battery CHRYSLER VOYAGER 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 215 of 2339

CHANICAL/ICU (INTEGRATED CONTROL UNIT) -

DISASSEMBLY).

REMOVAL - RHD

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION)

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

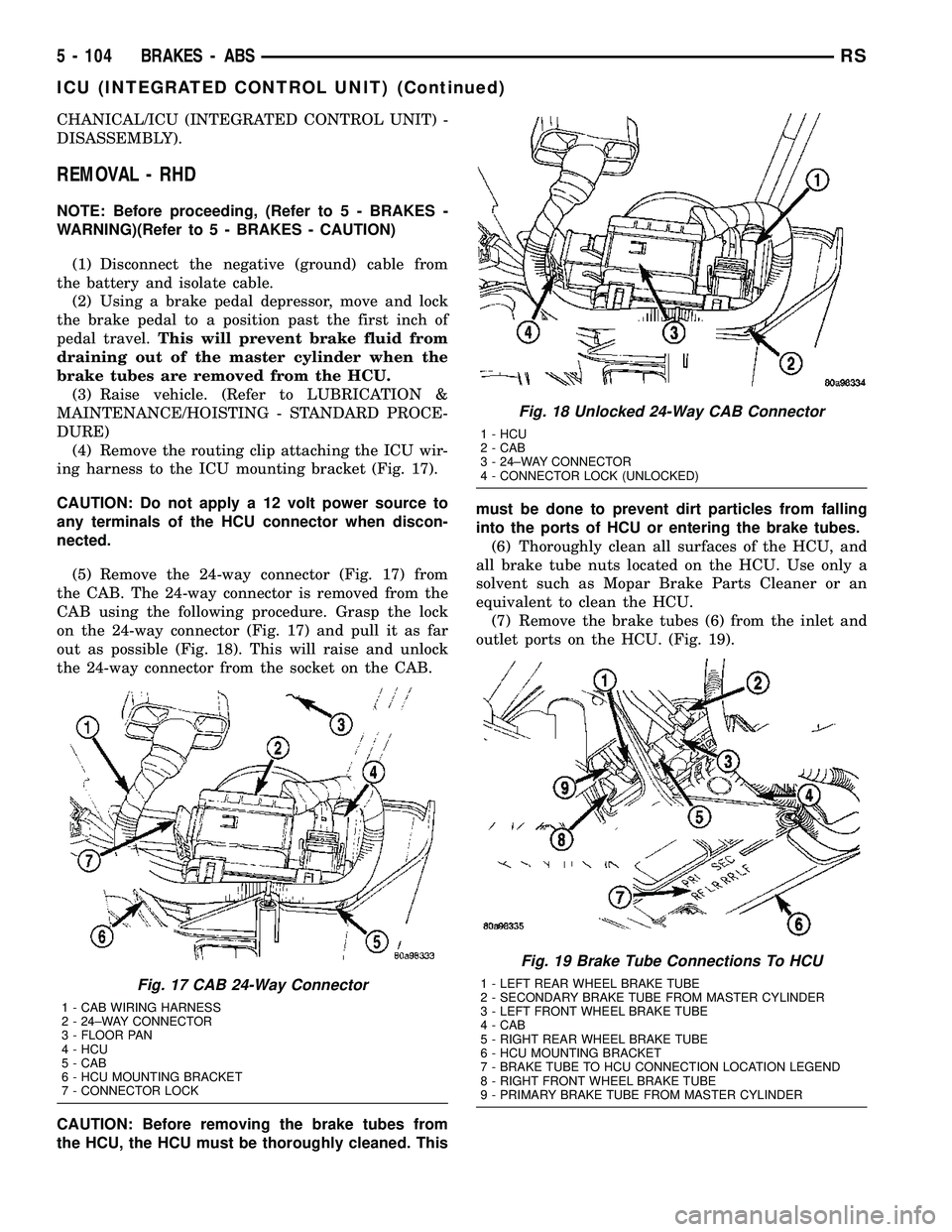

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 17).

CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

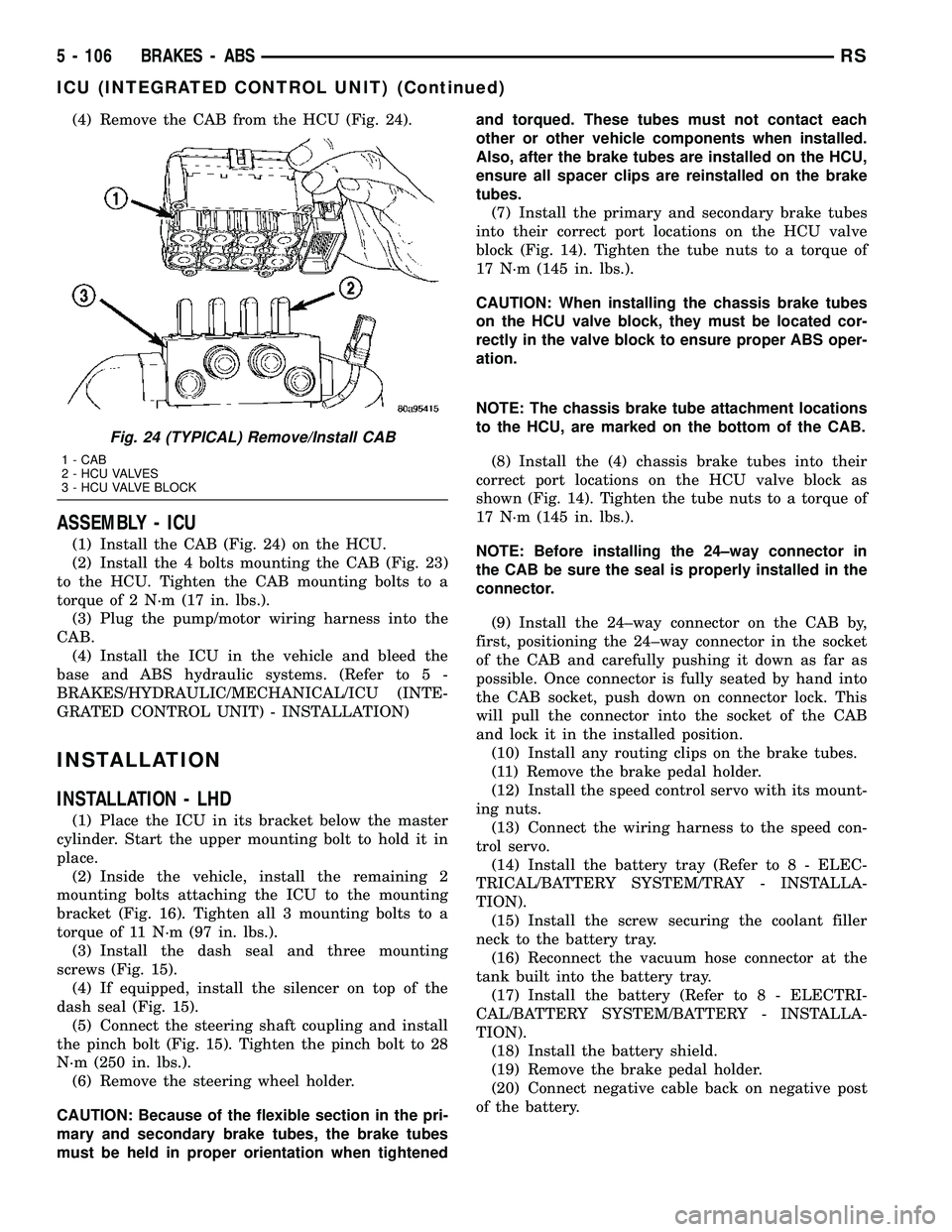

(5) Remove the 24-way connector (Fig. 17) from

the CAB. The 24-way connector is removed from the

CAB using the following procedure. Grasp the lock

on the 24-way connector (Fig. 17) and pull it as far

out as possible (Fig. 18). This will raise and unlock

the 24-way connector from the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. Thismust be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

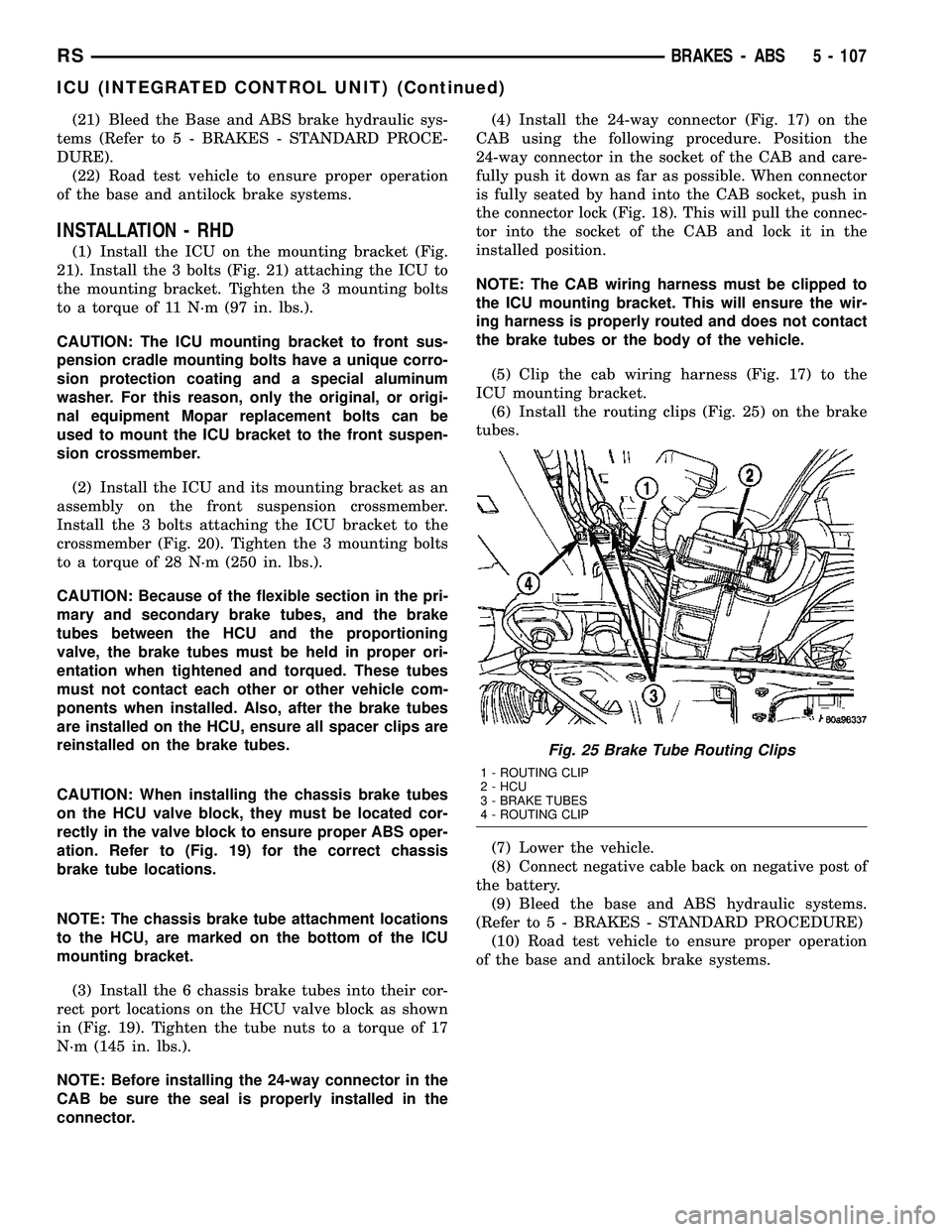

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

Fig. 17 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

Fig. 18 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

5 - 104 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 217 of 2339

(4) Remove the CAB from the HCU (Fig. 24).

ASSEMBLY - ICU

(1) Install the CAB (Fig. 24) on the HCU.

(2) Install the 4 bolts mounting the CAB (Fig. 23)

to the HCU. Tighten the CAB mounting bolts to a

torque of 2 N´m (17 in. lbs.).

(3) Plug the pump/motor wiring harness into the

CAB.

(4) Install the ICU in the vehicle and bleed the

base and ABS hydraulic systems. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - INSTALLATION)

INSTALLATION

INSTALLATION - LHD

(1) Place the ICU in its bracket below the master

cylinder. Start the upper mounting bolt to hold it in

place.

(2) Inside the vehicle, install the remaining 2

mounting bolts attaching the ICU to the mounting

bracket (Fig. 16). Tighten all 3 mounting bolts to a

torque of 11 N´m (97 in. lbs.).

(3) Install the dash seal and three mounting

screws (Fig. 15).

(4) If equipped, install the silencer on top of the

dash seal (Fig. 15).

(5) Connect the steering shaft coupling and install

the pinch bolt (Fig. 15). Tighten the pinch bolt to 28

N´m (250 in. lbs.).

(6) Remove the steering wheel holder.

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, the brake tubes

must be held in proper orientation when tightenedand torqued. These tubes must not contact each

other or other vehicle components when installed.

Also, after the brake tubes are installed on the HCU,

ensure all spacer clips are reinstalled on the brake

tubes.

(7) Install the primary and secondary brake tubes

into their correct port locations on the HCU valve

block (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the CAB.

(8) Install the (4) chassis brake tubes into their

correct port locations on the HCU valve block as

shown (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

NOTE: Before installing the 24±way connector in

the CAB be sure the seal is properly installed in the

connector.

(9) Install the 24±way connector on the CAB by,

first, positioning the 24±way connector in the socket

of the CAB and carefully pushing it down as far as

possible. Once connector is fully seated by hand into

the CAB socket, push down on connector lock. This

will pull the connector into the socket of the CAB

and lock it in the installed position.

(10) Install any routing clips on the brake tubes.

(11) Remove the brake pedal holder.

(12) Install the speed control servo with its mount-

ing nuts.

(13) Connect the wiring harness to the speed con-

trol servo.

(14) Install the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION).

(15) Install the screw securing the coolant filler

neck to the battery tray.

(16) Reconnect the vacuum hose connector at the

tank built into the battery tray.

(17) Install the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION).

(18) Install the battery shield.

(19) Remove the brake pedal holder.

(20) Connect negative cable back on negative post

of the battery.

Fig. 24 (TYPICAL) Remove/Install CAB

1 - CAB

2 - HCU VALVES

3 - HCU VALVE BLOCK

5 - 106 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 218 of 2339

(21) Bleed the Base and ABS brake hydraulic sys-

tems (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(22) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

INSTALLATION - RHD

(1) Install the ICU on the mounting bracket (Fig.

21). Install the 3 bolts (Fig. 21) attaching the ICU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The ICU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the ICU bracket to the front suspen-

sion crossmember.

(2) Install the ICU and its mounting bracket as an

assembly on the front suspension crossmember.

Install the 3 bolts attaching the ICU bracket to the

crossmember (Fig. 20). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 19) for the correct chassis

brake tube locations.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the ICU

mounting bracket.

(3) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 19). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 24-way connector in the

CAB be sure the seal is properly installed in the

connector.(4) Install the 24-way connector (Fig. 17) on the

CAB using the following procedure. Position the

24-way connector in the socket of the CAB and care-

fully push it down as far as possible. When connector

is fully seated by hand into the CAB socket, push in

the connector lock (Fig. 18). This will pull the connec-

tor into the socket of the CAB and lock it in the

installed position.

NOTE: The CAB wiring harness must be clipped to

the ICU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(5) Clip the cab wiring harness (Fig. 17) to the

ICU mounting bracket.

(6) Install the routing clips (Fig. 25) on the brake

tubes.

(7) Lower the vehicle.

(8) Connect negative cable back on negative post of

the battery.

(9) Bleed the base and ABS hydraulic systems.

(Refer to 5 - BRAKES - STANDARD PROCEDURE)

(10) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

Fig. 25 Brake Tube Routing Clips

1 - ROUTING CLIP

2 - HCU

3 - BRAKE TUBES

4 - ROUTING CLIP

RSBRAKES - ABS5 - 107

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 245 of 2339

RADIATOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove radiator upper crossmember support.

(Refer to 23 - BODY/EXTERIOR/GRILLE OPENING

REINFORCEMENT - REMOVAL)

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(3) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(4) Remove the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL)

(5) Disconnect coolant reserve/recovery hose.

(6) Remove vapor purge solenoid from mounting

bracket.

(7) Disconnect upper and lower hoses from the

radiator (Fig. 13) or (Fig. 14).

(8) Lift the A/C condenser straight up to disengage

the lower A/C condenser mounting brackets from the

radiator. (Fig. 15). Separate the condenser from the

radiator by lifting upward to disengage from lower

mounts (Fig. 15). Allow the condenser to rest in front

of radiator.(9) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

Fig. 13 Radiator Hoses to Radiator - 2.4L

1 - UPPER HOSE

2 - LOWER HOSE

3 - HOSE SUPPORT CLIP

Fig. 14 Radiator Hoses to Radiator - 3.3/3.8L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 15 A/C Condenser ± 2.4L/3.3L/3.8L Engines

1 - A/C CONDENSER

2 - AUTO TRANS COOLER TAPPING BLOCK

3 - UPPER CONDENSER MOUNTING BRACKET (2)

4 - RADIATOR

5 - LOWER CONDENSER MOUNTING BRACKET (2)

7 - 26 ENGINERS

Page 246 of 2339

INSTALLATION

(1)Be sure the air seal is in position before

radiator is installed.Slide radiator down into posi-

tion. Seat the radiator with the rubber isolators into

the mounting holes provided, with a 10 lbs. force.

(2) Position air conditioning condenser onto the

radiator lower mounts and ingage upper mounting

tabs. (Fig. 15).

(3) Install the radiator upper and lower hoses (Fig.

13) or (Fig. 14).

(4) Connect the coolant reserve/recovery hose.

(5) Connect the vapor purge solenoid to the mount-

ing bracket.

(6) Install the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION)

(7) Install the radiator upper crossmember sup-

port. (Refer to 23 - BODY/EXTERIOR/GRILLE

OPENING REINFORCEMENT - INSTALLATION)

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

(9) Connect negative cable to battery.

RADIATOR DRAINCOCK

REMOVAL

NOTE: It is not necessary to remove draincock dur-

ing a routine coolant drain.

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Using a screwdriver, open the draincock by

turning it counterclockwise until it stops.

(3) Pull the draincock from the radiator tank.

INSTALLATION

(1) Align draincock stem to radiator tank opening.

(2) Push draincock into the radiator tank opening.

CAUTION: Do not overtighten. The head of the

draincock may break off.

(3) Using a screwdriver, tighten the draincock by

turning clockwise until it stops.

(4) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

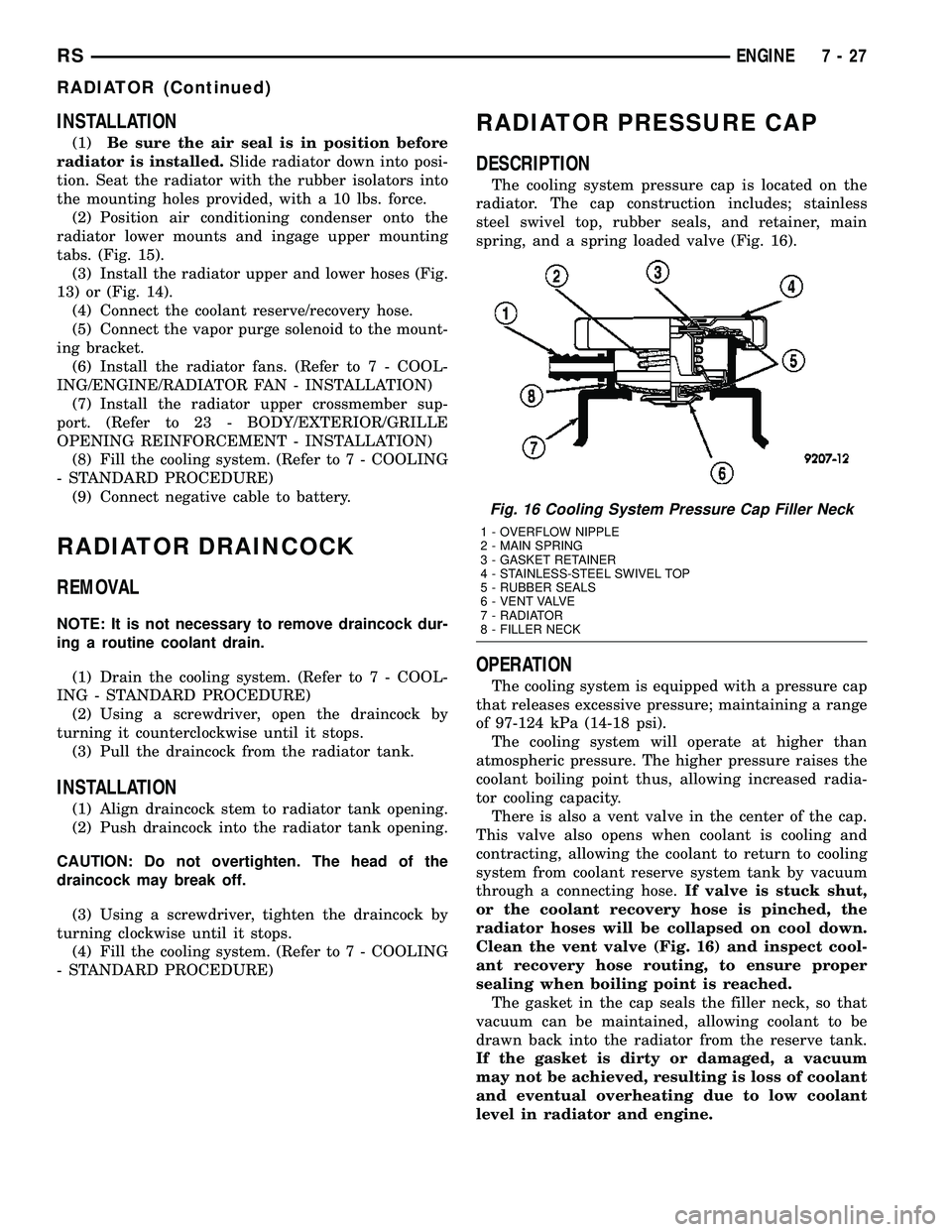

RADIATOR PRESSURE CAP

DESCRIPTION

The cooling system pressure cap is located on the

radiator. The cap construction includes; stainless

steel swivel top, rubber seals, and retainer, main

spring, and a spring loaded valve (Fig. 16).

OPERATION

The cooling system is equipped with a pressure cap

that releases excessive pressure; maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is also a vent valve in the center of the cap.

This valve also opens when coolant is cooling and

contracting, allowing the coolant to return to cooling

system from coolant reserve system tank by vacuum

through a connecting hose.If valve is stuck shut,

or the coolant recovery hose is pinched, the

radiator hoses will be collapsed on cool down.

Clean the vent valve (Fig. 16) and inspect cool-

ant recovery hose routing, to ensure proper

sealing when boiling point is reached.

The gasket in the cap seals the filler neck, so that

vacuum can be maintained, allowing coolant to be

drawn back into the radiator from the reserve tank.

If the gasket is dirty or damaged, a vacuum

may not be achieved, resulting is loss of coolant

and eventual overheating due to low coolant

level in radiator and engine.

Fig. 16 Cooling System Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

RSENGINE7-27

RADIATOR (Continued)

Page 250 of 2339

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

RADIATOR FAN RELAY

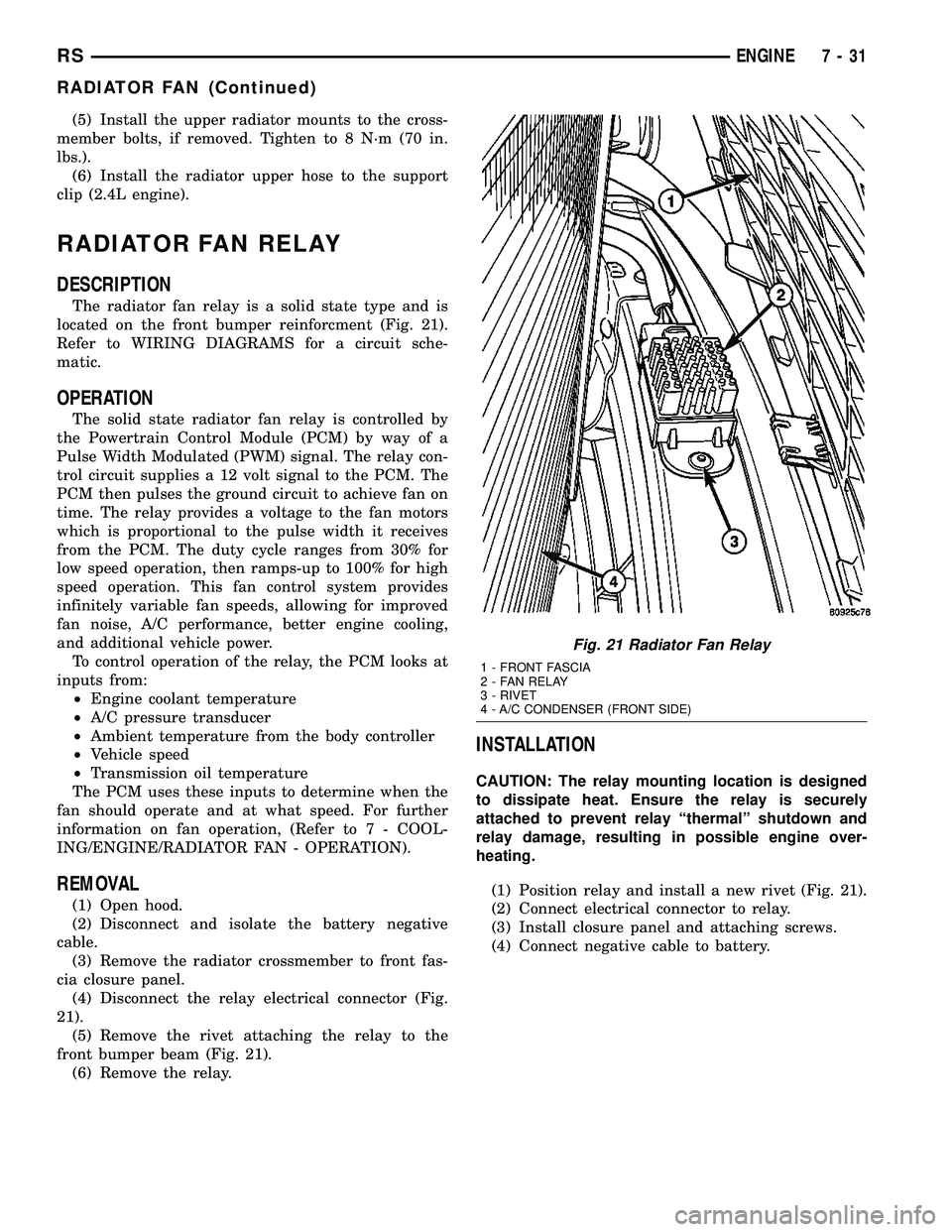

DESCRIPTION

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 21).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

21).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 21).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

(1) Position relay and install a new rivet (Fig. 21).

(2) Connect electrical connector to relay.

(3) Install closure panel and attaching screws.

(4) Connect negative cable to battery.

Fig. 21 Radiator Fan Relay

1 - FRONT FASCIA

2 - FAN RELAY

3 - RIVET

4 - A/C CONDENSER (FRONT SIDE)

RSENGINE7-31

RADIATOR FAN (Continued)

Page 251 of 2339

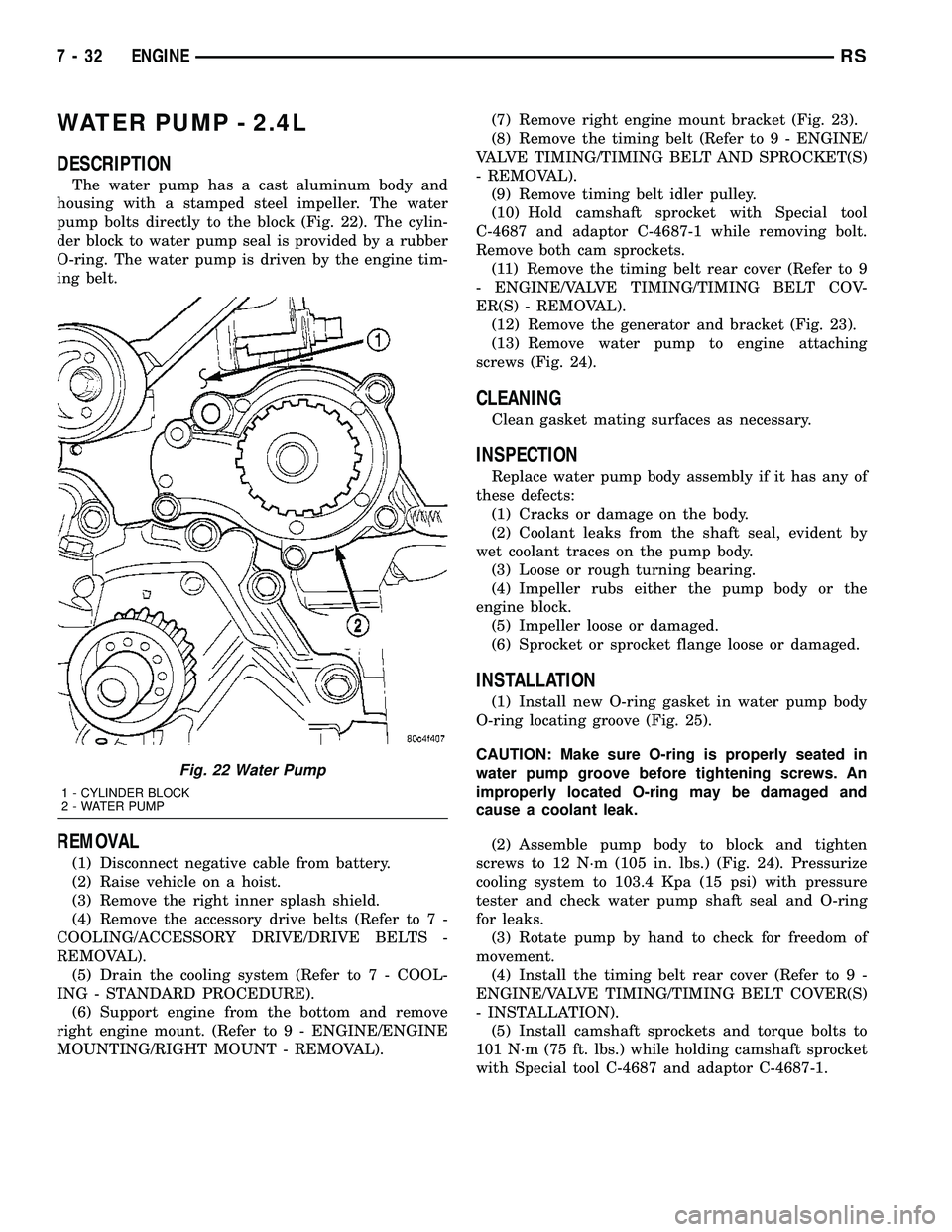

WATER PUMP - 2.4L

DESCRIPTION

The water pump has a cast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 22). The cylin-

der block to water pump seal is provided by a rubber

O-ring. The water pump is driven by the engine tim-

ing belt.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist.

(3) Remove the right inner splash shield.

(4) Remove the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(6) Support engine from the bottom and remove

right engine mount. (Refer to 9 - ENGINE/ENGINE

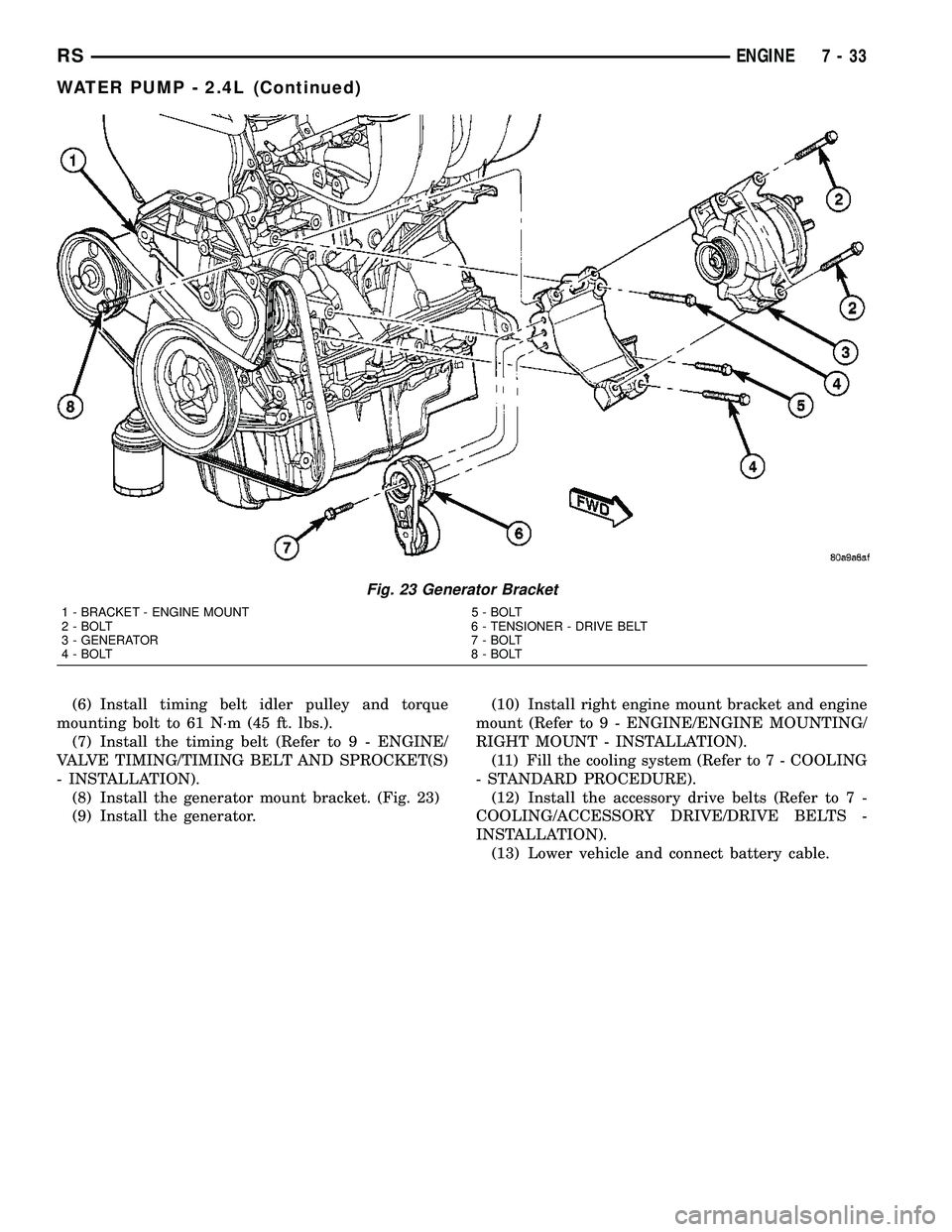

MOUNTING/RIGHT MOUNT - REMOVAL).(7) Remove right engine mount bracket (Fig. 23).

(8) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- REMOVAL).

(9) Remove timing belt idler pulley.

(10) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(11) Remove the timing belt rear cover (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - REMOVAL).

(12) Remove the generator and bracket (Fig. 23).

(13) Remove water pump to engine attaching

screws (Fig. 24).

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

wet coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring locating groove (Fig. 25).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may be damaged and

cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.) (Fig. 24). Pressurize

cooling system to 103.4 Kpa (15 psi) with pressure

tester and check water pump shaft seal and O-ring

for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(5) Install camshaft sprockets and torque bolts to

101 N´m (75 ft. lbs.) while holding camshaft sprocket

with Special tool C-4687 and adaptor C-4687-1.

Fig. 22 Water Pump

1 - CYLINDER BLOCK

2 - WATER PUMP

7 - 32 ENGINERS

Page 252 of 2339

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

(7) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- INSTALLATION).

(8) Install the generator mount bracket. (Fig. 23)

(9) Install the generator.(10) Install right engine mount bracket and engine

mount (Refer to 9 - ENGINE/ENGINE MOUNTING/

RIGHT MOUNT - INSTALLATION).

(11) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(12) Install the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Lower vehicle and connect battery cable.

Fig. 23 Generator Bracket

1 - BRACKET - ENGINE MOUNT 5 - BOLT

2 - BOLT 6 - TENSIONER - DRIVE BELT

3 - GENERATOR 7 - BOLT

4 - BOLT 8 - BOLT

RSENGINE7-33

WATER PUMP - 2.4L (Continued)

Page 260 of 2339

AUDIO/VIDEO

TABLE OF CONTENTS

page page

AUDIO/VIDEO

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

AUDIO/VIDEO.........................2

AMPLIFIER

REMOVAL.............................7

INSTALLATION..........................7

ANTENNA BODY AND CABLE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING

ANTENNA BODY AND CABLE.............8

REMOVAL.............................8

INSTALLATION..........................8

ANTENNA MODULE - EXPORT

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING

ANTENNA MODULE - EXPORT...........10

REMOVAL.............................10

INSTALLATION.........................10

ANTENNA - NAVIGATION RADIO

REMOVAL.............................11

INSTALLATION.........................11

CD CHANGER

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

DVD PLAYER

DESCRIPTION.........................12

REMOVAL.............................12

INSTALLATION.........................12

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................12INSTALLATION.........................12

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT............................13

RADIO

DESCRIPTION.........................13

OPERATION...........................14

DIAGNOSIS AND TESTING

RADIO..............................14

REMOVAL.............................14

INSTALLATION.........................15

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION.........................15

OPERATION...........................15

REMOTE SWITCHES

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING

REMOTE SWITCHES..................16

REMOVAL.............................17

INSTALLATION.........................17

SPEAKER

DIAGNOSIS AND TESTING

SPEAKER...........................18

REMOVAL.............................18

INSTALLATION.........................19

VIDEO SCREEN

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

AUDIO/VIDEO

DESCRIPTION

An audio system is standard on this model. A rear

seat video system is an available option. Several com-

binations of radio receivers are offered on this model.

The audio/video system uses an ignition switched

source of battery current so that the system will only

operate when the ignition switch is in the RUN or

ACCESSORY/ACCESSORY DELAY positions.

The audio system includes the following compo-

nents:²Amplifier

²Antenna

²CD changer (if equipped)

²DVD player (if equipped)

²Radio noise suppression components

²Radio receiver

²Speakers

²Video screen (if equipped)

Certain functions and features of the audio/video

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communication Interface (PCI) bus network. The

data bus network allows the sharing of sensor infor-

RSAUDIO/VIDEO8A-1

Page 261 of 2339

mation. For diagnosis of these electronic modules or

of the data bus network, the use of a DRB IIItscan

tool and the proper Diagnostic Procedures informa-

tion is recommended.

DIAGNOSIS AND TESTING

AUDIO/VIDEO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRBIIIt, refer to the appropriate Diagnostic Service

information.

Refer to the appropriate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

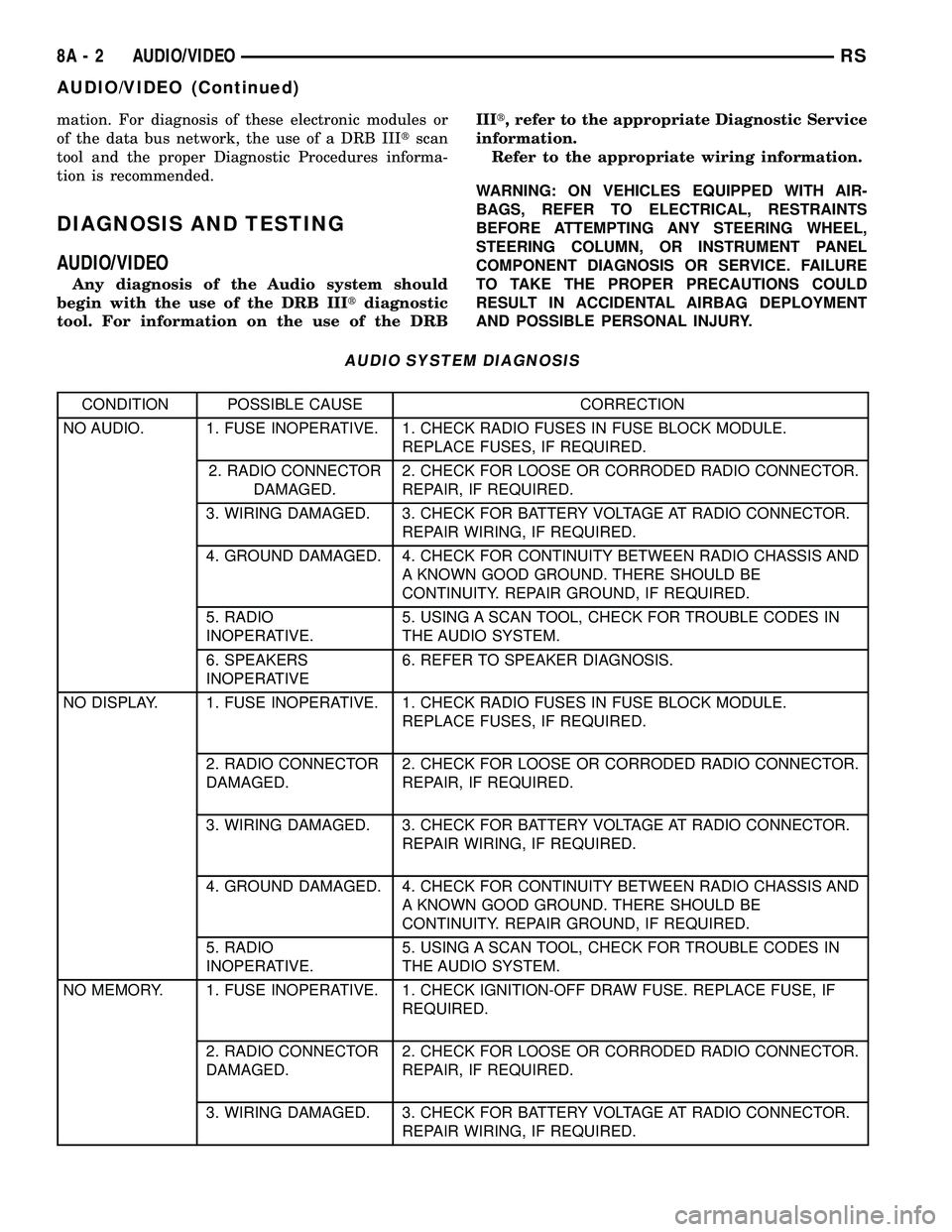

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE INOPERATIVE. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

DAMAGED.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING DAMAGED. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND DAMAGED. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO

INOPERATIVE.5. USING A SCAN TOOL, CHECK FOR TROUBLE CODES IN

THE AUDIO SYSTEM.

6. SPEAKERS

INOPERATIVE6. REFER TO SPEAKER DIAGNOSIS.

NO DISPLAY. 1. FUSE INOPERATIVE. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

DAMAGED.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING DAMAGED. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND DAMAGED. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO

INOPERATIVE.5. USING A SCAN TOOL, CHECK FOR TROUBLE CODES IN

THE AUDIO SYSTEM.

NO MEMORY. 1. FUSE INOPERATIVE. 1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. RADIO CONNECTOR

DAMAGED.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING DAMAGED. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

8A - 2 AUDIO/VIDEORS

AUDIO/VIDEO (Continued)