warning CITROEN C3 AIRCROSS 2022 Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2022, Model line: C3 AIRCROSS, Model: CITROEN C3 AIRCROSS 2022Pages: 308, PDF Size: 9.13 MB

Page 164 of 308

162

Checking tyre pressures

This check should be done when the tyres

are "cold" (vehicle stopped for 1 hour or

after a journey of less than 6

miles (10 km)

at moderate speeds).

Other wise, add 0.3

bar to the pressures

shown on the label.

Snow chains

The system does not have to be

reinitialised after fitting or removing snow

chains.

Under-inflation alert

This warning is indicated by

continuous illumination of this

warning lamp, an audible signal

and, depending on equipment, a

message displayed on the screen.

F

R

educe speed immediately, avoid excessive

steering movements and sudden braking.

F

S

top the vehicle as soon as it is safe to do

so. The loss of pressure detected does not

always cause visible bulging of the tyre.

Do not satisfy yourself with just a visual

check.

F

I

f you have a compressor, such as the one

in the temporary puncture repair kit, check

the pressures of the four tyres when cold.

F

I

f it is not possible to make this check

immediately, drive carefully at reduced

speed.

or

F

I

n case of a puncture, use the temporary

tyre repair kit or the spare wheel (depending

on equipment).

The alert is kept active until the system is

reinitialised.

Reinitialisation

The system must be reinitialised after any

adjustment to the pressures of one or more

tyres, and after changing one or more wheels. Before reinitialising the system, ensure

that the pressures of the four tyres

are correct for the conditions of use

of the vehicle and conform to the

recommendations on the tyre pressure

label.

The under-inflation alert can only be relied

on if the reinitialisation of the system has

been done with the pressures in the four

tyres correctly adjusted.

The under-inflation detection system

does not give a warning if a pressure is

incorrect at the time of reinitialisation.

The system must be reinitialised with the

ignition on and the vehicle stationary:

-

i

n the vehicle configuration menu for

vehicles fitted with a touch screen.

-

v

ia the button on the dashboard for vehicles

without a touch screen.

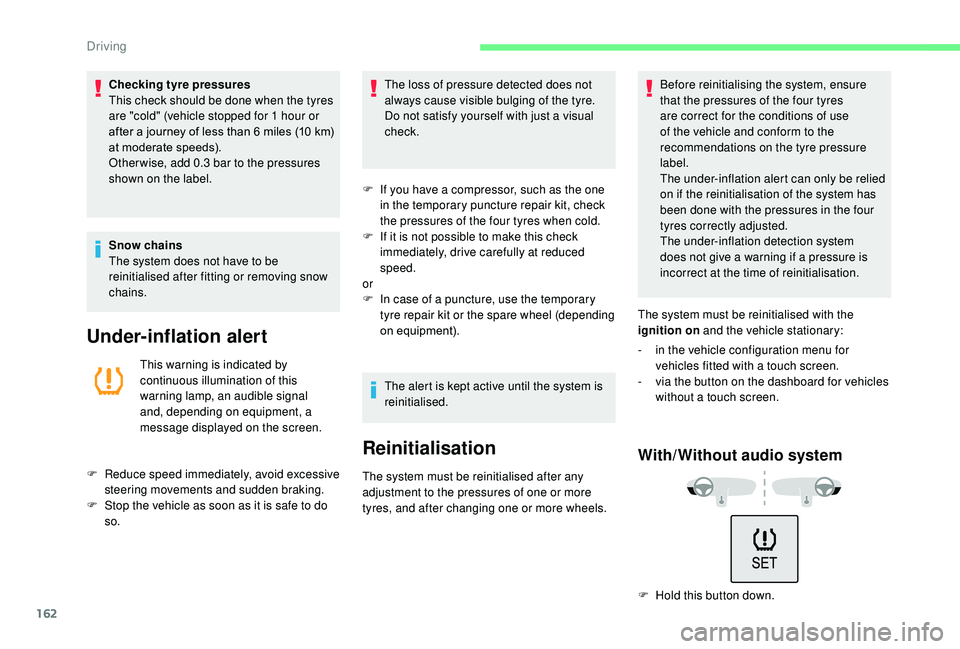

With/Without audio system

F Hold this button down.

Driving

Page 165 of 308

163

Reinitialisation is confirmed by a high-pitched

audible signal.

A deep tone audible signal indicates that the

reinitialisation has not been carried out.

With touch screen

F In the Driving/Vehicle menu,

select the " Driving functions "

tab, then " Reset under-

inflation detection ".

F

Sel

ect " Ye s" to confirm.

A message is displayed and an audible signal

sounds to confirm the reset operation.

Malfunction

In this case, under-inflation monitoring of the

tyres is no longer assured.

Have the system checked by a CITROËN

dealer or a qualified workshop. Before doing anything to the system,

the pressures of the four tyres must be

checked and the system reinitialised.

The flashing and then constant illumination of

the under-inflation warning lamp accompanied

by illumination of the Ser vice warning lamp

indicates a fault in the system.

A message appears, accompanied by an

audible signal.

6

Driving

Page 168 of 308

166

Fuel tank

Tank capacity: approximately 45 litres.

I f you have put the wrong fuel in your

vehicle, you must have the fuel tank

drained and filled with the correct fuel

before star ting the engine.

Low fuel level

When the low fuel level in the

tank is reached, this warning lamp

comes on in the instrument panel,

accompanied by an audible warning

and a message.

When it first comes on, about 5

litres of fuel

remain in the tank.

This warning lamp will come on every time

the ignition is switched on, accompanied

by a message and an audible signal, until

a sufficient addition of fuel is made. This

audible signal and message are repeated with

increasing frequency as the fuel level drops

and approaches " 0".

Refuel as soon as possible to avoid running

out.

For more information on Running out of

fuel (Diesel) , refer to the corresponding

section.

Refilling

A self-adhesive label on the inner face of the

filler flap reminds you of the type of fuel to use,

depending on your engine.

Additions of fuel must be of at least 5

litres, in

order to be registered by the fuel gauge.

Opening the filler cap may create a noise

caused by an inrush of air. This vacuum is

entirely normal, resulting from the sealing of the

fuel system.

To refuel in complete safety:

F

Y

ou must switch off the engine.

F

W

ith the vehicle unlocked, press the rear-

central part of the filler flap to open it.

F

T

ake care to select the pump that delivers

the correct type of fuel for your vehicle.

F

T

urn the filler cap to the left. F

R

emove the cap and place it on its support

(on the filler flap).

F

I

nsert the filler nozzle and push it in as far

as possible before starting to refuel (risk of

blowback).

F

F

ill up the tank completely, but do not

continue after the 3

rd cut-off of the nozzle;

this could cause malfunctions.

Once you have finished refuelling:

F

R

efit the filler cap.

F

T

urn it to the right.

F

P

ush the filler flap to close it.

If your vehicle is fitted with Stop & Start,

never refuel with the engine in STOP

mode; you must switch off the ignition

using the key, or the START/STOP button

if your vehicle has

K

eyless Entry and

Starting.

Practical information

Page 176 of 308

174

Version with longitudinal

bars

You must fit the transverse bars to the

longitudinal bars at the fixing points under the

longitudinal bars.Sunroof

Check that the load does not pass below

the roof bars so that it does not impede

the movements of the sunroof.

Recommendations

F D istribute the load uniformly, taking care

to avoid overloading one of the sides.

F

A

rrange the heaviest part of the load as

close as possible to the roof.

F

S

ecure the load securely and fit a

warning flag if it overhangs the vehicle.

F

D

rive gently: the vehicle will be more

susceptible to the effects of side winds

(the stability of the vehicle may be

affected).

F

R

emove the roof bars once they are no

longer needed.

Maximum load, distributed over the roof

bars, for a loading height not exceeding

40

cm:

-

w

ithout longitudinal bars: 50 kg,

-

w

ith longitudinal bars: 45 kg.

As this value may be changed, please

verify the maximum load quoted in the

user guide supplied with the roof bars.

If the height exceeds 40

cm, adapt the

speed of the vehicle to the profile of the

road to avoid damaging the roof bars and

the fixings on the vehicle.

Be sure to refer to national legislation in

order to comply with the regulations for

transporting objects which are longer than

the vehicle.

Bonnet

Opening

F Open the left-hand front door.

F

S

hift the lever to the left and raise the

bonnet.

F

P

ull the lever, located at the bottom of the

door aperture, towards you.

Practical information

Page 180 of 308

178

When the engine is warm, the temperature of

the coolant is regulated by the fan.

In addition, as the cooling system is

pressurised, wait at least one hour after

switching off the engine before carrying out any

work.

To avoid the risk of scalding when you need to

top up in an emergency, place a cloth around

the cap and unscrew the cap by two turns to

allow the pressure to drop.

Once the pressure has dropped, remove the

cap and top up the coolant.The cooling fan may star t after

switching off the engine: take care

with articles and clothing that might be

caught by the fan blades.

Fluid specification

The fluid must conform to the manufacturer's

recommendations.

Screenwash fluid level

A low coolant level presents a risk of serious

damage to your engine.

Top up the fluid when necessary.Fluid specification

The screenwash fluid must be topped up with a

ready for use mix.

In winter (temperatures below zero), a fluid with

antifreeze must be used that is appropriate for

the prevailing conditions, in order to preser ve

the elements of the system (pump, tank, ducts,

e t c .) .

Filling with pure water is prohibited under all

circumstances (risk of freezing, limestone

deposits, etc.).

Diesel fuel additive level

(Diesel with particle filter)

The additive tank minimum level is

indicated by fixed illumination of this

warning lamp, accompanied by an

audible signal and a message that

the particle filter additive level is

too low.

To p p i n g u p

The reser voir must be topped up without delay

by a CITROËN dealer or a qualified workshop.

AdBlue level

An alert is triggered once the reser ve level is

reached.

To avoid the vehicle being immobilised as per

regulations, you must top up with AdBlue.

For more information on AdBlue

® and the SCR

system, and, in particular, topping it up, refer to

the corresponding section.

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule and according

to your engine.

Other wise, have them checked by a CITROËN

dealer or a qualified workshop.

12 V battery

The battery does not require any

maintenance.

However, check regularly that the

terminals are correctly tightened

(versions without quick release

terminals) and that the connections

are clean.

Practical information

Page 181 of 308

179

For more information on the precautions

to take before starting work on the 12 V

battery , refer to the corresponding

section.

Versions equipped with Stop & Start are

fitted with a 12

V lead-acid battery of

specific technology and specification.

Its replacement should be carried out

only by a CITROËN dealer or a qualified

workshop.

Air filter

Depending on the environment

(e.g. dusty atmosphere) and the

use of the vehicle (e.g. city driving),

replace it twice as often if

necessary .

Passenger compartment filter

Depending on the environment

(e.g. dusty atmosphere) and the

use of the vehicle (e.g. city driving),

replace it twice as often if

necessary. A clogged passenger compartment

filter may have an adverse effect on

the per formance of the air conditioning

system and generate undesirable odours.

Oil filter

Replace the oil filter each time the

engine oil is changed.

Particle filter (Diesel)

The start of saturation of the particle

filter is indicated by the constant

illumination of this warning lamp

accompanied by an alert message.

As soon as the traffic conditions permit,

regenerate the filter by driving at a speed

of at least 37

mph (60 km/h) until the

warning lamp goes off.

If the warning lamp stays on, this indicates

a low Diesel additive level.

For more information on Checking levels

and particularly on the level of Diesel

additive, refer to the corresponding

section.

On a new vehicle, the first particle

filter regeneration operations may be

accompanied by a "burning" smell, which

is per fectly normal.

Following prolonged operation of the

vehicle at very low speed or at idle,

you may, in exceptional circumstances,

notice the emission of water vapour at the

exhaust on acceleration. This does not

affect the behaviour of the vehicle or the

environment.

Manual gearbox

The gearbox does not require any

maintenance (no oil change).

7

Practical information

Page 183 of 308

181

During each scheduled ser vice of your vehicle

by a CITROËN dealer or a qualified workshop,

the AdBlue

® tank is refilled in order to allow

normal operation of the SCR system.

If the estimated mileage of your vehicle

between two ser vices is greater than around

12,000

miles (20,000 km), it will be necessary

to top up the AdBlue

®.

Once the AdBlue

® tank is empty, a system

r

equired by regulations prevents starting

of the engine.

If the SCR

system is faulty, the level of

emissions from your vehicle will no longer

meet the Euro 6 standard: your vehicle

becomes polluting.

In the event of a confirmed fault with the

SCR system, you must go to a CITROËN

dealer or a qualified workshop as soon

as possible: after a running distance of

680

miles (1,100

km), a system will be

triggered automatically to prevent engine

starting.

In either case, a range indicator gives you

the distance you can travel before the

vehicle is immobilised.

For more information on the Warning

and indicator lamps and the associated

alerts, refer to the corresponding section. Freezing of AdBlue

®

AdBlue® freezes at temperatures below

around -11°C.

The SCR system includes a heater for the

AdBlue

® tank, allowing you to continue

driving in all weather conditions.

Topping up with AdBlue®

Before topping up, please read the

following warnings carefully.

Precautions for use

The AdBlue® solution is based on urea. This

liquid is non-flammable, colourless and

odourless (when kept in a cool place).

In the event of contact with the skin, wash the

affected area with soap and water. In the event

of contact with the eyes, wash (irrigate) the

eyes with large amounts of water or with an eye

wash solution for at least 15

minutes. If you feel

a persistent burning sensation or irritation, get

medical attention.

If swallowed, immediately wash out the mouth

with clean water and then drink plenty of water. Keep AdBlue

® out of the reach of children,

in its original container.

Never transfer AdBlue

® to another

container: it would become contaminated.

Use only AdBlue

® fluid that meets the

ISO

22241 standard.

Never dilute AdBlue

® with water.

Never pour AdBlue® into the Diesel fuel

tank.

Containers are available from a

CITROËN

dealer or a qualified workshop.

In certain conditions (at high temperature,

for example), the risk of release of ammonia

cannot be excluded: do not inhale the vapour.

Ammonia has an irritant effect on mucous

membranes (eyes, nose and throat).

You can also visit a ser vice station

equipped with AdBlue pumps specially

designed for private vehicles and light

goods vehicles.

7

Practical information

Page 186 of 308

184

Running out of fuel

(Diesel)

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel.

If the engine does not start first time, do not

keep trying but start the procedure again from

the beginning.For more information on Misfuel

prevention (Diesel) , refer to the

corresponding section.

BlueHDi engines

F Fill the fuel tank with at least five litres of Diesel fuel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10 times.

F

O

perate the starter to run the engine.

Other HDi engines

(Except BlueHDi version)

F

F

ill the fuel tank with at least five litres of

Diesel fuel. F

O

perate the priming pump repeatedly until

resistance is felt (there may be resistance at

the first press).

F

O

perate the starter to start the engine (if the

engine does not start at the first attempt,

wait around 15 seconds before trying

again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again,

then start the engine.

F

P

ut the cover in place and clip it in.

F

C

lose the bonnet.

Temporary puncture

repair kit

Scan the QR code on page 3 to view

explanatory videos.Comprising a compressor and a sealant

cartridge, it allows the temporary repair

of

a tyre so that you can drive to the nearest

garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Only the 12 V socket at the front of

the vehicle allows the compressor to be

connected for long enough to repair or

inflate the vehicle tyre.

The other 12 V sockets of the vehicle

are not designed to be used with the

compressor.

Under-inflation detection

After repair of the tyre, the warning

lamp will remain on until the system is

reinitialised.

For more information on Under-inflation

detection , refer to the corresponding

section.

F

O

pen the bonnet.

F

I

f necessary, unclip the cover to access the

priming pump.

In the event of a breakdown

Page 187 of 308

185

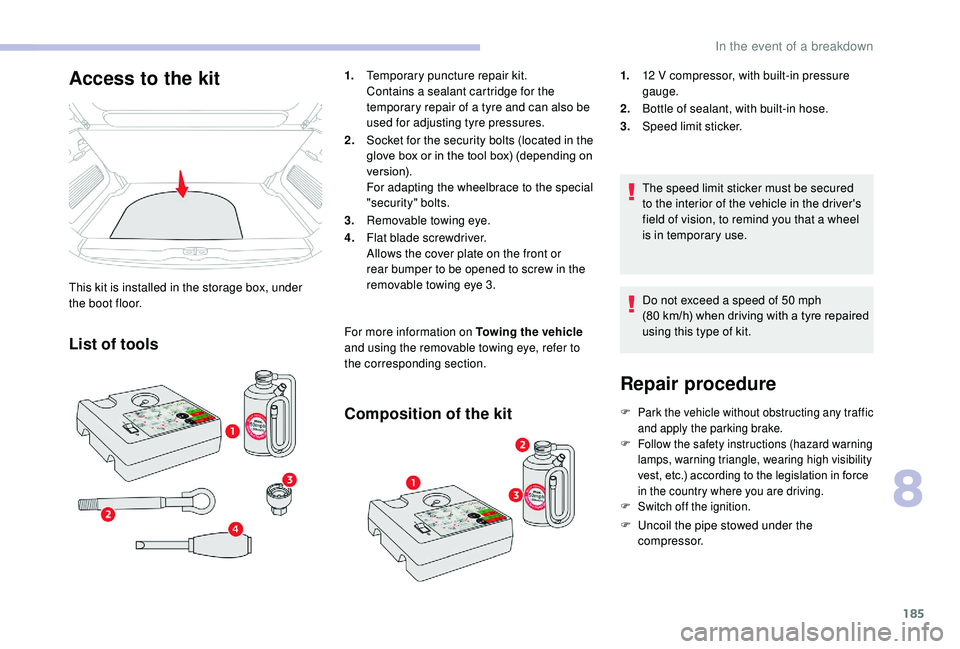

Repair procedure

F Park the vehicle without obstructing any traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard warning

lamps, warning triangle, wearing high visibility

vest, etc.) according to the legislation in force

in the country where you are driving.

F

S

witch off the ignition.

F Uncoil the pipe stowed under the compressor.

Access to the kit

This kit is installed in the storage box, under

the boot floor.

List of tools

1. Temporary puncture repair kit.

Contains a sealant cartridge for the

temporary repair of a tyre and can also be

used for adjusting tyre pressures.

2. Socket for the security bolts (located in the

glove box or in the tool box) (depending on

ve r s i o n).

For adapting the wheelbrace to the special

"security" bolts.

3. Removable towing eye.

4. Flat blade screwdriver.

Allows the cover plate on the front or

rear bumper to be opened to screw in the

removable towing eye 3.

For more information on Towing the vehicle

and using the removable towing eye, refer to

the corresponding section.

Composition of the kit

1. 12 V compressor, with built-in pressure

gauge.

2. Bottle of sealant, with built-in hose.

3. Speed limit sticker.

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a wheel

is in temporary use.

Do not exceed a speed of 50

mph

(80

km/h) when driving with a tyre repaired

using this type of kit.

8

In the event of a breakdown

Page 192 of 308

190

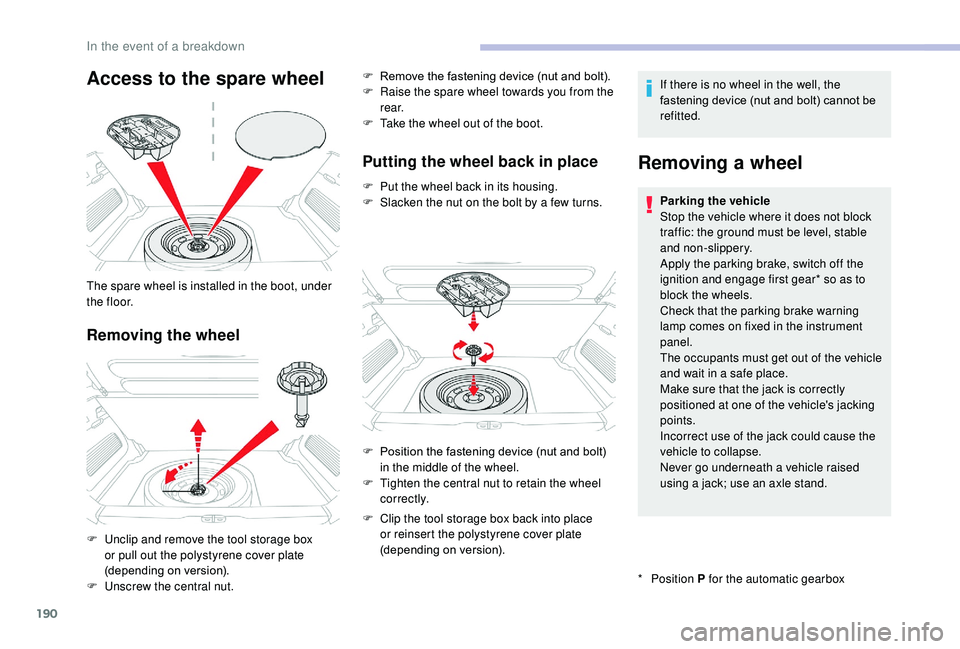

Access to the spare wheel

Removing the wheel

The spare wheel is installed in the boot, under

t h e f l o o r.

F

U

nclip and remove the tool storage box

or pull out the polystyrene cover plate

(depending on version).

F

U

nscrew the central nut. F

R

emove the fastening device (nut and bolt).

F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

Putting the wheel back in place

F Put the wheel back in its housing.

F

S lacken the nut on the bolt by a few turns. If there is no wheel in the well, the

fastening device (nut and bolt) cannot be

refitted.

Removing a wheel

* Position

P for the automatic gearbox

Parking the vehicle

Stop the vehicle where it does not block

traffic: the ground must be level, stable

and non-slippery.

Apply the parking brake, switch off the

ignition and engage first gear* so as to

block the wheels.

Check that the parking brake warning

lamp comes on fixed in the instrument

panel.

The occupants must get out of the vehicle

and wait in a safe place.

Make sure that the jack is correctly

positioned at one of the vehicle's jacking

points.

Incorrect use of the jack could cause the

vehicle to collapse.

Never go underneath a vehicle raised

using a jack; use an axle stand.

F

P

osition the fastening device (nut and bolt)

in the middle of the wheel.

F

T

ighten the central nut to retain the wheel

c o r r e c t l y.

F

C

lip the tool storage box back into place

or reinsert the polystyrene cover plate

(depending on version).

In the event of a breakdown