weight CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 111 of 1938

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove rear wheel and tire assemblies from

vehicle.

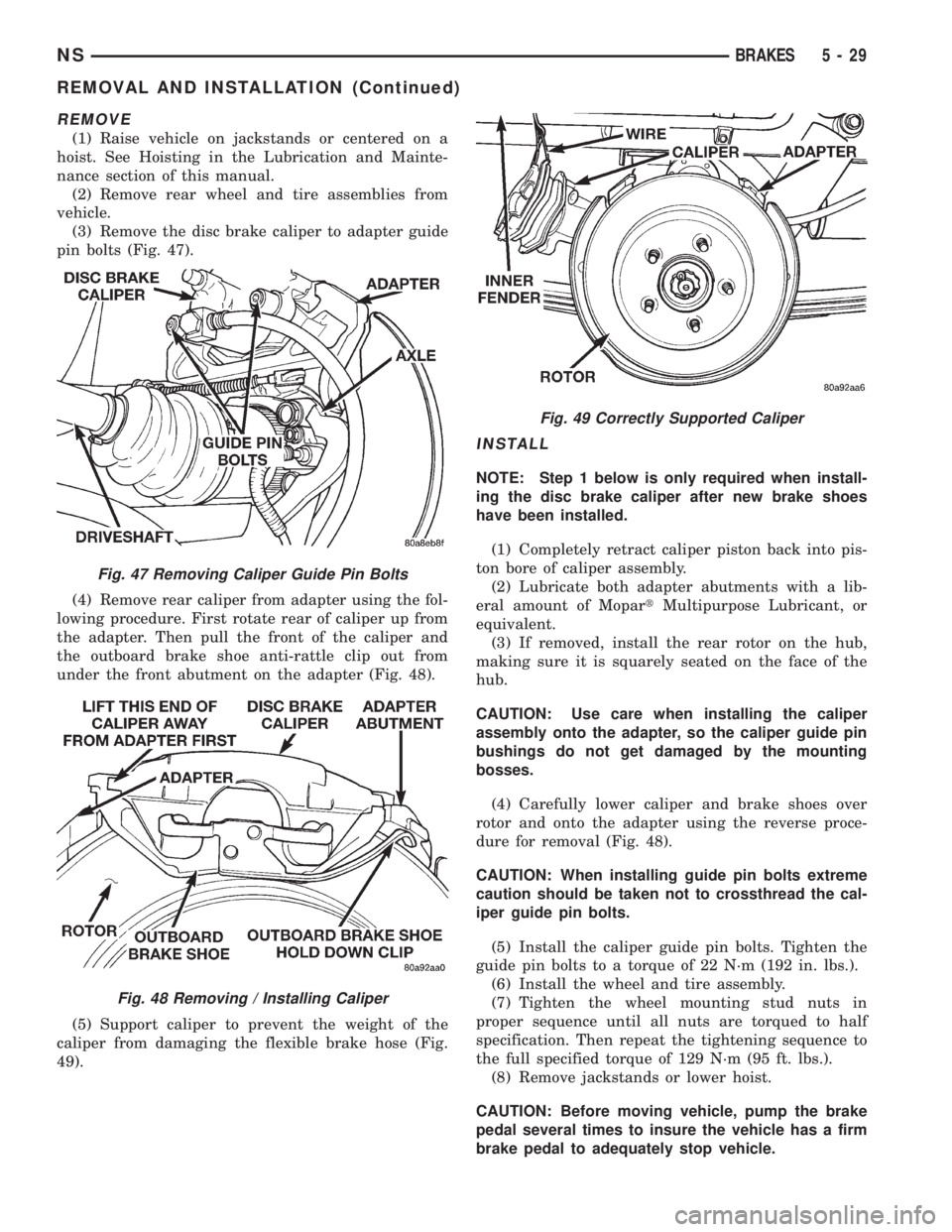

(3) Remove the disc brake caliper to adapter guide

pin bolts (Fig. 47).

(4) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate rear of caliper up from

the adapter. Then pull the front of the caliper and

the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 48).

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

49).

INSTALL

NOTE: Step 1 below is only required when install-

ing the disc brake caliper after new brake shoes

have been installed.

(1) Completely retract caliper piston back into pis-

ton bore of caliper assembly.

(2) Lubricate both adapter abutments with a lib-

eral amount of MopartMultipurpose Lubricant, or

equivalent.

(3) If removed, install the rear rotor on the hub,

making sure it is squarely seated on the face of the

hub.

CAUTION: Use care when installing the caliper

assembly onto the adapter, so the caliper guide pin

bushings do not get damaged by the mounting

bosses.

(4) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 48).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(5) Install the caliper guide pin bolts. Tighten the

guide pin bolts to a torque of 22 N´m (192 in. lbs.).

(6) Install the wheel and tire assembly.

(7) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 129 N´m (95 ft. lbs.).

(8) Remove jackstands or lower hoist.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

Fig. 47 Removing Caliper Guide Pin Bolts

Fig. 48 Removing / Installing Caliper

Fig. 49 Correctly Supported Caliper

NSBRAKES 5 - 29

REMOVAL AND INSTALLATION (Continued)

Page 113 of 1938

REAR DISC BRAKE SHOES

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKELININGS ARE MADE FROM ASBESTOSFREE MATERIALS, SOME AFTER MARKET BRAKE-

LINING MAY CONTAIN ASBESTOS. THIS SHOULD

BE TAKEN INTO ACCOUNT WHEN SERVICING A

VEHICLE'S BRAKE SYSTEM, WHEN AFTERMARKET

BRAKELININGS MAY HAVE BEEN INSTALLED ON

THE VEHICLE. ALWAYS WEAR A RESPIRATOR

WHEN CLEANING BRAKE COMPONENTS AS

ASBESTOS CAN CAUSE SERIOUS BODILY HARM

SUCH AS ASBESTOSIS AND OR CANCER. NEVER

CLEAN BRAKE COMPONENTS BY USING COM-

PRESSED AIR, USE ONLY A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR THE REMOVAL OF

BRAKE DUST. IF A VACUUM CLEANER IS NOT

AVAILABLE, CLEAN BRAKE PARTS USING ONLY

WATER DAMPENED SHOP TOWELS. DO NOT CRE-

ATE BRAKELINING DUST BY SANDING BRAKE LIN-

INGS WHEN SERVICING A VEHICLE. DISPOSE OF

ALL DUST AND DIRT SUSPECTED OF CONTAINING

ASBESTOS FIBERS USING ONLY SEALED AIR-

TIGHT BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMIN-

ISTRATION (OSHA) AND THE ENVIRONMENTAL

PROTECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBES-

TOS.

During service procedures, grease or any other for-

eign material must be kept off brake shoe assem-

blies, and braking surfaces of brake drum and

external surfaces of hub/bearing assembly.

Handling of the braking disc and caliper is to be

done in such a way as to avoid deformation of the

disc and scratching or nicking of brake linings.

If inspection reveals that the square sectioned cal-

iper piston seal is worn or damaged, itMUSTbe

replaced immediately.

During removal and installation of a wheel and

tire assembly, use care not to strike the caliper.

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove rear wheel and tire assemblies from

vehicle.

(3) Remove the caliper to adapter guide pin bolts

(Fig. 55).

(4) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate rear of caliper up from

the adapter. Then pull the front of the caliper and

the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 56).

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

57).

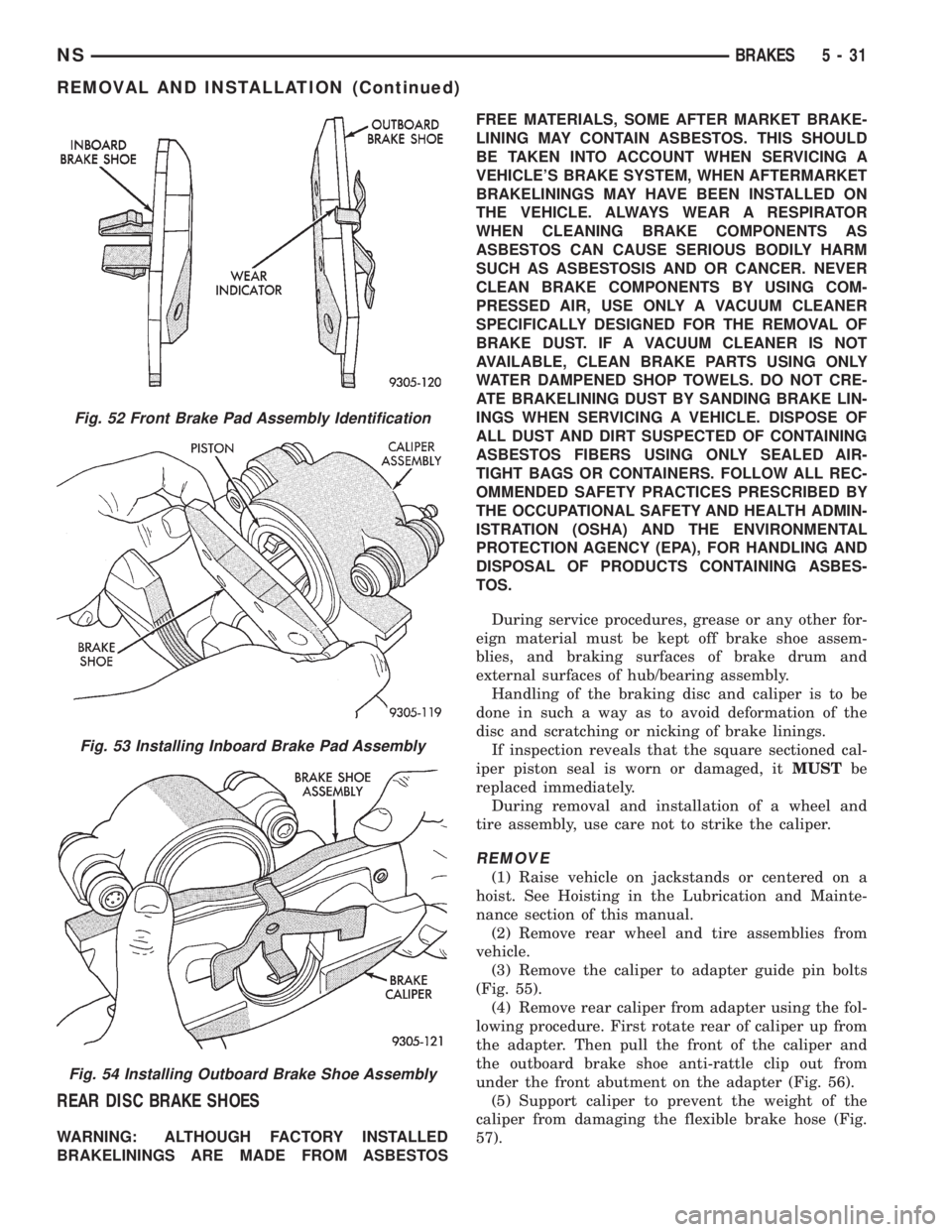

Fig. 52 Front Brake Pad Assembly Identification

Fig. 53 Installing Inboard Brake Pad Assembly

Fig. 54 Installing Outboard Brake Shoe Assembly

NSBRAKES 5 - 31

REMOVAL AND INSTALLATION (Continued)

Page 124 of 1938

from the adapter. Then pull the front of the caliper

and the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 92).(12) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

93).

(13) Remove the rotor from the hub/bearing.

Fig. 87 Spring Washer

Fig. 88 Hub Nut And Washer

Fig. 89 Driveshaft Attachment To Driveline Module

Fig. 90 Wheel Speed Sensor

Fig. 91 Caliper Guide Pin Bolts

Fig. 92 Removing / Installing Caliper

5 - 42 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 142 of 1938

(23) Install the negative (ground) cable on the bat-

tery.

(24) Cycle the park brake pedal one time. This will

seat the park brake cables and will allow the auto-

matic self adjuster to properly tension the park brake

cables.

PARK BRAKE SHOES (WITH REAR DISC BRAKES)

On this vehicle, the park brake shoes are removed

from the disc brake adapter with the disc brake

adapter removed from the vehicle.

REMOVE

(1) Set the parking brake.The parking brake is

set to keep the hub/bearing and axle shaft from

rotating when loosening the hub nut.

(2) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or on a frame contact type

hoist. See Hoisting in the Lubrication And Mainte-

nance section of this service manual.

(3) Remove the wheel/tire.

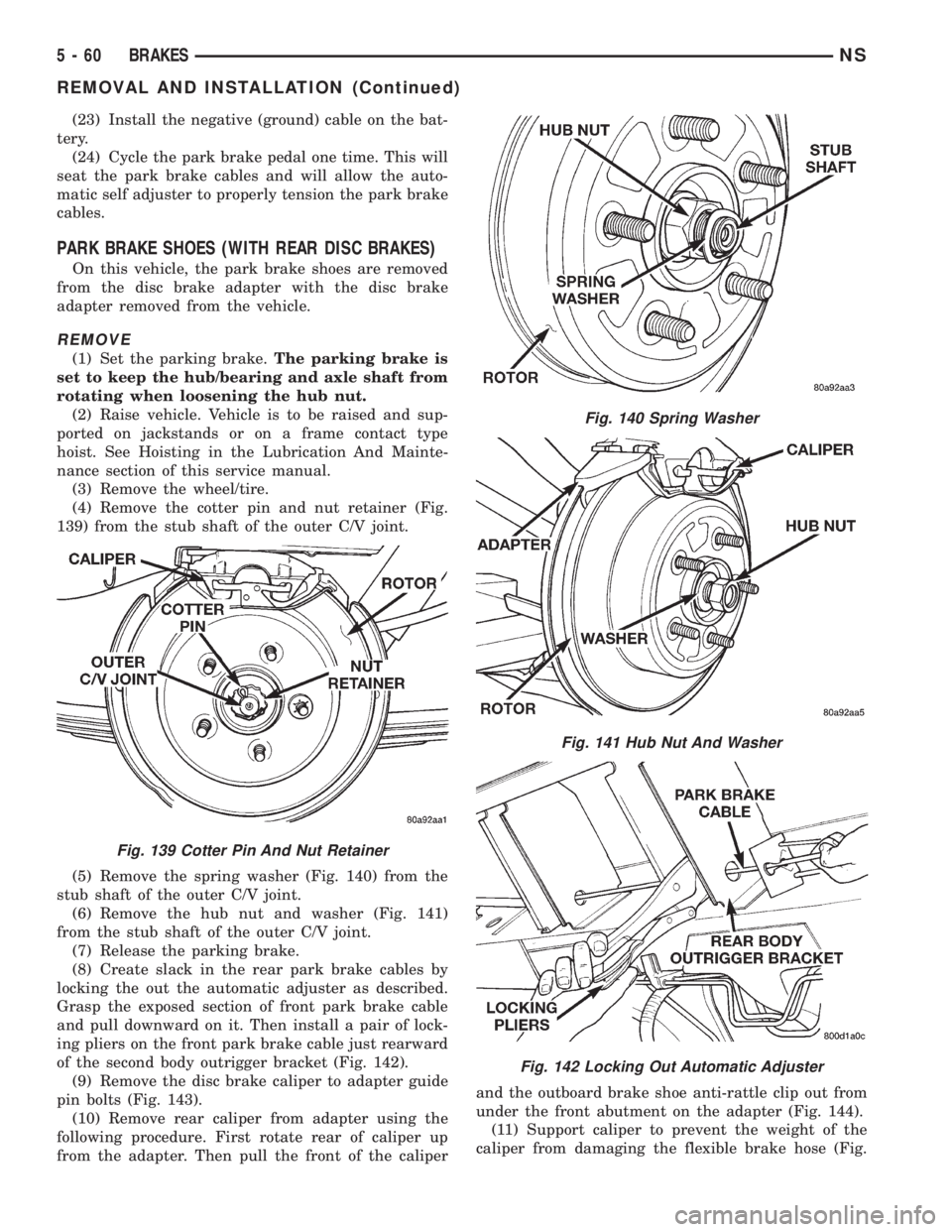

(4) Remove the cotter pin and nut retainer (Fig.

139) from the stub shaft of the outer C/V joint.

(5) Remove the spring washer (Fig. 140) from the

stub shaft of the outer C/V joint.

(6) Remove the hub nut and washer (Fig. 141)

from the stub shaft of the outer C/V joint.

(7) Release the parking brake.

(8) Create slack in the rear park brake cables by

locking the out the automatic adjuster as described.

Grasp the exposed section of front park brake cable

and pull downward on it. Then install a pair of lock-

ing pliers on the front park brake cable just rearward

of the second body outrigger bracket (Fig. 142).

(9) Remove the disc brake caliper to adapter guide

pin bolts (Fig. 143).

(10) Remove rear caliper from adapter using the

following procedure. First rotate rear of caliper up

from the adapter. Then pull the front of the caliperand the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 144).

(11) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

Fig. 139 Cotter Pin And Nut Retainer

Fig. 140 Spring Washer

Fig. 141 Hub Nut And Washer

Fig. 142 Locking Out Automatic Adjuster

5 - 60 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 164 of 1938

(13) Lower the vehicle to the ground.Be sure

that the suspension is supporting the full

weight of the vehicle.

(14) Tighten the spring to front hanger pivot bolts

to a torque of 156 N´m (115 ft. lbs.).

(15) Tighten the shock absorber mounting bolts to

a torque of 101 N´m (75 ft. lbs.).

(16) Tighten the track bar mounting bolt to a

torque of 95 N´m (70 ft. lbs.).

(17) Road test vehicle to ensure that the prema-

ture rear wheel lockup condition has been corrected.

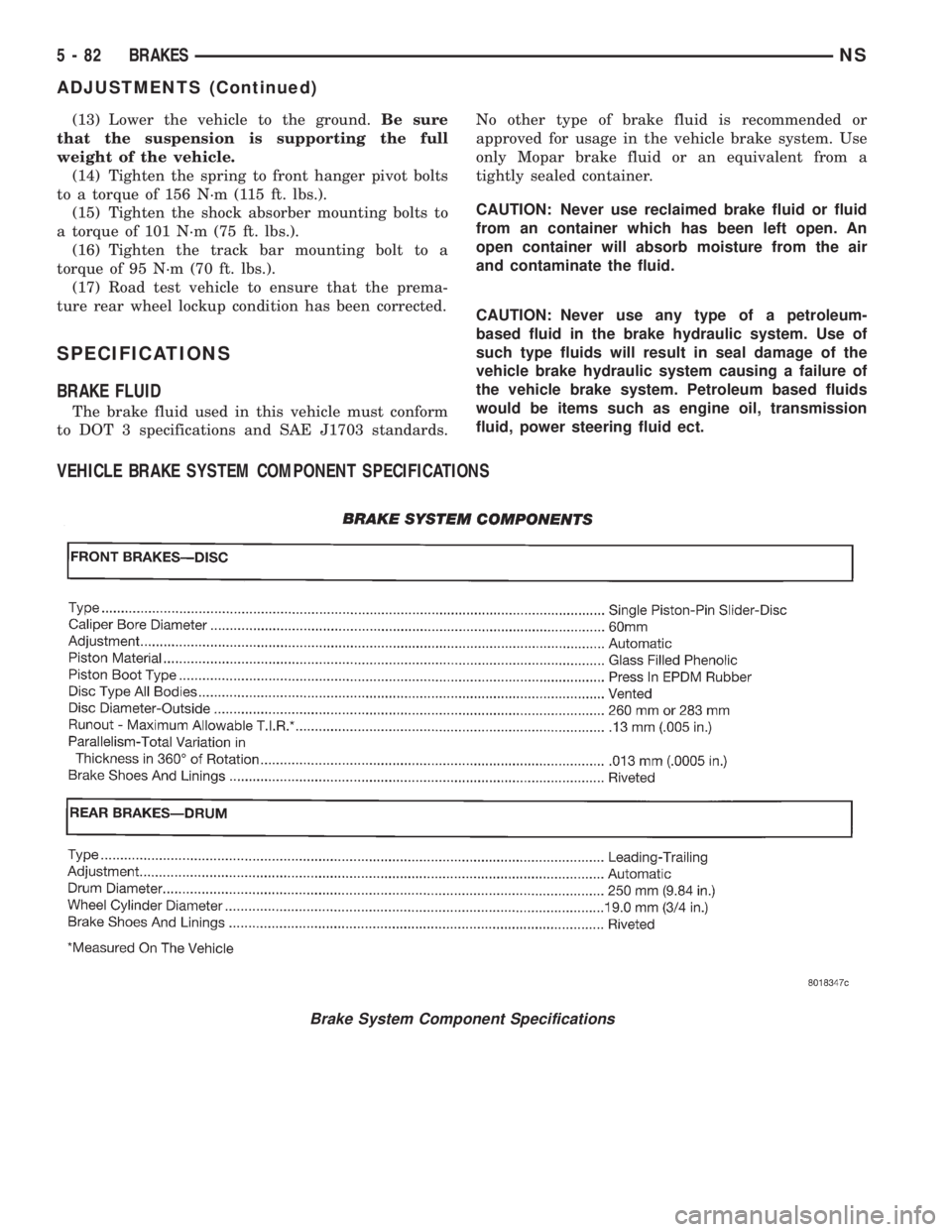

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid ect.

VEHICLE BRAKE SYSTEM COMPONENT SPECIFICATIONS

Brake System Component Specifications

5 - 82 BRAKESNS

ADJUSTMENTS (Continued)

Page 168 of 1938

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE

This ABS System represents the current state-of-

the-art in vehicle braking systems and offers the

driver increased safety and control during braking.

This is accomplished by a sophisticated system of

electrical and hydraulic components. As a result,

there are a few performance characteristics that may

at first seem different but should be considered nor-

mal. These characteristics are discussed below.

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions the same as a standard brake system with

a diagonally split master cylinder and conventional

vacuum assist.

ABS SYSTEM OPERATION

If a wheel locking tendency is detected during a

brake application, the brake system will enter the

ABS mode. During ABS braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel circuit is

designed with a set of electric solenoids to allow mod-

ulation, although for vehicle stability, both rear

wheel solenoids receive the same electrical signal.

During an ABS stop, the brakes hydraulic system

is still diagonally split. However, the brake system

pressure is further split into four control channels.

During antilock operation of the vehicle's brake sys-

tem the front wheels are controlled independently

and are on two separate control channels and the

rear wheels of the vehicle are controlled together.

The system can build and release pressure at each

wheel, depending on signals generated by the wheel

speed sensors (WSS) at each wheel and received at

the Controller Antilock Brake (CAB).

ABS operation is available at all vehicle speeds

above 3 to 5 mph. Wheel lockup may be perceived at

the very end of an ABS stop and is considered nor-

mal.

VEHICLE HANDLING PERFORMANCE DURING

ABS BRAKING

It is important to remember that an antilock brake

system does not shorten a vehicle's stopping distance

under all driving conditions, but does provide

improved control of the vehicle while stopping. Vehi-

cle stopping distance is still dependent on vehicle

speed, weight, tires, road surfaces and other factors.

Though ABS provides the driver with some steer-

ing control during hard braking, there are conditions

however, where the system does not provide any ben-

efit. In particular, hydroplaning is still possible when

the tires ride on a film of water. This results in the

vehicles tires leaving the road surface rendering the

vehicle virtually uncontrollable. In addition, extremesteering maneuvers at high speed or high speed cor-

nering beyond the limits of tire adhesion to the road

surface may cause vehicle skidding, independent of

vehicle braking. For this reason, the ABS system is

termed Antilock instead of Anti-Skid.

NOISE AND BRAKE PEDAL FEEL

During ABS braking, some brake pedal movement

may be felt. In addition, ABS braking will create

ticking, popping and/or groaning noises heard by the

driver. This is normal due to pressurized fluid being

transferred between the master cylinder and the

brakes. If ABS operation occurs during hard braking,

some pulsation may be felt in the vehicle body due to

fore and aft movement of the suspension as brake

pressures are modulated.

At the end of an ABS stop, ABS will be turned off

when the vehicle is slowed to a speed of 3±4 mph.

There may be a slight brake pedal drop anytime that

the ABS is deactivated, such as at the end of the stop

when the vehicle speed is less then 3 mph or during

an ABS stop where ABS is no longer required. These

conditions will exist when a vehicle is being stopped

on a road surface with patches of ice, loose gravel or

sand on it. Also stopping a vehicle on a bumpy road

surface will activate ABS because of the wheel hop

caused by the bumps.

TIRE NOISE AND MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum braking performance. Wheel slip is

defined as follows, 0 percent slip means the wheel is

rolling freely and 100 percent slip means the wheel is

fully locked. During brake pressure modulation,

wheel slip is allowed to reach up to 25 to30%. This

means that the wheel rolling velocity is 25 to 30%

less than that of a free rolling wheel at a given vehi-

cle speed. This slip may result in some tire chirping,

depending on the road surface. This sound should not

be interpreted as total wheel lock-up.

Complete wheel lock up normally leaves black tire

marks on dry pavement. The ABS System will not

leave dark black tire marks since the wheel never

reaches a fully locked condition. Tire marks may

however be noticeable as light patched marks.

START UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

Additionally, when the vehicle is first driven off a

humming may be heard and/or felt by the driver at

approximately 20 to 40 kph (12 to 25 mph). The ABS

warning lamp will also be on for up to 5 seconds

after the ignition is turned on. All of these conditions

are a normal function of ABS as the system is per-

forming a diagnosis check.

5 - 86 BRAKESNS

DESCRIPTION AND OPERATION (Continued)

Page 314 of 1938

2.4L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

CAMSHAFT POSITION SENSOR............ 17

CRANKSHAFT POSITION SENSOR.......... 16

FIRING ORDERÐ2.4L.................... 16

INTAKE AIR TEMPERATURE SENSORÐ2.4L . . . 17

REMOVAL AND INSTALLATION

CAMSHAFT POSITION SENSOR............ 19

CRANKSHAFT POSITION SENSOR.......... 19

ENGINE COOLANT TEMPERATURE SENSORÐ

2.4L................................. 20

IGNITION COILÐ2.4L..................... 18

INTAKE AIR TEMPERATURE SENSORÐ2.4L . . . 21KNOCK SENSORÐ2.4L................... 21

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.4/3.3/3.8L.................. 20

SPARK PLUG CABLE SERVICEÐ2.4L........ 18

SPARK PLUG SERVICE................... 18

THROTTLE POSITION SENSOR............ 20

SPECIFICATIONS

IGNITION COIL......................... 22

SPARK PLUG CABLE RESISTANCEÐ2.4L..... 22

SPARK PLUG........................... 22

TORQUE.............................. 22

DESCRIPTION AND OPERATION

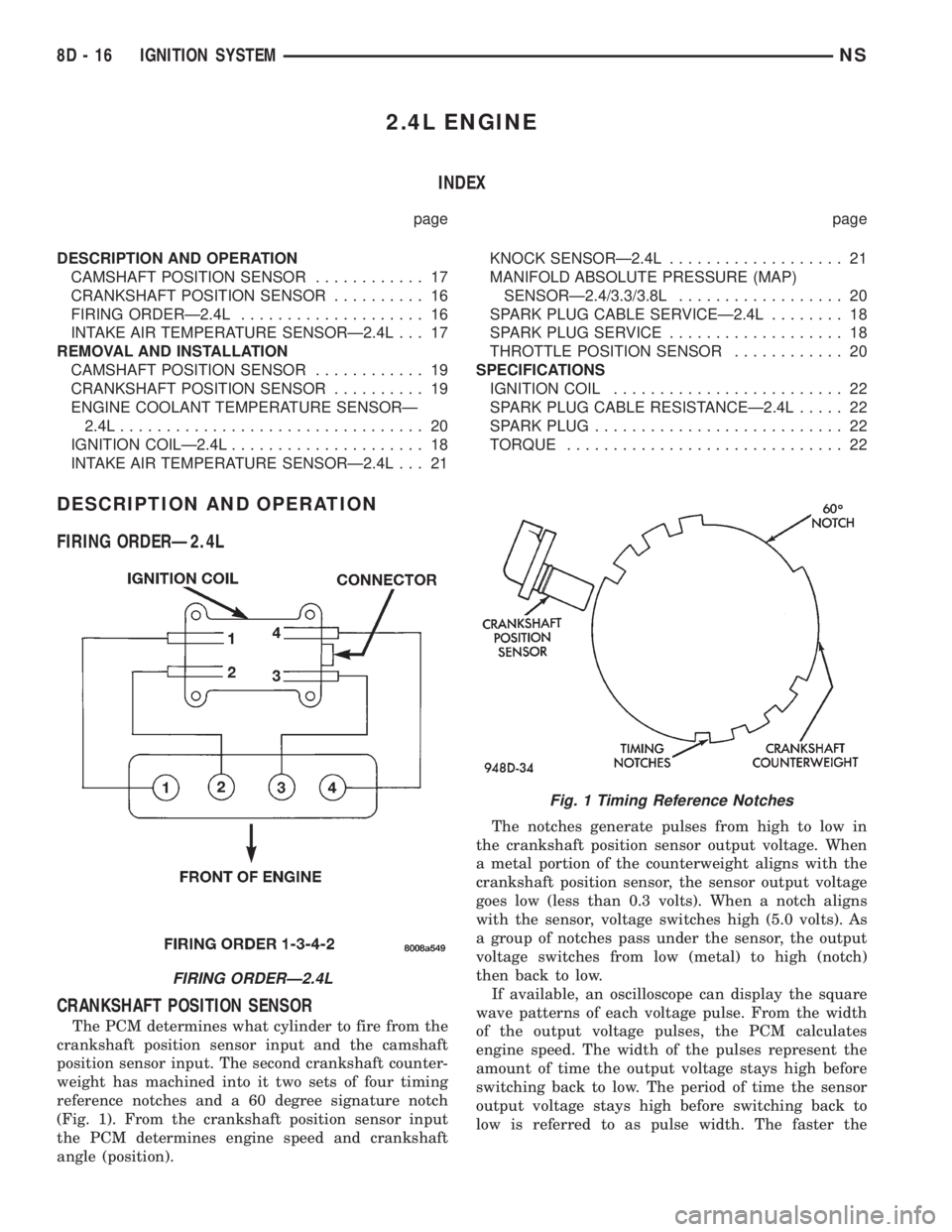

FIRING ORDERÐ2.4L

CRANKSHAFT POSITION SENSOR

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has machined into it two sets of four timing

reference notches and a 60 degree signature notch

(Fig. 1). From the crankshaft position sensor input

the PCM determines engine speed and crankshaft

angle (position).The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.3 volts). When a notch aligns

with the sensor, voltage switches high (5.0 volts). As

a group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

FIRING ORDERÐ2.4L

Fig. 1 Timing Reference Notches

8D - 16 IGNITION SYSTEMNS

Page 457 of 1938

HEADLAMP ALIGNMENT

INDEX

page page

GENERAL INFORMATION

HEADLAMP ALIGNMENT................... 5

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION....... 5ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN.................... 5

GENERAL INFORMATION

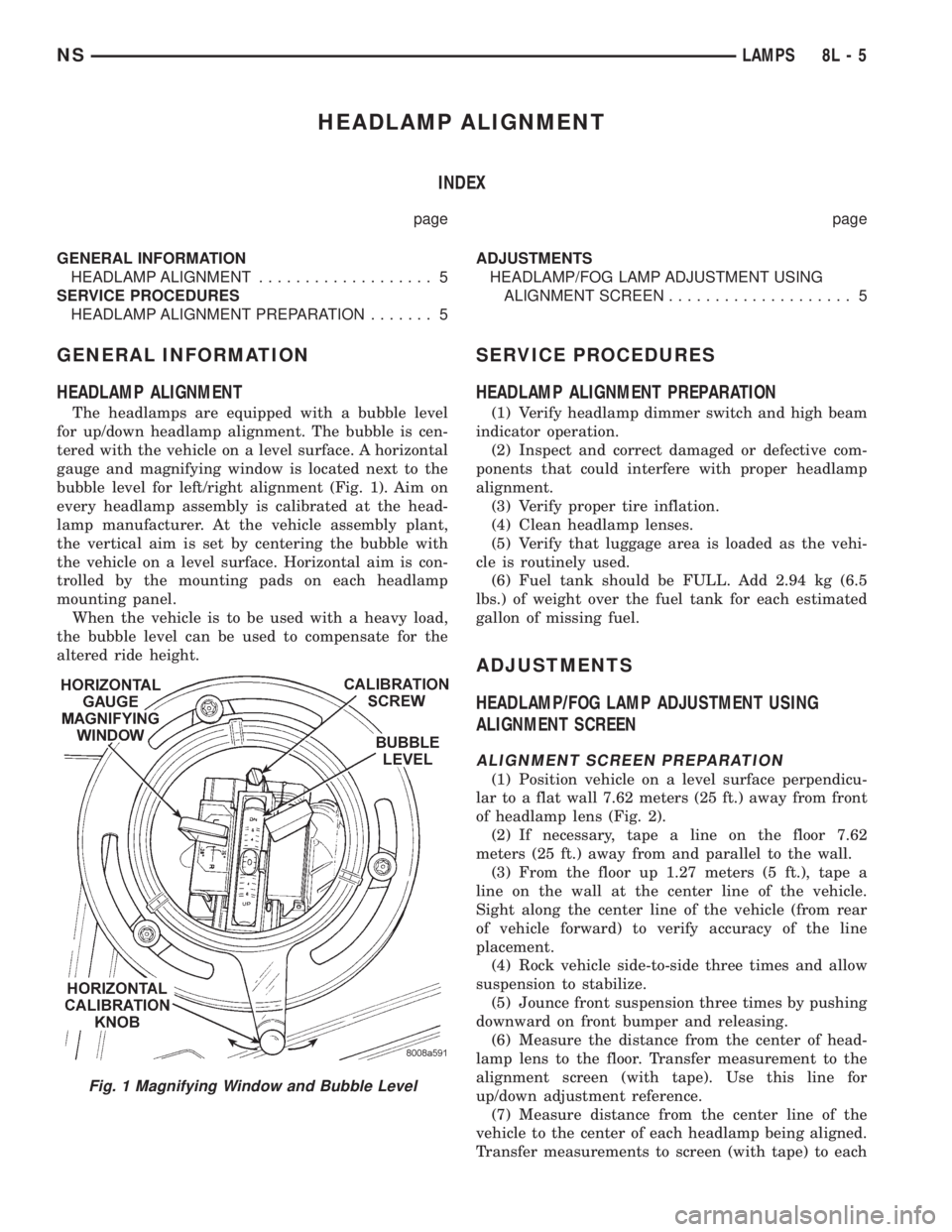

HEADLAMP ALIGNMENT

The headlamps are equipped with a bubble level

for up/down headlamp alignment. The bubble is cen-

tered with the vehicle on a level surface. A horizontal

gauge and magnifying window is located next to the

bubble level for left/right alignment (Fig. 1). Aim on

every headlamp assembly is calibrated at the head-

lamp manufacturer. At the vehicle assembly plant,

the vertical aim is set by centering the bubble with

the vehicle on a level surface. Horizontal aim is con-

trolled by the mounting pads on each headlamp

mounting panel.

When the vehicle is to be used with a heavy load,

the bubble level can be used to compensate for the

altered ride height.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is loaded as the vehi-

cle is routinely used.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens (Fig. 2).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall.

(3) From the floor up 1.27 meters (5 ft.), tape a

line on the wall at the center line of the vehicle.

Sight along the center line of the vehicle (from rear

of vehicle forward) to verify accuracy of the line

placement.

(4) Rock vehicle side-to-side three times and allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the center line of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

Fig. 1 Magnifying Window and Bubble Level

NSLAMPS 8L - 5

Page 483 of 1938

HEADLAMP ALIGNMENT

INDEX

page page

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION...... 5ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN.................. 5

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Verify that the headlamp leveling switch is in

the ª0º position.

(3) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(4) Verify proper tire inflation.

(5) Clean headlamp lenses.

(6) Verify that luggage area is loaded as the vehi-

cle is routinely used.

(7) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP/FOG LAMP ADJUSTMENT USING

ALIGNMENT SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 10 meters (32.8 ft.) away from front

of headlamp lens (Fig. 1).

(2) Place 75 kg in the driver's seat to simulate the

ride height of the vehicle when driven.

(3) If necessary, tape a line on the floor 10 meters

(32.8 ft) away from and parallel to the wall.

(4) From the floor up 1.27 meters (5 ft), tape a line

on the wall at the centerline of the vehicle. Sight

along the centerline of the vehicle (from rear of vehi-

cle forward) to verify accuracy of the line placement.

NS/GSLAMPS 8L - 5

Page 527 of 1938

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the master power window switch and

bezel assembly from the driver door. Refer to Group

23, Body for proper procedures.

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If light does not illuminate, check the 40 amp

fuse in the Power Distribution Center or for a broken

wire.

²The power window motors are protected with

Positive Temperature Coefficient (PTC) device that

prevents motor burn out. Check Junction Block.

²Refer to Group 8W, Wiring Diagrams for circuit

information and component locations.

REMOVAL AND INSTALLATION

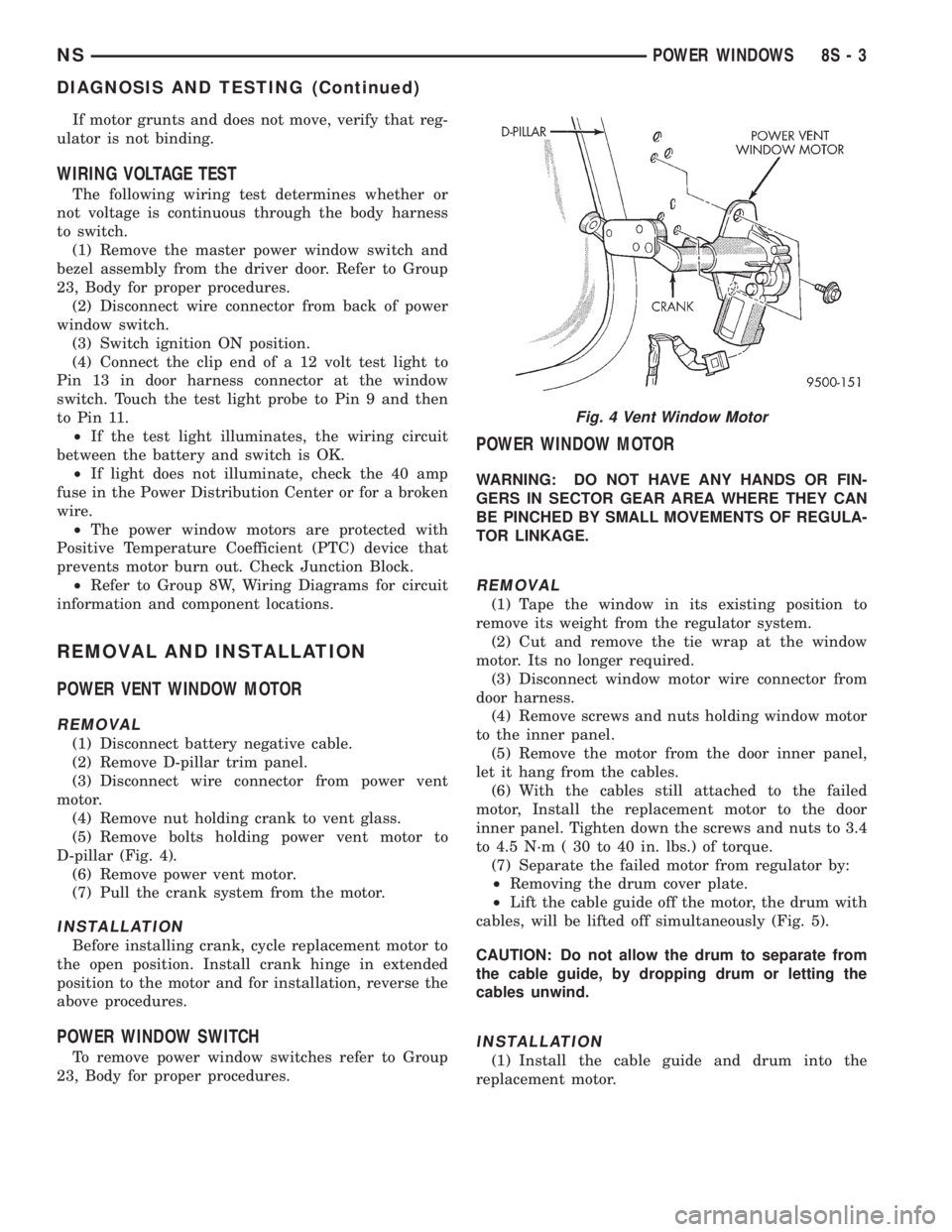

POWER VENT WINDOW MOTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove D-pillar trim panel.

(3) Disconnect wire connector from power vent

motor.

(4) Remove nut holding crank to vent glass.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 4).

(6) Remove power vent motor.

(7) Pull the crank system from the motor.

INSTALLATION

Before installing crank, cycle replacement motor to

the open position. Install crank hinge in extended

position to the motor and for installation, reverse the

above procedures.

POWER WINDOW SWITCH

To remove power window switches refer to Group

23, Body for proper procedures.

POWER WINDOW MOTOR

WARNING: DO NOT HAVE ANY HANDS OR FIN-

GERS IN SECTOR GEAR AREA WHERE THEY CAN

BE PINCHED BY SMALL MOVEMENTS OF REGULA-

TOR LINKAGE.

REMOVAL

(1) Tape the window in its existing position to

remove its weight from the regulator system.

(2) Cut and remove the tie wrap at the window

motor. Its no longer required.

(3) Disconnect window motor wire connector from

door harness.

(4) Remove screws and nuts holding window motor

to the inner panel.

(5) Remove the motor from the door inner panel,

let it hang from the cables.

(6) With the cables still attached to the failed

motor, Install the replacement motor to the door

inner panel. Tighten down the screws and nuts to 3.4

to 4.5 N´m ( 30 to 40 in. lbs.) of torque.

(7) Separate the failed motor from regulator by:

²Removing the drum cover plate.

²Lift the cable guide off the motor, the drum with

cables, will be lifted off simultaneously (Fig. 5).

CAUTION: Do not allow the drum to separate from

the cable guide, by dropping drum or letting the

cables unwind.

INSTALLATION

(1) Install the cable guide and drum into the

replacement motor.

Fig. 4 Vent Window Motor

NSPOWER WINDOWS 8S - 3

DIAGNOSIS AND TESTING (Continued)