tires DAEWOO NUBIRA 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 917 of 2643

2B – 10IWHEEL ALIGNMENT

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FOUR WHEEL ALIGNMENT

The first responsibility of engineering is to design safe

steering and suspension systems. Each component must

be strong enough to withstand and absorb extreme pun-

ishment. Both the steering system and the front and the

rear suspension must function geometrically with the body

mass.

The steering and the suspension systems require that the

front wheels self–return and that the tire rolling effort and

the road friction be held to a negligible force in order to al-

low the customer to direct the vehicle with the least effort

and the most comfort.

A complete wheel alignment check should include mea-

surements of the rear toe and camber.

Four–wheel alignment assures that all four wheels will be

running in precisely the same direction.

When the vehicle is geometrically aligned, fuel economy

and tire life are at their peak, and steering and perfor-

mance are maximized.

TOE

Toe–in is the turning in of the tires, while toe–out is the

turning out of the tires from the geometric centerline or

thrust line. The toe ensures parallel rolling of the wheels.

The toe serves to offset the small deflections of the wheel

support system which occur when the vehicle is rolling for-

ward. The specified toe angle is the setting which achieves

0 degrees of toe when the vehicle is moving.

Incorrect toe–in or toe–out will cause tire wear and re-

duced fuel economy. As the individual steering and sus-

pension components wear from vehicle mileage, addition-

al toe will be needed to compensate for the wear.

Always correct the toe dimension last.

CASTER

Caster is the tilting of the uppermost point of the steering

axis either forward or backward from the vertical when

viewed from the side of the vehicle. A backward tilt is posi-

tive, and a forward tilt is negative. Caster influences direc-

tional control of the steering but does not affect tire wear.

Weak springs or overloading a vehicle will affect caster.

One wheel with more positive caster will pull toward the

center of the car. This condition will cause the car to move

or lean toward the side with the least amount of positive

caster. Caster is measured in degrees and is not adjust-

able.

CAMBER

Camber is the tilting of the top of the tire from the vertical

when viewed from the front of the vehicle. When the tires

tilt outward, the camber is positive. When the tires tilt in-

ward, the camber is negative. The camber angle is mea-

sured in degrees from the vertical. Camber influences

both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too much

negative camber, the inside shoulder of the tire will wear.

Camber is not adjustable.

STEERING AXIS INCLINATION

Steering Axis Inclination (SAI) is the tilt at the top of the

steering knuckle from the vertical. Measure the SAI angle

from the true vertical to a line through the center of the strut

and the lower ball joint as viewed from the front of the ve-

hicle.

SAI helps the vehicle track straight down the road and as-

sists the wheel back into the straight ahead position. SAI

on front wheel drive vehicles should be negative.

INCLUDED ANGLE

The included angle is the angle measured from the cam-

ber angle to the line through the center of the strut and the

lower ball joint as viewed from the front of the vehicle.

The included angle is calculated in degrees. Most align-

ment racks will not measure the included angle directly. To

determine the included angle, subtract the negative or add

the positive camber readings to the Steering Axis Inclina-

tion (SAI).

SCRUB RADIUS

The scrub radius is the distance between true vertical and

the line through the center of the strut and lower ball joint

to the road surface. Scrub radius is built into the design of

the vehicle. Scrub radius is not adjustable.

SETBACK

The setback is the distance in which one front hub and

bearing assembly may be rearward of the other front hub

and bearing assembly. Setback is primarily caused by a

road hazard or vehicle collision.

TURNING ANGLE

The turning angle is the angle of each front wheel to the

vertical when the vehicle is making a turn.

Page 927 of 2643

2C – 10IFRONT SUSPENSION

DAEWOO V–121 BL4

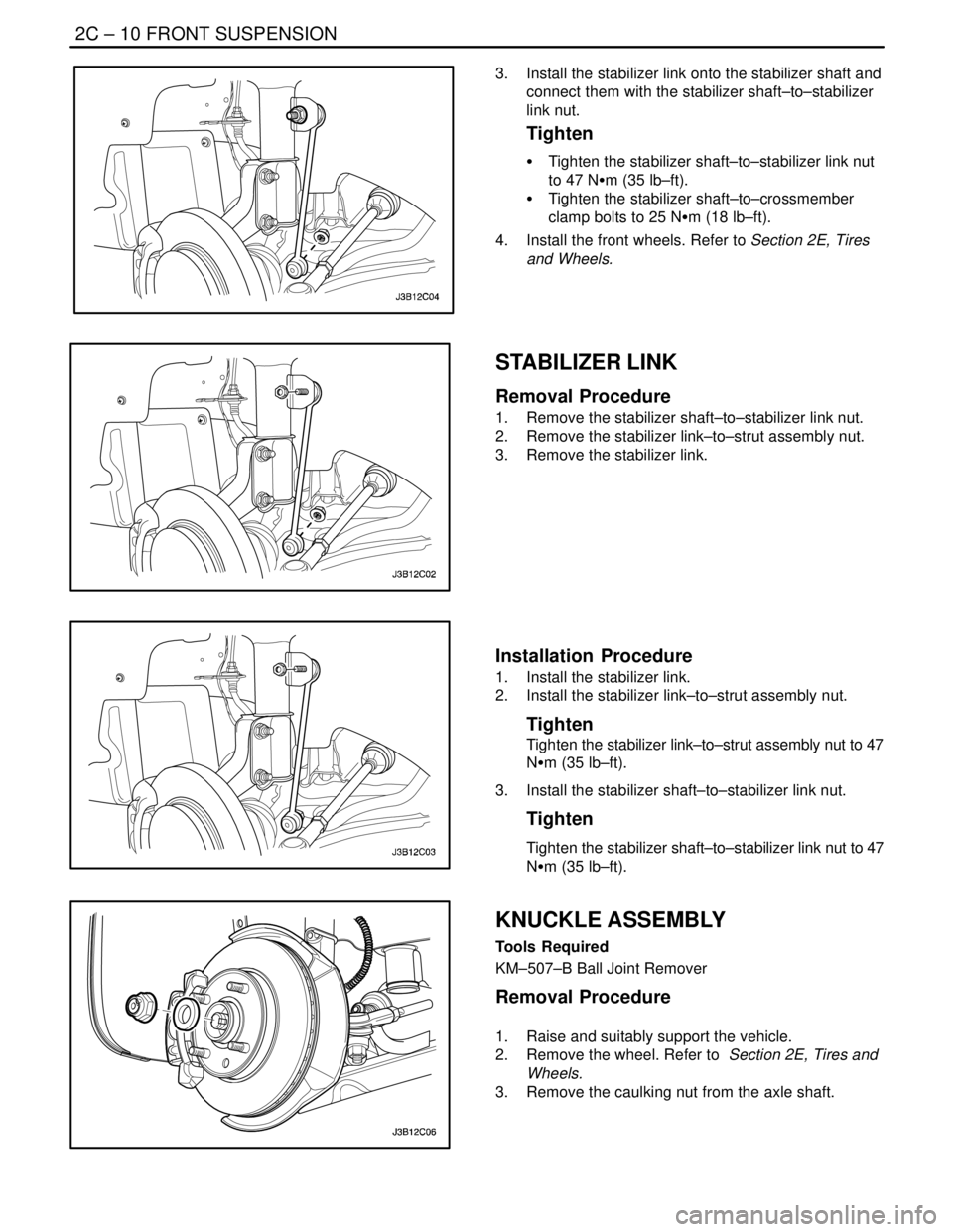

3. Install the stabilizer link onto the stabilizer shaft and

connect them with the stabilizer shaft–to–stabilizer

link nut.

Tighten

S Tighten the stabilizer shaft–to–stabilizer link nut

to 47 NSm (35 lb–ft).

S Tighten the stabilizer shaft–to–crossmember

clamp bolts to 25 NSm (18 lb–ft).

4. Install the front wheels. Refer to Section 2E, Tires

and Wheels.

STABILIZER LINK

Removal Procedure

1. Remove the stabilizer shaft–to–stabilizer link nut.

2. Remove the stabilizer link–to–strut assembly nut.

3. Remove the stabilizer link.

Installation Procedure

1. Install the stabilizer link.

2. Install the stabilizer link–to–strut assembly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

3. Install the stabilizer shaft–to–stabilizer link nut.

Tighten

Tighten the stabilizer shaft–to–stabilizer link nut to 47

NSm (35 lb–ft).

KNUCKLE ASSEMBLY

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the caulking nut from the axle shaft.

Page 930 of 2643

FRONT SUSPENSION 2C – 13

DAEWOO V–121 BL4

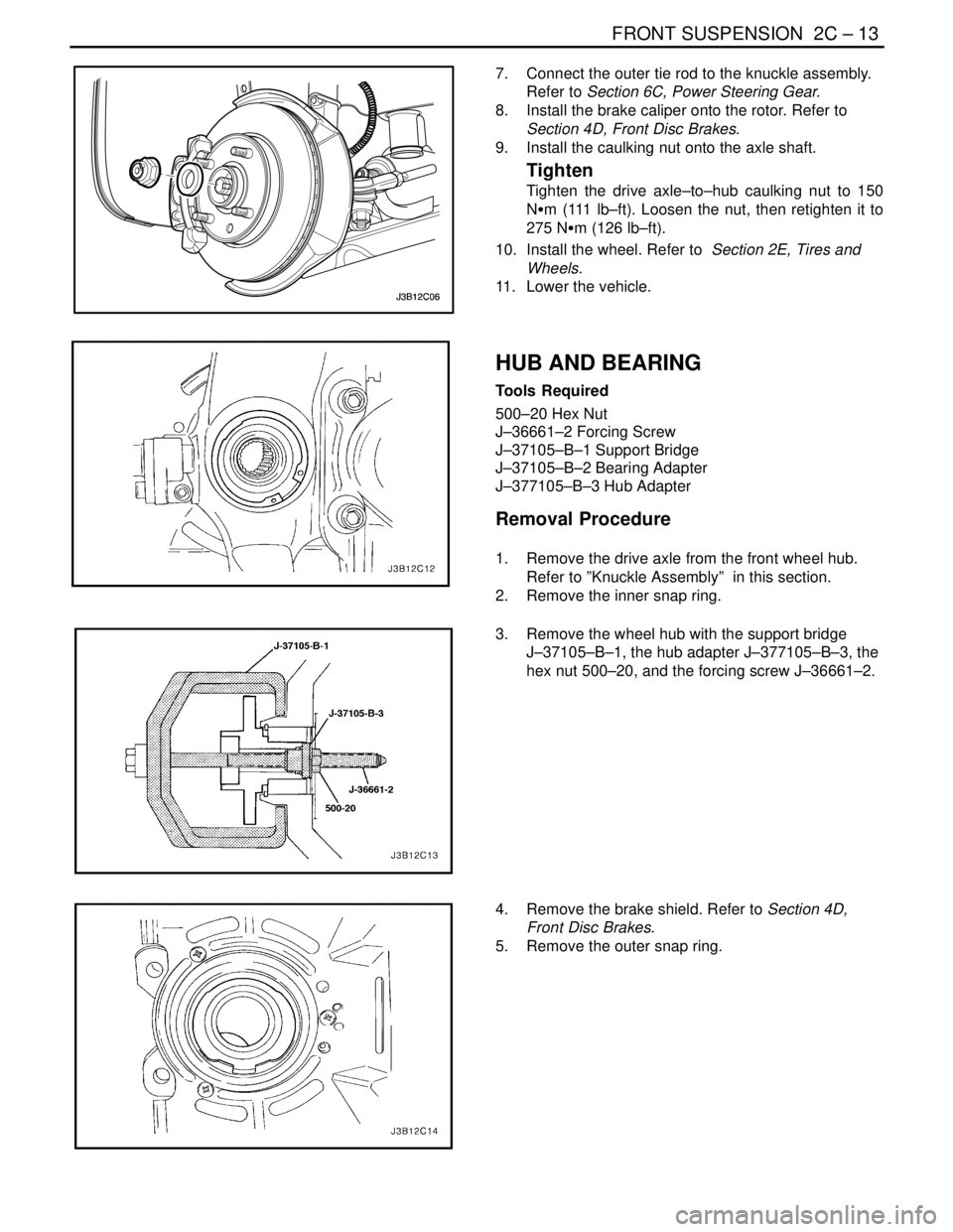

7. Connect the outer tie rod to the knuckle assembly.

Refer to Section 6C, Power Steering Gear.

8. Install the brake caliper onto the rotor. Refer to

Section 4D, Front Disc Brakes.

9. Install the caulking nut onto the axle shaft.

Tighten

Tighten the drive axle–to–hub caulking nut to 150

NSm (111 lb–ft). Loosen the nut, then retighten it to

275 NSm (126 lb–ft).

10. Install the wheel. Refer to Section 2E, Tires and

Wheels.

11. Lower the vehicle.

HUB AND BEARING

Tools Required

500–20 Hex Nut

J–36661–2 Forcing Screw

J–37105–B–1 Support Bridge

J–37105–B–2 Bearing Adapter

J–377105–B–3 Hub Adapter

Removal Procedure

1. Remove the drive axle from the front wheel hub.

Refer to ”Knuckle Assembly” in this section.

2. Remove the inner snap ring.

3. Remove the wheel hub with the support bridge

J–37105–B–1, the hub adapter J–377105–B–3, the

hex nut 500–20, and the forcing screw J–36661–2.

4. Remove the brake shield. Refer to Section 4D,

Front Disc Brakes.

5. Remove the outer snap ring.

Page 931 of 2643

2C – 14IFRONT SUSPENSION

DAEWOO V–121 BL4

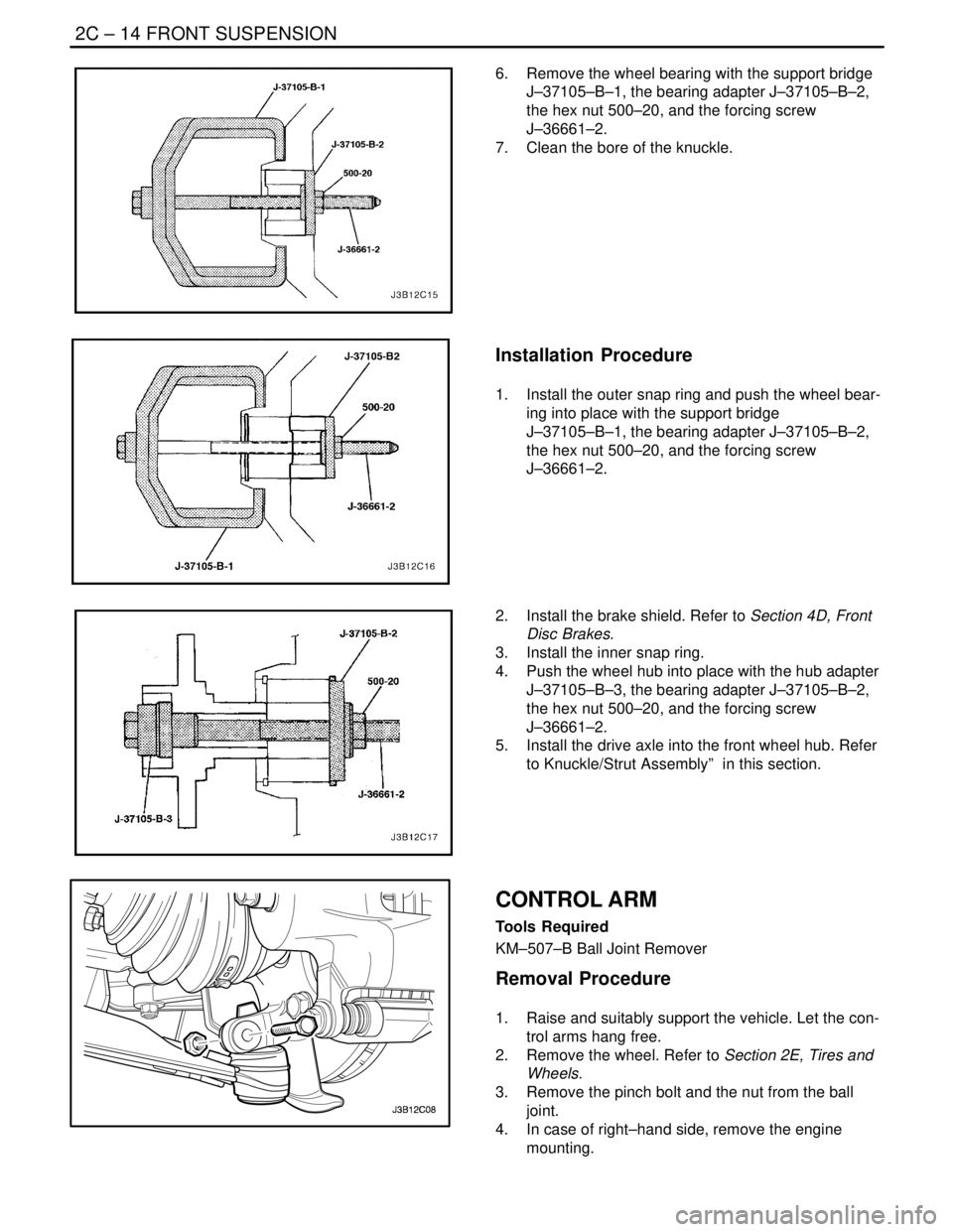

6. Remove the wheel bearing with the support bridge

J–37105–B–1, the bearing adapter J–37105–B–2,

the hex nut 500–20, and the forcing screw

J–36661–2.

7. Clean the bore of the knuckle.

Installation Procedure

1. Install the outer snap ring and push the wheel bear-

ing into place with the support bridge

J–37105–B–1, the bearing adapter J–37105–B–2,

the hex nut 500–20, and the forcing screw

J–36661–2.

2. Install the brake shield. Refer to Section 4D, Front

Disc Brakes.

3. Install the inner snap ring.

4. Push the wheel hub into place with the hub adapter

J–37105–B–3, the bearing adapter J–37105–B–2,

the hex nut 500–20, and the forcing screw

J–36661–2.

5. Install the drive axle into the front wheel hub. Refer

to Knuckle/Strut Assembly” in this section.

CONTROL ARM

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Raise and suitably support the vehicle. Let the con-

trol arms hang free.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the pinch bolt and the nut from the ball

joint.

4. In case of right–hand side, remove the engine

mounting.

Page 933 of 2643

2C – 16IFRONT SUSPENSION

DAEWOO V–121 BL4

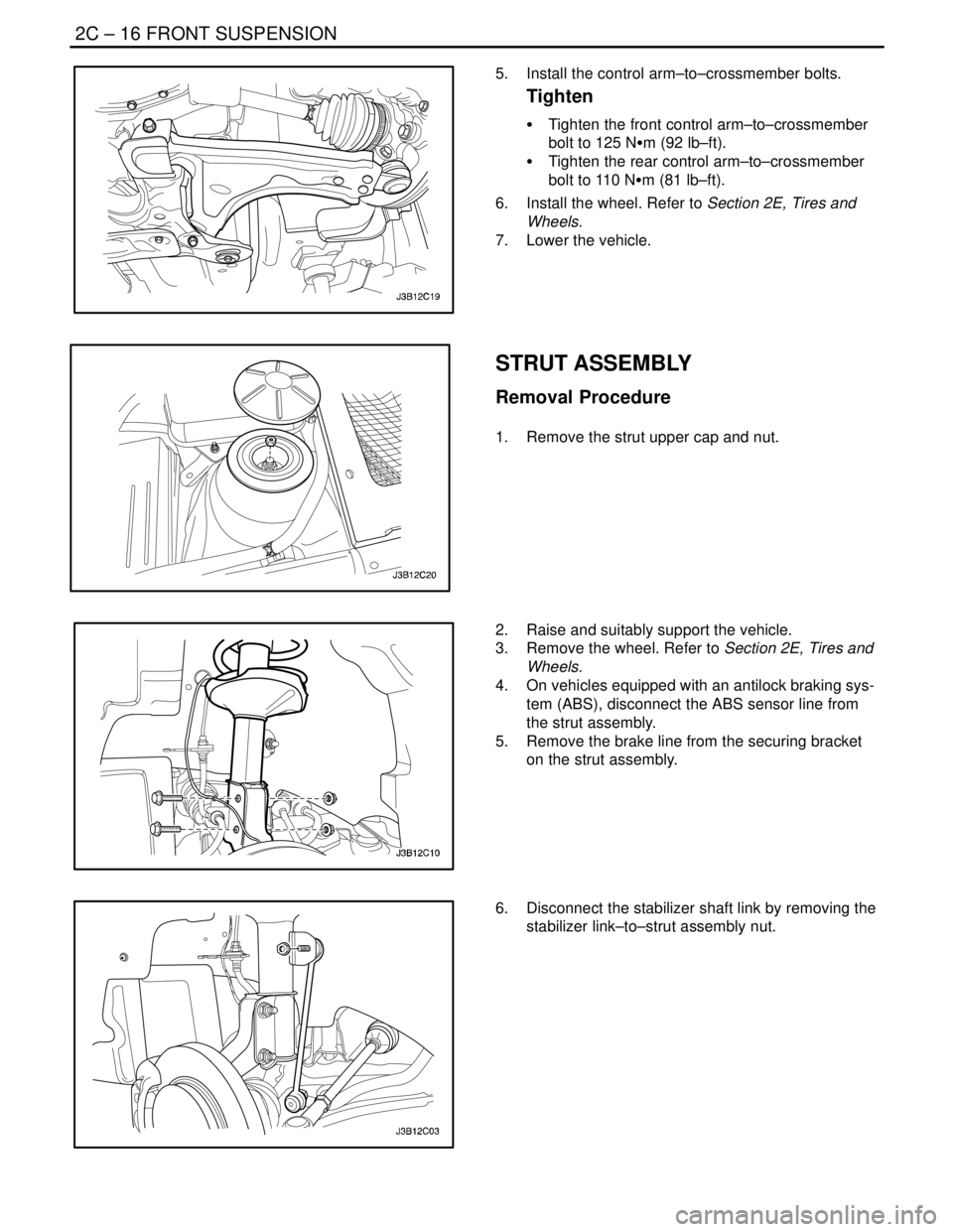

5. Install the control arm–to–crossmember bolts.

Tighten

S Tighten the front control arm–to–crossmember

bolt to 125 NSm (92 lb–ft).

S Tighten the rear control arm–to–crossmember

bolt to 110 NSm (81 lb–ft).

6. Install the wheel. Refer to Section 2E, Tires and

Wheels.

7. Lower the vehicle.

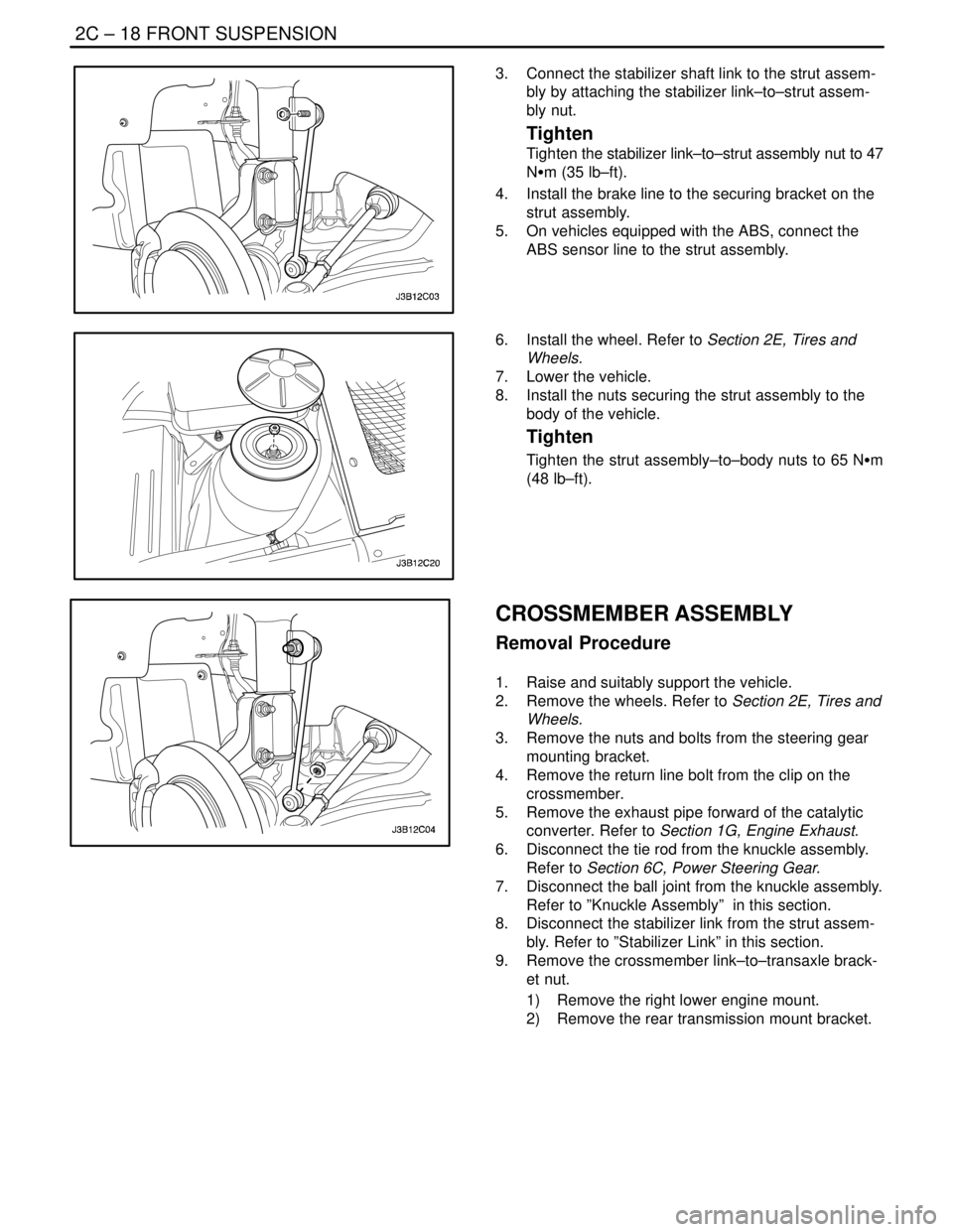

STRUT ASSEMBLY

Removal Procedure

1. Remove the strut upper cap and nut.

2. Raise and suitably support the vehicle.

3. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

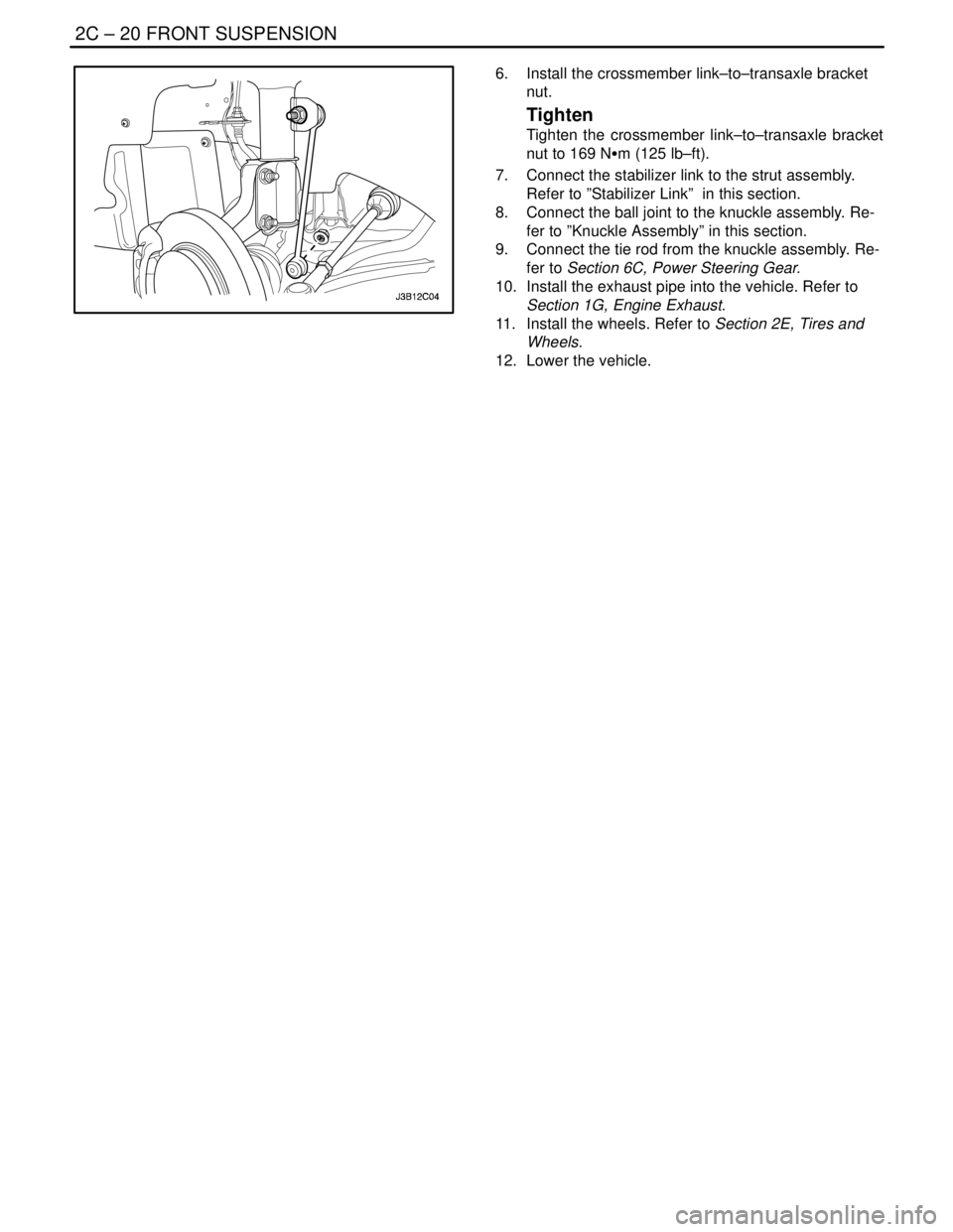

4. On vehicles equipped with an antilock braking sys-

tem (ABS), disconnect the ABS sensor line from

the strut assembly.

5. Remove the brake line from the securing bracket

on the strut assembly.

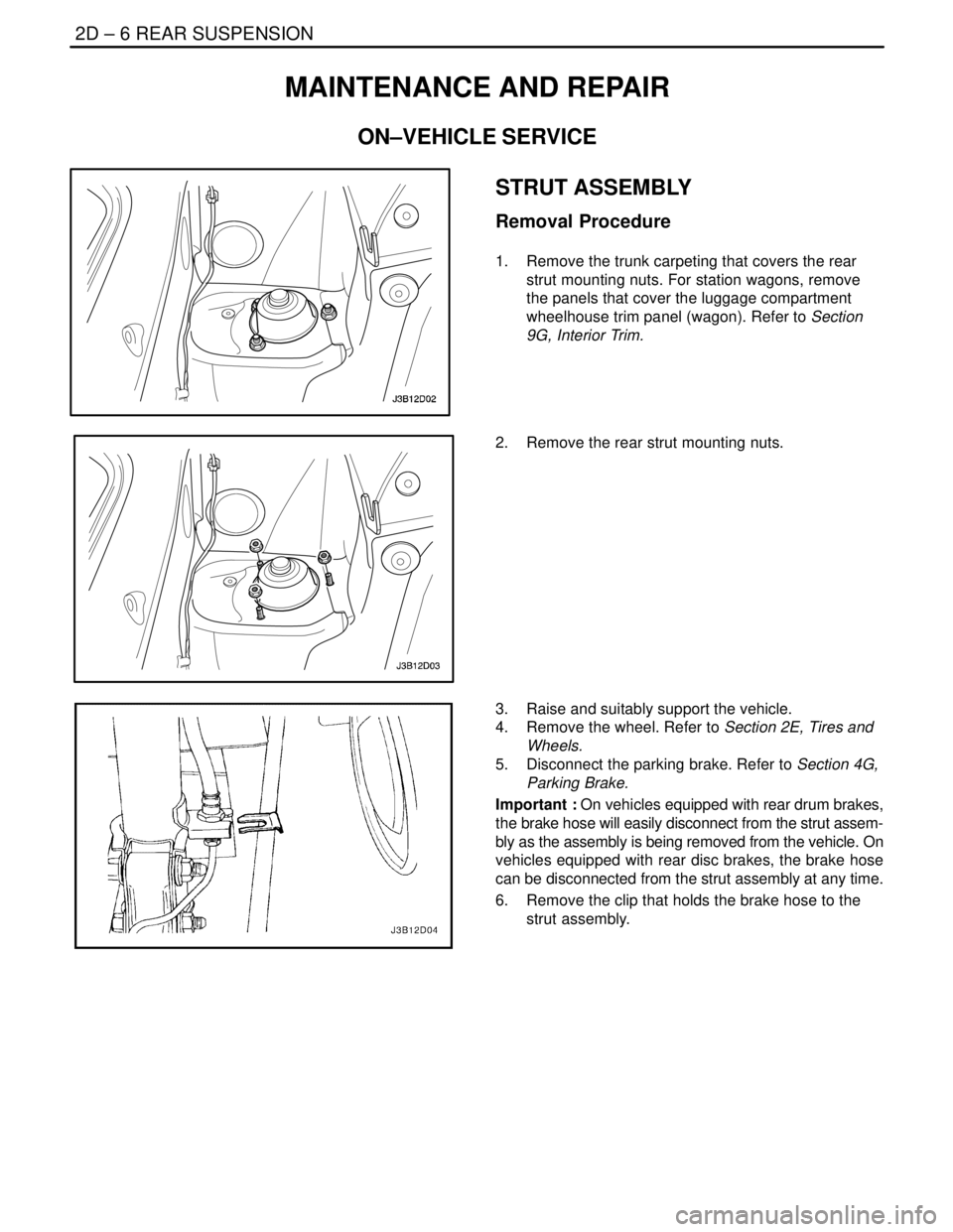

6. Disconnect the stabilizer shaft link by removing the

stabilizer link–to–strut assembly nut.

Page 935 of 2643

2C – 18IFRONT SUSPENSION

DAEWOO V–121 BL4

3. Connect the stabilizer shaft link to the strut assem-

bly by attaching the stabilizer link–to–strut assem-

bly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

4. Install the brake line to the securing bracket on the

strut assembly.

5. On vehicles equipped with the ABS, connect the

ABS sensor line to the strut assembly.

6. Install the wheel. Refer to Section 2E, Tires and

Wheels.

7. Lower the vehicle.

8. Install the nuts securing the strut assembly to the

body of the vehicle.

Tighten

Tighten the strut assembly–to–body nuts to 65 NSm

(48 lb–ft).

CROSSMEMBER ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheels. Refer to Section 2E, Tires and

Wheels.

3. Remove the nuts and bolts from the steering gear

mounting bracket.

4. Remove the return line bolt from the clip on the

crossmember.

5. Remove the exhaust pipe forward of the catalytic

converter. Refer to Section 1G, Engine Exhaust.

6. Disconnect the tie rod from the knuckle assembly.

Refer to Section 6C, Power Steering Gear.

7. Disconnect the ball joint from the knuckle assembly.

Refer to ”Knuckle Assembly” in this section.

8. Disconnect the stabilizer link from the strut assem-

bly. Refer to ”Stabilizer Link” in this section.

9. Remove the crossmember link–to–transaxle brack-

et nut.

1) Remove the right lower engine mount.

2) Remove the rear transmission mount bracket.

Page 937 of 2643

2C – 20IFRONT SUSPENSION

DAEWOO V–121 BL4

6. Install the crossmember link–to–transaxle bracket

nut.

Tighten

Tighten the crossmember link–to–transaxle bracket

nut to 169 NSm (125 lb–ft).

7. Connect the stabilizer link to the strut assembly.

Refer to ”Stabilizer Link” in this section.

8. Connect the ball joint to the knuckle assembly. Re-

fer to ”Knuckle Assembly” in this section.

9. Connect the tie rod from the knuckle assembly. Re-

fer to Section 6C, Power Steering Gear.

10. Install the exhaust pipe into the vehicle. Refer to

Section 1G, Engine Exhaust.

11. Install the wheels. Refer to Section 2E, Tires and

Wheels.

12. Lower the vehicle.

Page 948 of 2643

2D – 6IREAR SUSPENSION

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

STRUT ASSEMBLY

Removal Procedure

1. Remove the trunk carpeting that covers the rear

strut mounting nuts. For station wagons, remove

the panels that cover the luggage compartment

wheelhouse trim panel (wagon). Refer to Section

9G, Interior Trim.

2. Remove the rear strut mounting nuts.

3. Raise and suitably support the vehicle.

4. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

5. Disconnect the parking brake. Refer to Section 4G,

Parking Brake.

Important : On vehicles equipped with rear drum brakes,

the brake hose will easily disconnect from the strut assem-

bly as the assembly is being removed from the vehicle. On

vehicles equipped with rear disc brakes, the brake hose

can be disconnected from the strut assembly at any time.

6. Remove the clip that holds the brake hose to the

strut assembly.

Page 950 of 2643

2D – 8IREAR SUSPENSION

DAEWOO V–121 BL4

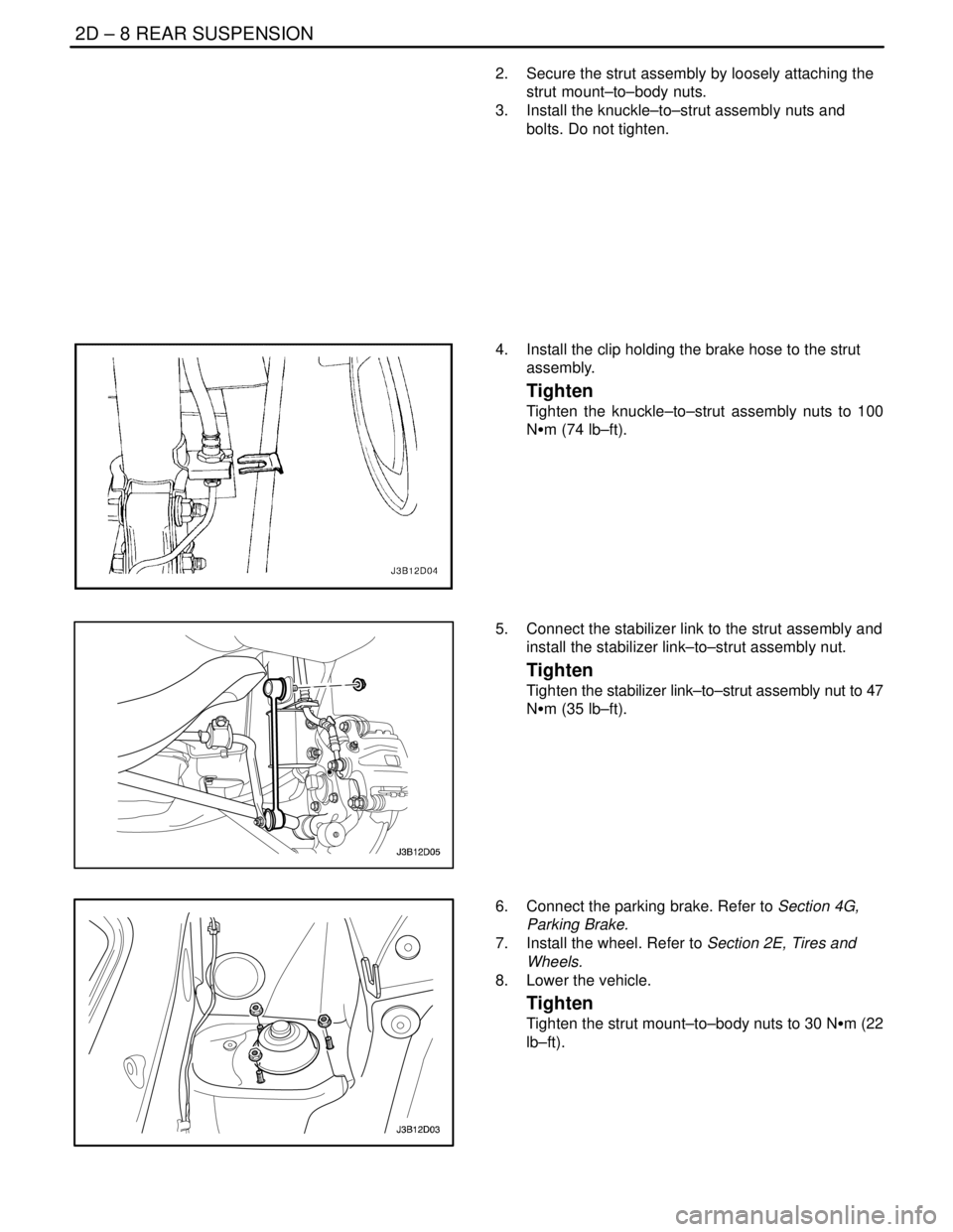

2. Secure the strut assembly by loosely attaching the

strut mount–to–body nuts.

3. Install the knuckle–to–strut assembly nuts and

bolts. Do not tighten.

4. Install the clip holding the brake hose to the strut

assembly.

Tighten

Tighten the knuckle–to–strut assembly nuts to 100

NSm (74 lb–ft).

5. Connect the stabilizer link to the strut assembly and

install the stabilizer link–to–strut assembly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

6. Connect the parking brake. Refer to Section 4G,

Parking Brake.

7. Install the wheel. Refer to Section 2E, Tires and

Wheels.

8. Lower the vehicle.

Tighten

Tighten the strut mount–to–body nuts to 30 NSm (22

lb–ft).

Page 951 of 2643

REAR SUSPENSION 2D – 9

DAEWOO V–121 BL4

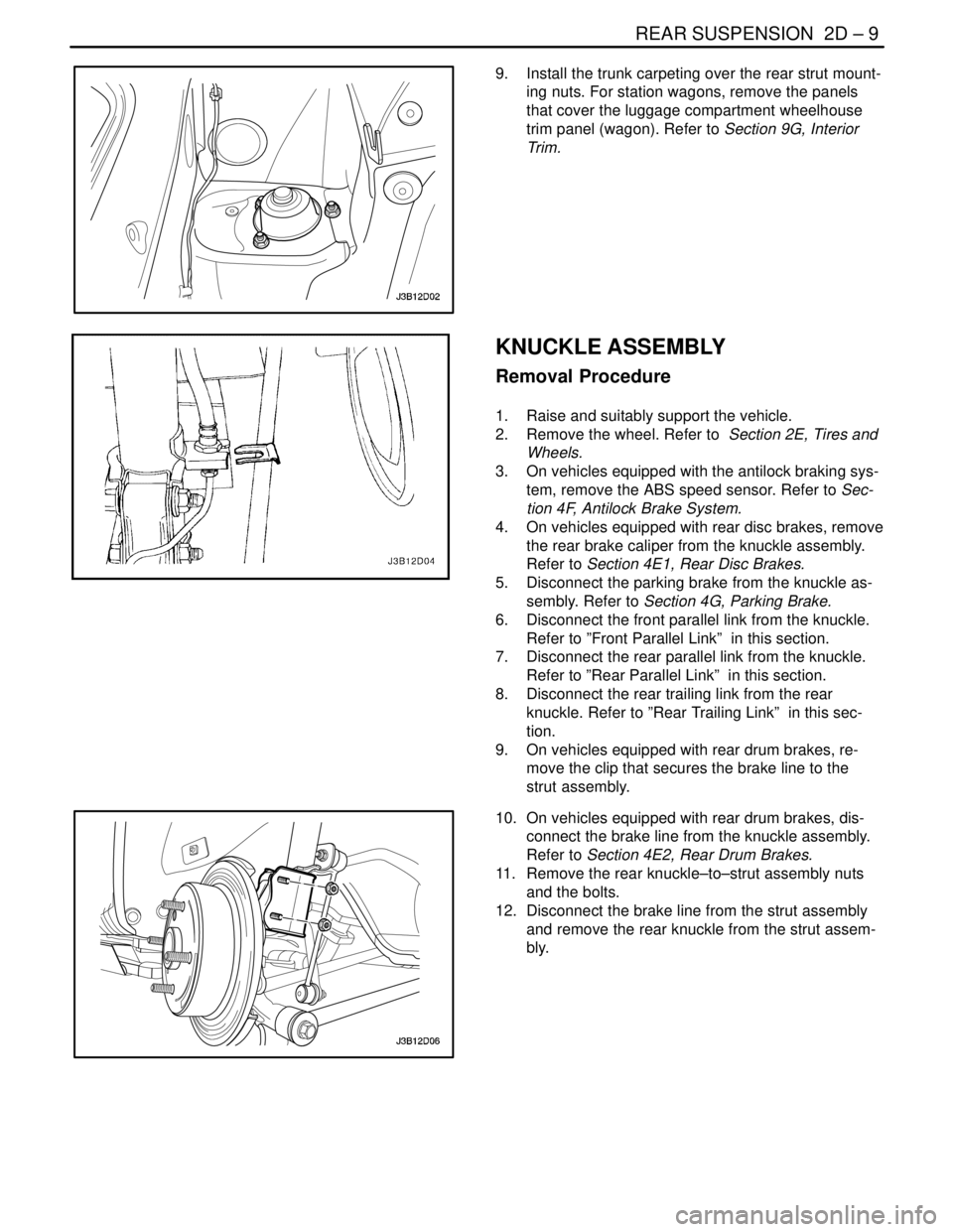

9. Install the trunk carpeting over the rear strut mount-

ing nuts. For station wagons, remove the panels

that cover the luggage compartment wheelhouse

trim panel (wagon). Refer to Section 9G, Interior

Trim.

KNUCKLE ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. On vehicles equipped with the antilock braking sys-

tem, remove the ABS speed sensor. Refer to Sec-

tion 4F, Antilock Brake System.

4. On vehicles equipped with rear disc brakes, remove

the rear brake caliper from the knuckle assembly.

Refer to Section 4E1, Rear Disc Brakes.

5. Disconnect the parking brake from the knuckle as-

sembly. Refer to Section 4G, Parking Brake.

6. Disconnect the front parallel link from the knuckle.

Refer to ”Front Parallel Link” in this section.

7. Disconnect the rear parallel link from the knuckle.

Refer to ”Rear Parallel Link” in this section.

8. Disconnect the rear trailing link from the rear

knuckle. Refer to ”Rear Trailing Link” in this sec-

tion.

9. On vehicles equipped with rear drum brakes, re-

move the clip that secures the brake line to the

strut assembly.

10. On vehicles equipped with rear drum brakes, dis-

connect the brake line from the knuckle assembly.

Refer to Section 4E2, Rear Drum Brakes.

11. Remove the rear knuckle–to–strut assembly nuts

and the bolts.

12. Disconnect the brake line from the strut assembly

and remove the rear knuckle from the strut assem-

bly.