tire pressure CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1413 of 2339

STEERING WHEEL FEEL

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL/

COLUMN CLICKING,

CLUNKING OR RATTLING.1. Loose steering coupling pinch

bolt.1. Replace pinch bolt and torque to

specifications.

2. Steering column bearings. 2. Replace steering column.

3. Excessive intermediate shaft

coupling free-play.3. Replace intermediate shaft.

STEERING WHEEL HAS

FORE AND AFT

LOOSENESS.1. Steering wheel retaining nut not

properly tightened and torqued.1. Tighten the steering wheel retaining nut

to its specified torque.

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

3. Loose steering column to

instrument panel fasteners.3. Tighten fasteners to specified torque.

STEERING WHEEL, DASH

OR VEHICLE VIBRATES

DURING LOW SPEED OR

STANDSTILL STEERING

MANEUVERS.1. Air in the fluid of the power

steering system.1. Bleed air from system following the

power steering pump initial operation

service procedure.*

2. Tires not properly inflated. 2. Inflate tires to the specified pressure.

3. Excessive engine vibration. 3. Ensure that the engine is tuned properly.

4. Loose tie rod end jam nut. 4. Tighten the inner to outer tie rod jam nut

to the specified torque.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure and correct as necessary.

6. Grounded engine mount. 6. Repair as necessary.

7. Loose outer tie rod. 7. Replace outer tie rod.

STEERING CATCHES,

SURGES OR STICKS IN

CERTAIN POSITIONS OR

IS DIFFICULT TO TURN. ***1. Low power steering fluid level. 1. Fill power steering fluid reservoir to

specified level and check for leaks.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified pressure.

3. Lack of lubrication in front lower

control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated-for-life type ball joint. If ball joint

is a lubricated-for-life ball joint, replace ball

joint.

4. Worn or binding lower control arm

ball joint.4. Replace lower control arm ball joint.

5. Lack of lubrication in steering gear

outer tie rod ends.5. Lubricate tie rod ends if they are not a

lubricated-for-life type. If tie rod end is a

lubricated-for-life type, replace tie rod end.

19 - 6 STEERINGRS

STEERING (Continued)

Page 1414 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

6. Loose power steering pump drive

belt.6. Tighten the power steering pump drive

belt to specifications or replace automatic

tensioner where applicable. If drive belt is

worn or glazed, replace belt.

7. Faulty power steering pump

(Perform Power Steering Flow and

Pressure Test).7. Replace power steering pump.

8. Faulty power steering gear

(Perform Power Steering Flow and

Pressure Test).8. Replace power steering gear.

9. Excessive friction in steering

column or intermediate shaft/coupler.9. Isolate and correct condition.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

11. Worn or binding seat and bearing

in front strut assembly.11. Replace seat and bearing in front strut

assembly.

STEERING WHEEL DOES

NOT RETURN TO

CENTER POSITION.1. Tires not inflated properly. 1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust wheel alignment as

necessary.

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mispositioned or

unlubricated steering column coupler

to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding mount bearing in front

strut assembly.7. Replace mount bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

RSSTEERING19-7

STEERING (Continued)

Page 1439 of 2339

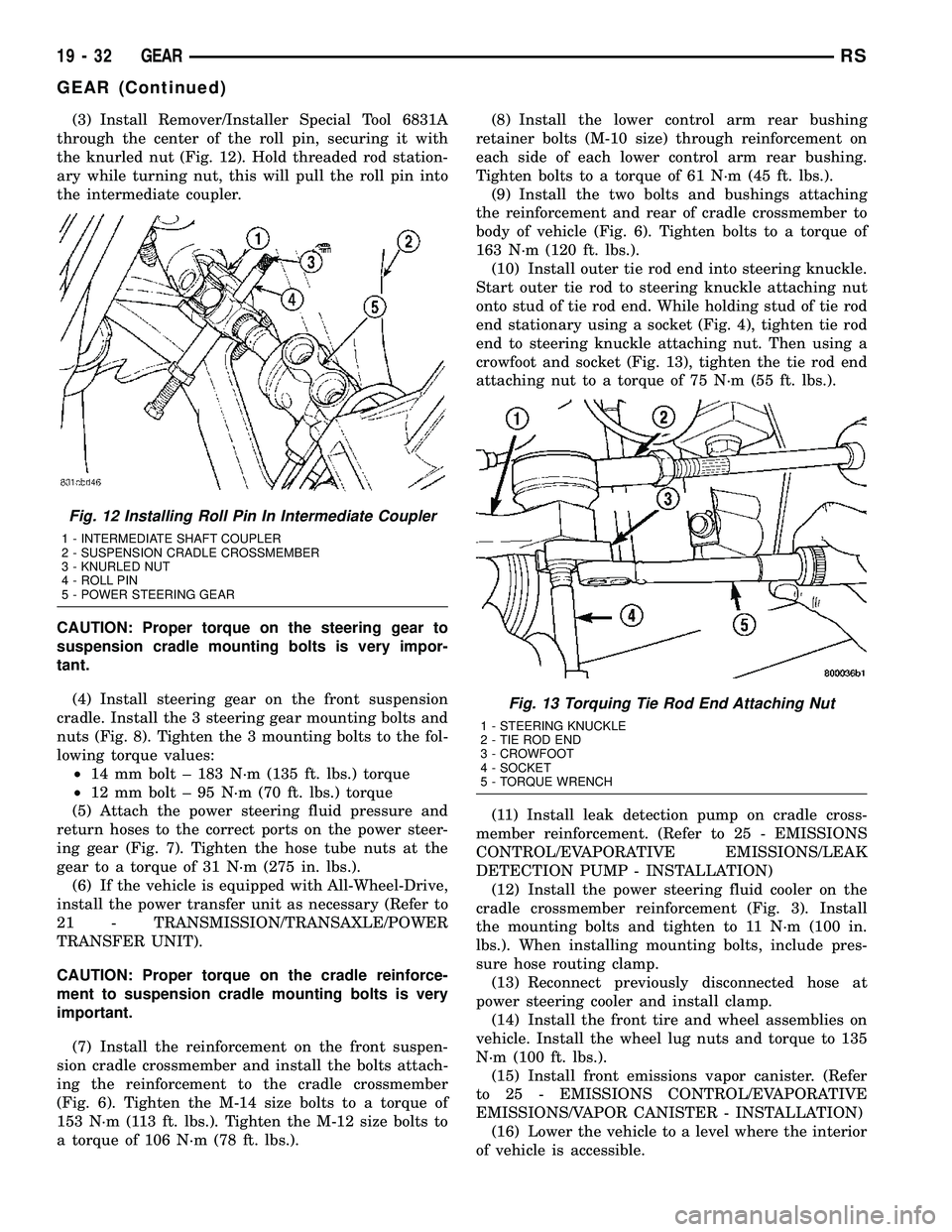

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 12). Hold threaded rod station-

ary while turning nut, this will pull the roll pin into

the intermediate coupler.

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(4) Install steering gear on the front suspension

cradle. Install the 3 steering gear mounting bolts and

nuts (Fig. 8). Tighten the 3 mounting bolts to the fol-

lowing torque values:

²14 mm bolt ± 183 N´m (135 ft. lbs.) torque

²12 mm bolt ± 95 N´m (70 ft. lbs.) torque

(5) Attach the power steering fluid pressure and

return hoses to the correct ports on the power steer-

ing gear (Fig. 7). Tighten the hose tube nuts at the

gear to a torque of 31 N´m (275 in. lbs.).

(6) If the vehicle is equipped with All-Wheel-Drive,

install the power transfer unit as necessary (Refer to

21 - TRANSMISSION/TRANSAXLE/POWER

TRANSFER UNIT).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(7) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 6). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).(8) Install the lower control arm rear bushing

retainer bolts (M-10 size) through reinforcement on

each side of each lower control arm rear bushing.

Tighten bolts to a torque of 61 N´m (45 ft. lbs.).

(9) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 6). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

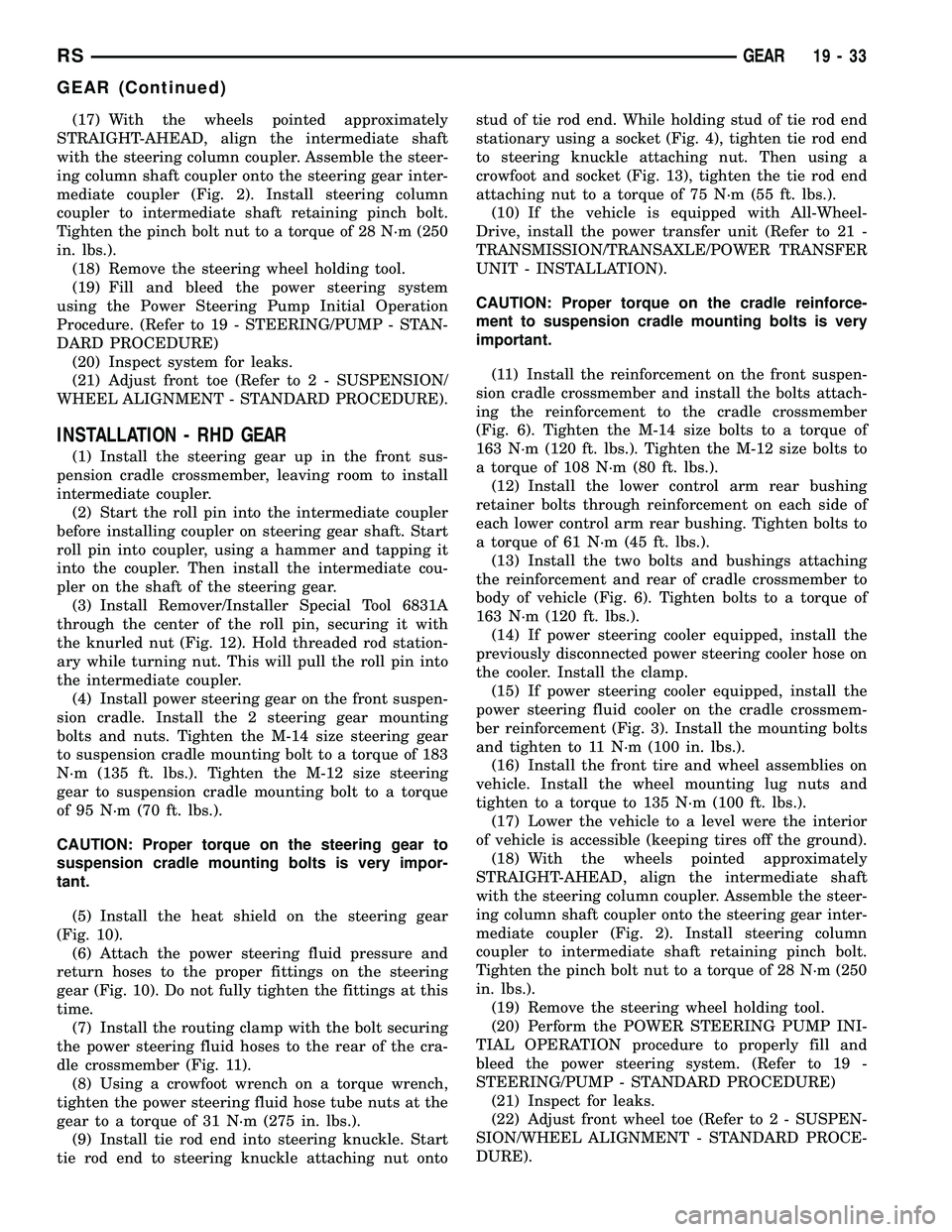

(10) Install outer tie rod end into steering knuckle.

Start outer tie rod to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary using a socket (Fig. 4), tighten tie rod

end to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 13), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(11) Install leak detection pump on cradle cross-

member reinforcement. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE EMISSIONS/LEAK

DETECTION PUMP - INSTALLATION)

(12) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 3). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.). When installing mounting bolts, include pres-

sure hose routing clamp.

(13) Reconnect previously disconnected hose at

power steering cooler and install clamp.

(14) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 135

N´m (100 ft. lbs.).

(15) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(16) Lower the vehicle to a level where the interior

of vehicle is accessible.

Fig. 12 Installing Roll Pin In Intermediate Coupler

1 - INTERMEDIATE SHAFT COUPLER

2 - SUSPENSION CRADLE CROSSMEMBER

3 - KNURLED NUT

4 - ROLL PIN

5 - POWER STEERING GEAR

Fig. 13 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

19 - 32 GEARRS

GEAR (Continued)

Page 1440 of 2339

(17) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(18) Remove the steering wheel holding tool.

(19) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(20) Inspect system for leaks.

(21) Adjust front toe (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION - RHD GEAR

(1) Install the steering gear up in the front sus-

pension cradle crossmember, leaving room to install

intermediate coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 12). Hold threaded rod station-

ary while turning nut. This will pull the roll pin into

the intermediate coupler.

(4) Install power steering gear on the front suspen-

sion cradle. Install the 2 steering gear mounting

bolts and nuts. Tighten the M-14 size steering gear

to suspension cradle mounting bolt to a torque of 183

N´m (135 ft. lbs.). Tighten the M-12 size steering

gear to suspension cradle mounting bolt to a torque

of 95 N´m (70 ft. lbs.).

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Install the heat shield on the steering gear

(Fig. 10).

(6) Attach the power steering fluid pressure and

return hoses to the proper fittings on the steering

gear (Fig. 10). Do not fully tighten the fittings at this

time.

(7) Install the routing clamp with the bolt securing

the power steering fluid hoses to the rear of the cra-

dle crossmember (Fig. 11).

(8) Using a crowfoot wrench on a torque wrench,

tighten the power steering fluid hose tube nuts at the

gear to a torque of 31 N´m (275 in. lbs.).

(9) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut ontostud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 4), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 13), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(10) If the vehicle is equipped with All-Wheel-

Drive, install the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(11) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 6). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(12) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(13) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 6). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(14) If power steering cooler equipped, install the

previously disconnected power steering cooler hose on

the cooler. Install the clamp.

(15) If power steering cooler equipped, install the

power steering fluid cooler on the cradle crossmem-

ber reinforcement (Fig. 3). Install the mounting bolts

and tighten to 11 N´m (100 in. lbs.).

(16) Install the front tire and wheel assemblies on

vehicle. Install the wheel mounting lug nuts and

tighten to a torque to 135 N´m (100 ft. lbs.).

(17) Lower the vehicle to a level were the interior

of vehicle is accessible (keeping tires off the ground).

(18) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(19) Remove the steering wheel holding tool.

(20) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(21) Inspect for leaks.

(22) Adjust front wheel toe (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

RSGEAR19-33

GEAR (Continued)

Page 1450 of 2339

INSTALLATION

INSTALLATION - PUMP (2.4L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket (Fig. 7), then install the nut and

bolt attaching the front bracket to the cast bracket

(Fig. 8).Do not fully tighten at this time..

(3) Install the rear nut (Fig. 7).

(4) Install the power steering pump drive belt on

pulley and adjust (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - INSTALLATION).

(5) Tighten the two adjustment slot bolts and the

one pivot bolt to 54 N´m (40 ft. lbs.) torque.

(6) Install the accessory drive splash shield.

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(7) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 6). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(8) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 6).Be sure hose clamps are properly

reinstalled.

(9) Install the power steering fluid supply hose on

the power steering pump fluid fitting.Be sure hose

is clear of accessory drive belts all hose clamps

are properly reinstalled.

CAUTION: Heat sleeve must cover entire rubber

portion of return hose to ensure desired thermal

protection from exhaust.

(10) Properly position the protective heat sleeve

over the power steering return hose. Securely tie

strap the heat sleeve to the power steering hose to

keep in it's proper position.

(11)

Install the exhaust system (Fig. 4). Install all

exhaust system isolators/hangers on the exhaust sys-

tem brackets, then the four bolts and flag nuts (Fig. 3).

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness.

(13) Lower vehicle.

(14) Connect the negative battery cable on the

negative battery post.

(15) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(16) Inspect for leaks.

INSTALLATION - PUMP (3.3L/3.8L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

engine compartment of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket.

(3) Install the 3 front power steering pump mount-

ing bolts (Fig. 11). Tighten the 3 front power steering

pump mounting bolts to a torque of 54 N´m (40 ft.

lbs.).

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure line

into the pressure output fitting of the power steering

pump (Fig. 10).Do not fully tighten tube nut at

this time.

(5) Install the power steering fluid supply hose on

the power steering pump supply fitting (Fig. 10).Be

sure hose clamp is properly installed.

(6) Raise the vehicle.

(7) Install the routing clip on the engine for the

pressure hose (Fig. 9) and tighten fastener.

(8) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(9) Install the drive belt splash shield.

(10) Lower the vehicle.

(11) Tighten the pressure line to pump pressure

fitting tube nut to a torque of 31 N´m (275 in. lbs.).

(12) Install the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(13) Connect the negative battery cable on the

negative battery post.

(14) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(15) Inspect for leaks.

INSTALLATION - PUMP (DIESEL)

(1) Install the power steering pump on its cast

mounting bracket.

(2) Install the three front power steering pump

mounting bolts. Tighten the mounting bolts to a

torque of 54 N´m (40 ft. lbs.).

(3) Install the rear mounting bolt fastening the

stamped bracket to the cast bracket (Fig. 13).

Tighten the mounting bolt to a torque of 54 N´m (40

ft. lbs.).

RSPUMP19-43

PUMP (Continued)

Page 1512 of 2339

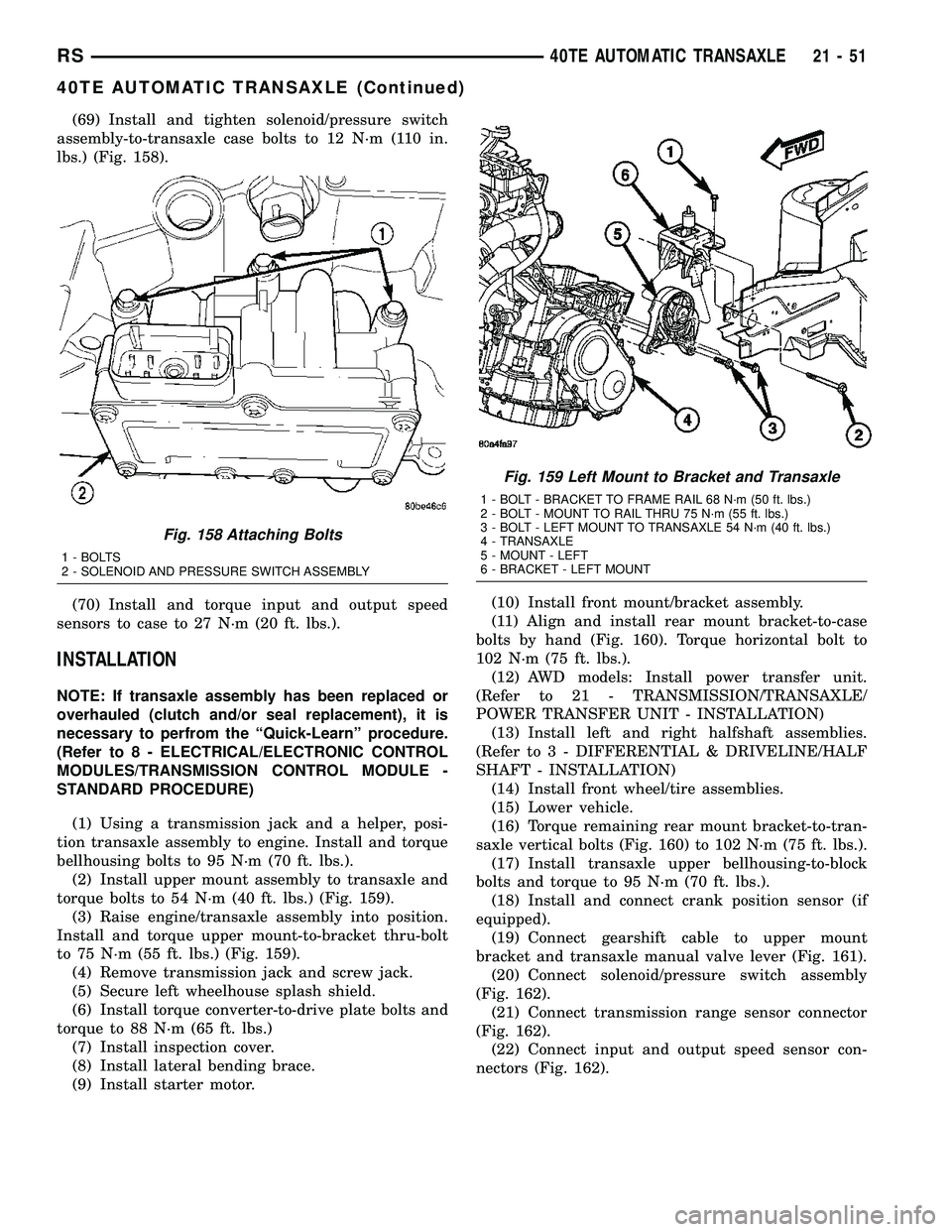

(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 158).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the ªQuick-Learnº procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 159).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 159).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.(10) Install front mount/bracket assembly.

(11) Align and install rear mount bracket-to-case

bolts by hand (Fig. 160). Torque horizontal bolt to

102 N´m (75 ft. lbs.).

(12) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(13) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 160) to 102 N´m (75 ft. lbs.).

(17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(18) Install and connect crank position sensor (if

equipped).

(19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 161).

(20) Connect solenoid/pressure switch assembly

(Fig. 162).

(21) Connect transmission range sensor connector

(Fig. 162).

(22) Connect input and output speed sensor con-

nectors (Fig. 162).

Fig. 158 Attaching Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 159 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

RS40TE AUTOMATIC TRANSAXLE21-51

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1610 of 2339

TRANSAXLE IDENTIFICATION

The 41TE transaxle is identified by a barcode label

that is fixed to the transaxle case as shown in (Fig.

2).

The label contains a series of digits that can be

translated into useful information such as transaxle

part number, date of manufacture, manufacturing

origin, plant shift number, build sequence number,

etc. Refer to (Fig. 3) for identification label break-

down.

If the tag is not legible or missing, the ªPKº num-

ber, which is stamped into the transaxle case behind

the transfer gear cover, can be referred to for identi-

fication. This number differs slightly in that it con-

tains the entire transaxle part number, rather than

the last three digits.

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

First...............................2.84 : 1

Second.............................1.57 : 1

Third..............................1.00 : 1

Overdrive...........................0.69 : 1

Reverse............................2.21 : 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 4XTE TRANSAXLE

GENERAL DIAGNOSIS

NOTE: Before attempting any repair on a 4XTE four-

speed automatic transaxle, check for diagnostic trou-

ble codes (DTC's) using the DRB scan tool. Refer to

the Transmission Diagnostic Procedures Manual.

Transaxle malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or that more diagnosis is necessary. If the

problem persists after the preliminary tests and cor-

rections are completed, hydraulic pressure checks

should be performed.

Fig. 2 Transaxle Identification Label

1 - IDENTIFICATION LABEL

Fig. 3 Identification Label Breakdown

1 - T=TRACEABILITY

2 - SUPPLIER CODE (PK=KOKOMO)

3 - COMPONENT CODE (TK=KOKOMO TRANSMISSION)

4 - BUILD DAY (344=DEC. 9)

5 - BUILD YEAR (9=1999)

6 - LINE/SHIFT CODE (3=3RD SHIFT)

7 - BUILD SEQUENCE NUMBER

8 - LAST THREE OF P/N

9 - ALPHA

10 - TRANSAXLE PART NUMBER

11 - P=PART NUMBER

RS41TE AUTOMATIC TRANSAXLE21 - 149

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1657 of 2339

(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 158).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the ªQuick-Learnº procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 159).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 159).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

(11) Align and install rear mount bracket-to-case

bolts by hand (Fig. 160). Torque horizontal bolt to

102 N´m (75 ft. lbs.).(12) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(13) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(14) Install front wheel/tire assemblies.

(15) Lower vehicle.

(16) Torque remaining rear mount bracket-to-tran-

saxle vertical bolts (Fig. 160) to 102 N´m (75 ft. lbs.).

(17) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(18) Install and connect crank position sensor (if

equipped).

(19) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 161).

(20) Connect solenoid/pressure switch assembly

(Fig. 162).

(21) Connect transmission range sensor connector

(Fig. 162).

(22) Connect input and output speed sensor con-

nectors (Fig. 162).

(23) Remove plugs and connect transaxle oil cooler

lines. (Refer to 7 - COOLING/TRANSMISSION -

STANDARD PROCEDURE)

(24) Remove plug and Install fluid level indicator/

tube assembly.

Fig. 158 Solenoid Pack-to-Transaxle Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 159 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

21 - 196 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1758 of 2339

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL VIBRATION.....................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................5

STANDARD PROCEDURE - TIRE AND

WHEEL MATCH MOUNTING..............7

STANDARD PROCEDURE - TIRE AND

WHEEL ROTATION.....................7

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)....................8

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL).......................8

INSTALLATION

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (ALUMINUM WHEEL)..........8

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (STEEL WHEEL)..............8

TIRE PRESSURE MONITORING

DESCRIPTION..........................9

OPERATION...........................10

SENSOR - TPM

DESCRIPTION.........................10

OPERATION...........................10

CAUTION.............................11

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR............................11

REMOVAL.............................11

INSTALLATION.........................11

TIRES

DESCRIPTION

DESCRIPTION - TIRE..................13

DESCRIPTION - RADIAL-PLY TIRES.......13

DESCRIPTION - REPLACEMENT TIRES....14

DESCRIPTION - SPARE TIRE

(TEMPORARY).......................14DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE . . . 14

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD...............................14

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS..........................16

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS.........................16

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE INFLATION

PRESSURES.........................16

STANDARD PROCEDURE - TIRE

PRESSURE FOR HIGH SPEED

OPERATION.........................17

STANDARD PROCEDURE - TIRE LEAK

REPAIRING..........................17

CLEANING - TIRES.....................18

WHEELS

DESCRIPTION - WHEEL..................18

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................19

CLEANING

WHEEL AND WHEEL TRIM CARE.........19

SPECIFICATIONS

WHEEL.............................19

WHEEL COVER

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................20

WHEEL MOUNTING STUDS - FRONT

REMOVAL.............................21

INSTALLATION.........................21

WHEEL MOUNTING STUDS - REAR

REMOVAL.............................22

INSTALLATION.........................22

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

VIBRATION

Tire and wheel imbalance, runout and force varia-

tion can cause vehicles to exhibit steering wheel

vibration.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended

prior to road testing or performing any other proce-

dure. Raise vehicle on a suitable hoist. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

Inspect for the following:

²Verify correct (OEM) wheel and tire, as well as

correct wheel weights. Aluminum wheels require

RSTIRES/WHEELS22-1

Page 1759 of 2339

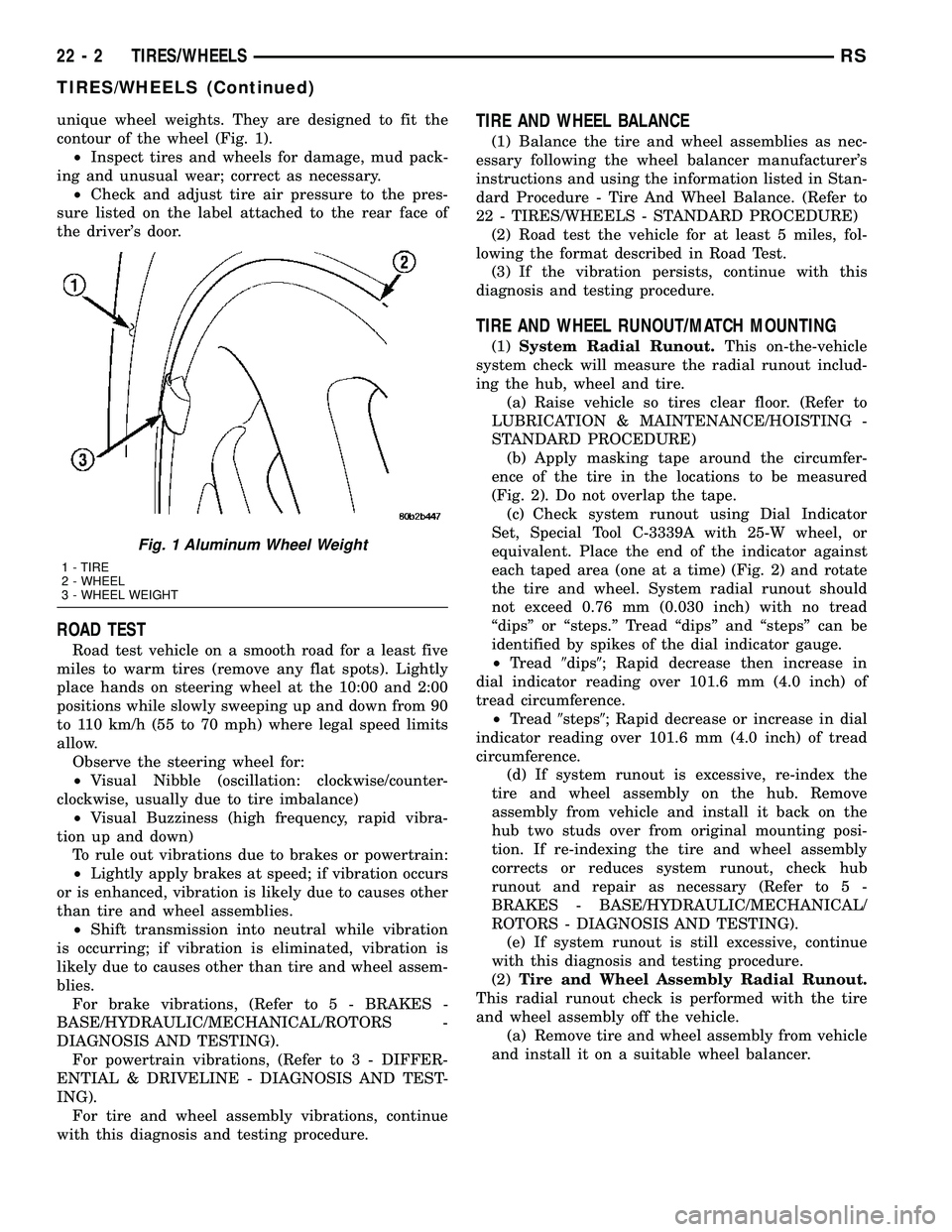

unique wheel weights. They are designed to fit the

contour of the wheel (Fig. 1).

²Inspect tires and wheels for damage, mud pack-

ing and unusual wear; correct as necessary.

²Check and adjust tire air pressure to the pres-

sure listed on the label attached to the rear face of

the driver's door.

ROAD TEST

Road test vehicle on a smooth road for a least five

miles to warm tires (remove any flat spots). Lightly

place hands on steering wheel at the 10:00 and 2:00

positions while slowly sweeping up and down from 90

to 110 km/h (55 to 70 mph) where legal speed limits

allow.

Observe the steering wheel for:

²Visual Nibble (oscillation: clockwise/counter-

clockwise, usually due to tire imbalance)

²Visual Buzziness (high frequency, rapid vibra-

tion up and down)

To rule out vibrations due to brakes or powertrain:

²Lightly apply brakes at speed; if vibration occurs

or is enhanced, vibration is likely due to causes other

than tire and wheel assemblies.

²Shift transmission into neutral while vibration

is occurring; if vibration is eliminated, vibration is

likely due to causes other than tire and wheel assem-

blies.

For brake vibrations, (Refer to 5 - BRAKES -

BASE/HYDRAULIC/MECHANICAL/ROTORS -

DIAGNOSIS AND TESTING).

For powertrain vibrations, (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE - DIAGNOSIS AND TEST-

ING).

For tire and wheel assembly vibrations, continue

with this diagnosis and testing procedure.

TIRE AND WHEEL BALANCE

(1) Balance the tire and wheel assemblies as nec-

essary following the wheel balancer manufacturer's

instructions and using the information listed in Stan-

dard Procedure - Tire And Wheel Balance. (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE)

(2) Road test the vehicle for at least 5 miles, fol-

lowing the format described in Road Test.

(3) If the vibration persists, continue with this

diagnosis and testing procedure.

TIRE AND WHEEL RUNOUT/MATCH MOUNTING

(1)System Radial Runout.This on-the-vehicle

system check will measure the radial runout includ-

ing the hub, wheel and tire.

(a) Raise vehicle so tires clear floor. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(b) Apply masking tape around the circumfer-

ence of the tire in the locations to be measured

(Fig. 2). Do not overlap the tape.

(c) Check system runout using Dial Indicator

Set, Special Tool C-3339A with 25-W wheel, or

equivalent. Place the end of the indicator against

each taped area (one at a time) (Fig. 2) and rotate

the tire and wheel. System radial runout should

not exceed 0.76 mm (0.030 inch) with no tread

ªdipsº or ªsteps.º Tread ªdipsº and ªstepsº can be

identified by spikes of the dial indicator gauge.

²Tread9dips9; Rapid decrease then increase in

dial indicator reading over 101.6 mm (4.0 inch) of

tread circumference.

²Tread9steps9; Rapid decrease or increase in dial

indicator reading over 101.6 mm (4.0 inch) of tread

circumference.

(d) If system runout is excessive, re-index the

tire and wheel assembly on the hub. Remove

assembly from vehicle and install it back on the

hub two studs over from original mounting posi-

tion. If re-indexing the tire and wheel assembly

corrects or reduces system runout, check hub

runout and repair as necessary (Refer to 5 -

BRAKES - BASE/HYDRAULIC/MECHANICAL/

ROTORS - DIAGNOSIS AND TESTING).

(e) If system runout is still excessive, continue

with this diagnosis and testing procedure.

(2)Tire and Wheel Assembly Radial Runout.

This radial runout check is performed with the tire

and wheel assembly off the vehicle.

(a) Remove tire and wheel assembly from vehicle

and install it on a suitable wheel balancer.

Fig. 1 Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - WHEEL WEIGHT

22 - 2 TIRES/WHEELSRS

TIRES/WHEELS (Continued)