automatic transmission CHRYSLER ASPEN 2008 2.G Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: ASPEN, Model: CHRYSLER ASPEN 2008 2.GPages: 479, PDF Size: 4.3 MB

Page 377 of 479

JUMP±STARTING PROCEDURES

WARNING!

²Battery fluid is a corrosive acid solution; do not

allow battery fluid to contact eyes, skin or cloth-

ing. Don't lean over battery when attaching

clamps or allow the clamps to touch each other. If

acid splashes in eyes or on skin, flush the contami-

nated area immediately with large quantities of

water.

²A battery generates hydrogen gas which is flam-

mable and explosive. Keep flame or spark away

from the vent holes. Do not use a booster battery

or any other booster source with an output that

exceeds 12 volts.Check the Battery Test Indicator (if equipped). If a light or

bright colored dot is visible in the indicator (if equipped),

DO NOT jump-start the battery.

If the indicator (if equipped) is dark or shows a green dot,

proceed as follows:

1. Wear eye protection and remove all metal jewelry such

as watch bands or bracelets which might make an

unintended electrical contact.

2. Park the booster vehicle within cable reach but with-

out letting the vehicles touch. Set the parking brake, place

the automatic transmission in PARK and turn the ignition

OFF on both vehicles.

3. Turn OFF heater, radio and all unnecessary electrical

loads.

376 WHAT TO DO IN EMERGENCIES

Page 383 of 479

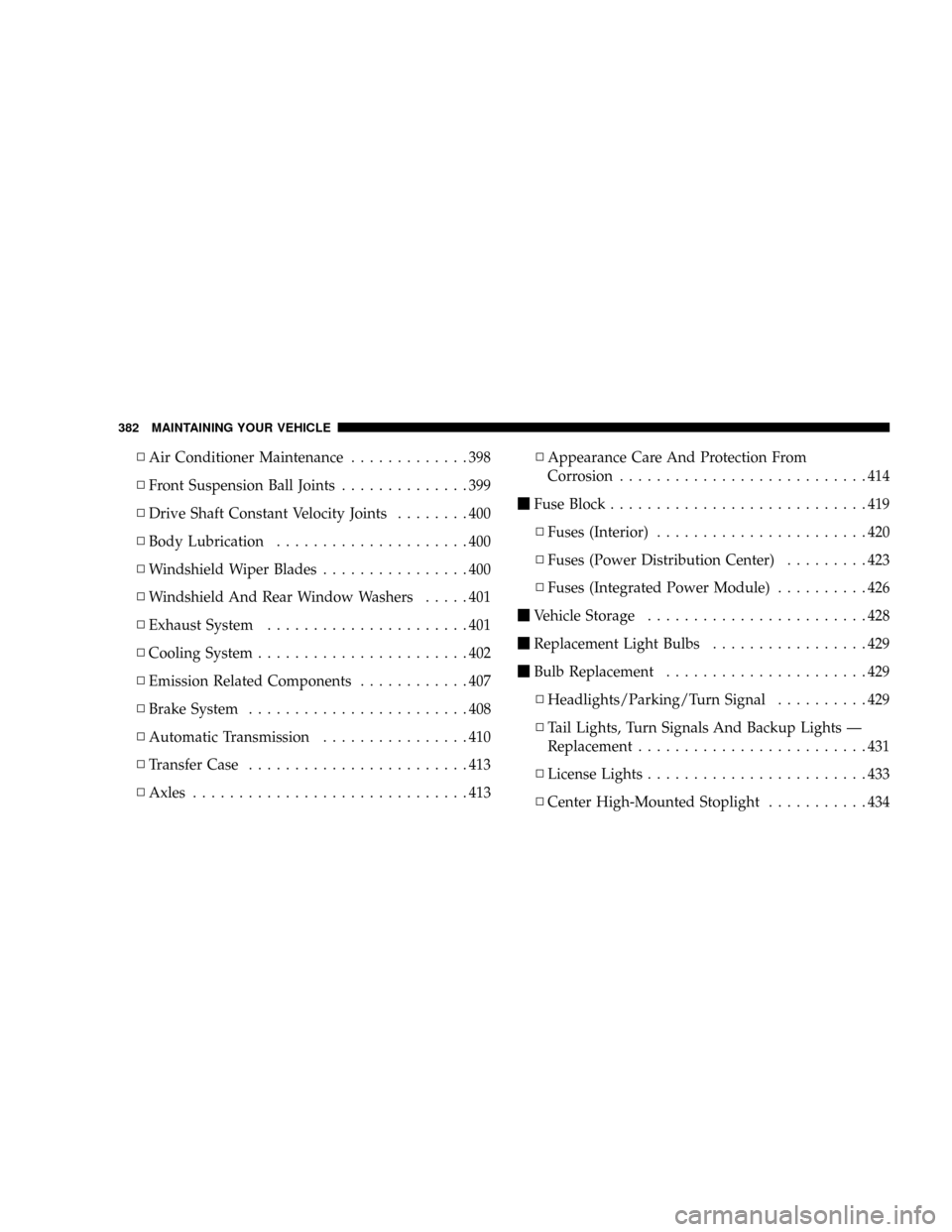

NAir Conditioner Maintenance.............398

NFront Suspension Ball Joints..............399

NDrive Shaft Constant Velocity Joints........400

NBody Lubrication.....................400

NWindshield Wiper Blades................400

NWindshield And Rear Window Washers.....401

NExhaust System......................401

NCooling System.......................402

NEmission Related Components............407

NBrake System........................408

NAutomatic Transmission................410

NTransfer Case........................413

NAxles..............................413NAppearance Care And Protection From

Corrosion...........................414

mFuse Block............................419

NFuses (Interior).......................420

NFuses (Power Distribution Center).........423

NFuses (Integrated Power Module)..........426

mVehicle Storage........................428

mReplacement Light Bulbs.................429

mBulb Replacement......................429

NHeadlights/Parking/Turn Signal..........429

NTail Lights, Turn Signals And Backup Lights Ð

Replacement.........................431

NLicense Lights........................433

NCenter High-Mounted Stoplight...........434

382 MAINTAINING YOUR VEHICLE

Page 387 of 479

ONBOARD DIAGNOSTIC SYSTEM Ð OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the Malfunction Indicator Light (MIL). It will

also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your authorized dealer for service as

soon as possible.CAUTION!

²Prolonged driving with the MIL on could cause

further damage to the emission control system. It

could also affect fuel economy and driveability.

The vehicle must be serviced before any emissions

tests can be performed.

²If the MIL is flashing while the engine is running,

severe catalytic converter damage and power loss

will soon occur. Immediate service is required.

Loose Fuel Filler Cap Message

After fuel is added, the vehicle diagnostic system can

determine if the fuel filler cap is possibly loose, improp-

erly installed, or damaged. A loose fuel filler cap message

will be displayed in the instrument cluster. Tighten the

gas cap until a9clicking9sound is heard. This is an

indication that the gas cap is properly tightened. Press

386 MAINTAINING YOUR VEHICLE

Page 411 of 479

CAUTION!

Do not allow a petroleum-base fluid to contaminate

the brake fluid. Seal damage may result.

Brake Hoses

Inspection should be performed whenever the brake

system is serviced or at intervals specified. Inspect hy-

draulic brake hoses for surface cracking, scuffing or worn

spots. If there is any evidence of cracking, scuffing, or

worn spots, the hose should be replaced immediately!

Eventual deterioration of the hose can take place with

possible burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any sign of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Automatic Transmission

Fluid Level Check

NOTE:If equipped with a dipstick, use the following

procedure. If your vehicle has a capped dipstick, it is

sealed and should not be tampered with. Your authorized

dealer has the proper tools to ensure that the fluid level

is set properly.

Check the fluid level while the transmission is at normal

operating temperature 180ÉF (82ÉC). This occurs after at

410 MAINTAINING YOUR VEHICLE

Page 412 of 479

least 15 miles (24 km) of driving. At normal operating

temperature the fluid cannot be held comfortably be-

tween the fingertips.

To check the automatic transmission fluid level properly,

the following procedure must be used:

1. Operate the engine at idle speed and normal operating

temperature.

2. The vehicle must be on level ground.

3. Fully apply the parking brake and press the brake

pedal.

4. Place the shift lever momentarily in each gear position

ending with the lever in PARK.

5. Remove the dipstick, wipe it clean and reinsert it until

seated.6. Remove the dipstick again and note the fluid level on

both sides. The fluid level should be between the ªHOTº

(upper) reference holes on the dipstick at normal operat-

ing temperature. Verify that solid coating of oil is seen on

both sides of the dipstick. If the fluid is low, add as

required into the dipstick tube.Do not overfill.After

adding any quantity of oil through the oil fill tube, wait

a minimum of two minutes for the oil to fully drain into

the transmission before rechecking the fluid level.

NOTE:If it is necessary to check the transmissionbelow

the operating temperature, the fluid level should be

between the two ªCOLDº (lower) holes on the dipstick

with the fluid at approximately 70ÉF (21ÉC) (room tem-

perature). If the fluid level is correctly established at

room temperature, it should be between the ªHOTº

(upper) reference holes when the transmission reaches

180ÉF ( 82ÉC). Remember it is best to check the level at the

normal operating temperature.

MAINTAINING YOUR VEHICLE 411

7

Page 413 of 479

CAUTION!

Be aware that if the fluid temperature is below 50ÉF

(10ÉC) it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough to

produce an accurate reading.

7. Check for leaks. Release parking brake.

To prevent dirt and water from entering the transmission

after checking or replenishing fluid, make certain that the

dipstick cap is properly reseated. It is normal for the

dipstick cap to spring back slightly from its fully seated

position, as long as its seal remains engaged in the

dipstick tube.

Automatic Transmission Fluid And Filter Change

Follow the Maintenance Schedule for recommended

transmission fluid and filter change intervals.

Selection of Lubricant

It is important that the proper lubricant is used in the

transmission to assure optimum transmission perfor-

mance. Use only manufacturer 's recommended transmis-

sion fluid; for correct fluid type, refer to ªAutomatic

Transmissionº under ªFluids, Lubricants and Genuine

Partsº in this section. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluid.

Special Additives

Automatic Transmission Fluid (ATF) is an engineered

product and its performance may be impaired by supple-

mental additives. Therefore, do not add any fluid addi-

tives to the transmission. The only exception to this

policy is the use of special dyes to aid in detecting fluid

leaks. In addition, avoid using transmission sealers as

they may adversely affect seals.

412 MAINTAINING YOUR VEHICLE

Page 414 of 479

CAUTION!

Using a transmission fluid other than the manufac-

turer's recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturer's recommended fluid will result in

more frequent fluid and filter changes. For correct

fluid type, refer to ªAutomatic Transmissionº under

ªFluids, Lubricants and Genuine Partsº in this

section.

Transfer Case

Inspect the transfer case for fluid leaks. If a fluid leak is

evident the transfer case fluid level may be low. Have the

transfer case serviced immediately.

CAUTION!

Damage may result from operation of the vehicle

with low transfer case fluid.

Drain And Refill

Follow the Maintenance Schedule for recommended

transfer case fluid change intervals.

Lubricant Selection

For correct fluid type, refer to ºTransfer Caseº under

ªFluids, Lubricants and Genuine Partsº in this section.

Axles

For correct fluid type, refer to ºFront or Rear Axleº under

ªFluids, Lubricants and Genuine Partsº in this section.

Drain And Refill

Follow the Maintenance Schedule for recommended axle

fluid change intervals.

MAINTAINING YOUR VEHICLE 413

7

Page 439 of 479

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4, Automatic Transmission Fluid.

Transfer Case MopartATF+4, Automatic Transmission Fluid.

Front Axle SAE 75W-90 Multipurpose Type, GL-5 Gear Lubricant or equivalent.

Rear Axle SAE 75W-140 Synthetic Gear Lubricant or equivalent.

Brake Master Cylinder MopartDOT 3 and SAE J1703 should be used or equivalent. If DOT 3

brake fluid is not available, then DOT 4 is acceptable. Use only recom-

mended brake fluids.

Power Steering Reservoir MopartATF+4, Automatic Transmission Fluid.

438 MAINTAINING YOUR VEHICLE

Page 445 of 479

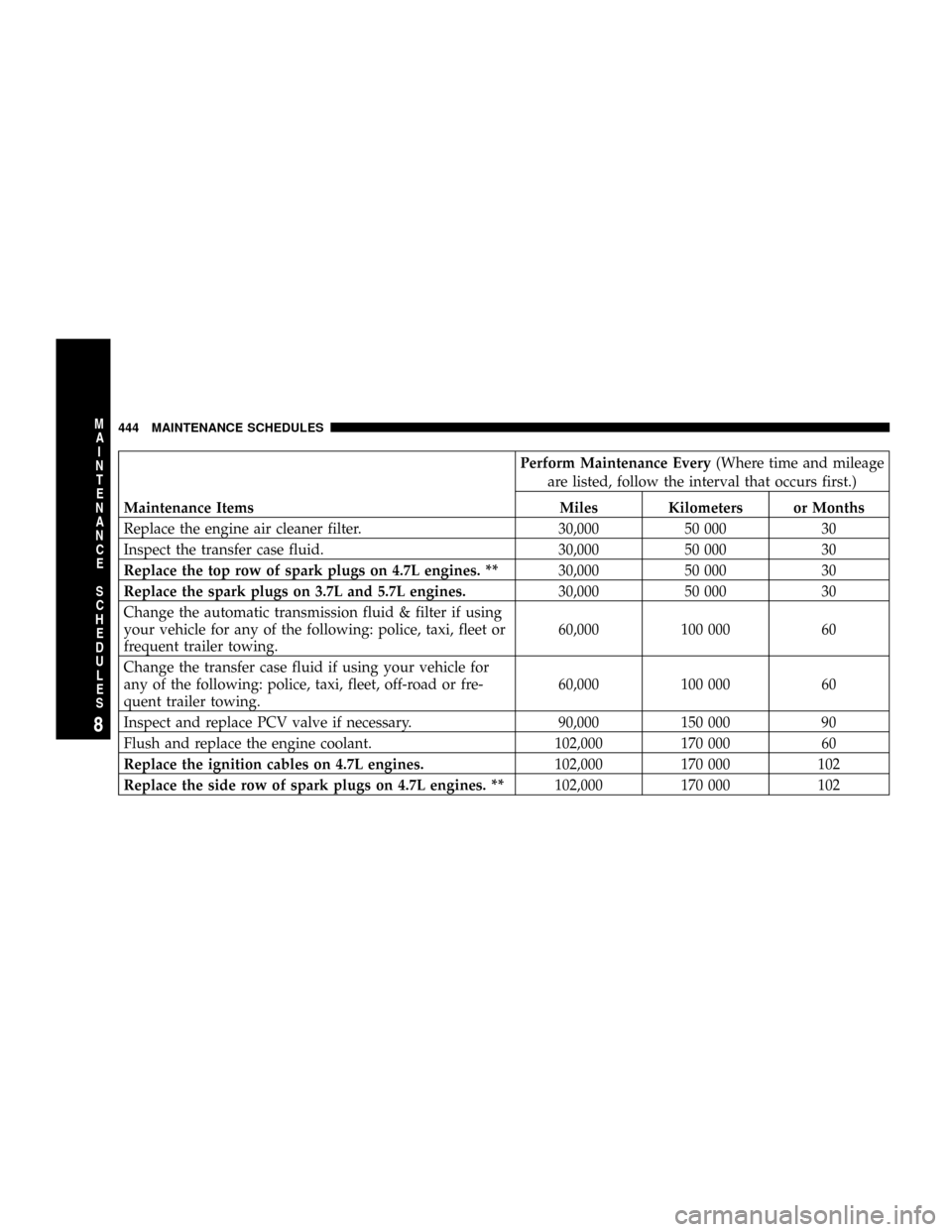

Perform Maintenance Every(Where time and mileage

are listed, follow the interval that occurs first.)

Maintenance Items Miles Kilometers or Months

Replace the engine air cleaner filter. 30,000 50 000 30

Inspect the transfer case fluid. 30,000 50 000 30

Replace the top row of spark plugs on 4.7L engines. **30,000 50 000 30

Replace the spark plugs on 3.7L and 5.7L engines.30,000 50 000 30

Change the automatic transmission fluid & filter if using

your vehicle for any of the following: police, taxi, fleet or

frequent trailer towing.60,000 100 000 60

Change the transfer case fluid if using your vehicle for

any of the following: police, taxi, fleet, off-road or fre-

quent trailer towing.60,000 100 000 60

Inspect and replace PCV valve if necessary. 90,000 150 000 90

Flush and replace the engine coolant. 102,000 170 000 60

Replace the ignition cables on 4.7L engines.102,000 170 000 102

Replace the side row of spark plugs on 4.7L engines. **102,000 170 000 102

444 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 446 of 479

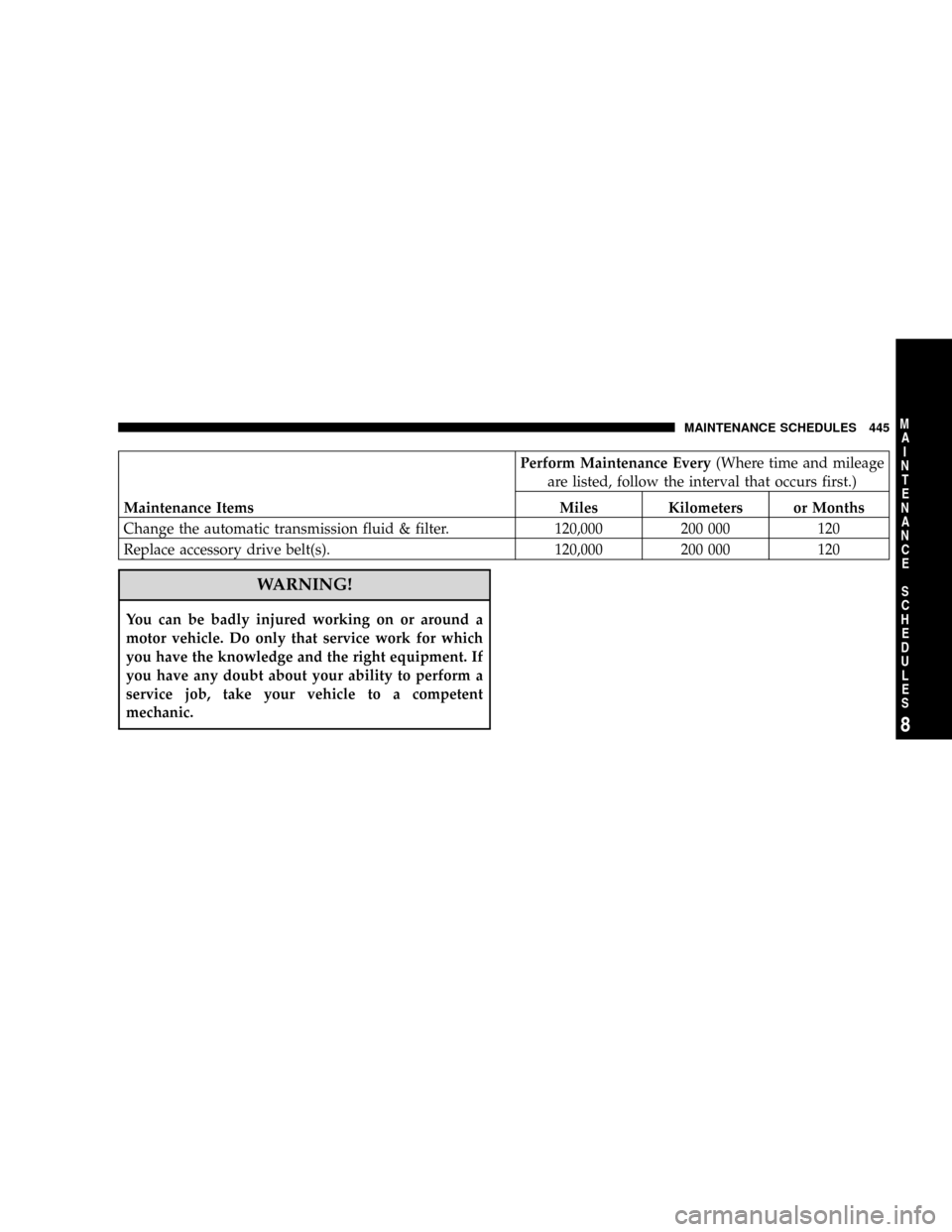

Perform Maintenance Every(Where time and mileage

are listed, follow the interval that occurs first.)

Maintenance Items Miles Kilometers or Months

Change the automatic transmission fluid & filter. 120,000 200 000 120

Replace accessory drive belt(s). 120,000 200 000 120

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the right equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent

mechanic.

MAINTENANCE SCHEDULES 445

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S