oil dipstick CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1920 of 2438

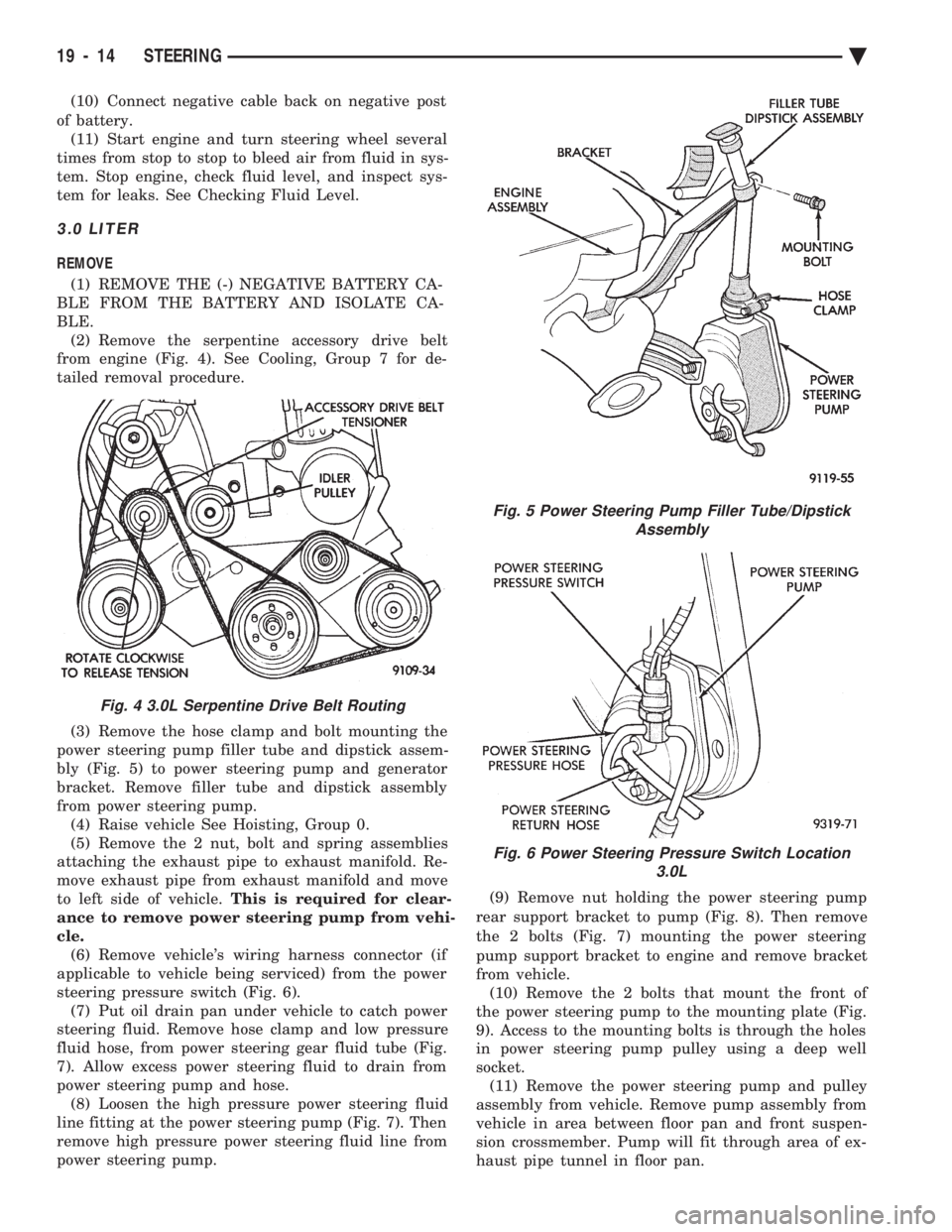

cle and or engine application the Saginaw T/C style

power steering pump is used on, it will be equipped

with a plastic integral or remote mounted power

steering fluid reservoir. Drive tangs on the power steering gear pinion, mate

loosely with the stub shaft of the steering gear. This

will allow manual steering control to be maintained, if

the drive belt on the power steering pump should

break. However, under these conditions, steering effort

will significantly increase.

STEERING COMPONENTS SERVICE DIAGNOSIS

POWER STEERING PUMP SERVICE

The service procedures for the Saginaw power steer-

ing pump are limited to the areas and components

listed below. No repair procedures are to be done

on internal components of the Saginaw power

steering pumps.

² Repair of power steering fluid leaks from areas of

the power steering pump sealed by O-rings is allowed

(See Pump Leak Diagnosis). However power steering

pump shaft seal leakage will require replacement of

the pump.

² Power steering fluid reservoirs, related components

and attaching hardware.

² Power steering fluid reservoir filler cap/dipstick as-

semblies. Because of unique shaft bearings, flow control levels

or pump displacements, power steering pumps may be

used only on specific vehicle applications. Be sure that

all power steering pumps are only replaced with a

pump that is the correct replacement for that specific

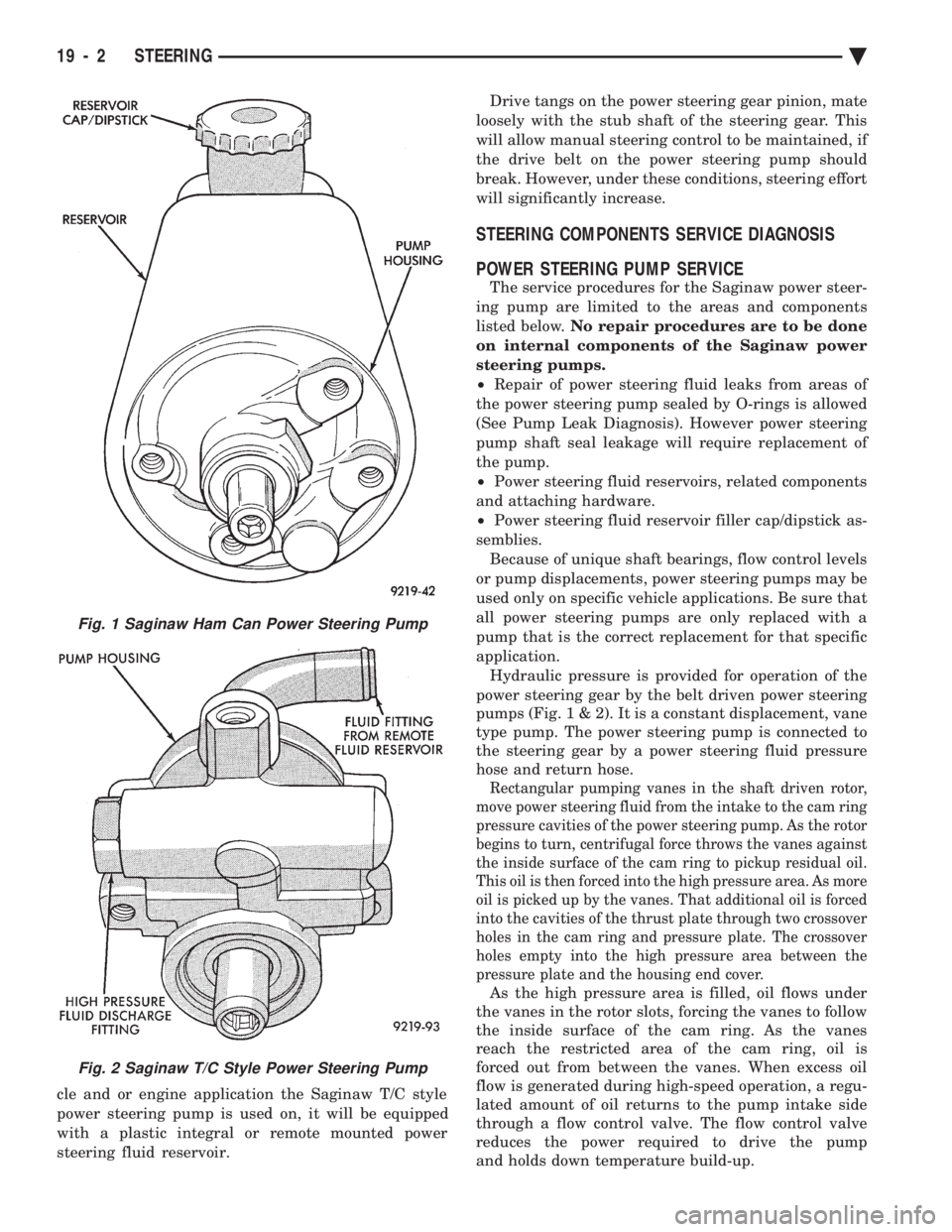

application. Hydraulic pressure is provided for operation of the

power steering gear by the belt driven power steering

pumps (Fig . 1 & 2). It is a constant displacement, vane

type pump. The power steering pump is connected to

the steering gear by a power steering fluid pressure

hose and return hose.

Rectangular pumping vanes in the shaft driven rotor,

move power steering fluid from the intake to the cam ring

pressure cavities of the power steering pump. As the rotor

begins to turn, centrifugal force throws the vanes against

the inside surface of the cam ring to pickup residual oil.

This oil is then forced into the high pressure area. As more

oil is picked up by the vanes. That additional oil is forced

into the cavities of the thrust plate through two crossover

holes in the cam ring and pressure plate. The crossover

holes empty into the high pressure area between the

pressure plate and the housing end cover.

As the high pressure area is filled, oil flows under

the vanes in the rotor slots, forcing the vanes to follow

the inside surface of the cam ring. As the vanes

reach the restricted area of the cam ring, oil is

forced out from between the vanes. When excess oil

flow is generated during high-speed operation, a regu-

lated amount of oil returns to the pump intake side

through a flow control valve. The flow control valve

reduces the power required to drive the pump

and holds down temperature build-up.

Fig. 1 Saginaw Ham Can Power Steering Pump

Fig. 2 Saginaw T/C Style Power Steering Pump

19 - 2 STEERING Ä

Page 1927 of 2438

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the re-

lief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level. Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to re-

main closed.

CHECKING POWER STEERING FLUID LEVEL

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt, before check-

ing power steering fluid level. The dipstick should in- dicate FULL COLD when fluid is at normal ambient

temperature, approximately 21ÉC to 27ÉC (70ÉF to

80ÉF). In all pumps add fluid as necessary to obtain

proper level, using only MopartPower Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP PRESSURE TEST

The following procedure can be used to test the op-

eration of the power steering system on the vehicle. (1) Check power steering pump drive belt tension

and adjust as necessary. (2) Disconnect power steering fluid pressure hose,

at steering gear or power steering pump. Use a con-

tainer for dripping fluid. (3) Connect Pressure Gauge, Special Tool C-3309-E

(Fig. 1) to both hoses using adapter fittings. Connect

spare pressure hose to gear or pump. (4) Completely open valve on Special Tool

C-3309-E (Fig. 1). (5) Start engine and let idle.

(6) Check power steering fluid level, and add fluid

as necessary. (7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).

PUMP LEAKAGE DIAGNOSIS

Ä STEERING 19 - 9

Page 1932 of 2438

(10) Connect negative cable back on negative post

of battery. (11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.0 LITER

REMOVE

(1) REMOVE THE (-) NEGATIVE BATTERY CA-

BLE FROM THE BATTERY AND ISOLATE CA-

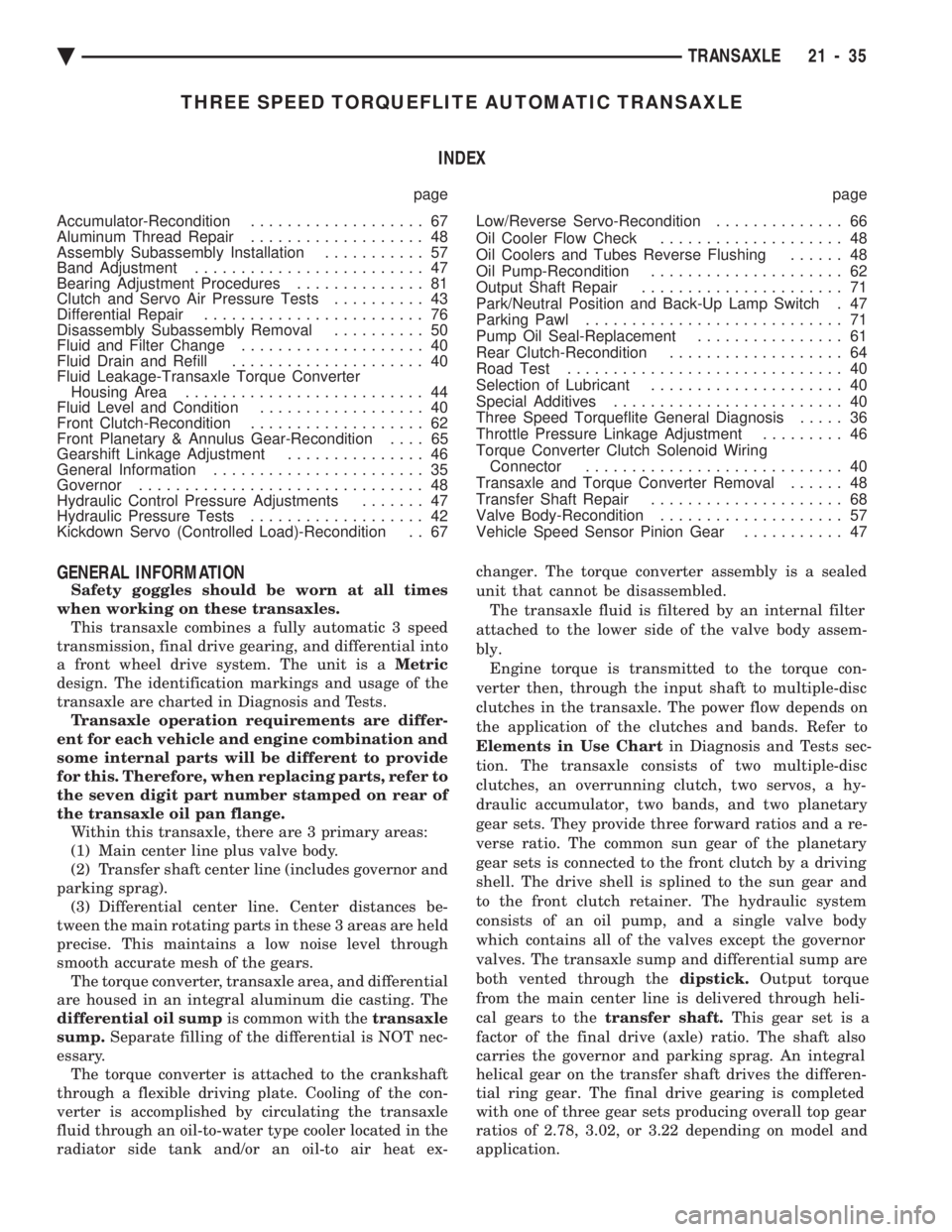

BLE. (2) Remove the serpentine accessory drive belt

from engine (Fig. 4). See Cooling, Group 7 for de-

tailed removal procedure.

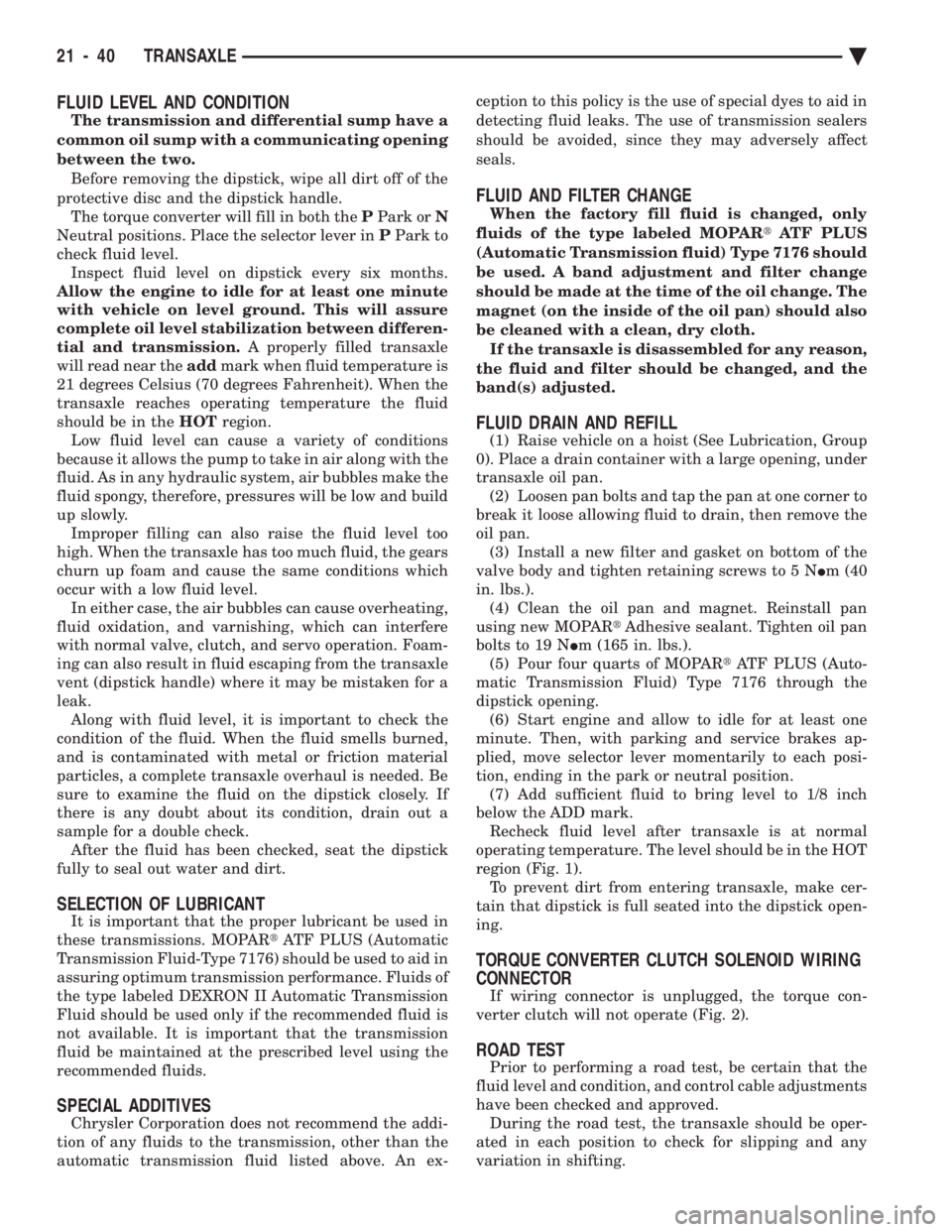

(3) Remove the hose clamp and bolt mounting the

power steering pump filler tube and dipstick assem-

bly (Fig. 5) to power steering pump and generator

bracket. Remove filler tube and dipstick assembly

from power steering pump. (4) Raise vehicle See Hoisting, Group 0.

(5) Remove the 2 nut, bolt and spring assemblies

attaching the exhaust pipe to exhaust manifold. Re-

move exhaust pipe from exhaust manifold and move

to left side of vehicle. This is required for clear-

ance to remove power steering pump from vehi-

cle. (6) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig. 6). (7) Put oil drain pan under vehicle to catch power

steering fluid. Remove hose clamp and low pressure

fluid hose, from power steering gear fluid tube (Fig.

7). Allow excess power steering fluid to drain from

power steering pump and hose. (8) Loosen the high pressure power steering fluid

line fitting at the power steering pump (Fig. 7). Then

remove high pressure power steering fluid line from

power steering pump. (9) Remove nut holding the power steering pump

rear support bracket to pump (Fig. 8). Then remove

the 2 bolts (Fig. 7) mounting the power steering

pump support bracket to engine and remove bracket

from vehicle. (10) Remove the 2 bolts that mount the front of

the power steering pump to the mounting plate (Fig.

9). Access to the mounting bolts is through the holes

in power steering pump pulley using a deep well

socket. (11) Remove the power steering pump and pulley

assembly from vehicle. Remove pump assembly from

vehicle in area between floor pan and front suspen-

sion crossmember. Pump will fit through area of ex-

haust pipe tunnel in floor pan.

Fig. 4 3.0L Serpentine Drive Belt Routing

Fig. 5 Power Steering Pump Filler Tube/Dipstick Assembly

Fig. 6 Power Steering Pressure Switch Location 3.0L

19 - 14 STEERING Ä

Page 1995 of 2438

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE INDEX

page page

Accumulator-Recondition ................... 67

Aluminum Thread Repair ................... 48

Assembly Subassembly Installation ........... 57

Band Adjustment ......................... 47

Bearing Adjustment Procedures .............. 81

Clutch and Servo Air Pressure Tests .......... 43

Differential Repair ........................ 76

Disassembly Subassembly Removal .......... 50

Fluid and Filter Change .................... 40

Fluid Drain and Refill ..................... 40

Fluid Leakage-Transaxle Torque Converter Housing Area .......................... 44

Fluid Level and Condition .................. 40

Front Clutch-Recondition ................... 62

Front Planetary & Annulus Gear-Recondition .... 65

Gearshift Linkage Adjustment ............... 46

General Information ....................... 35

Governor ............................... 48

Hydraulic Control Pressure Adjustments ....... 47

Hydraulic Pressure Tests ................... 42

Kickdown Servo (Controlled Load)-Recondition . . 67 Low/Reverse Servo-Recondition

.............. 66

Oil Cooler Flow Check .................... 48

Oil Coolers and Tubes Reverse Flushing ...... 48

Oil Pump-Recondition ..................... 62

Output Shaft Repair ...................... 71

Park/Neutral Position and Back-Up Lamp Switch . 47

Parking Pawl ............................ 71

Pump Oil Seal-Replacement ................ 61

Rear Clutch-Recondition ................... 64

Road Test .............................. 40

Selection of Lubricant ..................... 40

Special Additives ......................... 40

Three Speed Torqueflite General Diagnosis ..... 36

Throttle Pressure Linkage Adjustment ......... 46

Torque Converter Clutch Solenoid Wiring Connector ............................ 40

Transaxle and Torque Converter Removal ...... 48

Transfer Shaft Repair ..................... 68

Valve Body-Recondition .................... 57

Vehicle Speed Sensor Pinion Gear ........... 47

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on these transaxles. This transaxle combines a fully automatic 3 speed

transmission, final drive gearing, and differential into

a front wheel drive system. The unit is a Metric

design. The identification markings and usage of the

transaxle are charted in Diagnosis and Tests. Transaxle operation requirements are differ-

ent for each vehicle and engine combination and

some internal parts will be different to provide

for this. Therefore, when replacing parts, refer to

the seven digit part number stamped on rear of

the transaxle oil pan flange. Within this transaxle, there are 3 primary areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor and

parking sprag). (3) Differential center line. Center distances be-

tween the main rotating parts in these 3 areas are held

precise. This maintains a low noise level through

smooth accurate mesh of the gears. The torque converter, transaxle area, and differential

are housed in an integral aluminum die casting. The

differential oil sump is common with thetransaxle

sump. Separate filling of the differential is NOT nec-

essary. The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through an oil-to-water type cooler located in the

radiator side tank and/or an oil-to air heat ex- changer. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assem-

bly. Engine torque is transmitted to the torque con-

verter then, through the input shaft to multiple-disc

clutches in the transaxle. The power flow depends on

the application of the clutches and bands. Refer to

Elements in Use Chart in Diagnosis and Tests sec-

tion. The transaxle consists of two multiple-disc

clutches, an overrunning clutch, two servos, a hy-

draulic accumulator, two bands, and two planetary

gear sets. They provide three forward ratios and a re-

verse ratio. The common sun gear of the planetary

gear sets is connected to the front clutch by a driving

shell. The drive shell is splined to the sun gear and

to the front clutch retainer. The hydraulic system

consists of an oil pump, and a single valve body

which contains all of the valves except the governor

valves. The transaxle sump and differential sump are

both vented through the dipstick.Output torque

from the main center line is delivered through heli-

cal gears to the transfer shaft.This gear set is a

factor of the final drive (axle) ratio. The shaft also

carries the governor and parking sprag. An integral

helical gear on the transfer shaft drives the differen-

tial ring gear. The final drive gearing is completed

with one of three gear sets producing overall top gear

ratios of 2.78, 3.02, or 3.22 depending on model and

application.

Ä TRANSAXLE 21 - 35

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä

Page 2004 of 2438

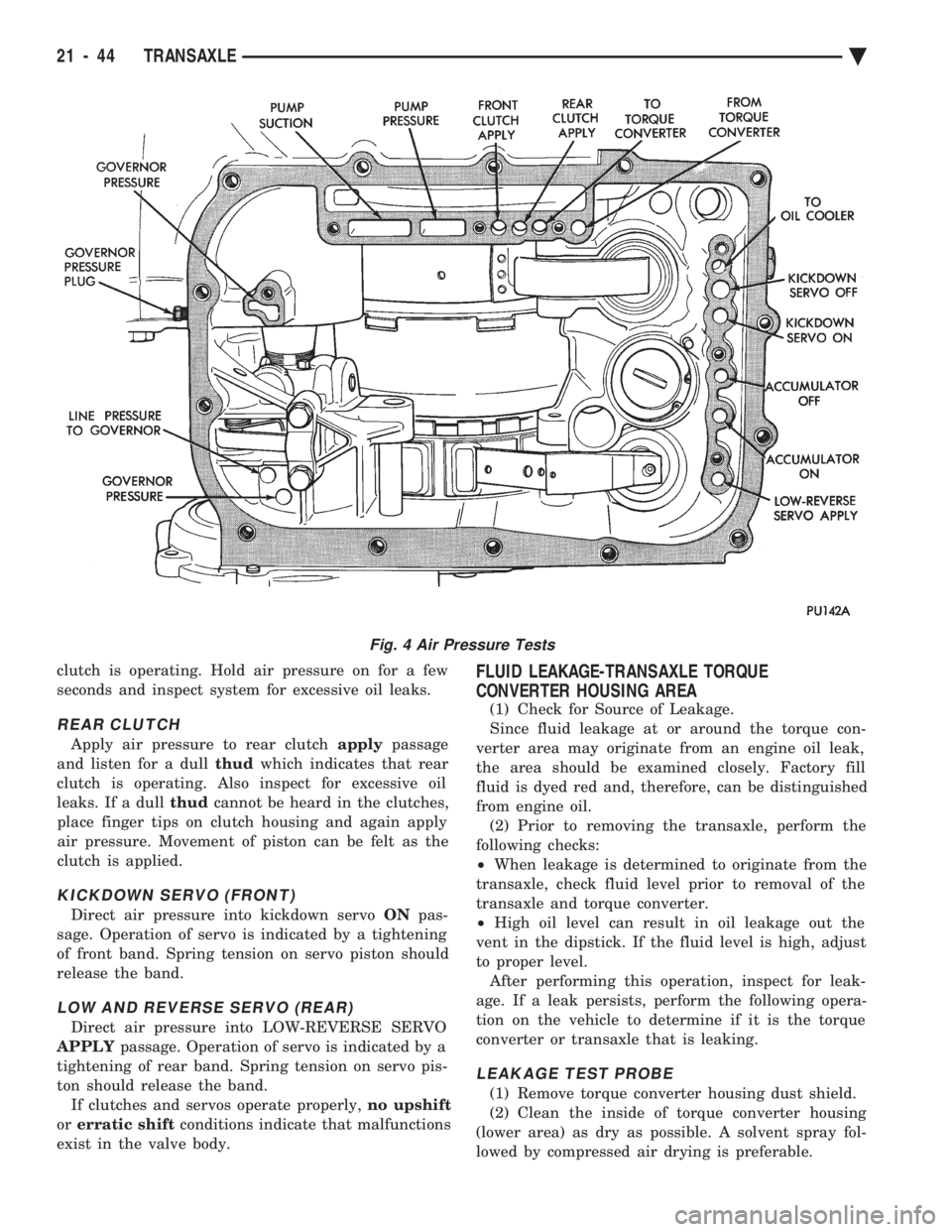

clutch is operating. Hold air pressure on for a few

seconds and inspect system for excessive oil leaks.

REAR CLUTCH

Apply air pressure to rear clutch applypassage

and listen for a dull thudwhich indicates that rear

clutch is operating. Also inspect for excessive oil

leaks. If a dull thudcannot be heard in the clutches,

place finger tips on clutch housing and again apply

air pressure. Movement of piston can be felt as the

clutch is applied.

KICKDOWN SERVO (FRONT)

Direct air pressure into kickdown servo ONpas-

sage. Operation of servo is indicated by a tightening

of front band. Spring tension on servo piston should

release the band.

LOW AND REVERSE SERVO (REAR)

Direct air pressure into LOW-REVERSE SERVO

APPLY passage. Operation of servo is indicated by a

tightening of rear band. Spring tension on servo pis-

ton should release the band. If clutches and servos operate properly, no upshift

or erratic shift conditions indicate that malfunctions

exist in the valve body.

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA

(1) Check for Source of Leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks:

² When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter.

² High oil level can result in oil leakage out the

vent in the dipstick. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable.

Fig. 4 Air Pressure Tests

21 - 44 TRANSAXLE Ä

Page 2005 of 2438

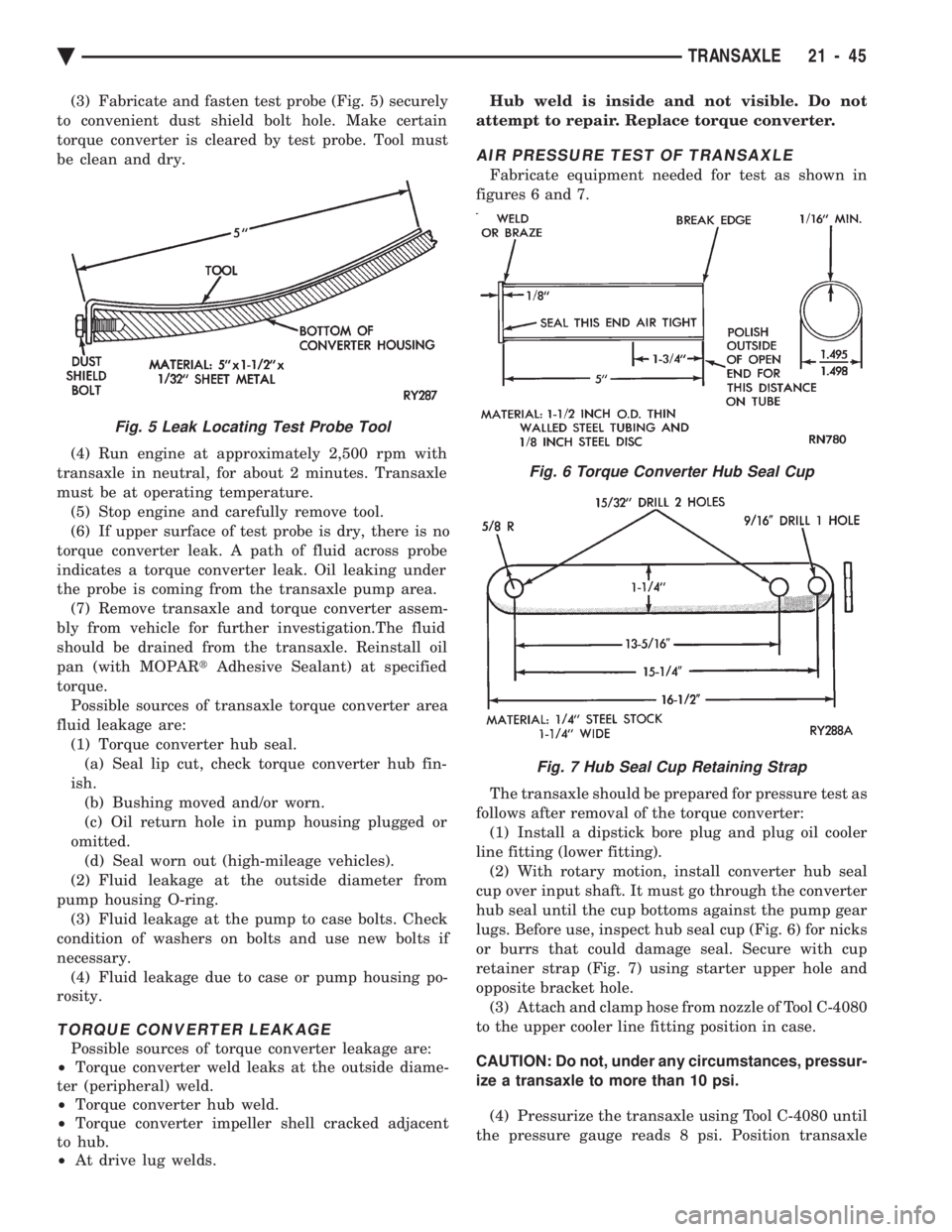

(3) Fabricate and fasten test probe (Fig. 5) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must

be clean and dry.

(4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under

the probe is coming from the transaxle pump area. (7) Remove transaxle and torque converter assem-

bly from vehicle for further investigation.The fluid

should be drained from the transaxle. Reinstall oil

pan (with MOPAR tAdhesive Sealant) at specified

torque. Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.(a) Seal lip cut, check torque converter hub fin-

ish. (b) Bushing moved and/or worn.

(c) Oil return hole in pump housing plugged or

omitted. (d) Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from

pump housing O-ring. (3) Fluid leakage at the pump to case bolts. Check

condition of washers on bolts and use new bolts if

necessary. (4) Fluid leakage due to case or pump housing po-

rosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the outside diame-

ter (peripheral) weld.

² Torque converter hub weld.

² Torque converter impeller shell cracked adjacent

to hub.

² At drive lug welds. Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

figures 6 and 7.

The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Install a dipstick bore plug and plug oil cooler

line fitting (lower fitting). (2) With rotary motion, install converter hub seal

cup over input shaft. It must go through the converter

hub seal until the cup bottoms against the pump gear

lugs. Before use, inspect hub seal cup (Fig. 6) for nicks

or burrs that could damage seal. Secure with cup

retainer strap (Fig. 7) using starter upper hole and

opposite bracket hole. (3) Attach and clamp hose from nozzle of Tool C-4080

to the upper cooler line fitting position in case.

CAUTION: Do not, under any circumstances, pressur-

ize a transaxle to more than 10 psi. (4) Pressurize the transaxle using Tool C-4080 until

the pressure gauge reads 8 psi. Position transaxle

Fig. 5 Leak Locating Test Probe Tool

Fig. 6 Torque Converter Hub Seal Cup

Fig. 7 Hub Seal Cup Retaining Strap

Ä TRANSAXLE 21 - 45

Page 2009 of 2438

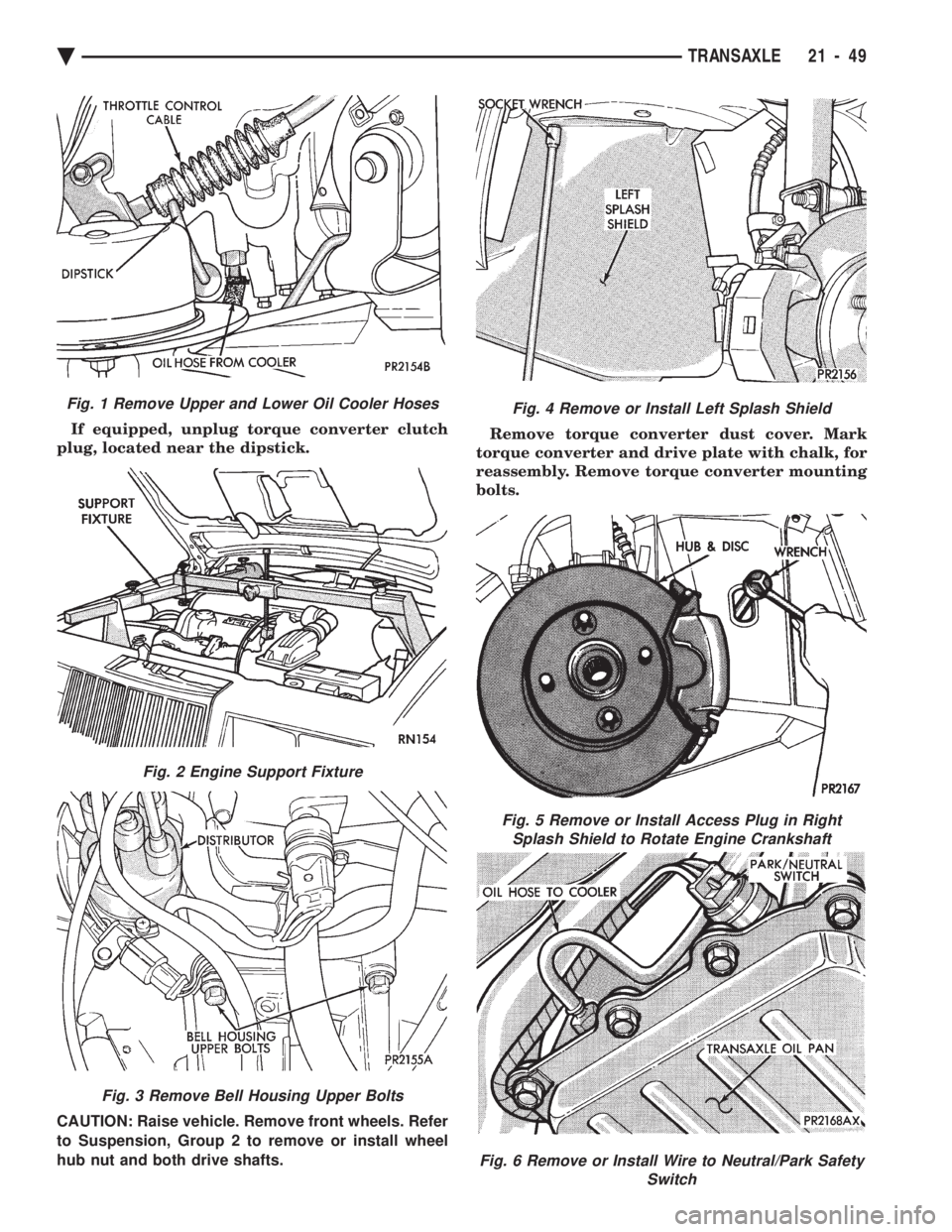

If equipped, unplug torque converter clutch

plug, located near the dipstick.

CAUTION: Raise vehicle. Remove front wheels. Refer

to Suspension, Group 2 to remove or install wheel

hub nut and both drive shafts. Remove torque converter dust cover. Mark

torque converter and drive plate with chalk, for

reassembly. Remove torque converter mounting

bolts.

Fig. 1 Remove Upper and Lower Oil Cooler Hoses

Fig. 2 Engine Support Fixture

Fig. 3 Remove Bell Housing Upper Bolts

Fig. 4 Remove or Install Left Splash Shield

Fig. 5 Remove or Install Access Plug in Right Splash Shield to Rotate Engine Crankshaft

Fig. 6 Remove or Install Wire to Neutral/Park Safety Switch

Ä TRANSAXLE 21 - 49

Page 2053 of 2438

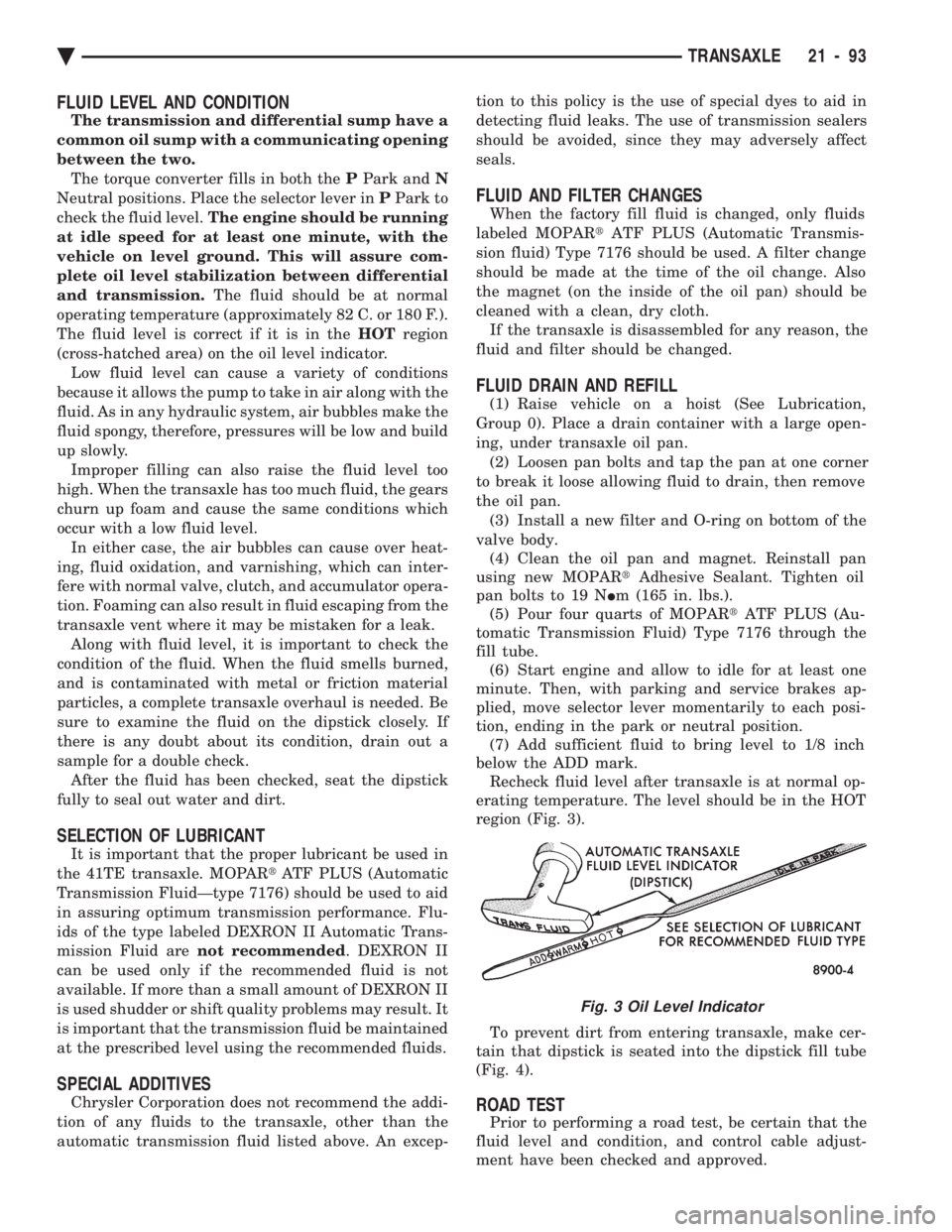

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. The torque converter fills in both the PPark and N

Neutral positions. Place the selector lever in PPark to

check the fluid level. The engine should be running

at idle speed for at least one minute, with the

vehicle on level ground. This will assure com-

plete oil level stabilization between differential

and transmission. The fluid should be at normal

operating temperature (approximately 82 C. or 180 F.).

The fluid level is correct if it is in the HOTregion

(cross-hatched area) on the oil level indicator. Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause over heat-

ing, fluid oxidation, and varnishing, which can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transaxle vent where it may be mistaken for a leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

the 41TE transaxle. MOPAR tATF PLUS (Automatic

Transmission FluidÐtype 7176) should be used to aid

in assuring optimum transmission performance. Flu-

ids of the type labeled DEXRON II Automatic Trans-

mission Fluid are not recommended . DEXRON II

can be used only if the recommended fluid is not

available. If more than a small amount of DEXRON II

is used shudder or shift quality problems may result. It

is important that the transmission fluid be maintained

at the prescribed level using the recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transaxle, other than the

automatic transmission fluid listed above. An excep- tion to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGES

When the factory fill fluid is changed, only fluids

labeled MOPAR tATF PLUS (Automatic Transmis-

sion fluid) Type 7176 should be used. A filter change

should be made at the time of the oil change. Also

the magnet (on the inside of the oil pan) should be

cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication,

Group 0). Place a drain container with a large open-

ing, under transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan. (3) Install a new filter and O-ring on bottom of the

valve body. (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive Sealant. Tighten oil

pan bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Au-

tomatic Transmission Fluid) Type 7176 through the

fill tube. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal op-

erating temperature. The level should be in the HOT

region (Fig. 3).

To prevent dirt from entering transaxle, make cer-

tain that dipstick is seated into the dipstick fill tube

(Fig. 4).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjust-

ment have been checked and approved.

Fig. 3 Oil Level Indicator

Ä TRANSAXLE 21 - 93

Page 2057 of 2438

first separator plate and watch carefully for the pis-

ton to move forward. The piston should return to its

original position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks

the output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not ro-

tate with hand torque. Release the air pressure and

confirm that the input shaft will rotate.

FLUID LEAKAGE-TORQUE CONVERTER HOUSING

AREA

(1) Check for source of leakage.

Since fluid leakage at or around the torque con-

verter area may originate from an engine oil leak,

the area should be examined closely. Factory fill

fluid is dyed red and, therefore, can be distinguished

from engine oil. (2) Prior to removing the transaxle, perform the

following checks: When leakage is determined to originate from the

transaxle, check fluid level prior to removal of the

transaxle and torque converter. High oil level can result in oil leakage out the vent

in the manual shaft. If the fluid level is high, adjust

to proper level. After performing this operation, inspect for leak-

age. If a leak persists, perform the following opera-

tion on the vehicle to determine if it is the torque

converter or transaxle that is leaking.

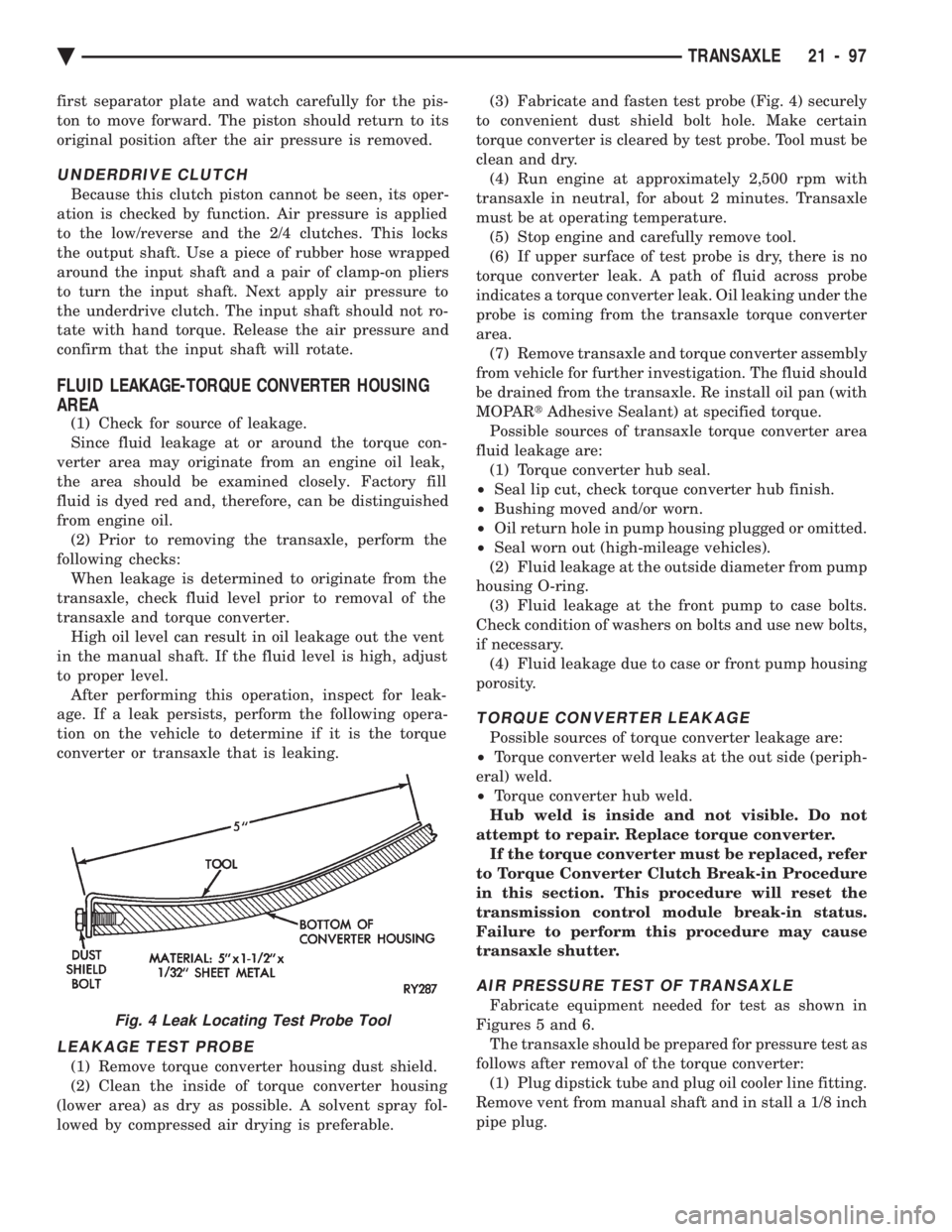

LEAKAGE TEST PROBE

(1) Remove torque converter housing dust shield.

(2) Clean the inside of torque converter housing

(lower area) as dry as possible. A solvent spray fol-

lowed by compressed air drying is preferable. (3) Fabricate and fasten test probe (Fig. 4) securely

to convenient dust shield bolt hole. Make certain

torque converter is cleared by test probe. Tool must be

clean and dry. (4) Run engine at approximately 2,500 rpm with

transaxle in neutral, for about 2 minutes. Transaxle

must be at operating temperature. (5) Stop engine and carefully remove tool.

(6) If upper surface of test probe is dry, there is no

torque converter leak. A path of fluid across probe

indicates a torque converter leak. Oil leaking under the

probe is coming from the transaxle torque converter

area. (7) Remove transaxle and torque converter assembly

from vehicle for further investigation. The fluid should

be drained from the transaxle. Re install oil pan (with

MOPAR tAdhesive Sealant) at specified torque.

Possible sources of transaxle torque converter area

fluid leakage are: (1) Torque converter hub seal.

² Seal lip cut, check torque converter hub finish.

² Bushing moved and/or worn.

² Oil return hole in pump housing plugged or omitted.

² Seal worn out (high-mileage vehicles).

(2) Fluid leakage at the outside diameter from pump

housing O-ring. (3) Fluid leakage at the front pump to case bolts.

Check condition of washers on bolts and use new bolts,

if necessary. (4) Fluid leakage due to case or front pump housing

porosity.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

² Torque converter weld leaks at the out side (periph-

eral) weld.

² Torque converter hub weld.

Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter. If the torque converter must be replaced, refer

to Torque Converter Clutch Break-in Procedure

in this section. This procedure will reset the

transmission control module break-in status.

Failure to perform this procedure may cause

transaxle shutter.

AIR PRESSURE TEST OF TRANSAXLE

Fabricate equipment needed for test as shown in

Figures 5 and 6. The transaxle should be prepared for pressure test as

follows after removal of the torque converter: (1) Plug dipstick tube and plug oil cooler line fitting.

Remove vent from manual shaft and in stall a 1/8 inch

pipe plug.Fig. 4 Leak Locating Test Probe Tool

Ä TRANSAXLE 21 - 97