belt CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 20 of 1938

52,500 Miles (84 000 km) or at 42 months

²Change engine oil.

²Flush and replace engine coolant if not done at

36 months.

60,000 Miles (96 000 km) or at 48 months

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Check PCV valve and replace, if necessary.

*

²Inspect serpentine drive belt, replace if neces-

sary.

²Inspect tie rod ends and boot seals.

67,500 Miles (108 000 km) or at 54 months

²Change engine oil.

²Inspect brake linings.

75,000 Miles (120 000 km) or at 60 months

²Change engine oil.

²Replace engine oil filter.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

82,500 Miles (132 000 km) or at 66 months

²Change engine oil.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

90,000 Miles (144 000 km) or at 72 months

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Check PCV valve and replace, if necessary.

Not required if previously changed. *

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Inspect tie rod ends and boot seals.

²Inspect brake linings.

97,500 Miles (156 000 km) or at 78 months

²Change engine oil.

100,000 Miles (160,000 km)

²Replace spark plugs on 3.3L and 3.8L

engines.

²Replace ignition cables on 3.3L and 3.8L

engines.

105,000 Miles (168 000 km) or at 84 months

²Change engine oil.

²Replace engine oil filter.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

112,500 Miles (180 000 km) or at 90 months

²Change engine oil.

²Inspect brake linings.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

120,000 Miles (192 000 km) or at 96 months

²Change engine oil.

²Replace engine oil filter.

²Replace automatic transmission fluid.

²Replace engine air cleaner element.

²Check and replace PCV valve, if necessary.

*

²Inspect serpentine drive belt. Not required if

replaced at 75,000, 90,000 or 105,000 miles.

²Inspect tie rod ends and boot seals.

* This maintenance is recommended by Chrysler to

the owner but is not required to maintain the war-

ranty on the PCV valve.

** If California vehicle, this maintenance is recom-

mended by Chrysler to the owner but is not required

to maintain the warranty of the timing belt.

SCHEDULE ± B

3,000 Miles (5 000 km)

²Change engine oil.

6,000 Miles (10 000 km)

²Change engine oil.

²Replace engine oil filter.

9,000 Miles (14 000 km)

²Change engine oil.

²Inspect brake linings.

12,000 Miles (19 000 km)

²Change engine oil.

²Replace engine oil filter.

15,000 Miles (24 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.

0 - 4 LUBRICATION AND MAINTENANCENS

GENERAL INFORMATION (Continued)

Page 21 of 1938

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD powertransfer fluid unit.

18,000 Miles (29 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

21,000 Miles (34 000 km)

²Change engine oil.

²Check AWD overrunning clutch and rear carrier

fluid.

24,000 Miles (38 000 km)

²Change engine oil.

²Replace engine oil filter.

27,000 Miles (43 000 km)

²Change engine oil.

²Inspect brake linings.

30,000 Miles (48 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect PCV valve. Replace as necessary. *

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

33,000 Miles (53 000 km)

²Change engine oil.

36,000 Miles (58 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

39,000 Miles (62 000 km)

²Change engine oil.

42,000 Miles (67 000 km)

²Change engine oil.

²Replace engine oil filter.

²Change AWD overrunning clutch and rear car-

rier fluid.

45,000 Miles (72 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Inspect brake linings.

²Change AWD power transfer unit fluid.

48,000 Miles (77 000 km)

²Change engine oil.

²Replace engine oil filter.

51,000 Miles (82 000 km)

²Change engine oil.

²Flush and replace engine coolant.

54,000 Miles (86 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

57,000 Miles (91 000 km)

²Change engine oil.

60,000 Miles (96 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect PCV valve, replace if necessary. *

²Inspect serpentine drive belt, replace if neces-

sary.

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

63,000 Miles (101 000 km)

²Change engine oil.

²Change AWD overrunning clutch and rear car-

rier fluid.

²Inspect brake linings.

66,000 Miles (106 000 km)

²Change engine oil.

²Replace engine oil filter.

69,000 Miles (110 000 km)

²Change engine oil.

72,000 Miles (115 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

75,000 Miles (120 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.

NSLUBRICATION AND MAINTENANCE 0 - 5

GENERAL INFORMATION (Continued)

Page 22 of 1938

²Replace spark plugs.

²Replace ignition cables.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Drain and refill automatic transaxle fluid and

replace filter. Adjust band, if so equipped. (See note)

²Change AWD power transfer unit fluid.

78,000 Miles (125 000 km)

²Change engine oil.

²Replace engine oil filter.

81,000 Miles (130 000 km)

²Change engine oil.

²Inspect brake linings.

²Flush and replace engine coolant.

84,000 Miles (134 000 km)

²Change engine oil.

²Replace engine oil filter.

²Change AWD overrunning clutch and rear car-

rier fluid.

87,000 Miles (139 000 km)

²Change engine oil.

90,000 Miles (144 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Check PCV valve and replace if necessary.

Not required if previously changed. *

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

²Inspect brake linings.

93,000 Miles (149 000 km)

²Change engine oil.

96,000 Miles (154 000 km)

²Change engine oil.

²Replace engine oil filter.

99,000 Miles (158 000 km)

²Change engine oil.

²Inspect brake linings.

102,000 Miles (163 000 km)

²Change engine oil.

²Replace engine oil filter.

105,000 Miles (168 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Drain and refill automatic transmission fluid

and filter. Adjust bands, if so equipped. (See note)

²Change AWD power transfer unit fluid.

²Change AWD overrunning clutch and rear car-

rier fluid.

108,000 Miles (173 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

111,000 Miles (178 000 km)

²Change engine oil.

²Flush and replace engine coolant.

114,000 Miles (182 000 km)

²Change engine oil.

²Replace engine oil filter.

117,000 Miles (187 000 km)

²Change engine oil.

²Inspect brake linings.

120,000 Miles (192 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect PCV valve. Replace as necessary. *

²Inspect serpentine drive belt. Not required if

replaced at 75,000, 90,000 or 105,000 miles.

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped.

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

* This maintenance is recommended by Chrysler to

the owner but is not required to maintain the war-

ranty on the PCV valve.

** If California vehicle, this maintenance is recom-

mended by Chrysler to the owner but is not required

to maintain the warranty of the timing belt.

NOTE: Operating vehicle more than 50% in heavy

traffic during hot weather, above 90ÉF (32ÉC), using

vehicle for police, taxi, limousine type operation or

trailer towing require the more frequent transaxle

service noted in Schedule ± B. Perform these ser-

vices if vehicle is usually operated under these con-

ditions.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

0 - 6 LUBRICATION AND MAINTENANCENS

GENERAL INFORMATION (Continued)

Page 23 of 1938

JUMP STARTING, HOISTING AND TOWING

INDEX

page page

SERVICE PROCEDURES

HOISTING RECOMMENDATIONS............ 9JUMP STARTING PROCEDURE.............. 7

TOWING RECOMMENDATIONS.............. 8

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, placethe automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

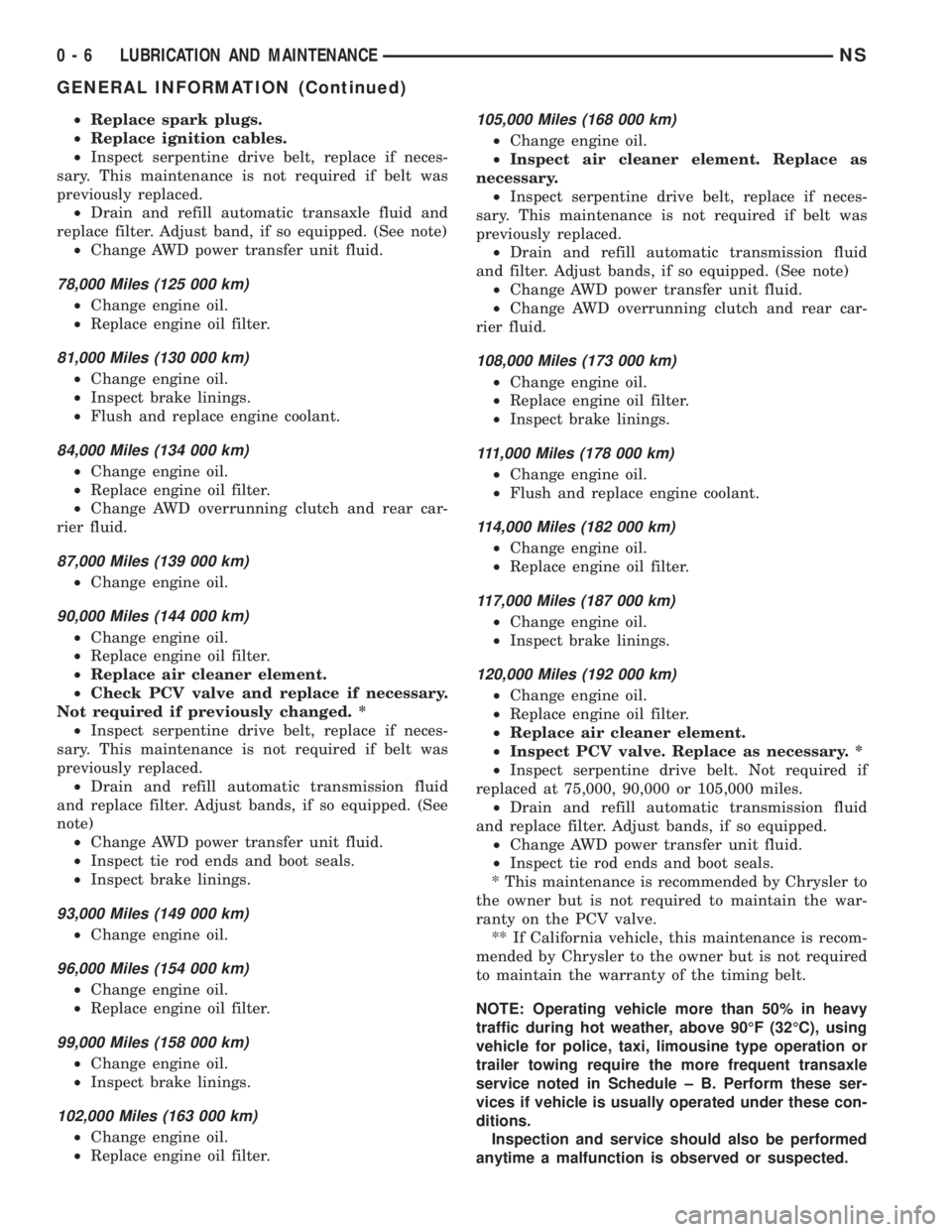

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

Fig. 1 Jumper Cable Clamp Connections

NSLUBRICATION AND MAINTENANCE 0 - 7

Page 29 of 1938

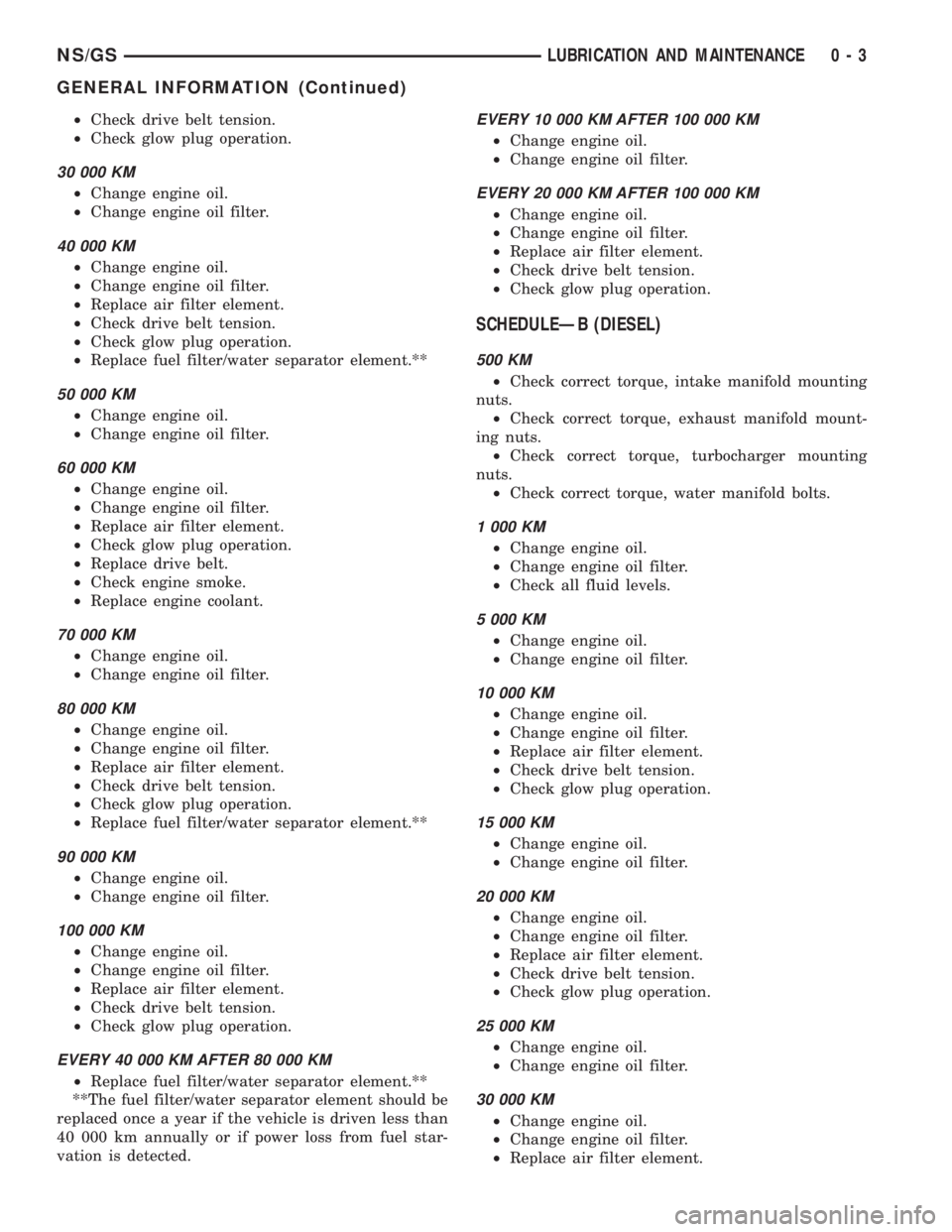

²Check drive belt tension.

²Check glow plug operation.

30 000 KM

²Change engine oil.

²Change engine oil filter.

40 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Replace fuel filter/water separator element.**

50 000 KM

²Change engine oil.

²Change engine oil filter.

60 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

70 000 KM

²Change engine oil.

²Change engine oil filter.

80 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Replace fuel filter/water separator element.**

90 000 KM

²Change engine oil.

²Change engine oil filter.

100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

EVERY 40 000 KM AFTER 80 000 KM

²Replace fuel filter/water separator element.**

**The fuel filter/water separator element should be

replaced once a year if the vehicle is driven less than

40 000 km annually or if power loss from fuel star-

vation is detected.

EVERY 10 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

EVERY 20 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

SCHEDULEÐB (DIESEL)

500 KM

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

5 000 KM

²Change engine oil.

²Change engine oil filter.

10 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

15 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

25 000 KM

²Change engine oil.

²Change engine oil filter.

30 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

NS/GSLUBRICATION AND MAINTENANCE 0 - 3

GENERAL INFORMATION (Continued)

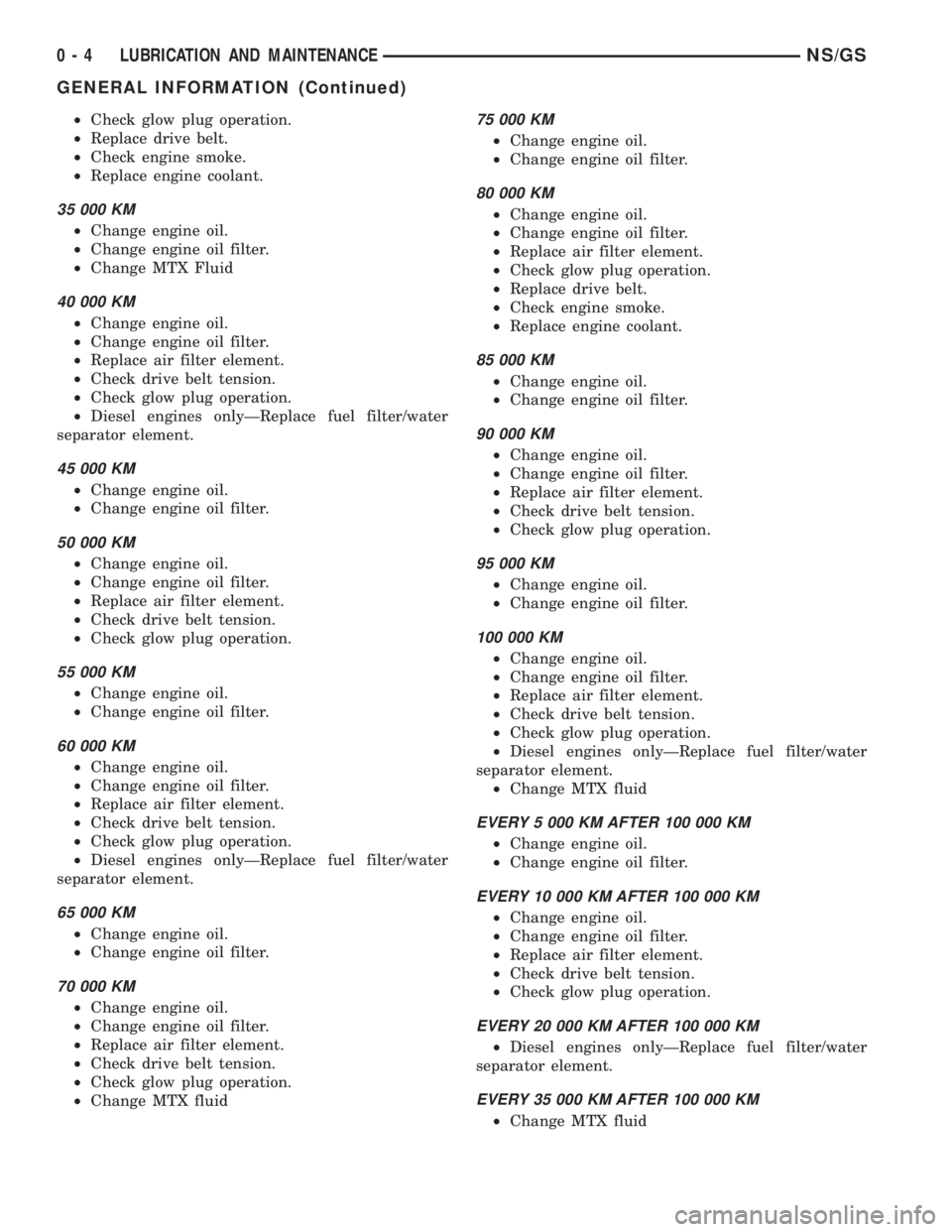

Page 30 of 1938

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

35 000 KM

²Change engine oil.

²Change engine oil filter.

²Change MTX Fluid

40 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Diesel engines onlyÐReplace fuel filter/water

separator element.

45 000 KM

²Change engine oil.

²Change engine oil filter.

50 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

55 000 KM

²Change engine oil.

²Change engine oil filter.

60 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Diesel engines onlyÐReplace fuel filter/water

separator element.

65 000 KM

²Change engine oil.

²Change engine oil filter.

70 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Change MTX fluid

75 000 KM

²Change engine oil.

²Change engine oil filter.

80 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

85 000 KM

²Change engine oil.

²Change engine oil filter.

90 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

95 000 KM

²Change engine oil.

²Change engine oil filter.

100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Diesel engines onlyÐReplace fuel filter/water

separator element.

²Change MTX fluid

EVERY 5 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

EVERY 10 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

EVERY 20 000 KM AFTER 100 000 KM

²Diesel engines onlyÐReplace fuel filter/water

separator element.

EVERY 35 000 KM AFTER 100 000 KM

²Change MTX fluid

0 - 4 LUBRICATION AND MAINTENANCENS/GS

GENERAL INFORMATION (Continued)

Page 36 of 1938

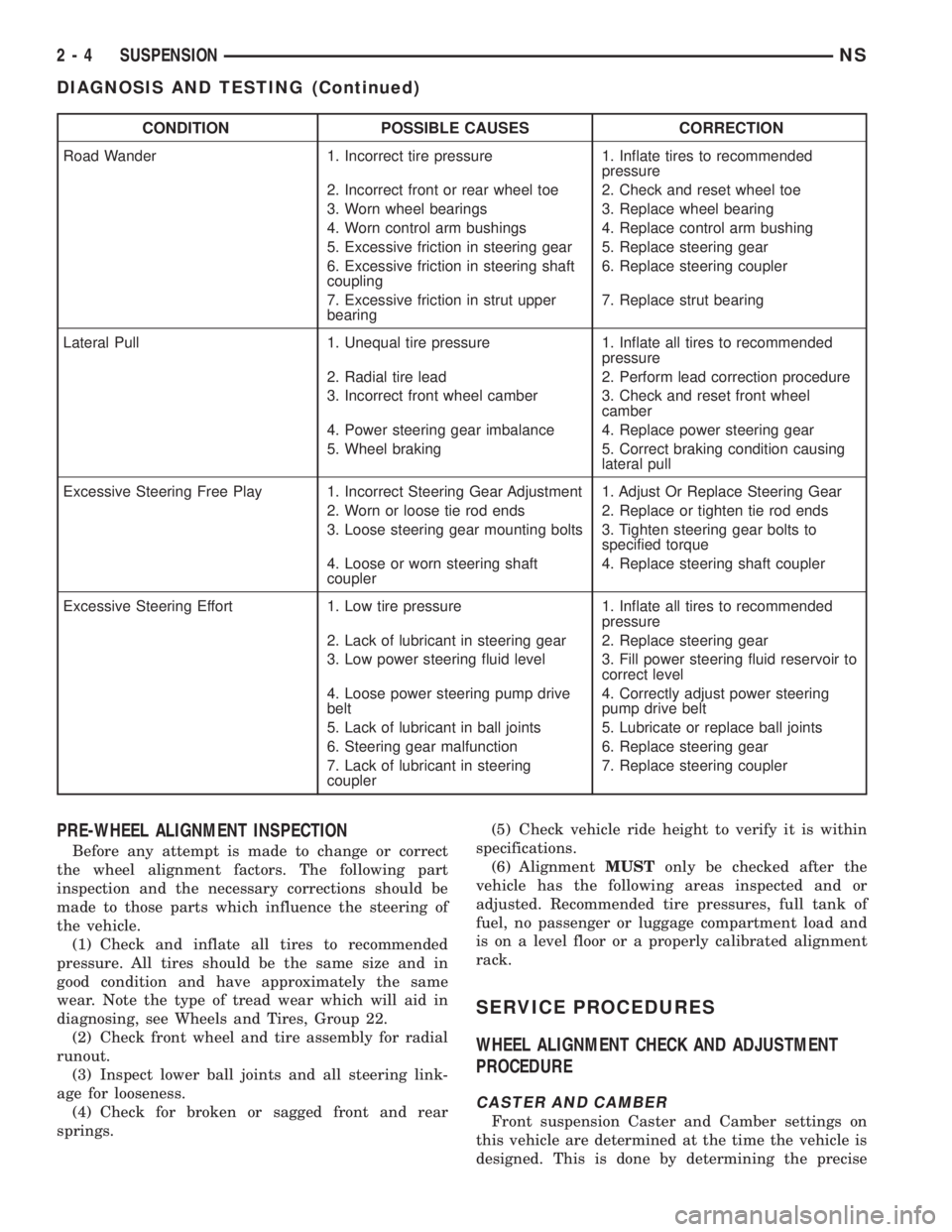

CONDITION POSSIBLE CAUSES CORRECTION

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended

pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel

camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free Play 1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to

specified torque

4. Loose or worn steering shaft

coupler4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering

pump drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering

coupler7. Replace steering coupler

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment factors. The following part

inspection and the necessary corrections should be

made to those parts which influence the steering of

the vehicle.

(1) Check and inflate all tires to recommended

pressure. All tires should be the same size and in

good condition and have approximately the same

wear. Note the type of tread wear which will aid in

diagnosing, see Wheels and Tires, Group 22.

(2) Check front wheel and tire assembly for radial

runout.

(3) Inspect lower ball joints and all steering link-

age for looseness.

(4) Check for broken or sagged front and rear

springs.(5) Check vehicle ride height to verify it is within

specifications.

(6) AlignmentMUSTonly be checked after the

vehicle has the following areas inspected and or

adjusted. Recommended tire pressures, full tank of

fuel, no passenger or luggage compartment load and

is on a level floor or a properly calibrated alignment

rack.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER AND CAMBER

Front suspension Caster and Camber settings on

this vehicle are determined at the time the vehicle is

designed. This is done by determining the precise

2 - 4 SUSPENSIONNS

DIAGNOSIS AND TESTING (Continued)

Page 215 of 1938

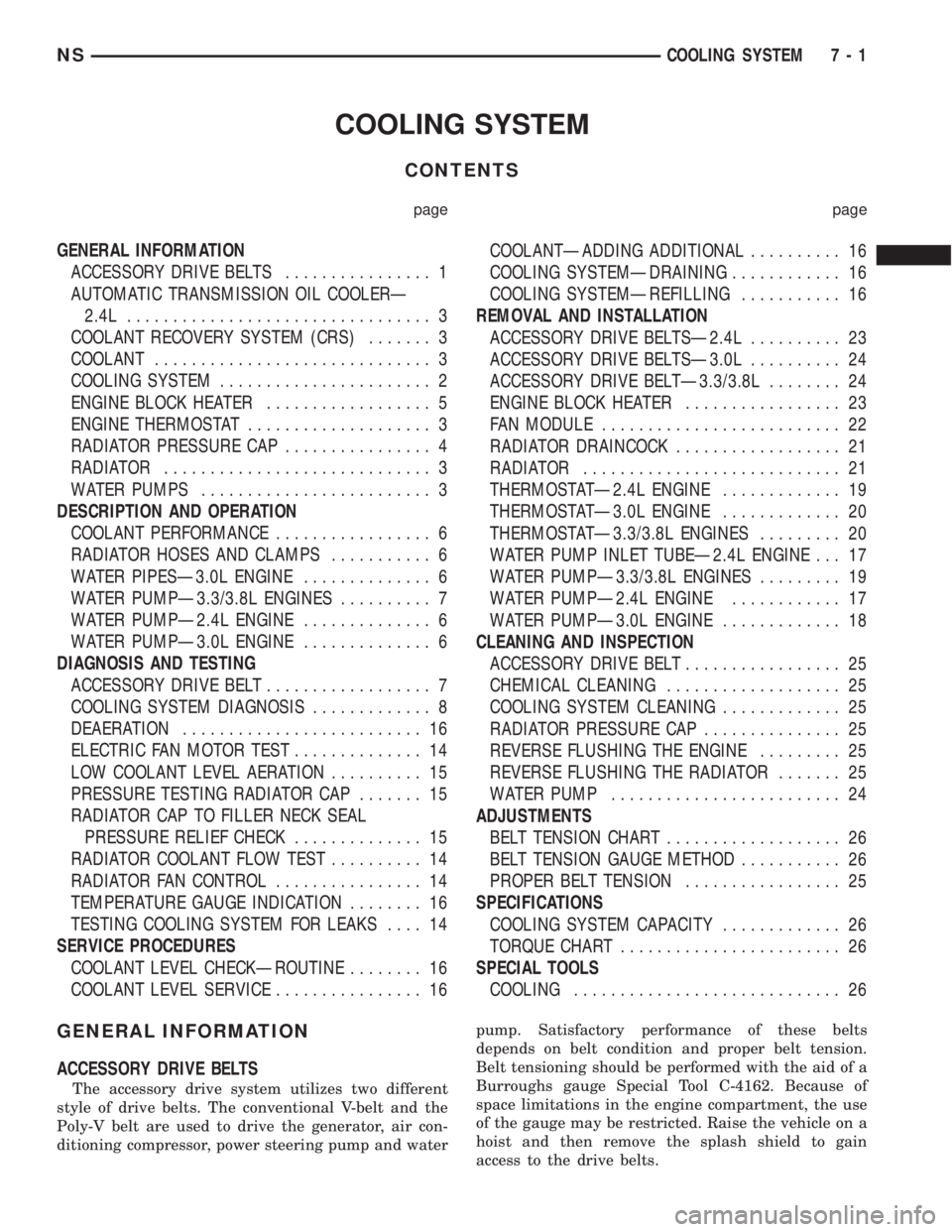

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

ACCESSORY DRIVE BELTS................ 1

AUTOMATIC TRANSMISSION OIL COOLERÐ

2.4L................................. 3

COOLANT RECOVERY SYSTEM (CRS)....... 3

COOLANT.............................. 3

COOLING SYSTEM....................... 2

ENGINE BLOCK HEATER.................. 5

ENGINE THERMOSTAT.................... 3

RADIATOR PRESSURE CAP................ 4

RADIATOR............................. 3

WATER PUMPS......................... 3

DESCRIPTION AND OPERATION

COOLANT PERFORMANCE................. 6

RADIATOR HOSES AND CLAMPS........... 6

WATER PIPESÐ3.0L ENGINE.............. 6

WATER PUMPÐ3.3/3.8L ENGINES.......... 7

WATER PUMPÐ2.4L ENGINE.............. 6

WATER PUMPÐ3.0L ENGINE.............. 6

DIAGNOSIS AND TESTING

ACCESSORY DRIVE BELT.................. 7

COOLING SYSTEM DIAGNOSIS............. 8

DEAERATION.......................... 16

ELECTRIC FAN MOTOR TEST.............. 14

LOW COOLANT LEVEL AERATION.......... 15

PRESSURE TESTING RADIATOR CAP....... 15

RADIATOR CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK.............. 15

RADIATOR COOLANT FLOW TEST.......... 14

RADIATOR FAN CONTROL................ 14

TEMPERATURE GAUGE INDICATION........ 16

TESTING COOLING SYSTEM FOR LEAKS.... 14

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE........ 16

COOLANT LEVEL SERVICE................ 16COOLANTÐADDING ADDITIONAL.......... 16

COOLING SYSTEMÐDRAINING............ 16

COOLING SYSTEMÐREFILLING........... 16

REMOVAL AND INSTALLATION

ACCESSORY DRIVE BELTSÐ2.4L.......... 23

ACCESSORY DRIVE BELTSÐ3.0L.......... 24

ACCESSORY DRIVE BELTÐ3.3/3.8L........ 24

ENGINE BLOCK HEATER................. 23

FAN MODULE.......................... 22

RADIATOR DRAINCOCK.................. 21

RADIATOR............................ 21

THERMOSTATÐ2.4L ENGINE............. 19

THERMOSTATÐ3.0L ENGINE............. 20

THERMOSTATÐ3.3/3.8L ENGINES......... 20

WATER PUMP INLET TUBEÐ2.4L ENGINE . . . 17

WATER PUMPÐ3.3/3.8L ENGINES......... 19

WATER PUMPÐ2.4L ENGINE............ 17

WATER PUMPÐ3.0L ENGINE............. 18

CLEANING AND INSPECTION

ACCESSORY DRIVE BELT................. 25

CHEMICAL CLEANING................... 25

COOLING SYSTEM CLEANING............. 25

RADIATOR PRESSURE CAP............... 25

REVERSE FLUSHING THE ENGINE......... 25

REVERSE FLUSHING THE RADIATOR....... 25

WATER PUMP......................... 24

ADJUSTMENTS

BELT TENSION CHART................... 26

BELT TENSION GAUGE METHOD........... 26

PROPER BELT TENSION................. 25

SPECIFICATIONS

COOLING SYSTEM CAPACITY............. 26

TORQUE CHART........................ 26

SPECIAL TOOLS

COOLING............................. 26

GENERAL INFORMATION

ACCESSORY DRIVE BELTS

The accessory drive system utilizes two different

style of drive belts. The conventional V-belt and the

Poly-V belt are used to drive the generator, air con-

ditioning compressor, power steering pump and waterpump. Satisfactory performance of these belts

depends on belt condition and proper belt tension.

Belt tensioning should be performed with the aid of a

Burroughs gauge Special Tool C-4162. Because of

space limitations in the engine compartment, the use

of the gauge may be restricted. Raise the vehicle on a

hoist and then remove the splash shield to gain

access to the drive belts.

NSCOOLING SYSTEM 7 - 1

Page 220 of 1938

DESCRIPTION AND OPERATION

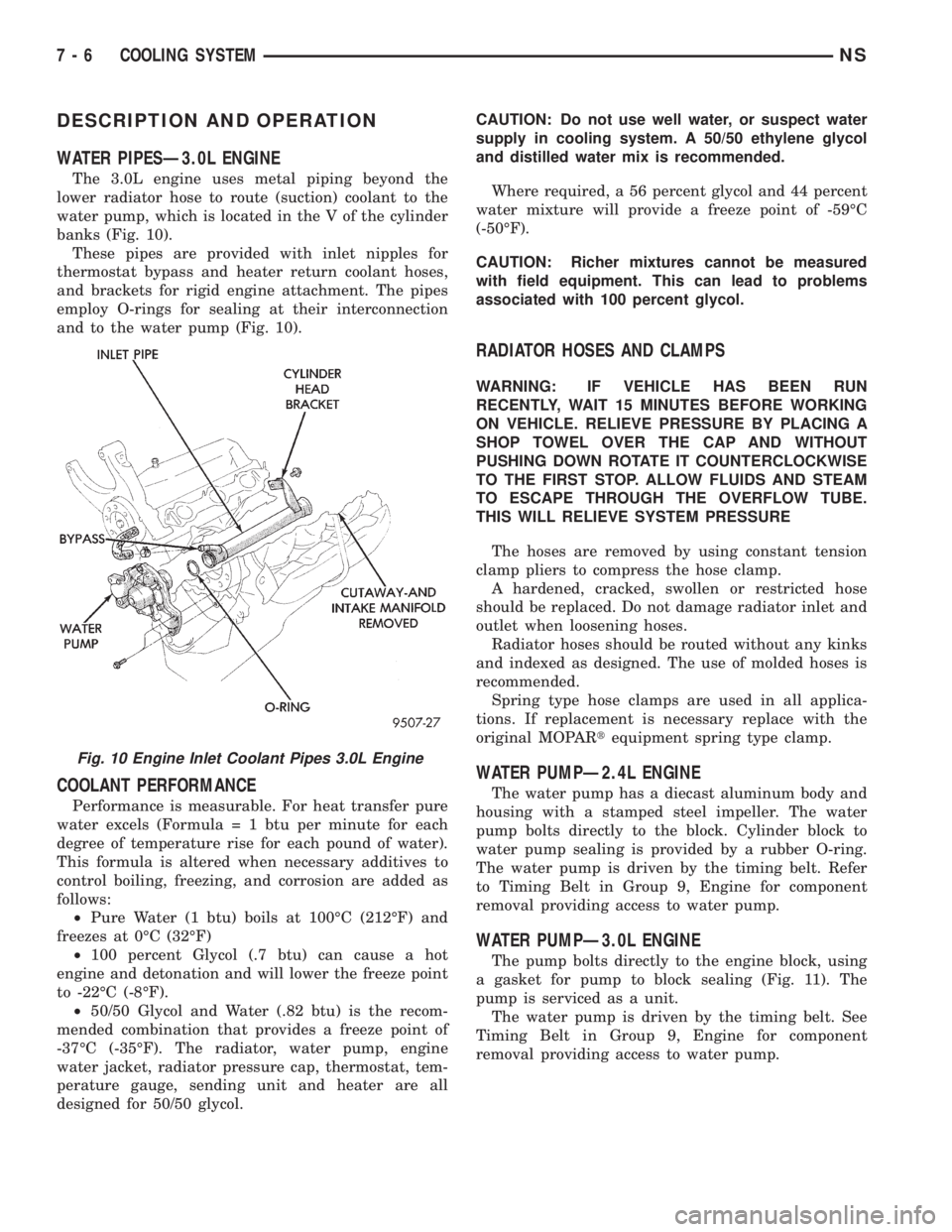

WATER PIPESÐ3.0L ENGINE

The 3.0L engine uses metal piping beyond the

lower radiator hose to route (suction) coolant to the

water pump, which is located in the V of the cylinder

banks (Fig. 10).

These pipes are provided with inlet nipples for

thermostat bypass and heater return coolant hoses,

and brackets for rigid engine attachment. The pipes

employ O-rings for sealing at their interconnection

and to the water pump (Fig. 10).

COOLANT PERFORMANCE

Performance is measurable. For heat transfer pure

water excels (Formula = 1 btu per minute for each

degree of temperature rise for each pound of water).

This formula is altered when necessary additives to

control boiling, freezing, and corrosion are added as

follows:

²Pure Water (1 btu) boils at 100ÉC (212ÉF) and

freezes at 0ÉC (32ÉF)

²100 percent Glycol (.7 btu) can cause a hot

engine and detonation and will lower the freeze point

to -22ÉC (-8ÉF).

²50/50 Glycol and Water (.82 btu) is the recom-

mended combination that provides a freeze point of

-37ÉC (-35ÉF). The radiator, water pump, engine

water jacket, radiator pressure cap, thermostat, tem-

perature gauge, sending unit and heater are all

designed for 50/50 glycol.CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

Where required, a 56 percent glycol and 44 percent

water mixture will provide a freeze point of -59ÉC

(-50ÉF).

CAUTION: Richer mixtures cannot be measured

with field equipment. This can lead to problems

associated with 100 percent glycol.

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE WORKING

ON VEHICLE. RELIEVE PRESSURE BY PLACING A

SHOP TOWEL OVER THE CAP AND WITHOUT

PUSHING DOWN ROTATE IT COUNTERCLOCKWISE

TO THE FIRST STOP. ALLOW FLUIDS AND STEAM

TO ESCAPE THROUGH THE OVERFLOW TUBE.

THIS WILL RELIEVE SYSTEM PRESSURE

The hoses are removed by using constant tension

clamp pliers to compress the hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original MOPARtequipment spring type clamp.

WATER PUMPÐ2.4L ENGINE

The water pump has a diecast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block. Cylinder block to

water pump sealing is provided by a rubber O-ring.

The water pump is driven by the timing belt. Refer

to Timing Belt in Group 9, Engine for component

removal providing access to water pump.

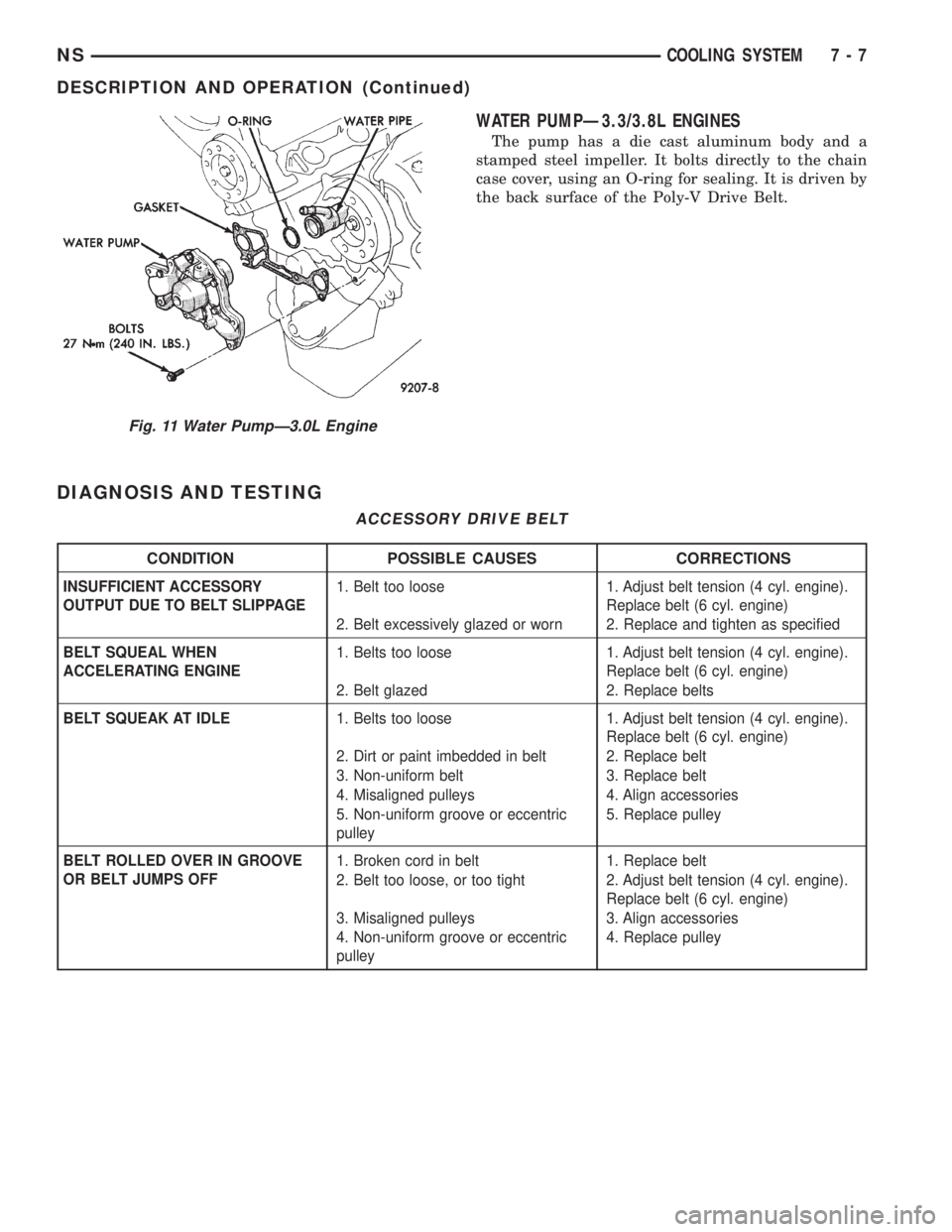

WATER PUMPÐ3.0L ENGINE

The pump bolts directly to the engine block, using

a gasket for pump to block sealing (Fig. 11). The

pump is serviced as a unit.

The water pump is driven by the timing belt. See

Timing Belt in Group 9, Engine for component

removal providing access to water pump.

Fig. 10 Engine Inlet Coolant Pipes 3.0L Engine

7 - 6 COOLING SYSTEMNS

Page 221 of 1938

WATER PUMPÐ3.3/3.8L ENGINES

The pump has a die cast aluminum body and a

stamped steel impeller. It bolts directly to the chain

case cover, using an O-ring for sealing. It is driven by

the back surface of the Poly-V Drive Belt.

DIAGNOSIS AND TESTING

Fig. 11 Water PumpÐ3.0L Engine

ACCESSORY DRIVE BELT

CONDITION POSSIBLE CAUSES CORRECTIONS

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT SLIPPAGE1. Belt too loose 1. Adjust belt tension (4 cyl. engine).

Replace belt (6 cyl. engine)

2. Belt excessively glazed or worn 2. Replace and tighten as specified

BELT SQUEAL WHEN

ACCELERATING ENGINE1. Belts too loose 1. Adjust belt tension (4 cyl. engine).

Replace belt (6 cyl. engine)

2. Belt glazed 2. Replace belts

BELT SQUEAK AT IDLE1. Belts too loose 1. Adjust belt tension (4 cyl. engine).

Replace belt (6 cyl. engine)

2. Dirt or paint imbedded in belt 2. Replace belt

3. Non-uniform belt 3. Replace belt

4. Misaligned pulleys 4. Align accessories

5. Non-uniform groove or eccentric

pulley5. Replace pulley

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt 1. Replace belt

2. Belt too loose, or too tight 2. Adjust belt tension (4 cyl. engine).

Replace belt (6 cyl. engine)

3. Misaligned pulleys 3. Align accessories

4. Non-uniform groove or eccentric

pulley4. Replace pulley

NSCOOLING SYSTEM 7 - 7

DESCRIPTION AND OPERATION (Continued)