weight CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1191 of 2339

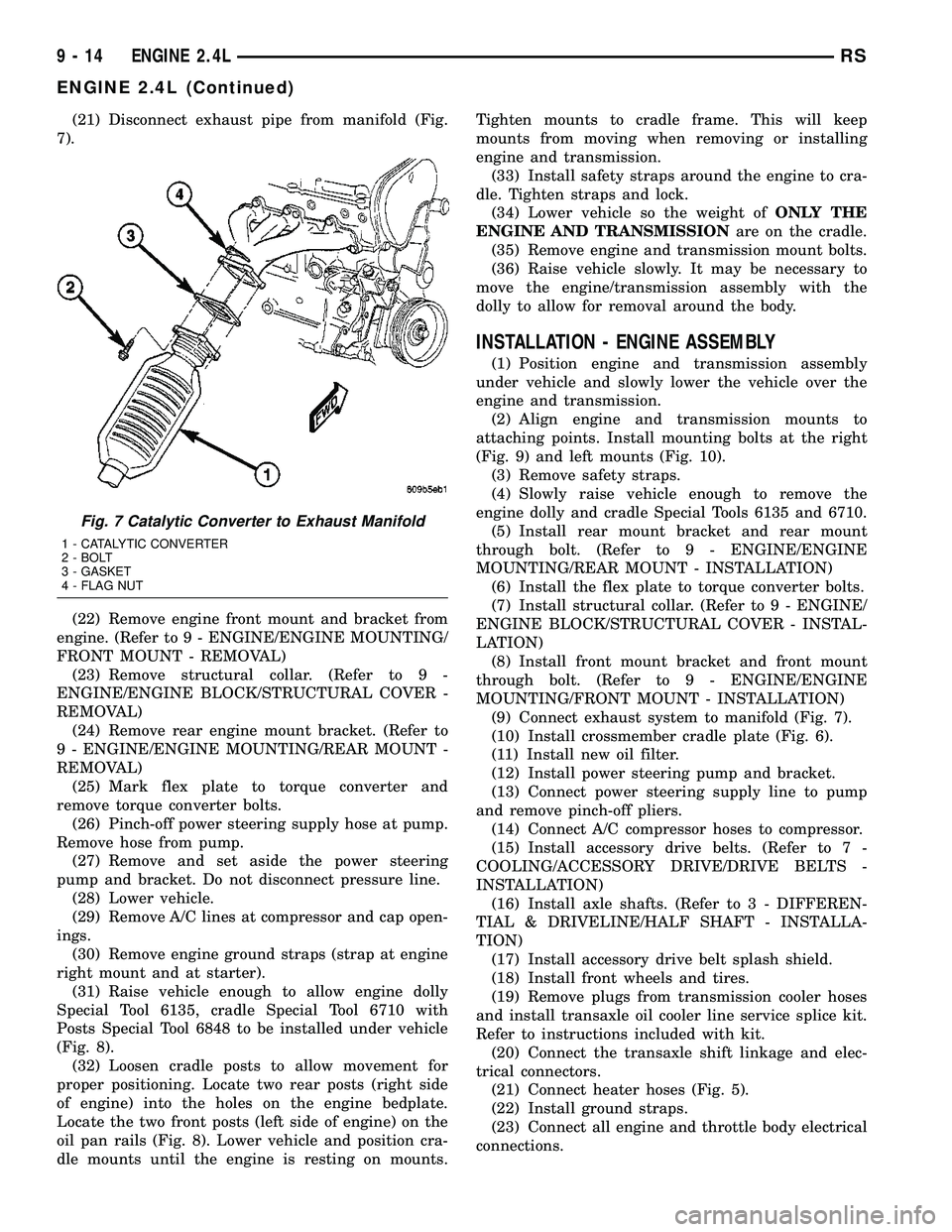

(21) Disconnect exhaust pipe from manifold (Fig.

7).

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(24) Remove rear engine mount bracket. (Refer to

9 - ENGINE/ENGINE MOUNTING/REAR MOUNT -

REMOVAL)

(25) Mark flex plate to torque converter and

remove torque converter bolts.

(26) Pinch-off power steering supply hose at pump.

Remove hose from pump.

(27) Remove and set aside the power steering

pump and bracket. Do not disconnect pressure line.

(28) Lower vehicle.

(29) Remove A/C lines at compressor and cap open-

ings.

(30) Remove engine ground straps (strap at engine

right mount and at starter).

(31) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 to be installed under vehicle

(Fig. 8).

(32) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

oil pan rails (Fig. 8). Lower vehicle and position cra-

dle mounts until the engine is resting on mounts.Tighten mounts to cradle frame. This will keep

mounts from moving when removing or installing

engine and transmission.

(33) Install safety straps around the engine to cra-

dle. Tighten straps and lock.

(34) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(35) Remove engine and transmission mount bolts.

(36) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly with the

dolly to allow for removal around the body.

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.

(13) Connect power steering supply line to pump

and remove pinch-off pliers.

(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

9 - 14 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1194 of 2339

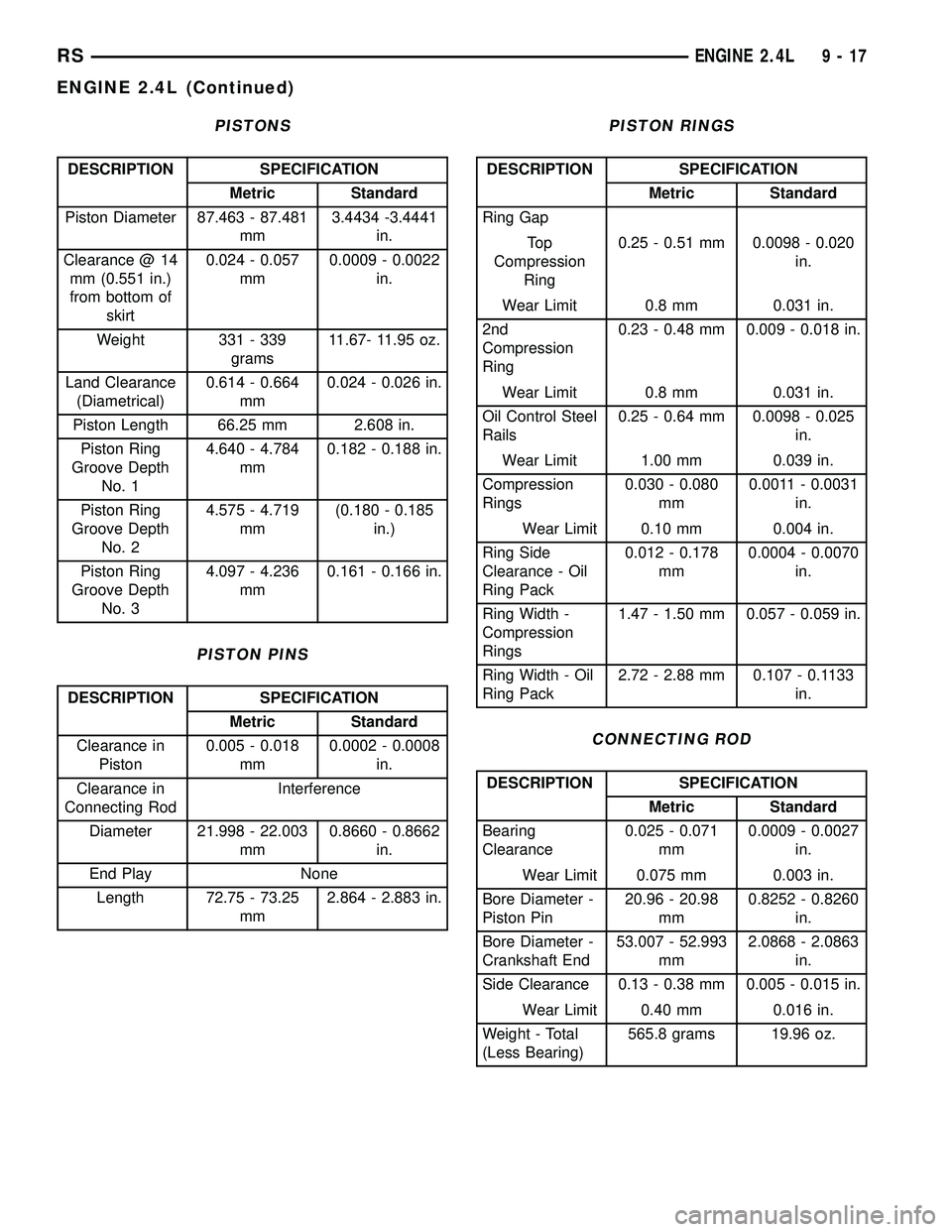

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Piston Diameter 87.463 - 87.481

mm3.4434 -3.4441

in.

Clearance @ 14

mm (0.551 in.)

from bottom of

skirt0.024 - 0.057

mm0.0009 - 0.0022

in.

Weight 331 - 339

grams11.67- 11.95 oz.

Land Clearance

(Diametrical)0.614 - 0.664

mm0.024 - 0.026 in.

Piston Length 66.25 mm 2.608 in.

Piston Ring

Groove Depth

No. 14.640 - 4.784

mm0.182 - 0.188 in.

Piston Ring

Groove Depth

No. 24.575 - 4.719

mm(0.180 - 0.185

in.)

Piston Ring

Groove Depth

No. 34.097 - 4.236

mm0.161 - 0.166 in.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Clearance in

Piston0.005 - 0.018

mm0.0002 - 0.0008

in.

Clearance in

Connecting RodInterference

Diameter 21.998 - 22.003

mm0.8660 - 0.8662

in.

End Play None

Length 72.75 - 73.25

mm2.864 - 2.883 in.

PISTON RINGS

DESCRIPTION SPECIFICATION

Metric Standard

Ring Gap

To p

Compression

Ring0.25 - 0.51 mm 0.0098 - 0.020

in.

Wear Limit 0.8 mm 0.031 in.

2nd

Compression

Ring0.23 - 0.48 mm 0.009 - 0.018 in.

Wear Limit 0.8 mm 0.031 in.

Oil Control Steel

Rails0.25 - 0.64 mm 0.0098 - 0.025

in.

Wear Limit 1.00 mm 0.039 in.

Compression

Rings0.030 - 0.080

mm0.0011 - 0.0031

in.

Wear Limit 0.10 mm 0.004 in.

Ring Side

Clearance - Oil

Ring Pack0.012 - 0.178

mm0.0004 - 0.0070

in.

Ring Width -

Compression

Rings1.47 - 1.50 mm 0.057 - 0.059 in.

Ring Width - Oil

Ring Pack2.72 - 2.88 mm 0.107 - 0.1133

in.

CONNECTING ROD

DESCRIPTION SPECIFICATION

Metric Standard

Bearing

Clearance0.025 - 0.071

mm0.0009 - 0.0027

in.

Wear Limit 0.075 mm 0.003 in.

Bore Diameter -

Piston Pin20.96 - 20.98

mm0.8252 - 0.8260

in.

Bore Diameter -

Crankshaft End53.007 - 52.993

mm2.0868 - 2.0863

in.

Side Clearance 0.13 - 0.38 mm 0.005 - 0.015 in.

Wear Limit 0.40 mm 0.016 in.

Weight - Total

(Less Bearing)565.8 grams 19.96 oz.

RSENGINE 2.4L9-17

ENGINE 2.4L (Continued)

Page 1217 of 2339

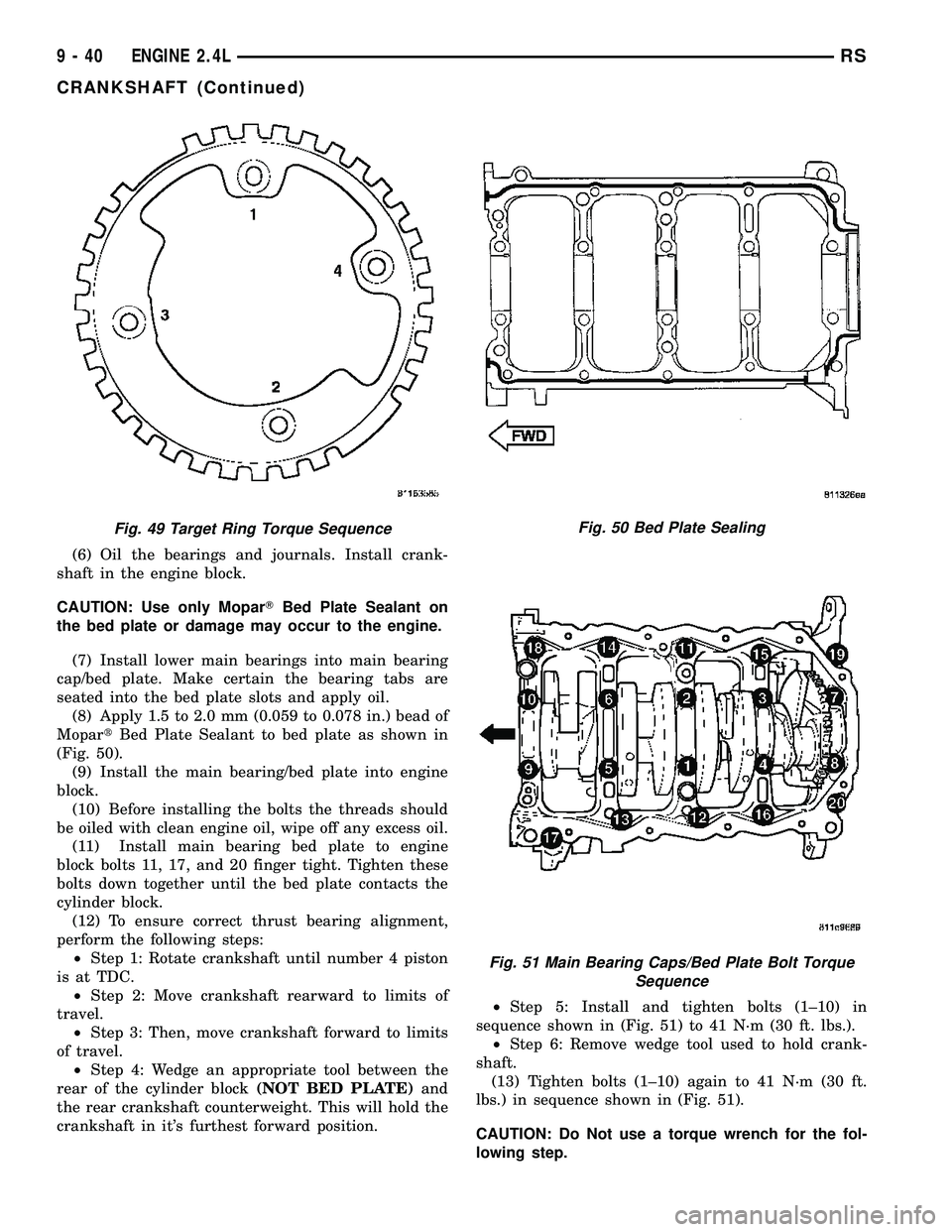

(6) Oil the bearings and journals. Install crank-

shaft in the engine block.

CAUTION: Use only MoparTBed Plate Sealant on

the bed plate or damage may occur to the engine.

(7) Install lower main bearings into main bearing

cap/bed plate. Make certain the bearing tabs are

seated into the bed plate slots and apply oil.

(8) Apply 1.5 to 2.0 mm (0.059 to 0.078 in.) bead of

MopartBed Plate Sealant to bed plate as shown in

(Fig. 50).

(9) Install the main bearing/bed plate into engine

block.

(10) Before installing the bolts the threads should

be oiled with clean engine oil, wipe off any excess oil.

(11) Install main bearing bed plate to engine

block bolts 11, 17, and 20 finger tight. Tighten these

bolts down together until the bed plate contacts the

cylinder block.

(12) To ensure correct thrust bearing alignment,

perform the following steps:

²Step 1: Rotate crankshaft until number 4 piston

is at TDC.

²Step 2: Move crankshaft rearward to limits of

travel.

²Step 3: Then, move crankshaft forward to limits

of travel.

²Step 4: Wedge an appropriate tool between the

rear of the cylinder block(NOT BED PLATE)and

the rear crankshaft counterweight. This will hold the

crankshaft in it's furthest forward position.²Step 5: Install and tighten bolts (1±10) in

sequence shown in (Fig. 51) to 41 N´m (30 ft. lbs.).

²Step 6: Remove wedge tool used to hold crank-

shaft.

(13) Tighten bolts (1±10) again to 41 N´m (30 ft.

lbs.) in sequence shown in (Fig. 51).

CAUTION: Do Not use a torque wrench for the fol-

lowing step.

Fig. 49 Target Ring Torque SequenceFig. 50 Bed Plate Sealing

Fig. 51 Main Bearing Caps/Bed Plate Bolt Torque

Sequence

9 - 40 ENGINE 2.4LRS

CRANKSHAFT (Continued)

Page 1267 of 2339

(41) Disconnect the knock sensor electrical connec-

tor (3.8L only).

(42) Disconnect the engine block heater electrical

connector (if equipped).

(43) Remove the accessory belt splash shield.

(44) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(45) Disconnect the radiator lower hose.

(46) Remove air conditioning compressor from

engine.

(47) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(48) Remove the water pump pulley attaching

bolts and position pulley between pump hub and

housing.

(49) Disconnect the oil pressure switch electrical

connector.

(50) Disconnect wiring harness support clip from

engine oil dipstick tube.

(51) Install Special Tools 6912 and 8444 Adapters

on the right side (rear) of engine block (Fig. 9).

(52) Lower the vehicle.

(53) Remove the power steering pump and set

aside.(54) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 12).

(55) Loosen cradle/post mounts to allow movement

for positioning posts into locating holes on the engine

(Fig. 10) and (Fig. 11). Slowly lower vehicle and posi-

tion cradle/post mounts until the engine is resting on

posts. Tighten all cradle/post mounts to cradle frame.

This will keep mounts from moving when removing

or installing engine and transmission.

(56) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(57) Install and secure the safety straps to the cra-

dle fixture and around the engine (Fig. 12).

(58) Remove the engine right side mount to engine

attaching bolts (Fig. 13).

(59) Remove the left mount through bolt (Fig. 14).

Fig. 8 POWERTRAIN SUPPORTS AND DUST COVER

1 - BRACKET - ENGINE REAR MOUNT

2 - BOLT - TRANSAXLE CASE COVER

3 - STRUT - TRANSAXLE TO ENGINE HORIZONTAL

4 - BOLT - HORIZONTAL STRUT

5 - BOLT - STRUT TO TRANSAXLE

6 - COVER - TRANSAXLE CASE LOWER

7 - STRUT - TRANSAXLE TO ENGINE

8 - BOLT - STRUT TO ENGINE

9 - BOLT - ENGINE REAR MOUNT BRACKET

Fig. 9 ADAPTER TOOLS MOUNTED ON BLOCK

1 - SPECIAL TOOL 6912

2 - SPECIAL TOOL 8444

Fig. 10 Positioning Special Tool 6848 for use with

Adapters 8444 & 6912

1 - SLOTS

2 - SPECIAL TOOLS 6848

9 - 90 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1271 of 2339

CONNECTING RODS

DESCRIPTION SPECIFICATION

Metric Standard

Bearing

Clearance0.019-0.065

mm.0.017-0.020 in.

Wear Limit 0.074 mm 0.003 in.

Side Clearance 0.13-0.32 mm 0.005-0.013 in.

Wear Limit 0.38 mm 0.015 in.

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Piston Diameter

3.3L-Measured

39.8 mm (1.567

in) From Piston

To p92.968-92.998

mm.3.660-3.661 in.

Piston Diameter

3.8L-Measured

33.01 mm (1.30

in) From Piston

To p95.968-95.998

mm.3.778-3.779 in.

Clearance in

Bore @ Size

Location (New)-0.005-0.039

mm-0.0002±0.0015

in.

Weight 3.3L 362 5 grams 12.77 0.1764

oz.

Weight 3.8L 426 5 grams 15.03 0.1764

oz.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Type Press Fit in Rod (Serviced as a

Assembly)

Clearance in

Piston @ 21C

(70ÉF)0.006-0.019

mm0.0002-0.0007

in.

Clearance in

Connecting RodInterference Fit

Diameter 22.87-22.88

mm0.9007-0.9009

in.

Length 3.3L 67.25-67.75

mm2.648-2.667 in.

Length 3.8L 71.25-71.75

mm2.805-2.824 in.

PISTON RINGS

DESCRIPTION SPECIFICATION

Metric Standard

Ring End Gap

To p

Compression

Ring0.18-0.38 mm 0.007-0.015 in.

Second

Compression

Ring0.28-0.57 mm 0.011-0.022 in.

Oil Control

(Steel Rails)0.23-0.78 mm 0.009-0.030 in.

Wear Limit-

Compression

Rings1.0 mm 0.039 in.

Wear Limit-Oil

Control Steel

Rails1.88 mm 0.074 in.

Ring Side

Clearance

To p

Compression

Ring 3.3L0.030-0.080

mm0.0012-0.0031

in.

To p

Compression

Ring 3.8L0.030-0.069

mm0.0012-0.0027

in.

Second

Compression

Ring 3.3L0.030-0.095

mm0.0012-0.0037

in.

Second

Compression

Ring 3.8L0.041-0.085

mm0.0016-0.0033

in.

Oil Ring (Steel

Ring)0.039-0.200

mm0.0015-0.0078

in.

Wear Limit- Top

Ring0.10 mm 0.004 in.

Wear Limit-2nd

Ring0.13 mm 0.005

Wear Limit Oil

Ring Pack0.266 mm 0.009

Ring Width-Top

Compression

Ring 3.3L1.46-1.49 mm 0.0575-0.058 in.

Ring Width-Top

Compression

Ring 3.8L1.175-1.190

mm0.0462-0.0468

9 - 94 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1303 of 2339

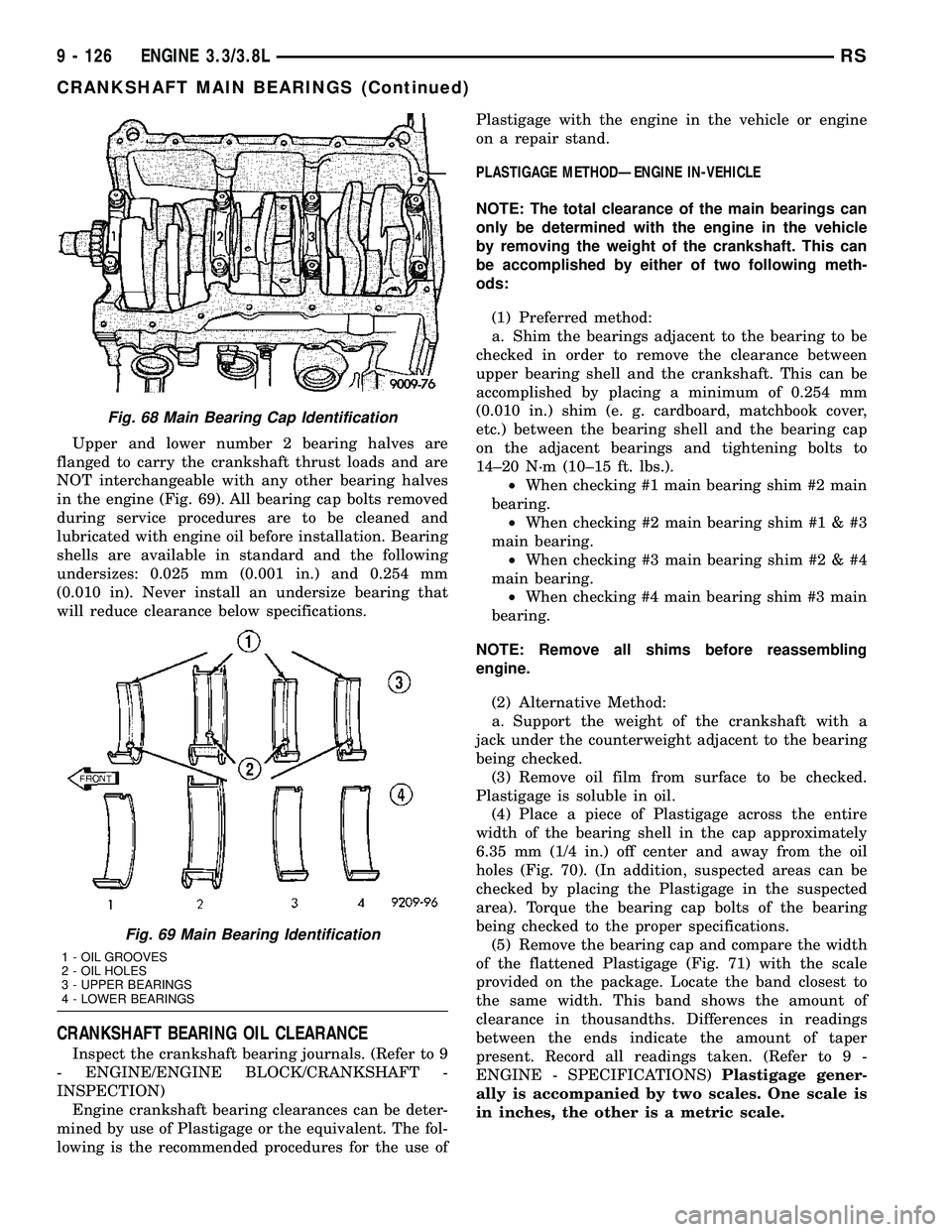

Upper and lower number 2 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 69). All bearing cap bolts removed

during service procedures are to be cleaned and

lubricated with engine oil before installation. Bearing

shells are available in standard and the following

undersizes: 0.025 mm (0.001 in.) and 0.254 mm

(0.010 in). Never install an undersize bearing that

will reduce clearance below specifications.

CRANKSHAFT BEARING OIL CLEARANCE

Inspect the crankshaft bearing journals. (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION)

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or the equivalent. The fol-

lowing is the recommended procedures for the use ofPlastigage with the engine in the vehicle or engine

on a repair stand.

PLASTIGAGE METHODÐENGINE IN-VEHICLE

NOTE: The total clearance of the main bearings can

only be determined with the engine in the vehicle

by removing the weight of the crankshaft. This can

be accomplished by either of two following meth-

ods:

(1) Preferred method:

a. Shim the bearings adjacent to the bearing to be

checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14±20 N´m (10±15 ft. lbs.).

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: Remove all shims before reassembling

engine.

(2) Alternative Method:

a. Support the weight of the crankshaft with a

jack under the counterweight adjacent to the bearing

being checked.

(3) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(4) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 70). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 71) with the scale

provided on the package. Locate the band closest to

the same width. This band shows the amount of

clearance in thousandths. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. (Refer to 9 -

ENGINE - SPECIFICATIONS)Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

Fig. 68 Main Bearing Cap Identification

Fig. 69 Main Bearing Identification

1 - OIL GROOVES

2 - OIL HOLES

3 - UPPER BEARINGS

4 - LOWER BEARINGS

9 - 126 ENGINE 3.3/3.8LRS

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1305 of 2339

(6) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).

(7) Rotate the crankshaft until the number 6 pis-

ton is at TDC.

(8) To ensure correct thrust bearing alignment the

following procedure must be done:

a. Move crankshaft all the way to the rear of its

travel.

b. Then, move crankshaft all the way to the front

of its travel.

c. Wedge an appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.

d. Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(9) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(10) Fill engine crankcase with proper oil to cor-

rect level.

CRANKSHAFT

DESCRIPTION

DESCRIPTION - 3.3L

The nodular iron crankshaft is supported by four

main bearings, with number two position the thrust

bearing (Fig. 76). Crankshaft end sealing is provided

by front and rear rubber seals.

DESCRIPTION - 3.8L

The nodular iron crankshaft is supported by four

main bearings, with number two position providing

thrust bearing location (Fig. 77). Each main bearing

cap has two vertical retaining bolts. The two center

main caps have horizontal bolts to add increasedrigidity to the lower engine block (Fig. 77). Crank-

shaft end sealing is provided by front and rear rub-

ber seals.

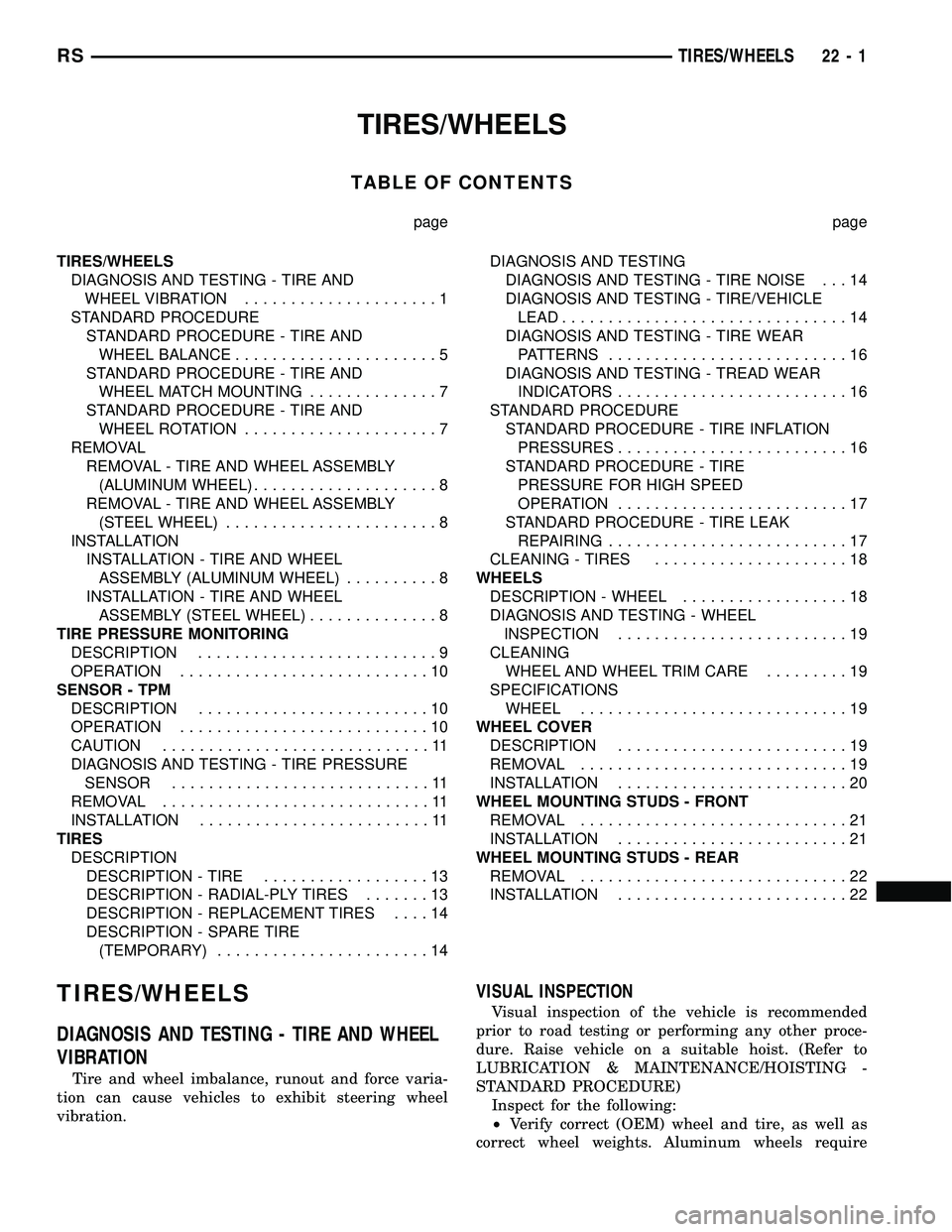

STANDARD PROCEDURE - MEASURING

CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine with

the locating probe on nose of crankshaft (Fig. 74).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. (Refer to 9 - ENGINE -

SPECIFICATIONS) for end play specification.

REMOVAL

(1) Remove the engine assembly (Refer to 9 -

ENGINE - REMOVAL).

(2) Separate transaxle from engine.

(3) Mount engine on an engine stand.

(4) Remove the oil filter.

(5) Remove the oil pan and oil pick-up tube (Refer

to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(6) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING CHAIN COVER -

REMOVAL).

(7) Remove timing chain and sprockets (Refer to 9

- ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - REMOVAL).

(8) Remove crankshaft rear oil seal and retainer

(Refer to 9 - ENGINE/ENGINE BLOCK/CRANK-

SHAFT OIL SEAL - REAR - REMOVAL).

(9) Rotate the crankshaft until connecting rod cap

is accessible.

(10) Mark connecting rod cap position using a suit-

able marker/scribe tool.

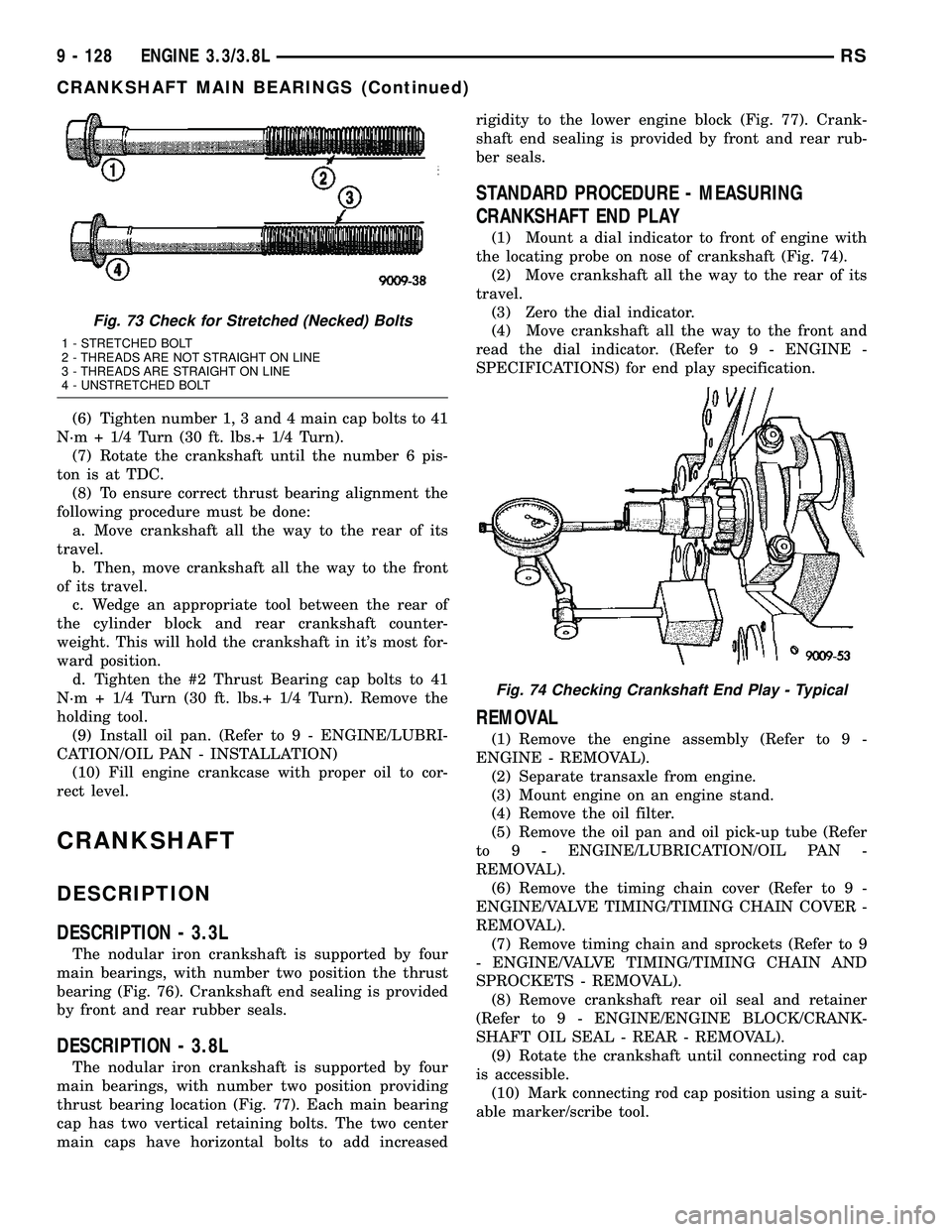

Fig. 73 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 74 Checking Crankshaft End Play - Typical

9 - 128 ENGINE 3.3/3.8LRS

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1344 of 2339

HEAT SHIELDS

DESCRIPTION

The exhaust system heat shields (Fig. 7), (Fig. 8),

or (Fig. 9) are attached to the under body of the vehi-

cle. On vehicles equipped with All Wheel Dive

(AWD), an additional heat shield is mounted to the

catalytic converter.

OPERATION

Heat shields are needed to protect both the vehicle

and the environment from the high temperatures

developed near the catalytic converter.Avoid application of rust prevention com-

pounds or undercoating materials to exhaust

system floor pan heat shields on cars so

equipped. Light over spray near the edges is

permitted. Application of coating will greatly

reduce the efficiency of the heat shields result-

ing in excessive floor pan temperatures and

objectionable fumes.

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove fasteners attaching applicable heat

shield (Fig. 7), (Fig. 8), or (Fig. 9).

(3) Remove heat shield(s).

INSTALLATION

(1) Position heat shield(s) to underbody.

(2) Install heat shield fasteners and tighten to 2.6

N´m (23 in. lbs.) (Fig. 7), (Fig. 8), or (Fig. 9).

(3) Lower vehicle.

(4) Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

(5) Check the exhaust system for contact with the

body panels. Make the necessary adjustments, if

needed.

MUFFLER

REMOVAL

(1) Raise vehicle on a body contact type hoist.

NOTE: To provide removal clearance between muf-

fler/resonator pipe and rear axle parts, the rear sus-

pension must be relieved of all body weight.

(2) Apply a penetrating oil to clamp nuts of com-

ponent requiring removal.

Fig. 7 CATALYTIC CONVERTER HEAT SHIELD

1 - HEAT SHIELD - CATALYTIC CONVERTER

2 - SCREW (QTY. 4)

Fig. 8 MUFFLER HEAT SHIELD

1 - HEAT SHIELD - MUFFLER

2 - SCREW (QTY. 6)

Fig. 9 RESONATOR PIPE HEAT SHIELD

1 - SCREW (QTY. 3)

2 - HEAT SHIELD - RESONATOR PIPE

3 - MUFFLER

RSEXHAUST SYSTEM11-7

Page 1380 of 2339

(9)The fuel pump module electrical connec-

tor has a retainer that locks it in place..Slide

fuel pump module electrical connector lock to unlock

(Fig. 27), (Fig. 28).

(10) Push down on connector retainer disconnect

the electrical connector.

(11) Lower tank slightly.

(12) Remove fuel filler vent tube from frame (Fig.

29).

(13) Lower tank from vehicle.

INSTALLATION

INSTALLATION

(1) Position fuel tank on transmission jack. Con-

nect check valve hose. Connect fuel filler tube vent

hose to fuel filler tube.

(2) Feed filler vent line thru frame rail.

(3) Raise tank into position and carefully work fuel

filler metal tube into the rubber hose on fuel tank. A

light coating of clean engine oil on the tube end may

be used to aid assembly.

(4) Tighten strap bolts to 54 N´m (40 ft. lbs.)

torque. Tighten T strap bolt to 28.2 N´m (250 in.

lbs.). Remove transmission jack.

(5) Tighten filler hose clamp to 3.3 N´m (30 in.

lbs.).

CAUTION: Ensure straps are not twisted or bent

before or after tightening strap screws.

(6) Connect fuel pump/module electrical connector.

Place retainer in locked position.

(7) Lubricate the fuel supply line with clean 30

weight engine oil, install the quick connect fuel fit-

ting. Refer to Tube/Fitting Assembly in the Fuel

Delivery section of this section.

(8) Connect the control vapor lines at front of

tank.

(9) Pull-pull-push on all connections to make sure

of connection.

(10) Fill fuel tank, replace cap, and connect bat-

tery negative cable.

(11) Use the DRBIIItscan tool to pressurize the

fuel system. Check for leaks.Fig. 27 ELECTRICAL CONNECTION

Fig. 28 ELECTRICAL CONNECTION REMOVED

Fig. 29 FILLER TUBE VENT LINE THRU RAIL

RSFUEL DELIVERY14-15

FUEL TANK (Continued)

Page 1758 of 2339

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL VIBRATION.....................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................5

STANDARD PROCEDURE - TIRE AND

WHEEL MATCH MOUNTING..............7

STANDARD PROCEDURE - TIRE AND

WHEEL ROTATION.....................7

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)....................8

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL).......................8

INSTALLATION

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (ALUMINUM WHEEL)..........8

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (STEEL WHEEL)..............8

TIRE PRESSURE MONITORING

DESCRIPTION..........................9

OPERATION...........................10

SENSOR - TPM

DESCRIPTION.........................10

OPERATION...........................10

CAUTION.............................11

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR............................11

REMOVAL.............................11

INSTALLATION.........................11

TIRES

DESCRIPTION

DESCRIPTION - TIRE..................13

DESCRIPTION - RADIAL-PLY TIRES.......13

DESCRIPTION - REPLACEMENT TIRES....14

DESCRIPTION - SPARE TIRE

(TEMPORARY).......................14DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE . . . 14

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD...............................14

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS..........................16

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS.........................16

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE INFLATION

PRESSURES.........................16

STANDARD PROCEDURE - TIRE

PRESSURE FOR HIGH SPEED

OPERATION.........................17

STANDARD PROCEDURE - TIRE LEAK

REPAIRING..........................17

CLEANING - TIRES.....................18

WHEELS

DESCRIPTION - WHEEL..................18

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................19

CLEANING

WHEEL AND WHEEL TRIM CARE.........19

SPECIFICATIONS

WHEEL.............................19

WHEEL COVER

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................20

WHEEL MOUNTING STUDS - FRONT

REMOVAL.............................21

INSTALLATION.........................21

WHEEL MOUNTING STUDS - REAR

REMOVAL.............................22

INSTALLATION.........................22

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

VIBRATION

Tire and wheel imbalance, runout and force varia-

tion can cause vehicles to exhibit steering wheel

vibration.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended

prior to road testing or performing any other proce-

dure. Raise vehicle on a suitable hoist. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

Inspect for the following:

²Verify correct (OEM) wheel and tire, as well as

correct wheel weights. Aluminum wheels require

RSTIRES/WHEELS22-1