seats CHRYSLER CARAVAN 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1287 of 2339

Fig. 34 Valve Spring - Type A

1 - VALVE SPRING (TOP - SMALLER DIAMETER)

Fig. 35 VALVE COMPONENTS

1 - VALVE LOCKS 5 - SPRING SEATS

2 - RETAINERS 6 - CYLINDER HEAD

3 - VALVE SPRINGS 7 - VALVE - EXHAUST

4 - VALVE STEM SEALS 8 - VALVE - INTAKE

Fig. 36 VALVE SPRING - REMOVE/INSTALL

1 - SPECIAL TOOL C-3422-D SPRING COMPRESSOR

2 - SPECIAL TOOL 8464 ADAPTER

9 - 110 ENGINE 3.3/3.8LRS

VALVE SPRINGS (Continued)

Page 1309 of 2339

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Remove crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

(2) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(3) Remove oil seal retainer screws (Fig. 83).

(4) Remove oil seal retainer (Fig. 83).

(5) Clean engine block and retainer of oil and gas-

ket material. Make sure surfaces are clean and free

of oil.

INSTALLATION

(1) Position new gasket and install retainer on

block (Fig. 83). Tighten attaching screws to 12 N´m

(105 in. lbs.).

(2) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(3) Install oil seal (Refer to 9 - ENGINE/ENGINE

BLOCK/CRANKSHAFT OIL SEAL - REAR -

INSTALLATION).

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove the right front wheel and inner splash

shield.

(4) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(5) Remove vibration damper bolt.

(6) Insert Special Tool 8450 into crankshaft nose

(Fig. 84).

(7) Position 3-jaw puller Special Tool 1026 on

damper as shown in (Fig. 84). Turn puller forcing

screw until damper releases from crankshaft.

(8) Remove the crankshaft vibration damper.

INSTALLATION

(1) Install crankshaft vibration damper using the

forcing screw, nut, and thrust bearing/washer from

Special Tool 8452 (Fig. 85).

NOTE: To minimize friction and prolong tool life,

lubricate the threads on the forcing screw of Spe-

cial Tool 8452.

(2) Position vibration damper on crankshaft.

(3) Screw Special Tool 8452 into crankshaft until

the bolt seats. Turn the nut to install damper until it

seats fully.

(4) Remove Special Tool 8452.

(5) Install vibration damper bolt. Torque bolt to 54

N´m (40 ft. lbs.).

Fig. 82 Rear Crankshaft Oil SealÐInstallation

1 - SPECIAL TOOLS:

2 - C-4171 HANDLE

3 - 6926±2 INSTALLER

4 - 6926±1 GUIDE

5 - SEAL

Fig. 83 CRANKSHAFT REAR OIL SEAL

1 - OIL SEAL

2 - BOLT

3 - RETAINER - OIL SEAL

4 - GASKET

9 - 132 ENGINE 3.3/3.8LRS

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1337 of 2339

INSTALLATION

INSTALLATION - CRANKSHAFT SPROCKET

(1) Position the sprocket on the crankshaft (timing

mark out) with the timing slot aligned with the tim-

ing pin.

(2) Install sprocket using Special Tool 8452 (Fig.

143). Install sprocket until it is fully seats on the

crankshaft.(3) Install the timing chain and camshaft sprocket.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)INSTALLATION - TIMING CHAIN AND

CAMSHAFT SPROCKET

(1) Rotate crankshaft so the timing arrow is to the

12 o'clock position (Fig. 141).

NOTE: Lubricate timing chain and sprockets with

clean engine oil before installation.

(2) While holding camshaft sprocket and chain in

hand, place timing chain around the sprocket, align-

ing the plated link with the dot on the sprocket. Posi-

tion the timing arrow to the 6 o'clock position (Fig.

141).

(3) Place timing chain around crankshaft sprocket

with the plated link lined up with the dot on the

sprocket. Install camshaft sprocket into position.

(4) Use a straight edge to check alignment of tim-

ing marks.

(5) Install camshaft sprocket bolt and washer.

Tighten bolt to 54 N´m (40 ft. lbs.).

(6) Rotate crankshaft 2 revolutions and check tim-

ing mark alignment (Fig. 141). If timing marks do

not line up, remove camshaft sprocket and realign.

(7) Install the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(8) Connect negative cable to battery.

Fig. 143 CRANKSHAFT SPROCKET - INSTALLATION

1 - SPECIAL TOOL 8452-3

2 - SPECIAL TOOL 8452-1

3 - CRANKSHAFT SPROCKET

4 - THRUST BEARING / WASHER

9 - 160 ENGINE 3.3/3.8LRS

TIMING CHAIN AND SPROCKETS (Continued)

Page 1348 of 2339

FRAME & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT FASCIA

REMOVAL.............................1

INSTALLATION..........................1

FRONT BUMPER REINFORCEMENT

REMOVAL.............................3

INSTALLATION..........................3

REAR FASCIA

REMOVAL.............................4

INSTALLATION..........................4

REAR BUMPER REINFORCEMENT

REMOVAL.............................5

INSTALLATION..........................5

REAR FASCIA - SCUFF PAD

REMOVAL.............................5

INSTALLATION..........................5FRAME

SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 6

SPECIFICATIONS - FRAME DIMENSIONS -

FOLD-IN-FLOOR SEATS ONLY...........11

SPECIFICATIONS - TORQUE............14

FRONT CRADLE CROSSMEMBER

DESCRIPTION

DESCRIPTION - FRONT CRADLE

CROSSMEMBER......................14

DESCRIPTION - FRONT CRADLE

CROSSMEMBER THREAD REPAIR........14

REMOVAL.............................15

INSTALLATION.........................16

FRONT CROSSMEMBER MOUNT BUSHINGS

REMOVAL.............................17

INSTALLATION.........................17

BUMPERS

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper reinforcement attaching nut 54 40 Ð

Rear bumper reinforcement attaching nut 27 20 Ð

FRONT FASCIA

REMOVAL

(1) Release hood latch and open hood.

(2) Remove the headlamp assemblies (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP - REMOVAL).

(3) Hoist vehicle and support with safety stands.

(4) Remove the five push pin fasteners attaching

bottom of fascia/air dam to radiator closure panel.

(5) Remove front wheels.

(6) Remove front wheelhouse splash shields fasten-

ers as necessary to gain access to bolts attaching

front fascia to fender. (Refer to 23 - BODY/EXTERI-

OR/ WHEELHOUSE SPLASH SHIELD -

REMOVAL).(7) Remove the two bolts and two nuts attaching

fascia to the front fenders (Fig. 1) and (Fig. 2).

(8) Disconnect fog lamp wire connectors, if neces-

sary.

(9) Lower vehicle.

(10) Remove two bolts attaching the upper grille

support to the headlamp mounting panel at each side

of the grille.

(11) Remove bumper fascia from vehicle.

INSTALLATION

(1) Position front bumper fascia on vehicle (Fig. 1)

and (Fig. 2).

(2) Install the two bolts attaching fascia to head-

lamp mounting panel at each side of grille.

(3) Hoist vehicle and support with safety stands.

RSFRAME & BUMPERS13-1

Page 1358 of 2339

SPECIFICATIONS - FRAME DIMENSIONS -

FOLD-IN-FLOOR SEATS ONLY

INDEX

DESCRIPTION FIGURE

FRAME - PLAN VIEW 12

FRAME - SIDE VIEW 13

RSFRAME & BUMPERS13-11

FRAME (Continued)

Page 1383 of 2339

QUICK CONNECT FITTING

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Make sure that the o-ring in installed in

fitting. Never install a quick-connect fitting without

the retainer being either on the fuel tube or already

in the quick-connect fitting. In either case, ensure

the retainer locks securely into the quick-connect

fitting by firmly push-pulling-push on fuel tube and

fitting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean engine oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

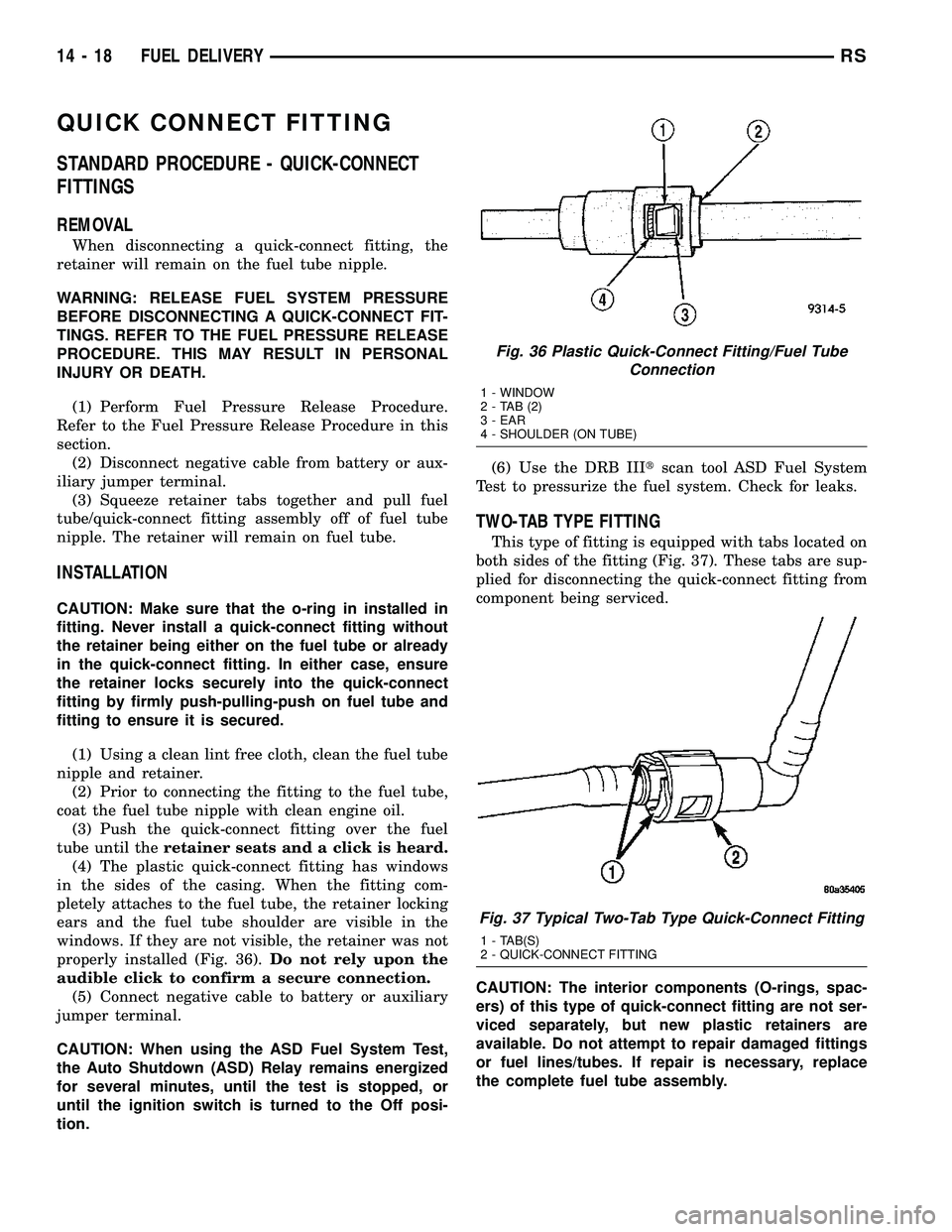

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 36).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for several minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 37). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

Fig. 36 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 - WINDOW

2-TAB(2)

3 - EAR

4 - SHOULDER (ON TUBE)

Fig. 37 Typical Two-Tab Type Quick-Connect Fitting

1 - TAB(S)

2 - QUICK-CONNECT FITTING

14 - 18 FUEL DELIVERYRS

Page 1780 of 2339

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

WATER LEAKS........................1

WIND NOISE..........................2

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . . 9

SPECIFICATIONS

TORQUE............................10

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......40

EXTERIOR.............................45

HOOD.................................62

INSTRUMENT PANEL.....................65

INTERIOR..............................78

PAINT................................100

SEATS...............................102

STATIONARY GLASS....................161

WEATHERSTRIP/SEALS..................166

SUNROOF.............................169

BODY STRUCTURE.....................177

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

RSBODY23-1

Page 1789 of 2339

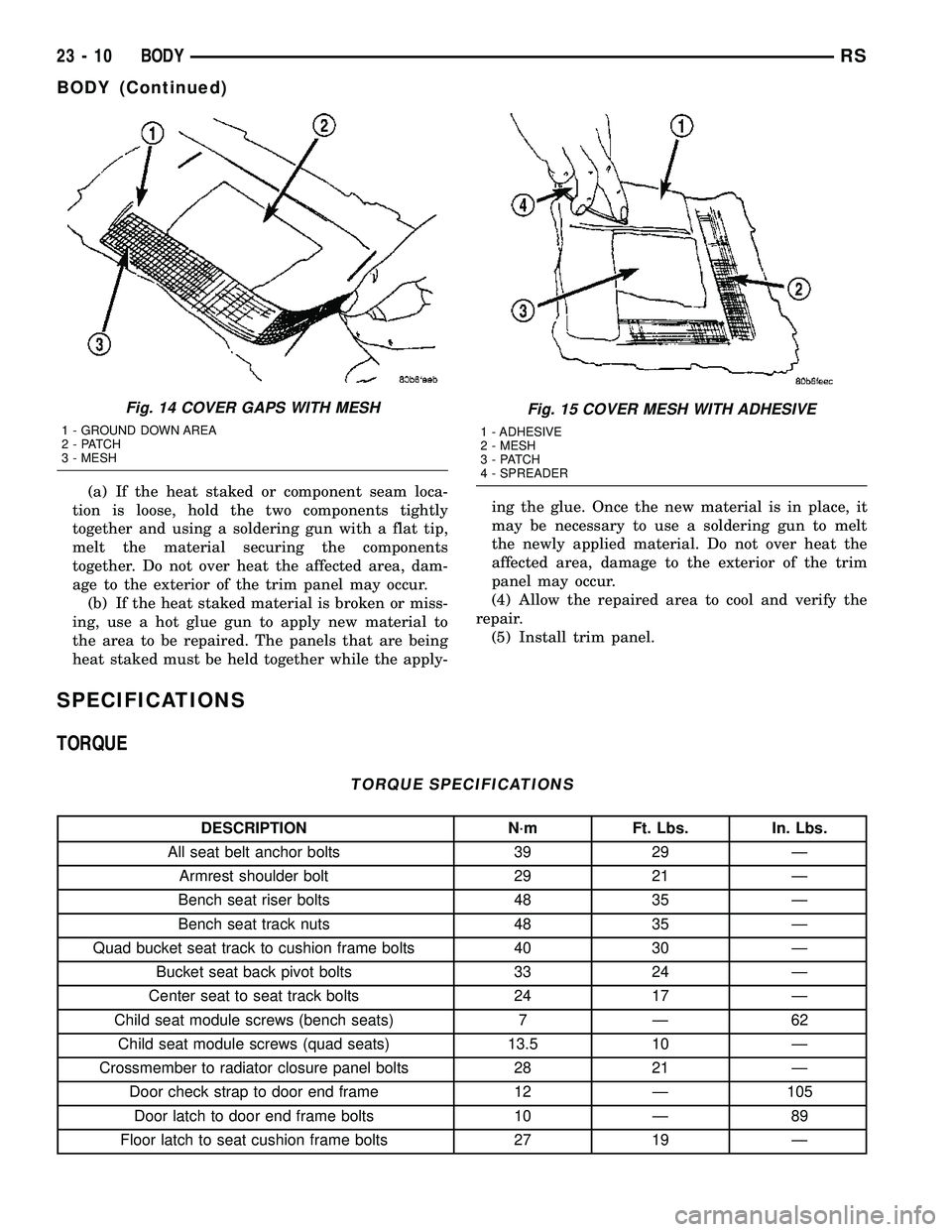

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-ing the glue. Once the new material is in place, it

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

All seat belt anchor bolts 39 29 Ð

Armrest shoulder bolt 29 21 Ð

Bench seat riser bolts 48 35 Ð

Bench seat track nuts 48 35 Ð

Quad bucket seat track to cushion frame bolts 40 30 Ð

Bucket seat back pivot bolts 33 24 Ð

Center seat to seat track bolts 24 17 Ð

Child seat module screws (bench seats) 7 Ð 62

Child seat module screws (quad seats) 13.5 10 Ð

Crossmember to radiator closure panel bolts 28 21 Ð

Door check strap to door end frame 12 Ð 105

Door latch to door end frame bolts 10 Ð 89

Floor latch to seat cushion frame bolts 27 19 Ð

Fig. 14 COVER GAPS WITH MESH

1 - GROUND DOWN AREA

2 - PATCH

3 - MESH

Fig. 15 COVER MESH WITH ADHESIVE

1 - ADHESIVE

2 - MESH

3 - PATCH

4 - SPREADER

23 - 10 BODYRS

BODY (Continued)

Page 1860 of 2339

CARPETS AND FLOOR MATS

REMOVAL

(1) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(2) Remove front center console.

(3) Remove heel blocker (plastic block below accel-

erator pedal).

(4) Remove the remaining seats. Refer to the Own-

er's Manual for the proper procedures.

(5) Remove front cowl panels and sill plates.

(6) Remove sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(7) Remove the cargo organizer, if equipped.

(8) Remove liftgate scuff plate. (Refer to 23 -

BODY/INTERIOR/LIFTGATE SCUFF PLATE -

REMOVAL)

(9) Remove lower B-pillar trim covers.

(10) Remove D-pillar trim covers.

(11) Remove Quarter trim panels.

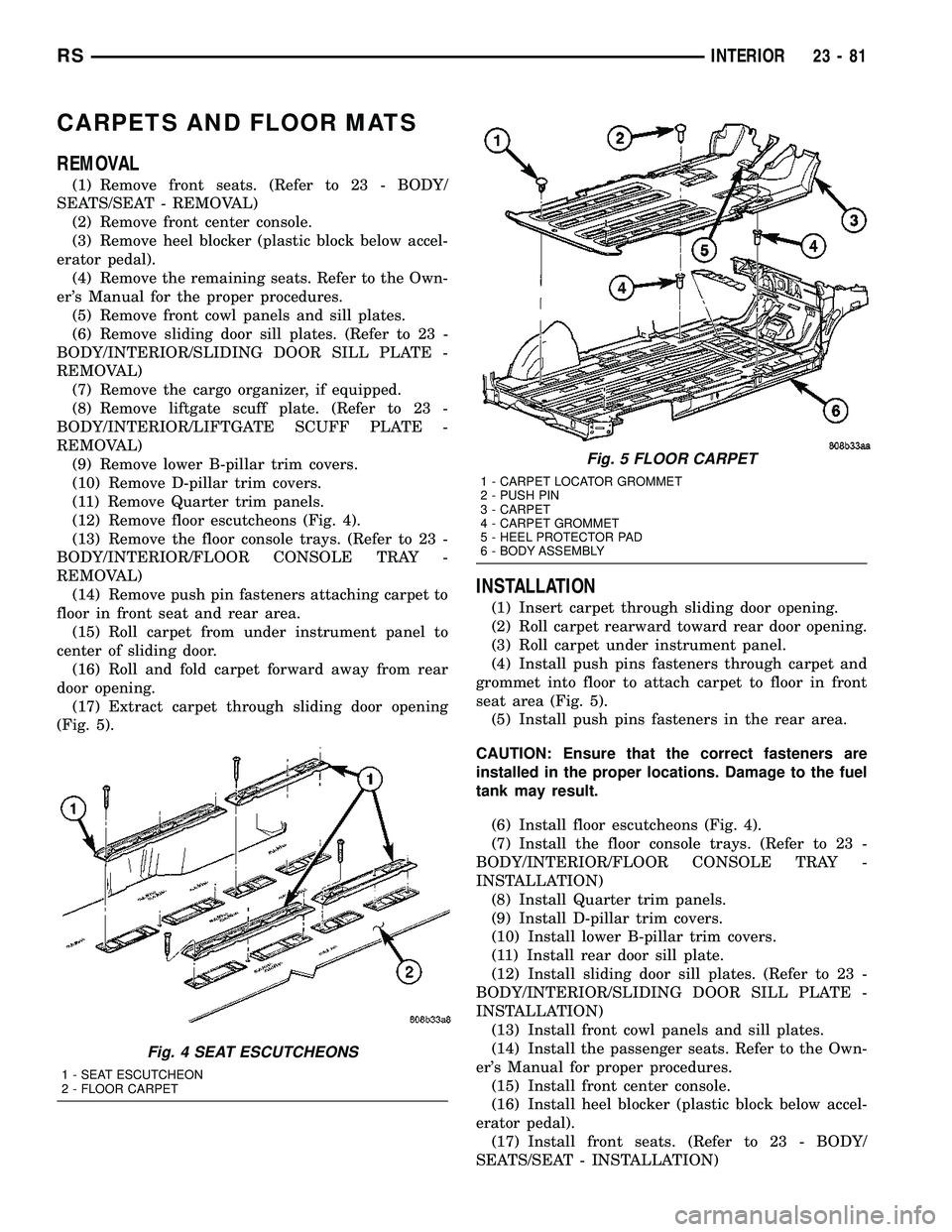

(12) Remove floor escutcheons (Fig. 4).

(13) Remove the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

REMOVAL)

(14) Remove push pin fasteners attaching carpet to

floor in front seat and rear area.

(15) Roll carpet from under instrument panel to

center of sliding door.

(16) Roll and fold carpet forward away from rear

door opening.

(17) Extract carpet through sliding door opening

(Fig. 5).

INSTALLATION

(1) Insert carpet through sliding door opening.

(2) Roll carpet rearward toward rear door opening.

(3) Roll carpet under instrument panel.

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area (Fig. 5).

(5) Install push pins fasteners in the rear area.

CAUTION: Ensure that the correct fasteners are

installed in the proper locations. Damage to the fuel

tank may result.

(6) Install floor escutcheons (Fig. 4).

(7) Install the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

INSTALLATION)

(8) Install Quarter trim panels.

(9) Install D-pillar trim covers.

(10) Install lower B-pillar trim covers.

(11) Install rear door sill plate.

(12) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(13) Install front cowl panels and sill plates.

(14) Install the passenger seats. Refer to the Own-

er's Manual for proper procedures.

(15) Install front center console.

(16) Install heel blocker (plastic block below accel-

erator pedal).

(17) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION)

Fig. 4 SEAT ESCUTCHEONS

1 - SEAT ESCUTCHEON

2 - FLOOR CARPET

Fig. 5 FLOOR CARPET

1 - CARPET LOCATOR GROMMET

2 - PUSH PIN

3 - CARPET

4 - CARPET GROMMET

5 - HEEL PROTECTOR PAD

6 - BODY ASSEMBLY

RSINTERIOR23-81

Page 1861 of 2339

CARPETS - FOLD-IN-FLOOR

REMOVAL

(1) Remove floor mats.

(2) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(3) Remove instrument panel lower console. (Refer

to 23 - BODY/INSTRUMENT PANEL/STORAGE

BIN - REMOVAL).

(4) Remove the floor console base tray and discon-

nect wire connector from the base tray.(Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE BASE TRAY -

REMOVAL)

(5) Remove heel blocker (plastic block below accel-

erator pedal).

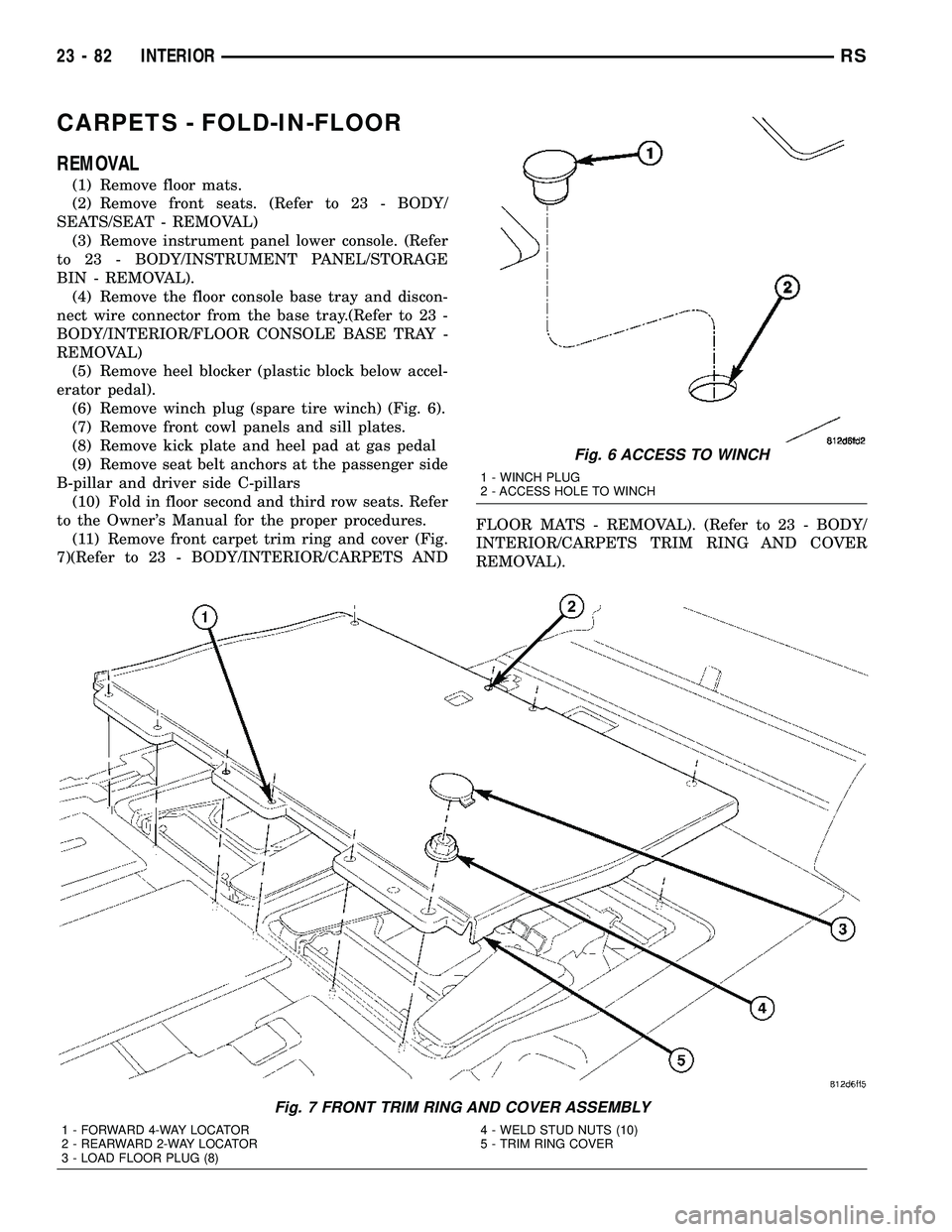

(6) Remove winch plug (spare tire winch) (Fig. 6).

(7) Remove front cowl panels and sill plates.

(8) Remove kick plate and heel pad at gas pedal

(9) Remove seat belt anchors at the passenger side

B-pillar and driver side C-pillars

(10) Fold in floor second and third row seats. Refer

to the Owner's Manual for the proper procedures.

(11) Remove front carpet trim ring and cover (Fig.

7)(Refer to 23 - BODY/INTERIOR/CARPETS ANDFLOOR MATS - REMOVAL). (Refer to 23 - BODY/

INTERIOR/CARPETS TRIM RING AND COVER

REMOVAL).

Fig. 6 ACCESS TO WINCH

1 - WINCH PLUG

2 - ACCESS HOLE TO WINCH

Fig. 7 FRONT TRIM RING AND COVER ASSEMBLY

1 - FORWARD 4-WAY LOCATOR

2 - REARWARD 2-WAY LOCATOR

3 - LOAD FLOOR PLUG (8)4 - WELD STUD NUTS (10)

5 - TRIM RING COVER

23 - 82 INTERIORRS