height DATSUN 610 1969 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 72 of 171

greased

Install

the

flange

washer

and

pinion

nut

Tighten

the

nut

to

a

torque

reading

of

14

17

kgm

101

130

Ib

fL

If

the

cotter

pin

hole

is

not

correctly

aligned

a

suitable

washer

should

be

fitted

Do

NOT

adjust

by

overtightening

the

pinion

nul

Van

Lubricate

the

front

bearing

with

oil

and

place

it

in

the

carrier

Grease

the

lip

of

the

oil

seal

and

install

it

to

the

final

drive

housing

Install

the

drive

pinion

the

new

collapsible

spacer

and

the

drive

flange

Fit

the

drive

pinion

nut

and

tighten

temporarily

until

all

slackness

is

eliminated

from

the

front

and

rear

of

the

drive

pinion

NOTE

Ensure

that

oil

and

grease

have

been

completely

removed

from

the

threads

of

the

pinion

gear

the

pinion

nut

and

the

washer

Tighten

the

pinion

nut

and

check

the

preload

with

a

preload

gauge

As

the

nut

is

tightened

to

the

specified

torque

reading

of

13

20

kgm

94

0

144

6Ib

fL

the

preload

must

be

measured

at

every

five

to

ten

degrees

turn

of

the

pinion

nut

As

the

pinion

nut

is

tightened

the

stepped

portion

of

the

spacer

is

deformed

See

Fig

G

29

J

and

the

length

between

the

bearings

adjusted

The

drive

pinion

bearing

preload

with

oil

seal

and

new

bearing

is

7

15

kg

cm

6

1

13

0

lb

in

Turn

the

drive

pinion

to

settle

the

bearing

and

re

check

the

preload

and

tightening

torque

If

the

preload

rate

is

exceeded

it

will

be

necessry

to

fit

a

new

spacer

the

old

spa

cr

cannot

be

reused

and

the

preload

must

not

be

adjusted

by

loosening

the

pinion

nul

Side

bearing

pre

load

adjusting

If

the

original

side

bearings

arc

to

be

used

the

shims

must

be

of

the

same

thickness

as

those

previously

fitted

To

select

shims

for

new

side

bearings

proceed

as

follows

The

standard

width

of

the

side

bearings

is

given

in

Technical

Data

This

width

must

be

measured

before

attempting

to

calculate

the

required

thickness

of

the

adjusting

shims

Place

a

weight

of

approximately

5

kg

5

5

lb

and

of

predetermined

height

onto

the

side

bearing

as

shown

in

Fig

G

30

Mcasure

the

width

of

the

bearing

with

a

dial

gauge

as

illustrated

turning

the

bearing

two

or

three

times

to

gain

an

accurate

meaSurement

Dimensional

variations

from

the

standard

measurements

are

marked

on

the

left

side

bearing

housing

of

the

gear

carrier

on

the

right

side

bearing

housing

of

the

gear

carrier

and

on

the

differential

case

These

variations

are

marked

in

units

of

l

lOOmm

and

are

used

for

the

f

rmula

to

calculate

t1H

thickness

of

the

adjusting

shims

in

the

following

manner

Where

TI

equals

the

left

side

bearing

shim

crownwhecl

side

T2

equals

the

right

side

bearing

shim

pinion

gear

A

equals

the

figure

marked

on

the

left

side

bearing

housing

B

equals

the

figure

marked

on

the

right

side

bearing

housing

C

and

0

equals

the

figure

marked

on

the

differential

case

and

E

and

F

is

the

difference

bctween

the

width

of

the

side

bearings

and

the

standard

bearing

width

H

the

figure

marked

on

the

crownwhcel

Fig

G

31

The

following

formulae

can

now

be

used

to

deter

mine

the

required

shim

thicknessl

s

for

both

side

bearings

I

OOcc

Estate

car

Left

side

bearing

TI

A

C

D

H

x

0

01

0

100

E

Right

side

bearingT2

B

D

H

x

0

01

0

090

F

I800cc

Van

Left

side

bearingTI

A

C

D

H

xO

OI

0

175

E

Right

side

bcaringT2

8

D

H

x

0

01

0

150

F

As

an

example

where

A

1

B

C

2

D

3

E

0

02mm

H

I

The

formula

for

the

left

side

bearing

is

T

I

I

1

3

1

x

0

01

0

175

0

02

0

205mm

1400

and

1600cc

Estate

car

The

required

thickness

of

shim

can

be

found

using

the

following

formula

in

a

similar

manner

to

that

previously

described

for

the

1800cc

models

Left

side

bearing

T

I

A

C

D

E

7

Right

side

bearing

T2

B

D

F

6

Shims

are

available

in

five

thicknesses

of

0

05

0

07

0

10

0

20

and

0

50

mm

0

002

0

0028

0

0039

0

0079

and

0

0197

in

Fit

the

selected

side

bearing

adjusting

shims

on

the

differential

cage

and

press

in

the

side

bearing

inner

races

using

a

suitable

ddfL

nstall

the

differential

cage

into

the

carrier

and

fit

the

bearing

caps

Ensure

that

the

marks

on

the

caps

coincide

with

the

marks

on

the

carrier

Tighten

the

bearing

cap

bolts

to

the

specified

torque

reading

See

Tighte

ing

torques

Measure

the

dimension

between

the

outer

edges

of

the

left

and

right

hand

caps

using

a

large

micrometer

as

shown

in

Fig

G

32

This

dimension

should

be

198

40

198

55

mm

7

8110

7

8169

in

for

the

1400

and

1600

ce

Estate

cars

and

1800

ce

Van

and

173

23

17329

mm

6

8201

6

8244

inl

for

the

1800

cc

Estate

cars

Measure

the

backlash

of

the

crownwhcel

and

pinion

with

a

dial

gauge

The

backlash

must

be

adjusted

to

0

13

0

18

mm

0

005

0

007

in

on

the

1800

CC

models

and

to

0

15

0

20mm

0

006

0

008

in

on

the

1400

and

1600

cc

models

Adjustment

can

be

carried

out

by

moving

side

bearing

shims

from

the

right

hand

side

to

the

left

hand

side

if

the

backlash

is

too

high

or

vice

verca

if

the

backlash

is

too

low

Tighten

the

bearing

cap

bolts

to

the

specified

torque

reading

after

adjusting

Ensure

that

the

run

out

at

the

rear

of

the

crown

wheel

does

not

exceed

O

05mm

0

002

in

Finally

heck

the

tooth

contact

pattern

as

described

below

TOOTH

CONTACT

PATTERN

Checking

The

final

check

on

reassembly

is

an

inspection

of

the

tooth

contact

markings

of

the

crownwhed

and

pinion

Apply

a

coal

of

red

lead

in

oil

to

4

or

5

teeth

of

the

crown

wheel

Turn

the

crownwheel

backwards

and

forwards

several

times

to

obtain

a

clear

impression

of

the

contact

areas

Heel

contact

Fig

G

3

1

71

Page 73 of 171

inter

Q1Ju@

j1l

J

Ikli

l1t

J

T

II

ill

4

LU

I

Il

lJr

I

I

II

Ii

wrllJ

I

l

Y

1iJ

u

r

1

o

77

1

I

l

0

L

J

Dm

hJtl

lllL

l

m

h

t

l

u

c

N

I

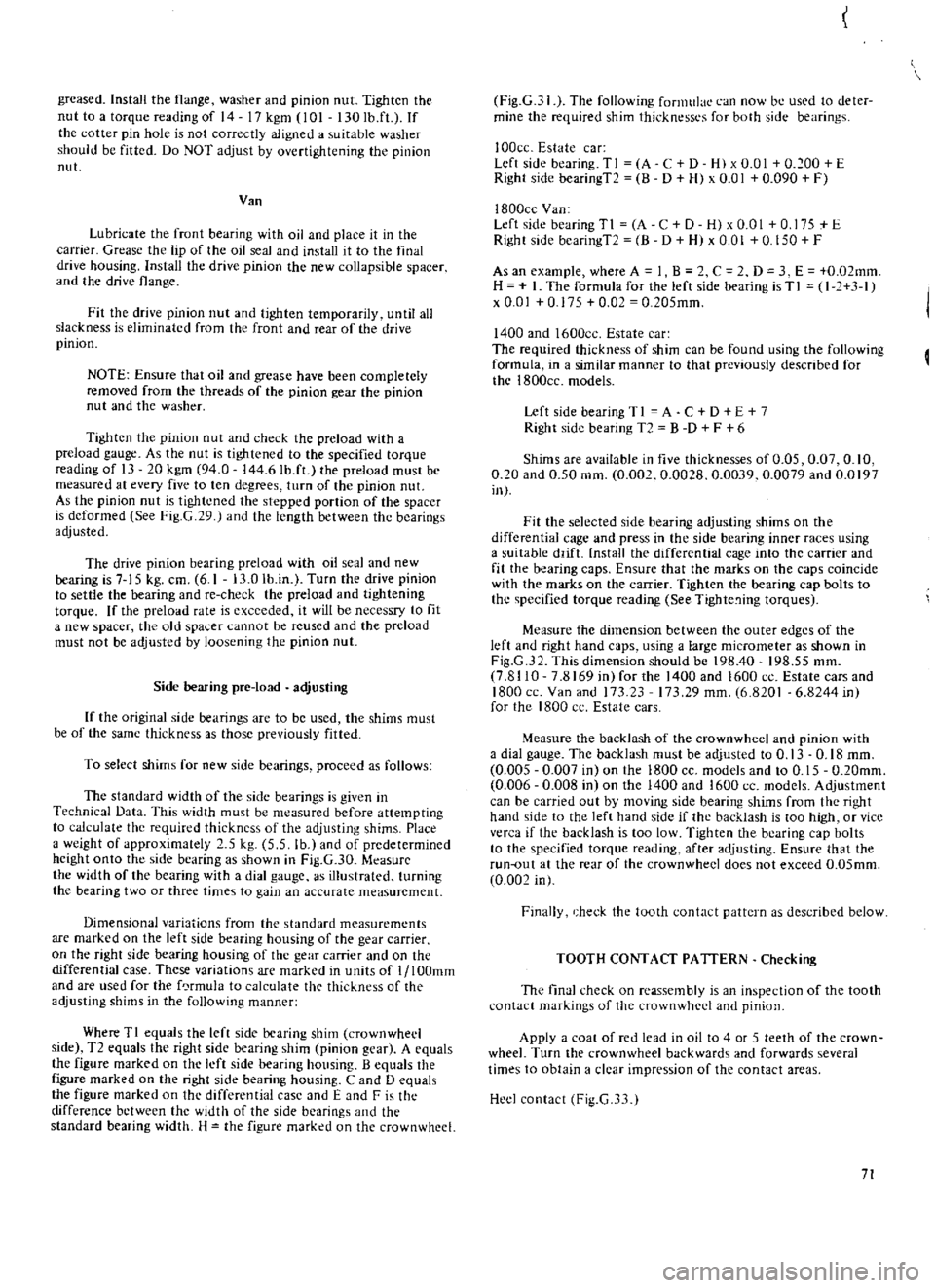

Fig

G

29

Measuring

the

clearance

between

the

height

gauge

and

dummy

shaft

3

i

T

O

O

1

L

Th

t

nn

mu

U

J

Fig

G

28

Location

of

the

dummy

shaft

and

drive

pinion

setting

gauge

Fig

G

JO

Measuring

the

width

of

the

side

bearing

under

load

j

Fig

G

32

Measuring

the

dimension

between

left

and

right

hand

bearing

caps

see

text

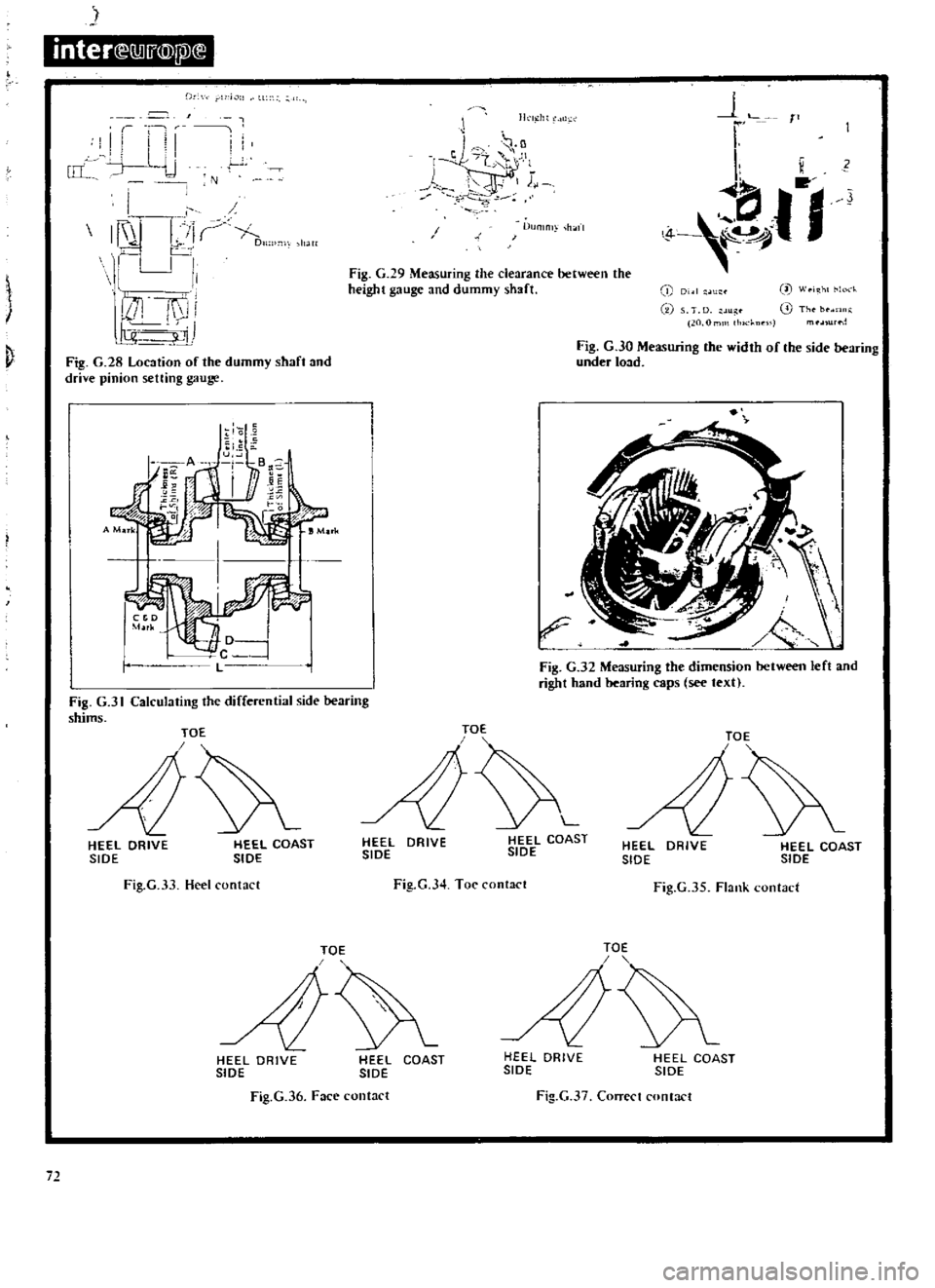

Fig

G

3

Calculating

the

differential

side

bearing

shims

Af

A

A

HEEL

DRIVE

HEEL

COAST

HEEL

DRIVE

HEEL

COAST

HEEL

DRIVE

HEEL

COAST

SIDE

SIDE

SlOE

SIDE

SIDE

SIDE

Fig

G

33

Heel

contact

Fig

G

34

Toe

contact

Fig

G

35

Flank

contact

TOE

TOE

A

A

HEEL

DRIVE

HEEL

COAST

HEEL

DRIVE

HEEL

COAST

SIDE

SIDE

SIDE

SIDE

Fig

G

36

Face

contact

Fig

G

37

Correct

contact

72

Page 74 of 171

increase

the

thickness

of

the

drive

pinion

adjusting

shim

and

washer

to

move

the

drive

pinion

closer

to

the

crown

wheel

A

correct

contact

pattern

showing

the

impressioll

ithill

a

range

of

2

3

to

4

of

the

distance

bct

l

en

t

h

tip

lllU

till

root

of

the

teeth

under

no

load

Toe

contact

Fig

G

34

Rcdu

e

the

thickness

of

the

drive

pinion

adjusting

shim

and

washer

to

move

the

drive

pinion

away

from

the

crown

wheel

It

will

be

neCL

ssary

to

rc

check

the

backlash

bl

tW

Cl1

drivt

pinion

and

crown

wheel

if

the

adjusting

shim

1l1d

washer

arc

changed

Flank

contact

Fig

G

35

DIFFERENTIAL

Installation

This

pattern

should

be

adjusted

in

a

similar

manner

to

toe

contact

Face

contact

Fig

G

36

Installation

of

the

differential

carrier

is

J

reversal

of

the

removal

procedure

Reference

should

be

made

to

the

section

REAR

AXLE

AND

REAR

SUSPENSION

for

a

dl

saipIion

of

the

operations

required

to

replace

the

axle

shafts

This

pattern

should

be

adjusted

in

a

similar

manner

to

heel

contact

Correct

contact

Fig

G

37

Technical

Data

PROPELLER

SHAFT

Axial

play

of

spider

journal

0800

Axial

play

of

spider

journal

1400

and

1600

cc

0

Q2

mm

0

0008

in

0

08

mm

0

003

in

Max

run

out

of

shaft

Wear

limit

of

spider

diameter

0

6

mm

0

024

in

0

15

mm

0

006

in

Permissible

dynamic

unbalance

Two

joint

shaft

Three

joint

sh

lft

15

gr

em

0

208

in

oz

at

4000

rpm

35

gr

cm

0

5

in

oz

at

5800

rpm

FINAL

GEAR

RATIOS

1800cc

Saloon

6101

ISOOcc

Estate

Car

610

1800cc

Van

610

1600cl

SJloon

610

1400

and

1600cc

510

4

Door

Saloon

RHO

4

Door

Saloon

LHD

De

Lu

e

4

Door

Saloon

RHO

SSS

4

Door

Saloon

RHO

Door

Saloon

LHO

3700

3

889

4

375

3

900

4375

4111

3

889

3

900

3

700

DRIVE

PINION

InitiJI

turning

torque

without

oil

sea

Saloon

modds

Estate

CJr

models

7

10

kg

em

0

506

0

723Ib

ft

10

13

kg

em

0

723

0

940Ib

ft

Thickness

of

pinion

height

adjusting

washers

1400

and

1600

CC

Saloon

1400

and

1600cc

510

Thickncss

of

pinion

height

adjusting

washers

0800

cc

Saloon

0

4

mm

0

078

0

086

0

094

in

3

09

3

66mm

0

1

17

0

1441

in

in

increments

of

0

03

mm

0

00

I

in

Thickness

of

pinion

height

adjusting

washers

0800

n

Estate

car

0

050

0

070

0

100

0

200

0

500mm

0

0020

0

0028

0

0039

0

0079

0

0197

in

Thickness

of

pinion

height

adjusting

washers

1800

CL

Van

37

97111m

0

0933

0

I

69

in

in

increments

of

0

03

mm

0

00

I

in

73

Page 75 of 171

J

Thickness

of

pinion

height

adjusting

shims

1400

and

160Occ

Saloon

Thickness

of

pinion

height

adjusting

shims

1400

and

1600

cc

Estate

Length

of

drive

pinion

bearing

adjusting

washers

Saloon

Estate

Length

of

drive

pinion

bearing

aqjusting

screws

Saloon

y

Length

of

drive

pinion

bearing

adjusting

spacers

1400

and

1600

cc

Estate

Length

of

drive

pinion

bearing

alljusting

spacer

1800cc

Estate

1800

cc

Van

Backlash

between

gears

Saloon

1400

1600

cc

Estate

1800

cc

Estate

Van

Run

out

at

rear

of

crown

wheel

1800

cc

1400

1600cc

Estate

1400

1600cc

Saloon

Thickness

of

side

gear

thrust

washers

Saloon

Estate

Qearance

between

side

gear

and

washer

Saloon

aearance

between

side

gear

and

washer

Estate

74

L09

1

27

mm

0

0429

0

0500

in

in

increments

of

0

02

mm

0

0008

in

0

75

0

50

0

25

0

125

mm

0

0295

0

0197

0

0098

0

0049

in

2

31

2

59mm

0

0909

0

1020

in

in

increments

of

0

02

mm

0

0008

in

56

20

57

20

mm

2

213

2

252

in

in

increments

of

0

02

mm

0

0008

in

59

25

59

50

597Omm

2

338

2

343

2

358

in

48

4

48

6

48

8

49

0

0

9055

1

9134

1

9213

1

9291

in

Non

adjustable

collapsible

SP3

O

L

CROWNWHEEL

0

10

0

20

mm

0

004

0

008

in

0

15

0

20

mm

0

006

0

008

in

0

13

0

18

mm

0

005

0

007

in

Less

than

0

05

mm

0

002

in

Less

than

0

08

mm

0

003

in

DIFFERENTIAL

GEARS

0

775

0

825

0

875

mm

0

0305

0

0325

0

0344

in

0

78

0

83

0

88

1

03

1

23

mm

0

10

0

20

mm

0

004

0

008

in

0

05

0

20

mm

0

002

0

008

in

Page 76 of 171

Rear

Axle

Rear

SuspensIon

DESCRIPTION

REAR

AXLE

AND

SUSPENSION

Removal

Saloons

COIL

SPRINGS

Saloons

REAR

SHOCK

ABSORBERS

Saloons

REAR

SUSPENSION

ARM

Saloons

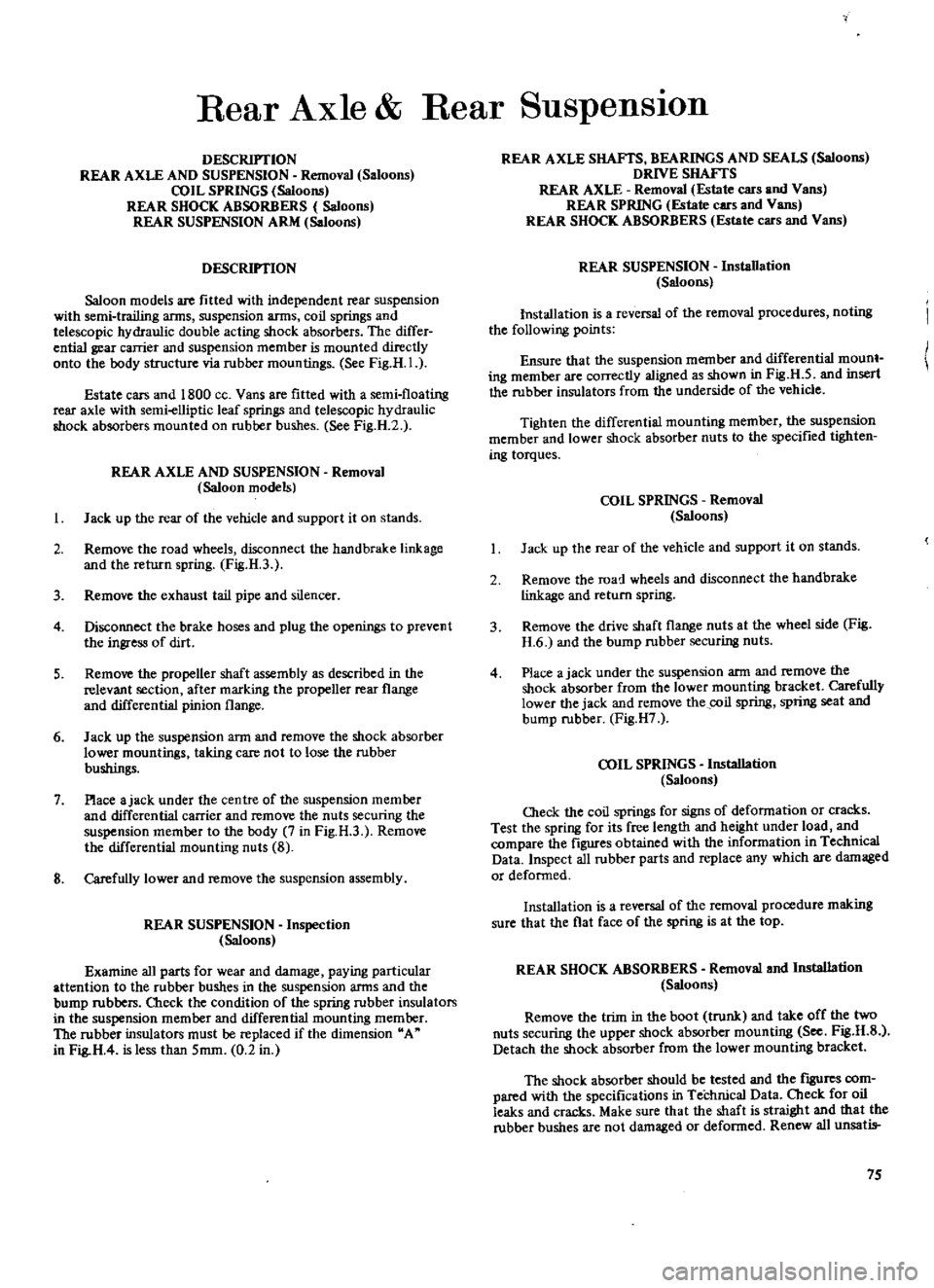

DESCRIPTION

Saloon

models

are

fitted

with

independent

rear

suspension

with

semi

trailing

arms

suspension

arms

coil

springs

and

telescopic

hydraulic

double

acting

shock

absorbers

The

differ

ential

gear

carrier

and

suspension

member

is

mounted

directly

onto

the

body

structure

via

rubber

mountings

See

Fig

H

I

Estate

cars

and

1800

ce

Vans

are

fitted

with

a

semi

floating

rear

axle

with

semi

elliptic

leaf

springs

and

telescopic

hydraulic

shock

absorbers

mounted

on

rubrer

bushes

See

Fig

H

2

REAR

AXLE

AND

SUSPENSION

Removal

Saloon

models

I

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

disconnect

the

hand

brake

linkage

and

the

return

spring

Fig

H

3

3

Remove

the

exhaust

tail

pipe

and

silencer

4

Disconnect

the

brake

hoses

and

plug

the

openings

to

prevent

the

ingress

of

dirt

5

Remove

the

propeller

shaft

assembly

as

described

in

the

relevant

section

after

marking

the

propeller

rear

flange

and

differential

pinion

flange

6

Jack

up

the

suspension

ann

and

remove

the

shock

absorber

lower

mountings

taking

care

not

to

lose

the

rubber

bushings

7

Place

ajack

under

the

centre

of

the

suspension

member

and

differential

carrier

and

remove

the

nuts

securing

the

suspension

member

to

the

body

7

in

Fig

H

3

Remove

the

differential

mounting

nuts

8

8

Carefully

lower

and

remove

the

suspension

assembly

REAR

SUSPENSION

Inspection

Saloons

Examine

all

parts

for

wear

and

damage

paying

particular

attention

to

the

rubber

bushes

in

the

suspension

arms

and

the

bump

rubbers

Check

the

condition

of

the

spring

rubber

insulators

in

the

suspension

member

and

differential

mounting

memrer

The

rubber

insulators

must

be

replaced

if

the

dimension

A

in

Fig

H

4

is

less

than

5mm

0

2

in

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloons

DRNE

SHAFTS

REAR

AXLE

Removal

Estate

cars

and

Vans

REAR

SPRING

Estate

cars

and

Vans

REAR

SHOCK

ABSORBERS

Estate

cars

and

Vans

REAR

SUSPENSION

Installation

Saloons

Installation

is

a

reversal

of

the

removal

procedures

noting

the

following

points

Ensure

that

the

suspension

member

and

differential

mount

ing

member

are

correctly

aligned

as

shown

in

Fig

U

5

and

insert

the

rubber

insulators

from

the

underside

of

the

vehicle

Tighten

the

differential

mounting

member

the

suspension

member

and

lower

shock

absorber

nuts

to

the

specified

tighten

ing

torques

COIL

SPRINGS

Removal

Saloons

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

and

disconnect

the

handbrake

linkage

and

return

spring

3

Remove

the

drive

shaft

flange

nuts

at

the

wheel

side

Fig

H

6

and

the

bump

rubber

securing

nuts

4

Place

ajack

under

the

suspension

ann

and

remove

the

shock

absorber

from

the

lower

mounting

bracket

Carefully

lower

the

jack

and

remove

the

coil

spring

spring

scat

and

bump

rubber

Fig

H7

COIL

SPRINGS

Installation

Saloons

Oleck

the

coil

springs

for

signs

of

deformation

or

cracks

Test

the

spring

for

its

free

length

and

height

under

load

and

compare

the

figures

obtained

with

the

information

in

Technical

Data

Inspect

all

rubber

parts

and

replace

any

which

are

damaged

or

deformed

Installation

is

a

reversal

of

the

removal

procedure

making

sure

that

the

flat

face

of

the

spring

is

at

the

top

REAR

SHOCK

ABSORBERS

Removal

and

Installation

Saloons

Remove

the

trim

in

the

boot

trunk

and

take

off

the

two

nuts

securing

the

upper

shock

absorber

mounting

See

Fig

H

S

Detach

the

shock

absorber

from

the

lower

mounting

bracket

The

shock

absorber

should

be

tested

and

the

fIgUres

com

pared

with

the

specifications

in

Technical

Data

Cbeck

for

oil

leaks

and

cracks

Make

sure

that

the

shaft

is

straight

and

that

the

rubber

bushes

are

not

damaged

or

defonned

Renew

all

unsatis

75

Page 91 of 171

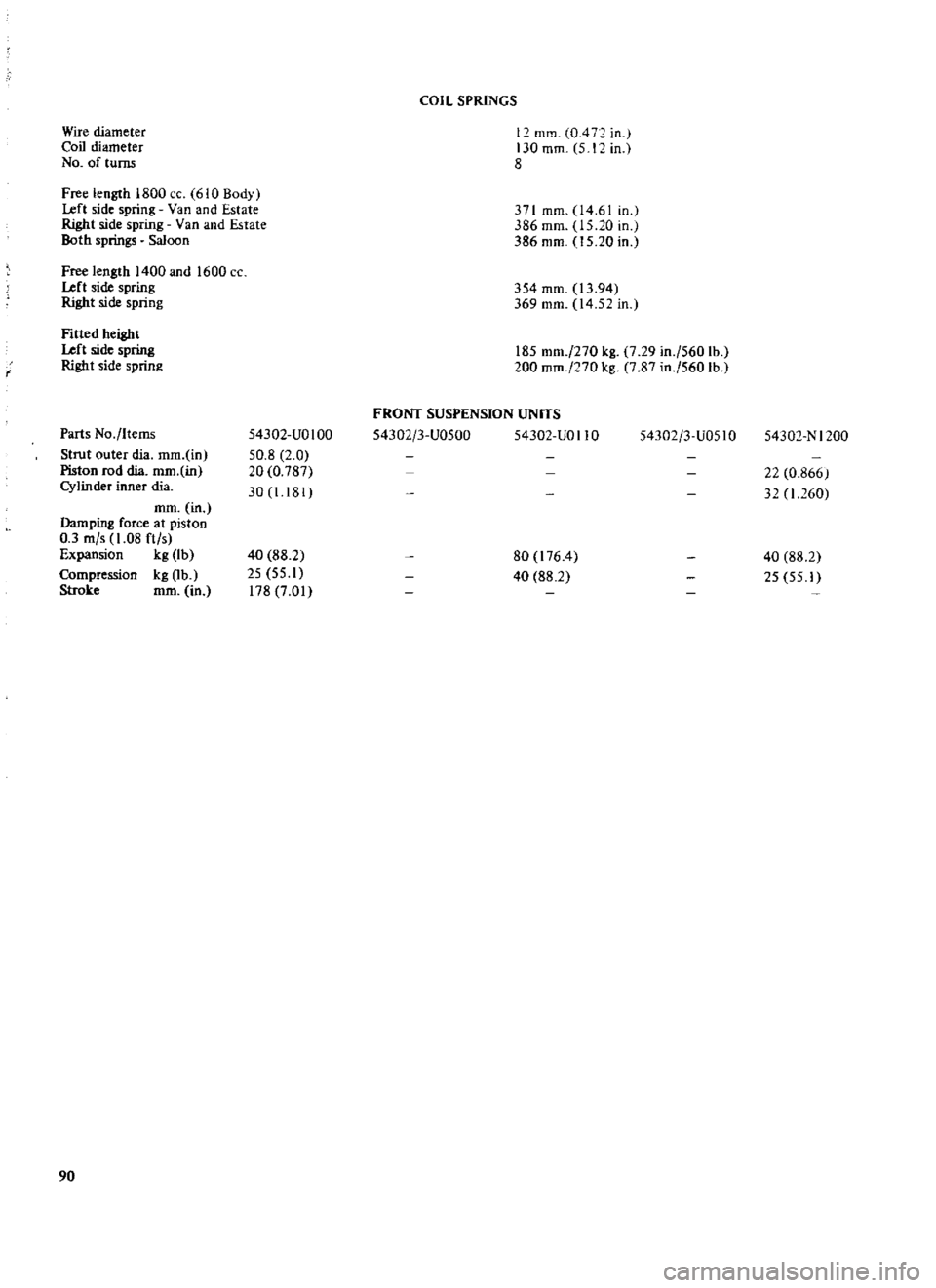

Wire

diameter

Coil

diameter

No

of

turns

Free

length

1800

CC

1610

Body

Left

side

spring

Van

and

Estate

Right

side

spring

Van

and

Estate

Both

springs

Saloon

Free

length

1400

and

1600

cc

Left

side

spring

Right

side

spring

f

Fitted

height

Left

side

spring

Right

side

spring

Parts

No

Items

Strut

outer

dia

mm

in

Piston

rod

dia

mm

in

Cylinder

inner

dia

mm

in

Damping

force

at

piston

0

3

m

s

1

08

ft

s

Expansion

kg

Ib

Compression

kg

Ob

Stroke

mm

in

90

54302

UO

100

50

8

2

0

20

0

787

30

I

181

40

88

2

25

55

1

178

7

01

COIL

SPRINGS

12

mill

0

4

in

130

mm

5

I

in

8

371

mm

04

61

in

386

mm

15

20

in

386

mm

15

20

in

354

mm

13

94

369

mm

14

52

in

185

mm

270

kg

7

29

in

560

lb

200

mm

270

kg

7

87

in

560

lb

FRONT

SUSPENSION

UNITS

54302

3

U0500

54302

UOI10

54302

3

U051O

80

176

4

40

88

2

54302

N

1200

22

0

866

32

1

260

40

88

2

25

55

1

Page 100 of 171

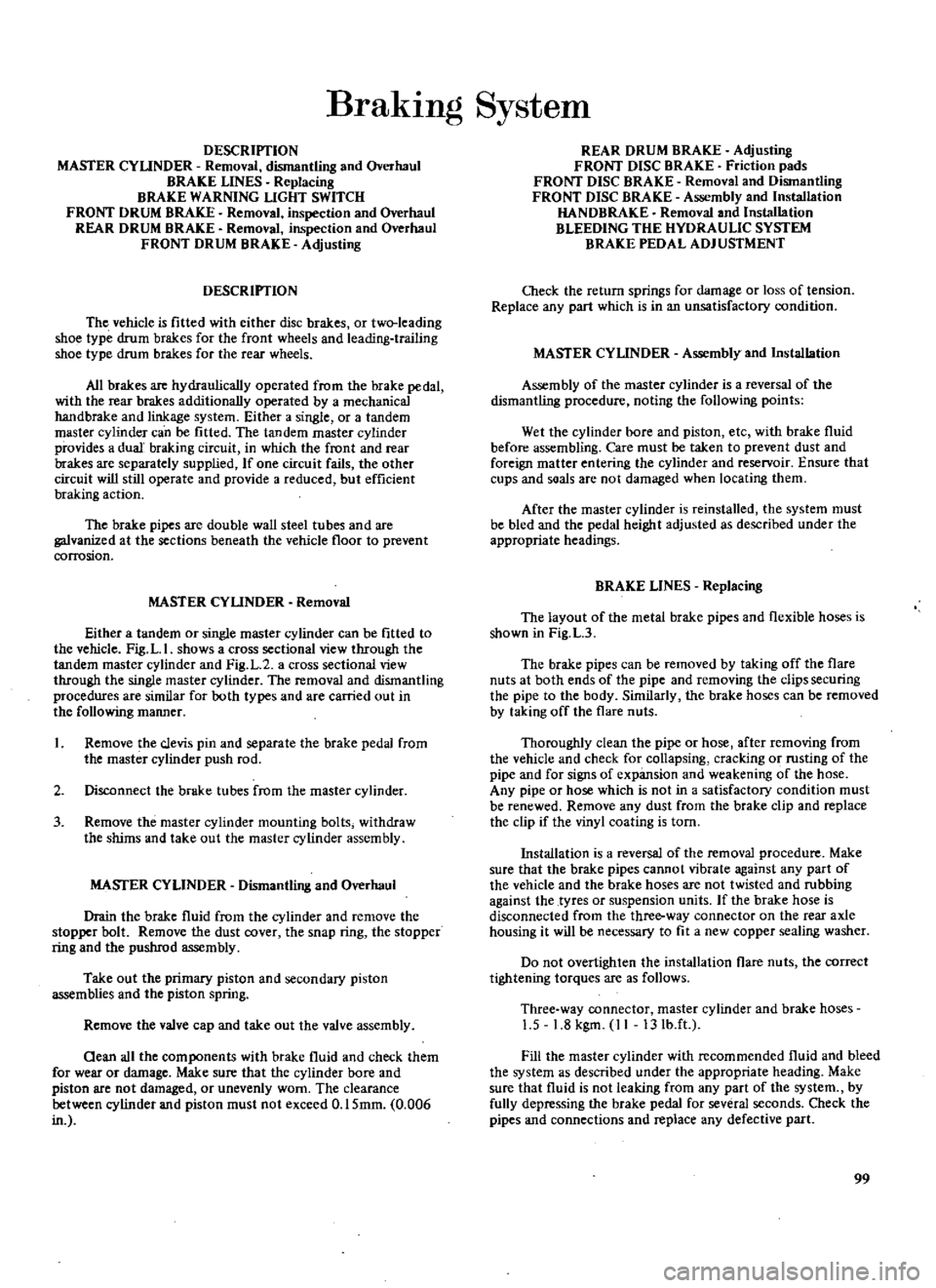

BrakIng

System

DESCRIPTION

MASTER

CYLINDER

Removal

dismantling

and

Overhaul

BRAKE

LINES

Replacing

BRAKE

WARNING

LIGHT

SWITCH

FRONT

DRUM

BRAKE

Removal

inspection

and

Overhaul

REAR

DRUM

BRAKE

Removal

inspection

and

Overhaul

FRONT

DRUM

BRAKE

Adjusting

DESCRIPTION

The

vehicle

is

fitted

with

either

disc

brakes

or

two

leading

shoe

type

drum

brakes

for

the

front

wheels

and

leading

trailing

shoe

type

drum

brakes

for

the

rear

wheels

All

brakes

are

hydraulically

operated

from

the

brake

pedal

with

the

rear

brakes

additionally

operated

by

a

mechanical

handbrake

and

linkage

system

Either

a

single

or

a

tandem

master

cylinder

can

be

fitted

The

tandem

master

cylinder

provides

a

dual

braking

circuit

in

which

the

front

and

rear

brakes

are

separately

supplied

If

ODe

circuit

fails

the

other

circuit

will

still

operate

and

provide

a

reduced

but

efficient

braking

action

The

brake

pipes

are

double

wall

steel

tubes

and

are

galvanized

at

the

sections

beneath

the

vehicle

floor

to

prevent

corrosion

MASTER

CYLINDER

Removal

Either

a

tandem

or

single

master

cylinder

can

be

fitted

to

the

vehicle

Fig

L

I

shows

a

cross

sectional

view

through

the

tandem

master

cylinder

and

Fig

L

2

a

cross

sectional

view

through

the

single

master

cylinder

The

removal

and

dismantling

procedures

are

similar

for

both

types

and

are

carried

out

in

the

following

manner

1

Remove

the

clevis

pin

and

separate

the

brake

pedal

from

the

master

cylinder

push

rod

2

Disconnect

the

brake

tubes

from

the

master

cylinder

3

Remove

the

master

cylinder

mounting

bolts

withdraw

the

shims

and

take

out

the

master

cylinder

assembly

MASfER

CYLINDER

Dismantling

and

Overhaul

Drain

the

brake

fluid

from

the

cylinder

and

remove

the

stopper

bolt

Remove

the

dust

cover

the

snap

ring

the

stopper

ring

and

the

pusbrod

assembly

Take

out

the

primary

piston

and

secondary

piston

assemblies

and

the

piston

spring

Remove

the

valve

cap

and

take

out

the

valve

assembly

Oean

all

the

components

with

brake

fluid

and

check

them

for

wear

or

damage

Make

sure

that

the

cylinder

bore

and

piston

are

not

damaged

or

unevenly

worn

The

clearance

between

cylinder

and

piston

must

not

exceed

0

15mm

0

006

in

REAR

DRUM

BRAKE

Adjusting

FRONT

DISC

BRAKE

Friction

pads

FRONT

DISC

BRAKE

Removal

and

Dismantling

FRONT

DISC

BRAKE

Assembly

and

Installation

HANDBRAKE

Removal

and

Installation

BLEEDING

THE

HYDRAULIC

SYSTEM

BRAKE

PEDAL

ADJUSTMENT

Check

the

return

springs

for

damage

or

loss

of

tension

Replace

any

part

which

is

in

an

unsatisfactory

condition

MASfER

CYLINDER

Assembly

and

Installation

Assembly

of

the

master

cylinder

is

a

reversal

of

the

dismantling

procedure

noting

the

following

points

Wet

the

cylinder

bore

and

piston

etc

with

brake

fluid

before

assembling

Care

must

be

taken

to

prevent

dust

and

foreign

matter

entering

the

cylinder

and

reservoir

Ensure

that

cups

and

soals

are

not

damaged

when

locating

them

After

the

master

cylinder

is

reinstalled

the

system

must

be

bled

and

the

pedal

height

adjusted

as

described

under

the

appropriate

headings

BRAKE

LINES

Replacing

The

layout

of

the

metal

brake

pipes

and

flexible

hoses

is

shown

in

Fig

L

3

The

brake

pipes

can

be

removed

by

taking

off

the

flare

nuts

at

both

ends

of

the

pipe

and

removing

the

clips

securing

the

pipe

to

the

body

Similarly

the

brake

hoses

can

be

removed

by

taking

off

the

flare

nuts

Thoroughly

clean

the

pipe

or

hose

after

removing

from

the

vehicle

and

check

for

collapsing

cracking

or

rusting

of

the

pipe

and

for

signs

of

expansion

and

weakening

of

the

hose

Any

pipe

or

hose

which

is

not

in

a

satisfactory

condition

must

be

renewed

Remove

any

dust

from

the

brake

clip

and

replace

the

clip

if

the

vinyl

coating

is

torn

Installation

is

a

reversal

of

the

removal

procedure

Make

sure

that

the

brake

pipes

cannot

vibrate

against

any

part

of

the

vehicle

and

the

brake

hoses

are

not

twisted

and

rubbing

against

the

tyres

or

suspension

units

If

the

brake

hose

is

disconnected

from

the

three

way

connector

on

the

rear

axle

housing

it

will

be

necessary

to

fit

a

new

copper

sealing

washer

Do

not

overtighten

the

installation

flare

nuts

the

correct

tightening

torques

are

as

follows

Three

way

connector

master

cylinder

and

brake

hoses

1

5

1

8

kgm

II

13Ib

ft

Fill

the

master

cylinder

with

recommended

fluid

and

bleed

the

system

as

described

under

the

appropriate

heading

Make

sure

that

fluid

is

not

leaking

from

any

part

of

the

system

by

fully

depressing

the

brake

pedal

for

several

seconds

Check

the

pipes

and

connections

and

replace

any

defective

part

99

Page 107 of 171

inter

jjiC@

V

6iIiIIlli

I

Ii

r

f

r

7

r

Y

t

I

10

1

L

u

N

c

I

F

ll

L

2S

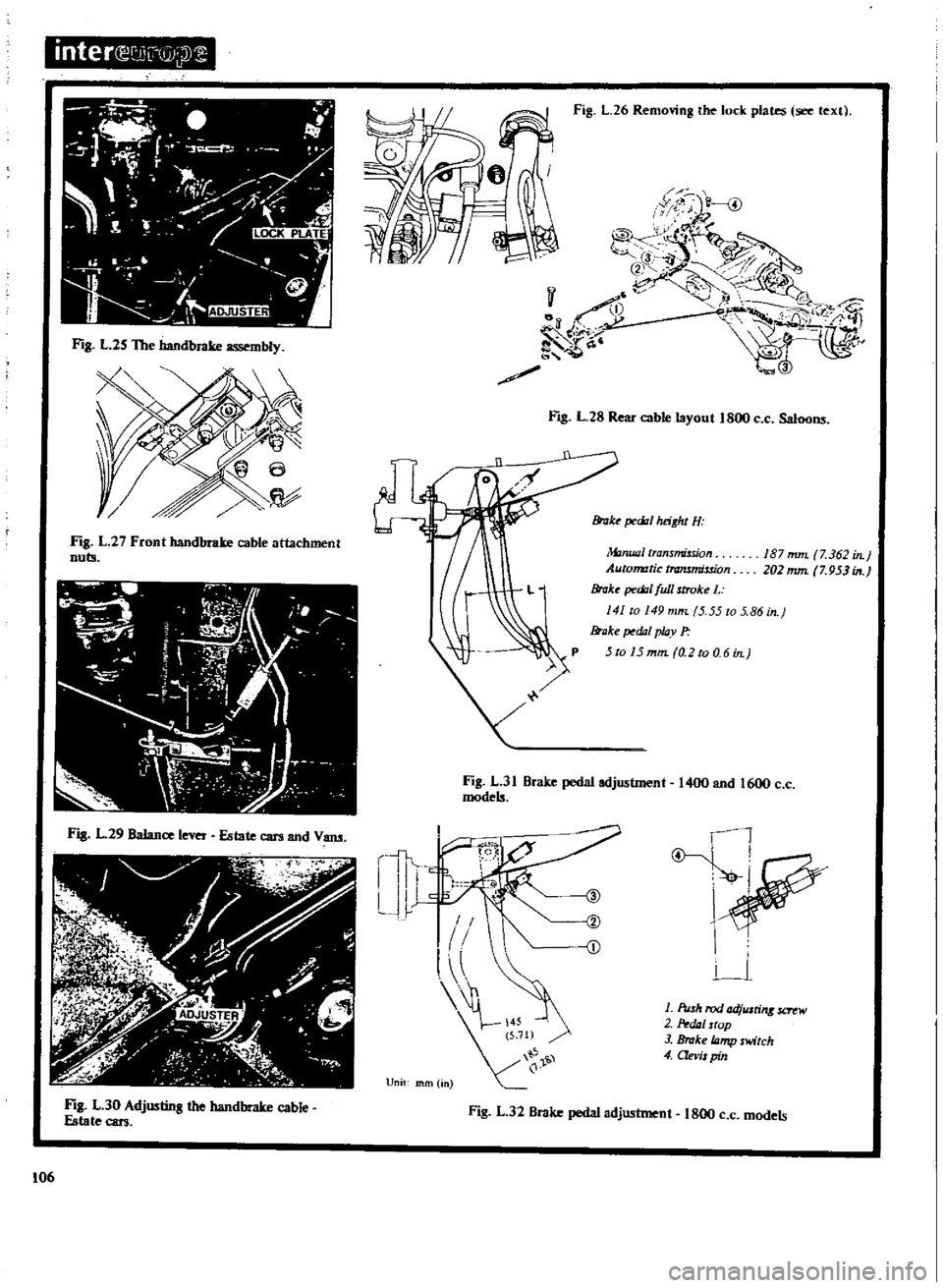

The

handbrake

mbly

Fig

L

27

Front

handbrake

cable

attachment

nuts

e7

rl

A

I

r

I

r

J

i

I

f

I

I

I

of

II

J

F

F

ll

L29

Balance

lever

Estate

ClU1l

and

Vans

F

ll

L

30

AdjWltins

the

handbrake

cable

Estate

ClU1l

106

J

ei

Fig

L

26

Removing

the

lock

plates

see

text

I

7

I

i

1

@

i

1

0

1

e

V

O

V

I

r

r

if1

1i

cl

t

Ji

Y

a

t

3

F

ll

L

28

Rear

cable

layout

1800

C

c

SatOOWl

ok

pedat

height

H

87

mm

7

362

in

202

mm

7

953

ill

Jltznual

transmission

AutomItic

transmission

y

Brake

pedal

full

stroke

L

141

0149

mm

5

55

to

5

86

in

Brake

pedal

p

tJv

P

5

to

15

mm

0

2

to

0

6

ilL

Fig

L

31

Brake

pedal

adjWltment

1400

and

1600

c

c

models

l

car

Ll

1

f

1

J

111

I

l

j

u

n

l

71

t

i1

Unit

mfll

in

1

Push

rod

adjusting

scrt

W

2

Ptdlz

stop

3

Brake

Iilmp

switch

4

Clevis

pin

Fig

L

32

Brake

pedaladjWltment

800

c

c

models

Page 108 of 171

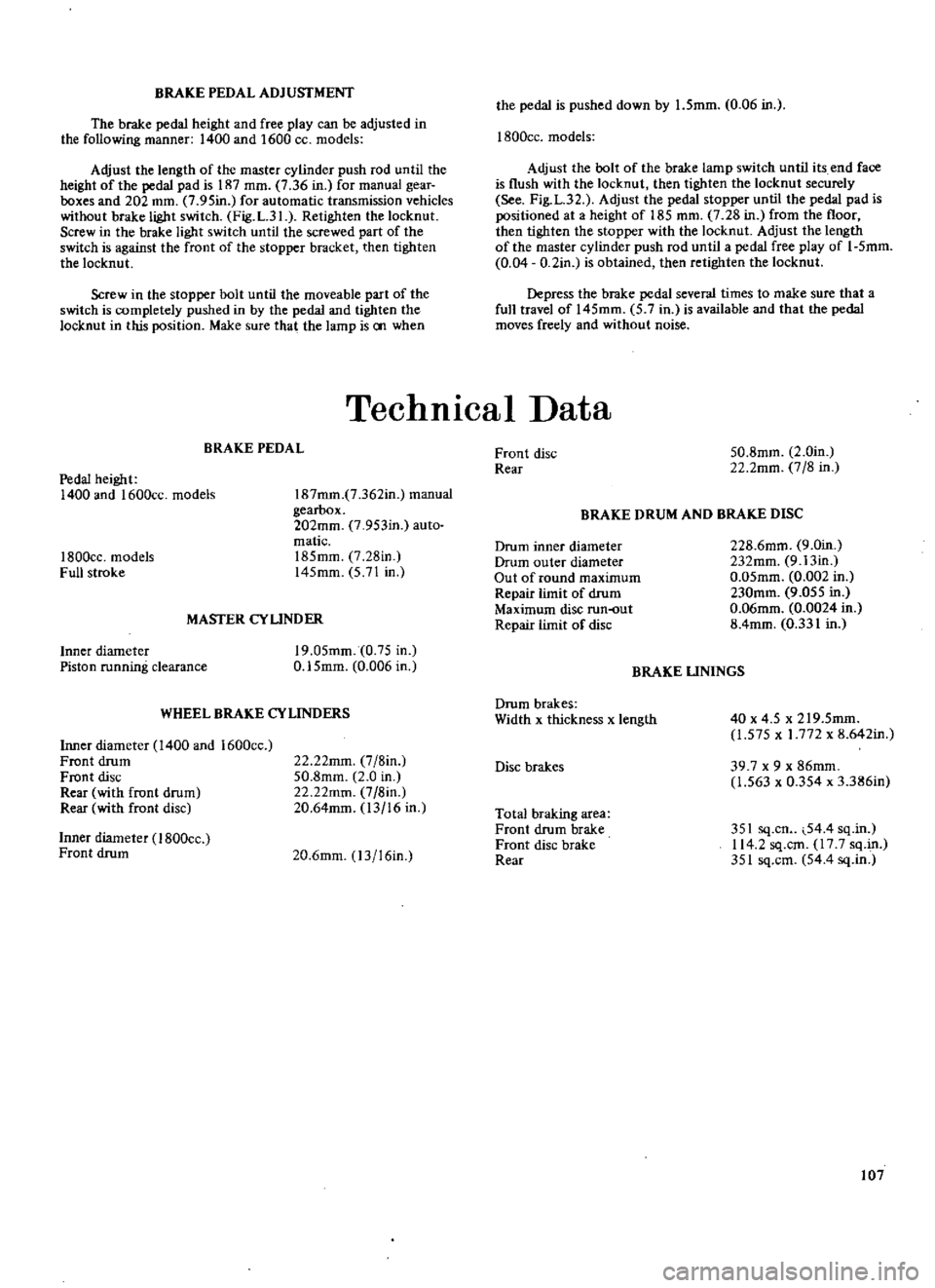

BRAKE

PEDAL

ADJUSTMENT

The

brake

pedal

height

and

free

play

can

be

adjusted

in

the

following

manner

1400

and

1600

CC

models

Adjust

the

length

of

the

master

cylinder

push

rod

until

the

height

of

the

pedal

pad

is

187

mm

7

36

in

for

manual

gear

boxes

and

202

mm

7

95in

for

automatic

transmission

vehicles

without

brake

light

switch

Fig

L

31

Retighten

the

locknut

Screw

in

the

brake

light

switch

until

the

screwed

part

of

the

switch

is

against

the

front

of

the

stopper

bracket

then

tighten

the

locknut

Screw

in

the

stopper

bolt

until

the

moveable

part

of

the

switch

is

completely

pushed

in

by

the

pedal

and

tighten

the

locknut

in

this

position

Make

sure

that

the

lamp

is

00

when

the

pedal

is

pushed

down

by

1

5mm

0

06

in

1800cc

models

Adjust

the

bolt

of

the

brake

lamp

switch

until

its

end

face

is

flush

with

the

locknut

then

tighten

the

locknut

securely

See

Fig

L

32

Adjust

the

pedal

stopper

until

the

pedal

pad

is

positioned

at

a

height

of

185

mrn

7

28

in

from

the

floor

then

tighten

the

stopper

with

the

locknut

Adjust

the

length

of

the

master

cylinder

push

rod

until

a

pedal

free

play

of

I

5mm

0

04

D

2in

is

obtained

then

retighten

the

locknut

Depress

the

brake

pedal

several

times

to

make

sure

that

a

full

travel

of

145mm

5

7

in

is

available

and

that

the

pedal

moves

freely

and

without

noise

Technical

Data

BRAKE

PEDAL

Pedal

height

1400

and

1600cc

models

I

87mm

7

362in

manual

gearbox

202mm

7

953in

auto

matic

185mm

7

28in

145mm

5

71

in

1800cc

models

Full

stroke

MASTER

CYUNDER

Inner

diameter

Piston

running

clearance

19

05mm

0

75

in

0

15mm

0

006

in

WHEEL

BRAKE

CYLINDERS

Inner

diameter

1400

and

1600cc

Front

drum

Front

disc

Rear

with

front

drum

Rear

with

front

disc

22

22mm

7

8in

50

8mm

2

0

in

22

22mm

7

8in

20

64mm

13

16

in

Inner

diameter

I

BOOcc

Front

drum

20

6mm

13

16in

Front

disc

Rear

50

8mm

2

0in

22

2mm

7

8

in

BRAKE

DRUM

AND

BRAKE

DISC

Drum

inner

diameter

Drum

outer

diameter

Out

of

round

maximum

Repair

limit

of

drum

Maximum

disc

run

out

Repair

limit

of

disc

228

6mm

9

0in

232mm

9

13in

0

05mm

0

002

in

230mm

9

055

in

0

06mm

0

0024

in

8

4mm

0

331

in

BRAKE

UNINGS

Drum

brakes

Width

x

thickness

x

length

40

x

4

5

x

219

5mm

1

575

x

1

772

x

8

642in

Disc

brakes

39

7

x

9

x

86mm

1

563

x

0

354

x

3

386in

Total

braking

area

Front

drum

brake

Front

disc

brake

Rear

351

sq

cn

54

4

sq

in

114

2

sq

cm

17

7

sq

in

351

sq

cm

54

4

sq

in

107

Page 145 of 171

4

Cylinder

head

gasket

Cylinder

block

side

6

Oil

pump

5

Intake

manifold

Block

installing

surface

near

to

oil

exit

Control

valve

Angle

tube

connector

7

Rocker

cover

Tapping

screw

of

bume

plate

installing

SPECIFICATION

a

Valve

mechanism

Valve

clearance

cold

In

0

25

mm

0

0098

in

Ex

0

25

mm

0

0098

in

Hot

Reference

value

0

0098

in

In

0

28

mm

0

011

in

Ex

0

28

mm

0

011

in

Valve

head

diameter

In

42mm

1

654

in

Ex

35mm

1

378

in

Valve

stem

diameter

In

Ex

8mm

0

3150

in

Valve

length

In

116

4

mm

4

58

in

Ex

117

2

mm

4

61

in

Valve

lift

9

0mm

0

354

in

Valve

spring

free

length

Outer

42

5

mm

1

673

in

Inner

414mm

1

630

in

Valve

spring

loaded

length

Outer

29

0

mm

I

142

in

Inner

26

0

mm

1

024

in

Valve

spring

assembling

height

Outer

37

0mm

I

457

in

Inner

34

0

mm

1

339

in

Valve

spring

effective

wind

number

Outer

4

5mm

0

1772

in

Inner

6

25

mm

0

2461

in

Valve

spring

wire

diameter

Outer

4

2mm

0

1654

in

Inner

29mm

0

1142

in

Valve

spring

coil

diameter

Outer

27

5

mm

1

083

in

Inner

19

9mm

0

733

in

Valve

guide

length

In

48mm

1

890

in

Ex

60mm

2

362

in

Valve

guide

height

from

cylinder

head

In

Ex

16

7mm

0

657

in

Valve

guide

inner

diameter

In

Ex

7mm

0

2756

in

Valve

guide

outer

diameter

In

Ex

14

2mm

0

559

in

Valve

guide

to

stem

clearance

In

0

025

0

055

mm

0

0010

0

0022

in

Ex

0

04

0

077

mm

0

0016

0

0030

in

Valve

guide

interference

fit

In

Ex

0

040

0

069

mm

0

0016

0

0027

in

Max

tolerance

of

above

clearance

In

Ex

0

1

mm

0

0049

in

Valve

seat

width

In

Ex

2

05

2

33mm

0

0807

0

0917

in

Valve

seat

angle

In

Ex

900

b

Camshaft

and

timing

chain

Camshaft

end

play

0

07

0

148

mm

0

0028

0

0058

in

Cam

height

36

53

mm

1

438

in

Camshaft

journal

diameter

37

45

37

475

mm

1

474

1

475

in

S14