fuel tank removal CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1378 of 2339

(9) Disconnect the fuel fill hose at the fuel tank

filler metal tubeNOT AT THE FUEL TANK(Fig.

19).

(10) Disconnect fuel line and vapor line at the

front of the fuel tank.

The fuel pump module electrical connector

has a retainer that locks it in place.

(11) Slide fuel pump module electrical connector

lock to unlock.

(12) Push down on connector retainer (Fig. 20) and

pull connector off module.(13) Lower tank from vehicle. Remove fuel filler

vent tube from frame (Fig. 21).REMOVAL - FOLD-IN-FLOOR

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from battery.

(3) Drain fuel tank dry into holding tank or a

properly labeledGASOLINEsafety container.

(4) Raise vehicle on hoist and support (Fig. 22).

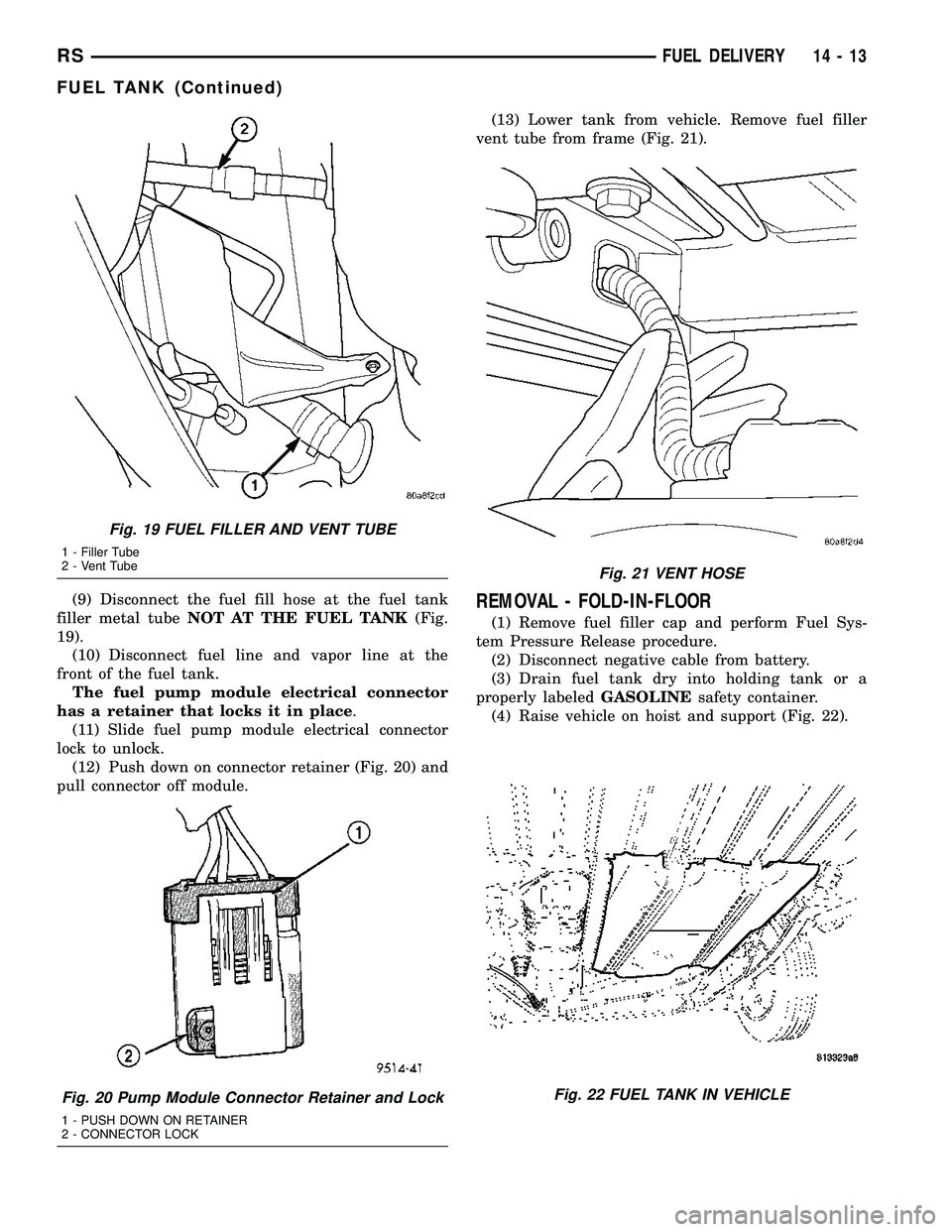

Fig. 19 FUEL FILLER AND VENT TUBE

1 - Filler Tube

2 - Vent Tube

Fig. 20 Pump Module Connector Retainer and Lock

1 - PUSH DOWN ON RETAINER

2 - CONNECTOR LOCK

Fig. 21 VENT HOSE

Fig. 22 FUEL TANK IN VEHICLE

RSFUEL DELIVERY14-13

FUEL TANK (Continued)

Page 1381 of 2339

INSTALLATION - FOLD-IN-FLOOR

(1) Use a transmission jack to support fuel tank.

(2) Raise tank and install fuel filler vent tube thru

frame (Fig. 29).

(3) Raise tank.

(4) Connect the fuel fill hose at the fuel tank filler

metal tube and tighten clamp.

CAUTION: Ensure straps are not twisted or bent

before or after tightening strap bolts.

(5) Install bolts for fuel tank straps (Fig. 23).

(6) Tighten strap bolts to 54 N´m (40 ft. lbs.)

torque. Remove transmission jack.

(7) Connect the fuel filler vent tube.

(8) Connect fuel line and vapor line at the front of

the fuel tank (Fig. 25), (Fig. 26).

(9) Connect the electrical connector.

(10) Slide fuel pump module electrical connector

lock to lock (Fig. 27), (Fig. 28).

(11) Lower vehicle.

(12) Fill fuel tank, replace cap, and connect bat-

tery negative cable.

(13) Use the DRBIIItscan tool to pressurize the

fuel system. Check for leaks.

FUEL TANK FILLER TUBE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the 3 screws at the filler door.

(3) Raise and support vehicle

(4) Remove the left rear tire.

(5) Remove the splash shield (Fig. 32) or (Fig. 31).

(6) Remove the metal shield (Fig. 30).(7)For RGRemove the canister from filler tube

(Fig. 33).

Fig. 30 FILLER TUBE SHIELD

Fig. 31 FUEL FILLER TUBE (RS)

Fig. 32 FUEL FILLER TUBE AND VENT TUBE (RG)

14 - 16 FUEL DELIVERYRS

FUEL TANK (Continued)

Page 1382 of 2339

(8)For RGDisconnect the vent at the top of the

filler tube.

(9) Remove the ground strap.

(10) Remove filler tube at tank.

INSTALLATION

(1) Install filler tube to tank (Fig. 32).

(2) Install filler tube shield (Fig. 34).

(3) Install the ground strap.

(4)For RGConnect the vent at the top of the filler

tube.

(5) Install the 3 screws at the filler door.(6)For RGInstall the canister from filler tube

(Fig. 33).

(7) Install the splash shield.

(8) Install the left rear tire.

(9) lower vehicle.

(10) Connect the negative battery cable.

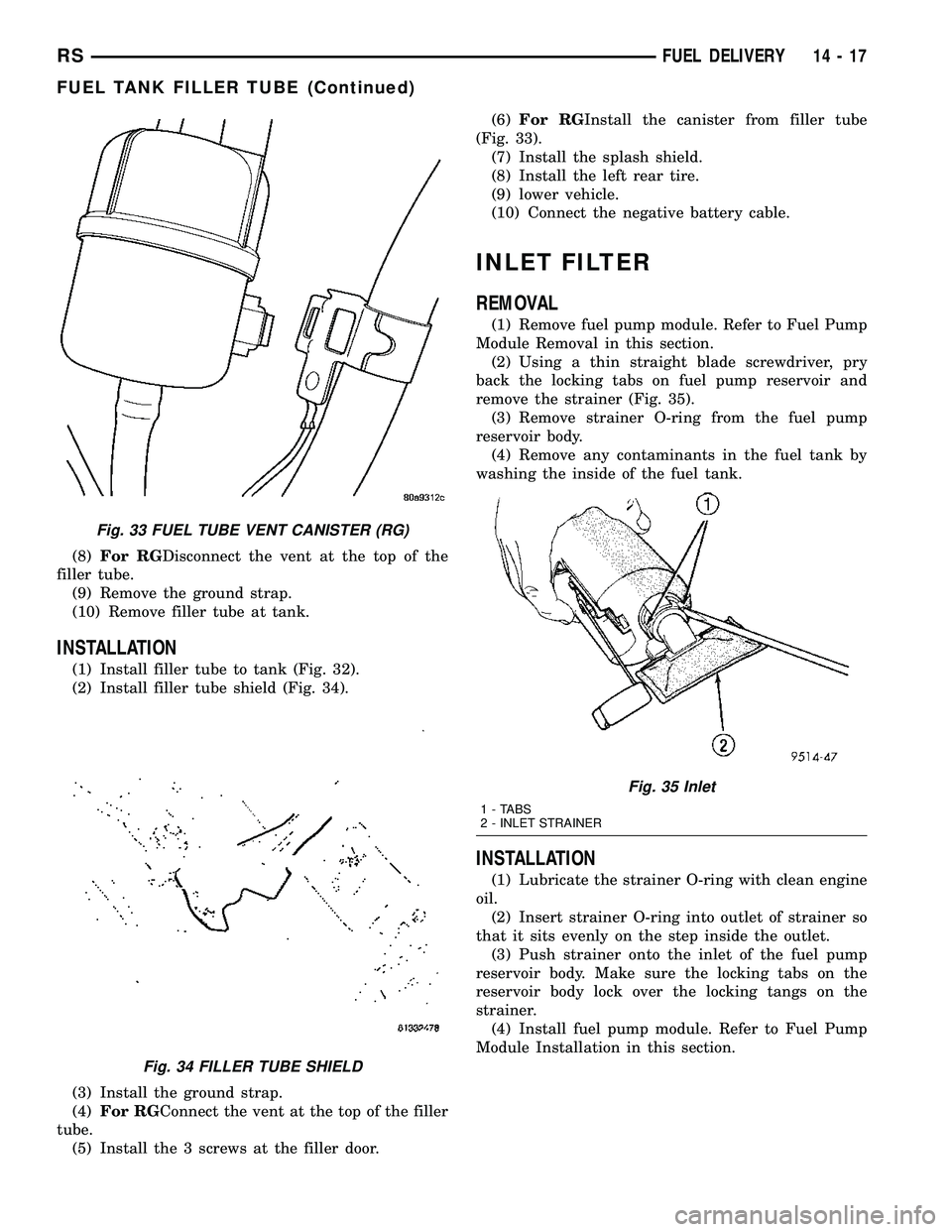

INLET FILTER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 35).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

Fig. 33 FUEL TUBE VENT CANISTER (RG)

Fig. 34 FILLER TUBE SHIELD

Fig. 35 Inlet

1 - TABS

2 - INLET STRAINER

RSFUEL DELIVERY14-17

FUEL TANK FILLER TUBE (Continued)

Page 1860 of 2339

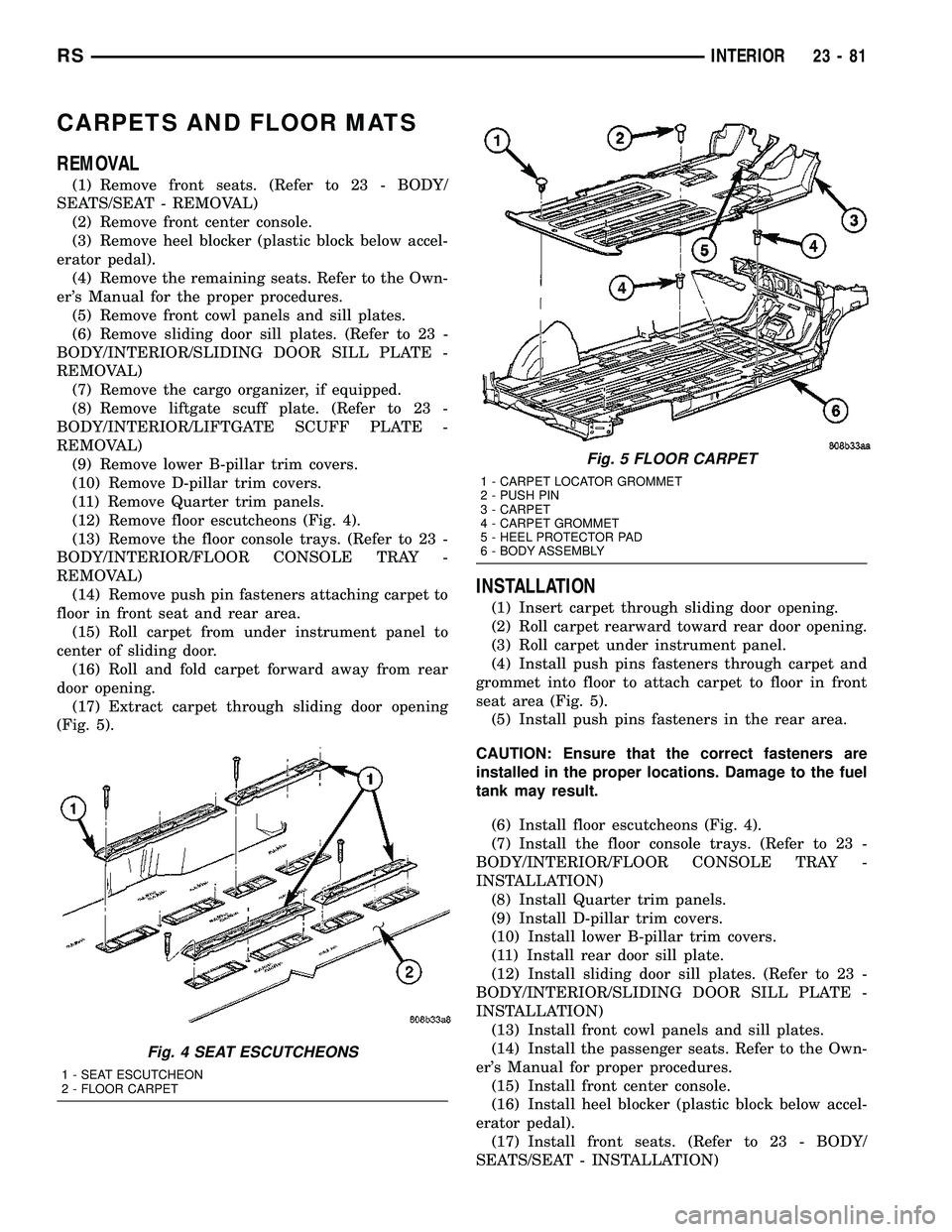

CARPETS AND FLOOR MATS

REMOVAL

(1) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(2) Remove front center console.

(3) Remove heel blocker (plastic block below accel-

erator pedal).

(4) Remove the remaining seats. Refer to the Own-

er's Manual for the proper procedures.

(5) Remove front cowl panels and sill plates.

(6) Remove sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(7) Remove the cargo organizer, if equipped.

(8) Remove liftgate scuff plate. (Refer to 23 -

BODY/INTERIOR/LIFTGATE SCUFF PLATE -

REMOVAL)

(9) Remove lower B-pillar trim covers.

(10) Remove D-pillar trim covers.

(11) Remove Quarter trim panels.

(12) Remove floor escutcheons (Fig. 4).

(13) Remove the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

REMOVAL)

(14) Remove push pin fasteners attaching carpet to

floor in front seat and rear area.

(15) Roll carpet from under instrument panel to

center of sliding door.

(16) Roll and fold carpet forward away from rear

door opening.

(17) Extract carpet through sliding door opening

(Fig. 5).

INSTALLATION

(1) Insert carpet through sliding door opening.

(2) Roll carpet rearward toward rear door opening.

(3) Roll carpet under instrument panel.

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area (Fig. 5).

(5) Install push pins fasteners in the rear area.

CAUTION: Ensure that the correct fasteners are

installed in the proper locations. Damage to the fuel

tank may result.

(6) Install floor escutcheons (Fig. 4).

(7) Install the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

INSTALLATION)

(8) Install Quarter trim panels.

(9) Install D-pillar trim covers.

(10) Install lower B-pillar trim covers.

(11) Install rear door sill plate.

(12) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(13) Install front cowl panels and sill plates.

(14) Install the passenger seats. Refer to the Own-

er's Manual for proper procedures.

(15) Install front center console.

(16) Install heel blocker (plastic block below accel-

erator pedal).

(17) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION)

Fig. 4 SEAT ESCUTCHEONS

1 - SEAT ESCUTCHEON

2 - FLOOR CARPET

Fig. 5 FLOOR CARPET

1 - CARPET LOCATOR GROMMET

2 - PUSH PIN

3 - CARPET

4 - CARPET GROMMET

5 - HEEL PROTECTOR PAD

6 - BODY ASSEMBLY

RSINTERIOR23-81

Page 2268 of 2339

FUEL DOSING PUMP

DESCRIPTION

The dosing pump is a combined delivery, dosing

and shut-off system for the fuel supply to the supple-

mental cabin heater from the vehicle fuel tank.

OPERATION

The dosing pump is an electrically operated pump

that receives its operation instructions from the sup-

plemental cabin heater control module. The pump

supplies diesel fuel from the vehicle fuel tank to the

cabin heater.

REMOVAL

NOTE: The dosing pump is serviceable without

removing the supplemental cabin heater from the

vehicle.

(1) Disconnect and isolate the negative battery

cable.

CAUTION: Make sure that the hoist is properly posi-

tioned under the vehicle to prevent damage to the

flexible section of the cabin heater exhaust tube.

(2) Raise and support the vehicle.

(3) Disconnect the wiring harness connector to the

dosing pump by depressing the integral spring and

pulling the connector away from the pump.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel that may drain from the

heater fuel hose or the dosing pump.

(4) Remove the clamp that secures the heater fuel

hose to the dosing pump (Fig. 4).

(5) Disconnect the heater fuel hose from the dosing

pump.

NOTE: Position and retain the heater fuel line to

prevent fuel leakage from the cabin heater unit

while servicing the dosing pump.

(6) Disconnect the fuel line between the dosing

pump and the cabin heater unit.

NOTE: Have an approved fuel storage container

ready to catch any residual fuel that may drain from

the fuel line or the cabin heater unit.(7) Remove the dosing pump from the rubber iso-

lator and the vehicle.

INSTALLATION

(1) Position the dosing pump to the vehicle and

onto the rubber isolator.

(2) Connect the fuel line between the dosing pump

and the cabin heater unit.

NOTE: The connectors should point towards the

cabin heater fuel line.

(3) Connect the heater fuel hose to the dosing

pump.

(4) Install the clamp that secures the heater fuel

hose to the dosing pump. Tighten the clamp securely.

(5) Connect the wire harness connector to the dos-

ing pump by depressing the integral spring and

pushing the connector toward the pump. Verify con-

nector installation.

(6) Lower the vehicle

(7) Reconnect the negative battery cable.

(8) Verify function of the supplemental cabin

heater.

Fig. 4 Dosing Pump Fuel Line

1 - HEATER FUEL LINE

2 - HEATER FUEL HOSE

3 - HEATER AIR INTAKE PIPE

4 - RETAINING CLAMP (2)

5 - DOSING PUMP

RSCABIN HEATER24 - 117

Page 2269 of 2339

FUEL LINE

STANDARD PROCEDURE

CLEANING

(1) Remove the cabin heater fuel line (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/FUEL LINE - REMOVAL).

(2) With the cabin heater fuel line removed from

the vehicle, place a shop cloth on the fuel tank end of

the fuel line to catch any residue, then apply a small

amount of air pressure to the other end of the fuel

line.

(3) Check to see if air pressure is coming from the

tank end of the line. If pressure is flowing unre-

stricted the line is clean.

(4) If the fuel line shows any signs of being

restricted after air pressure is applied, the fuel line

should be replaced.

(5) Install the cabin heater fuel line (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/FUEL LINE - INSTALLATION).

(6) Verify function of the cabin heater.

REMOVAL

CAUTION: Make sure that the hoist is properly posi-

tioned under the vehicle to prevent damage to the

flexible section of the cabin heater exhaust tube.

(1) Raise and support the vehicle.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel that may drain from the

heater fuel hose or the dosing pump.

(2) Remove the two clamps that secure the heater

fuel hose to the dosing pump and the heater fuel line

(Fig. 5).

(3) Disconnect the heater fuel hose from the dosing

pump and the heater fuel line.

(4) Remove the clamp that secures the heater fuel

line to the fuel tank.

(5) Disconnect the heater fuel line from the fuel

tank.

(6) Disconnect the fuel line from the body retain-

ing clips and remove the fuel line from vehicle.

INSTALLATION

WARNING: DO NOT OPERATE THE DIESEL SUP-

PLEMENTAL CABIN HEATER IN AN ENCLOSED

AREA SUCH AS A GARAGE THAT DOES NOT HAVE

EXHAUST VENTILATION FACILITIES. ALWAYS VENT

THE CABIN HEATER EXHAUST WHEN OPERATING

THE CABIN HEATER. ALLOW THE DIESEL SUPPLE-

MENTAL CABIN HEATER TO COOL BEFORE PER-

FORMING ANY SERVICE PROCEDURES TO THE

CABIN HEATER. VERIFY THAT ALL DIESEL SUP-

PLEMENTAL CABIN HEATER FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING ANY SER-

VICE PROCEDURES TO THE CABIN HEATER. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY OR DEATH.

(1) Position the cabin heater fuel line to the vehi-

cle and connect the body retaining clips.

(2) Connect the heater fuel line to the fuel tank.

(3) Install the clamp that secure the heater fuel

line to the fuel tank. Tighten the clamp securely.

(4) Connect the heater fuel hose to the dosing

pump and the heater fuel line.

(5) Install the clamps that secure the heater fuel

hose to the dosing pump and the heater fuel line.

Tighten the clamps securely.

(6) Lower the vehicle.

Fig. 5 Dosing Pump Fuel Line

1 - HEATER FUEL LINE

2 - HEATER FUEL HOSE

3 - HEATER AIR INTAKE PIPE

4 - RETAINING CLAMP (2)

5 - DOSING PUMP

24 - 118 CABIN HEATERRS

Page 2270 of 2339

NOTE: Verify that there is more than 1/8 of a tank of

fuel in the vehicle's fuel tank before performing this

procedure. Add fuel, if necessary.

NOTE: Failure to prime the dosing pump after drain-

ing the supplemental cabin fuel line will prevent

cabin heater activation during the first attempt to

start the cabin heater. This will also set a diagnostic

trouble code (DTC) in the cabin heater control's

memory. Do not perform the Dosing Pump Priming

procedure if an attempt was made to start the cabin

heater without priming the dosing pump first. This

will put excess fuel in the cabin heater and cause

smoke to emit from the cabin heater exhaust pipe

when cabin heater activation occurs.

(7) Connect the DRBIIItscan tool to the diagnos-

tic link connector.

(8) Turn the ignition to the ON position.

NOTE: Do not activate the dosing pump prime more

than one time. This will put excess fuel in the sup-

plemental cabin heater and cause smoke to emit

from the cabin heater exhaust pipe when cabin

heater activation occurs.

NOTE: A clicking noise heard coming from the dos-

ing pump indicates that the pump is operational.

(9) With the DRBIIItscan tool in Cabin Heater,

select System Tests and Dosing Pump Prime. Allow

the dosing pump to run for the full 45 second cycle

time. When the 45 second cycle is complete, press

Page Back on the DRBIIItscan tool key pad to exit

the Dosing Pump Prime. The Dosing Pump Priming

procedure is now complete.

HEATER HOSES

REMOVAL

(1) Raise and support the vehicle. Take note of the

location of the flexible section of the cabin heater

exhaust tube.

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

NOTE: Complete removal of the supplemental cabin

heater from vehicle is not required, lowering the

cabin heater allows easier access to coolant line

clamps.(3) Lower the supplemental cabin heater from the

vehicle (Refer to 24 - HEATING & AIR CONDITION-

ING/CABIN HEATER/HEATER UNIT - REMOVAL).

(4) Remove the clamps from both flexible coolant

line ends.

NOTE: It is recommended that both flexible cabin

heater coolant lines be replaced if either cabin

heater coolant line is damaged.

(5) Remove both coolant lines from vehicle.

INSTALLATION

(1) Install both flexible coolant lines to the supple-

mental cabin heater and install the clamps.

(2) Install the flexible coolant lines to the coolant

pipes and install the clamps.

(3) Install the supplemental cabin heater into the

vehicle (Refer to 24 - HEATING & AIR CONDITION-

ING/CABIN HEATER/HEATER UNIT - INSTALLA-

TION).

(4) Lower the vehicle.

(5) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(6) Verify operation of the supplemental cabin

heater.

HEATER PIPES

REMOVAL

WARNING: ALLOW THE ENGINE COOLING SYSTEM

TO COOL COMPLETELY BEFORE REMOVING RADI-

ATOR CAP OR DRAINING THE ENGINE COOLING

SYSTEM. PERSONAL INJURY MAY RESULT IF THE

ENGINE COOLING SYSTEM IS OPENED WHILE

ENGINE COOLANT IS HOT AND UNDER PRES-

SURE.

NOTE: Steel heater lines from engine compartment

to the supplemental cabin heater are part of an

assembly that includes the air intake pipe. If the

cabin heater lines or air intake pipe require removal

or replacement the entire cabin heater assembly

will require removal or replacement.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(2) Remove clamps from both the EGR cooler and

the lower heater port. Separate hoses from the mat-

ing plumbing port (Fig. 6).

RSCABIN HEATER24 - 119

FUEL LINE (Continued)

Page 2284 of 2339

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

OPERATION - EVAPORATION CONTROL

SYSTEM............................11

SPECIFICATIONS

TORQUE............................12

EVAP/PURGE SOLENOID

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

FUEL FILLER CAP

DESCRIPTION.........................13

OPERATION...........................13

NATURAL VAC LEAK DETECTION ASSY

REMOVAL.............................14

INSTALLATION.........................14

LEAK DETECTION PUMP

REMOVAL.............................15

INSTALLATION.........................15

ORVR

OPERATION...........................15DIAGNOSIS AND TESTING - VEHICLE DOES

NOT FILL............................17

P C V VA LV E

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - PCV SYSTEM . . . 18

VAPOR CANISTER

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL

REMOVAL...........................19

REMOVAL - WITH NVLD - FOLD-IN-FLOOR . 20

REMOVAL - REAR EVAP CANISTER.......20

INSTALLATION

INSTALLATION.......................20

INSTALLATION - WITH NVLD - FOLD-IN-

FLOOR.............................20

INSTALLATION - REAR EVAP CANISTER . . . 21

EVAPORATIVE EMISSIONS

OPERATION - EVAPORATION CONTROL

SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through vent hoses or tubes to an activated carbon

filled evaporative canister. The canister temporarily

holds the vapors. The Powertrain Control Module

(PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions (Fig. 1).All engines use a proportional purge solenoid sys-

tem. The PCM controls vapor flow by operating the

purge solenoid. Refer to Proportional Purge Solenoid

in this section.

NOTE: The evaporative system uses specially man-

ufactured hoses. If they need replacement, only use

fuel resistant hose. Also the hoses must be able to

pass an Ozone compliance test.

NOTE: For more information on Onboard Refueling

Vapor Recovery (ORVR), refer to the Fuel Delivery

section.

RSEVAPORATIVE EMISSIONS25-11

Page 2286 of 2339

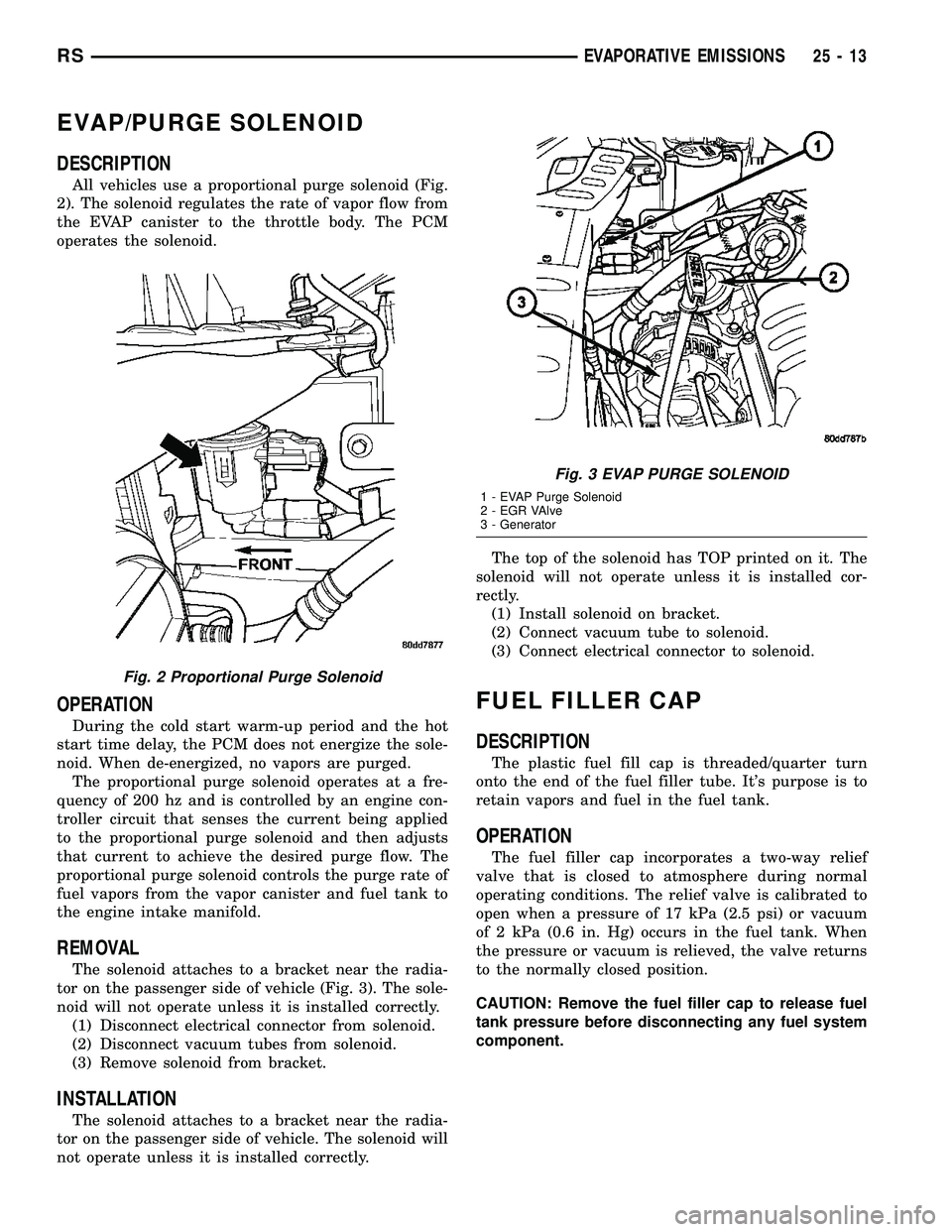

EVAP/PURGE SOLENOID

DESCRIPTION

All vehicles use a proportional purge solenoid (Fig.

2). The solenoid regulates the rate of vapor flow from

the EVAP canister to the throttle body. The PCM

operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid and then adjusts

that current to achieve the desired purge flow. The

proportional purge solenoid controls the purge rate of

fuel vapors from the vapor canister and fuel tank to

the engine intake manifold.

REMOVAL

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle (Fig. 3). The sole-

noid will not operate unless it is installed correctly.

(1) Disconnect electrical connector from solenoid.

(2) Disconnect vacuum tubes from solenoid.

(3) Remove solenoid from bracket.

INSTALLATION

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle. The solenoid will

not operate unless it is installed correctly.The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel fill cap is threaded/quarter turn

onto the end of the fuel filler tube. It's purpose is to

retain vapors and fuel in the fuel tank.

OPERATION

The fuel filler cap incorporates a two-way relief

valve that is closed to atmosphere during normal

operating conditions. The relief valve is calibrated to

open when a pressure of 17 kPa (2.5 psi) or vacuum

of 2 kPa (0.6 in. Hg) occurs in the fuel tank. When

the pressure or vacuum is relieved, the valve returns

to the normally closed position.

CAUTION: Remove the fuel filler cap to release fuel

tank pressure before disconnecting any fuel system

component.

Fig. 2 Proportional Purge Solenoid

Fig. 3 EVAP PURGE SOLENOID

1 - EVAP Purge Solenoid

2 - EGR VAlve

3 - Generator

RSEVAPORATIVE EMISSIONS25-13

Page 2288 of 2339

LEAK DETECTION PUMP

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Remove 3 hoses (Fig. 7).

(4) Remove the electrical connector (Fig. 8).

(5) Remove the 3 screws and remove LDP pump.

INSTALLATION

(1) Install LDP.

(2) Install the 3 screws and tighten (Fig. 8).

(3) Install the electrical connector.

(4) Install the 3 hoses (Fig. 7).

(5) Lower vehicle.

(6) Connect the negative battery cable.

ORVR

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I.D.) creates an aspiration effect which

draws air into the fill tube (Fig. 9). During refueling,

the fuel tank is vented to the vapor canister to cap-

ture escaping vapors. With air flowing into the filler

tube, there are no fuel vapors escaping to the atmo-

sphere. Once the refueling vapors are captured by

the canister, the vehicle's computer controlled purge

system draws vapor out of the canister for the engine

to burn. The vapors flow is metered by the purge

solenoid so that there is no or minimal impact on

driveability or tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve(Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL TANK - OPERATION)

contains a float that rises to seal the large diameter

vent path to the canister. At this point in the fueling

of the vehicle, the tank pressure increases, the check

valve closes (preventing tank fuel from spitting back

at the operator), and fuel then rises up the filler tube

to shut-off the dispensing nozzle.

If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

Fig. 7 LDP LOCATION

Fig. 8 LDP REMOVAL/INSTALLATION

RSEVAPORATIVE EMISSIONS25-15