battery CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1615 of 2339

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE

When diagnosing converter housing fluid leaks,

three actions must be taken before repair:

(1) Verify proper transmission fluid level.

(2) Verify that the leak originates from the con-

verter housing area and is transmission fluid.

(3) Determine the true source of the leak.

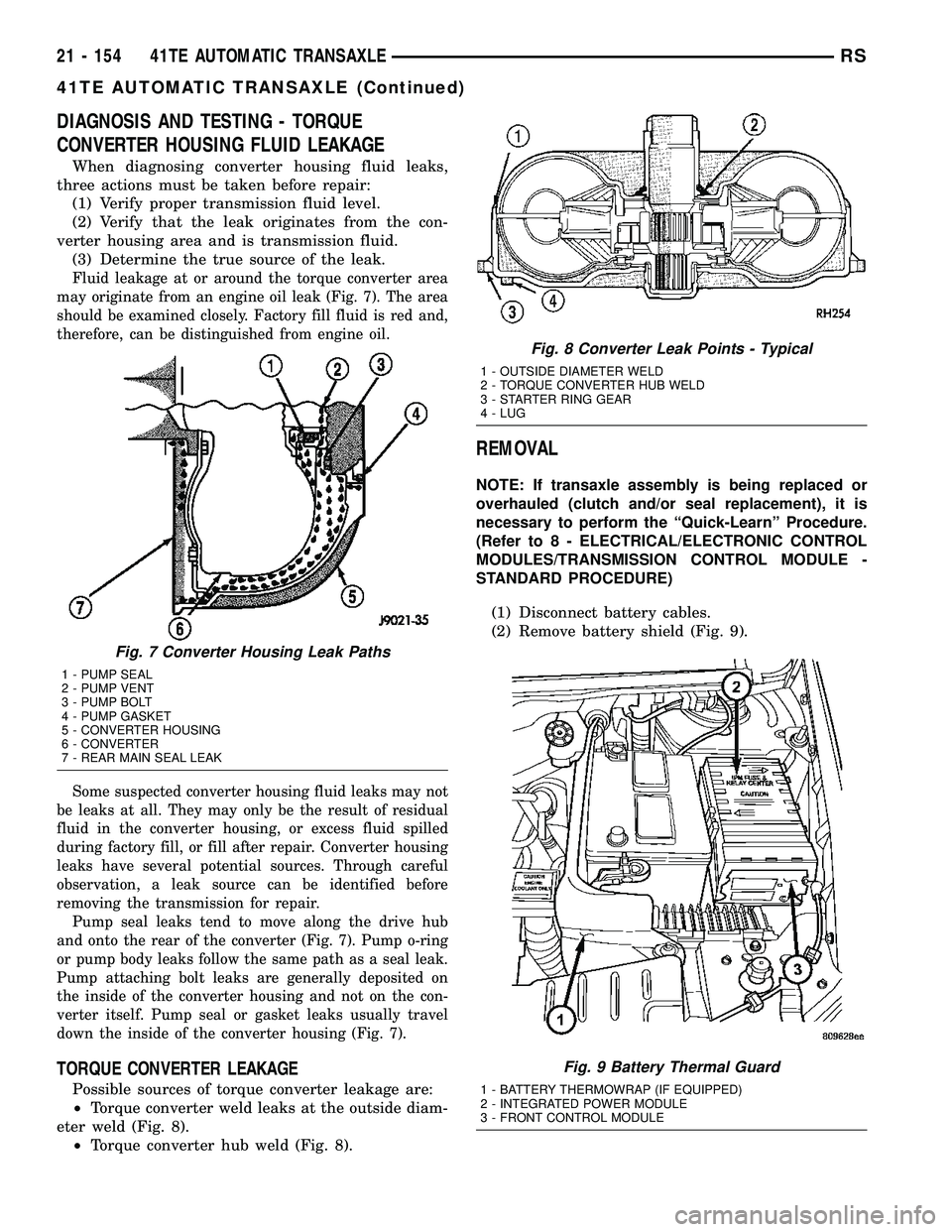

Fluid leakage at or around the torque converter area

may originate from an engine oil leak (Fig. 7). The area

should be examined closely. Factory fill fluid is red and,

therefore, can be distinguished from engine oil.

Some suspected converter housing fluid leaks may not

be leaks at all. They may only be the result of residual

fluid in the converter housing, or excess fluid spilled

during factory fill, or fill after repair. Converter housing

leaks have several potential sources. Through careful

observation, a leak source can be identified before

removing the transmission for repair.

Pump seal leaks tend to move along the drive hub

and onto the rear of the converter (Fig. 7). Pump o-ring

or pump body leaks follow the same path as a seal leak.

Pump attaching bolt leaks are generally deposited on

the inside of the converter housing and not on the con-

verter itself. Pump seal or gasket leaks usually travel

down the inside of the converter housing (Fig. 7).

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside diam-

eter weld (Fig. 8).

²Torque converter hub weld (Fig. 8).

REMOVAL

NOTE: If transaxle assembly is being replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perform the ªQuick-Learnº Procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Disconnect battery cables.

(2) Remove battery shield (Fig. 9).

Fig. 7 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

Fig. 8 Converter Leak Points - Typical

1 - OUTSIDE DIAMETER WELD

2 - TORQUE CONVERTER HUB WELD

3 - STARTER RING GEAR

4 - LUG

Fig. 9 Battery Thermal Guard

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

21 - 154 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1659 of 2339

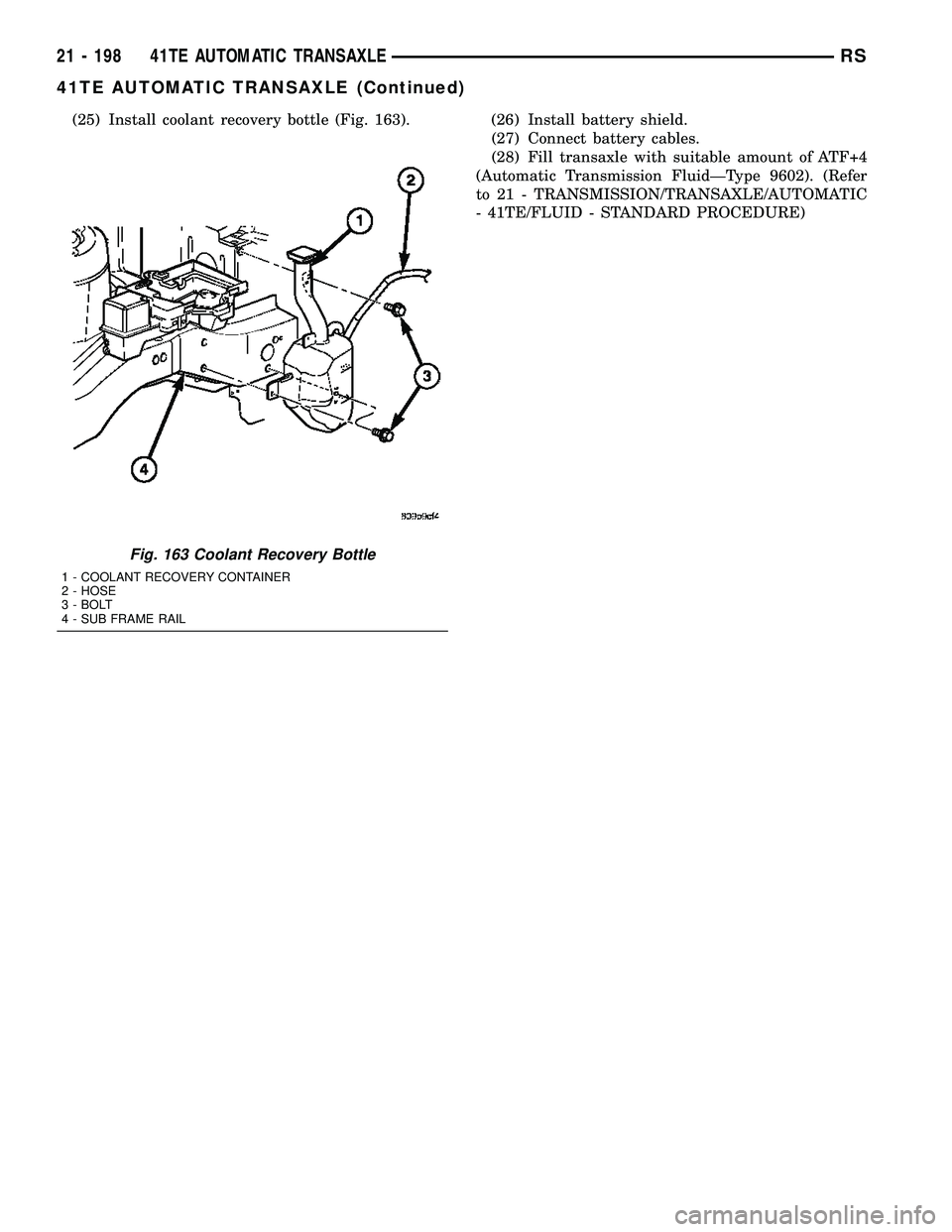

(25) Install coolant recovery bottle (Fig. 163). (26) Install battery shield.

(27) Connect battery cables.

(28) Fill transaxle with suitable amount of ATF+4

(Automatic Transmission FluidÐType 9602). (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/FLUID - STANDARD PROCEDURE)

Fig. 163 Coolant Recovery Bottle

1 - COOLANT RECOVERY CONTAINER

2 - HOSE

3 - BOLT

4 - SUB FRAME RAIL

21 - 198 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1694 of 2339

GEAR SHIFT CABLE

REMOVAL

(1) Disconnect battery cables.

(2) Remove battery shield.

(3) Remove battery.

(4) Remove speed control servo and position out of

way.

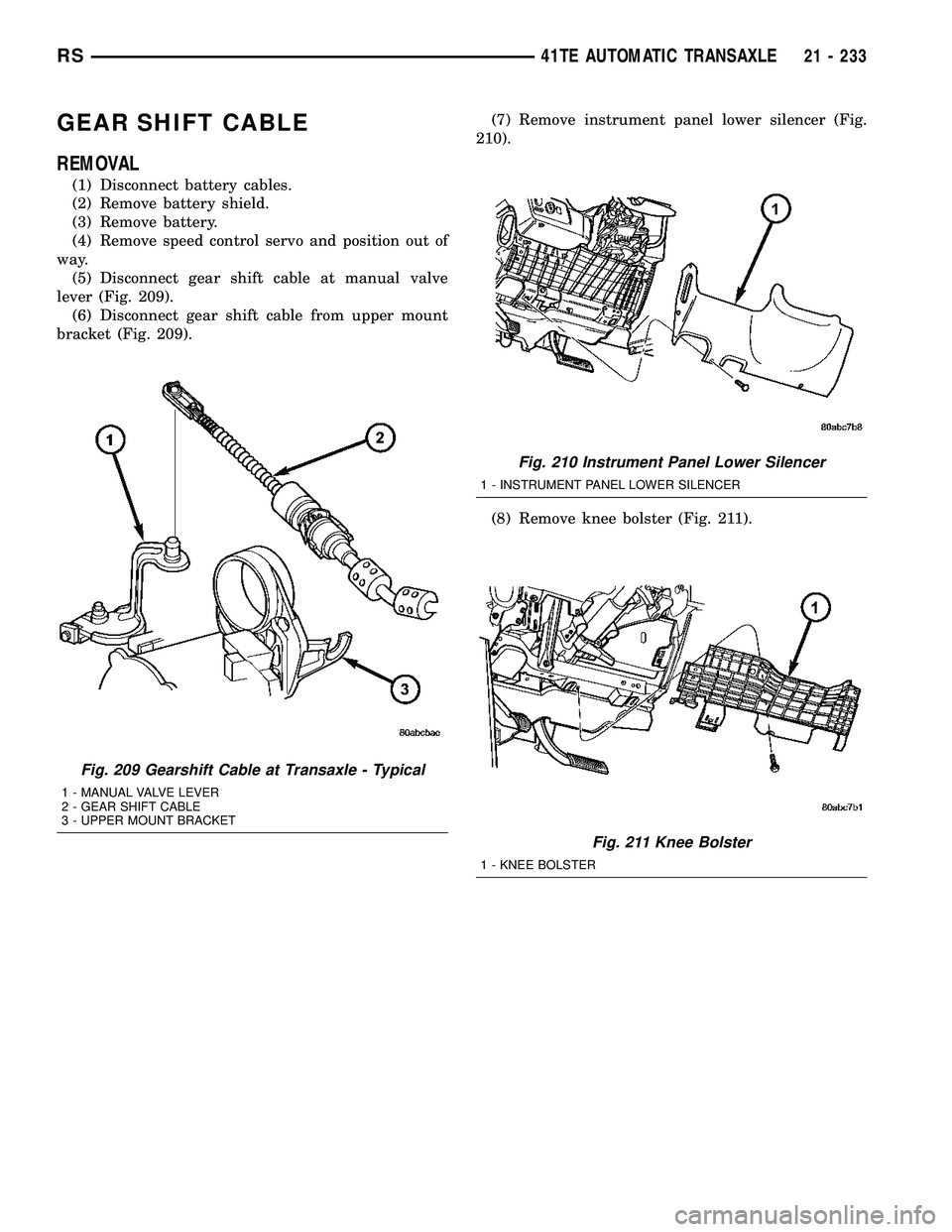

(5) Disconnect gear shift cable at manual valve

lever (Fig. 209).

(6) Disconnect gear shift cable from upper mount

bracket (Fig. 209).(7) Remove instrument panel lower silencer (Fig.

210).

(8) Remove knee bolster (Fig. 211).

Fig. 209 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 210 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 211 Knee Bolster

1 - KNEE BOLSTER

RS41TE AUTOMATIC TRANSAXLE21 - 233

Page 1696 of 2339

(4) Install knee bolster (Fig. 216).

(5) Install instrument panel lower silencer (Fig.

217).

(6) Install gear shift cable to transaxle upper

mount bracket (Fig. 218). An audible ªclickº should

be heard.

(7) Connect gear shift cable end to transaxle man-

ual valve lever (Fig. 218).

(8) Adjust gearshift cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 41TE/GEAR

SHIFT CABLE - ADJUSTMENTS)

(9) Install speed control servo into position.

(10) Install battery.

(11) Install battery shield.

(12) Connect battery cables.

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT

VERIFICATION

(1) Place gearshift lever in gated park (P).

(2) Attempt to move vehicle by rocking back and

forth on level ground. If vehicle does not move,

attempt to start engine. If engine starts, the park

position is correct.

(3) Set parking brake.

(4) Turn key to on/run and depress brake pedal.

Place gearshift lever in neutral (N).

(5) Attempt to start engine. If engine starts in

both neutral (N) or park (P), gearshift cable is

adjusted properly. No adjustment is required.

(6) If engine does not start in either park (P) or

neutral (N), perform adjustment procedure.

ADJUSTMENT

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in gated park (P) and

remove ignition key.

(3) Loosen the cable adjustment screw at the

transaxle manual valve lever (Fig. 219).

(4) Pull the gearshift lever fully forward to the

park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park. Reset the park brake.

Fig. 216 Knee Bolster

1 - KNEE BOLSTER

Fig. 217 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 218 Gearshift Cable at Transaxle

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

RS41TE AUTOMATIC TRANSAXLE21 - 235

GEAR SHIFT CABLE (Continued)

Page 1726 of 2339

OPERATION

The Brake/Transmission Shift Interlock (BTSI)

Solenoid prevents the transmission shift lever from

being moved out of PARK (P) unless the brake pedal

is applied. The BTSI solenoid is hardwired to and

controlled by the Intelligent Power Module (IPM).

Battery voltage is applied to one side of the solenoid

with the ignition key is in either the OFF, ON/RUN,

or START positions (Fig. 293). The ground side of the

solenoid is controlled by a driver within the IPM. It

relies on voltage supplied from the stop lamp switch

to the stop lamp sense circuit within the IPM to tell

when the brake pedal is depressed. When the brake

pedal is depressed, the ground circuit opens, de-ener-

gizing the solenoid. When the brake pedal is

released, the ground circuit is closed, energizing the

solenoid.

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 294). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 295), allow-

ing the shift lever to be moved into any gear position.

Fig. 293 Ignition Key/Switch Positions

1 - ACC

2 - LOCK

3 - OFF

4 - ON/RUN

5-START

Fig. 294 Pawl Engaged to Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

Fig. 295 Pawl Disengaged From Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

RS41TE AUTOMATIC TRANSAXLE21 - 265

SHIFT INTERLOCK SOLENOID (Continued)

Page 1727 of 2339

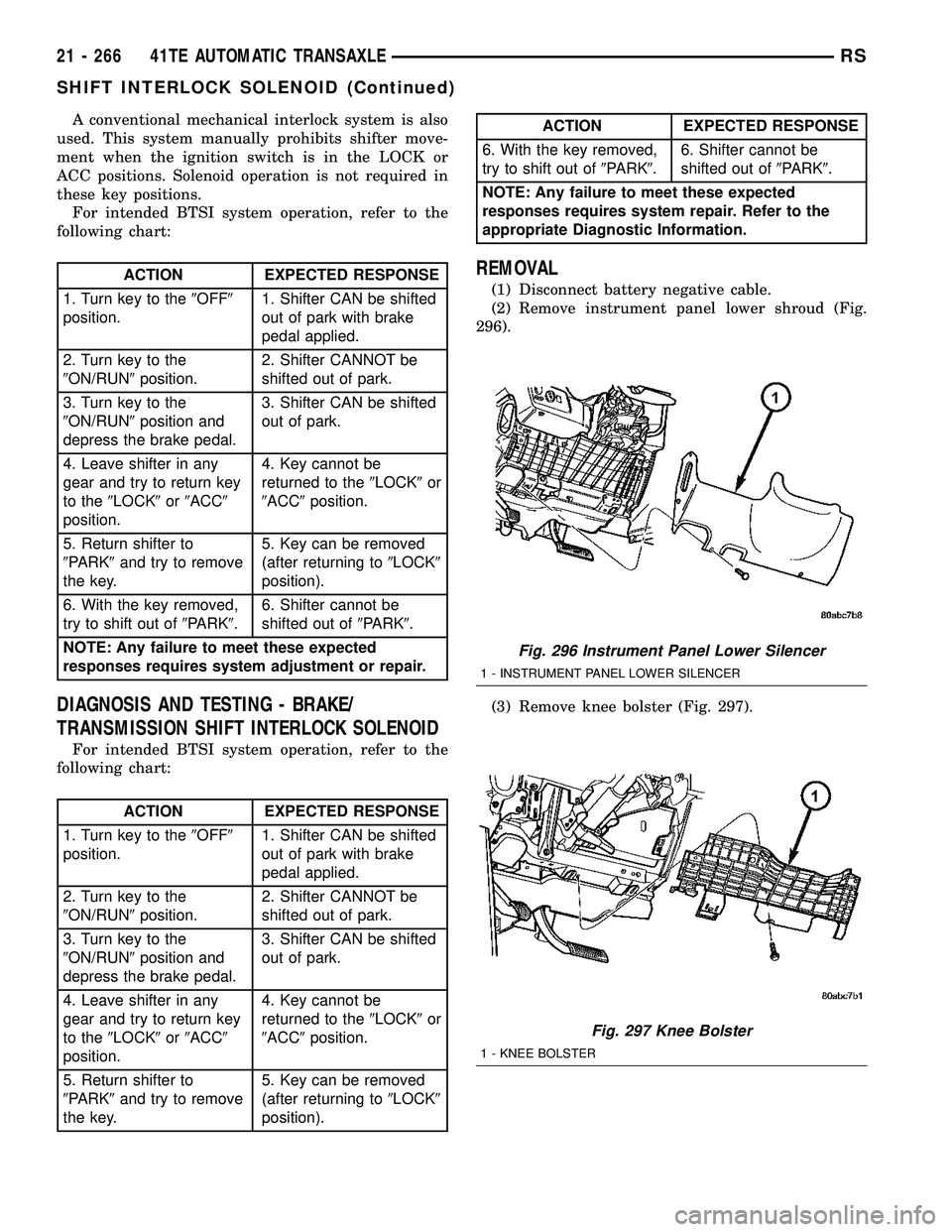

A conventional mechanical interlock system is also

used. This system manually prohibits shifter move-

ment when the ignition switch is in the LOCK or

ACC positions. Solenoid operation is not required in

these key positions.

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK SOLENOID

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

ACTION EXPECTED RESPONSE

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system repair. Refer to the

appropriate Diagnostic Information.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower shroud (Fig.

296).

(3) Remove knee bolster (Fig. 297).

Fig. 296 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 297 Knee Bolster

1 - KNEE BOLSTER

21 - 266 41TE AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

Page 1729 of 2339

(3) Install steering column lower shroud.

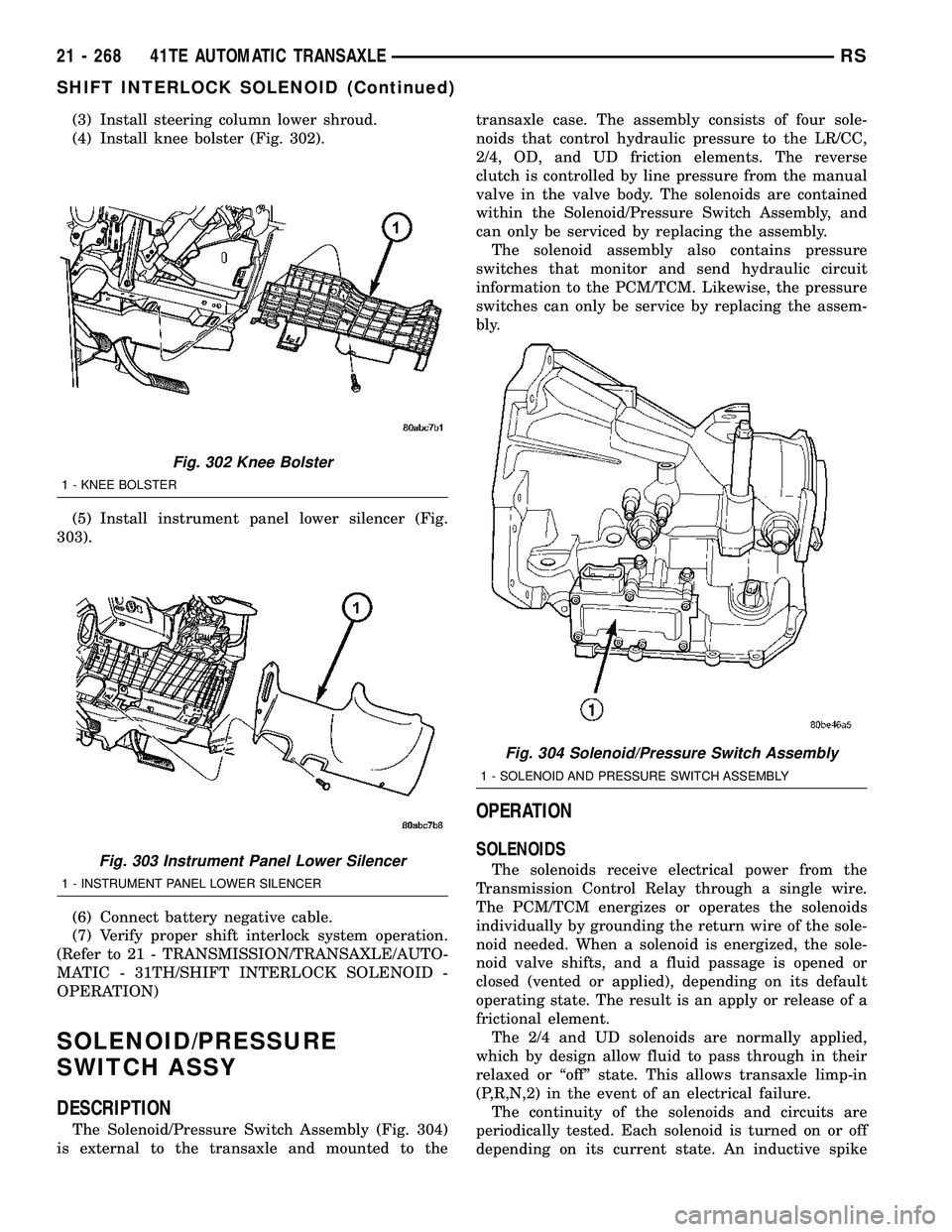

(4) Install knee bolster (Fig. 302).

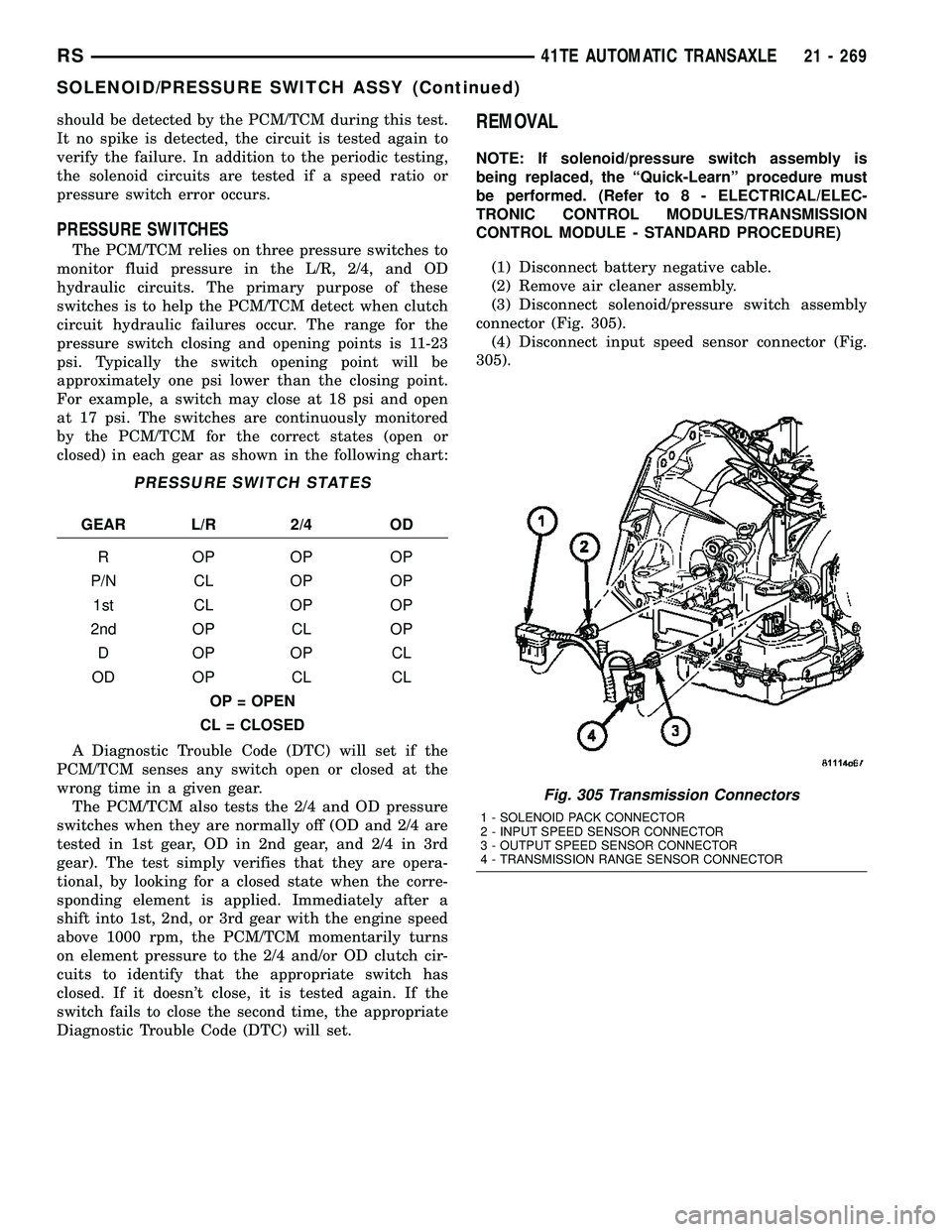

(5) Install instrument panel lower silencer (Fig.

303).

(6) Connect battery negative cable.

(7) Verify proper shift interlock system operation.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/SHIFT INTERLOCK SOLENOID -

OPERATION)

SOLENOID/PRESSURE

SWITCH ASSY

DESCRIPTION

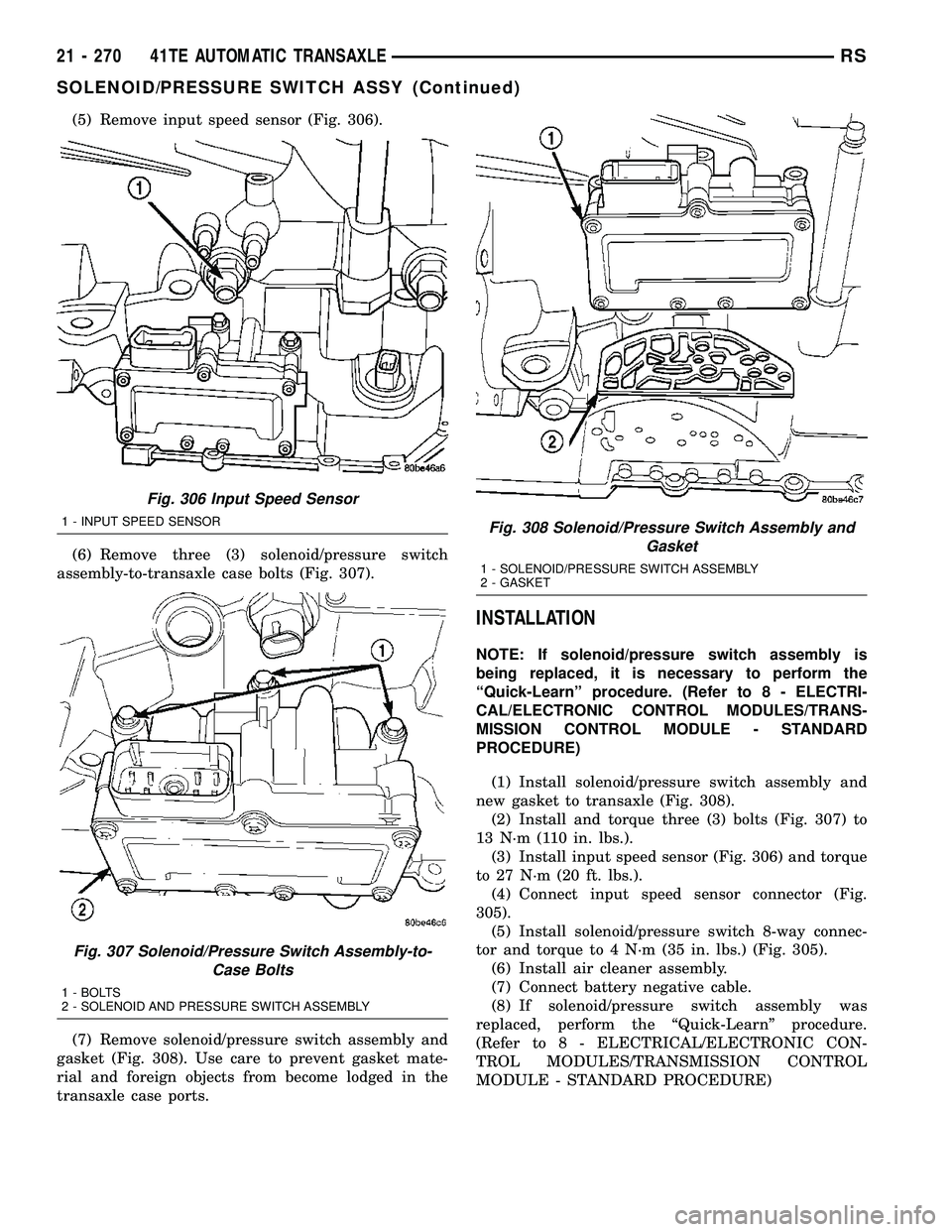

The Solenoid/Pressure Switch Assembly (Fig. 304)

is external to the transaxle and mounted to thetransaxle case. The assembly consists of four sole-

noids that control hydraulic pressure to the LR/CC,

2/4, OD, and UD friction elements. The reverse

clutch is controlled by line pressure from the manual

valve in the valve body. The solenoids are contained

within the Solenoid/Pressure Switch Assembly, and

can only be serviced by replacing the assembly.

The solenoid assembly also contains pressure

switches that monitor and send hydraulic circuit

information to the PCM/TCM. Likewise, the pressure

switches can only be service by replacing the assem-

bly.

OPERATION

SOLENOIDS

The solenoids receive electrical power from the

Transmission Control Relay through a single wire.

The PCM/TCM energizes or operates the solenoids

individually by grounding the return wire of the sole-

noid needed. When a solenoid is energized, the sole-

noid valve shifts, and a fluid passage is opened or

closed (vented or applied), depending on its default

operating state. The result is an apply or release of a

frictional element.

The 2/4 and UD solenoids are normally applied,

which by design allow fluid to pass through in their

relaxed or ªoffº state. This allows transaxle limp-in

(P,R,N,2) in the event of an electrical failure.

The continuity of the solenoids and circuits are

periodically tested. Each solenoid is turned on or off

depending on its current state. An inductive spike

Fig. 302 Knee Bolster

1 - KNEE BOLSTER

Fig. 303 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 304 Solenoid/Pressure Switch Assembly

1 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

21 - 268 41TE AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

Page 1730 of 2339

should be detected by the PCM/TCM during this test.

It no spike is detected, the circuit is tested again to

verify the failure. In addition to the periodic testing,

the solenoid circuits are tested if a speed ratio or

pressure switch error occurs.

PRESSURE SWITCHES

The PCM/TCM relies on three pressure switches to

monitor fluid pressure in the L/R, 2/4, and OD

hydraulic circuits. The primary purpose of these

switches is to help the PCM/TCM detect when clutch

circuit hydraulic failures occur. The range for the

pressure switch closing and opening points is 11-23

psi. Typically the switch opening point will be

approximately one psi lower than the closing point.

For example, a switch may close at 18 psi and open

at 17 psi. The switches are continuously monitored

by the PCM/TCM for the correct states (open or

closed) in each gear as shown in the following chart:

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP

1st CL OP OP

2nd OP CL OP

DOPOPCL

OD OP CL CL

OP = OPEN

CL = CLOSED

A Diagnostic Trouble Code (DTC) will set if the

PCM/TCM senses any switch open or closed at the

wrong time in a given gear.

The PCM/TCM also tests the 2/4 and OD pressure

switches when they are normally off (OD and 2/4 are

tested in 1st gear, OD in 2nd gear, and 2/4 in 3rd

gear). The test simply verifies that they are opera-

tional, by looking for a closed state when the corre-

sponding element is applied. Immediately after a

shift into 1st, 2nd, or 3rd gear with the engine speed

above 1000 rpm, the PCM/TCM momentarily turns

on element pressure to the 2/4 and/or OD clutch cir-

cuits to identify that the appropriate switch has

closed. If it doesn't close, it is tested again. If the

switch fails to close the second time, the appropriate

Diagnostic Trouble Code (DTC) will set.

REMOVAL

NOTE: If solenoid/pressure switch assembly is

being replaced, the ªQuick-Learnº procedure must

be performed. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly.

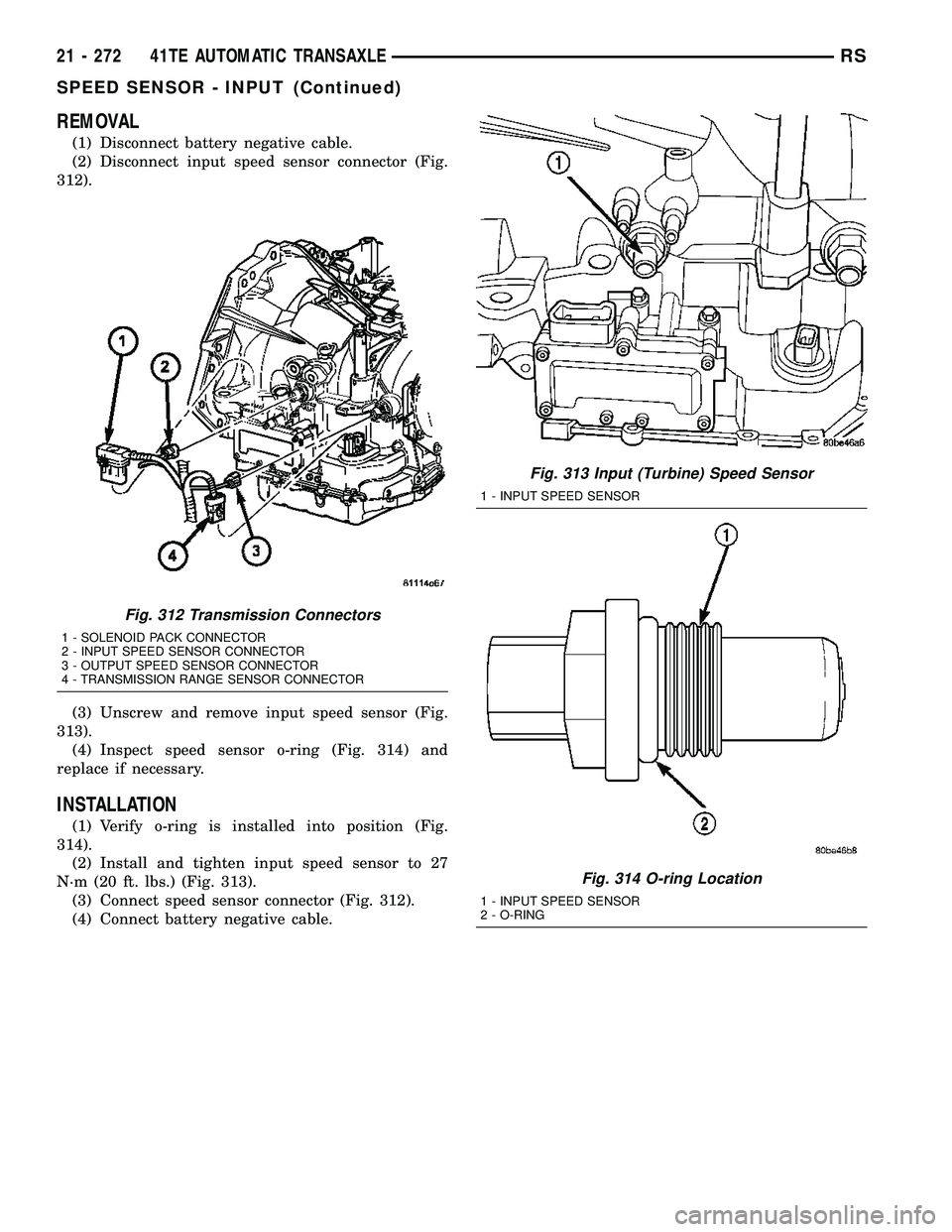

(3) Disconnect solenoid/pressure switch assembly

connector (Fig. 305).

(4) Disconnect input speed sensor connector (Fig.

305).

Fig. 305 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

RS41TE AUTOMATIC TRANSAXLE21 - 269

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 1731 of 2339

(5) Remove input speed sensor (Fig. 306).

(6) Remove three (3) solenoid/pressure switch

assembly-to-transaxle case bolts (Fig. 307).

(7) Remove solenoid/pressure switch assembly and

gasket (Fig. 308). Use care to prevent gasket mate-

rial and foreign objects from become lodged in the

transaxle case ports.

INSTALLATION

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the

ªQuick-Learnº procedure. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/TRANS-

MISSION CONTROL MODULE - STANDARD

PROCEDURE)

(1) Install solenoid/pressure switch assembly and

new gasket to transaxle (Fig. 308).

(2) Install and torque three (3) bolts (Fig. 307) to

13 N´m (110 in. lbs.).

(3) Install input speed sensor (Fig. 306) and torque

to 27 N´m (20 ft. lbs.).

(4) Connect input speed sensor connector (Fig.

305).

(5) Install solenoid/pressure switch 8-way connec-

tor and torque to 4 N´m (35 in. lbs.) (Fig. 305).

(6) Install air cleaner assembly.

(7) Connect battery negative cable.

(8) If solenoid/pressure switch assembly was

replaced, perform the ªQuick-Learnº procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

Fig. 306 Input Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 307 Solenoid/Pressure Switch Assembly-to-

Case Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 308 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

21 - 270 41TE AUTOMATIC TRANSAXLERS

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 1733 of 2339

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect input speed sensor connector (Fig.

312).

(3) Unscrew and remove input speed sensor (Fig.

313).

(4) Inspect speed sensor o-ring (Fig. 314) and

replace if necessary.

INSTALLATION

(1) Verify o-ring is installed into position (Fig.

314).

(2) Install and tighten input speed sensor to 27

N´m (20 ft. lbs.) (Fig. 313).

(3) Connect speed sensor connector (Fig. 312).

(4) Connect battery negative cable.

Fig. 312 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 313 Input (Turbine) Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 314 O-ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

21 - 272 41TE AUTOMATIC TRANSAXLERS

SPEED SENSOR - INPUT (Continued)