differential CHEVROLET PLYMOUTH ACCLAIM 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 322 of 2438

(12) Remove hydraulic brake tube assembly rout-

ing bracket, from the engine mounting bracket (Fig.

10). (13) Remove the 6 hydraulic brake tubes and rout-

ing bracket as an assembly from the vehicle.

INSTALL (1) Install the 6 hydraulic brake tubes, clips and

routing bracket as an assembly into the vehicle. (2) Align the 6 hydraulic brake tubes with their

correct locations on the junction block. Thread the 6

brake line tube nuts by handinto the junction block

tube ports. Then torque all 6 brake tube nuts to 18

N Im (159 in.lbs.).

(3) Install the primary and secondary hydraulic

brake tubes, from master cylinder to junction block

(Fig. 9). Then torque the brake line tube nuts at both

the master cylinder and junction block to 18 N Im

(159 in. lbs.). (4) Install the hydraulic brake tube assembly rout-

ing bracket onto the engine mounting bracket (Fig. 10). Torque the brake tube routing bracket attaching

bolt to 11 N

Im (95 in. lbs.).

(5) Align the 6 hydraulic brake lines with their ap-

propriate fitting locations on the modulator assembly

(Fig. 11). Thread the 6 brake line tube nuts by hand

into proportioning valves and thread savers on mod-

ulator assembly. (6) Using a crow foot and torque wrench (Fig. 12),

torque the 6 hydraulic brake line tube nuts to 18

N Im (159 in. lbs.).

(7) Using approved battery jumper cables, attach

battery, to the vehicles negative and positive battery

cables (Fig. 13). (8) Bleed the vehicles base brake and Antilock

brake hydraulic systems. Refer to Bleeding Bendix

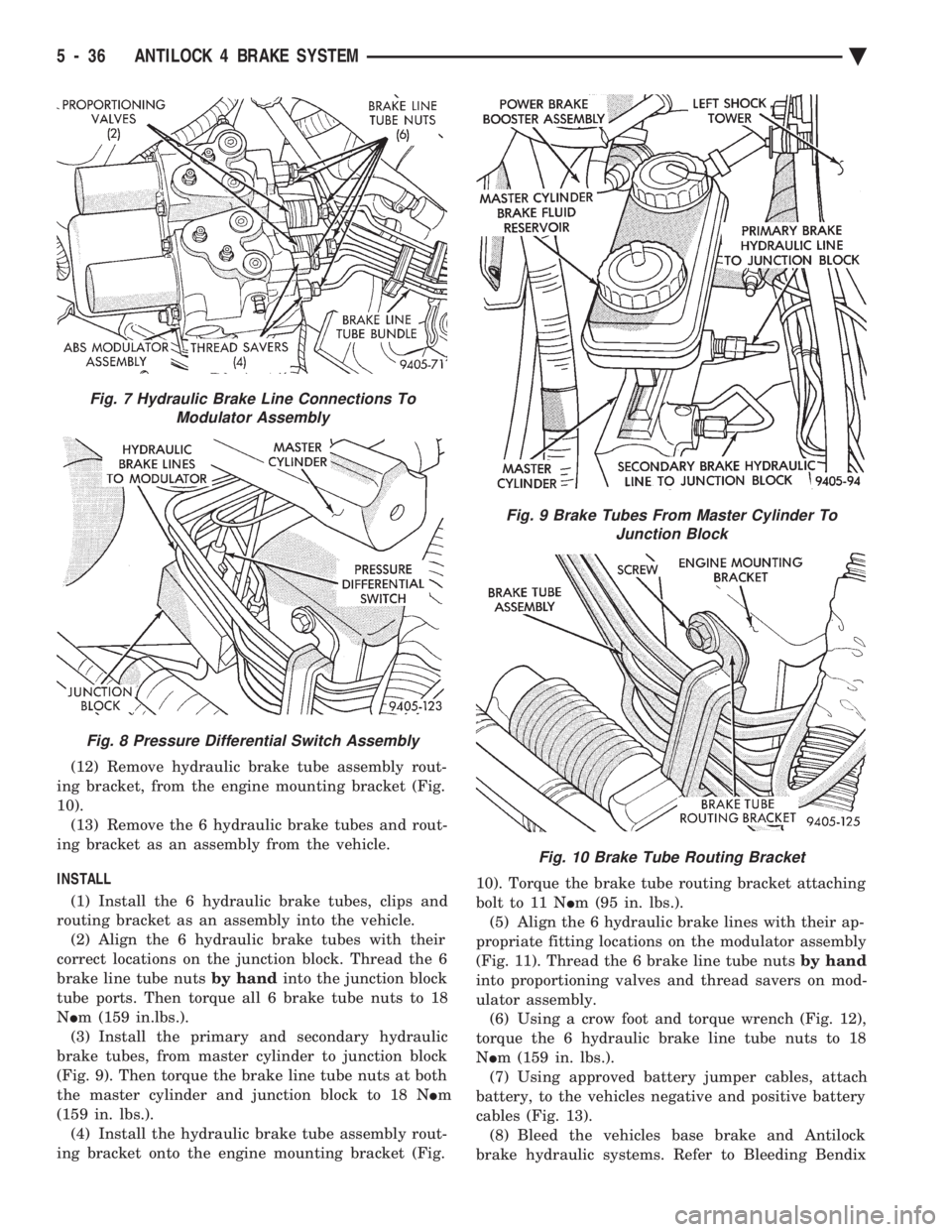

Fig. 7 Hydraulic Brake Line Connections To Modulator Assembly

Fig. 8 Pressure Differential Switch Assembly

Fig. 9 Brake Tubes From Master Cylinder To Junction Block

Fig. 10 Brake Tube Routing Bracket

5 - 36 ANTILOCK 4 BRAKE SYSTEM Ä

Page 1961 of 2438

TRANSAXLE

CONTENTS

page page

41TE FOUR SPEED AUTOMATIC TRANSAXLE . 85

41TE FOUR SPEED TRANSAXLE HYDRAULICSCHEMATICS ........................ 170

41TE ON-BOARD DIAGNOSTICS .......... 145

A-523, A-543, and A-568 MANUAL TRANSAXLE ........................... 1 SPECIFICATIONS

...................... 183

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE .......................... 35

THREE SPEED TRANSAXLE HYDRAULIC SCHEMATICS ........................ 162

A-523, A-543, and A-568 MANUAL TRANSAXLE INDEX

page page

Bearing Adjustment Procedure .............. 31

Differential Bearing Preload Adjustment ........ 33

Gearshift Linkage Adjustment (Cable Operated) . . 2

General Information ........................ 1 In-Car Transaxle Disassemble/Assemble

........ 4

Out of Car TransaxleÐDisassemble and Assemble . 6

Subassembly-Recondition .................. 15

Transaxle Removal and Installation ............ 5

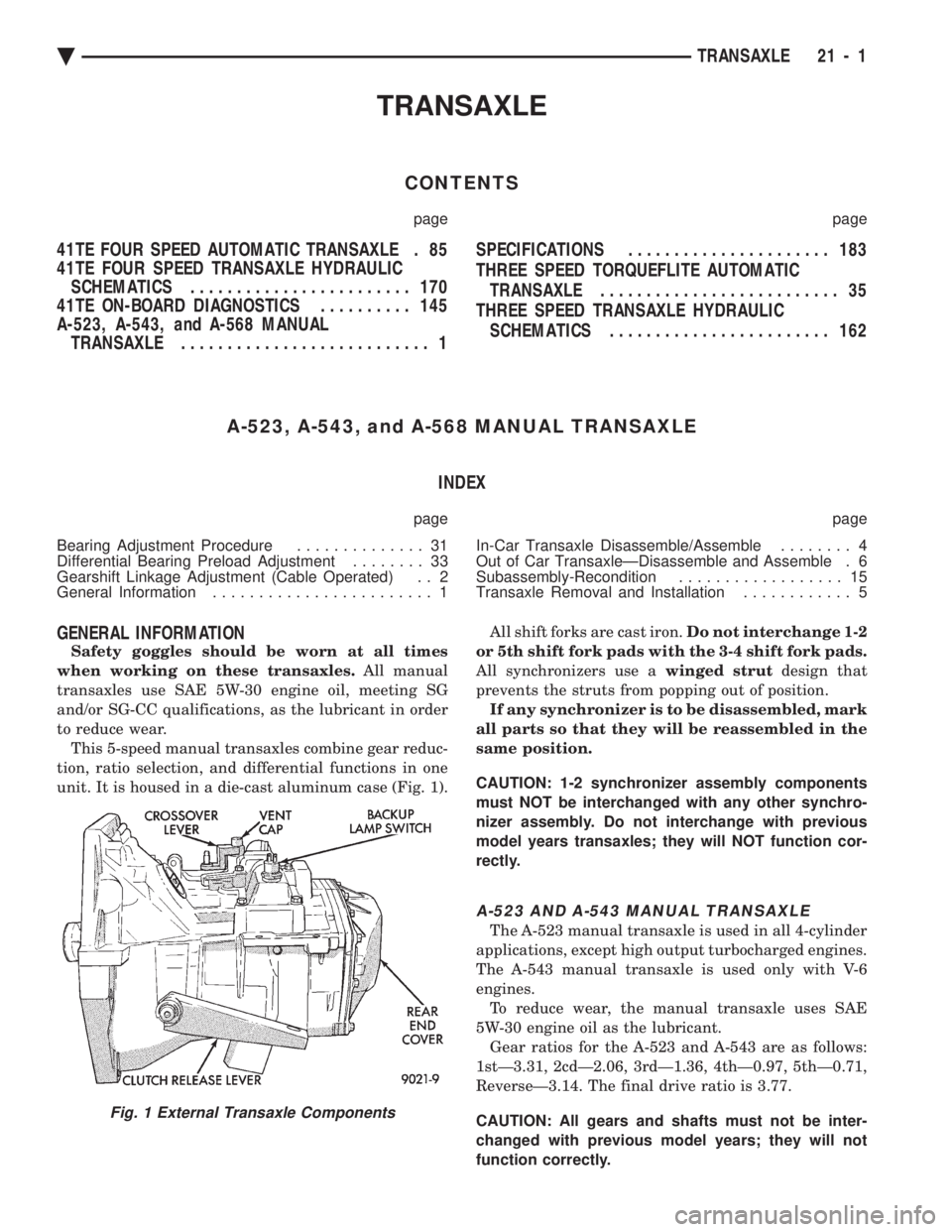

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on these transaxles. All manual

transaxles use SAE 5W-30 engine oil, meeting SG

and/or SG-CC qualifications, as the lubricant in order

to reduce wear. This 5-speed manual transaxles combine gear reduc-

tion, ratio selection, and differential functions in one

unit. It is housed in a die-cast aluminum case (Fig. 1). All shift forks are cast iron.

Do not interchange 1-2

or 5th shift fork pads with the 3-4 shift fork pads.

All synchronizers use a winged strutdesign that

prevents the struts from popping out of position. If any synchronizer is to be disassembled, mark

all parts so that they will be reassembled in the

same position.

CAUTION: 1-2 synchronizer assembly components

must NOT be interchanged with any other synchro-

nizer assembly. Do not interchange with previous

model years transaxles; they will NOT function cor-

rectly.

A-523 AND A-543 MANUAL TRANSAXLE

The A-523 manual transaxle is used in all 4-cylinder

applications, except high output turbocharged engines.

The A-543 manual transaxle is used only with V-6

engines. To reduce wear, the manual transaxle uses SAE

5W-30 engine oil as the lubricant. Gear ratios for the A-523 and A-543 are as follows:

1stÐ3.31, 2cdÐ2.06, 3rdÐ1.36, 4thÐ0.97, 5thÐ0.71,

ReverseÐ3.14. The final drive ratio is 3.77.

CAUTION: All gears and shafts must not be inter-

changed with previous model years; they will not

function correctly.

Fig. 1 External Transaxle Components

Ä TRANSAXLE 21 - 1

Page 1964 of 2438

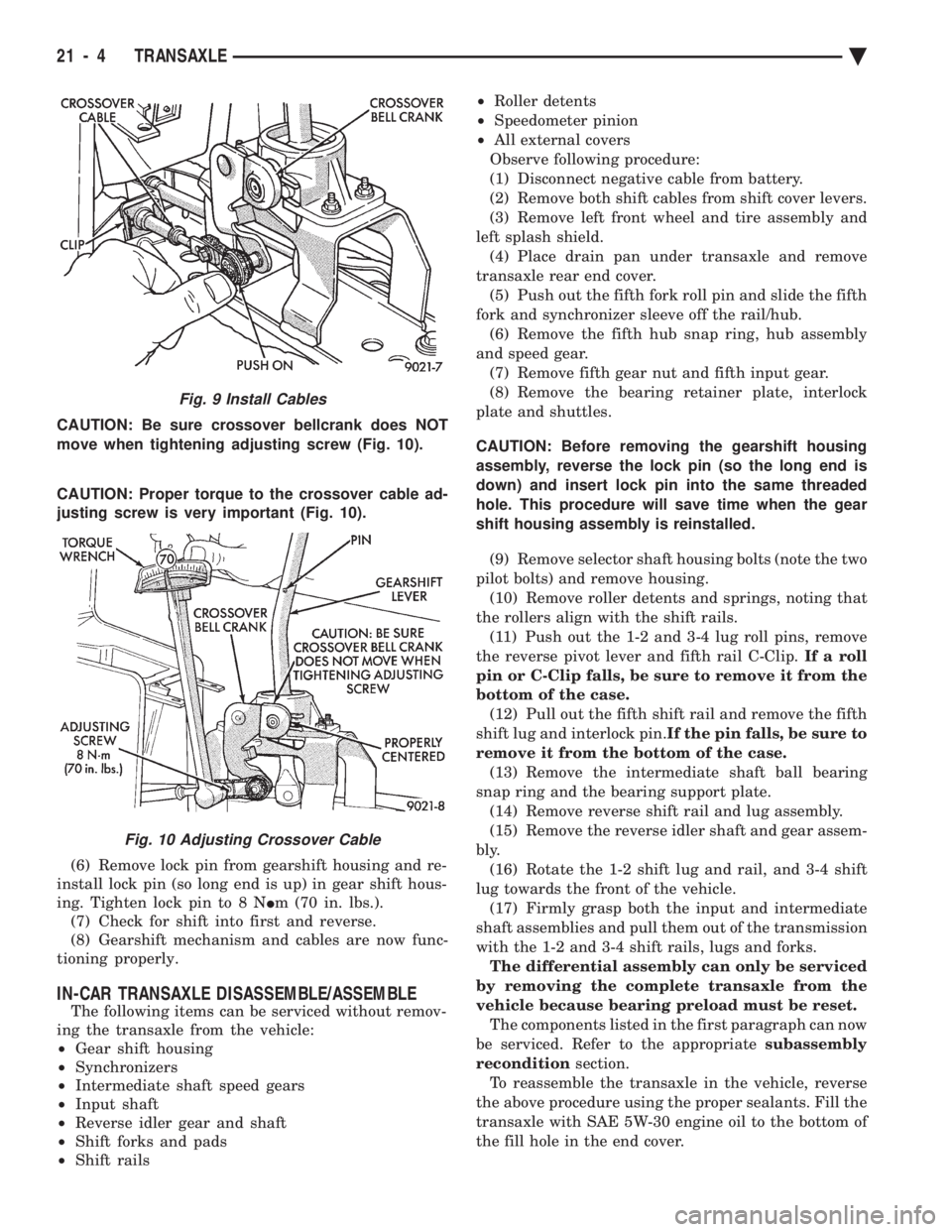

CAUTION: Be sure crossover bellcrank does NOT

move when tightening adjusting screw (Fig. 10).

CAUTION: Proper torque to the crossover cable ad-

justing screw is very important (Fig. 10).

(6) Remove lock pin from gearshift housing and re-

install lock pin (so long end is up) in gear shift hous-

ing. Tighten lock pin to 8 N Im (70 in. lbs.).

(7) Check for shift into first and reverse.

(8) Gearshift mechanism and cables are now func-

tioning properly.

IN-CAR TRANSAXLE DISASSEMBLE/ASSEMBLE

The following items can be serviced without remov-

ing the transaxle from the vehicle:

² Gear shift housing

² Synchronizers

² Intermediate shaft speed gears

² Input shaft

² Reverse idler gear and shaft

² Shift forks and pads

² Shift rails ²

Roller detents

² Speedometer pinion

² All external covers

Observe following procedure:

(1) Disconnect negative cable from battery.

(2) Remove both shift cables from shift cover levers.

(3) Remove left front wheel and tire assembly and

left splash shield. (4) Place drain pan under transaxle and remove

transaxle rear end cover. (5) Push out the fifth fork roll pin and slide the fifth

fork and synchronizer sleeve off the rail/hub. (6) Remove the fifth hub snap ring, hub assembly

and speed gear. (7) Remove fifth gear nut and fifth input gear.

(8) Remove the bearing retainer plate, interlock

plate and shuttles.

CAUTION: Before removing the gearshift housing

assembly, reverse the lock pin (so the long end is

down) and insert lock pin into the same threaded

hole. This procedure will save time when the gear

shift housing assembly is reinstalled. (9) Remove selector shaft housing bolts (note the two

pilot bolts) and remove housing. (10) Remove roller detents and springs, noting that

the rollers align with the shift rails. (11) Push out the 1-2 and 3-4 lug roll pins, remove

the reverse pivot lever and fifth rail C-Clip. If a roll

pin or C-Clip falls, be sure to remove it from the

bottom of the case. (12) Pull out the fifth shift rail and remove the fifth

shift lug and interlock pin. If the pin falls, be sure to

remove it from the bottom of the case. (13) Remove the intermediate shaft ball bearing

snap ring and the bearing support plate. (14) Remove reverse shift rail and lug assembly.

(15) Remove the reverse idler shaft and gear assem-

bly. (16) Rotate the 1-2 shift lug and rail, and 3-4 shift

lug towards the front of the vehicle. (17) Firmly grasp both the input and intermediate

shaft assemblies and pull them out of the transmission

with the 1-2 and 3-4 shift rails, lugs and forks. The differential assembly can only be serviced

by removing the complete transaxle from the

vehicle because bearing preload must be reset. The components listed in the first paragraph can now

be serviced. Refer to the appropriate subassembly

recondition section.

To reassemble the transaxle in the vehicle, reverse

the above procedure using the proper sealants. Fill the

transaxle with SAE 5W-30 engine oil to the bottom of

the fill hole in the end cover.

Fig. 9 Install Cables

Fig. 10 Adjusting Crossover Cable

21 - 4 TRANSAXLE Ä

Page 1966 of 2438

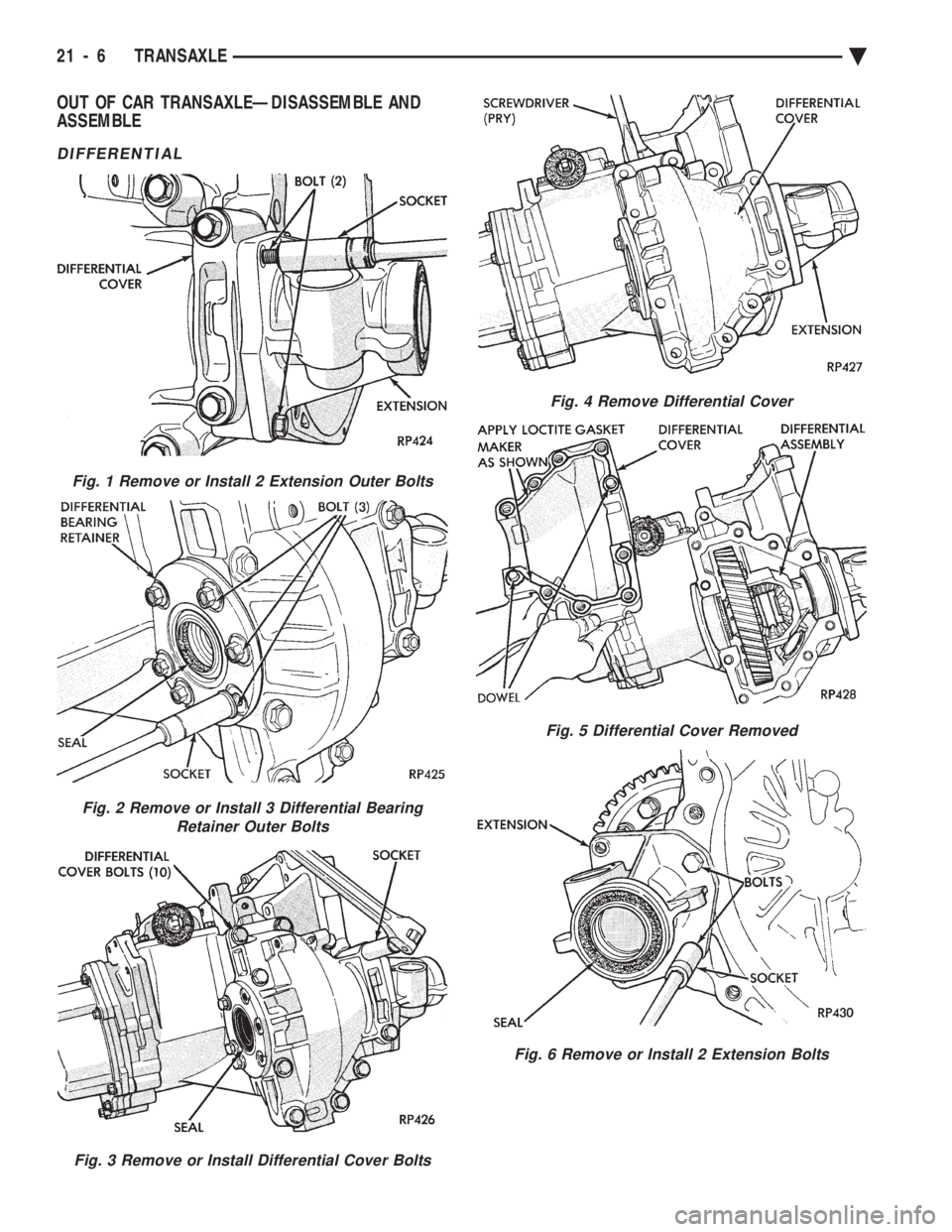

OUT OF CAR TRANSAXLEÐDISASSEMBLE AND

ASSEMBLE

DIFFERENTIAL

Fig. 1 Remove or Install 2 Extension Outer Bolts

Fig. 2 Remove or Install 3 Differential Bearing Retainer Outer Bolts

Fig. 3 Remove or Install Differential Cover Bolts

Fig. 4 Remove Differential Cover

Fig. 5 Differential Cover Removed

Fig. 6 Remove or Install 2 Extension Bolts

21 - 6 TRANSAXLE Ä

Page 1967 of 2438

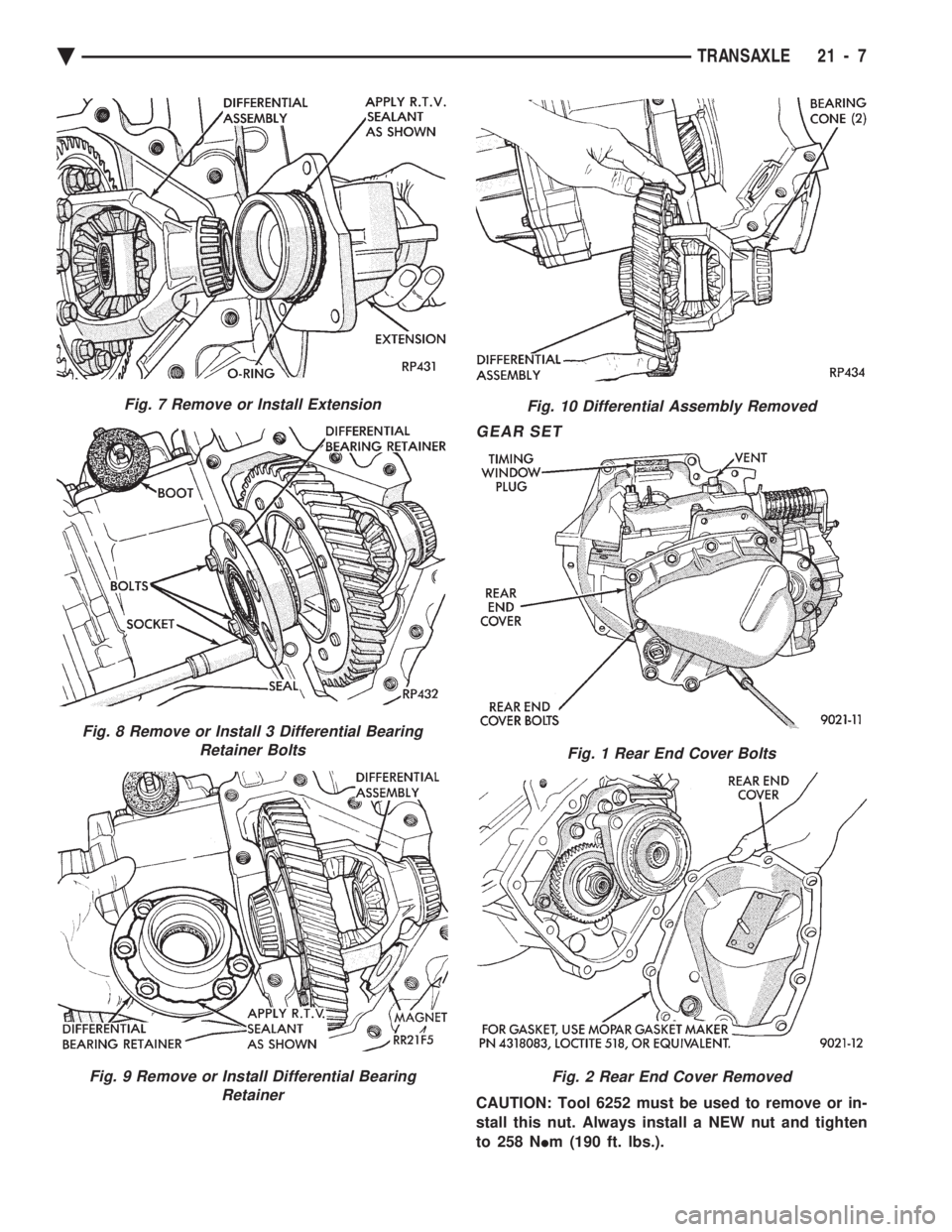

GEAR SET

CAUTION: Tool 6252 must be used to remove or in-

stall this nut. Always install a NEW nut and tighten

to 258 N Im (190 ft. lbs.).

Fig. 7 Remove or Install Extension

Fig. 8 Remove or Install 3 Differential Bearing

Retainer Bolts

Fig. 9 Remove or Install Differential Bearing Retainer

Fig. 10 Differential Assembly Removed

Fig. 1 Rear End Cover Bolts

Fig. 2 Rear End Cover Removed

Ä TRANSAXLE 21 - 7

Page 1984 of 2438

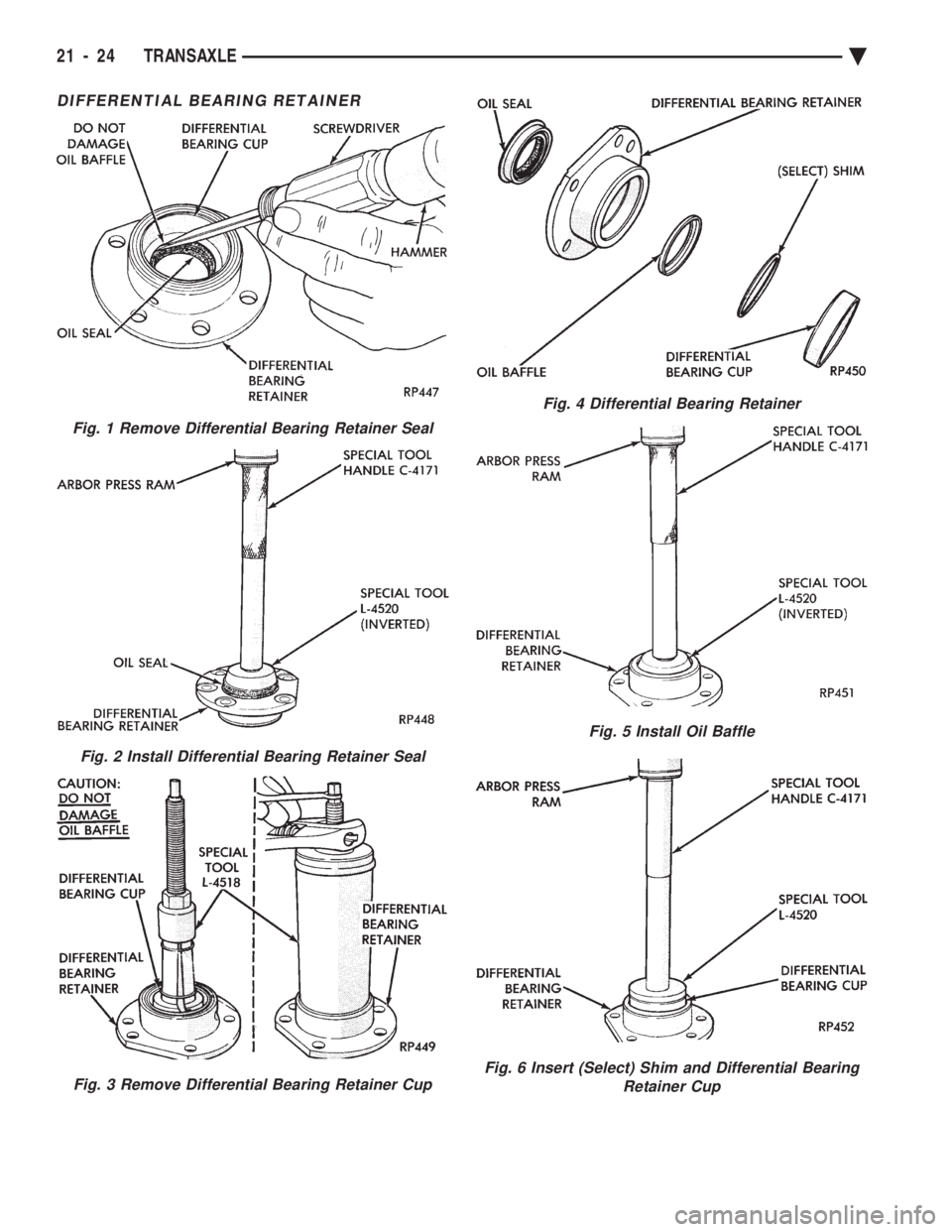

DIFFERENTIAL BEARING RETAINER

Fig. 1 Remove Differential Bearing Retainer Seal

Fig. 2 Install Differential Bearing Retainer Seal

Fig. 3 Remove Differential Bearing Retainer Cup

Fig. 4 Differential Bearing Retainer

Fig. 5 Install Oil Baffle

Fig. 6 Insert (Select) Shim and Differential Bearing Retainer Cup

21 - 24 TRANSAXLE Ä

Page 1987 of 2438

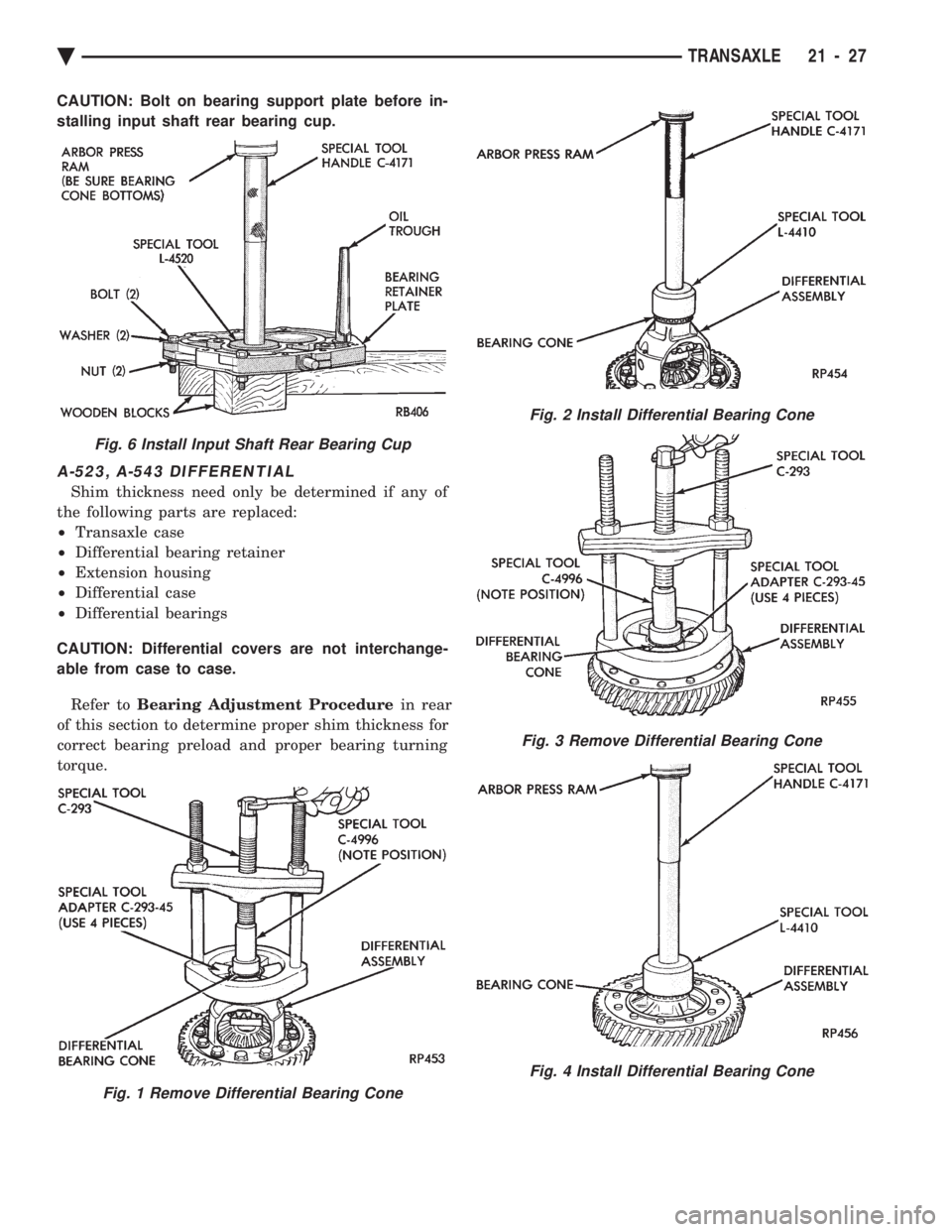

CAUTION: Bolt on bearing support plate before in-

stalling input shaft rear bearing cup.

A-523, A-543 DIFFERENTIAL

Shim thickness need only be determined if any of

the following parts are replaced:

² Transaxle case

² Differential bearing retainer

² Extension housing

² Differential case

² Differential bearings

CAUTION: Differential covers are not interchange-

able from case to case.

Refer to Bearing Adjustment Procedure in rear

of this section to determine proper shim thickness for

correct bearing preload and proper bearing turning

torque.

Fig. 6 Install Input Shaft Rear Bearing Cup

Fig. 1 Remove Differential Bearing Cone

Fig. 2 Install Differential Bearing Cone

Fig. 3 Remove Differential Bearing Cone

Fig. 4 Install Differential Bearing Cone

Ä TRANSAXLE 21 - 27

Page 1988 of 2438

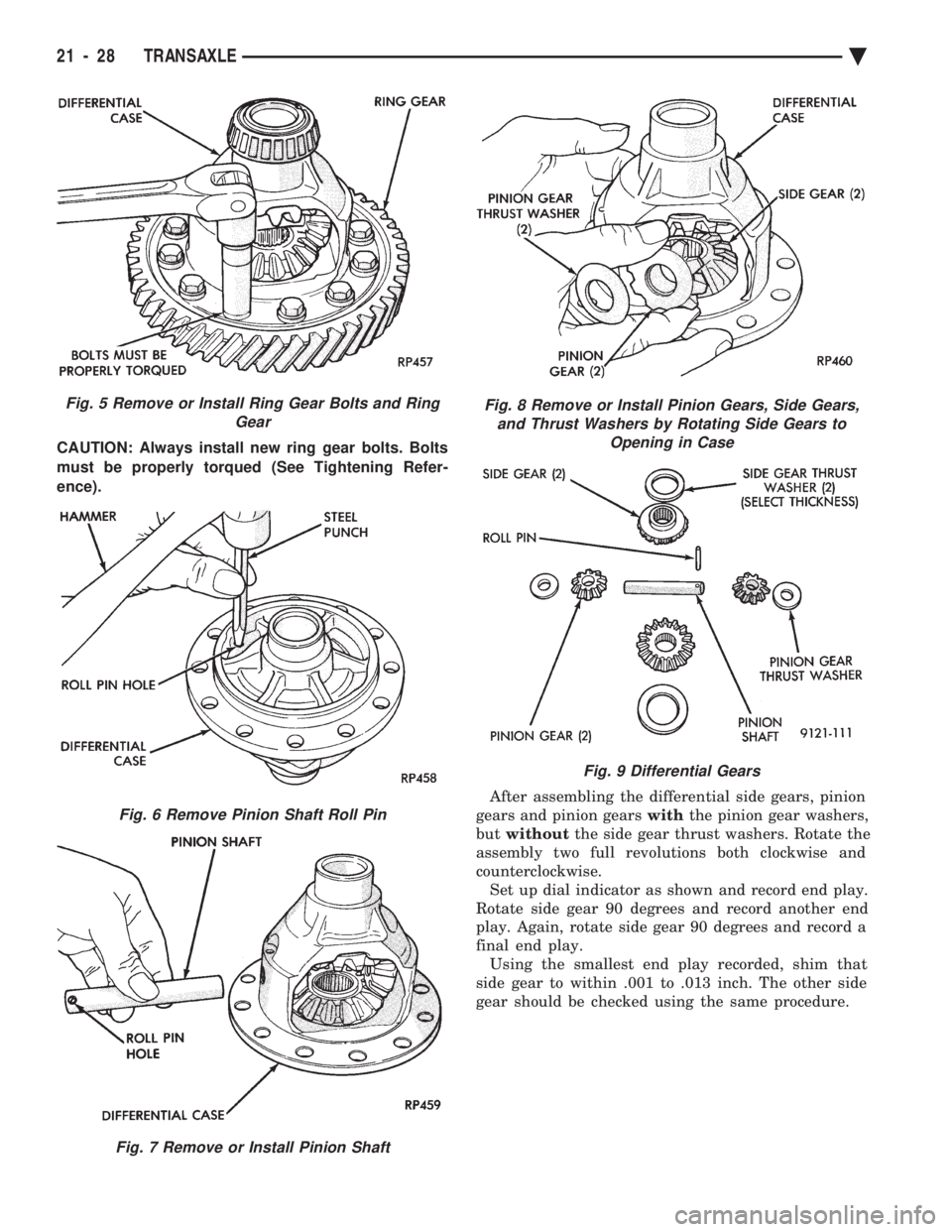

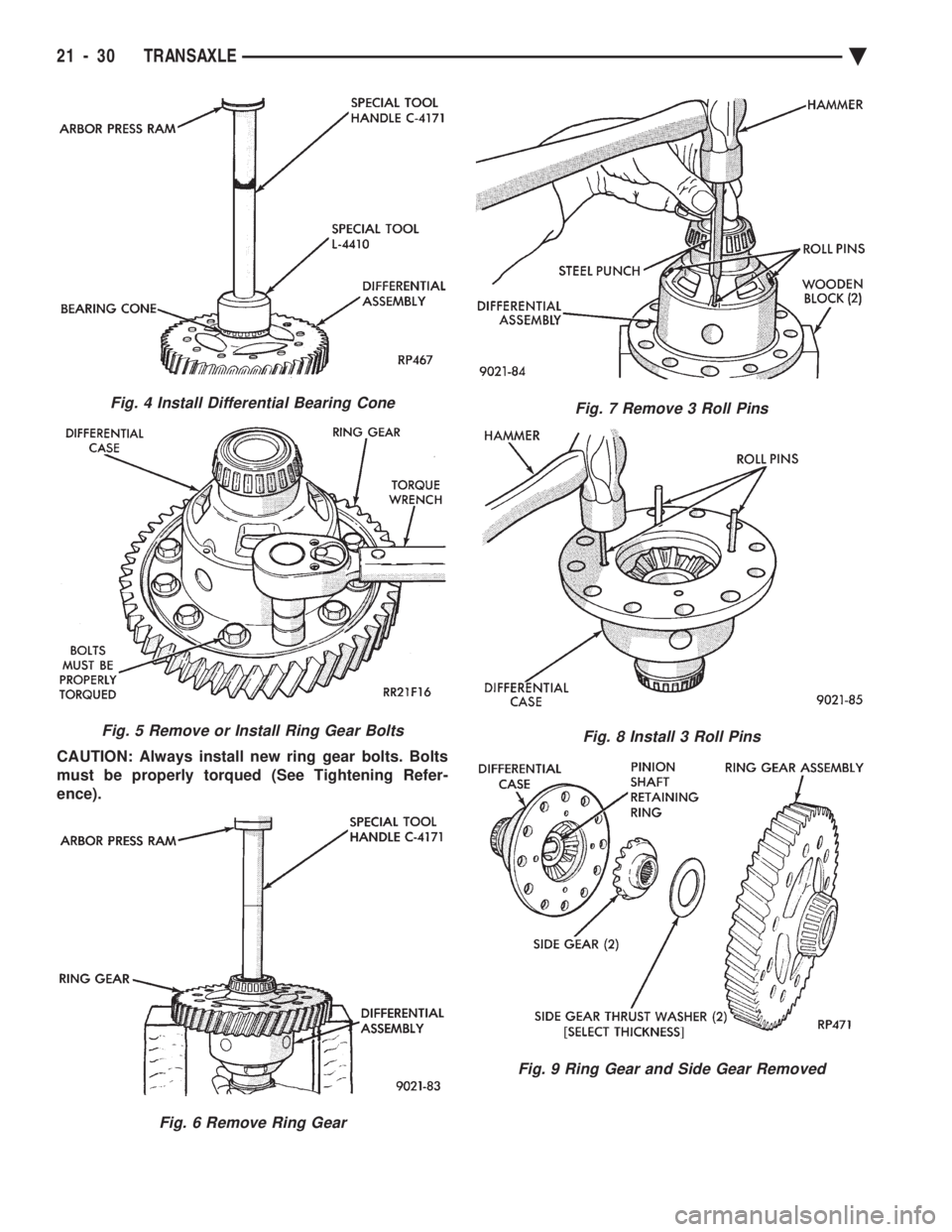

CAUTION: Always install new ring gear bolts. Bolts

must be properly torqued (See Tightening Refer-

ence). After assembling the differential side gears, pinion

gears and pinion gears withthe pinion gear washers,

but without the side gear thrust washers. Rotate the

assembly two full revolutions both clockwise and

counterclockwise. Set up dial indicator as shown and record end play.

Rotate side gear 90 degrees and record another end

play. Again, rotate side gear 90 degrees and record a

final end play. Using the smallest end play recorded, shim that

side gear to within .001 to .013 inch. The other side

gear should be checked using the same procedure.

Fig. 5 Remove or Install Ring Gear Bolts and Ring Gear

Fig. 6 Remove Pinion Shaft Roll Pin

Fig. 7 Remove or Install Pinion Shaft

Fig. 8 Remove or Install Pinion Gears, Side Gears,and Thrust Washers by Rotating Side Gears to Opening in Case

Fig. 9 Differential Gears

21 - 28 TRANSAXLE Ä

Page 1989 of 2438

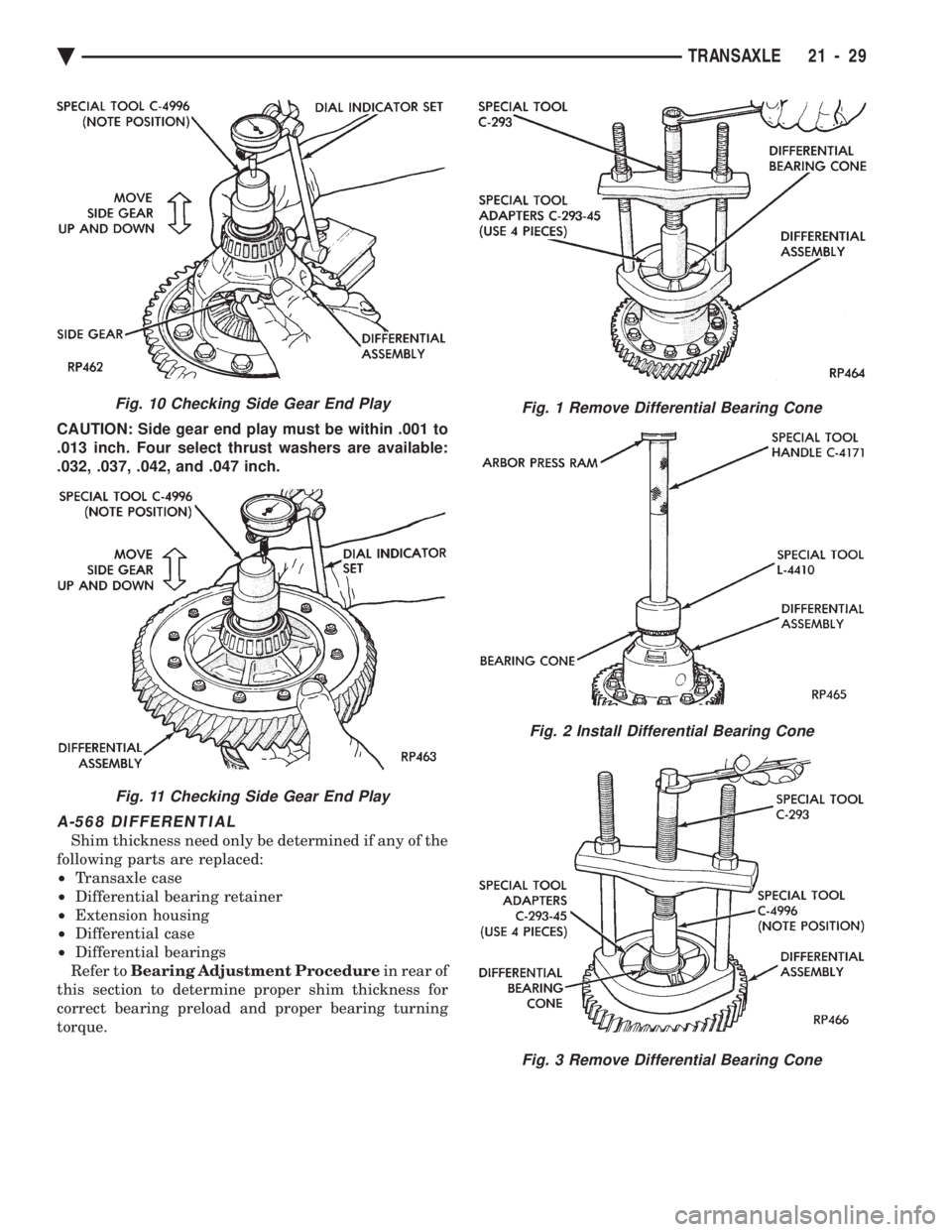

CAUTION: Side gear end play must be within .001 to

.013 inch. Four select thrust washers are available:

.032, .037, .042, and .047 inch.

A-568 DIFFERENTIAL

Shim thickness need only be determined if any of the

following parts are replaced:

² Transaxle case

² Differential bearing retainer

² Extension housing

² Differential case

² Differential bearings

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness for

correct bearing preload and proper bearing turning

torque.

Fig. 1 Remove Differential Bearing Cone

Fig. 2 Install Differential Bearing Cone

Fig. 3 Remove Differential Bearing Cone

Fig. 10 Checking Side Gear End Play

Fig. 11 Checking Side Gear End Play

Ä TRANSAXLE 21 - 29

Page 1990 of 2438

CAUTION: Always install new ring gear bolts. Bolts

must be properly torqued (See Tightening Refer-

ence).

Fig. 4 Install Differential Bearing Cone

Fig. 5 Remove or Install Ring Gear Bolts

Fig. 6 Remove Ring Gear

Fig. 7 Remove 3 Roll Pins

Fig. 8 Install 3 Roll Pins

Fig. 9 Ring Gear and Side Gear Removed

21 - 30 TRANSAXLE Ä