drain bolt CHRYSLER VOYAGER 2004 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1965 of 2585

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparTATF+4

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan. (2) Remove both engine mount-to-engine cross-

member cradle nuts. Using suitable screw jack and

wood block, raise engine and transmission slightly to

facilitate transaxle oil pan removal and installation. (3) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

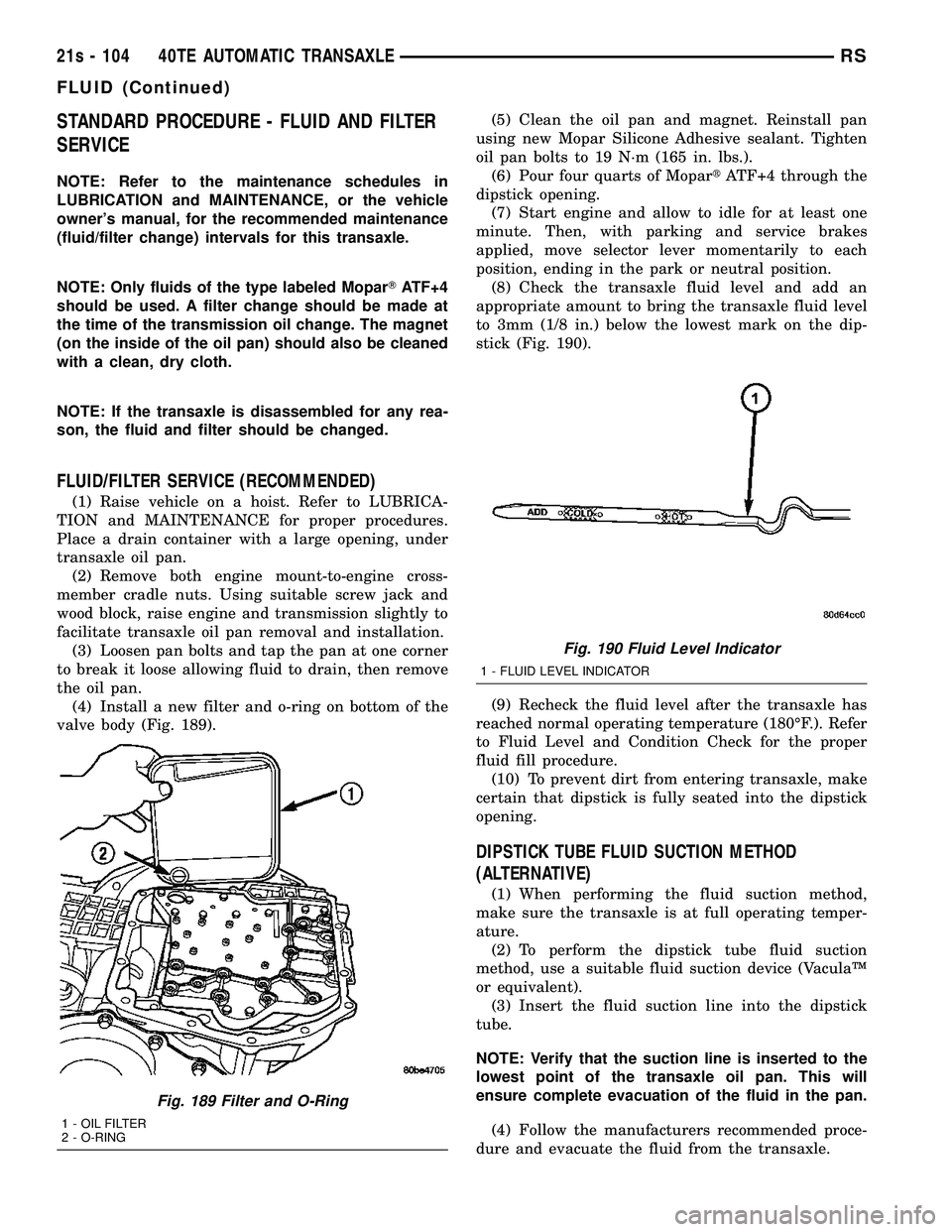

the oil pan. (4) Install a new filter and o-ring on bottom of the

valve body (Fig. 189). (5) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.). (6) Pour four quarts of Mopar tATF+4 through the

dipstick opening. (7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position. (8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 190).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.). Refer

to Fluid Level and Condition Check for the proper

fluid fill procedure. (10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature. (2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent). (3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

Fig. 189 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 190 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21s - 104 40TE AUTOMATIC TRANSAXLERS

FLUID (Continued)

Page 2170 of 2585

SIDE VIEW MIRROR

REMOVAL

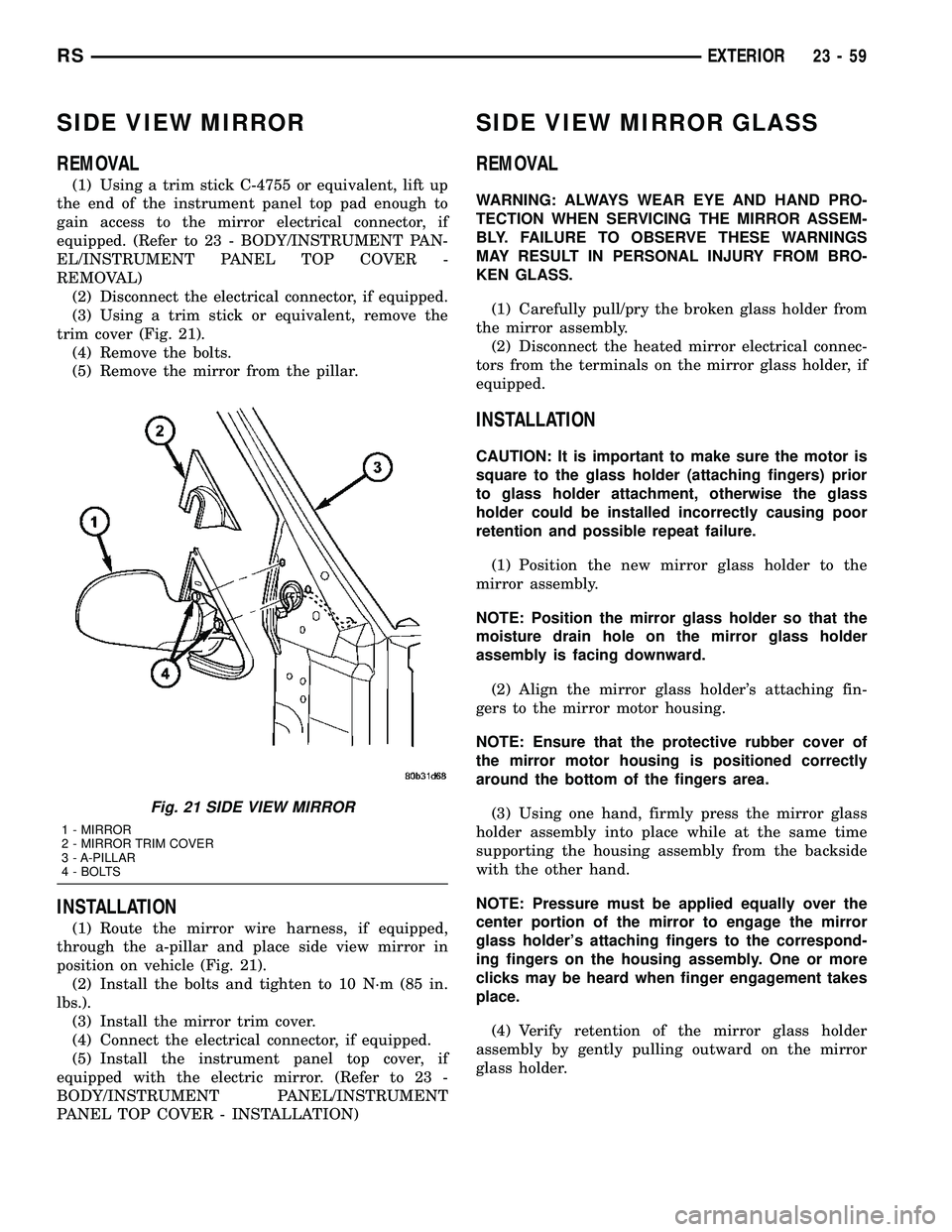

(1) Using a trim stick C-4755 or equivalent, lift up

the end of the instrument panel top pad enough to

gain access to the mirror electrical connector, if

equipped. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/INSTRUMENT PANEL TOP COVER -

REMOVAL)

(2) Disconnect the electrical connector, if equipped.

(3) Using a trim stick or equivalent, remove the

trim cover (Fig. 21).

(4) Remove the bolts.

(5) Remove the mirror from the pillar.

INSTALLATION

(1) Route the mirror wire harness, if equipped,

through the a-pillar and place side view mirror in

position on vehicle (Fig. 21).

(2) Install the bolts and tighten to 10 N´m (85 in.

lbs.).

(3) Install the mirror trim cover.

(4) Connect the electrical connector, if equipped.

(5) Install the instrument panel top cover, if

equipped with the electric mirror. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

SIDE VIEW MIRROR GLASS

REMOVAL

WARNING: ALWAYS WEAR EYE AND HAND PRO-

TECTION WHEN SERVICING THE MIRROR ASSEM-

BLY. FAILURE TO OBSERVE THESE WARNINGS

MAY RESULT IN PERSONAL INJURY FROM BRO-

KEN GLASS.

(1) Carefully pull/pry the broken glass holder from

the mirror assembly.

(2) Disconnect the heated mirror electrical connec-

tors from the terminals on the mirror glass holder, if

equipped.

INSTALLATION

CAUTION: It is important to make sure the motor is

square to the glass holder (attaching fingers) prior

to glass holder attachment, otherwise the glass

holder could be installed incorrectly causing poor

retention and possible repeat failure.

(1) Position the new mirror glass holder to the

mirror assembly.

NOTE: Position the mirror glass holder so that the

moisture drain hole on the mirror glass holder

assembly is facing downward.

(2) Align the mirror glass holder's attaching fin-

gers to the mirror motor housing.

NOTE: Ensure that the protective rubber cover of

the mirror motor housing is positioned correctly

around the bottom of the fingers area.

(3) Using one hand, firmly press the mirror glass

holder assembly into place while at the same time

supporting the housing assembly from the backside

with the other hand.

NOTE: Pressure must be applied equally over the

center portion of the mirror to engage the mirror

glass holder's attaching fingers to the correspond-

ing fingers on the housing assembly. One or more

clicks may be heard when finger engagement takes

place.

(4) Verify retention of the mirror glass holder

assembly by gently pulling outward on the mirror

glass holder.

Fig. 21 SIDE VIEW MIRROR

1 - MIRROR

2 - MIRROR TRIM COVER

3 - A-PILLAR

4 - BOLTS

RSEXTERIOR23-59

Page 2446 of 2585

(3) Align the locator hole on the center floor distri-

bution duct with the weld stud on the front floor

panel.

(4) Using hand pressure, push the locator hole of

the center floor distribution duct down over the weld

stud on the front floor panel.

(5) Reinstall the carpet onto the front floor panel

and under the instrument panel (Refer to 23 - BODY/

INTERIOR/CARPETS AND FLOOR MATS -

INSTALLATION).

HVAC HOUSING

REMOVAL

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) AND (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(3) Disconnect and isolate the negative battery

cable.

(4) Remove the windshield wiper module from the

vehicle (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER MODULE - REMOVAL).

(5) Disconnect the liquid line and suction line from

the expansion valve (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - FRONT/LIQUID

LINE - REMOVAL) and (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - FRONT/SUC-

TION LINE - REMOVAL).

(6) Disconnect the heater hoses from the heater

core tubes (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/HEATER HOSE -

REMOVAL).

(7) On LHD models, remove the one bolt that

secures the HVAC housing to the dash panel (Fig.

12).

(8) Remove the three nuts that secure the HVAC

housing to the dash panel.

(9) Remove the instrument panel from the passen-

ger compartment (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL ASSEMBLY -

REMOVAL).

(10) Remove the floor distribution duct (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION - FRONT/FLOOR DISTRIBUTION DUCTS -

REMOVAL).

(11) Remove the bolt or bolts (depending on appli-

cation) that secure the HVAC housing to the passen-

ger compartment side of the dash panel (Fig. 13) or

(Fig. 14).

(12) Pull the HVAC housing rearward far enough

for the mounting studs to clear the dash panel and

remove the housing from the passenger compart-

ment.

DISSASEMBLY

(1) Remove the HVAC housing from the vehicle

and place it on a workbench (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION - FRONT/

HVAC HOUSING - REMOVAL).

Fig. 11 Floor Distribution Ducts - LHD Shown, RHD

Typical

1 - CENTER FLOOR DISTRIBUTION DUCT

2 - RIGHT FLOOR DISTRIBUTION DUCT

3 - LEFT FLOOR DISTRIBUTION DUCT

4 - WELD STUD

RSDISTRIBUTION - FRONT24-51

FLOOR DISTRIBUTION DUCTS (Continued)

Page 2470 of 2585

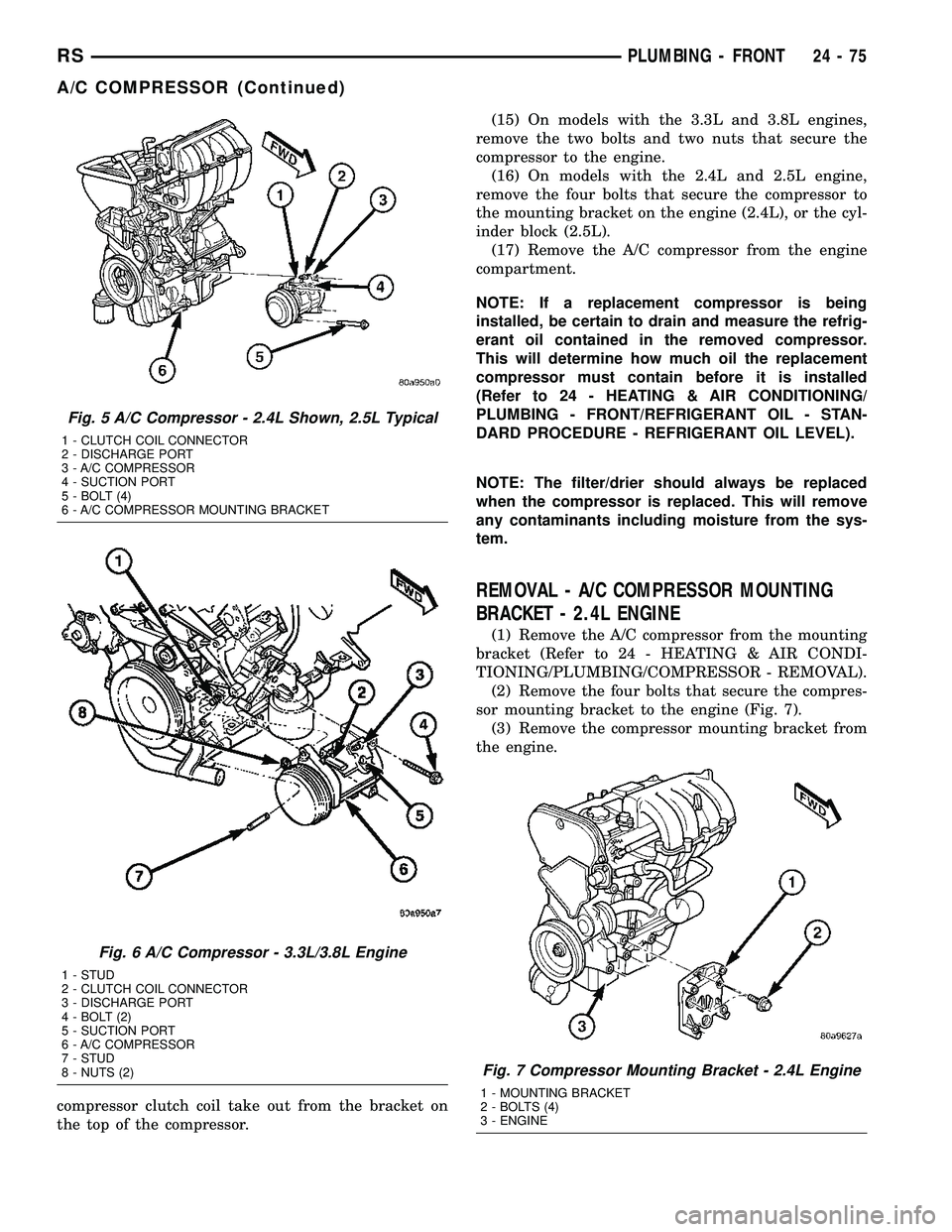

compressor clutch coil take out from the bracket on

the top of the compressor.(15) On models with the 3.3L and 3.8L engines,

remove the two bolts and two nuts that secure the

compressor to the engine.

(16) On models with the 2.4L and 2.5L engine,

remove the four bolts that secure the compressor to

the mounting bracket on the engine (2.4L), or the cyl-

inder block (2.5L).

(17) Remove the A/C compressor from the engine

compartment.

NOTE: If a replacement compressor is being

installed, be certain to drain and measure the refrig-

erant oil contained in the removed compressor.

This will determine how much oil the replacement

compressor must contain before it is installed

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT/REFRIGERANT OIL - STAN-

DARD PROCEDURE - REFRIGERANT OIL LEVEL).

NOTE: The filter/drier should always be replaced

when the compressor is replaced. This will remove

any contaminants including moisture from the sys-

tem.

REMOVAL - A/C COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE

(1) Remove the A/C compressor from the mounting

bracket (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/COMPRESSOR - REMOVAL).

(2) Remove the four bolts that secure the compres-

sor mounting bracket to the engine (Fig. 7).

(3) Remove the compressor mounting bracket from

the engine.

Fig. 5 A/C Compressor - 2.4L Shown, 2.5L Typical

1 - CLUTCH COIL CONNECTOR

2 - DISCHARGE PORT

3 - A/C COMPRESSOR

4 - SUCTION PORT

5 - BOLT (4)

6 - A/C COMPRESSOR MOUNTING BRACKET

Fig. 6 A/C Compressor - 3.3L/3.8L Engine

1 - STUD

2 - CLUTCH COIL CONNECTOR

3 - DISCHARGE PORT

4 - BOLT (2)

5 - SUCTION PORT

6 - A/C COMPRESSOR

7 - STUD

8 - NUTS (2)

Fig. 7 Compressor Mounting Bracket - 2.4L Engine

1 - MOUNTING BRACKET

2 - BOLTS (4)

3 - ENGINE

RSPLUMBING - FRONT24-75

A/C COMPRESSOR (Continued)

Page 2484 of 2585

REAR SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER -

REMOVAL).

(6) If equipped, remove the nut that secures the

A/C ground strap to the weld stud on the top of the

right front strut tower (Fig. 25).

(7) If equipped, remove the A/C ground strap eye-

let terminal connector from the weld stud.(8) Remove the bolt that secures the liquid line

rear section fitting to the top of the receiver/drier.

(9) Disconnect the liquid line fitting from the

receiver/drier outlet port.

(10) Remove the O-ring seal from the liquid line

fitting and discard.

(11) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(12) Remove the nut that secures the suction line

and liquid line fittings to the expansion valve.

(13) Disconnect the suction line and liquid line fit-

tings from the expansion valve.

(14) Remove the seals from the suction line and

liquid line fittings and discard.

(15) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(16) On RHD models, remove the liquid line from

the retaining bracket located at the top of the dash

panel

(17) If the vehicle is equipped with the optional

rear air conditioner, go to Step 18. If the vehicle does

not have the optional rear air conditioner, go to Step

24.

(18) Raise and support the vehicle.

(19) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear

heater and air conditioner (Fig. 26).

(20) Disconnect the front liquid line extension fit-

ting from the underbody liquid line fitting for the

rear air conditioner.

(21) Remove the O-ring seal from the underbody

liquid line fitting and discard.

Fig. 25 Liquid Line - LHD Shown, RHD Typical

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - EXPANSION VALVE

7 - FRONT LIQUID LINE REAR SECTION

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - FRONT LIQUID LINE FRONT SECTION

Fig. 26 Underbody A/C Line Connections

1 - SUCTION LINE EXTENSION

2 - LIQUID LINE EXTENSION

3 - RETAINER STRAP (3)

4 - HEATER TUBES

5 - UNDERBODY REFRIGERANT LINES

RSPLUMBING - FRONT24-89

LIQUID LINE (Continued)

Page 2485 of 2585

(22) Install plugs in, or tape over the opened liquid

line fittings.

(23) Lower the vehicle.

(24) Remove the front liquid line rear section from

the engine compartment.

INSTALLATION

FRONT SECTION

(1) Position the front section of the front liquid

line into the engine compartment.

(2) Remove the tape or plugs from the liquid line

front section fitting for the receiver/drier and the

receiver/drier inlet port.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(4) Reconnect the liquid line fitting to the receiver/

drier inlet port on the top of the receiver/drier.

(5) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(6) Engage the retainer that secures the liquid line

routing clip to the top of the right frame rail ahead of

the front strut tower in the engine compartment.

(7) Remove the tape or plugs from the A/C con-

denser outlet port and the liquid line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Install a new dual plane seal and reconnect the

liquid line fitting to the condenser outlet port on the

right side of the cooling module.

(10) Install the nut that secures the liquid line fit-

ting to the condenser. Tighten the nut to 23 N´m (17

ft. lbs.).

(11) Position the radiator sight shield onto the

radiator closure panel crossmember.

(12) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(13) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.).

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Reconnect the battery negative cable.

(16) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(17) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).REAR SECTION

(1) Position the rear section of the front liquid line

into the engine compartment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install the nut that secures the suction line

and liquid line fittings to the expansion valve.

Tighten the nut to 23 N´m (17 ft. lbs.).

(6) Remove the tape or plugs from the liquid line

rear section fitting for the receiver/drier and the

receiver/drier outlet port.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the liquid line fitting to the receiver/

drier outlet port on the top of the receiver/drier.

(9) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(10) If equipped, reinstall the A/C ground strap

eyelet terminal connector onto the weld stud on the

top of the right front strut tower (if equipped).

(11) If equipped, install the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.)

(12) Install the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER - INSTAL-

LATION).

(13) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) On RHD models, install the liquid line into

the retaining bracket located at the top of the dash

panel.

(16) If the vehicle is equipped with the optional

rear air conditioner, go to Step 17. If the vehicle does

not have the optional rear air conditioner, go to Step

23.

(17) Raise and support the vehicle.

(18) Remove the tape or plugs from the liquid line

rear section extension fitting and the underbody liq-

uid line fitting.

(19) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(20) Reconnect the liquid line rear section exten-

sion fitting to the underbody liquid line fitting.

Tighten the fittings to 23 N´m (17 ft. lbs.).

24 - 90 PLUMBING - FRONTRS

LIQUID LINE (Continued)

Page 2499 of 2585

INSTALLATION

(1) Install the front underbody heater inlet and

return hoses by carefully twisting the hoses back and

forth on the underbody tubes, while gently pushing

them onto the end of the tubes.

CAUTION:

DO NOT apply excessive pressure on heater tubes

or connections when removing heater hoses.

Excessive pressure may damage or deform the

tubes, causing an engine coolant leak.

(2) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose over the tubes. Release the clamp when

it is over the tube.

(3) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

LIQUID LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: On models equipped with the optional rear

A/C system, the rear section of the front air condi-

tioner liquid line also includes a liquid line hose

and tube extension that connects the front liquid

line to the underbody liquid line for the rear A/C

system.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER -

REMOVAL).(6) If equipped, remove the nut that secures the

A/C ground strap to the weld stud on the top of the

right front strut tower (Fig. 7).

(7) If equipped, remove the A/C ground strap eye-

let terminal connector from the weld stud.

(8) Remove the bolt that secures the liquid line

rear section fitting to the top of the receiver/drier.

(9) Disconnect the liquid line fitting from the

receiver/drier outlet port.

(10) Remove the O-ring seal from the liquid line

fitting and discard.

(11) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(12) Remove the nut that secures the suction line

and liquid line fittings to the expansion valve.

(13) Disconnect the suction line and liquid line fit-

tings from the expansion valve.

(14) Remove the seals from the suction line and

liquid line fittings and discard.

(15) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(16) Raise and support the vehicle.

Fig. 7 Liquid Line

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - EXPANSION VALVE

7 - FRONT LIQUID LINE REAR SECTION

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - FRONT LIQUID LINE FRONT SECTION

24 - 104 PLUMBING - REARRS

HEATER HOSES (Continued)

Page 2500 of 2585

(17) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear heat-

er-A/C system (Fig. 8).

(18) Disconnect the front liquid line extension fit-

ting from the underbody liquid line fitting for the

rear air conditioner.

(19) Remove the O-ring seal from the underbody

liquid line fitting and discard.

(20) Install plugs in, or tape over the opened liquid

line fittings.

(21) Lower the vehicle.

(22) Remove the liquid line from the engine com-

partment.

INSTALLATION

(1) Position the rear section of the front liquid line

into the engine compartment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install the nut that secures the suction line

and liquid line fittings to the expansion valve.

Tighten the nut to 23 N´m (17 ft. lbs.).(6) Remove the tape or plugs from the liquid line

rear section fitting for the receiver/drier and the

receiver/drier outlet port.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the liquid line fitting to the receiver/

drier outlet port on the top of the receiver/drier.

(9) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(10) If equipped, reinstall the A/C ground strap

eyelet terminal connector onto the weld stud on the

top of the right front strut tower (if equipped).

(11) If equipped, install the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.)

(12) Install the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS/

A/C PRESSURE TRANSDUCER - INSTALLATION).

(13) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Raise and support the vehicle.

(16) Remove the tape or plugs from the liquid line

rear section extension fitting and the underbody liq-

uid line fitting.

(17) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(18) Reconnect the liquid line rear section exten-

sion fitting to the underbody liquid line fitting.

Tighten the fittings to 23 N´m (17 ft. lbs.).

(19) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heater-

A/C system.

(20) Lower the vehicle.

(21) Reconnect the battery negative cable.

(22) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(23) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

Fig. 8 Underbody A/C Line Connections

1 - SUCTION LINE EXTENSION

2 - LIQUID LINE EXTENSION

3 - RETAINER STRAP (3)

4 - HEATER TUBES

5 - UNDERBODY REFRIGERANT LINES

RSPLUMBING - REAR24 - 105

LIQUID LINE (Continued)

Page 2514 of 2585

(9) Loosen the two fasteners at the rail. Take care

to notice that the exhaust tube bracket tab is on top

of the heater bracket and that there are two spacer

washers installed between the rubber grommets.

(10) Remove the flexible section of the cabin

heater exhaust tube from the exhaust tube by loos-

ening the clamp. Remove the hose from the exhaust

tube. Removal of the rail tube assembly may aid in

this service operation (Refer to 24 - HEATING & AIR

CONDITIONING/CABIN HEATER/EXHAUST TUBE

- REMOVAL).

(11) Remove seat hex nut at the heater mounting

flange to crossmember.

(12) Loosen the remaining fasteners which mount

the exhaust tube assembly to the vehicle.

(a) Install a suitable support device under the

cabin heater and secure the cabin heater to the

support.

(13) Loosen the remaining three fasteners to the

crossmembers.

(14) Remove the loosened fasteners that support

the cabin heater while supporting the weight of the

heater.

(15) Swing the cabin heater mounting bracket

from between the exhaust bracket and rail mounting

location. Drain any residual coolant from the cabin

heater.

(16) Remove the cabin heater from the vehicle.

INSTALLATION

(1) Install the cabin heater mounting bracket

between the exhaust bracket and the rail mounting

location.

(2) Support the cabin heater and install the fasten-

ers that secure the cabin heater to the mounting

bracket.

(3) Install the three fasteners to the crossmem-

bers. Tighten the M6 fasteners to 7 N´m (62 in. lbs.).

(4) Position the two spacer washers between the

body and the rubber grommets for the two mounting

points on the rail.

(5) Tighten the remaining M6 fasteners to 7 N´m

(62 in. lbs.) and the M8 fasteners to 23 N´m (17 ft.

lbs.) which mount the exhaust tube assembly to the

vehicle.

(6) Install the seat hex nut at the heater mounting

flange to the crossmembers. Tighten the nut to 60

N´m (44 ft. lbs.)

(7) Install the flexible section of the cabin heater

exhaust tube to the exhaust tube. Tighten the M6

bolt of the clamp securley. Install the hose to the

exhaust tube.

(8) Tighten the two M8 fasteners at the rail to 23

N´m (17 ft. lbs.). Taking care so that the exhaust

tube bracket tab is on the top of the heater bracket.(9) Install the wiring harness (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CABIN HEATER/

HEATER UNIT - INSTALLATION).

(10) Tighten the hose and tube assembly to the

toe-board crossmember at two locations.

(11) Install the second hose to the underbody hose

and tube assembly.

(12) Connect the rubber fuel hose between the

body tube assembly and the fuel pump nipple at the

body tube joint. Close the fuel fill cap.

(13) Remove the cabin heater support device from

under the vehicle.

(14) Lower the vehicle.

(15) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Verify function of the cabin heater.

SUPPLEMENTAL DIESEL

HEATER WIRING

REMOVAL

(1) Elevate vehicle on a lift taking note of the

exhaust tube flexible section.

(2) Unplug connector from vehicle wiring harness

to cabin heater harness.

(3) Unplug connector from cabin heater harness to

dosing pump connector.

(4) Unplug two connectors from cabin heater har-

ness to cabin heater controller connectors.

(5) Remove two wiring harness connectors from

underbody.

(6) Remove two wiring harness connectors from

cabin heater shield.

(7) Carefully route the cabin heater harness to the

left side between the cabin heater unit and the cabin

heater shield.

INSTALLATION

(1) Carefully route the cabin heater harness from

the left side of the cabin heater between the cabin

heater unit and the cabin heater shield.

(2) Install the two wiring harness retaining con-

nectors to the cabin heater shield.

(3) Route the wiring harness along the underside

of the vehicle and install the two wiring harness

retaining connectors.

(4) Plug the two connectors from the cabin heater

harness to the cabin heater controller.

(5) Plug the connector to the cabin heater harness

to the dosing pump connector.

(6) Plug the connector from the vehicle wiring har-

ness to the cabin heater harness.

(7) Lower the vehicle.

(8) Verify function of the cabin heater.

RSCABIN HEATER24 - 119

HEATER UNIT (Continued)