windshield wipers CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 985 of 4284

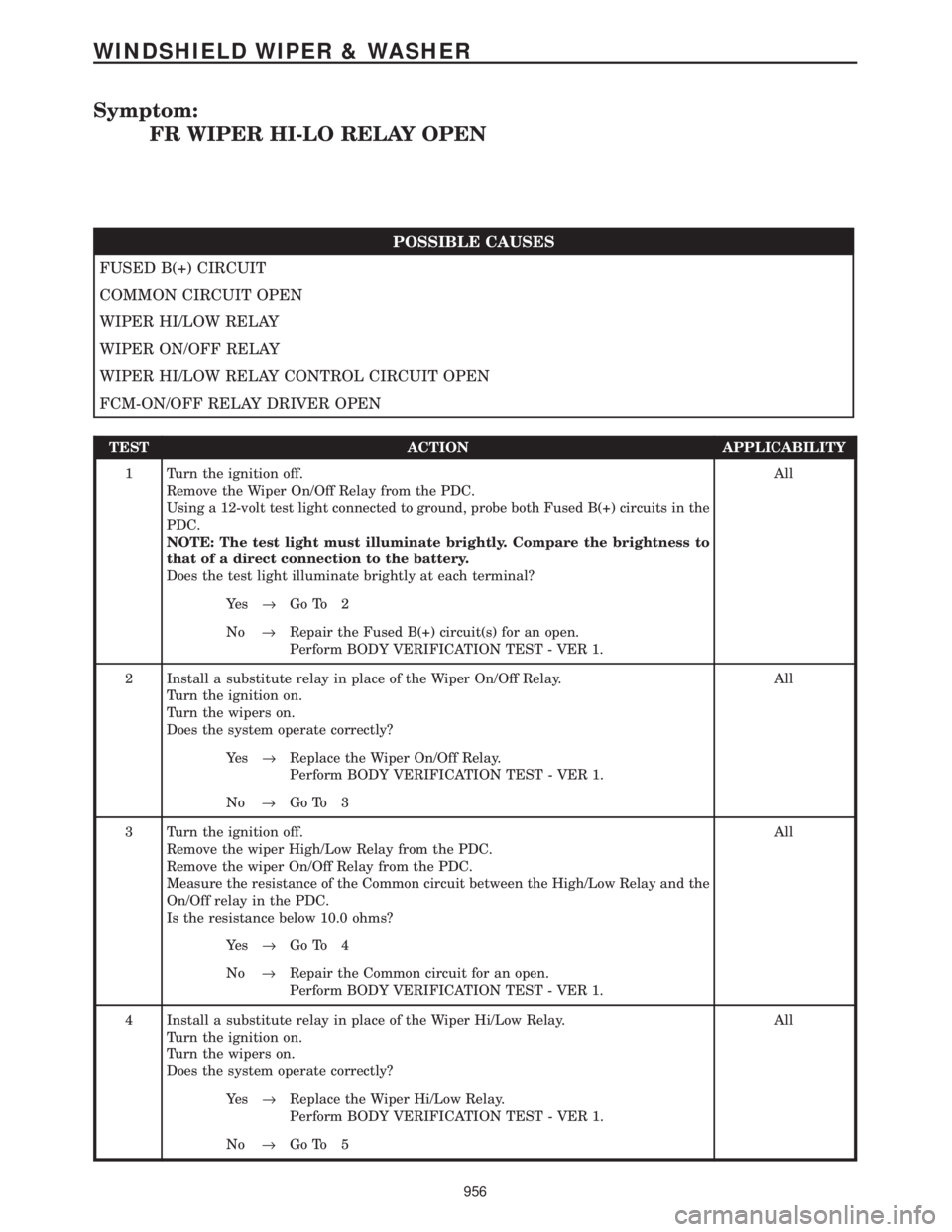

Symptom:

FR WIPER HI-LO RELAY OPEN

POSSIBLE CAUSES

FUSED B(+) CIRCUIT

COMMON CIRCUIT OPEN

WIPER HI/LOW RELAY

WIPER ON/OFF RELAY

WIPER HI/LOW RELAY CONTROL CIRCUIT OPEN

FCM-ON/OFF RELAY DRIVER OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Remove the Wiper On/Off Relay from the PDC.

Using a 12-volt test light connected to ground, probe both Fused B(+) circuits in the

PDC.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly at each terminal?All

Ye s®Go To 2

No®Repair the Fused B(+) circuit(s) for an open.

Perform BODY VERIFICATION TEST - VER 1.

2 Install a substitute relay in place of the Wiper On/Off Relay.

Turn the ignition on.

Turn the wipers on.

Does the system operate correctly?All

Ye s®Replace the Wiper On/Off Relay.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Remove the wiper High/Low Relay from the PDC.

Remove the wiper On/Off Relay from the PDC.

Measure the resistance of the Common circuit between the High/Low Relay and the

On/Off relay in the PDC.

Is the resistance below 10.0 ohms?All

Ye s®Go To 4

No®Repair the Common circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

4 Install a substitute relay in place of the Wiper Hi/Low Relay.

Turn the ignition on.

Turn the wipers on.

Does the system operate correctly?All

Ye s®Replace the Wiper Hi/Low Relay.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

956

WINDSHIELD WIPER & WASHER

Page 987 of 4284

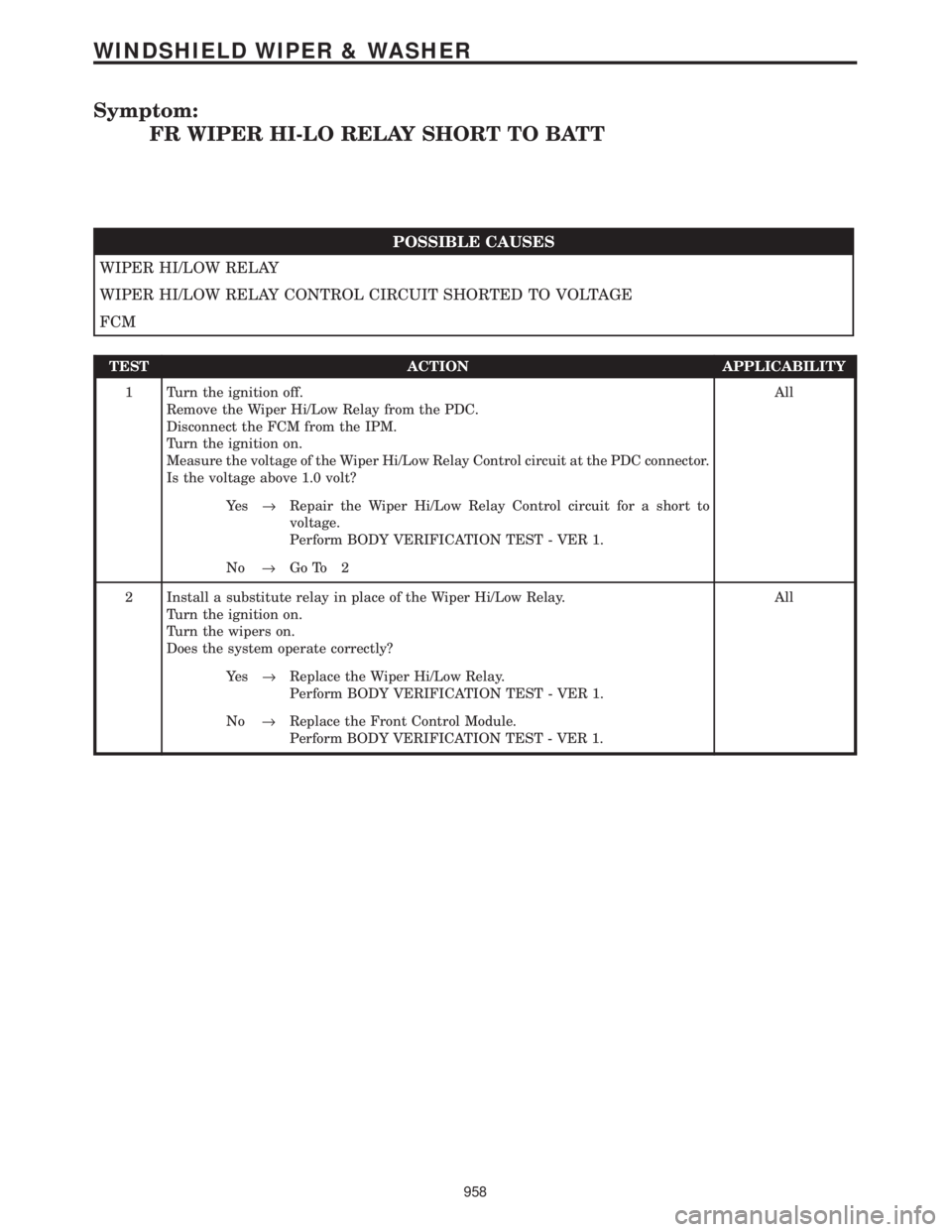

Symptom:

FR WIPER HI-LO RELAY SHORT TO BATT

POSSIBLE CAUSES

WIPER HI/LOW RELAY

WIPER HI/LOW RELAY CONTROL CIRCUIT SHORTED TO VOLTAGE

FCM

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Remove the Wiper Hi/Low Relay from the PDC.

Disconnect the FCM from the IPM.

Turn the ignition on.

Measure the voltage of the Wiper Hi/Low Relay Control circuit at the PDC connector.

Is the voltage above 1.0 volt?All

Ye s®Repair the Wiper Hi/Low Relay Control circuit for a short to

voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2 Install a substitute relay in place of the Wiper Hi/Low Relay.

Turn the ignition on.

Turn the wipers on.

Does the system operate correctly?All

Ye s®Replace the Wiper Hi/Low Relay.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

958

WINDSHIELD WIPER & WASHER

Page 992 of 4284

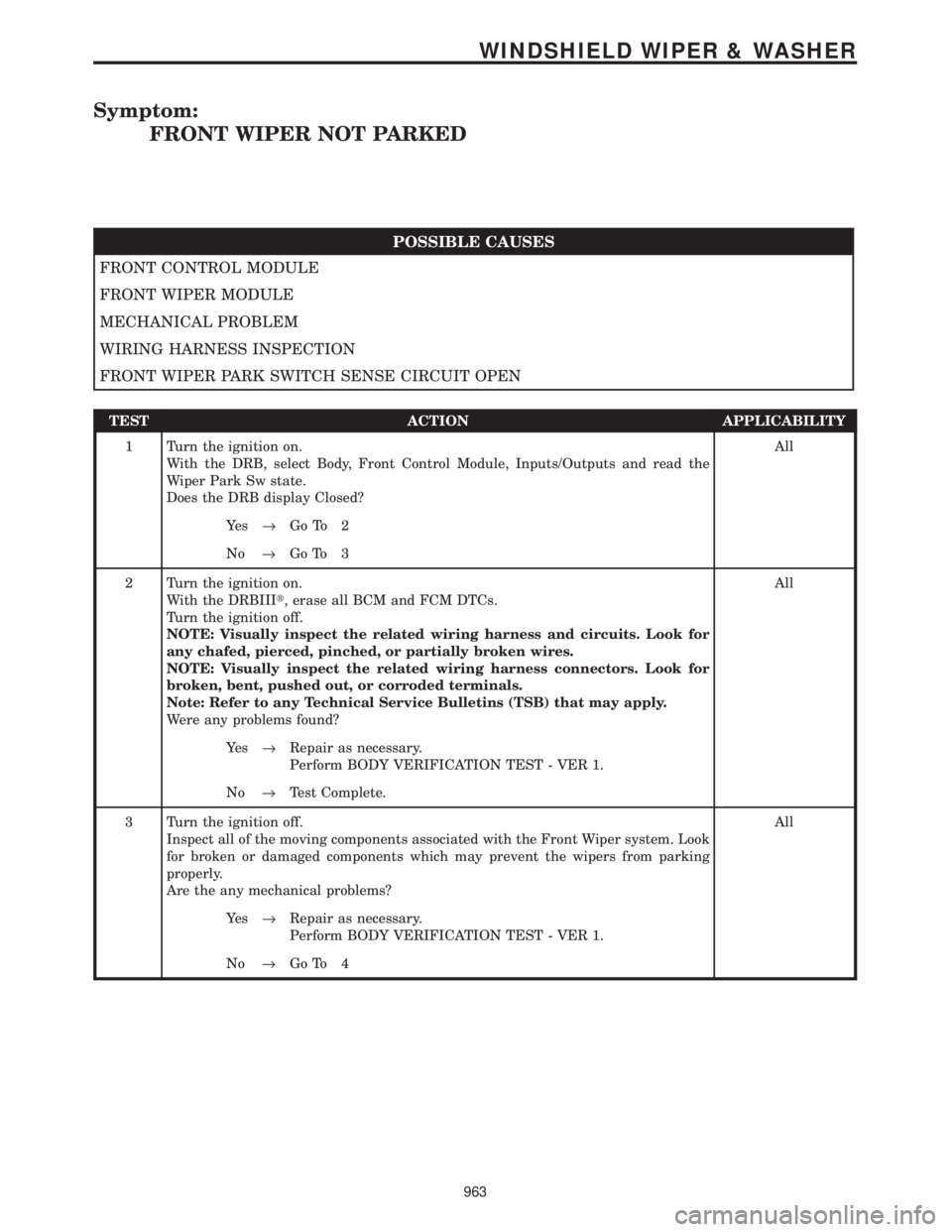

Symptom:

FRONT WIPER NOT PARKED

POSSIBLE CAUSES

FRONT CONTROL MODULE

FRONT WIPER MODULE

MECHANICAL PROBLEM

WIRING HARNESS INSPECTION

FRONT WIPER PARK SWITCH SENSE CIRCUIT OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, select Body, Front Control Module, Inputs/Outputs and read the

Wiper Park Sw state.

Does the DRB display Closed?All

Ye s®Go To 2

No®Go To 3

2 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

NOTE: Visually inspect the related wiring harness and circuits. Look for

any chafed, pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

3 Turn the ignition off.

Inspect all of the moving components associated with the Front Wiper system. Look

for broken or damaged components which may prevent the wipers from parking

properly.

Are the any mechanical problems?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

963

WINDSHIELD WIPER & WASHER

Page 994 of 4284

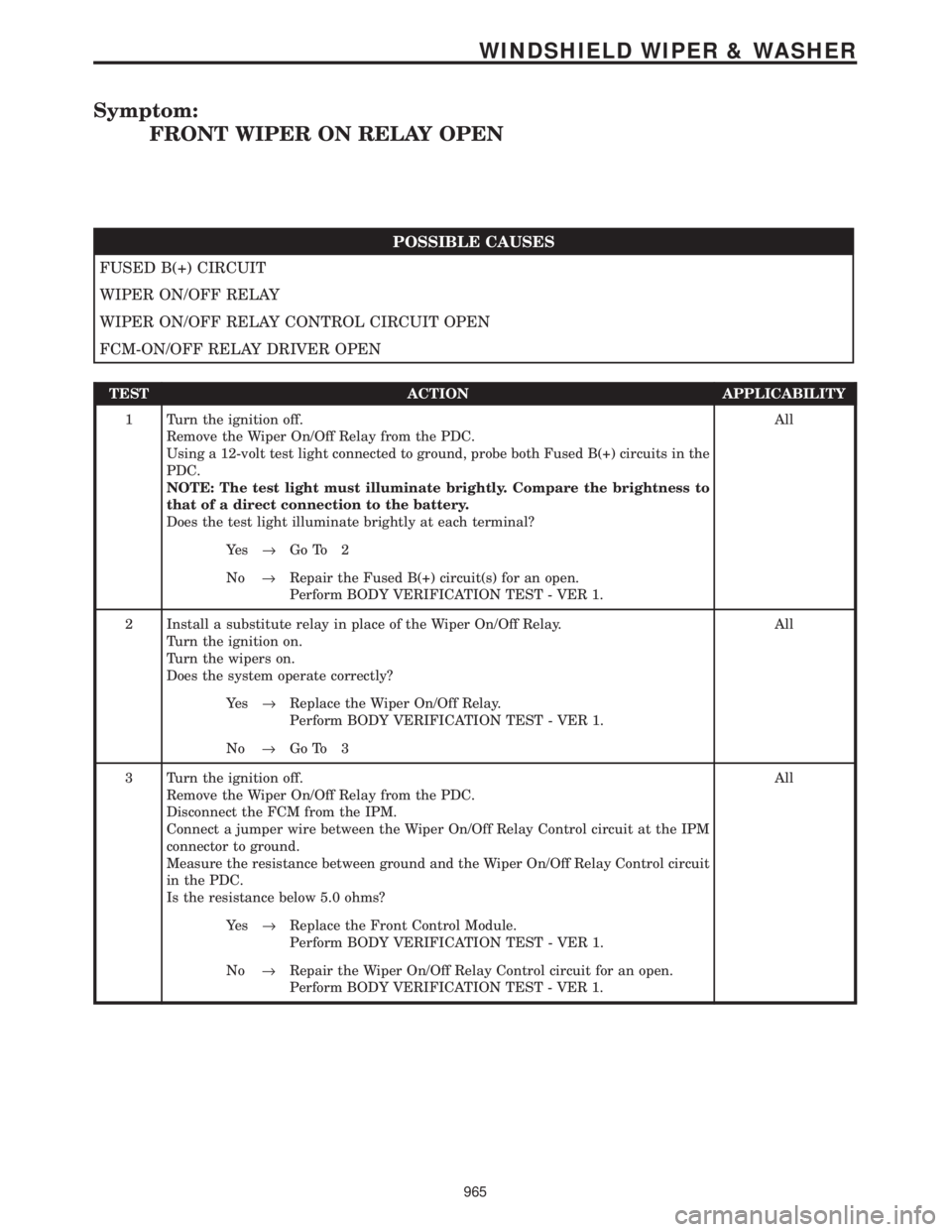

Symptom:

FRONT WIPER ON RELAY OPEN

POSSIBLE CAUSES

FUSED B(+) CIRCUIT

WIPER ON/OFF RELAY

WIPER ON/OFF RELAY CONTROL CIRCUIT OPEN

FCM-ON/OFF RELAY DRIVER OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Remove the Wiper On/Off Relay from the PDC.

Using a 12-volt test light connected to ground, probe both Fused B(+) circuits in the

PDC.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly at each terminal?All

Ye s®Go To 2

No®Repair the Fused B(+) circuit(s) for an open.

Perform BODY VERIFICATION TEST - VER 1.

2 Install a substitute relay in place of the Wiper On/Off Relay.

Turn the ignition on.

Turn the wipers on.

Does the system operate correctly?All

Ye s®Replace the Wiper On/Off Relay.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Remove the Wiper On/Off Relay from the PDC.

Disconnect the FCM from the IPM.

Connect a jumper wire between the Wiper On/Off Relay Control circuit at the IPM

connector to ground.

Measure the resistance between ground and the Wiper On/Off Relay Control circuit

in the PDC.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Repair the Wiper On/Off Relay Control circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

965

WINDSHIELD WIPER & WASHER

Page 995 of 4284

Symptom:

FRONT WIPER ON RELAY SHORT TO BATT

POSSIBLE CAUSES

WIPER ON/OFF RELAY

WIPER ON/OFF RELAY CONTROL CIRCUIT SHORTED TO VOLTAGE

FCM

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Remove the Wiper On/Off Relay from the PDC.

Disconnect the FCM from the IPM.

Turn the ignition on.

Measure the voltage of the Wiper On/Off Relay Control circuit at the PDC connector.

Is the voltage above 1.0 volt?All

Ye s®Repair the Wiper On/Off Relay Control circuit for a short to

voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2 Install a substitute relay in place of the Wiper On/Off Relay.

Turn the ignition on.

Turn the wipers on.

Does the system operate correctly?All

Ye s®Replace the Wiper On/Off Relay.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

966

WINDSHIELD WIPER & WASHER

Page 996 of 4284

Symptom:

FRONT WIPER PARK SWITCH SHORT TO GND

POSSIBLE CAUSES

FRONT CONTROL MODULE

FRONT WIPER MODULE

WIRING HARNESS INSPECTION

FRONT WIPER PARK SWITCH SENSE CIRCUIT SHORTED TO GROUND

TEST ACTION APPLICABILITY

1 Turn the ignition on.

Turn the Wipers on one of the intermittent settings.

With the DRB, select Body, Front Control Module, Inputs/Outputs and read the

Wiper Park Sw state.

Does the switch state change from Open to Closed during wiper operation?All

Ye s®Go To 2

No®Go To 3

2 Turn the ignition on.

With the DRBIIIt, erase all BCM and FCM DTCs.

Turn the ignition off.

NOTE: Visually inspect the related wiring harness and circuits. Look for

any chafed, pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

3 Turn the ignition off.

Disconnect the Front Wiper Module harness connector.

Disconnect the FCM from the IPM.

Measure the resistance between ground and the Front Wiper Park Switch Sense

circuit.

Is the resistance below 1000.0 ohms?All

Ye s®Repair the Front Wiper Park Switch Sense circuit for a short to

ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

967

WINDSHIELD WIPER & WASHER

Page 997 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition on.

Turn the front wipers to an intermittent setting.

Using a 12-volt test light connected to 12-volts, back probe the Front Wiper Park

Switch Sense circuit at the Front Wiper Module harness connector.

NOTE: The test light should illuminate when the wipers are parked, then

turn off when the wipers move off of the parked position.

Does the test light turn on and off properly?All

Ye s®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Wiper Module.

Perform BODY VERIFICATION TEST - VER 1.

968

WINDSHIELD WIPER & WASHER

FRONT WIPER PARK SWITCH SHORT TO GND ÐContinued

Page 1731 of 4284

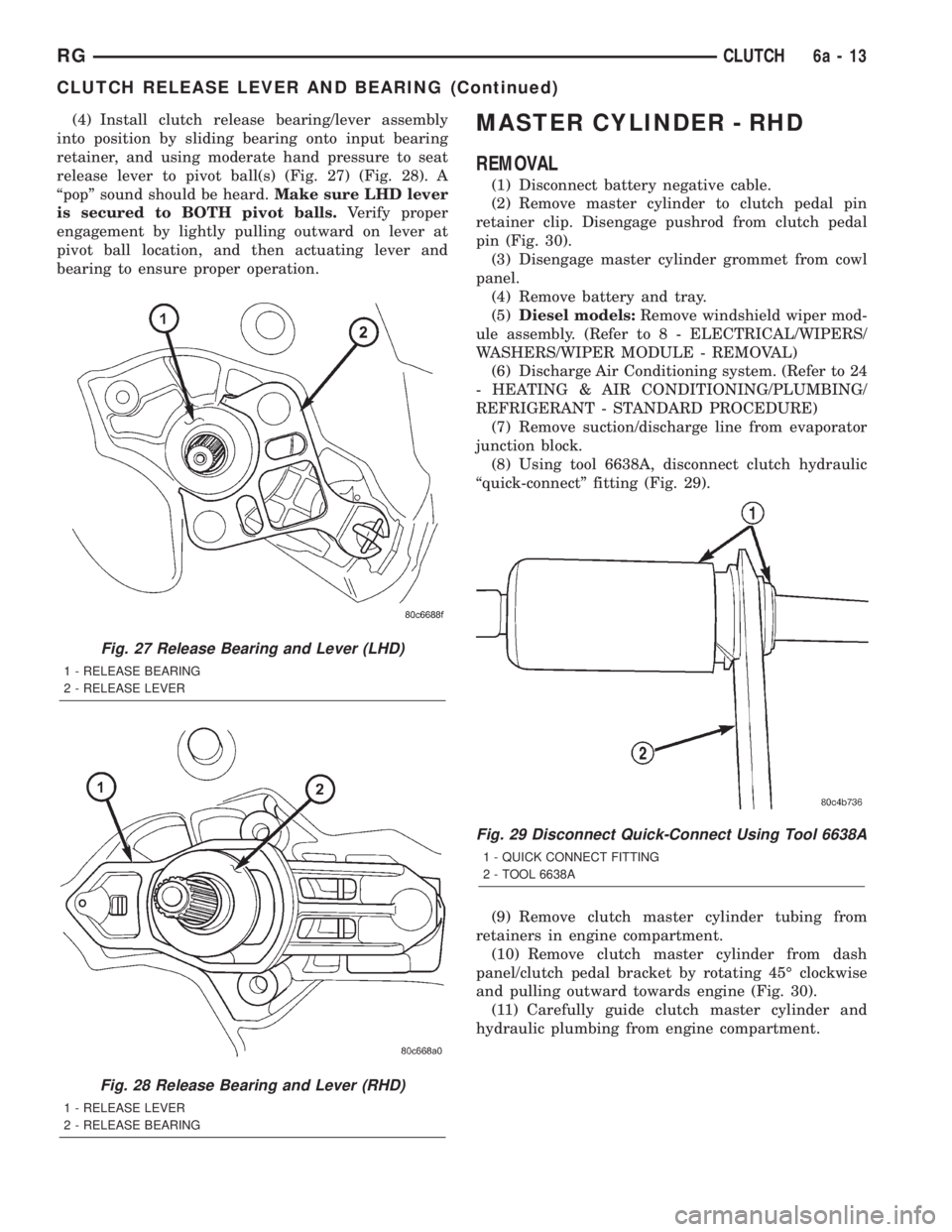

(4) Install clutch release bearing/lever assembly

into position by sliding bearing onto input bearing

retainer, and using moderate hand pressure to seat

release lever to pivot ball(s) (Fig. 27) (Fig. 28). A

ªpopº sound should be heard.Make sure LHD lever

is secured to BOTH pivot balls.Verify proper

engagement by lightly pulling outward on lever at

pivot ball location, and then actuating lever and

bearing to ensure proper operation.MASTER CYLINDER - RHD

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove master cylinder to clutch pedal pin

retainer clip. Disengage pushrod from clutch pedal

pin (Fig. 30).

(3) Disengage master cylinder grommet from cowl

panel.

(4) Remove battery and tray.

(5)Diesel models:Remove windshield wiper mod-

ule assembly. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL)

(6) Discharge Air Conditioning system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

REFRIGERANT - STANDARD PROCEDURE)

(7) Remove suction/discharge line from evaporator

junction block.

(8) Using tool 6638A, disconnect clutch hydraulic

ªquick-connectº fitting (Fig. 29).

(9) Remove clutch master cylinder tubing from

retainers in engine compartment.

(10) Remove clutch master cylinder from dash

panel/clutch pedal bracket by rotating 45É clockwise

and pulling outward towards engine (Fig. 30).

(11) Carefully guide clutch master cylinder and

hydraulic plumbing from engine compartment.

Fig. 27 Release Bearing and Lever (LHD)

1 - RELEASE BEARING

2 - RELEASE LEVER

Fig. 28 Release Bearing and Lever (RHD)

1 - RELEASE LEVER

2 - RELEASE BEARING

Fig. 29 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

RGCLUTCH6a-13

CLUTCH RELEASE LEVER AND BEARING (Continued)

Page 1942 of 4284

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

LAMP SYSTEMS

RS vehicles use lighting on the interior and exte-

rior of the vehicle for illuminating and indicating

purposes. Lighting circuits are protected by fuses.

Lighting circuits require an overload protected power

source, on/off device, lamps and body ground to oper-

ate properly. Plastic lamps require a wire in the har-

ness to supply body ground to the lamp socket.

Replace sockets and bulbs that are corroded.

Some of the interior and exterior lighting functions

are governed by the Body Control Module. The head-

lamp, dome, and the door ajar switches provide sig-

nals to the Body Control Module. The Body Control

Module in turn sends a J1850 message to the Front

Control Module (FCM) to enable the necessary driv-

ers to set the required illumination configuration.

Wire connectors can make intermittent contact or

become corroded. Before coupling wire connectors,

inspect the terminals inside the connector. Male termi-

nals should not be bent or disengaged from the insu-

lator. Female terminals should not be sprung open or

disengaged from the insulator. Bent and sprung termi-

nals can be repaired using needle nose pliers and pick

tool. Corroded terminals appear chalky or green. Cor-

roded terminals should be replaced to avoid recur-

rence of the problem symptoms.

Begin electrical system failure diagnosis by testing

related fuses in the fuse block and intelligent power

module. Verify that bulbs are in good condition and

test continuity of the circuit ground. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

AUTOMATIC HEADLAMP SYSTEM

The Automatic Headlamp system turns the instru-

mentation and exterior illumination lamps ON when

the ambient light levels are Night and OFF when

light levels are Day.

DAYTIME RUNNING LAMPS

Operating the high-beam headlamps at reduced

power provides daytime running lamps, which are

required on all new Canadian vehicles.

HEADLAMPS ON WITH WINDSHIELD WIPERS

For vehicles equipped with the Automatic Head-

lamp System, the instrumentation and exterior illu-

mination lamps will be turned ON when theheadlamp switch is in the AUTO position, RPM >

450 and the windshield wipers have been in the

intermittent, low or high mode of operation for more

than ten seconds. When the windshield wipers are

turned OFF the Body Control Module will determine

if the instrumentation and exterior illumination

lamps should remain ON base upon the current

ambient light level.

HEADLAMP SYSTEM

The configuration of the headlamp system of head-

lamps, park lamps and fog lamps is determined by

the BCM. The BCM determines the lighting configu-

ration as a result of the inputs from the ignition

switch, headlamp switch and multifunction switch. A

J1850 is transmitted from the BCM to the FCM to

enable the necessary drivers to set the illumination

configuration. Four wires are connected between the

headlamp switch and the BCM. The first wire con-

tains information regarding the position of the head-

lamp switch (Off, Automatic Headlamps, Automatic

Headlamp switch fog, Park with Fog, Head, or Head

with Fog Lamps). The second wire contains informa-

tion regarding the position of the dimmer switch

(Dome Lamp, Daytime Brightness, Dimming Level or

Off). The third wire is a dedicated signal return

(ground) wire. The fourth wire provides power to the

front fog lamp indicator.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is controlled by

the Body Control Module (BCM) via a J1850 message

transmitted by the BCM to the FCM to turn off the

headlamps.

OPERATION

AUTOMATIC HEADLAMP SYSTEM

Automatic headlamps are controlled by the Body

Control Module (BCM). With the headlamp switch in

the AUTO position, the BCM will control the head-

lamp, parking, side marker, tail and instrumentation

lamps based on ambient light levels. Ambient light

levels are monitored by the BCM using the Day/

Night signal and Electrochromatic Mirror (ECM)

present from the Compass Mini Trip (CMTC) located

on the front windshield in front of the rear view mir-

ror (ECM). Ambient light readings are averaged to

limit cycling the lamps ON and OFF when passing

through areas with varying light levels. The auto-

matic headlamps will only function when the engine

is running with RPM > 450. When the headlamp

switch is in the AUTO position (Automatic mode), the

Headlamp Time Delay system will function when the

ignition switch is placed in any position other than

run/start.

8L - 2 LAMPS/LIGHTING - EXTERIORRS

Page 1977 of 4284

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps will

only turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²POWER ACCESSORY DELAY?- The options

include Yes and No. The default is Yes. When No is

selected, the accessory powered components will turn

off automatically when the ignition key is turned off.

When Yes is selected, the accessory powered compo-

nents will remain on for 45 seconds when the igni-

tion key is turned off.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Remove overhead console. Refer to Overhead

Console Removal and Installation in this section(Re-

fer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL) .

(3) Remove the ten screws holding the EVIC mod-

ule in the overhead console.

(4) Remove EVIC module from console assembly.

INSTALLATION

(1) Position the EVIC module in the overhead con-

sole.

(2) Install the ten screws holding the EVIC module

in the overhead console.

(3) Install the overhead console. Refer to Overhead

Console Removal and Installation in this section.

(4) Connect the battery negative cable.

NOTE: If a new EVIC module has been installed, the

compass will have to be calibrated and the variance

set. Refer to Compass Variation Adjustment and

Compass Calibration in the Service Procedures sec-

tion of this group for the procedures.

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The Compass Mini-Trip Computer (CMTC) and

Compass Temperature (CT) computer are modules

located in the overhead console. Vehicles are

equipped with either the CMTC or the CT computers

not both. The CMTC is different in the fact that it is

equipped with the mini-trip feature. The CMTC, CT

consists of a electronic control module with a vacuum

fluorescent display (VFD) and function switches. The

CMTC, CT consists of a electronic module that dis-

plays compass, trip computer (CMTC only), and tem-

perature features. Actuating the STEP push button

(CMTC only) will cause the CMTC to change mode of

operation when ignition is ON. Actuating the STEP

push button (CMTC only) will cause the CMTC to

change mode of operation when ignition is ON.

Example:

²Average miles per gallon (ECO)

²Distance to empty (DTE)

²Instant miles per gallon (ECO)

²Trip odometer (ODO)

²Elapsed time (ET)

²Off

Actuating the C/T push button will cause the

CMTC, CT to change to Compass/Temperature dis-

play.

RSOVERHEAD CONSOLE8M-9

ELECTRONIC VEHICLE INFO CENTER (Continued)