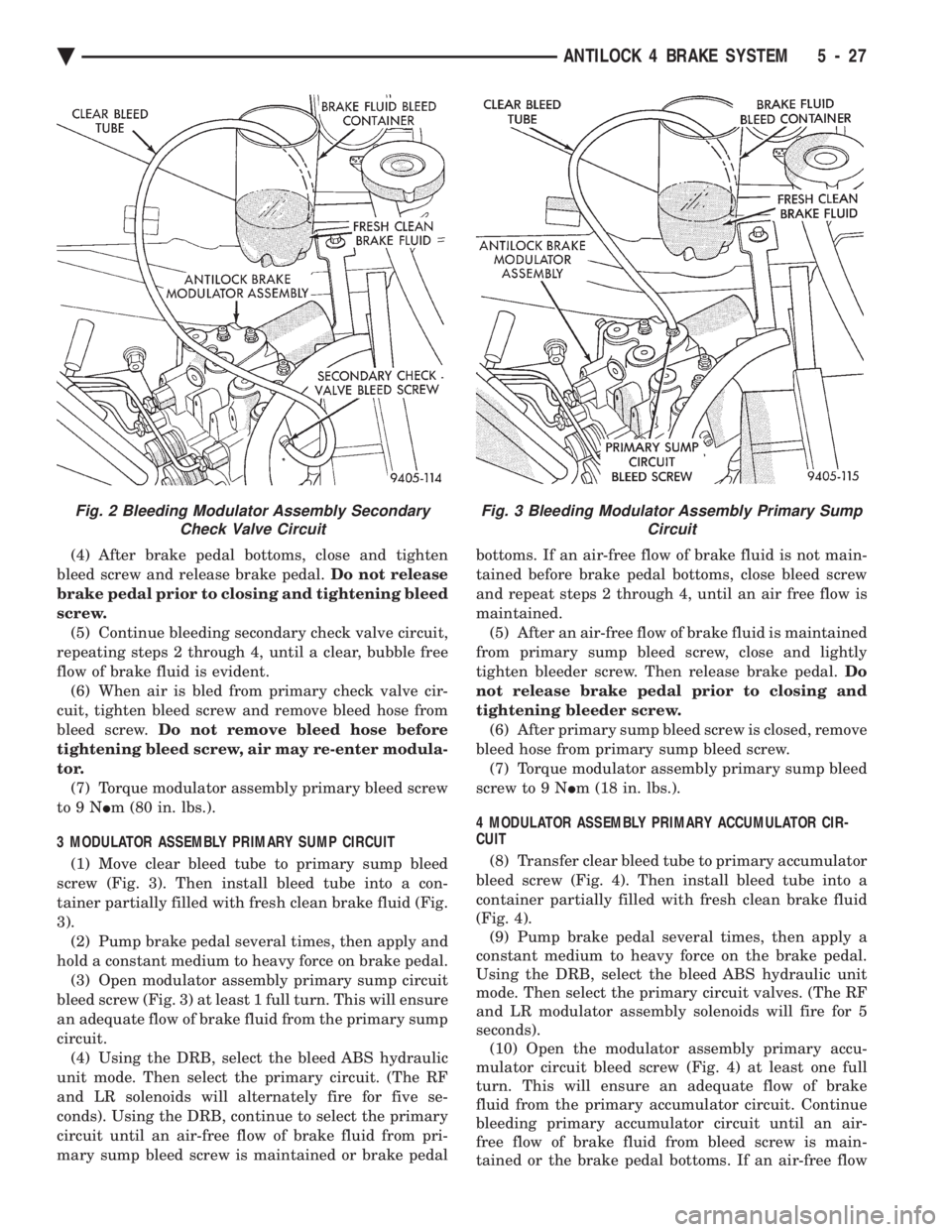

(4) After brake pedal bottoms, close and tighten

bleed screw and release brake pedal. Do not release

brake pedal prior to closing and tightening bleed

screw. (5) Continue bleeding secondary check valve circuit,

repeating steps 2 through 4, until a clear, bubble free

flow of brake fluid is evident. (6) When air is bled from primary check valve cir-

cuit, tighten bleed screw and remove bleed hose from

bleed screw. Do not remove bleed hose before

tightening bleed screw, air may re-enter modula-

tor. (7) Torque modulator assembly primary bleed screw

to9N Im (80 in. lbs.).

3 MODULATOR ASSEMBLY PRIMARY SUMP CIRCUIT (1) Move clear bleed tube to primary sump bleed

screw (Fig. 3). Then install bleed tube into a con-

tainer partially filled with fresh clean brake fluid (Fig.

3). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open modulator assembly primary sump circuit

bleed screw (Fig. 3) at least 1 full turn. This will ensure

an adequate flow of brake fluid from the primary sump

circuit. (4) Using the DRB, select the bleed ABS hydraulic

unit mode. Then select the primary circuit. (The RF

and LR solenoids will alternately fire for five se-

conds). Using the DRB, continue to select the primary

circuit until an air-free flow of brake fluid from pri-

mary sump bleed screw is maintained or brake pedal bottoms. If an air-free flow of brake fluid is not main-

tained before brake pedal bottoms, close bleed screw

and repeat steps 2 through 4, until an air free flow is

maintained.

(5) After an air-free flow of brake fluid is maintained

from primary sump bleed screw, close and lightly

tighten bleeder screw. Then release brake pedal. Do

not release brake pedal prior to closing and

tightening bleeder screw. (6) After primary sump bleed screw is closed, remove

bleed hose from primary sump bleed screw. (7) Torque modulator assembly primary sump bleed

screw to 9 N Im (18 in. lbs.).

4 MODULATOR ASSEMBLY PRIMARY ACCUMULATOR CIR-

CUIT

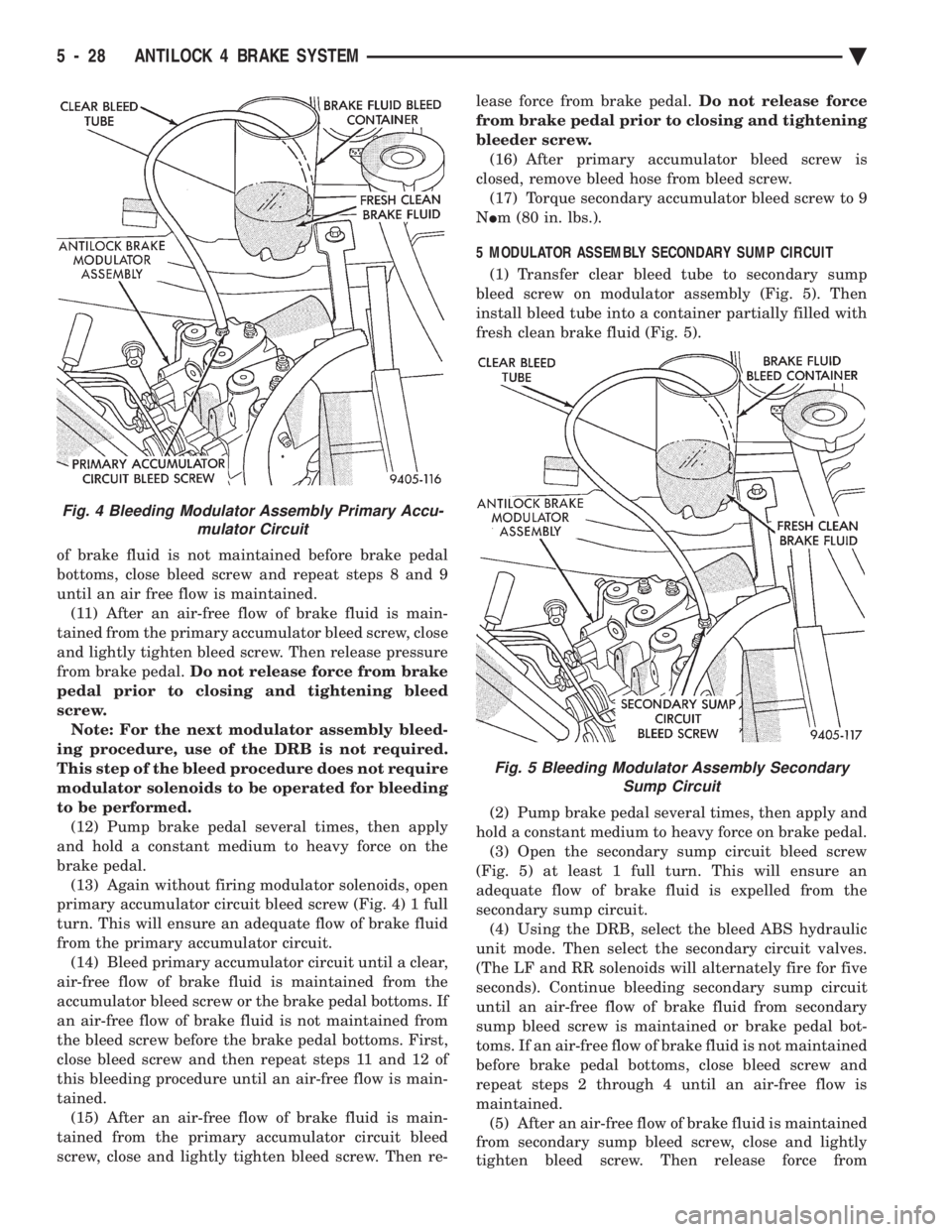

(8) Transfer clear bleed tube to primary accumulator

bleed screw (Fig. 4). Then install bleed tube into a

container partially filled with fresh clean brake fluid

(Fig. 4). (9) Pump brake pedal several times, then apply a

constant medium to heavy force on the brake pedal.

Using the DRB, select the bleed ABS hydraulic unit

mode. Then select the primary circuit valves. (The RF

and LR modulator assembly solenoids will fire for 5

seconds). (10) Open the modulator assembly primary accu-

mulator circuit bleed screw (Fig. 4) at least one full

turn. This will ensure an adequate flow of brake

fluid from the primary accumulator circuit. Continue

bleeding primary accumulator circuit until an air-

free flow of brake fluid from bleed screw is main-

tained or the brake pedal bottoms. If an air-free flow

Fig. 3 Bleeding Modulator Assembly Primary Sump CircuitFig. 2 Bleeding Modulator Assembly SecondaryCheck Valve Circuit

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 27

Page 314 of 2438

of brake fluid is not maintained before brake pedal

bottoms, close bleed screw and repeat steps 8 and 9

until an air free flow is maintained.(11) After an air-free flow of brake fluid is main-

tained from the primary accumulator bleed screw, close

and lightly tighten bleed screw. Then release pressure

from brake pedal. Do not release force from brake

pedal prior to closing and tightening bleed

screw. Note: For the next modulator assembly bleed-

ing procedure, use of the DRB is not required.

This step of the bleed procedure does not require

modulator solenoids to be operated for bleeding

to be performed. (12) Pump brake pedal several times, then apply

and hold a constant medium to heavy force on the

brake pedal. (13) Again without firing modulator solenoids, open

primary accumulator circuit bleed screw (Fig. 4) 1 full

turn. This will ensure an adequate flow of brake fluid

from the primary accumulator circuit. (14) Bleed primary accumulator circuit until a clear,

air-free flow of brake fluid is maintained from the

accumulator bleed screw or the brake pedal bottoms. If

an air-free flow of brake fluid is not maintained from

the bleed screw before the brake pedal bottoms. First,

close bleed screw and then repeat steps 11 and 12 of

this bleeding procedure until an air-free flow is main-

tained. (15) After an air-free flow of brake fluid is main-

tained from the primary accumulator circuit bleed

screw, close and lightly tighten bleed screw. Then re- lease force from brake pedal.

Do not release force

from brake pedal prior to closing and tightening

bleeder screw. (16) After primary accumulator bleed screw is

closed, remove bleed hose from bleed screw. (17) Torque secondary accumulator bleed screw to 9

N Im (80 in. lbs.).

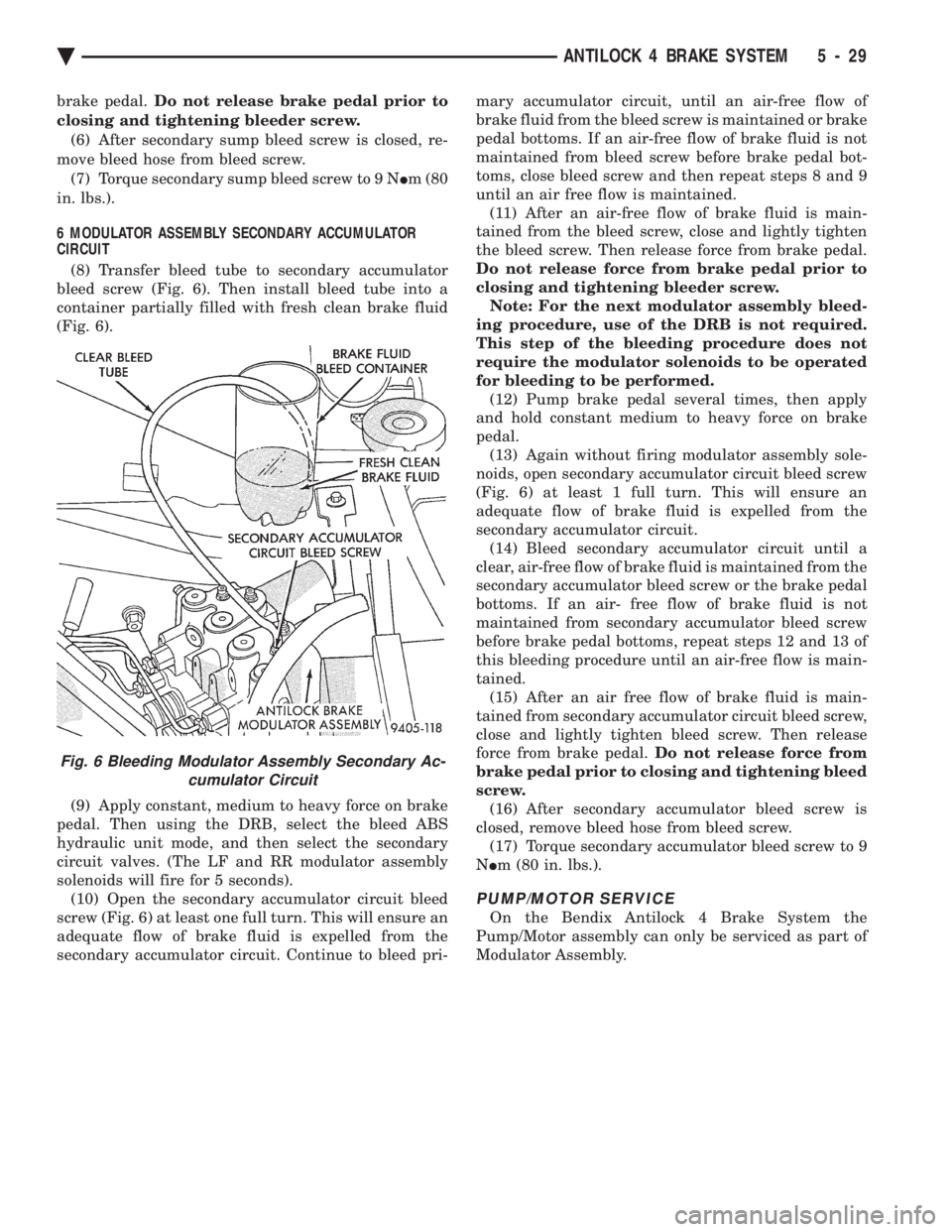

5 MODULATOR ASSEMBLY SECONDARY SUMP CIRCUIT (1) Transfer clear bleed tube to secondary sump

bleed screw on modulator assembly (Fig. 5). Then

install bleed tube into a container partially filled with

fresh clean brake fluid (Fig. 5).

(2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open the secondary sump circuit bleed screw

(Fig. 5) at least 1 full turn. This will ensure an

adequate flow of brake fluid is expelled from the

secondary sump circuit. (4) Using the DRB, select the bleed ABS hydraulic

unit mode. Then select the secondary circuit valves.

(The LF and RR solenoids will alternately fire for five

seconds). Continue bleeding secondary sump circuit

until an air-free flow of brake fluid from secondary

sump bleed screw is maintained or brake pedal bot-

toms. If an air-free flow of brake fluid is not maintained

before brake pedal bottoms, close bleed screw and

repeat steps 2 through 4 until an air-free flow is

maintained. (5) After an air-free flow of brake fluid is maintained

from secondary sump bleed screw, close and lightly

tighten bleed screw. Then release force from

Fig. 4 Bleeding Modulator Assembly Primary Accu- mulator Circuit

Fig. 5 Bleeding Modulator Assembly SecondarySump Circuit

5 - 28 ANTILOCK 4 BRAKE SYSTEM Ä

Page 315 of 2438

brake pedal. Do not release brake pedal prior to

closing and tightening bleeder screw. (6) After secondary sump bleed screw is closed, re-

move bleed hose from bleed screw. (7) Torque secondary sump bleed screw to 9 N Im (80

in. lbs.).

6 MODULATOR ASSEMBLY SECONDARY ACCUMULATOR

CIRCUIT

(8) Transfer bleed tube to secondary accumulator

bleed screw (Fig. 6). Then install bleed tube into a

container partially filled with fresh clean brake fluid

(Fig. 6).

(9) Apply constant, medium to heavy force on brake

pedal. Then using the DRB, select the bleed ABS

hydraulic unit mode, and then select the secondary

circuit valves. (The LF and RR modulator assembly

solenoids will fire for 5 seconds). (10) Open the secondary accumulator circuit bleed

screw (Fig. 6) at least one full turn. This will ensure an

adequate flow of brake fluid is expelled from the

secondary accumulator circuit. Continue to bleed pri- mary accumulator circuit, until an air-free flow of

brake fluid from the bleed screw is maintained or brake

pedal bottoms. If an air-free flow of brake fluid is not

maintained from bleed screw before brake pedal bot-

toms, close bleed screw and then repeat steps 8 and 9

until an air free flow is maintained. (11) After an air-free flow of brake fluid is main-

tained from the bleed screw, close and lightly tighten

the bleed screw. Then release force from brake pedal.

Do not release force from brake pedal prior to

closing and tightening bleeder screw. Note: For the next modulator assembly bleed-

ing procedure, use of the DRB is not required.

This step of the bleeding procedure does not

require the modulator solenoids to be operated

for bleeding to be performed. (12) Pump brake pedal several times, then apply

and hold constant medium to heavy force on brake

pedal. (13) Again without firing modulator assembly sole-

noids, open secondary accumulator circuit bleed screw

(Fig. 6) at least 1 full turn. This will ensure an

adequate flow of brake fluid is expelled from the

secondary accumulator circuit. (14) Bleed secondary accumulator circuit until a

clear, air-free flow of brake fluid is maintained from the

secondary accumulator bleed screw or the brake pedal

bottoms. If an air- free flow of brake fluid is not

maintained from secondary accumulator bleed screw

before brake pedal bottoms, repeat steps 12 and 13 of

this bleeding procedure until an air-free flow is main-

tained. (15) After an air free flow of brake fluid is main-

tained from secondary accumulator circuit bleed screw,

close and lightly tighten bleed screw. Then release

force from brake pedal. Do not release force from

brake pedal prior to closing and tightening bleed

screw. (16) After secondary accumulator bleed screw is

closed, remove bleed hose from bleed screw. (17) Torque secondary accumulator bleed screw to 9

N Im (80 in. lbs.).

PUMP/MOTOR SERVICE

On the Bendix Antilock 4 Brake System the

Pump/Motor assembly can only be serviced as part of

Modulator Assembly.

Fig. 6 Bleeding Modulator Assembly Secondary Ac- cumulator Circuit

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 29