audio CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1092 of 2339

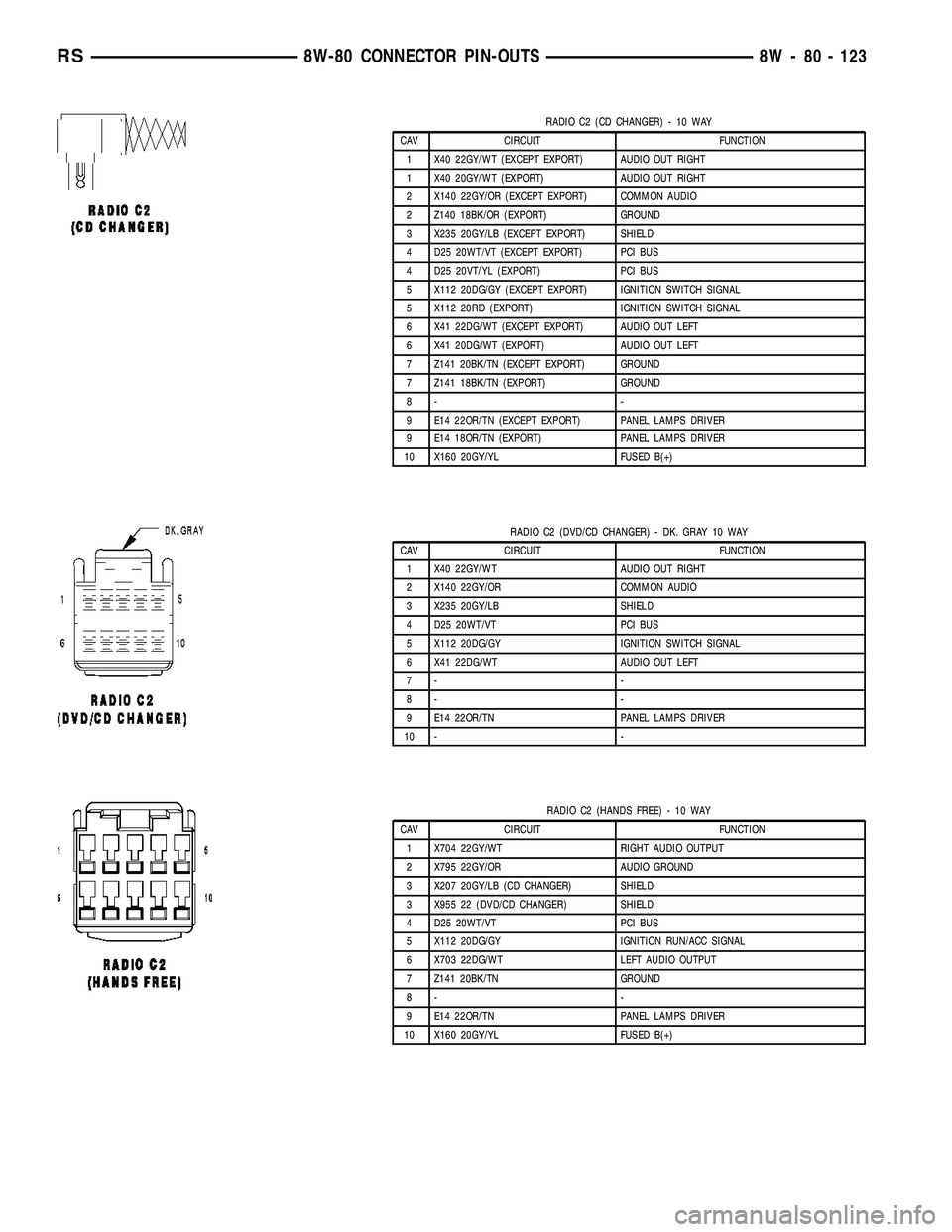

RADIO C2 (CD CHANGER) - 10 WAY

CAV CIRCUIT FUNCTION

1 X40 22GY/WT (EXCEPT EXPORT) AUDIO OUT RIGHT

1 X40 20GY/WT (EXPORT) AUDIO OUT RIGHT

2 X140 22GY/OR (EXCEPT EXPORT) COMMON AUDIO

2 Z140 18BK/OR (EXPORT) GROUND

3 X235 20GY/LB (EXCEPT EXPORT) SHIELD

4 D25 20WT/VT (EXCEPT EXPORT) PCI BUS

4 D25 20VT/YL (EXPORT) PCI BUS

5 X112 20DG/GY (EXCEPT EXPORT) IGNITION SWITCH SIGNAL

5 X112 20RD (EXPORT) IGNITION SWITCH SIGNAL

6 X41 22DG/WT (EXCEPT EXPORT) AUDIO OUT LEFT

6 X41 20DG/WT (EXPORT) AUDIO OUT LEFT

7 Z141 20BK/TN (EXCEPT EXPORT) GROUND

7 Z141 18BK/TN (EXPORT) GROUND

8- -

9 E14 22OR/TN (EXCEPT EXPORT) PANEL LAMPS DRIVER

9 E14 18OR/TN (EXPORT) PANEL LAMPS DRIVER

10 X160 20GY/YL FUSED B(+)

RADIO C2 (DVD/CD CHANGER) - DK. GRAY 10 WAY

CAV CIRCUIT FUNCTION

1 X40 22GY/WT AUDIO OUT RIGHT

2 X140 22GY/OR COMMON AUDIO

3 X235 20GY/LB SHIELD

4 D25 20WT/VT PCI BUS

5 X112 20DG/GY IGNITION SWITCH SIGNAL

6 X41 22DG/WT AUDIO OUT LEFT

7- -

8- -

9 E14 22OR/TN PANEL LAMPS DRIVER

10 - -

RADIO C2 (HANDS FREE) - 10 WAY

CAV CIRCUIT FUNCTION

1 X704 22GY/WT RIGHT AUDIO OUTPUT

2 X795 22GY/OR AUDIO GROUND

3 X207 20GY/LB (CD CHANGER) SHIELD

3 X955 22 (DVD/CD CHANGER) SHIELD

4 D25 20WT/VT PCI BUS

5 X112 20DG/GY IGNITION RUN/ACC SIGNAL

6 X703 22DG/WT LEFT AUDIO OUTPUT

7 Z141 20BK/TN GROUND

8- -

9 E14 22OR/TN PANEL LAMPS DRIVER

10 X160 20GY/YL FUSED B(+)

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 123

Page 1103 of 2339

RIGHT REAR LAMP ASSEMBLY - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L62 18WT/BR (EXCEPT EXPORT) RIGHT REAR TURN SIGNAL DRIVER

1 Z362 18BK/BR (EXPORT) GROUND

2 L62 18WT/BR (EXPORT) RIGHT REAR TURN SIGNAL DRIVER

3 L50 18WT/TN (DIESEL) PRIMARY BRAKE SWITCH SIGNAL

3 L78 18WT/OR (EXCEPT EXPORT/EX-

CEPT TRAILER TOW)FUSED PARK LAMP RELAY OUTPUT (RIGHT)

3 L50 18WT/TN (GAS EXPORT) BRAKE LAMP SWITCH OUTPUT

3 L78 18WT/TN (TRAILER TOW) FUSED PARK LAMP RELAY OUTPUT (RIGHT)

4 L1 18WT/LG (EXCEPT TRAILER TOW) BACK-UP LAMP FEED

4 L1 18 WT/PK (TRAILER TOW) BACK-UP LAMP FEED

5 Z362 18BK/BR (EXCEPT EXPORT/EX-

CEPT TRAILER TOW)GROUND

5 L38 20WT/YL (EXPORT) REAR FOG LAMP SWITCH OUTPUT

5 Z362 18BR/OR (TRAILER TOW) GROUND

6 L78 18WT/OR (EXPORT) FUSED PARK LAMP RELAY OUTPUT (RIGHT)

RIGHT REAR PILLAR SPEAKER (HIGHLINE AUDIO) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X212 18GY/DB (EXCEPT EXPORT) AMPLIFIED RIGHT REAR TWEETER (-)

1 X212 20GY/DB (EXPORT) AMPLIFIED RIGHT REAR TWEETER (-)

2 X282 18GY/TN (EXCEPT EXPORT) AMPLIFIED RIGHT REAR TWEETER (+)

2 X282 20GY/TN (EXPORT) AMPLIFIED RIGHT REAR TWEETER (+)

RIGHT REAR READING LAMP (LUXURY) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 M22 20YL/OR COURTESY LAMPS DRIVER

2 Z327 20BK/OR GROUND

3 M27 20YL/LB READING LAMPS DRIVER

RIGHT REAR SPEAKER-3WAY

CAV CIRCUIT FUNCTION

1 X296 18DG/GY (HIGHLINE EXCEPT

EXPORT)AMPLIFIED RIGHT REAR SPEAKER (-)

1 X296 20DG/GY (HIGHLINE EXPORT) AMPLIFIED RIGHT REAR SPEAKER (-)

1 X58 20GY/OR (LOWLINE) RIGHT REAR SPEAKER (-)

2- -

3 X206 18GY/DB (HIGHLINE EXCEPT

EXPORTAMPLIFIED RIGHT REAR SPEAKER (+)

3 X206 20GY/DB (HIGHLINE EXPORT) AMPLIFIED RIGHT REAR SPEAKER (+)

3 X52 20GY/DB (LOWLINE) RIGHT REAR SPEAKER (+)

8W - 80 - 134 8W-80 CONNECTOR PIN-OUTSRS

Page 1120 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Left Full Open Switch (Power

Sliding Door)BK Left Sliding Door N/S

Left Headlamp Caravan/Voyager

(Except Export)BK At Lamp 1

Left Headlamp (Town & Country) GN At Lamp 1

Left Headlamp Leveling Motor

(Export)WT At Motor N/S

Left High Beam Lamp (Export) BK At Lamp N/S

Left Instrument Panel Speaker WT At Speaker 20, 21, 27

Left Liftgate Flood Lamp (Power

Liftgate)GY At Lamp 49

Left Low Beam Lamp (Export) BK At Lamp N/S

Left Mid Reading Lamp

(Premium/Luxury)GY At Lamp N/S

Left Park Lamp (Export) BK At Lamp NS

Left Power Mirror BK At Mirror 27

Left Rear Lamp Assembly BK At Lamp 47

Left Rear Pillar Speaker (Highline

Audio)BK Left of Liftgate 47

Left Rear Reading Lamp (Luxury) GY At Lamp N/S

Left Rear Speaker (Highline) BK/RD At Speaker 47

Left Rear Speaker (Lowline) At Speaker N/S

Left Rear Vent Motor NAT At Motor 46, 47

Left Rear Wheel Speed Sensor BK Center Rear of Floor Pan 47

Left Remote Radio Switch BK Steering Wheel N/S

Left Repeater Lamp (Export) GY Left Front Fender 4, 36

Left Side Impact Sensor 1 DKGY Left B Pillar 40

Left Side Impact Sensor 2 Left Sliding Door N/S

Left Side Impact Sensor 3 BK Left Quarter Panel 47

Left Sliding Door Control Module

C1BK Left Sliding Door N/S

Left Sliding Door Control Module

C2Left Sliding Door N/S

Left Sliding Door Latch Sensing

SwitchBK Left Sliding Door N/S

Left Sliding Door Lock Motor BK Left Sliding Door N/S

Left Sliding Door Lock Motor/Ajar

Switch (Manual Sliding Door)BK Left Sliding Door N/S

Left Sliding Door Motor BK Left Sliding Door N/S

Left Speed Control Switch WT Steering Wheel N/S

Left Turn Signal Lamp (Export) OR AT Lamp N/S

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp DKGY At Lamp 49

Lift Pump Motor (Diesel) BK Left Rear Engine Compartment N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1124 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Front Door Ajar Switch

(Base)BK At B Pillar N/S

Right Front Door Lock Motor/Ajar

Switch (Except Base)BK Right Front Door 44

Right Front Impact Sensor BK Near T/O for C303 N/S

Right Front Park/Turn Signal

Lamp (Except Export)BK At Lamp 1, 3

Right Front Wheel Speed Sensor GY Right Fender Side Shield 3,10, 16, 17

Right Full Open Switch (Power

Sliding Door)BK Right Sliding Door 45

Right Headlamp (Caravan/

Voyager Except Export)BK At Lamp 1, 3

Right Headlamp Leveling Motor

(Export)WT At Right Headlamp N/S

Right High Beam Lamp (Export) BK At Right Headlamp N/S

Right Instrument Panel Speaker WT At Speaker 20, 23, 24

Right Liftgate Flood Lamp (Power

Liftgate)GY At Lamp 49

Right Low Beam Lamp (Export) BK At Right Headlamp N/S

Right Mid Reading Lamp

(Premium/ Luxury)GY At Lamp N/S

Right Park Lamp (Export) BK AT Lamp N/S

Right Power Mirror BK At Mirror 20, 24, 28

Right Rear Lamp Assembly BK At Lamp 48

Right Rear Pillar Speaker

(Highline Audio)BK At Speaker 48

Right Rear Reading Lamp

(Luxury)GY At Lamp N/S

Right Rear Speaker) At Speaker 48

Right Rear Vent Motor NAT At Motor 48

Right Rear Wheel Speed Sensor BK Right Rear of Floor Pan 48

Right Remote Radio Switch BK At Steering Wheel N/S

Right Repeater Lamp (Export) GY Right Front Fender 39

Right Side Impact Sensor 1 Right B Pillar 39

Right Side Impact Sensor 2 Right Sliding Door 32

Right Side Impact Sensor 3 BK Right Quarter Panel 48

Right Sliding Door Control

Module C1BK Right Sliding Door 45, 46

Right Sliding Door Control

Module C2Right Sliding Door 45, 46

Right Sliding Door Latch Sensing

SwitchBK Right Sliding Door 45

Right Sliding Door Lock Motor BK Right Sliding Door 45

Right Sliding Door Lock

Motor/Ajar Switch (Manual Sliding

Door)BK Right Sliding Door N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1129 of 2339

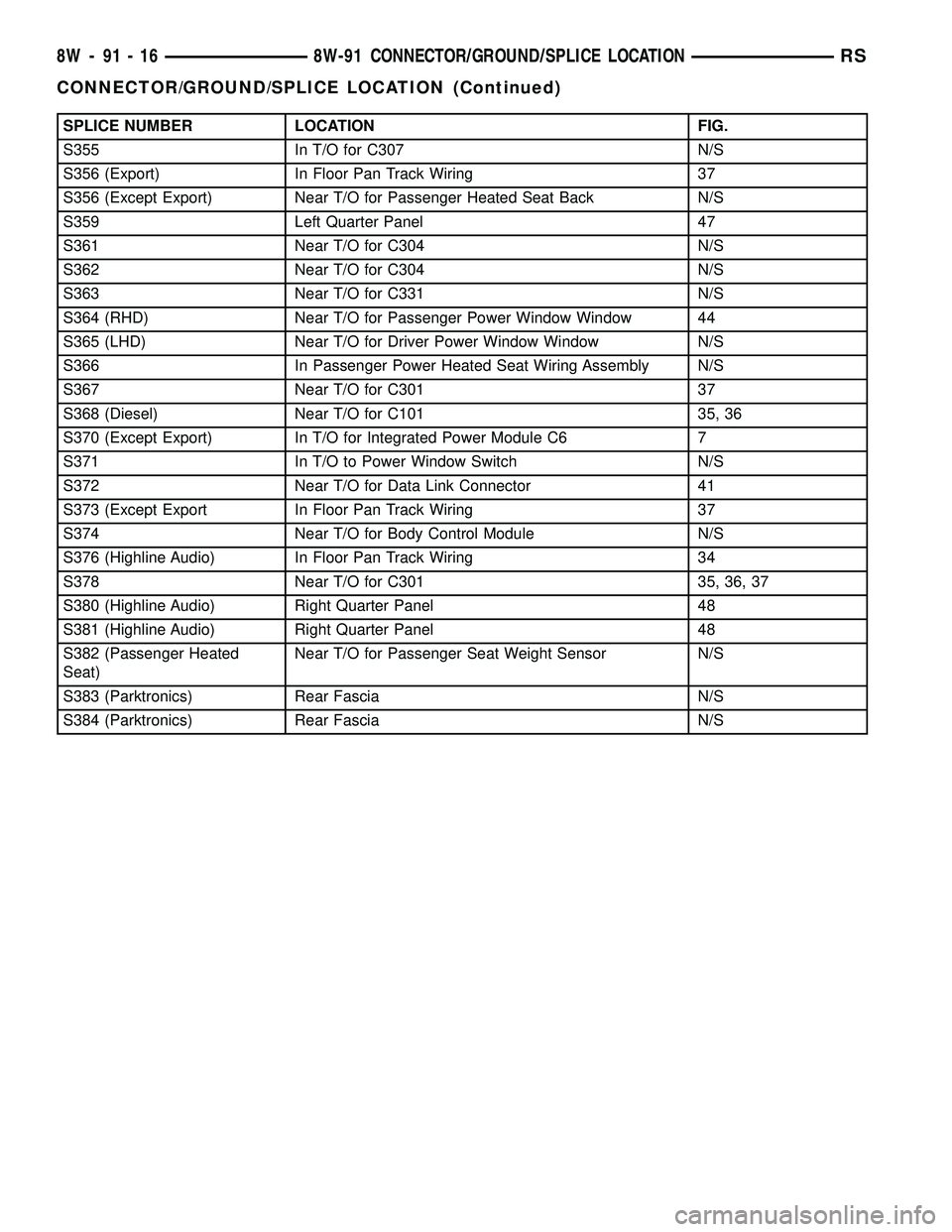

SPLICE NUMBER LOCATION FIG.

S355 In T/O for C307 N/S

S356 (Export) In Floor Pan Track Wiring 37

S356 (Except Export) Near T/O for Passenger Heated Seat Back N/S

S359 Left Quarter Panel 47

S361 Near T/O for C304 N/S

S362 Near T/O for C304 N/S

S363 Near T/O for C331 N/S

S364 (RHD) Near T/O for Passenger Power Window Window 44

S365 (LHD) Near T/O for Driver Power Window Window N/S

S366 In Passenger Power Heated Seat Wiring Assembly N/S

S367 Near T/O for C301 37

S368 (Diesel) Near T/O for C101 35, 36

S370 (Except Export) In T/O for Integrated Power Module C6 7

S371 In T/O to Power Window Switch N/S

S372 Near T/O for Data Link Connector 41

S373 (Except Export In Floor Pan Track Wiring 37

S374 Near T/O for Body Control Module N/S

S376 (Highline Audio) In Floor Pan Track Wiring 34

S378 Near T/O for C301 35, 36, 37

S380 (Highline Audio) Right Quarter Panel 48

S381 (Highline Audio) Right Quarter Panel 48

S382 (Passenger Heated

Seat)Near T/O for Passenger Seat Weight Sensor N/S

S383 (Parktronics) Rear Fascia N/S

S384 (Parktronics) Rear Fascia N/S

8W - 91 - 16 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1418 of 2339

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING - STEERING

COLUMN

For diagnosis of conditions relating to the steering

column, (Refer to 19 - STEERING - DIAGNOSIS

AND TESTING).

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect and isolate the negative (ground)

cable from the battery. Wait at least two minutes for

the airbag system reserve capacitor to discharge

before beginning any steering column, instrument

panel, or airbag system/component service.WARNING: WHEN AN UNDEPLOYED AIRBAG IS TO

BE REMOVED FROM THE VEHICLE, FIRST DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE. ALLOW THE AIRBAG SYSTEM

RESERVE CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE BEGINNING ANY AIRBAG SYS-

TEM OR COMPONENT SERVICE. PERSONAL

INJURY MAY RESULT IF THIS PROCEDURE IS NOT

FOLLOWED.

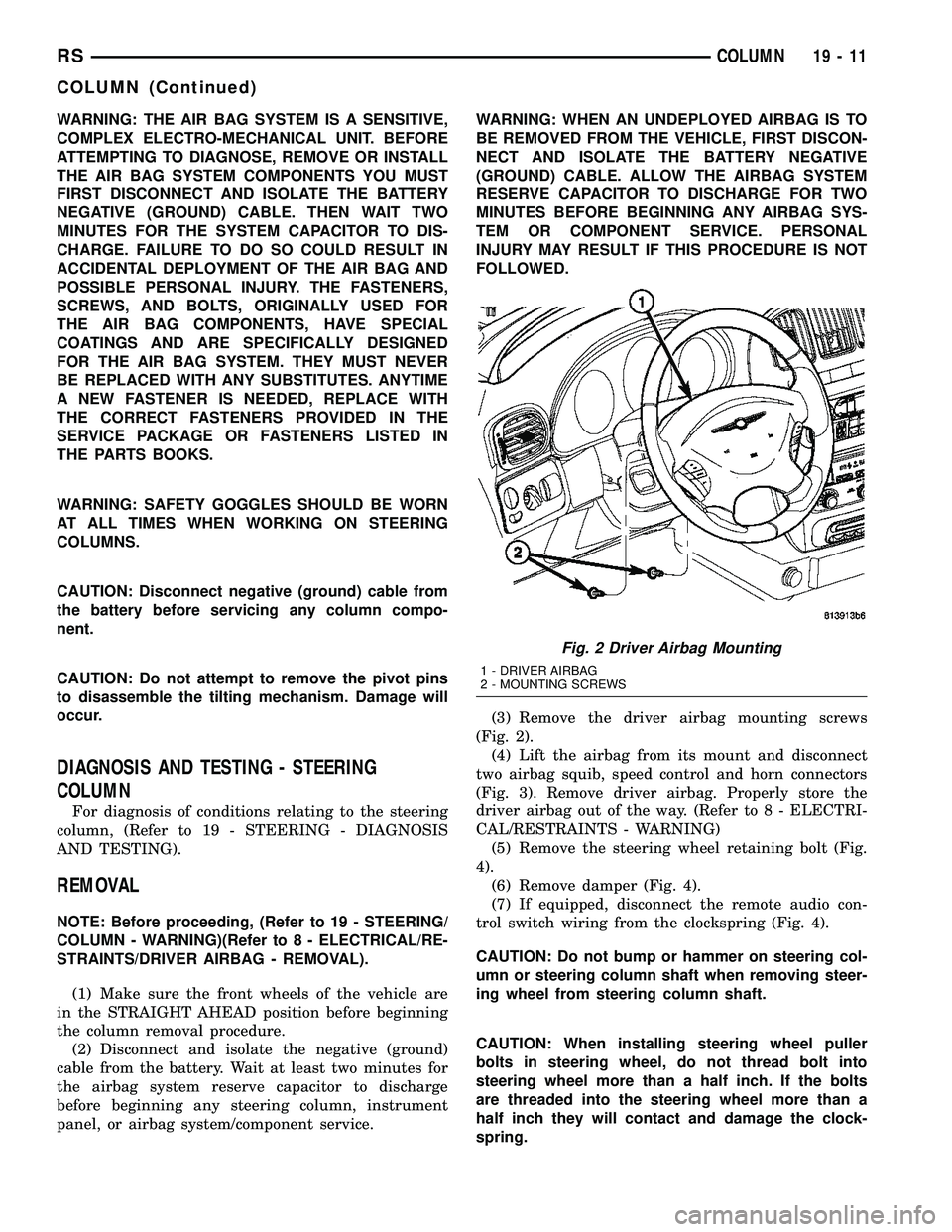

(3) Remove the driver airbag mounting screws

(Fig. 2).

(4) Lift the airbag from its mount and disconnect

two airbag squib, speed control and horn connectors

(Fig. 3). Remove driver airbag. Properly store the

driver airbag out of the way. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - WARNING)

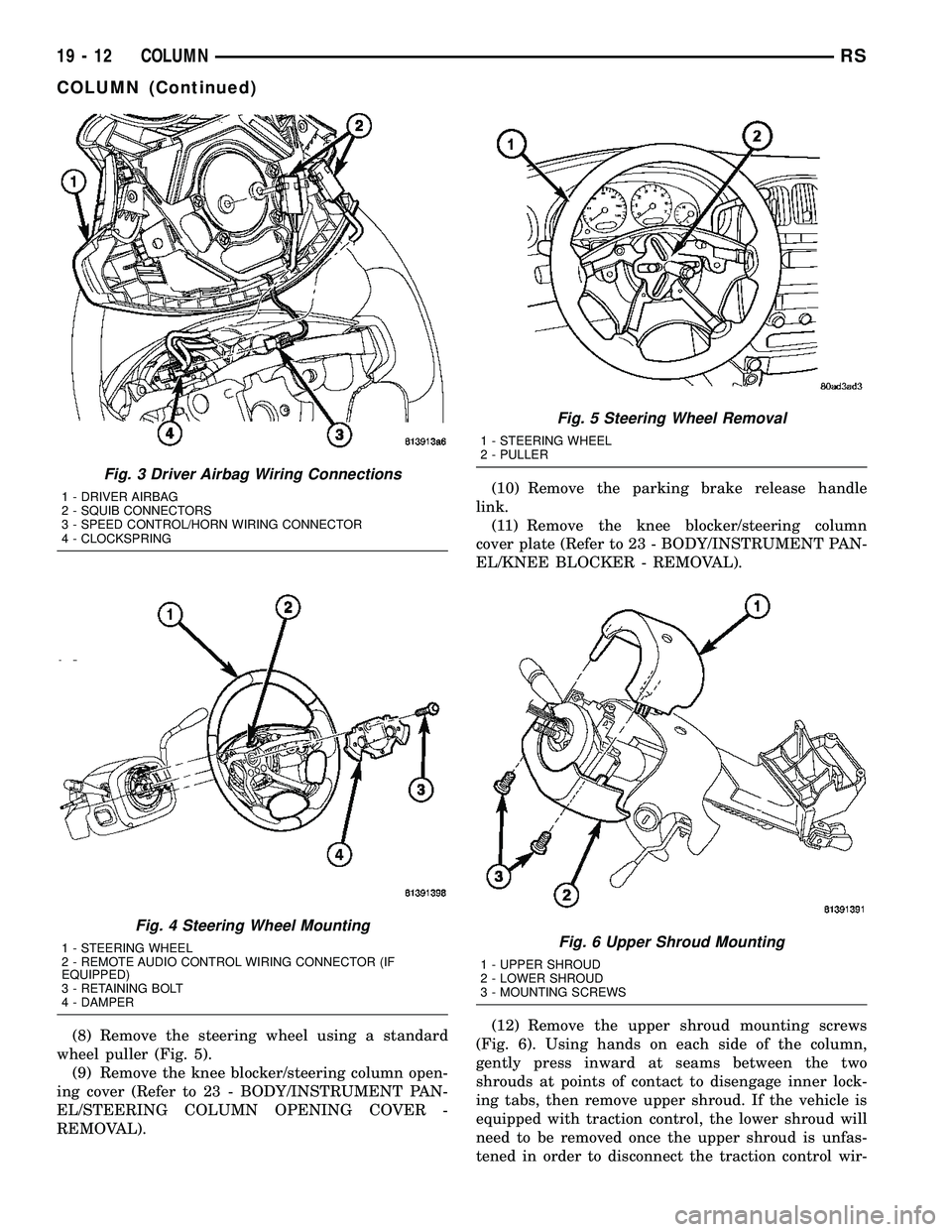

(5) Remove the steering wheel retaining bolt (Fig.

4).

(6) Remove damper (Fig. 4).

(7) If equipped, disconnect the remote audio con-

trol switch wiring from the clockspring (Fig. 4).

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.

CAUTION: When installing steering wheel puller

bolts in steering wheel, do not thread bolt into

steering wheel more than a half inch. If the bolts

are threaded into the steering wheel more than a

half inch they will contact and damage the clock-

spring.

Fig. 2 Driver Airbag Mounting

1 - DRIVER AIRBAG

2 - MOUNTING SCREWS

RSCOLUMN19-11

COLUMN (Continued)

Page 1419 of 2339

(8) Remove the steering wheel using a standard

wheel puller (Fig. 5).

(9) Remove the knee blocker/steering column open-

ing cover (Refer to 23 - BODY/INSTRUMENT PAN-

EL/STEERING COLUMN OPENING COVER -

REMOVAL).(10) Remove the parking brake release handle

link.

(11) Remove the knee blocker/steering column

cover plate (Refer to 23 - BODY/INSTRUMENT PAN-

EL/KNEE BLOCKER - REMOVAL).

(12) Remove the upper shroud mounting screws

(Fig. 6). Using hands on each side of the column,

gently press inward at seams between the two

shrouds at points of contact to disengage inner lock-

ing tabs, then remove upper shroud. If the vehicle is

equipped with traction control, the lower shroud will

need to be removed once the upper shroud is unfas-

tened in order to disconnect the traction control wir-

Fig. 3 Driver Airbag Wiring Connections

1 - DRIVER AIRBAG

2 - SQUIB CONNECTORS

3 - SPEED CONTROL/HORN WIRING CONNECTOR

4 - CLOCKSPRING

Fig. 4 Steering Wheel Mounting

1 - STEERING WHEEL

2 - REMOTE AUDIO CONTROL WIRING CONNECTOR (IF

EQUIPPED)

3 - RETAINING BOLT

4 - DAMPER

Fig. 5 Steering Wheel Removal

1 - STEERING WHEEL

2 - PULLER

Fig. 6 Upper Shroud Mounting

1 - UPPER SHROUD

2 - LOWER SHROUD

3 - MOUNTING SCREWS

19 - 12 COLUMNRS

COLUMN (Continued)

Page 1424 of 2339

(19) Position the lower shroud on the column (Fig.

8). Install the lower shroud mounting screw. Tighten

the screw to 2 N´m (17 in. lbs.) torque.

(20) If equipped with adjustable pedals, Connect

the wiring connector for the switch (Fig. 7) to the col-

umn wiring harness.

(21) Position the upper shroud on top of the lower

shroud and snap it into place. Install the upper

shroud mounting screws (Fig. 6). Tighten the screws

to 2 N´m (17 in. lbs.) torque.

(22) Inspect shroud mating surfaces for excessive

gaps and correct as necessary.

(23) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(24) Install the knee blocker/steering column cover

plate. (Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - INSTALLATION)

(25) Install the parking brake handle link.

(26) Install the knee blocker/steering column open-

ing cover. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/STEERING COLUMN OPENING COVER -

INSTALLATION)

(27) Align the splines and install the steering

wheel on the steering column shaft(Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(28) Install the damper over the steering column

shaft (Fig. 4).

(29) Install the steering wheel retaining bolt (Fig.

4). Tighten the bolt to 61 N´m (45 ft. lbs.) torque.

(30) If the steering wheel is equipped with remote

audio controls, connect the wiring connector to the

clockspring (Fig. 4).

(31) Connect the two squib connectors to the

driver airbag (Fig. 3). The connectors are color coded

to avoid connector mix-up.

(32) Connect the speed control and horn connector

to the clockspring (Fig. 3).

(33) Install the airbag to the steering wheel.

Install the driver airbag mounting screws (Fig. 2).

Tighten screws to 10 N´m (90 in. lbs.) torque.

(34) Connect the battery negative (ground) cable to

battery post following special Diagnosis And Testing

procedure. (Refer to 8 - ELECTRICAL/RESTRAINTS

- DIAGNOSIS AND TESTING)

(35) Check operation of all steering column

mounted components.

(36) Road test vehicle to ensure proper operation

of steering.SPECIFICATIONS

COLUMN FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Driver Airbag Mounting Screws 10 Ð 90

Multi-Function Switch Mounting

Housing Set-Screw14 Ð 124

Shroud Attaching Screws - Fixed 3 Ð 23

Shroud Attaching Screws -

Lower/Upper2Ð17

SKIM Attaching Screw 4 Ð 30

Steering Column Coupling Pinch

Bolt28 Ð 250

Steering Column Mounting Nuts 12 Ð 105

Steering Wheel Retaining Bolt 61 45 Ð

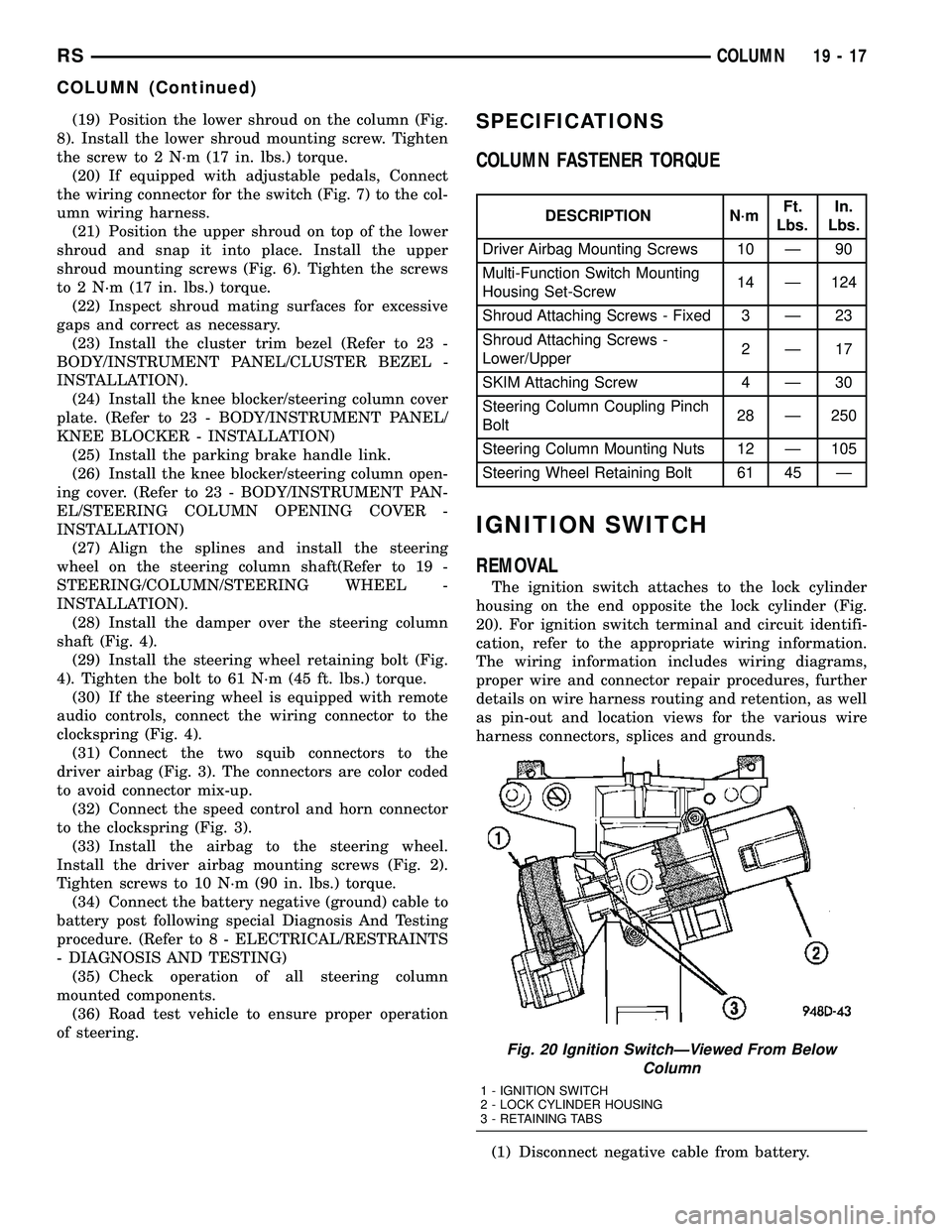

IGNITION SWITCH

REMOVAL

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig.

20). For ignition switch terminal and circuit identifi-

cation, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect negative cable from battery.

Fig. 20 Ignition SwitchÐViewed From Below

Column

1 - IGNITION SWITCH

2 - LOCK CYLINDER HOUSING

3 - RETAINING TABS

RSCOLUMN19-17

COLUMN (Continued)

Page 1431 of 2339

(2) Remove the driver airbag mounting screws

(Fig. 40).

(3) Lift the airbag from its mount and disconnect

two airbag squib, speed control and horn connectors

(Fig. 41). Remove driver airbag. Properly store the

driver airbag out of the way. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - WARNING)(4) Remove the steering wheel retaining bolt (Fig.

42).

(5) Remove damper (Fig. 42).

(6) If equipped, disconnect the remote audio con-

trol switch wiring from the clockspring (Fig. 42).

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.

CAUTION: When installing steering wheel puller

bolts in steering wheel, do not thread bolt into

steering wheel more than a half inch. If the bolts

are threaded into the steering wheel more than a

half inch they will contact and damage the clock-

spring.

(7) While holding the steering wheel firmly in the

straight-aheadposition, remove the steering wheel

from steering column shaft using a steering wheel

puller (Fig. 43).

(8) Remove the puller from the steering wheel.

(9) If the remote audio switches need removed

from the steering wheel, (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

INSTALLATION

(1) If the remote radio switches need to be

installed on the steering wheel, (Refer to 8 - ELEC-

TRICAL/AUDIO/REMOTE SWITCHES - INSTALLA-

TION).

CAUTION: Do not force steering wheel onto steer-

ing column shaft by driving it on. Pull steering

wheel down onto shaft using only the steering

wheel retaining nut.

Fig. 41 Driver Airbag Wiring Connections

1 - DRIVER AIRBAG

2 - SQUIB CONNECTORS

3 - SPEED CONTROL/HORN WIRING CONNECTOR

4 - CLOCKSPRING

Fig. 42 Steering Wheel Mounting

1 - STEERING WHEEL

2 - REMOTE AUDIO CONTROL WIRING CONNECTOR (IF

EQUIPPED)

3 - RETAINING BOLT

4 - DAMPER

Fig. 43 Steering Wheel Removal

1 - STEERING WHEEL

2 - PULLER

19 - 24 COLUMNRS

STEERING WHEEL (Continued)

Page 1432 of 2339

(2) Feed and route wiring from clockspring

through upper access hole in steering wheel.

(3) Align master serrations in steering wheel with

omitted spline on steering column shaft (at 12 o'clock

position). Slide the steering wheel onto the steering

column shaft by hand (Fig. 42). Use care not to pinch

any wiring.

NOTE: Before installing the damper on the steering

wheel, inspect the damper to ensure the rubber iso-

lator on the damper is not deteriorated or damaged.

If the damper is installed with a damaged isolator, a

buzz, squeak or rattle condition may develop.

(4) Install the damper on the steering wheel (Fig.

42).

(5) Install the steering wheel retaining bolt.

Tighten the steering wheel retaining bolt to 61 N´m

(45 ft. lbs.) torque.(6) If the steering wheel is equipped with remote

audio controls, connect the wiring connector to the

clockspring (Fig. 42).

(7) Connect the airbag squib wiring connectors to

the airbag and the horn and speed control switch

connector to the clockspring (Fig. 41).

(8) Install the driver airbag in the steering wheel

(Fig. 40). Install and tighten the airbag attaching

screws to 10 N´m (90 in. lbs.) torque.

(9) Connect the battery negative (ground) cable to

battery post following special Diagnosis And Testing

procedure. (Refer to 8 - ELECTRICAL/RESTRAINTS

- DIAGNOSIS AND TESTING)

(10) Check operation of all steering wheel mounted

components.

(11) Road test vehicle to ensure proper operation of

steering.

RSCOLUMN19-25

STEERING WHEEL (Continued)