ad blue CHRYSLER VOYAGER 2004 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1401 of 2585

(2) Assemble gasket to cylinder cover by inserting

the fasteners through each bolt hole on cover and

gasket (Fig. 25).

(3) Install the cylinder head cover and bolts (Fig.

26).

(4) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 26).

(5) Connect crankcase vent hose.

(6) Connect spark plug wires to spark plugs.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves have chrome plated valve stems with

four-bead lock grooves. The valve stem seals are

made of Viton rubber.

OPERATION

The two valves per cylinder are opened using

hydraulic lifters, push rods, and rocker arms.

STANDARD PROCEDURE - REFACING VALVES

AND VALVE SEATS

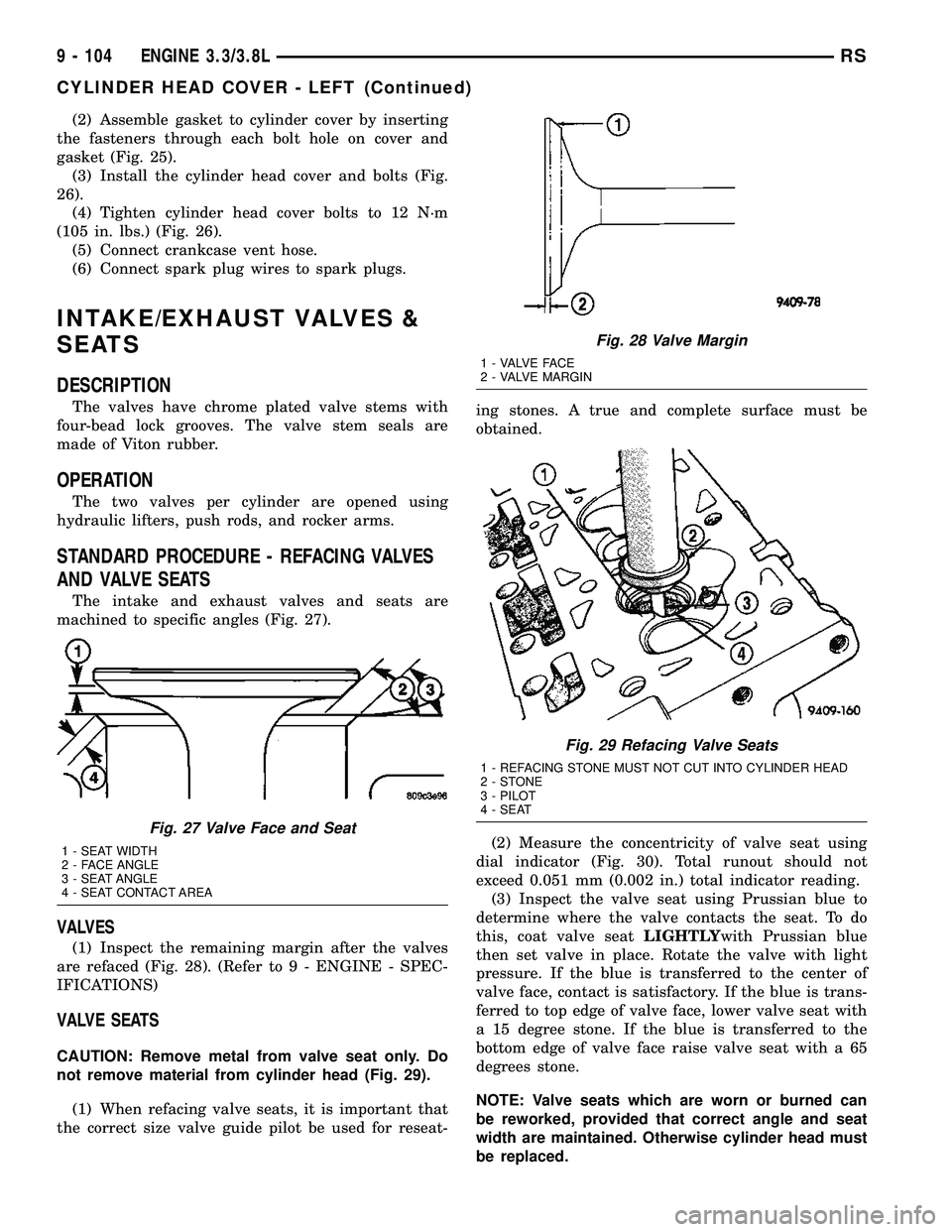

The intake and exhaust valves and seats are

machined to specific angles (Fig. 27).

VALVES

(1) Inspect the remaining margin after the valves

are refaced (Fig. 28). (Refer to 9 - ENGINE - SPEC-

IFICATIONS)

VALVE SEATS

CAUTION: Remove metal from valve seat only. Do

not remove material from cylinder head (Fig. 29).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using

dial indicator (Fig. 30). Total runout should not

exceed 0.051 mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat using Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, lower valve seat with

a 15 degree stone. If the blue is transferred to the

bottom edge of valve face raise valve seat with a 65

degrees stone.

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

Fig. 27 Valve Face and Seat

1 - SEAT WIDTH

2 - FACE ANGLE

3 - SEAT ANGLE

4 - SEAT CONTACT AREA

Fig. 28 Valve Margin

1 - VALVE FACE

2 - VALVE MARGIN

Fig. 29 Refacing Valve Seats

1 - REFACING STONE MUST NOT CUT INTO CYLINDER HEAD

2-STONE

3 - PILOT

4 - SEAT

9 - 104 ENGINE 3.3/3.8LRS

CYLINDER HEAD COVER - LEFT (Continued)

Page 1477 of 2585

(2) Measure the concentricity of valve seat using

dial indicator (Fig. 14). Total runout should not

exceed 0.051 mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat using Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, lower valve seat with

a 15 degree stone. If the blue is transferred to the

bottom edge of valve face raise valve seat with a 65

degrees stone.

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

intake and exhaust seats should be 1.50±2.00 mm

(0.059±0.078 in.) (Fig. 11).

(5) After grinding the valve seats or faces, install

the valve in cylinder head and check valve installed

height by measuring from valve tip to spring seat

(Fig. 15). Remove valve from cylinder head and grind

valve tip until within specifications. Check valve tip

for scoring. The tip chamfer should be reground (if

necessary) to prevent seal damage when the valve is

installed.

(6) Check the valve spring installed height after

refacing the valve and seat (Fig. 15).

If valves and/or seats are reground, measure

the installed height of springs (Fig. 15), make

sure measurements are taken from top of

spring seat to the bottom surface of spring

retainer. If height is greater than specifica-tions, install a 0.794 mm (0.0312 in.) spacer in

head counterbore to bring spring height back

within specifications.

REMOVAL

(1) With cylinder head removed, compress valve

springs using Valve Spring Compressor Tool

C-3422-D with adapter 8464 (Refer to 9 - ENGINE -

SPECIAL TOOLS).

(2) Remove valve retaining locks.

(3) Slowly release valve spring compressor.

Remove valve spring retainer, valve spring, and valve

stem seal.

(4) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

INSPECTION

VALVES

(1) Clean and inspect valves thoroughly. Replace

burned, warped and cracked valves.

(2) Measure valve stems for wear (Fig. 16). For

valve specifications, (Refer to 9 - ENGINE - SPECI-

FICATIONS).

NOTE: Valve stems are chrome plated and should

not be polished (Fig. 16).

Fig. 14 Measurement of Valve Seat Runout

1 - DIAL INDICATOR

Fig. 15 Checking Valve and Spring Installed Height

1 - SPRING RETAINER

2 - VALVE INSTALLED HEIGHT* - 48.1±49.7 mm (1.89±1.95 in.)

3 - CYINDER HEAD SURFACE

4 - SPRING INSTALLED HEIGHT* - 41.1±42.7 mm (1.61±1.68 in.)

*(MEASURED FROM TOP OF SPRING SEAT)

9s - 22 ENGINE 3.3/3.8L SUPPLEMENTRS

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 2149 of 2585

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(7) Trace the inside handle cable along its routing

path and disconnect from its retaining clips.

(8) Disconnect the inside handle cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(9) Remove the inside handle cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the inside handle cable on the side

door.

(3) Connect the inside handle cable on the handle

assembly. Hook the swedged cable end on the handle

link and gently push the cable sleeve retainer in the

handle bracket.

(4) Install the inside handle assembly on the side

door. (Refer to 23 - BODY/DOORS - SLIDING/IN-

SIDE LATCH HANDLE - INSTALLATION)

NOTE: The inside handle cable is marked with blue

tape and must be attached to the latch at the center

(just above the lower cable). This position is

marked with a ªBº on the latch.

(5) Connect the inside handle cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(6) Trace the inside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.

(7) Install the latch assembly. Refer to the Power

Side Doors section for the procedure.

(8) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.(9) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(10) Connect the negative battery cable.

HOLD OPEN LATCH CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel

from the vehicle. (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

(4) Open the side door and remove the latch

assembly. (Refer to 8 - ELECTRICAL/POWER

DOORS/LATCH - REMOVAL)

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(5) Trace the hold open latch cable along its rout-

ing path and disconnect from its retaining clips.

(6) Disconnect the hold open latch cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(7) Remove the hold open latch from the side door.

(Refer to 23 - BODY/DOORS - SLIDING/HOLD

OPEN LATCH - REMOVAL)

(8) Disconnect the hold open latch cable from the

hold open latch. Gently pry cable sleeve retainer out

of the handle bracket and then unhook swedged

cable end from the latch link.

(9) Remove the hold open latch cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the hold open latch cable on the side

door.

23 - 38 DOORS - SLIDINGRS

INSIDE HANDLE CABLE (Continued)

Page 2195 of 2585

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - COLOR CODE CHARTS . . 84

BASE COAT/CLEARCOAT FINISH

DESCRIPTION.........................85

PAINT CODE

DESCRIPTION.........................85PAINTED TOUCH-UP

DESCRIPTION.........................85

FINESSE SANDING/BUFFING & POLISHING

DESCRIPTION.........................85

PAINT

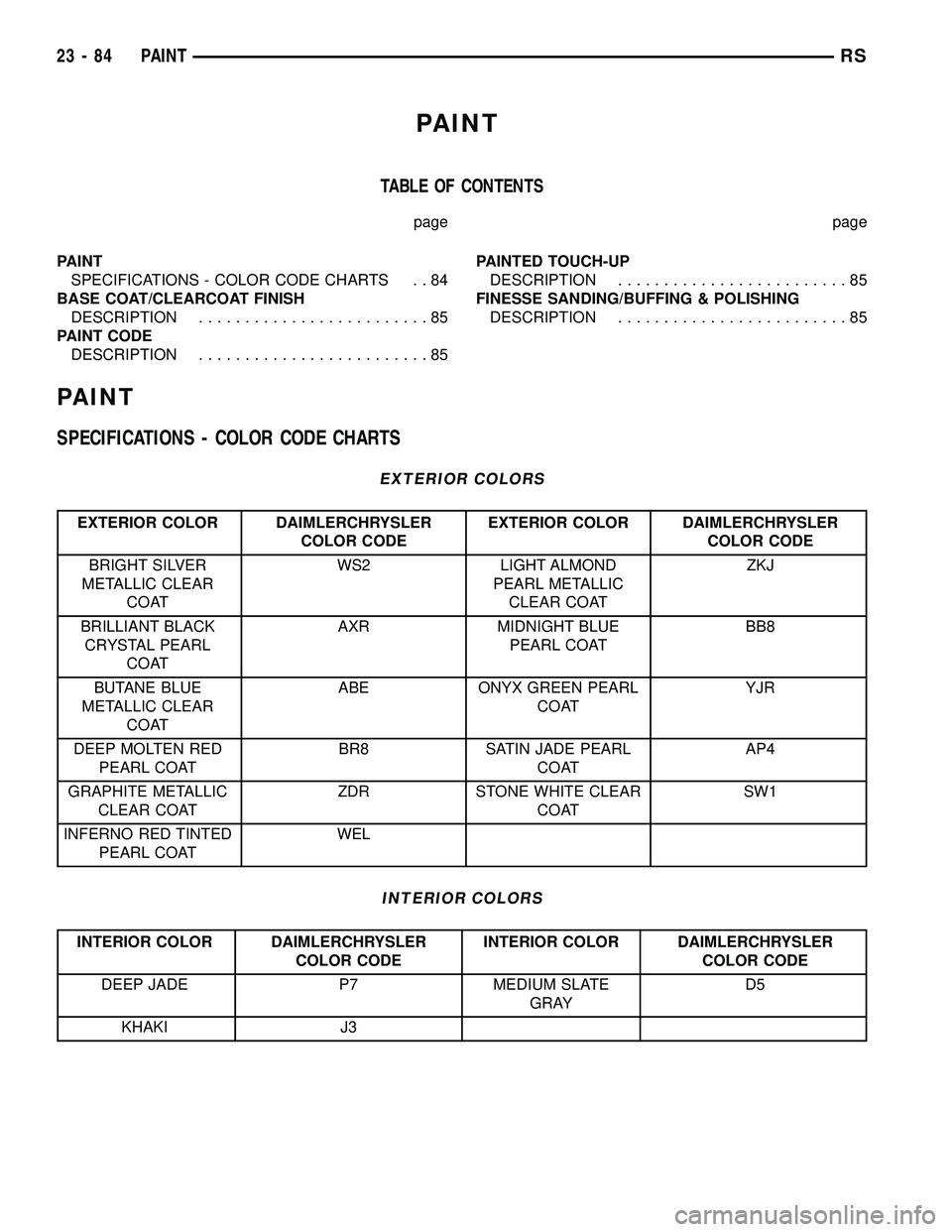

SPECIFICATIONS - COLOR CODE CHARTS

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEEXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

BRIGHT SILVER

METALLIC CLEAR

COATWS2 LIGHT ALMOND

PEARL METALLIC

CLEAR COATZKJ

BRILLIANT BLACK

CRYSTAL PEARL

COATAXR MIDNIGHT BLUE

PEARL COATBB8

BUTANE BLUE

METALLIC CLEAR

COATABE ONYX GREEN PEARL

COATYJR

DEEP MOLTEN RED

PEARL COATBR8 SATIN JADE PEARL

COATAP4

GRAPHITE METALLIC

CLEAR COATZDR STONE WHITE CLEAR

COATSW1

INFERNO RED TINTED

PEARL COATWEL

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEINTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

DEEP JADE P7 MEDIUM SLATE

GRAYD5

KHAKI J3

23 - 84 PAINTRS

Page 2466 of 2585

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

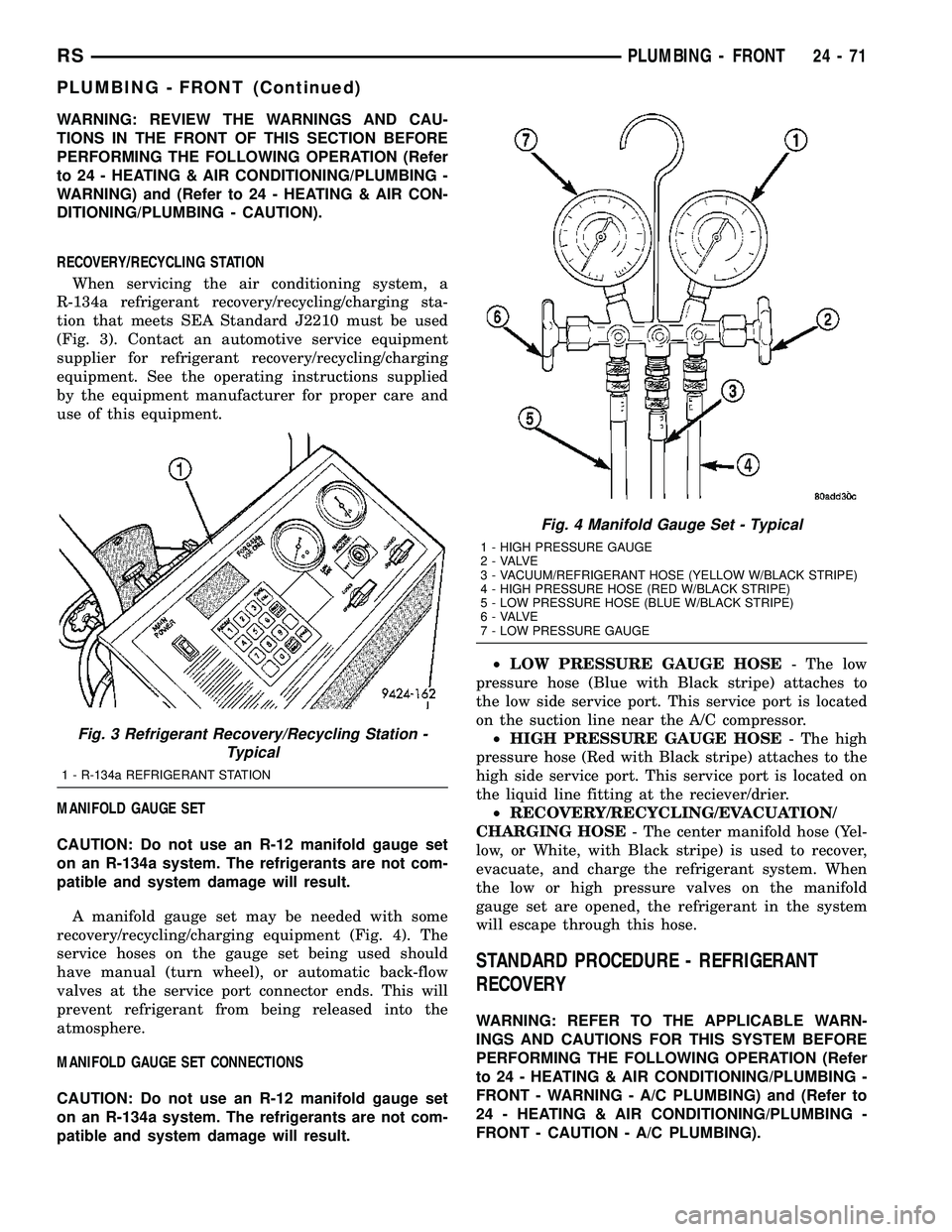

RECOVERY/RECYCLING STATION

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SEA Standard J2210 must be used

(Fig. 3). Contact an automotive service equipment

supplier for refrigerant recovery/recycling/charging

equipment. See the operating instructions supplied

by the equipment manufacturer for proper care and

use of this equipment.

MANIFOLD GAUGE SET

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 4). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.²LOW PRESSURE GAUGE HOSE- The low

pressure hose (Blue with Black stripe) attaches to

the low side service port. This service port is located

on the suction line near the A/C compressor.

²HIGH PRESSURE GAUGE HOSE- The high

pressure hose (Red with Black stripe) attaches to the

high side service port. This service port is located on

the liquid line fitting at the reciever/drier.

²RECOVERY/RECYCLING/EVACUATION/

CHARGING HOSE- The center manifold hose (Yel-

low, or White, with Black stripe) is used to recover,

evacuate, and charge the refrigerant system. When

the low or high pressure valves on the manifold

gauge set are opened, the refrigerant in the system

will escape through this hose.

STANDARD PROCEDURE - REFRIGERANT

RECOVERY

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

Fig. 3 Refrigerant Recovery/Recycling Station -

Typical

1 - R-134a REFRIGERANT STATION

Fig. 4 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK STRIPE)

4 - HIGH PRESSURE HOSE (RED W/BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

RSPLUMBING - FRONT24-71

PLUMBING - FRONT (Continued)