wheel torque DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 326 of 548

Turning

engie

of

front

wheel

Inner

wheel

380

to

42

Outel

wheel

31

0

to

35

0

Tightening

torque

of

bolts

and

nuts

kg

m

ft

lb

@

3

9

to

5

3

28

to

38

@

3

0

to

3

5

22

to

25

@

5

5

to

10

0

40

to

72

@

7

3

to

9

9

53

to

72

@

5

1

to

6

1

371044

ear

wheels

with

chocks

fron

t

of

car

and

support

Front

Axle

Front

Suspension

FA125

Fig

FA

6

AdjU

ting

Steering

Angle

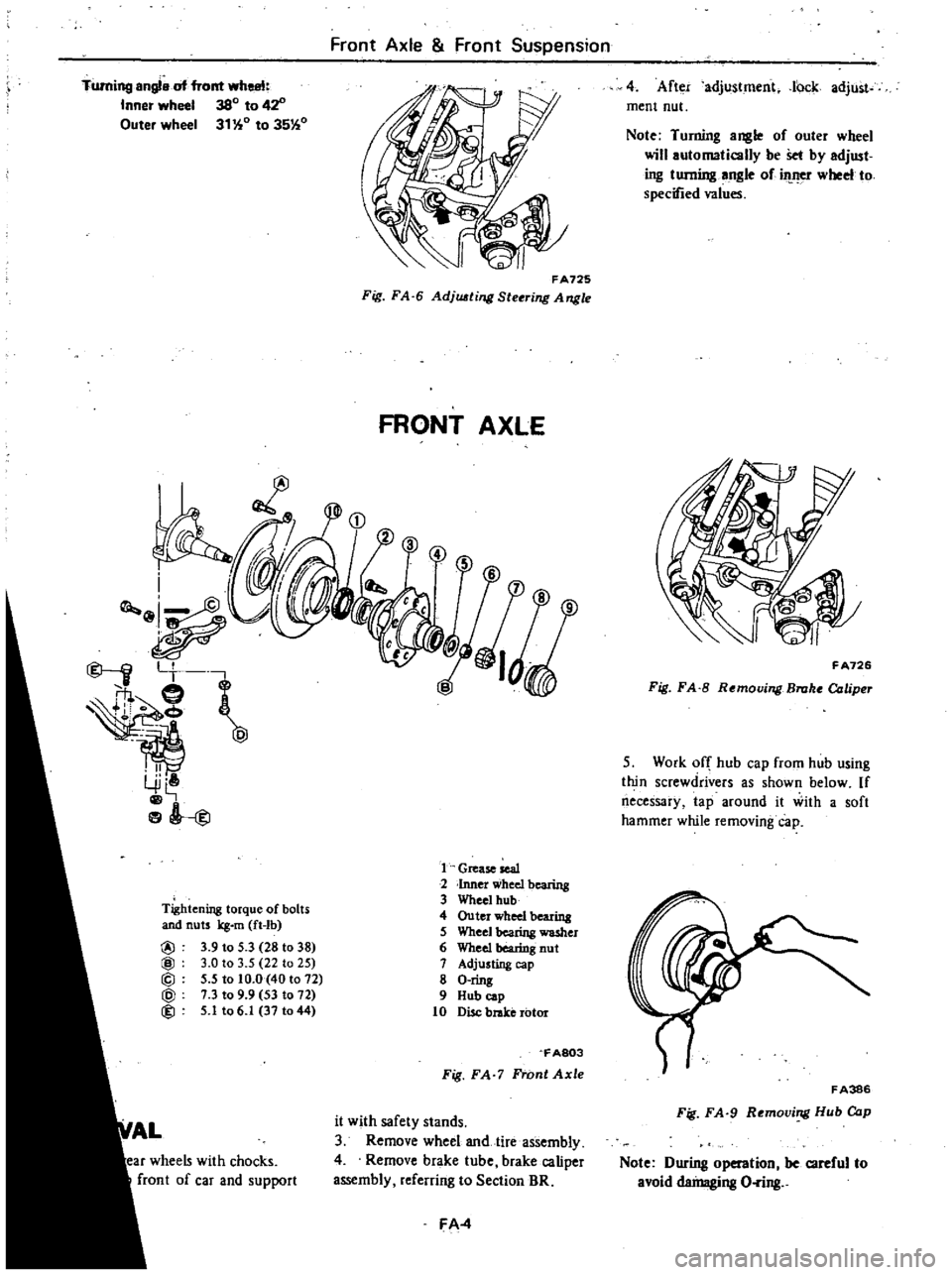

FRONT

AXLE

1

Grease

seal

2

Inner

wbeel

bearin

3

Wheel

hub

4

Outer

wheel

bearins

5

Wheel

bearing

washer

6

Wheel

bearing

nut

7

Adjusting

cap

8

O

ring

9

Hub

cap

10

Disc

brake

rotor

FA803

Fig

FA

7

Front

Axle

it

with

safety

stands

3

Remove

wheel

and

tire

assembly

4

Remove

brake

tube

brake

caliper

assembly

referring

to

Section

DR

FA

4

4

After

adjustment

l

ck

adju

ment

nut

Note

Turning

angle

of

outer

wheel

will

automatically

be

Set

by

adjust

ing

turning

angle

ofin

f

U

wheel

to

specified

values

FA726

Fig

FA

8

RemouingBroke

Caliper

5

Work

off

hub

cap

from

hub

using

t

n

screwdrivers

as

shown

below

If

necessary

tap

around

it

with

a

soft

hammer

while

removing

cap

F

A386

Fig

FA

9

Remouing

Hub

Cap

Note

During

operation

be

careful

to

avoid

deinaging

O

ring

Page 327 of 548

6

Pry

off

cotter

pin

take

out

ad

justing

cap

and

wheel

bearing

lock

nut

7

Remove

wheel

hub

with

disc

brake

rotor

from

spindle

with

bearing

installed

FA199

Fig

FA

10

Removing

Wheel

Hub

Note

Be

careful

not

to

drop

outer

bearing

DOne

out

of

hub

when

removing

hub

from

knuckle

spin

dle

8

Remove

outer

bearing

cone

9

Loosen

four

bolts

securing

brake

disc

remove

disc

brake

rotor

from

wheel

hub

assembly

Fig

FA

11

Removing

Due

Broke

Rotor

Loosen

screws

securing

baffle

plate

take

out

baffle

plate

10

Remove

inner

earing

cone

after

prying

out

grease

seaL

Discard

grease

seaL

11

If

it

is

necessary

to

replace

earing

outer

race

drive

it

out

from

hub

with

a

brass

drift

and

mallet

Evenly

tap

bearing

outer

race

through

two

grooves

inside

hub

Front

Axle

Front

Suspension

Fig

FA

12

Removing

Bearing

Outer

Race

INSPECTION

WHEEL

BEARING

Thoroughly

clean

grease

and

dirt

from

wheel

bearing

with

cleaning

sol

vent

and

dry

with

compressed

air

free

from

moisture

Check

wheel

bearing

to

see

that

it

rolls

freely

and

is

free

from

noise

crack

pitting

or

wear

WHEEL

HUB

Check

wheel

hub

for

crack

by

means

of

a

magnetic

exploration

or

dyeing

test

and

replace

if

cracked

INSTALLATION

Install

front

axle

in

the

reverse

order

of

removal

noting

the

fol

lowing

I

Install

bearing

outer

race

with

Front

Wheel

Bearing

Drift

Inner

ST35321000

Front

wheel

Bearing

Drift

Outer

ST35322000

and

Drift

Bar

ST35325000

until

they

seat

in

hub

2

Pack

hub

and

hub

cap

with

re

commended

multi

purpose

grease

up

to

shaded

portions

fA261

Fig

FA

13

LubriCating

Points

of

Wheel

Hub

FA

5

3

Coat

each

bearing

DOne

with

rec

ommended

multi

purpose

grease

FA781

Fig

FA

14

Coating

Bearing

Cone

with

Grease

4

Place

inner

bearing

cone

in

hub

and

install

a

new

grease

seal

coating

sealing

lips

with

recommended

multi

purpose

grease

5

Concerning

installation

of

brake

parts

refer

to

Section

BR

i

l

Tightening

tOlque

Disc

brake

Rotor

to

hub

3

9

to

5

3

kg

m

28

to

38

ft

lbl

6

Install

hub

with

rotor

and

outer

bearing

cone

7

Sparingly

apply

recommended

multi

purpose

grease

to

threaded

por

tion

of

spindle

and

bearing

washer

to

bearing

contacting

face

Then

install

washer

and

wheel

bearing

nut

Adjust

wheel

bearing

nut

as

de

scribed

in

Adjustment

in

this

section

Note

a

In

order

to

assure

DOrrect

bearing

starting

torque

and

to

extend

serv

ice

nfe

of

wheel

bearings

be

sure

to

avoid

dirt

and

foreign

particles

get

ting

iIi

bearings

grease

seal

Washer

bearing

nut

etc

b

Grease

should

be

changed

at

each

disassembly

end

in

aa

ordance

with

Periodic

Maintenance

Schedule

8

Install

O

ring

on

hub

cap

and

install

hub

cap

on

hub

9

Install

brake

caliper

assembly

re

ferring

to

Section

BR

10

Install

wheel

and

lire

Page 332 of 548

wheels

2

Remove

splaahboard

if

necessary

3

Back

off

nut

securing

tension

rod

to

bracket

and

remove

bolts

which

secure

tension

rod

to

lower

arm

Tension

rod

can

then

be

taken

out

4

Remove

nuts

securing

stabilizer

bar

to

connecting

rod

Note

Two

wrenches

are

n

1

in

this

B

5

Remove

bolts

and

nuts

securing

stabilizer

bar

bracket

in

position

Stabilizer

bar

can

then

be

iaken

o

t

CV

3

@

I

Lower

ann

5

Tension

rod

2

Stabilizer

bar

bracket

connecting

rod

6

Tension

rod

3

Stabilizer

bar

4

Stabilizer

bar

bracket

FA129

Fig

FA

31

Removing

Tension

Rod

and

Stabilizer

Bar

INSPECTION

I

Check

tension

rod

and

stabilizer

bar

for

evidence

of

deformation

or

cracks

if

necessary

replace

2

Check

rubber

parts

such

as

ten

sion

rod

and

stabilizer

bar

bushings

to

be

sure

they

are

not

deteriorated

or

cracked

if

1ecessary

replace

INSTAllATION

Install

tension

rod

and

stabilizer

bar

in

tJ

1e

reverse

order

of

removal

noting

the

following

I

Be

sure

stabilizer

bar

is

not

closer

to

either

side

but

is

located

at

the

middle

If

stabilizer

bar

is

new

use

the

following

procedure

to

center

the

stabilizer

bar

Position

arm

with

white

paipt

mark

toward

left

side

of

car

Front

Axle

Front

Suspension

Set

slabillz

rliar

mount

bushingS

So

that

outer

side

of

stabilizer

bar

bushing

is

brought

into

inner

side

of

marking

e

o

I

19

e

1

Marking

2

Bushing

3

Marking

4

While

painting

5

Marking

0

A

F

A667

Fig

FA

32

Centering

8lDbilize

Bar

2

Chec

to

be

sure

that

tension

rod

bushing

is

propelly

centered

in

its

seat

3

Be

sure

that

tension

rod

bracket

bolt

is

correctly

torqued

Note

a

Noting

direction

of

tension

rod

bushing

properly

center

bushing

in

tension

rod

bushing

washer

Fig

FA

33

Direclion

of

Tension

Rod

BUlhing

b

After

installation

make

sure

mini

mum

clearances

between

tension

rods

end

stabilizer

bar

are

equal

on

both

sides

c

Closely

observe

torq

ue

specification

when

tightening

tension

rod

bracket

retaining

bolts

d

First

tighten

tension

rod

on

bracket

side

to

specified

torque

setting

then

install

the

other

end

on

lower

arm

fJ

Tightening

tOlque

Tension

rod

bushing

installation

nut

4

5

to

5

11rg

33

to

37

ft

lbl

FA

10

Tension

rOd

to

Lower

ann

5

1

to

6

1

kg

m

137

to

44

ft

Ibl

Tension

rod

bracket

to

body

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Stabilizer

bar

bleck

t

1

6to2

11rg

112

to

15

ft

lbl

Stabilizel

bel

connecting

rod

1

6

to

2

1

kg

m

12

to

15

ft

lbl

LOWER

ARM

AND

LOWER

BALL

JOINT

The

lower

ann

is

connected

to

the

suspension

member

through

a

rubber

bwhing

end

to

the

strut

through

a

ball

joint

The

lower

ball

joint

is

assembled

at

the

factory

and

cannot

be

disassem

bled

REMOVAL

1

Block

rear

wheels

with

chocks

2

Jack

up

front

of

car

and

support

it

with

safety

stands

remove

wheel

3

Remove

splashboard

4

Separate

knuckle

arm

from

strut

5

Pry

colter

pin

off

and

separate

side

rod

fromknilckle

arm

using

Ball

Joint

Remover

HT72520000

FA661

Fig

FA

34

Remoliing8ideRod

Ball

Joint

6

Remove

tension

rod

and

stabilizer

bar

from

lower

ann

7

Remove

bolt

connecting

lower

ann

to

suspension

crossmember

Page 336 of 548

WHEEL

BEARING

Wheel

bearing

axial

play

Wheel

bearing

nut

tightening

torque

Return

angle

Rotation

starting

torque

With

new

grease

seal

With

used

grease

seal

At

wheel

hub

bolt

With

new

grease

seal

With

used

grease

seal

SUSPENSIONBA

JOINT

Turning

torque

New

parts

Used

parts

TIGHTENIN

TORQUE

LOWERBAl

L

JOINT

Ball

joint

socket

to

lower

arm

Ball

joint

to

knuckle

arm

Stud

nut

STRUT

Steering

knuckle

arm

to

strut

Strut

to

hoodledge

Piston

rod

self

locking

nut

Gland

packing

DISC

BRAKE

Rotor

to

hub

SIDE

ROD

Side

rod

ball

jOIDt

to

knuckle

arm

LOWER

ARM

Lower

arm

bolt

nut

Side

rod

adjusting

nut

TENSION

ROD

Tension

rod

bushing

installation

nut

Tension

rod

to

lower

arm

Tension

rod

bracket

to

body

Frpn

Axle

Front

Suspension

mm

in

0

0

kg

m

ft

lb

degree

3

0

to

3

5

22

to

25

900

kg

cm

in

lbr

kg

em

in

Ib

Less

than

7

0

6

1

1

0

to

4

5

0

9

to

3

9

kg

lb

kg

lb

Less

than

1

2

2

6

0

1

7

to

0

79

0

37

to

1

74

kg

cm

in

Ib

kg

cm

in

Ib

40

to

100

35

to

87

More

than

20

17

kg

m

ft

Ib

5

1

to

6

1

37

to

44

5

5

to

10

0

40

to

72

7

3

to

9

9

53

to

72

2

5

to

3

5

18

to

25

6

0

to

7

5

43

to

54

8

0

to

11

0

58

to

80

3

9

to

5

3

28

to

38

3

0

to

7

0

22

to

51

3

9

to

5

0

2810

36

8

0

to

10

0

58

to

72

4

5

to

5

1

33

to

37

5

1

to

6

1

37

to

44

3

2

to

4

3

23

to

31

FA

14

Page 342 of 548

DATSUN

210

Model

8310

Series

SECTIONRA

REAR

AXLE

REAR

SUSPENSION

CONTENTS

LINK

TYPE

REAR

AXLE

REAR

AXLE

ASSEMBLY

REAR

AXLE

SHAFT

AND

WHEEL

BEARING

REAR

AXLE

CASE

REAR

SUSPENSION

SHOCK

ABSORBER

COIL

SPRING

LI

N

K

ASSEMBLY

RA

2

RA

3

RA

3

RA

4

RA

5

RA

5

RA

5

RA

6

RA

6

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

SHOCK

ABSORBER

REAR

AXLE

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

RA

8

RA

8

RA

8

RA

8

RA

8

RA

9

RA

lO

RA

ll

Page 344 of 548

REAR

AXLE

REAR

AXLE

ASSEMBLY

Remove

L

Block

front

wheels

with

chocks

2

Raise

rear

of

car

high

enough

to

pennit

working

underneath

and

place

stands

solidly

under

body

member

on

both

sides

RA544

Fig

RA

2

Supporting

Point

3

Support

under

center

of

dif

ferential

carrier

with

a

garage

jack

4

Remove

rear

wheels

5

Disconnect

propeller

shaft

by

re

moving

bolts

CD

securing

propeller

shaft

flange

to

companion

flange

of

differential

carrier

6

Disconnect

brake

hose

from

brake

tube

at

body

@

and

rear

cable

adjuster

@

Fig

RA

3

Removing

Propeller

Shaft

and

Brohe

Hose

CAUTION

e

When

disconnecting

brake

tube

use

suitable

tube

wrench

Never

use

open

end

or

adjustable

wrench

b

Cover

brake

hose

end

pipe

open

ings

to

prevent

entrance

of

dirt

Rear

Axle

Rear

Suspension

7

Remove

bolts

securing

shock

absorber

lower

ends

on

each

side

RA485

Fig

RA

4

Removing

Bolt

Securing

Shock

Absorber

Lower

End

Note

When

removing

shock

absorber

lower

end

from

bracket

squeeze

shock

absorber

and

lift

it

out

right

above

to

accommodate

em

bossment

inside

bracket

C

AA486

Fig

RA

5

Shock

Absorber

Lower

End

8

Lower

jack

slowly

and

remove

cojI

springs

on

each

side

after

they

are

fully

extended

AA546

Fig

RA

6

Removing

Coil

Spring

9

Raise

jack

to

its

original

position

10

Remove

bolts

CD

and

@

se

curing

upper

and

lower

links

at

axle

case

side

RA

3

Fig

RA

7

Disconnecting

Upper

Link

and

Lower

Link

II

Release

garage

jack

slowly

and

pull

it

out

toward

rear

of

car

In

tenetlon

Install

rear

axle

in

the

reverse

order

of

removal

CAUTION

a

When

installing

brake

tubes

use

Flare

Nut

Torque

Wrench

GG94310000

b

Before

tightening

link

bushing

nuts

temporarily

attach

upper

and

lower

links

to

axle

case

Alter

jacking

up

center

of

differential

carrier

until

upper

Bnd

lower

links

are

almost

horizontal

securely

tighten

link

bushing

nuts

c

When

supporting

car

weight

at

Cl

nter

of

differential

carrier

do

not

put

a

load

in

car

j

Tightening

torque

Brake

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

Propeller

shaft

to

companion

flange

connecting

nut

2

4

to

3

3

kg

m

17

to

24

ft

Ibl

Shock

absorber

lower

end

nut

7

0

to

8

0

kg

m

51

to

58

ft

Ibl

lower

link

fixing

nut

7

0

to

8

0

kg

m

51

to

58

ft

Ib

Upper

link

fixing

nut

7

0

to

8

0

kg

m

51

to

58

ft

lb

Page 346 of 548

V

CD

l

t

177t

ID

@

A

5

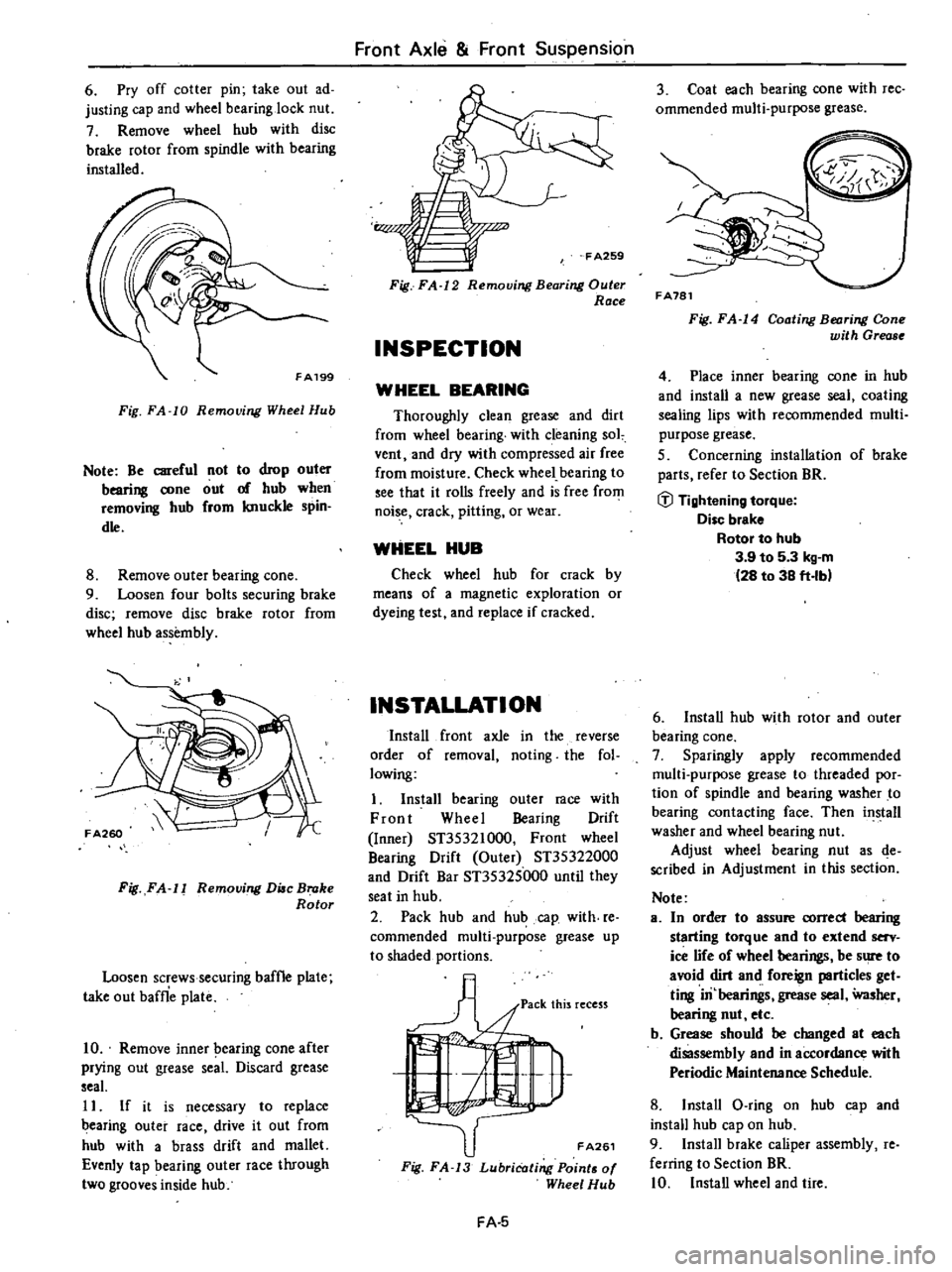

Adjust

gap

c

between

recess

of

rear

axle

tube

and

rear

axle

bearing

by

selecting

shinto

Gap

e

o

to

0

1

mm

0

to

0

004

in

Gap

c

can

be

calculated

by

c

a

b

d

where

a

Distance

from

rear

axle

tube

end

to

recess

b

Bearing

width

c

Gap

c

d

Shint

thickness

RA559

Fig

RA

15

Gap

C

Rear

axle

case

end

shim

Thickness

mm

in

om5

0

0030

0

1

50

0

0059

0

225

0

0089

0

300

0

0118

6

Measure

axial

end

play

of

axle

shaft

with

dial

indicator

Axial

end

plav

0

10

to

0

45

mm

0

0039

to

0

0177

in

Rear

Axle

Rear

Suspension

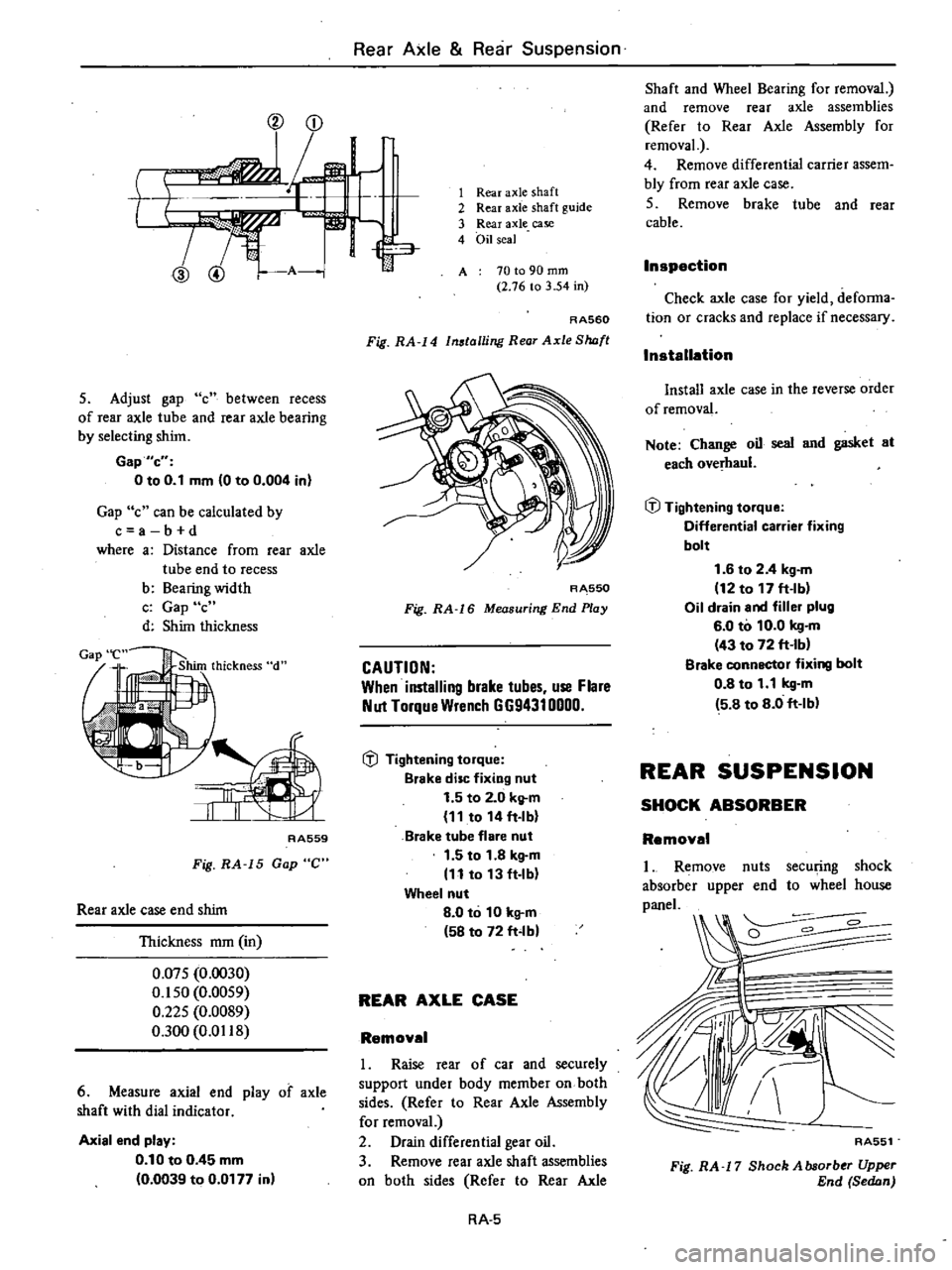

1

Rear

axle

shaft

2

Rear

axle

shaft

guide

3

Rear

axle

case

4

Oil

seal

I

ill

A

70

to

90

mm

2

76

to

3

54

in

A

A560

Fig

RA

14

Installing

Rear

Axle

Slwft

R

550

Fig

RA

16

Measuring

End

Play

CAUTION

When

installing

brake

1ubes

use

Flare

Nul

Torque

Wrench

GG94310000

ifl

Tightening

torque

Brake

disc

fixing

nut

1

5

to

2

0

kg

m

11

to

14

ft

lb

Brake

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

Wheel

nut

8

0

to

10

kg

m

58

to

72

ft

lb

REAR

AXLE

CASE

Remove

I

Raise

rear

of

car

and

securely

support

under

body

member

on

both

sides

Refer

to

Rear

Axle

Assembly

for

removal

2

Drain

differential

gear

oil

3

Remove

rear

axle

shaft

assemblies

on

both

sides

Refer

to

Rear

Axle

RA

5

Shaft

and

Wheel

Bearing

for

removal

and

remove

rear

axle

assemblies

Refer

to

Rear

Axle

Assembly

for

removal

4

Remove

differential

carrier

assem

bly

from

rear

axle

case

5

Remove

brake

tube

and

rear

cable

Inspection

Check

axle

case

for

yield

deforma

tion

or

cracks

and

replace

if

necessary

Installetion

Install

axle

case

in

the

reverse

order

of

removal

Note

Change

oil

seal

and

gasket

at

each

ove

haul

ifl

Tightening

tOlque

Differential

carrier

fixing

bolt

1

6

to

2

4

kg

m

12

to

17

ft

lbl

Oil

drain

and

filler

plug

6

0

to

10

0

kg

m

43

to

72

ft

lbl

Blake

connector

fixing

bolt

0

8

to

1

1

kg

m

5

8

to

8

0

ft

Ibl

REAR

SUSPENSION

SHOCK

ABSORBER

Removal

1

Remove

nuts

secu

ng

shock

absorber

upper

end

to

wheel

house

paneL

RA551

Fig

RA

17

Shock

Absorber

Upper

End

Sedan

Page 347 of 548

I

AA552

Fig

RA

18

Shock

A

bllOrber

Upper

End

2

Remove

bolt

securing

shock

ab

sorber

lower

end

and

remove

shock

absorber

Note

When

removing

shock

ebsorber

lower

end

from

bracket

Iueeze

shock

absorber

end

lift

it

out

right

aJ

o

J

to

accommodate

emb

ss

ment

inside

bracket

c

RA486

Fig

RA

19

Shock

Absorber

Lower

End

Brocket

Inspection

I

Test

shock

absorber

and

compare

with

specification

given

in

Service

Data

and

Specifications

Replace

if

nece

ry

2

Check

for

cracks

Also

check

pis

ton

rod

for

straightness

3

Check

all

rubber

parts

for

wear

cracks

damage

or

deformation

Re

place

if

necessary

Installation

Install

shock

absorber

in

the

reverse

order

of

removal

Note

Tighten

shock

absorber

upper

end

nut

to

specification

until

it

is

fully

tightened

to

thread

end

of

pis

ton

rod

Then

securely

tighten

lock

nut

Rear

Axle

Rear

Suspension

@

Tightening

tonlU1l

Shock

absorber

upper

end

nut

1

5

to

2

0

kg

m

11

to

14

ft

b

Shock

absorber

lower

end

n1

t

7

0

to

8

0

k

l

m

51

to

58

ft

bl

CAUTION

I

Be

careful

not

to

damage

or

bend

piston

rod

during

operation

b

Do

not

open

or

heat

gas

filled

type

shock

absorbers

COIL

SPRING

Removal

Block

front

wheels

with

chocks

2

Raise

rear

of

car

high

enough

to

permit

working

underneath

and

place

stands

solidly

under

body

member

on

both

sides

3

Support

under

center

of

dif

ferential

carrier

with

a

garage

jack

4

Remove

rear

wheels

5

Remove

bolts

securing

shock

absorber

lower

ends

on

each

side

C

J

1

v

I

JJJ

RA485

Fig

RA

20

RemoviTIII

Bolt

Securing

Shock

Abwrber

Lower

End

6

Lower

jack

slowly

and

remove

coil

springs

on

each

side

after

they

are

fully

extended

RA546

Fig

RA

21

Removing

Coil

Spring

RA

6

Inspection

1

Check

coil

spring

for

yield

defor

mation

or

cracks

2

Test

spring

and

compare

with

specifications

given

in

Service

Data

and

Specifications

3

Check

all

rubber

parts

for

wear

cracks

damage

or

deformation

Re

place

if

necessary

InsteDatlon

Install

coil

spring

in

the

reverse

order

ofremoval

CAUTION

Correctly

fit

open

end

on

spring

seat

CD

Tightening

torque

Shock

absorber

lowel

end

nut

7

010

8

0

kg

51

to

58

ft

b

LINK

ASSEMBLY

Removal

It

is

possible

to

remove

one

link

assembly

alone

When

removing

more

than

two

link

assemblies

remove

axle

assembly

first

Refer

to

Rear

Axle

Assembly

for

removal

Remove

upper

link

or

lower

link

alone

by

removing

bolt

on

each

end

Fig

RA

22

Removing

Upper

Link

RA553

Fig

RA

23

Remouing

Lower

Link

Page 350 of 548

TIGHTENING

TORQUE

Brake

tube

connector

flare

nut

Brake

disc

fixing

nut

PropelJer

shaft

to

companion

flange

connecting

nut

Wheel

nut

Drain

and

filler

ptug

Differential

carrier

to

axle

case

bolt

Shock

absorber

upper

end

nut

Shock

absorber

lower

end

nut

Upper

link

fixing

bolt

Upper

link

fixing

nut

Lower

link

fixing

nut

Rear

Axle

Rear

Suspension

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

tb

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

Ib

RA

9

1

5

to

1

8

II

to

13

1

5

to

2

0

II

to

14

2

4

to

3

3

17

to

24

8

0

to

10

0

58

to

72

6

0

to

10

0

43

to

72

1

6

to

2

4

12

to

17

1

5

to

2

0

II

to

14

7

0

to

8

0

51

to

58

7

0t08

0

51

to

58

7

0

to

8

0

51

to

58

7

0

to

8

0

51

to

58

Page 351 of 548

Rear

Axle

Rear

Suspension

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

rear

axle

and

suspension

is

suspected

of

being

noisy

it

is

advis

able

to

make

thorough

test

to

deter

mine

whether

the

noise

originates

in

the

tir

s

roads

rfac

exhaust

propeller

shaft

engine

transmission

universal

joint

wheel

bearings

or

suspension

Noise

which

originates

in

other

places

cannot

be

corrected

by

adjust

Condition

Noise

unusual

sound

Instability

in

driving

This

problem

is

also

related

to

the

front

suspension

For

trouble

diagnosis

also

refer

to

the

FA

section

Oil

leakage

Probable

cause

Loose

wheel

nuts

One

or

more

securing

bolts

loose

Lack

oflubricating

oil

or

grease

Faulty

shock

absorber

Incorrect

adjustment

of

rear

axle

shaft

end

play

Damaged

or

worn

wheel

bearing

Worn

spline

portion

of

rear

axle

shaft

Breakage

of

leaf

spring

ose

journal

connections

etc

Unbalance

of

wheel

and

tire

Damage

of

the

rubber

parts

such

as

link

bU

hing

shock

absorber

moun

ting

bush

ing

Faulty

universal

joints

Breakage

of

coil

spring

Loose

wheel

nuts

Damaged

rear

link

rubber

bushings

Worn

shock

absorber

Incorrect

wheel

alignment

Spring

wear

Damaged

oil

seal

on

rear

axle

shaft

Oil

leakage

from

the

differential

carrier

Damaged

grease

seal

of

rear

axle

shaft

RA

l0

ment

or

replacement

of

parts

in

the

rear

axle

and

rear

suspension

In

case

of

oil

leak

first

check

if

there

is

any

damage

or

restriction

in

breather

Corrective

action

Tighten

Tighten

to

specified

torque

Lubricate

as

required

Replace

Adjust

Replace

Replace

if

necessary

Replace

Tighten

to

torque

Balance

Replace

damaged

parts

Adjust

or

replace

Replace

Tighten

to

specified

torque

Replace

Replace

Adjust

Replace

Replace

Replace

parts

as

required

Replace