wheel CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 999 of 1938

Component/

GroundColor Location Fig.

Powertrain

Control Module

C1BK LT Fender Side

Shield3

Powertrain

Control Module

C2BK LT Fender Side

Shield3

Radiator Fan

No.1BK At Motor N/S

Radiator Fan

No.2BK At Motor N/S

Radiator Fan

RelayBK LT Front Frame

Rail3

Radio C1 GY Rear of Radio 11

Radio C2 BK Rear of Radio 11

Radio C3 BK Rear of Radio 11

Radio Choke LT/GY Rear of Radio N/S

Rear A/C-

Heater UnitLT/GN RT Quarter

Panel22

Rear Blower

Front Control

SwitchBK Rear of Switch 11

Rear Blower

Rear Control

SwitchBK At Switch N/S

Rear Cigar

Lighter/Power

OutletBK LT Quarter

Panel21

Rear Dome

LampBK At Lamp N/S

Rear Washer

MotorBK Bottom of

Reservior4

Rear Window

DefoggerBK On Liftgate 23

Rear Wiper

MotorBK At Motor 23

Recirculation

Door ActuatorNAT RT Side of

HVAC15

Remote Keyless

Entry ModuleRD Top RT of I.P. 11

Right

Combination

RelayBK LT Quarter

PanelN/S

Right Door

Arm/Disarm

SwitchBK At Switch 19

Right Door

Courtesy LampBK At Lamp 19Component/

GroundColor Location Fig.

Right Door

SpeakerBK At Speaker 19

RF3 BK At Radiator Fan

ModuleN/S

Right Fog Lamp GY At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 19

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar N/S

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 35

DESCRIPTION AND OPERATION (Continued)

Page 1000 of 1938

Component/

GroundColor Location Fig.

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorGY Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK RT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

Column at

Module11

Stop Lamp

SwitchGY Top of Brake

Pedal12

T05 BK LT Quarter

PanelN/S

T08 BK RT Quarter

PanelN/SComponent/

GroundColor Location Fig.

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7. 9

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

8W - 90 - 36 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1062 of 1938

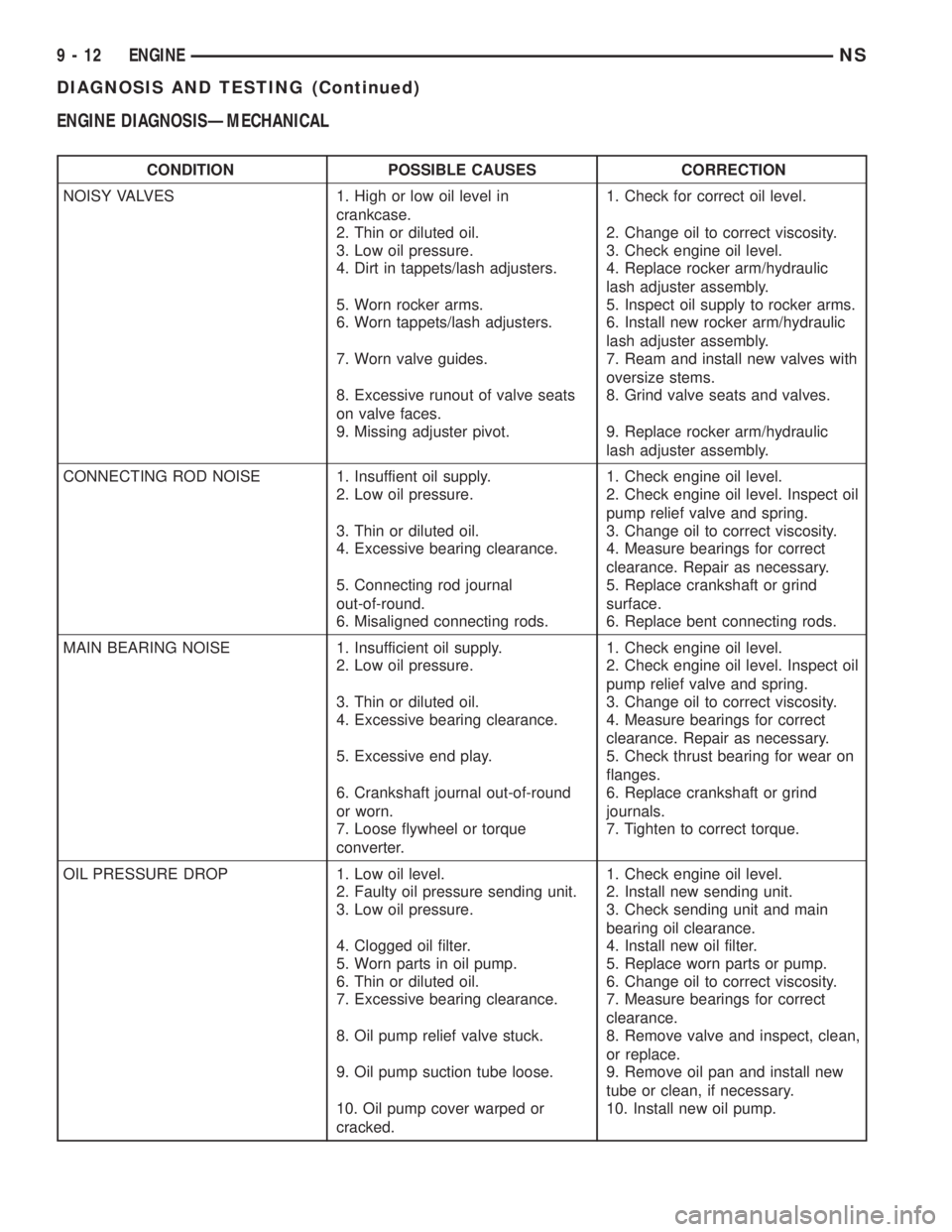

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check for correct oil level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check engine oil level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic

lash adjuster assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic

lash adjuster assembly.

7. Worn valve guides. 7. Ream and install new valves with

oversize stems.

8. Excessive runout of valve seats

on valve faces.8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insuffient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Connecting rod journal

out-of-round.5. Replace crankshaft or grind

surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round

or worn.6. Replace crankshaft or grind

journals.

7. Loose flywheel or torque

converter.7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Excessive bearing clearance. 7. Measure bearings for correct

clearance.

8. Oil pump relief valve stuck. 8. Remove valve and inspect, clean,

or replace.

9. Oil pump suction tube loose. 9. Remove oil pan and install new

tube or clean, if necessary.

10. Oil pump cover warped or

cracked.10. Install new oil pump.

9 - 12 ENGINENS

DIAGNOSIS AND TESTING (Continued)

Page 1065 of 1938

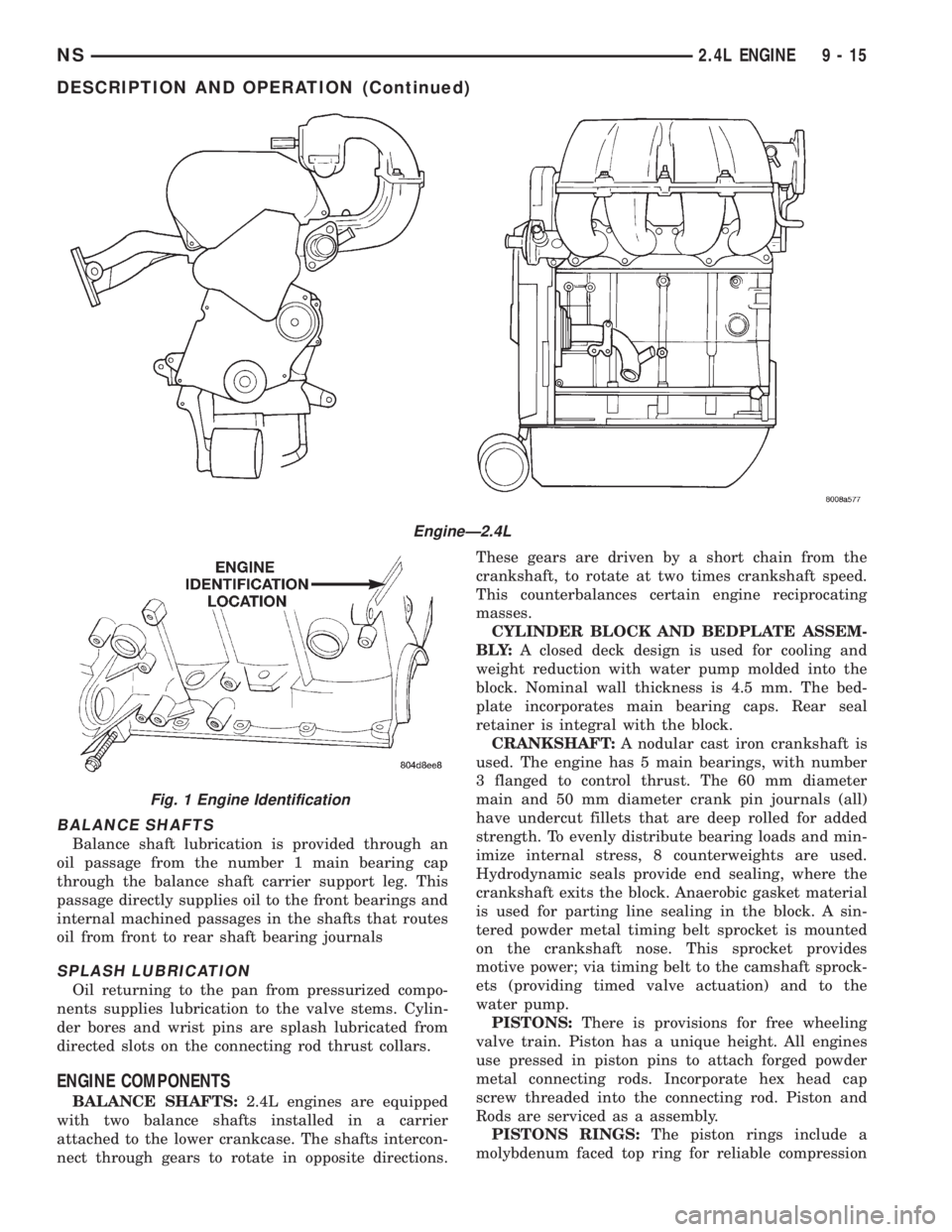

BALANCE SHAFTS

Balance shaft lubrication is provided through an

oil passage from the number 1 main bearing cap

through the balance shaft carrier support leg. This

passage directly supplies oil to the front bearings and

internal machined passages in the shafts that routes

oil from front to rear shaft bearing journals

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

BALANCE SHAFTS:2.4L engines are equipped

with two balance shafts installed in a carrier

attached to the lower crankcase. The shafts intercon-

nect through gears to rotate in opposite directions.These gears are driven by a short chain from the

crankshaft, to rotate at two times crankshaft speed.

This counterbalances certain engine reciprocating

masses.

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A closed deck design is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4.5 mm. The bed-

plate incorporates main bearing caps. Rear seal

retainer is integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 60 mm diameter

main and 50 mm diameter crank pin journals (all)

have undercut fillets that are deep rolled for added

strength. To evenly distribute bearing loads and min-

imize internal stress, 8 counterweights are used.

Hydrodynamic seals provide end sealing, where the

crankshaft exits the block. Anaerobic gasket material

is used for parting line sealing in the block. A sin-

tered powder metal timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides

motive power; via timing belt to the camshaft sprock-

ets (providing timed valve actuation) and to the

water pump.

PISTONS:There is provisions for free wheeling

valve train. Piston has a unique height. All engines

use pressed in piston pins to attach forged powder

metal connecting rods. Incorporate hex head cap

screw threaded into the connecting rod. Piston and

Rods are serviced as a assembly.

PISTONS RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

EngineÐ2.4L

Fig. 1 Engine Identification

NS2.4L ENGINE 9 - 15

DESCRIPTION AND OPERATION (Continued)

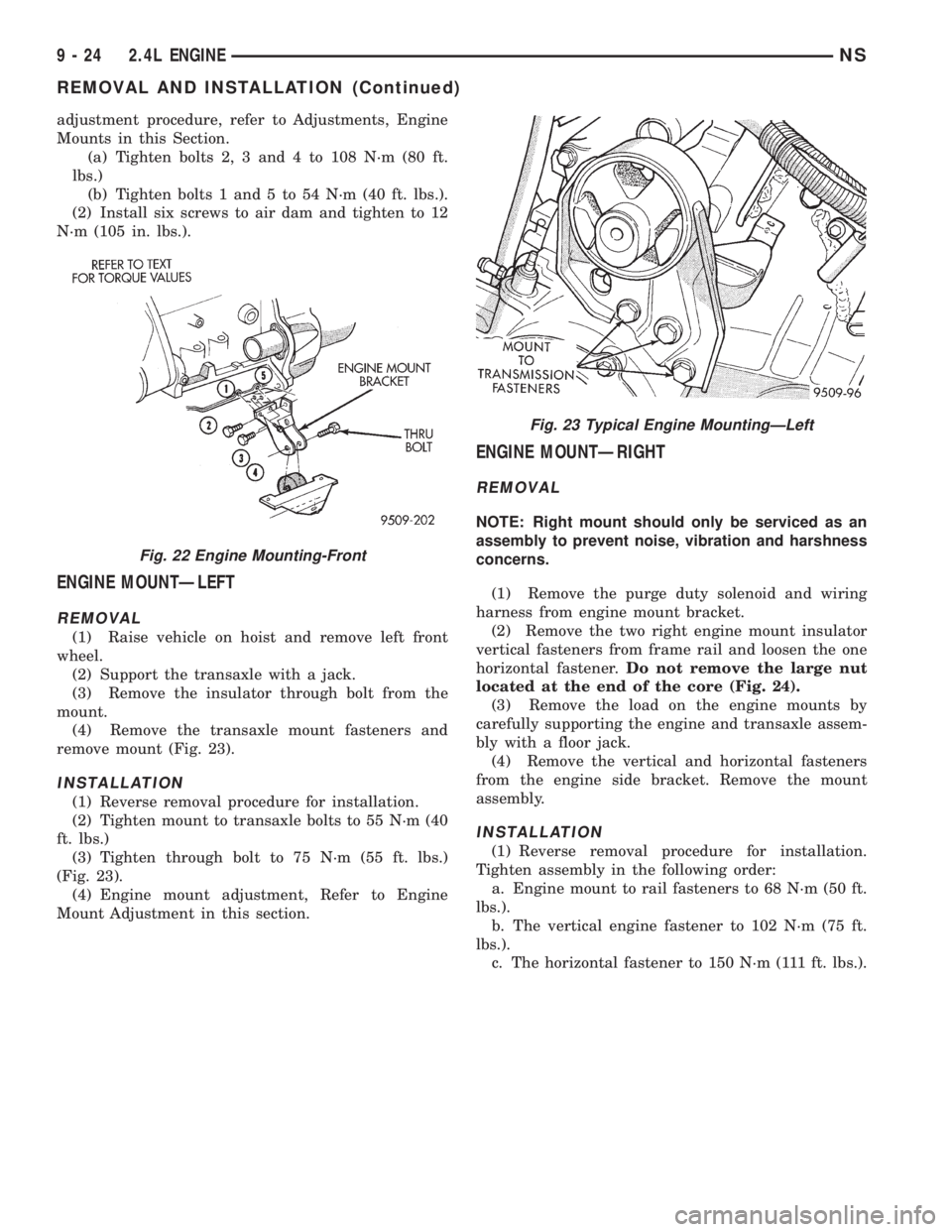

Page 1074 of 1938

adjustment procedure, refer to Adjustments, Engine

Mounts in this Section.

(a) Tighten bolts 2, 3 and 4 to 108 N´m (80 ft.

lbs.)

(b) Tighten bolts 1 and 5 to 54 N´m (40 ft. lbs.).

(2) Install six screws to air dam and tighten to 12

N´m (105 in. lbs.).

ENGINE MOUNTÐLEFT

REMOVAL

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Support the transaxle with a jack.

(3) Remove the insulator through bolt from the

mount.

(4) Remove the transaxle mount fasteners and

remove mount (Fig. 23).

INSTALLATION

(1) Reverse removal procedure for installation.

(2) Tighten mount to transaxle bolts to 55 N´m (40

ft. lbs.)

(3) Tighten through bolt to 75 N´m (55 ft. lbs.)

(Fig. 23).

(4) Engine mount adjustment, Refer to Engine

Mount Adjustment in this section.

ENGINE MOUNTÐRIGHT

REMOVAL

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount bracket.

(2) Remove the two right engine mount insulator

vertical fasteners from frame rail and loosen the one

horizontal fastener.Do not remove the large nut

located at the end of the core (Fig. 24).

(3) Remove the load on the engine mounts by

carefully supporting the engine and transaxle assem-

bly with a floor jack.

(4) Remove the vertical and horizontal fasteners

from the engine side bracket. Remove the mount

assembly.

INSTALLATION

(1) Reverse removal procedure for installation.

Tighten assembly in the following order:

a. Engine mount to rail fasteners to 68 N´m (50 ft.

lbs.).

b. The vertical engine fastener to 102 N´m (75 ft.

lbs.).

c. The horizontal fastener to 150 N´m (111 ft. lbs.).

Fig. 22 Engine Mounting-Front

Fig. 23 Typical Engine MountingÐLeft

9 - 24 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

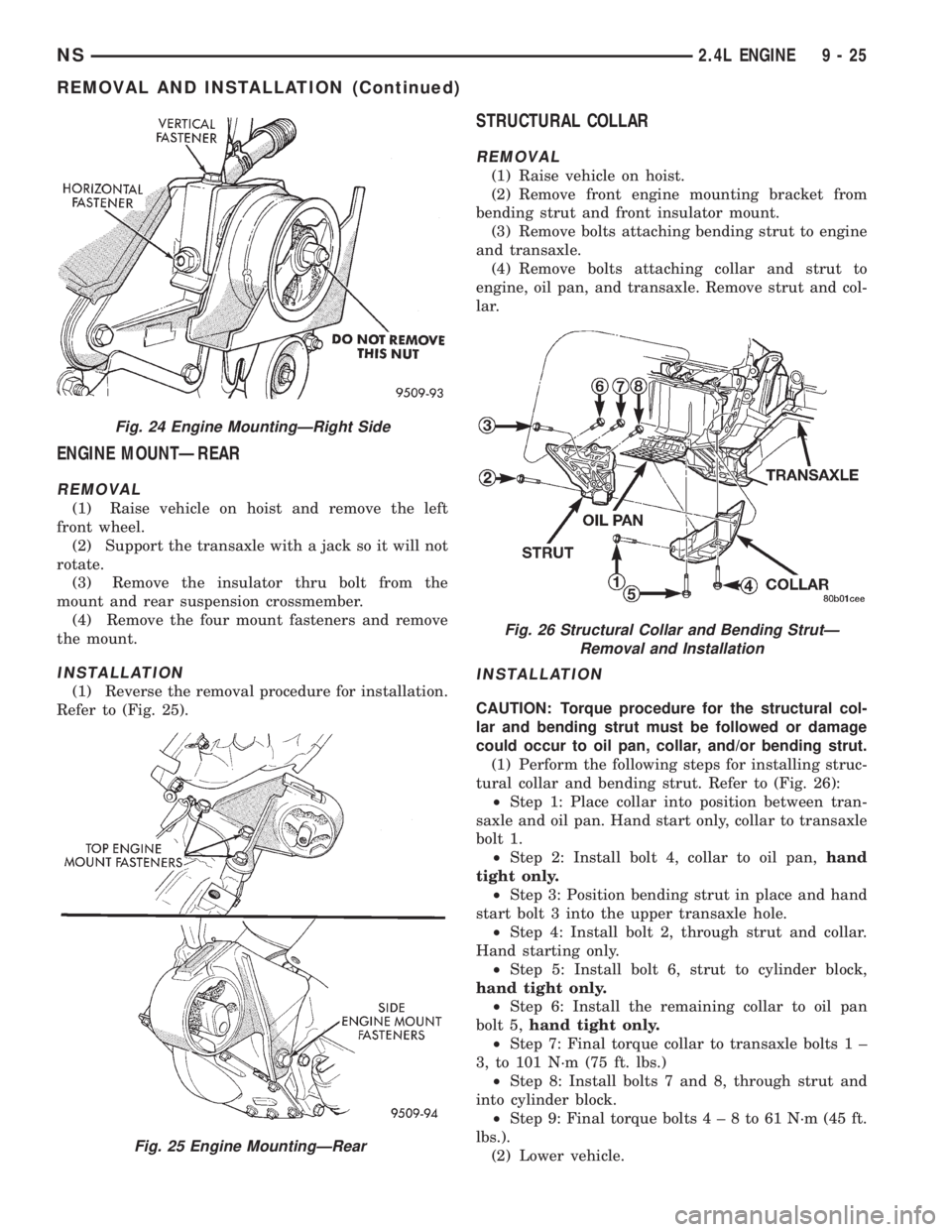

Page 1075 of 1938

ENGINE MOUNTÐREAR

REMOVAL

(1) Raise vehicle on hoist and remove the left

front wheel.

(2) Support the transaxle with a jack so it will not

rotate.

(3) Remove the insulator thru bolt from the

mount and rear suspension crossmember.

(4) Remove the four mount fasteners and remove

the mount.

INSTALLATION

(1) Reverse the removal procedure for installation.

Refer to (Fig. 25).

STRUCTURAL COLLAR

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove front engine mounting bracket from

bending strut and front insulator mount.

(3) Remove bolts attaching bending strut to engine

and transaxle.

(4) Remove bolts attaching collar and strut to

engine, oil pan, and transaxle. Remove strut and col-

lar.

INSTALLATION

CAUTION: Torque procedure for the structural col-

lar and bending strut must be followed or damage

could occur to oil pan, collar, and/or bending strut.

(1) Perform the following steps for installing struc-

tural collar and bending strut. Refer to (Fig. 26):

²Step 1: Place collar into position between tran-

saxle and oil pan. Hand start only, collar to transaxle

bolt 1.

²Step 2: Install bolt 4, collar to oil pan,hand

tight only.

²Step 3: Position bending strut in place and hand

start bolt 3 into the upper transaxle hole.

²Step 4: Install bolt 2, through strut and collar.

Hand starting only.

²Step 5: Install bolt 6, strut to cylinder block,

hand tight only.

²Step 6: Install the remaining collar to oil pan

bolt 5,hand tight only.

²Step 7: Final torque collar to transaxle bolts 1 ±

3, to 101 N´m (75 ft. lbs.)

²Step 8: Install bolts 7 and 8, through strut and

into cylinder block.

²Step 9: Final torque bolts4±8to61N´m(45ft.

lbs.).

(2) Lower vehicle.

Fig. 24 Engine MountingÐRight Side

Fig. 25 Engine MountingÐRear

Fig. 26 Structural Collar and Bending StrutÐ

Removal and Installation

NS2.4L ENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1076 of 1938

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose and remove radia-

tor fans. Refer to Group 7, Cooling System for proce-

dure.

(6) Remove lower radiator hose.

(7) Disconnect automatic transmission cooler lines

and plug, if equipped.

(8) Disconnect transmission shift linkage.

(9) Disconnect throttle body linkage.

(10) Disconnect engine wiring harness.

(11) Disconnect heater hoses.

(12) Discharge Air Conditioning System. Refer to

Group 24, Air Conditioning for procedure.

(13) Hoist vehicle and remove right inner splash

shield. Remove wheels and tires.

(14) Loosen power steering belt for pump removal.

Refer to Group 7, Cooling System for procedure.

(15) Remove axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front and rear engine mount brackets

from the body.

(18) Remove bending braces and front engine

mount bracket. Remove transmission inspection

cover.

(19) Mark flexplate to torque converter and

remove torque converter bolts.

(20) Install front engine mount bracket.

(21) Lower vehicle.

(22) Remove power steering pump. Set pump

aside.

(23) Remove A/C lines at compressor and cap.

(24) Remove ground straps to body.

(25) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 and Adaptor Special Tool

8130 to be installed under vehicle (Fig. 27).

(26) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

front engine bracket and A/C compressor bracket

(Fig. 27). Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.(27) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(28) Remove engine and transmission mount bolts.

(29) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around the body.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(4) Install axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(5) Install transmission and engine braces and

splash shields.

(6) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(7) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt ten-

sion adjustment.

(8) Install A/C compressor hoses. Refer to Group

24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front and rear engine mounts. Refer to

this section for procedure.

(11) Install inner splash shield. Install wheels and

tires.

(12) Connect automatic transmission cooler lines,

and shift linkage. Refer to Group 21, Transmission

for procedures.

(13) Connect fuel line and heater hoses.

(14) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(15) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(16) Install radiator fans. Install radiator hoses.

Fill cooling system. Refer to Group 7, Cooling System

for filling procedure.

(17) Connect battery.

(18) Install air cleaner and hoses.

(19) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(20) Start engine and run until operating temper-

ature is reached.

(21) Adjust transmission linkage, if necessary.

9 - 26 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1087 of 1938

TIMING BELT COVER

FRONT COVER

REMOVAL

(1) Remove crankshaft damper. Refer to crank-

shaft damper removal for procedure.

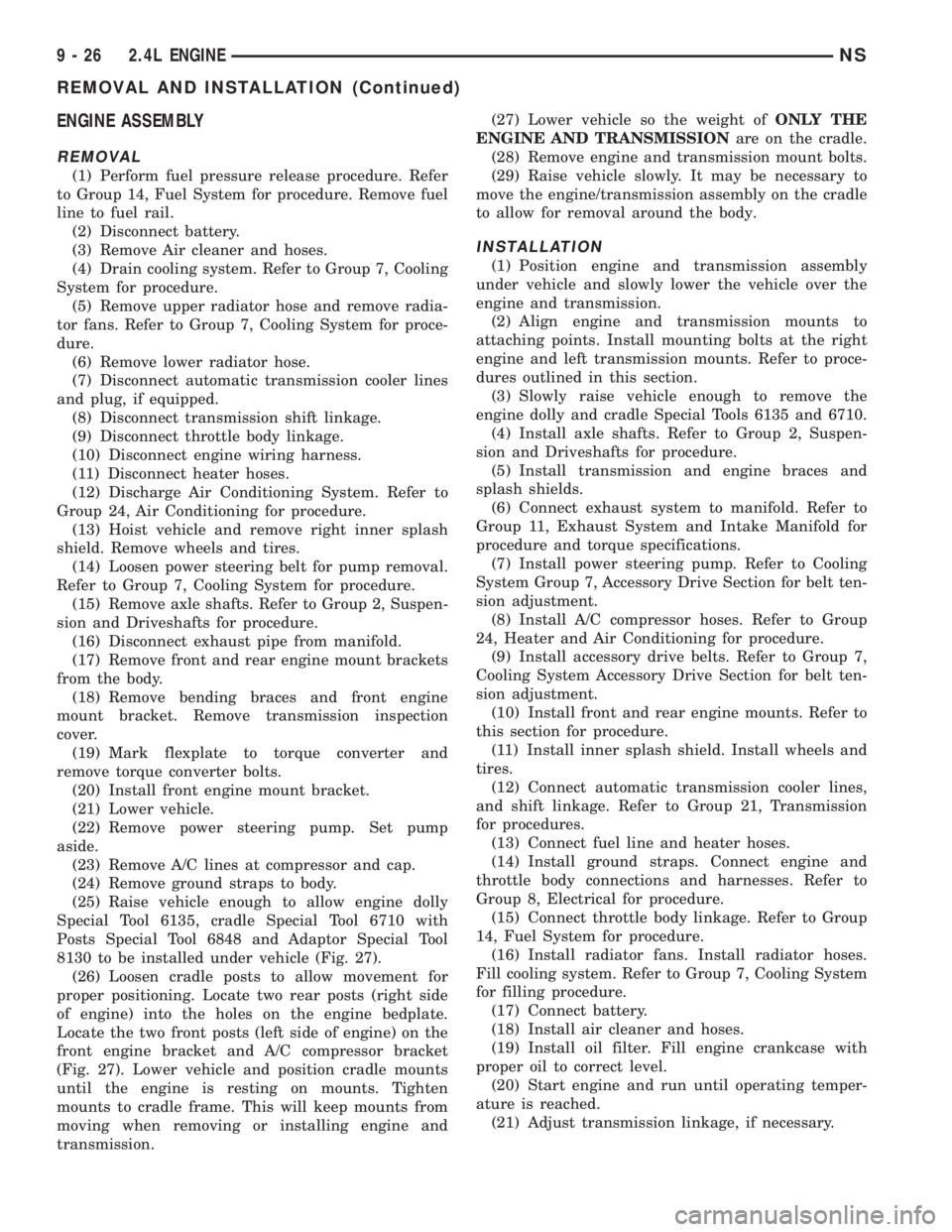

(2) Remove front timing belt cover fasteners (Fig.

55) and remove covers.

INSTALLATION

(1) Install front timing belt covers (Fig. 55).

Tighten bolts to 4.5 N´m (40 in. lbs.).

(2) Install crankshaft damper. Refer to crankshaft

damper installation for procedure.

REAR COVER

REMOVAL

(1) Remove front covers.

(2) Remove engine mount bracket (Fig. 55).

(3) Remove Timing Belt, Idler Pulley, and Cam-

shaft Sprockets. Refer to procedure outlined in this

section.

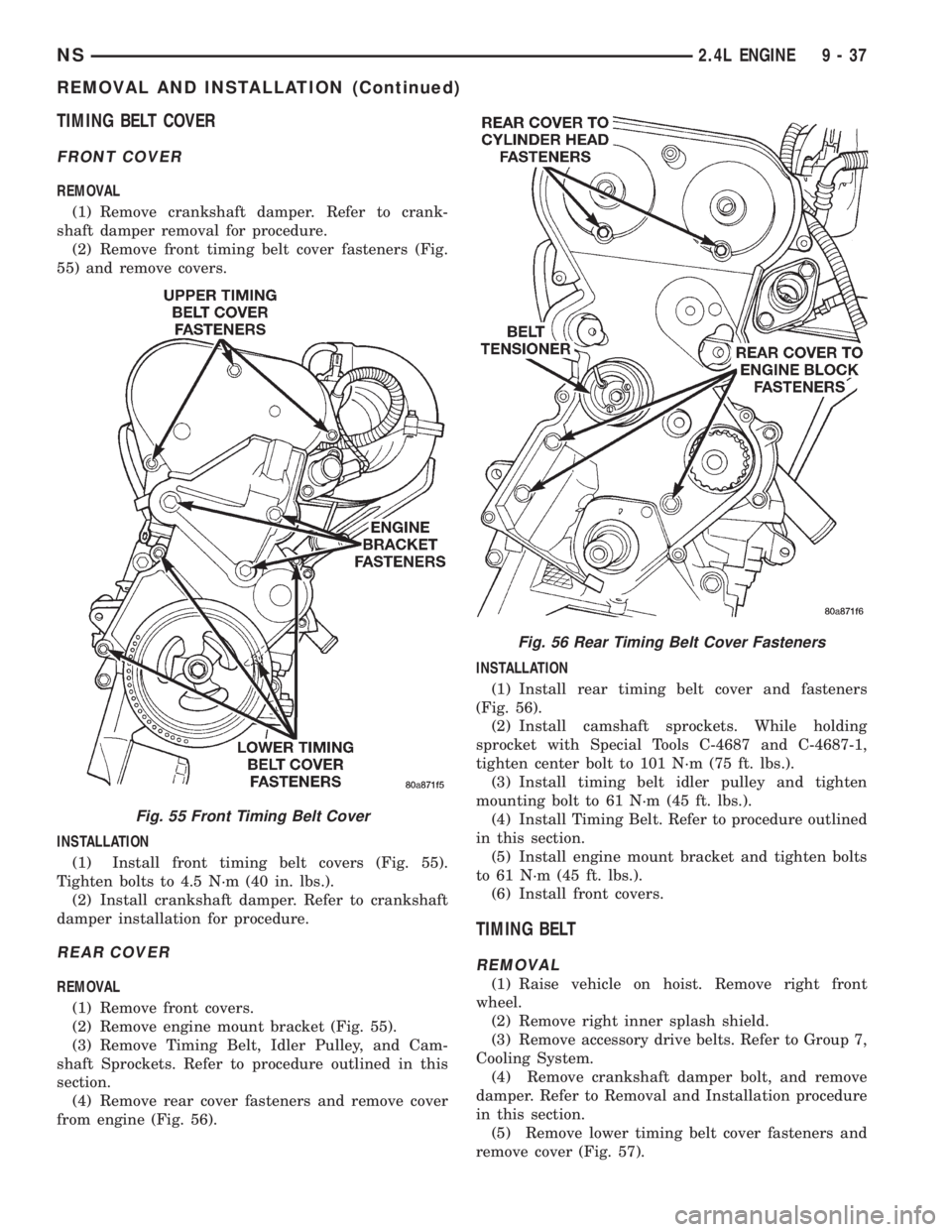

(4) Remove rear cover fasteners and remove cover

from engine (Fig. 56).INSTALLATION

(1) Install rear timing belt cover and fasteners

(Fig. 56).

(2) Install camshaft sprockets. While holding

sprocket with Special Tools C-4687 and C-4687-1,

tighten center bolt to 101 N´m (75 ft. lbs.).

(3) Install timing belt idler pulley and tighten

mounting bolt to 61 N´m (45 ft. lbs.).

(4) Install Timing Belt. Refer to procedure outlined

in this section.

(5) Install engine mount bracket and tighten bolts

to 61 N´m (45 ft. lbs.).

(6) Install front covers.

TIMING BELT

REMOVAL

(1) Raise vehicle on hoist. Remove right front

wheel.

(2) Remove right inner splash shield.

(3) Remove accessory drive belts. Refer to Group 7,

Cooling System.

(4) Remove crankshaft damper bolt, and remove

damper. Refer to Removal and Installation procedure

in this section.

(5) Remove lower timing belt cover fasteners and

remove cover (Fig. 57).

Fig. 55 Front Timing Belt Cover

Fig. 56 Rear Timing Belt Cover Fasteners

NS2.4L ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 1089 of 1938

CAUTION: If timing belt was damaged due to incor-

rect tracking (alignment), the belt tensioner assem-

bly must be replace. Refer to Timing Belt Tensioner

Assembly Removal and Installation procedure out-

lined in this section.

INSTALLATION

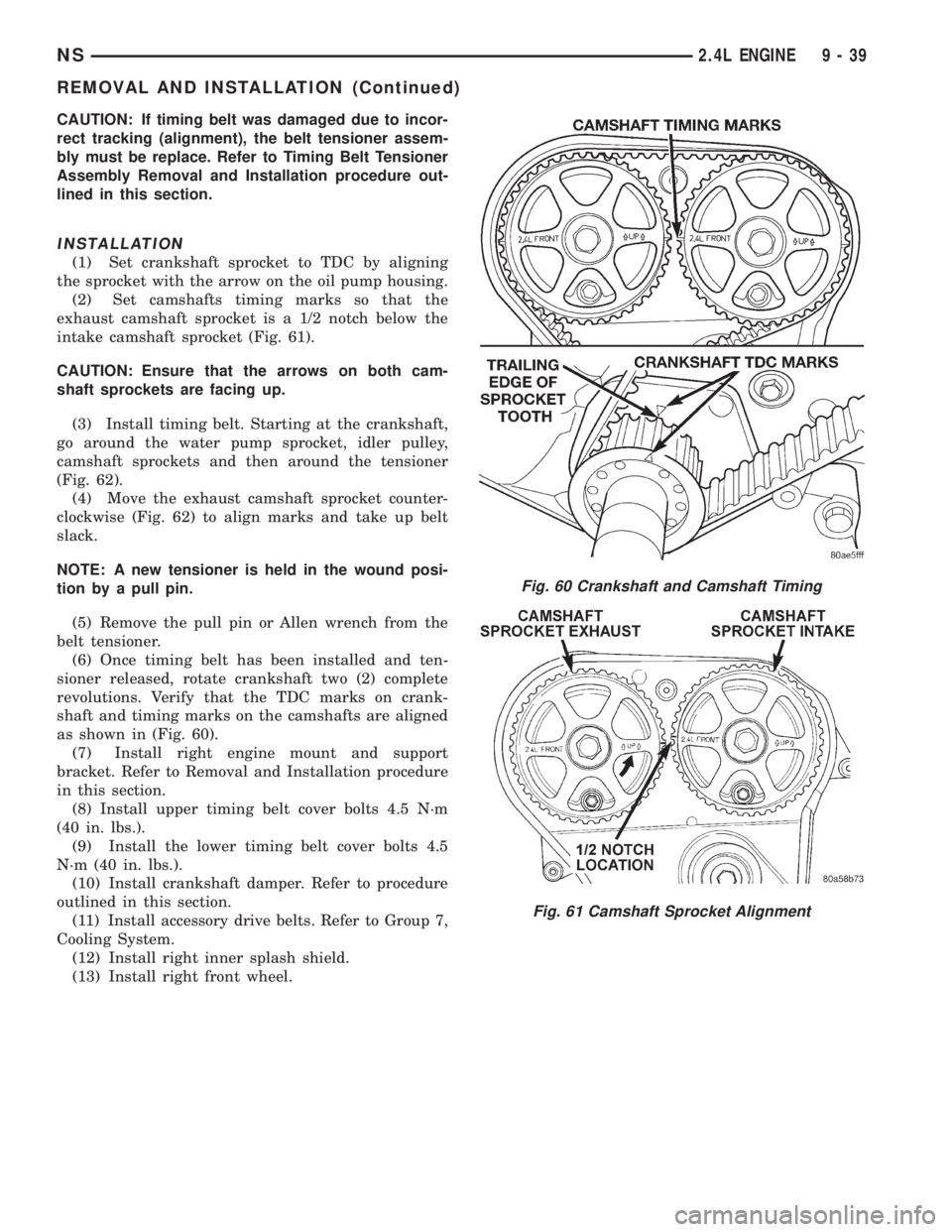

(1) Set crankshaft sprocket to TDC by aligning

the sprocket with the arrow on the oil pump housing.

(2) Set camshafts timing marks so that the

exhaust camshaft sprocket is a 1/2 notch below the

intake camshaft sprocket (Fig. 61).

CAUTION: Ensure that the arrows on both cam-

shaft sprockets are facing up.

(3) Install timing belt. Starting at the crankshaft,

go around the water pump sprocket, idler pulley,

camshaft sprockets and then around the tensioner

(Fig. 62).

(4) Move the exhaust camshaft sprocket counter-

clockwise (Fig. 62) to align marks and take up belt

slack.

NOTE: A new tensioner is held in the wound posi-

tion by a pull pin.

(5) Remove the pull pin or Allen wrench from the

belt tensioner.

(6) Once timing belt has been installed and ten-

sioner released, rotate crankshaft two (2) complete

revolutions. Verify that the TDC marks on crank-

shaft and timing marks on the camshafts are aligned

as shown in (Fig. 60).

(7) Install right engine mount and support

bracket. Refer to Removal and Installation procedure

in this section.

(8) Install upper timing belt cover bolts 4.5 N´m

(40 in. lbs.).

(9) Install the lower timing belt cover bolts 4.5

N´m (40 in. lbs.).

(10) Install crankshaft damper. Refer to procedure

outlined in this section.

(11) Install accessory drive belts. Refer to Group 7,

Cooling System.

(12) Install right inner splash shield.

(13) Install right front wheel.

Fig. 60 Crankshaft and Camshaft Timing

Fig. 61 Camshaft Sprocket Alignment

NS2.4L ENGINE 9 - 39

REMOVAL AND INSTALLATION (Continued)

Page 1118 of 1938

REMOVAL AND INSTALLATION

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

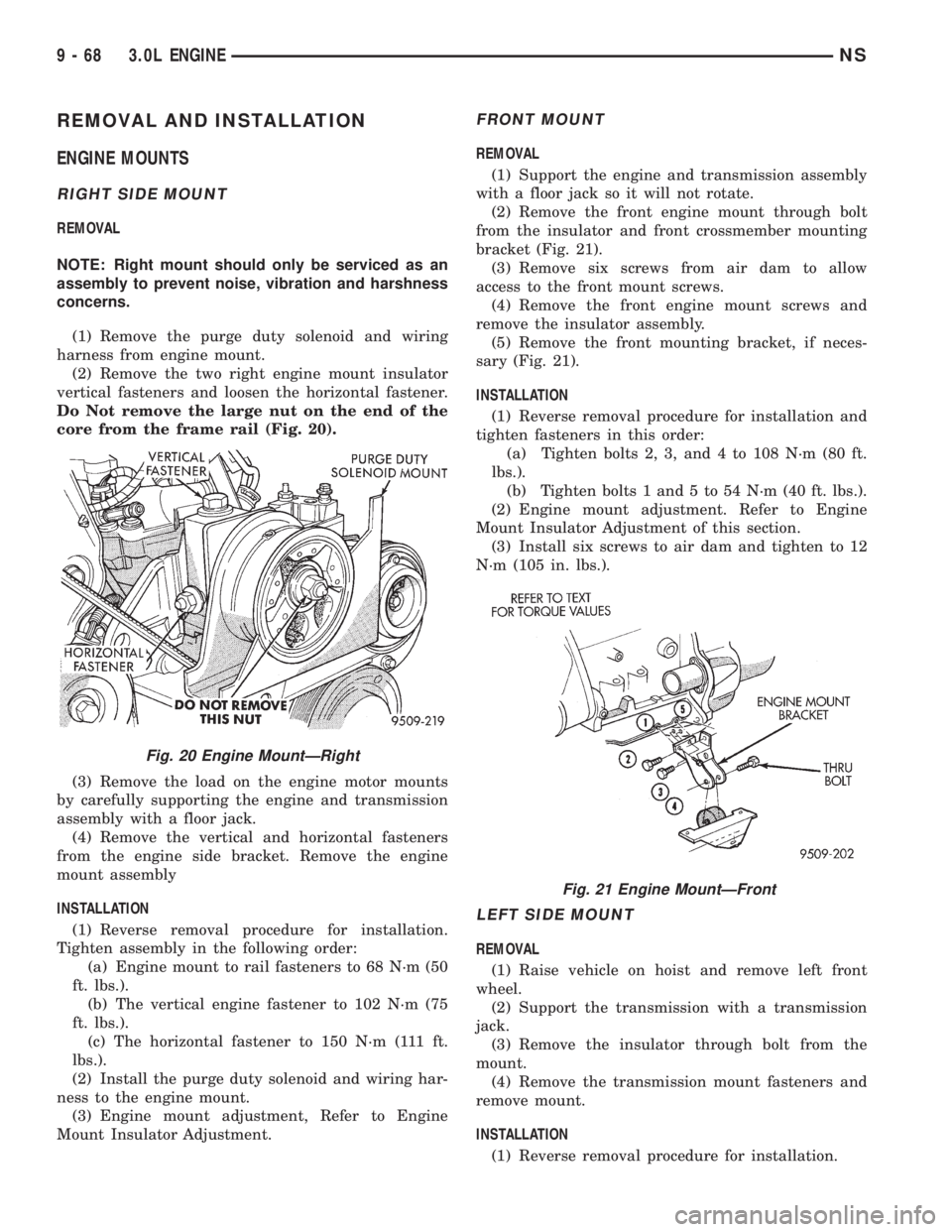

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener.

Do Not remove the large nut on the end of the

core from the frame rail (Fig. 20).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(4) Remove the vertical and horizontal fasteners

from the engine side bracket. Remove the engine

mount assembly

INSTALLATION

(1) Reverse removal procedure for installation.

Tighten assembly in the following order:

(a) Engine mount to rail fasteners to 68 N´m (50

ft. lbs.).

(b) The vertical engine fastener to 102 N´m (75

ft. lbs.).

(c) The horizontal fastener to 150 N´m (111 ft.

lbs.).

(2) Install the purge duty solenoid and wiring har-

ness to the engine mount.

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment.

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 21).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 21).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order:

(a) Tighten bolts 2, 3, and 4 to 108 N´m (80 ft.

lbs.).

(b) Tighten bolts 1 and 5 to 54 N´m (40 ft. lbs.).

(2) Engine mount adjustment. Refer to Engine

Mount Insulator Adjustment of this section.

(3) Install six screws to air dam and tighten to 12

N´m (105 in. lbs.).

LEFT SIDE MOUNT

REMOVAL

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Support the transmission with a transmission

jack.

(3) Remove the insulator through bolt from the

mount.

(4) Remove the transmission mount fasteners and

remove mount.

INSTALLATION

(1) Reverse removal procedure for installation.

Fig. 20 Engine MountÐRight

Fig. 21 Engine MountÐFront

9 - 68 3.0L ENGINENS