light CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1409 of 4284

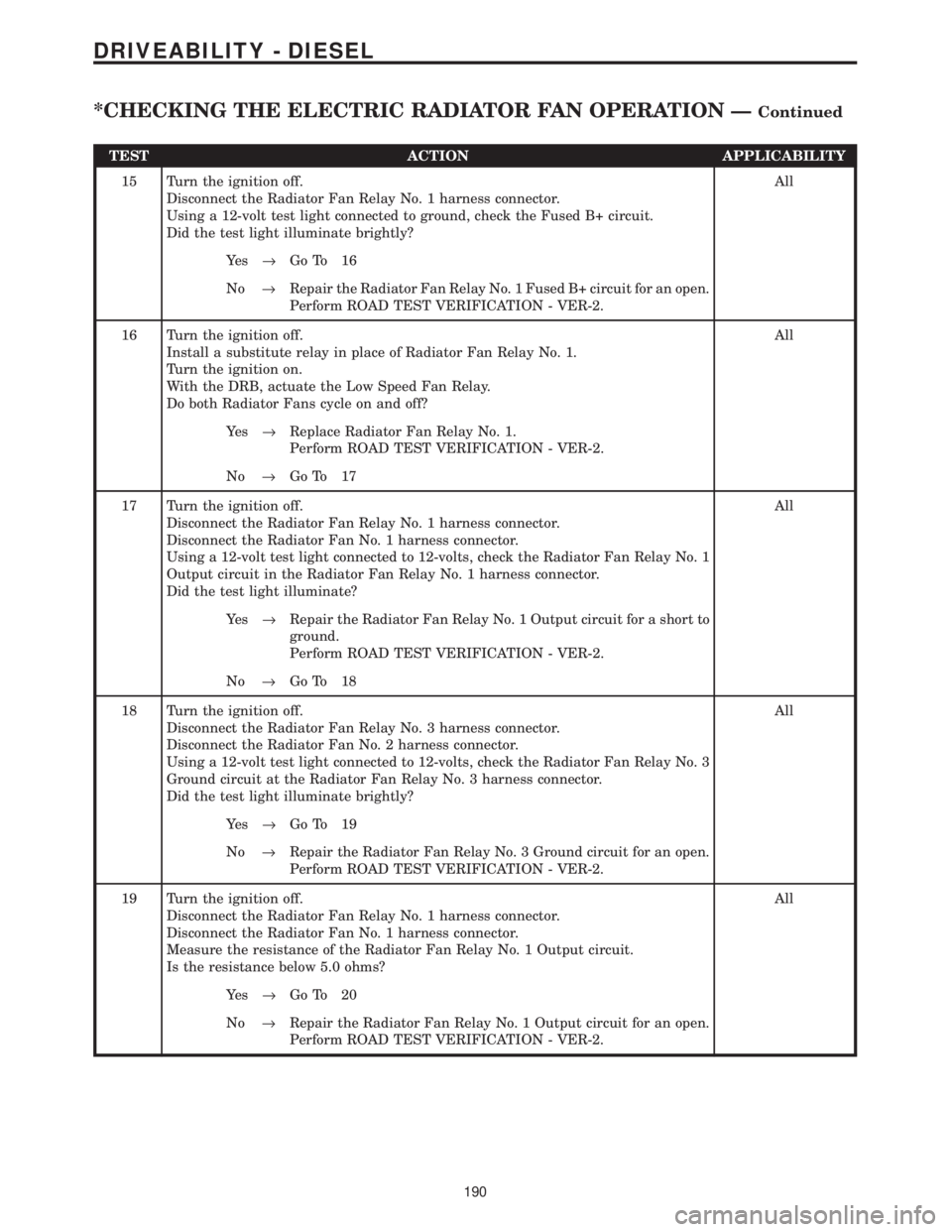

TEST ACTION APPLICABILITY

15 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 1 harness connector.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Did the test light illuminate brightly?All

Ye s®Go To 16

No®Repair the Radiator Fan Relay No. 1 Fused B+ circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

16 Turn the ignition off.

Install a substitute relay in place of Radiator Fan Relay No. 1.

Turn the ignition on.

With the DRB, actuate the Low Speed Fan Relay.

Do both Radiator Fans cycle on and off?All

Ye s®Replace Radiator Fan Relay No. 1.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 17

17 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 1 harness connector.

Disconnect the Radiator Fan No. 1 harness connector.

Using a 12-volt test light connected to 12-volts, check the Radiator Fan Relay No. 1

Output circuit in the Radiator Fan Relay No. 1 harness connector.

Did the test light illuminate?All

Ye s®Repair the Radiator Fan Relay No. 1 Output circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 18

18 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 3 harness connector.

Disconnect the Radiator Fan No. 2 harness connector.

Using a 12-volt test light connected to 12-volts, check the Radiator Fan Relay No. 3

Ground circuit at the Radiator Fan Relay No. 3 harness connector.

Did the test light illuminate brightly?All

Ye s®Go To 19

No®Repair the Radiator Fan Relay No. 3 Ground circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

19 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 1 harness connector.

Disconnect the Radiator Fan No. 1 harness connector.

Measure the resistance of the Radiator Fan Relay No. 1 Output circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 20

No®Repair the Radiator Fan Relay No. 1 Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

190

DRIVEABILITY - DIESEL

*CHECKING THE ELECTRIC RADIATOR FAN OPERATION ÐContinued

Page 1411 of 4284

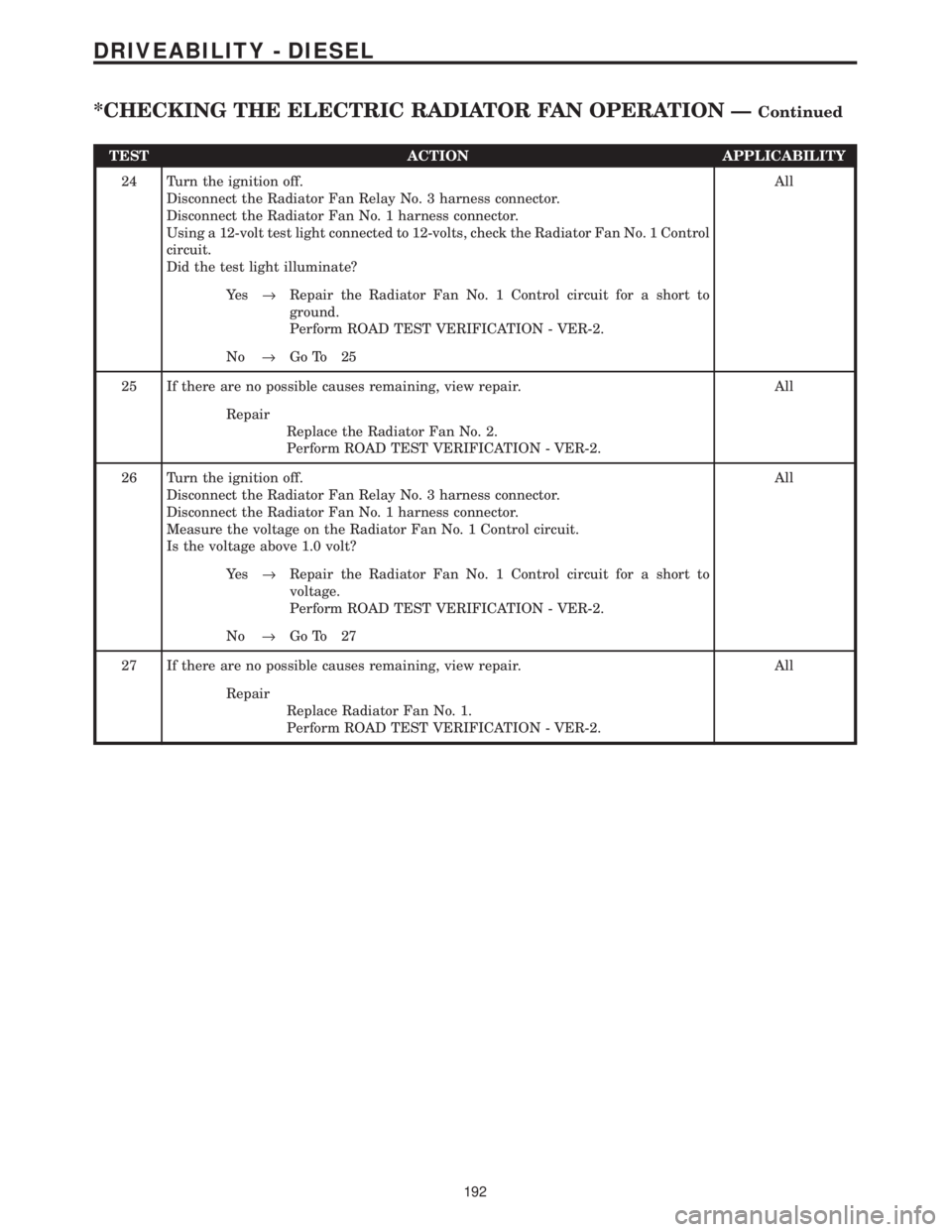

TEST ACTION APPLICABILITY

24 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 3 harness connector.

Disconnect the Radiator Fan No. 1 harness connector.

Using a 12-volt test light connected to 12-volts, check the Radiator Fan No. 1 Control

circuit.

Did the test light illuminate?All

Ye s®Repair the Radiator Fan No. 1 Control circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 25

25 If there are no possible causes remaining, view repair. All

Repair

Replace the Radiator Fan No. 2.

Perform ROAD TEST VERIFICATION - VER-2.

26 Turn the ignition off.

Disconnect the Radiator Fan Relay No. 3 harness connector.

Disconnect the Radiator Fan No. 1 harness connector.

Measure the voltage on the Radiator Fan No. 1 Control circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Radiator Fan No. 1 Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 27

27 If there are no possible causes remaining, view repair. All

Repair

Replace Radiator Fan No. 1.

Perform ROAD TEST VERIFICATION - VER-2.

192

DRIVEABILITY - DIESEL

*CHECKING THE ELECTRIC RADIATOR FAN OPERATION ÐContinued

Page 1414 of 4284

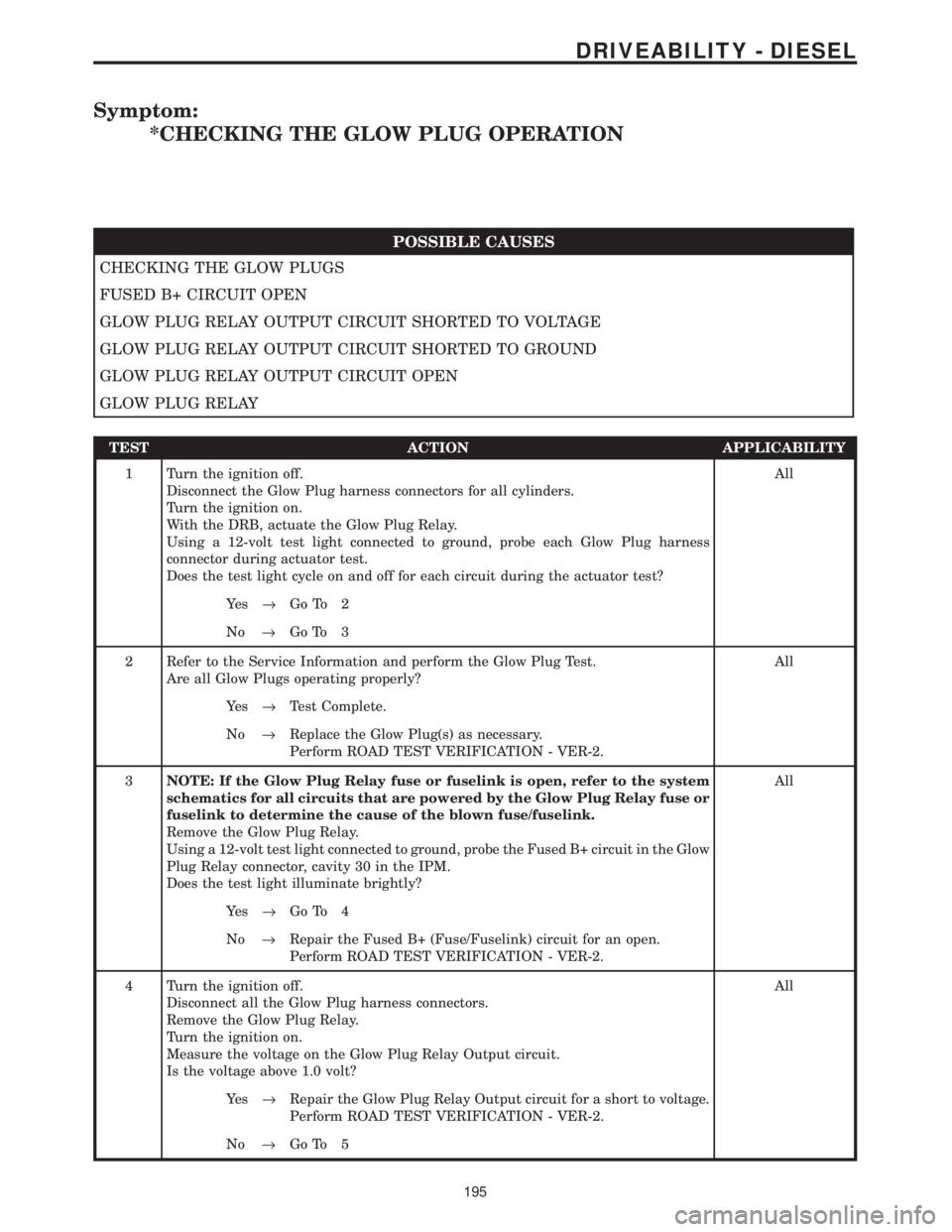

Symptom:

*CHECKING THE GLOW PLUG OPERATION

POSSIBLE CAUSES

CHECKING THE GLOW PLUGS

FUSED B+ CIRCUIT OPEN

GLOW PLUG RELAY OUTPUT CIRCUIT SHORTED TO VOLTAGE

GLOW PLUG RELAY OUTPUT CIRCUIT SHORTED TO GROUND

GLOW PLUG RELAY OUTPUT CIRCUIT OPEN

GLOW PLUG RELAY

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Glow Plug harness connectors for all cylinders.

Turn the ignition on.

With the DRB, actuate the Glow Plug Relay.

Using a 12-volt test light connected to ground, probe each Glow Plug harness

connector during actuator test.

Does the test light cycle on and off for each circuit during the actuator test?All

Ye s®Go To 2

No®Go To 3

2 Refer to the Service Information and perform the Glow Plug Test.

Are all Glow Plugs operating properly?All

Ye s®Test Complete.

No®Replace the Glow Plug(s) as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

3NOTE: If the Glow Plug Relay fuse or fuselink is open, refer to the system

schematics for all circuits that are powered by the Glow Plug Relay fuse or

fuselink to determine the cause of the blown fuse/fuselink.

Remove the Glow Plug Relay.

Using a 12-volt test light connected to ground, probe the Fused B+ circuit in the Glow

Plug Relay connector, cavity 30 in the IPM.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the Fused B+ (Fuse/Fuselink) circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect all the Glow Plug harness connectors.

Remove the Glow Plug Relay.

Turn the ignition on.

Measure the voltage on the Glow Plug Relay Output circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Glow Plug Relay Output circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

195

DRIVEABILITY - DIESEL

Page 1415 of 4284

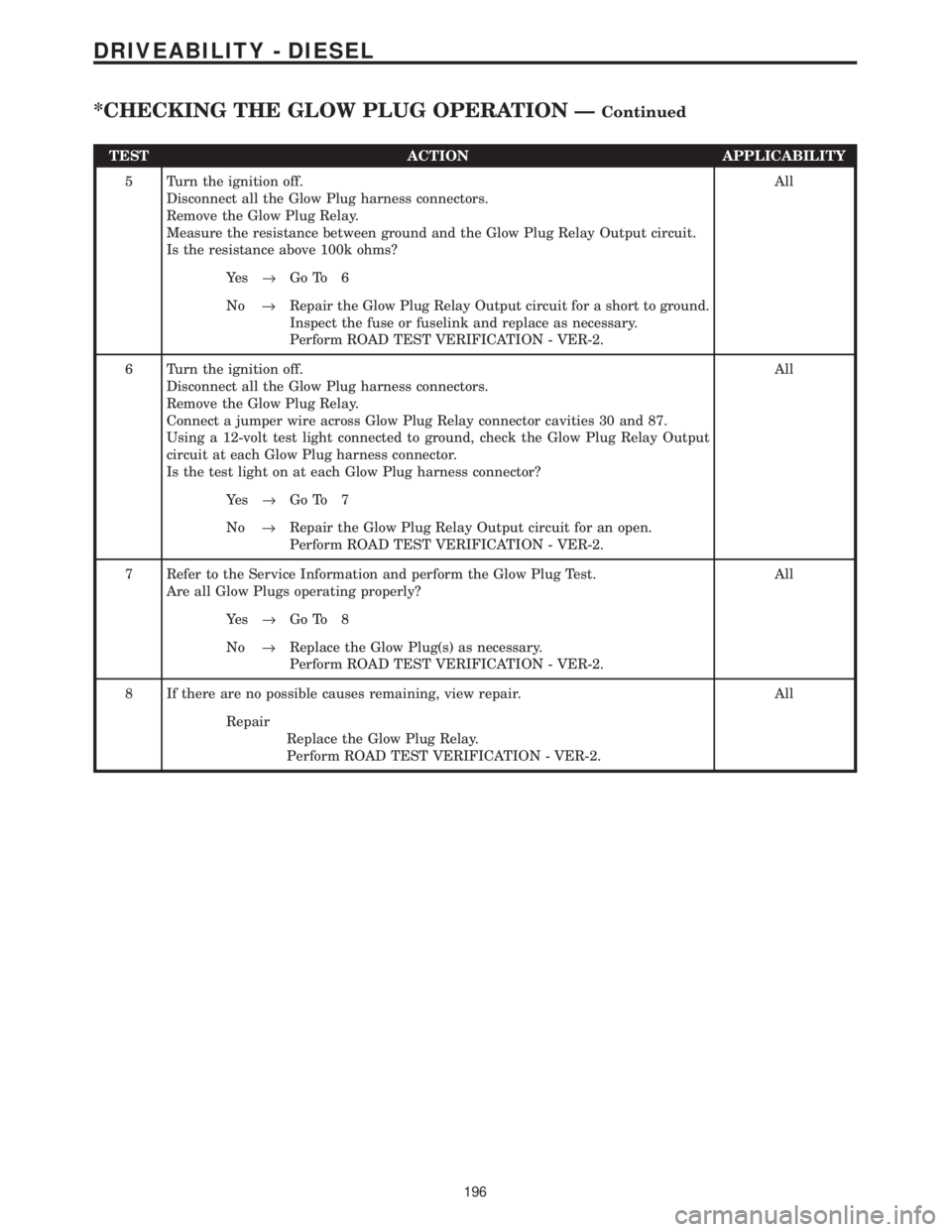

TEST ACTION APPLICABILITY

5 Turn the ignition off.

Disconnect all the Glow Plug harness connectors.

Remove the Glow Plug Relay.

Measure the resistance between ground and the Glow Plug Relay Output circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 6

No®Repair the Glow Plug Relay Output circuit for a short to ground.

Inspect the fuse or fuselink and replace as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

6 Turn the ignition off.

Disconnect all the Glow Plug harness connectors.

Remove the Glow Plug Relay.

Connect a jumper wire across Glow Plug Relay connector cavities 30 and 87.

Using a 12-volt test light connected to ground, check the Glow Plug Relay Output

circuit at each Glow Plug harness connector.

Is the test light on at each Glow Plug harness connector?All

Ye s®Go To 7

No®Repair the Glow Plug Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

7 Refer to the Service Information and perform the Glow Plug Test.

Are all Glow Plugs operating properly?All

Ye s®Go To 8

No®Replace the Glow Plug(s) as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

8 If there are no possible causes remaining, view repair. All

Repair

Replace the Glow Plug Relay.

Perform ROAD TEST VERIFICATION - VER-2.

196

DRIVEABILITY - DIESEL

*CHECKING THE GLOW PLUG OPERATION ÐContinued

Page 1416 of 4284

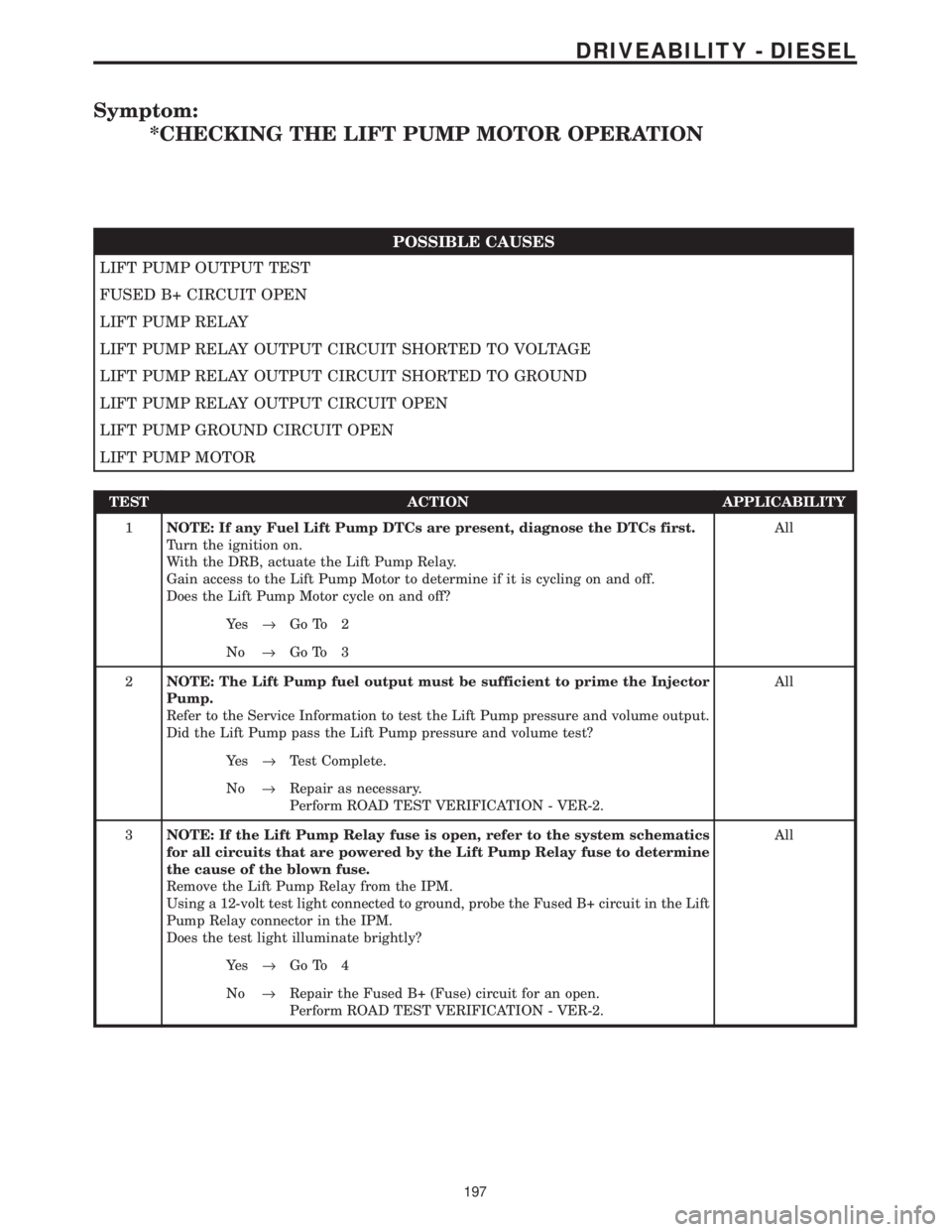

Symptom:

*CHECKING THE LIFT PUMP MOTOR OPERATION

POSSIBLE CAUSES

LIFT PUMP OUTPUT TEST

FUSED B+ CIRCUIT OPEN

LIFT PUMP RELAY

LIFT PUMP RELAY OUTPUT CIRCUIT SHORTED TO VOLTAGE

LIFT PUMP RELAY OUTPUT CIRCUIT SHORTED TO GROUND

LIFT PUMP RELAY OUTPUT CIRCUIT OPEN

LIFT PUMP GROUND CIRCUIT OPEN

LIFT PUMP MOTOR

TEST ACTION APPLICABILITY

1NOTE: If any Fuel Lift Pump DTCs are present, diagnose the DTCs first.

Turn the ignition on.

With the DRB, actuate the Lift Pump Relay.

Gain access to the Lift Pump Motor to determine if it is cycling on and off.

Does the Lift Pump Motor cycle on and off?All

Ye s®Go To 2

No®Go To 3

2NOTE: The Lift Pump fuel output must be sufficient to prime the Injector

Pump.

Refer to the Service Information to test the Lift Pump pressure and volume output.

Did the Lift Pump pass the Lift Pump pressure and volume test?All

Ye s®Test Complete.

No®Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

3NOTE: If the Lift Pump Relay fuse is open, refer to the system schematics

for all circuits that are powered by the Lift Pump Relay fuse to determine

the cause of the blown fuse.

Remove the Lift Pump Relay from the IPM.

Using a 12-volt test light connected to ground, probe the Fused B+ circuit in the Lift

Pump Relay connector in the IPM.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Repair the Fused B+ (Fuse) circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

197

DRIVEABILITY - DIESEL

Page 1417 of 4284

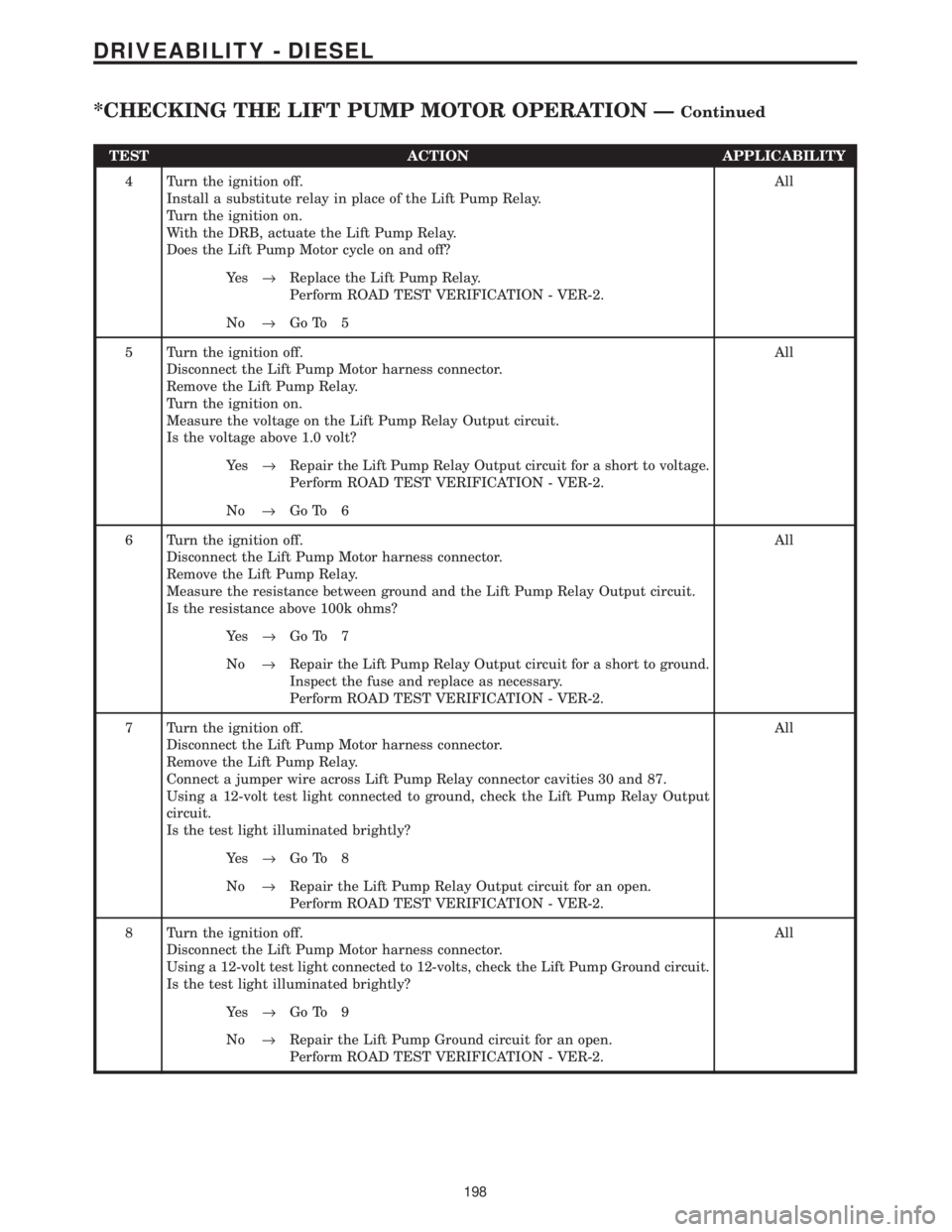

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Install a substitute relay in place of the Lift Pump Relay.

Turn the ignition on.

With the DRB, actuate the Lift Pump Relay.

Does the Lift Pump Motor cycle on and off?All

Ye s®Replace the Lift Pump Relay.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 5

5 Turn the ignition off.

Disconnect the Lift Pump Motor harness connector.

Remove the Lift Pump Relay.

Turn the ignition on.

Measure the voltage on the Lift Pump Relay Output circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Lift Pump Relay Output circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 6

6 Turn the ignition off.

Disconnect the Lift Pump Motor harness connector.

Remove the Lift Pump Relay.

Measure the resistance between ground and the Lift Pump Relay Output circuit.

Is the resistance above 100k ohms?All

Ye s®Go To 7

No®Repair the Lift Pump Relay Output circuit for a short to ground.

Inspect the fuse and replace as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

7 Turn the ignition off.

Disconnect the Lift Pump Motor harness connector.

Remove the Lift Pump Relay.

Connect a jumper wire across Lift Pump Relay connector cavities 30 and 87.

Using a 12-volt test light connected to ground, check the Lift Pump Relay Output

circuit.

Is the test light illuminated brightly?All

Ye s®Go To 8

No®Repair the Lift Pump Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

8 Turn the ignition off.

Disconnect the Lift Pump Motor harness connector.

Using a 12-volt test light connected to 12-volts, check the Lift Pump Ground circuit.

Is the test light illuminated brightly?All

Ye s®Go To 9

No®Repair the Lift Pump Ground circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

198

DRIVEABILITY - DIESEL

*CHECKING THE LIFT PUMP MOTOR OPERATION ÐContinued

Page 1430 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Relay from the PDC.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK

BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE

ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN.

DO NOT WEAR LOOSE CLOTHING.

Momentarily jumper Starter Relay connector cavities 30 and 87 in the IPM

connector.

Did the engine crank?All

Ye s®Go To 4

No®Go To 11

4 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit while fully depressing the clutch pedal and turning the ignition switch

to the START position.

Does the test light illuminate with the ignition switch in the START position?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Remove the Starter Relay From the PDC.

Install a substitute relay in place of the Starter Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s®Replace the Starter Relay.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, probe ECM harness connector cavity

49 while fully depressing the clutch pedal and turning the ignition switch to the

START position.

Does the test light illuminate while the ignition is in the Start position.All

Ye s®Go To 7

No®Repair the Ignition Switch Start Output circuit to the ECM.

Perform NO START VERIFICATION - VER-1.

211

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1431 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Remove the ECM/PCM Relay from the IPM.

Using a jumper wire, connect ECM/PCM relay connector cavities 30 and 87 in the

IPM.

Turn the ignition on.

Measure the voltage of the Starter Relay Control circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Starter Relay Control circuit for a short to voltage.

Perform NO START VERIFICATION - VER-1.

No®Go To 8

8 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Turn the ignition on.

Measure the resistance of the Starter Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace and program the ECM in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Starter Relay Control circuit for an open.

Perform NO START VERIFICATION - VER-1.

9 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Clutch Interlock Switch harness connector.

Connect a jumper wire across the Clutch Interlock Switch harness connector.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit at the Starter Relay connector in the PDC and turning the ignition

switch to the crank position.

Does the test light illuminate with the ignition switch in the crank position?All

Ye s®Replace the Clutch Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Go To 10

10 Turn the ignition off.

Disconnect the Clutch Interlock Switch harness connector.

Remove the Starter Relay from the PDC.

Measure the resistance of the Clutch Interlock Switch Output circuit between the

PDC and the Clutch Interlock Switch harness connector.

Is the resistance below 10.0 ohms?All

Ye s®Repair the Ignition Switch Start Output circuit to the Clutch

Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Repair the Clutch Interlock Switch Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

212

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1432 of 4284

TEST ACTION APPLICABILITY

11 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Is the test light on?All

Ye s®Go To 12

No®Repair the Fused B(+) circuit for an open.

Perform NO START VERIFICATION - VER-1.

12 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Starter Relay Output wire from the Starter Solenoid.

Connect the Starter Relay Output wire (at the Starter) to ground.

Using a 12-volt test light connected to 12-volts, check the Starter Relay Output

circuit at the Starter Relay connector in the IPM.

Does the test light illuminate brightly?All

Ye s®Go To 13

No®Repair the Starter Relay Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

13 Using the Service Information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 volts?All

Ye s®Replace the battery cable(s).

Perform NO START VERIFICATION - VER-1.

No®Go To 14

14 Turn the ignition off.

Attempt to manually rotate the crankshaft 360É.

Is the crankshaft able to rotate 360É?All

Ye s®Replace the Starter Motor.

Perform NO START VERIFICATION - VER-1.

No®Repair the engine mechanical problem.

Perform NO START VERIFICATION - VER-1.

213

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1473 of 4284

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts.

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

International Symbols

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

INTERNATIONAL SYMBOLS (Continued)