C3 voltage CHRYSLER VOYAGER 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 1389 of 2177

for the PCM to use as an intake air temperature sen-

sor and a battery temperature sensor.

The battery temperature information along with

data from monitored line voltage (B+), is used by the

PCM to vary the battery charging rate. System volt-

age will be higher at colder temperatures and is

gradually reduced at warmer temperatures.

The battery temperature information is also used

for OBD II diagnostics. Certain faults and OBD II

monitors are either enabled or disabled depending

upon the battery temperature sensor input (example:

disable purge, enable LDP). Most OBD II monitors

are disabled below 20ÉF.

MAP SENSOR

DESCRIPTION

The MAP sensor (Fig. 20) or (Fig. 21) mounts to

the intake manifold. The sensor is connects electri-

cally to the PCM.

OPERATION

The MAP serves as a PCM input, using a silicon

based sensing unit, to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When MAP equals Barometric pressure, the pulse

width will be at maximum.

Also like the cam and crank sensors, a 5 volt ref-

erence is supplied from the PCM and returns a volt-

age signal to the PCM that reflects manifold

pressure. The zero pressure reading is 0.5V and full

scale is 4.5V. For a pressure swing of0Ð15psithe

voltage changes 4.0V. The sensor is supplied a regu-lated 4.8 to 5.1 volts to operate the sensor. Like the

cam and crank sensors ground is provided through

the sensor return circuit.

The MAP sensor input is the number one contrib-

utor to pulse width. The most important function of

the MAP sensor is to determine barometric pressure.

The PCM needs to know if the vehicle is at sea level

or is it in Denver at 5000 feet above sea level,

because the air density changes with altitude. It will

also help to correct for varying weather conditions. If

a hurricane was coming through the pressure would

be very, very low or there could be a real fair

weather, high pressure area. This is important

because as air pressure changes the barometric pres-

sure changes. Barometric pressure and altitude have

a direct inverse correlation, as altitude goes up baro-

Fig. 19 3.3/3.8L IAT SENSORFig. 20 MAP SENSOR - 2.4L

Fig. 21 MAP SENSOR - 3.3/3.8L

14 - 30 FUEL INJECTIONRS

INLET AIR TEMPERATURE SENSOR (Continued)

ProCarManuals.com

Page 1390 of 2177

metric goes down. The first thing that happens as

the key is rolled on, before reaching the crank posi-

tion, the PCM powers up, comes around and looks at

the MAP voltage, and based upon the voltage it sees,

it knows the current barometric pressure relative to

altitude. Once the engine starts, the PCM looks at

the voltage again, continuously every 12 milliseconds,

and compares the current voltage to what it was at

key on. The difference between current and what it

was at key on is manifold vacuum.

During key On (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring known good sensor in

you work area.

As the altitude increases the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key On

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open throttle, based upon

TPS angle and RPM it will update barometric pres-

sure in the MAP memory cell. With periodic updates,

the PCM can make its calculations more effectively.

The PCM uses the MAP sensor to aid in calculat-

ing the following:

²Barometric pressure

²Engine load

²Manifold pressure

²Injector pulse-width

²Spark-advance programs

²Shift-point strategies (F4AC1 transmissions

only, via the PCI bus)

²Idle speed

²Decel fuel shutoff

The PCM recognizes a decrease in manifold pres-

sure by monitoring a decrease in voltage from the

reading stored in the barometric pressure memory

cell. The MAP sensor is a linear sensor; as pressure

changes, voltage changes proportionately. The range

of voltage output from the sensor is usually between

4.6 volts at sea level to as low as 0.3 volts at 26 in. of

Hg. Barometric pressure is the pressure exerted by

the atmosphere upon an object. At sea level on a

standard day, no storm, barometric pressure is 29.92

in Hg. For every 100 feet of altitude barometric pres-

sure drops .10 in. Hg. If a storm goes through it can

either add, high pressure, or decrease, low pressure,

from what should be present for that altitude. You

should make a habit of knowing what the average

pressure and corresponding barometric pressure is

for your area.

REMOVAL

REMOVAL - 2.4L

(1) Disconnect the negative battery cable.(2) Disconnect electrical connector and vacuum

hose from MAP sensor (Fig. 20).

(3) Remove two screws holding sensor to the

intake manifold.

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove vacuum hose and mounting screws

from manifold absolute pressure (MAP) sensor (Fig.

21).

(3) Disconnect electrical connector from sensor.

Remove sensor.

INSTALLATION

INSTALLATION - 2.4L

(1) Install sensor.

(2) Install two screws and tighten.

(3) Connect the electrical connector and vacuum

hose to the MAP sensor (Fig. 20).

(4) Connect the negative battery cable.

INSTALLATION - 3.3/3.8L

(1) Install sensor (Fig. 21).

(2) Install screws and tighten toPLASTIC MAN-

IFOLD 1.7 N´m (15 in. lbs.) ALUMINUM MANI-

FOLD 3.3 N´m (30 in. lbs.).

(3) Connect the electrical connector to the sensor.

Install vacuum hose.

(4) Connect the negative battery cable.

O2 SENSOR

DESCRIPTION

The upstream oxygen sensor threads into the out-

let flange of the exhaust manifold (Fig. 22) or (Fig.

23).

The downstream heated oxygen sensor threads into

the outlet pipe at the rear of the catalytic convertor

(Fig. 24).

OPERATION

For SBEC vehicles a single sensor ground is used

for all 4 O2 sensors (6 Cyl.). A seperate upstream and

downstream grounds are used on the NGC vehicles

(4 Cyl.).

As vehicles accumulate mileage, the catalytic con-

vertor deteriorates. The deterioration results in a

less efficient catalyst. To monitor catalytic convertor

deterioration, the fuel injection system uses two

heated oxygen sensors. One sensor upstream of the

catalytic convertor, one downstream of the convertor.

The PCM compares the reading from the sensors to

calculate the catalytic convertor oxygen storage

RSFUEL INJECTION14-31

MAP SENSOR (Continued)

ProCarManuals.com

Page 1391 of 2177

capacity and converter efficiency. Also, the PCM uses

the upstream heated oxygen sensor input when

adjusting injector pulse width.

When the catalytic converter efficiency drops below

emission standards, the PCM stores a diagnostic

trouble code and illuminates the malfunction indica-

tor lamp (MIL).

The O2 sensors produce voltages from 0 to 1 volt

(this voltage is offset by a constant 2.5 volts on NGC

vehicles), depending upon the oxygen content of the

exhaust gas. When a large amount of oxygen is

present (caused by a lean air/fuel mixture, can be

caused by misfire and exhaust leaks), the sensors

produces a low voltage. When there is a lesser

amount of oxygen present (caused by a rich air/fuel

mixture, can be caused by internal engine problems)it produces a higher voltage. By monitoring the oxy-

gen content and converting it to electrical voltage,

the sensors act as a rich-lean switch.

The oxygen sensors are equipped with a heating

element that keeps the sensors at proper operating

temperature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into closed loop operation sooner.

Also, it allows the system to remain in closed loop

operation during periods of extended idle.

In Closed Loop operation the PCM monitors the O2

sensors input (along with other inputs) and adjusts

the injector pulse width accordingly. During Open

Loop operation the PCM ignores the O2 sensor input.

The PCM adjusts injector pulse width based on pre-

programmed (fixed) values and inputs from other

sensors.

1.6L Siemens controller and SBEC controller - The

Automatic Shutdown (ASD) relay supplies battery

voltage to both the upstream and downstream heated

oxygen sensors. The oxygen sensors are equipped

with a heating element. The heating elements reduce

the time required for the sensors to reach operating

temperature. The PCM uses pulse width modulation

to control the ground side of the heater to regulate

the temperature on 4 cyl. upstream O2 heater only.

NGC Controller - Has a common ground for the

heater in the O2S. 12 volts is supplied to the heater

in the O2S by the NGC controller. Both the upstream

and downstream O2 sensors for NGC are pulse width

modulation (PWM).

UPSTREAM OXYGEN SENSOR

The input from the upstream heated oxygen sensor

tells the PCM the oxygen content of the exhaust gas.

Fig. 22 O2 SENSOR UPSTREAM 1/1 - 2.4L

Fig. 23 O2 SENSOR UPSTREAM 1/1 - 3.3/3.8L

Fig. 24 O2 SENSOR DOWNSTREAM 1/2 - 2.4/3.3/

3.8L

14 - 32 FUEL INJECTIONRS

O2 SENSOR (Continued)

ProCarManuals.com

Page 1392 of 2177

Based on this input, the PCM fine tunes the air-fuel

ratio by adjusting injector pulse width.

The sensor input switches from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold (this is offset by 2.5 voltage on

NGC vehicles). When a large amount of oxygen is

present (caused by a lean air-fuel mixture), the sen-

sor produces voltage as low as 0.1 volt. When there is

a lesser amount of oxygen present (rich air-fuel mix-

ture) the sensor produces a voltage as high as 1.0

volt. By monitoring the oxygen content and convert-

ing it to electrical voltage, the sensor acts as a rich-

lean switch.

The heating element in the sensor provides heat to

the sensor ceramic element. Heating the sensor

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop, the PCM adjusts injector pulse

width based on the upstream heated oxygen sensor

input along with other inputs. In Open Loop, the

PCM adjusts injector pulse width based on prepro-

grammed (fixed) values and inputs from other sen-

sors.

DOWNSTREAM OXYGEN SENSOR

The downstream heated oxygen sensor input is

used to detect catalytic convertor deterioration. As

the convertor deteriorates, the input from the down-

stream sensor begins to match the upstream sensor

input except for a slight time delay. By comparing

the downstream heated oxygen sensor input to the

input from the upstream sensor, the PCM calculates

catalytic convertor efficiency. Also used to establish

the upstream O2 goal voltage (switching point).

REMOVAL

REMOVAL - UPSTREAM 1/1 - 2.4L

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Disconnect the electrical connector (Fig. 23).

(4) Use a socket such as the Snap-OntYA8875 or

equivalent to remove the sensor

(5) When the sensor is removed, the threads must

be cleaned with an 18 mm X 1.5 + 6E tap. If using

the original sensor, coat the threads with Loctite

771±64 anti-seize compound or equivalent.

REMOVAL - UPSTREAM 1/1 - 3.3/3.8L

(1) Remove battery, refer to the Battery section for

more information.

(2) Remove the battery tray, refer to the Battery

section for more information.(3) Disconnect the speed control vacuum harness

from servo.

(4) Disconnect the electrical connector from servo.

(5) Remove the speed control servo and bracket

and reposition.

(6) Use a socket such as the Snap-OntYA8875 or

equivalent to remove the sensor (Fig. 25).

(7) When the sensor is removed, the threads must

be cleaned with an 18 mm X 1.5 + 6E tap. If using

the original sensor, coat the threads with Loctite

771±64 anti-seize compound or equivalent.

REMOVAL - DOWNSTREAM 1/2 - 2.4/3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Disconnect the electrical connector (Fig. 26).

(4) Use a socket such as the Snap-OntYA8875 or

equivalent to remove the sensor (Fig. 27).

(5) When the sensor is removed, the threads must

be cleaned with an 18 mm X 1.5 + 6E tap. If using

the original sensor, coat the threads with Loctite

771±64 anti-seize compound or equivalent.

INSTALLATION

INSTALLATION - UPSTREAM 1/1 - 2.4L

The engines uses two heated oxygen sensors.

(1) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctite

771- 64 or equivalent. New sensors have compound

Fig. 25 O2 SENSOR 1/1

RSFUEL INJECTION14-33

O2 SENSOR (Continued)

ProCarManuals.com

Page 1395 of 2177

(4) At the dash panel, install the cable retainer

clip between the end of the throttle cable fitting and

grommet

(5) From the engine compartment, rotate the

throttle lever wide open and install the throttle

cable.

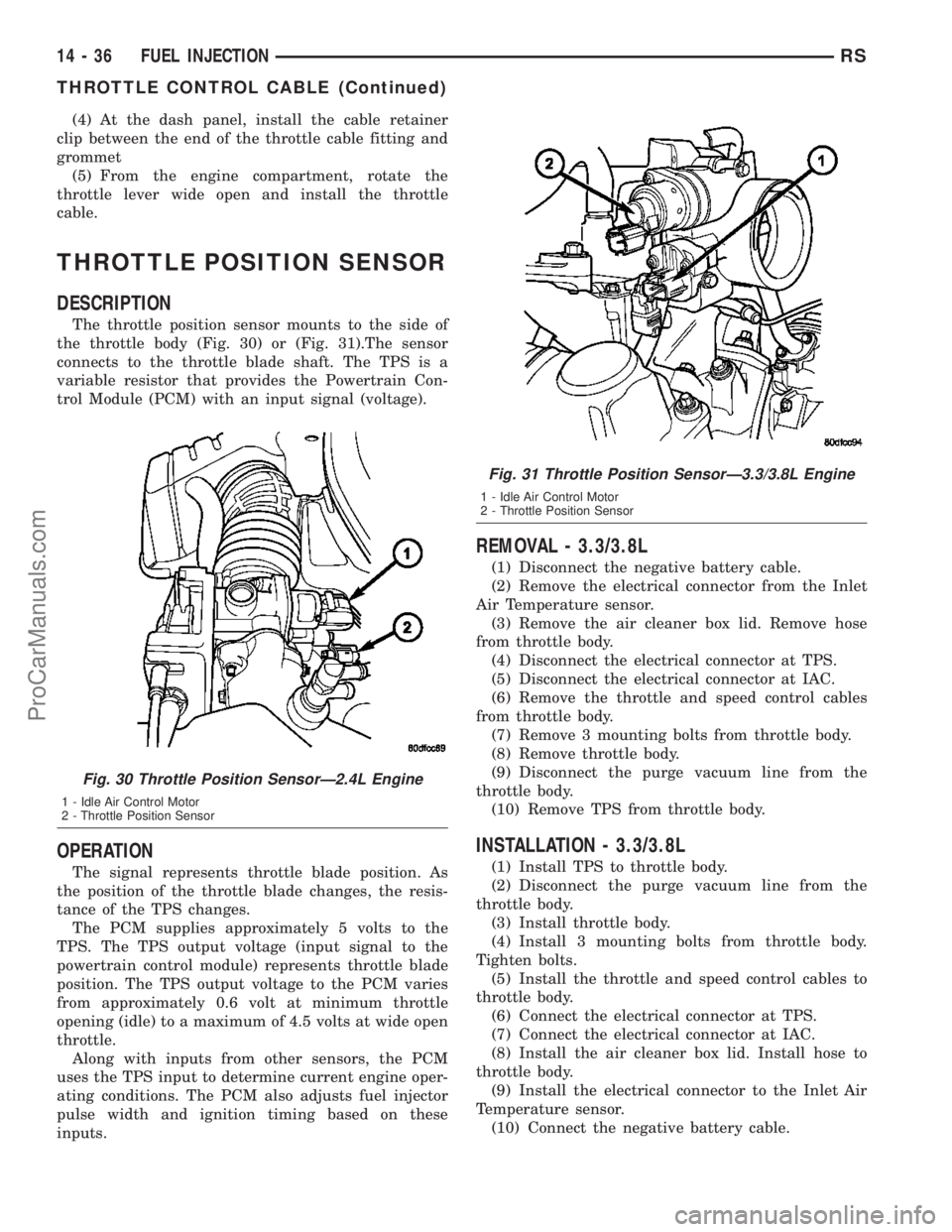

THROTTLE POSITION SENSOR

DESCRIPTION

The throttle position sensor mounts to the side of

the throttle body (Fig. 30) or (Fig. 31).The sensor

connects to the throttle blade shaft. The TPS is a

variable resistor that provides the Powertrain Con-

trol Module (PCM) with an input signal (voltage).

OPERATION

The signal represents throttle blade position. As

the position of the throttle blade changes, the resis-

tance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.6 volt at minimum throttle

opening (idle) to a maximum of 4.5 volts at wide open

throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove the electrical connector from the Inlet

Air Temperature sensor.

(3) Remove the air cleaner box lid. Remove hose

from throttle body.

(4) Disconnect the electrical connector at TPS.

(5) Disconnect the electrical connector at IAC.

(6) Remove the throttle and speed control cables

from throttle body.

(7) Remove 3 mounting bolts from throttle body.

(8) Remove throttle body.

(9) Disconnect the purge vacuum line from the

throttle body.

(10) Remove TPS from throttle body.

INSTALLATION - 3.3/3.8L

(1) Install TPS to throttle body.

(2) Disconnect the purge vacuum line from the

throttle body.

(3) Install throttle body.

(4) Install 3 mounting bolts from throttle body.

Tighten bolts.

(5) Install the throttle and speed control cables to

throttle body.

(6) Connect the electrical connector at TPS.

(7) Connect the electrical connector at IAC.

(8) Install the air cleaner box lid. Install hose to

throttle body.

(9) Install the electrical connector to the Inlet Air

Temperature sensor.

(10) Connect the negative battery cable.

Fig. 30 Throttle Position SensorÐ2.4L Engine

1 - Idle Air Control Motor

2 - Throttle Position Sensor

Fig. 31 Throttle Position SensorÐ3.3/3.8L Engine

1 - Idle Air Control Motor

2 - Throttle Position Sensor

14 - 36 FUEL INJECTIONRS

THROTTLE CONTROL CABLE (Continued)

ProCarManuals.com

Page 1636 of 2177

OPERATION

The function of an accumulator is to cushion the

application of a frictional clutch element. When pres-

surized fluid is applied to a clutch circuit, the appli-

cation force is dampened by fluid collecting in the

respective accumulator chamber against the piston

and spring(s). The intended result is a smooth, firm

clutch application.

AUTOSTICK SWITCH

DESCRIPTION

Autostick is a driver-interactive transaxle feature

that offers manual gear shifting capability. The control

switch is part of the transaxle gear shift lever as

shown in (Fig. 171). It can only be serviced by replac-

ing the gearshift lever assembly. (Refer to 19 - STEER-

ING/COLUMN/GEAR SHIFT LEVER - REMOVAL)

OPERATION

When the shift lever is moved into the Autostick

position (as indicated by the Shift Lever Position

Indicator in the cluster), the transaxle remains in

whatever gear it was using before Autostick was acti-

vated. The TCM sends a 5 volt signal through the

switch and then monitors the signal for voltage drop.

Each switch state (driver command) results in a spe-

cific voltage reading sensed by the TCM. The TCM

then determines transaxle operation (upshift/down-

shift/OD Lockout) based on their corresponding volt-

age. Refer to the following chart for corresponding

switch states and voltage readings:

Switch State Voltage Reading

Autostick DOWN

depressed0.3V-1.6V

Autostick UP depressed 1.6V-2.8V

Overdrive OFF9Lockout9

depressed2.8V-3.8V

All switches open 3.8V-4.8V

-Voltage values <.3V and >4.8V are considered

INVALID and will result in a DTC

Fig. 169 Low/Reverse Accumulator Assembly

1 - ACCUMULATOR PISTON

2 - SEAL RINGS

3 - RETURN SPRINGS

4 - (NOTE NOTCH)

Fig. 170 2/4 Accumulator Assembly

1 - VALVE BODY

2 - RETAINER PLATE

3 - DETENT SPRING

4 - SPRINGS

5 - SEALS

6 - PISTON

Fig. 171 Autostick Switch Location (if equipped)

RS41TE AUTOMATIC TRANSAXLE21 - 189

ACCUMULATOR (Continued)

ProCarManuals.com

Page 1680 of 2177

INSTALLATION

(1) Using Tool C-4193, install oil pump seal (Fig.

290).

(2) Install transaxle to vehicle (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 41TE

- INSTALLATION).

SHIFT INTERLOCK SOLENOID

DESCRIPTION

The Brake/Transmission Shift Interlock system

consists of an electro-magnetic solenoid mounted to

the steering column (Fig. 291). The solenoid's plunger

consists of an integrated hook, which operates the

shift lever pawl (part of shift lever assembly), and a

plunger return spring (Fig. 292). The solenoid also

has an integrated bracket, which facilitates fastening

to the steering column.

OPERATION

The Brake/Transmission Shift Interlock (BTSI) Sole-

noid prevents the transmission shift lever from being

moved out of PARK (P) unless the brake pedal is

applied. The BTSI solenoid is hardwired to and con-

trolled by the Intelligent Power Module (IPM). Battery

voltage is applied to one side of the solenoid with the

ignition key is in either the OFF, ON/RUN, or START

positions (Fig. 293). The ground side of the solenoid is

controlled by a driver within the IPM. It relies on volt-

age supplied from the stop lamp switch to the stop

lamp sense circuit within the IPM to tell when the

brake pedal is depressed. When the brake pedal is

depressed, the ground circuit opens, de-energizing the

solenoid. When the brake pedal is released, the ground

circuit is closed, energizing the solenoid.

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 294). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 295), allow-

ing the shift lever to be moved into any gear position.

Fig. 290 Install Oil Pump Seal

1 - TOOL C-4193

2 - HANDLE TOOL C-4171

Fig. 291 Brake/Transmission Shift Interlock (BTSI)

Solenoid Location

1 - BTSI SOLENOID

Fig. 292 Solenoid Plunger and Return Spring

1 - PLUNGER

2 - RETURN SPRING

3 - BTSI SOLENOID

RS41TE AUTOMATIC TRANSAXLE21 - 233

SEAL - OIL PUMP (Continued)

ProCarManuals.com

Page 1687 of 2177

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

310), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing:

²Torque converter clutch slippage

²Torque converter element speed ratio

REMOVAL

(1) Disconnect battery negative cable.

(2) If necessary, disconnect and cap off transmis-

sion oil cooler lines.

(3) Disconnect input speed sensor connector.

(4) Unscrew and remove input speed sensor (Fig.

311).

(5) Inspect speed sensor o-ring (Fig. 312) and

replace if necessary.

INSTALLATION

(1) Verify o-ring is installed into position.

(2) Install and tighten input speed sensor to 27

N´m (20 ft. lbs.).

(3) Connect speed sensor connector.

(4) Connect battery negative cable.

Fig. 310 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

Fig. 311 Input (Turbine) Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 312 O-ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

21 - 240 41TE AUTOMATIC TRANSAXLERS

SPEED SENSOR - INPUT (Continued)

ProCarManuals.com

Page 1688 of 2177

SPEED SENSOR - OUTPUT

DESCRIPTION

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

313), sealed with an o-ring (Fig. 314), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 315), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

VEHICLE SPEED SIGNAL

The vehicle speed signal is taken from the Output

Speed Sensor. The PCM converts this signal into a

pulse per mile signal and sends the vehicle speed

message across the communication bus to the BCM.

The BCM sends this signal to the Instrument Cluster

to display vehicle speed to the driver. The vehicle

speed signal pulse is roughly 8000 pulses per mile.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Disconnect output speed sensor connector.

(4) Unscrew and remove output speed sensor (Fig.

316).

(5) Inspect speed sensor o-ring (Fig. 317) and

replace if necessary.

Fig. 313 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 314 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 315 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

RS41TE AUTOMATIC TRANSAXLE21 - 241

ProCarManuals.com

Page 1695 of 2177

OPERATION

The relay is supplied fused B+ voltage, energized

by the PCM/TCM, and is used to supply power to the

solenoid pack when the transmission is in normal

operating mode. When the relay is ªoffº, no power is

supplied to the solenoid pack and the transmission is

in ªlimp-inº mode. After a controller reset (ignition

key turned to the ªrunº position or after cranking

engine), the PCM/TCM energizes the relay. Prior to

this, the PCM/TCM verifies that the contacts are

open by checking for no voltage at the switched bat-

tery terminals. After this is verified, the voltage at

the solenoid pack pressure switches is checked. After

the relay is energized, the PCM/TCM monitors the

terminals to verify that the voltage is greater than 3

volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle and

can only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 328).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 329).

OPERATION

The Transmission Range Sensor (TRS) (Fig. 328)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combination

of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM inter-

prets this information and determines the appropriate

transaxle gear position and shift schedule.

Fig. 327 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 328 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 329 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 248 41TE AUTOMATIC TRANSAXLERS

TRANSMISSION CONTROL RELAY (Continued)

ProCarManuals.com