ECU DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 69 of 513

CHASSIS

Mureover

excessive

sleeve

yoke

spline

ta

transmission

main

spline

lash

and

wear

of

both

front

and

rear

universal

joints

will

cause

vibrations

affecting

riding

comfort

REMOVAL

Disconnect

the

flange

yoke

and

the

pinion

flange

by

removing

bolts

at

the

rear

end

of

the

propeller

shaft

In

this

case

draw

out

the

sleeve

yoke

from

the

end

of

transmission

holding

the

disconnected

rear

end

of

the

propeller

shaft

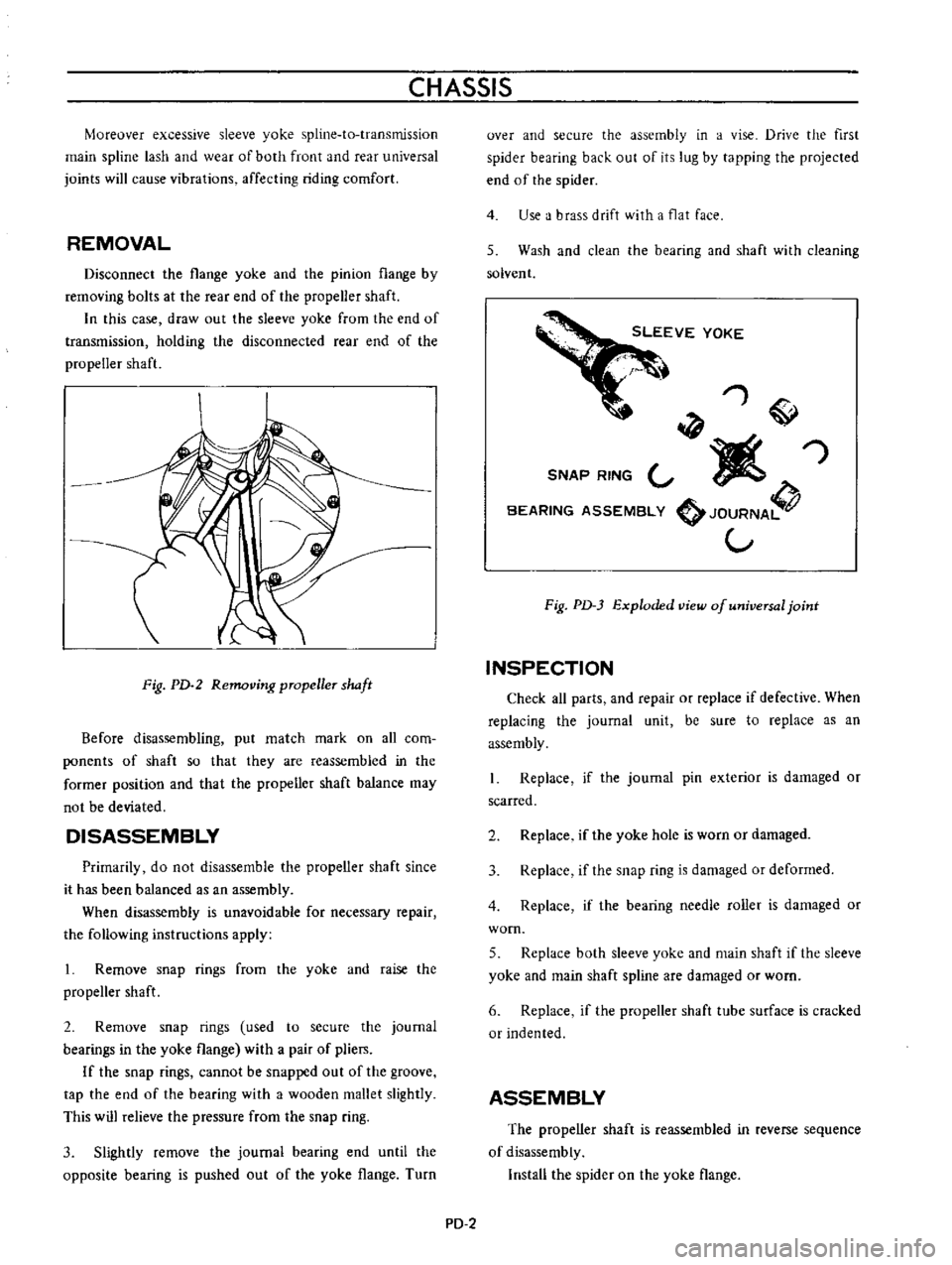

Fig

PD

2

Removing

pmpeller

shaft

Before

disassembling

put

match

mark

on

all

com

ponents

of

shaft

so

that

they

are

reassembled

in

the

former

position

and

that

the

propeller

shaft

balance

may

not

be

deviated

DISASSEMBLY

Primarily

do

not

disassemble

the

propeller

shaft

since

it

has

been

balanced

as

an

assembly

When

disassembly

is

unavoidable

for

necessary

repair

the

following

instructions

apply

1

Remove

snap

rings

from

the

yoke

and

raise

the

propeller

shaft

2

Remove

snap

rings

used

to

secure

the

journal

bearings

in

the

yoke

flange

with

a

pair

of

pliers

If

the

snap

rings

cannot

be

snapped

out

of

the

groove

tap

the

end

of

the

bearing

with

a

wooden

mallet

slightly

This

will

relieve

the

pressure

from

the

snap

ring

3

Slightly

remove

the

journal

bearing

end

until

the

opposite

bearing

is

pushed

out

of

the

yoke

flange

Turn

over

and

secure

the

assembly

in

a

vise

Drive

the

first

spider

bearing

back

out

of

its

lug

by

tapping

the

projected

end

of

the

spider

4

Use

a

brass

drift

with

a

flat

face

5

Wash

and

clean

the

bearing

and

shaft

with

cleaning

solvent

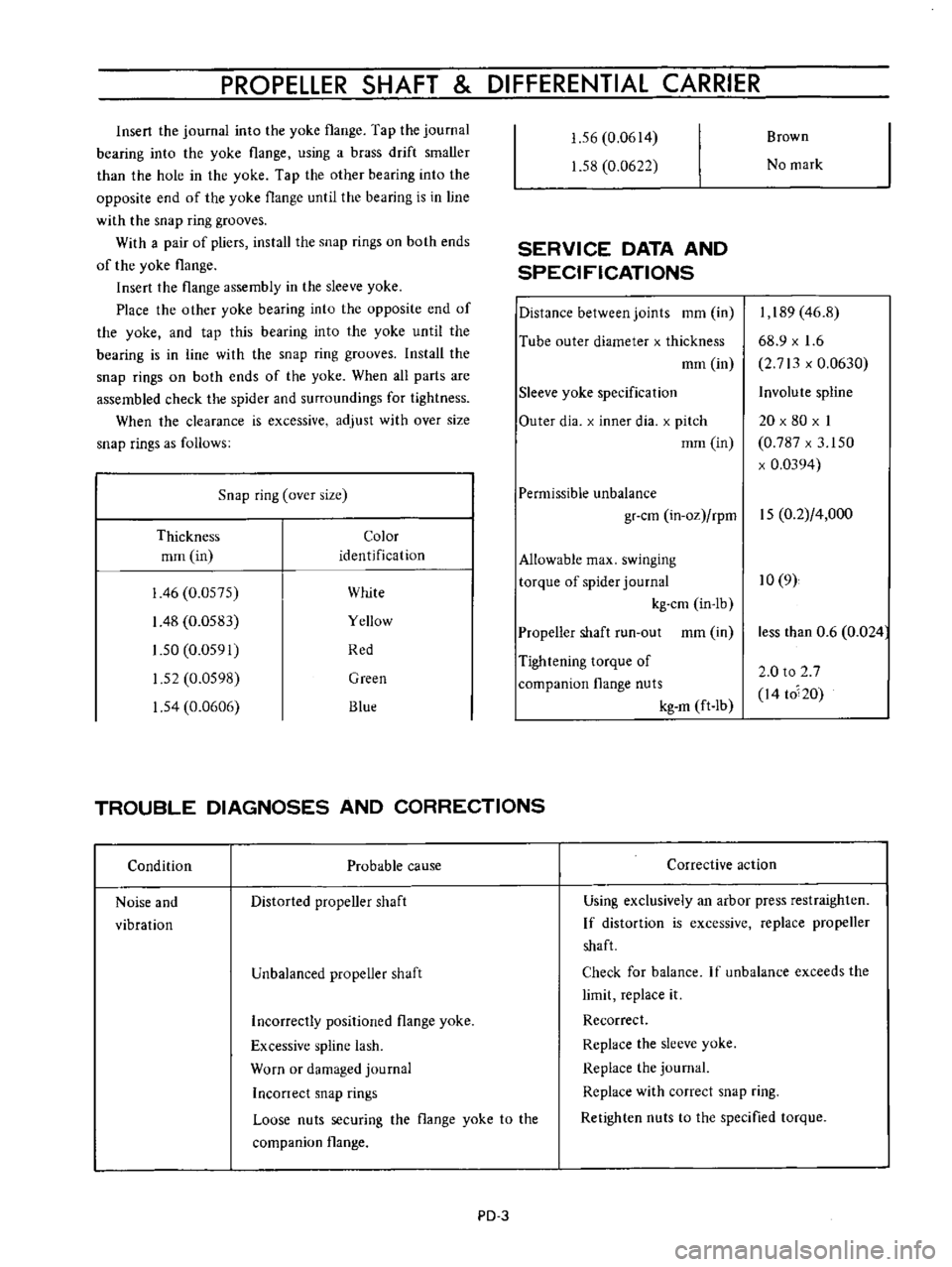

1

W

SNAP

RING

V

I

1Iiff

BEARING

ASSEMBLY

JOURNA

V

Fig

PD

3

Exploded

view

of

universal

joint

INSPECTION

Check

all

parts

and

repair

or

replace

if

defective

When

replacing

the

journal

unit

be

sure

to

replace

as

an

assembly

Replace

if

the

journal

pin

exterior

is

damaged

or

scarred

2

Replace

if

the

yoke

hole

is

worn

or

damaged

3

Replace

if

the

snap

ring

is

damaged

or

deformed

4

Replace

if

the

bearing

needle

roller

is

damaged

or

worn

5

Replace

both

sleeve

yoke

and

main

shaft

if

the

sleeve

yoke

and

main

shaft

spline

are

damaged

or

worn

6

Replace

if

the

propeller

shaft

tube

surface

is

cracked

or

Indented

ASSEMBLY

The

propeller

shaft

is

reassembled

in

reverse

sequence

of

disassembly

Install

the

spider

on

the

yoke

flange

PD

2

Page 70 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Insert

the

journal

into

the

yoke

flange

Tap

the

journal

bearing

into

the

yoke

flange

using

a

brass

drift

smaller

than

the

hole

in

the

yoke

Tap

the

other

bearing

into

the

opposite

end

of

the

yoke

flange

until

the

bearing

is

in

line

with

the

snap

ring

grooves

With

a

pair

of

pliers

install

the

snap

rings

on

both

ends

of

the

yoke

flange

Insert

the

flange

assembly

in

the

sleeve

yoke

Place

the

other

yoke

bearing

into

the

opposite

end

of

the

yoke

and

tap

this

bearing

into

the

yoke

until

the

bearing

is

in

line

with

the

snap

ring

grooves

Install

the

snap

rings

on

both

ends

of

the

yoke

When

all

parts

are

assembled

check

the

spider

and

surroundings

for

tightness

When

the

clearance

is

excessive

adjust

with

over

size

snap

rings

as

follows

Snap

ring

over

size

Thickness

Color

mrn

in

identification

I

46

0

0575

White

I

48

0

0583

Yellow

1

50

0

0591

Red

1

52

0

0598

Green

1

54

0

0606

Blue

1

56

0

0614

1

58

0

0622

SERVICE

DATA

AND

SPECIFICATIONS

Distance

between

joints

mm

in

Tube

outer

diameter

x

thickness

mm

in

Sleeve

yoke

specification

Outer

dia

x

inner

dia

x

pitch

mm

in

Brown

No

mark

I

189

46

8

68

9

x

1

6

2

713

x

0

0630

Involute

spline

20

x

80

x

I

0

787

x

3

150

x

0

0394

Permissible

unbalance

gr

cm

in

oz

rpm

15

0

2

4

000

Allowable

max

swinging

torque

of

spider

journal

10

9

kg

cm

in

lb

Propeller

shaft

run

out

mm

in

Tightening

torque

of

companion

flange

nuts

kg

m

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Noise

and

vibration

Distorted

propeller

shaft

Unbalanced

propeller

shaft

Corrective

action

less

than

0

6

0

024

2

0

to

2

7

I4

to

20

Using

exclusively

an

arbor

press

restraighten

If

distortion

is

excessive

replace

propeller

shaft

Check

for

balance

If

unbalance

exceeds

the

limit

replace

it

Recorrect

Replace

the

sleeve

yoke

Replace

the

journal

Replace

with

correct

snap

ring

Retighten

nuts

to

the

specified

torque

Incorrectly

positioned

flange

yoke

Excessive

spline

lash

Worn

or

damaged

journal

Inconect

snap

rings

Loose

nuts

securing

the

flange

yoke

to

the

companion

flange

PD

3

Page 89 of 513

FRONT

AXLE

FRONT

SUSPENSION

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Removal

1

Jack

up

the

vehicle

and

support

the

vehicle

with

stands

See

the

Section

GL

2

Remove

the

hub

nuts

and

remOve

the

wheel

3

Remove

the

splash

board

4

Loosen

the

brake

tube

connecting

nut

remove

the

brake

hose

locking

spring

withdraw

the

plate

and

remOve

the

brake

hose

from

the

strul

assembly

bracket

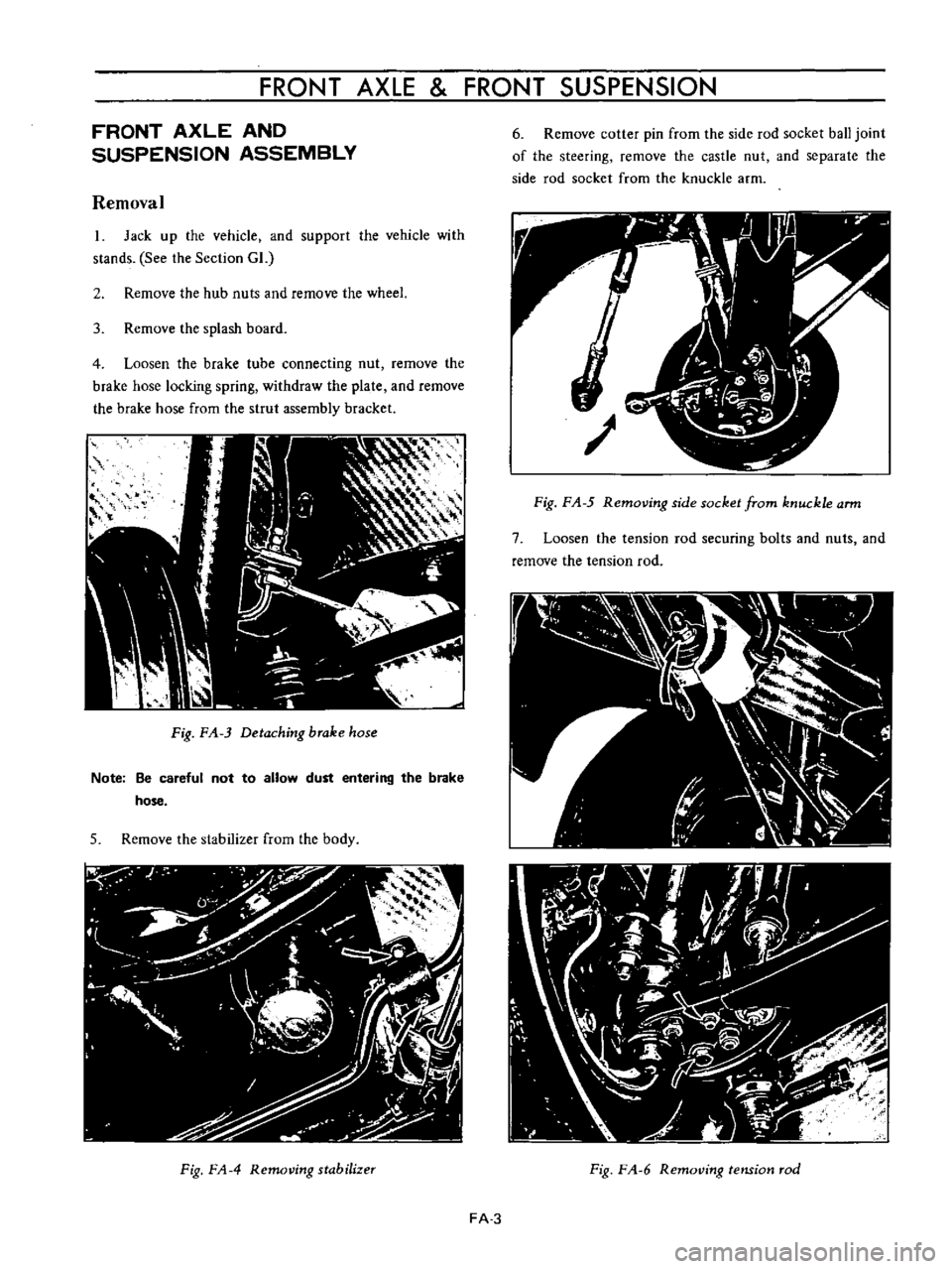

Fig

FA

3

Detaching

brake

hose

Note

Be

careful

not

to

allow

dust

entering

the

brake

hose

5

Remove

the

stabilizer

from

the

body

Fig

FA

4

Removing

stabilizer

6

Remove

cotter

pin

from

the

side

rod

socket

ball

joint

of

the

steering

remove

the

castle

nut

and

separate

the

side

rod

socket

from

the

knuckle

arm

Fig

F

A

5

Removing

side

socket

from

knuckle

arm

7

Loosen

the

tension

rod

securing

bolts

and

nuts

and

remove

the

tension

rod

Fig

F

A

6

RemotJing

tension

rod

FA

3

Page 91 of 513

FRONT

AXLE

FRONT

SUSPENSION

Reinstalla

tion

First

check

rubber

parts

such

as

tension

rod

mount

ing

bushing

stabilizer

bar

bushing

etc

for

deterioration

crack

and

other

defective

conditions

and

replace

as

required

2

Reinstall

the

front

axle

and

suspension

assembly

in

reverse

sequence

of

removal

noting

the

following

matters

1

Tighten

the

transverse

link

mounting

bolts

and

stabilizer

bar

body

side

installation

bolt

to

the

raled

tightening

torque

under

the

unladen

vehicle

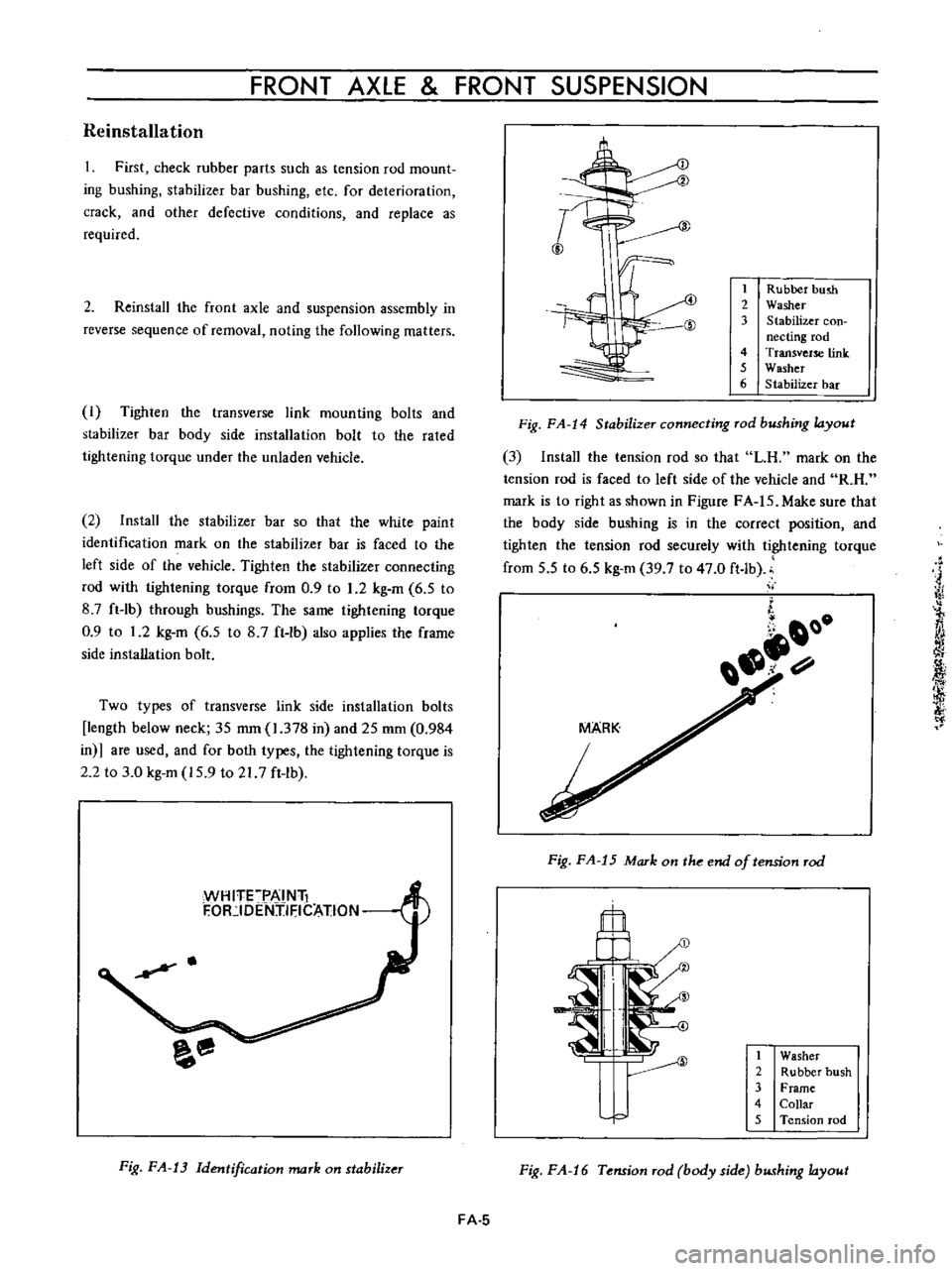

2

Install

the

stabilizer

bar

so

that

the

white

paint

identification

mark

on

the

stabilizer

bar

is

faced

to

the

left

side

of

the

vehicle

Tighten

the

stabilizer

connecting

rod

with

tightening

torque

from

0

9

to

1

2

kg

m

6

5

to

8

7

ft

lb

through

bushings

The

same

tightening

torque

0

9

to

1

2

kg

m

6

5

to

8

7

ft

Ib

also

applies

the

frame

side

installation

bolt

Two

types

of

transverse

link

side

installation

bolts

length

below

neck

35

mm

1

378

in

and

25

mm

0

984

in

are

used

and

for

both

types

the

tightening

torque

is

2

2

to

3

0

kg

m

15

9

to

217

ft

lb

WH

ITFPAI

Nli

F

OR

IDENjIFICATION

H

Fig

FA

13

Identification

mark

on

stabilizer

I

J

1

Rubber

hush

2

Washer

3

Stabilizer

con

necting

rod

4

Transverse

link

5

Washer

6

Stabilizer

bar

Fig

FA

14

Stabilizer

connecting

rod

bushing

layout

3

Install

the

tension

rod

so

that

LH

mark

on

the

tension

rod

is

faced

to

left

side

of

the

vehicle

and

R

H

mark

is

to

right

as

shown

in

Figure

FA

IS

Make

sure

that

the

body

side

bushing

is

in

the

correct

position

and

tighten

the

tension

rod

securely

with

tightening

torque

from

5

5

to

6

5

kg

m

39

7

to

47

0

ft

lb

ii

j

iY

l

fj

i

f

i

Of

1

0

Fig

FA

15

Mark

on

the

end

of

tension

rod

il

1

Washer

2

Rubber

bush

3

Frame

4

Collar

5

Tension

rod

Fig

FA

16

Tension

rod

body

side

bushing

layout

FA

5

Page 92 of 513

CHASSIS

Tightening

torque

of

front

suspension

cross

member

and

body

is

3

2

to

4

0

kg

m

23

1

to

28

9

ft

Ib

5

Tightening

torque

of

bolt

used

to

secure

the

upper

portion

of

the

strut

assembly

on

the

body

is

1

6

to

2

1

kg

m

11

6

to

15

2ft

lb

FRONT

AXLE

Removal

I

Jack

up

the

vehicle

remove

the

wheel

and

discon

nect

the

brake

hose

at

the

strut

outer

casing

bracket

unit

For

details

see

Removal

of

front

axle

and

suspension

assembly

2

Remove

the

brake

caliper

installation

bolts

and

remove

the

caliper

assembly

Disc

type

brake

3

Remove

the

brake

druOL

Drum

type

brake

4

Remove

the

hub

cap

with

a

flal

headed

screwdriver

or

other

proper

tool

and

hammer

Be

sure

to

tap

lightly

5

Remove

cotter

pin

from

the

wheel

bearing

lock

nut

and

remove

the

lock

nut

6

With

the

wheel

bearing

washer

and

wheel

bearing

installed

on

the

wheel

hub

remove

the

wheel

hub

from

the

spindle

In

the

case

of

a

disc

type

brake

the

wheel

hub

may

be

removed

with

the

disc

rotor

installed

on

the

wheel

hub

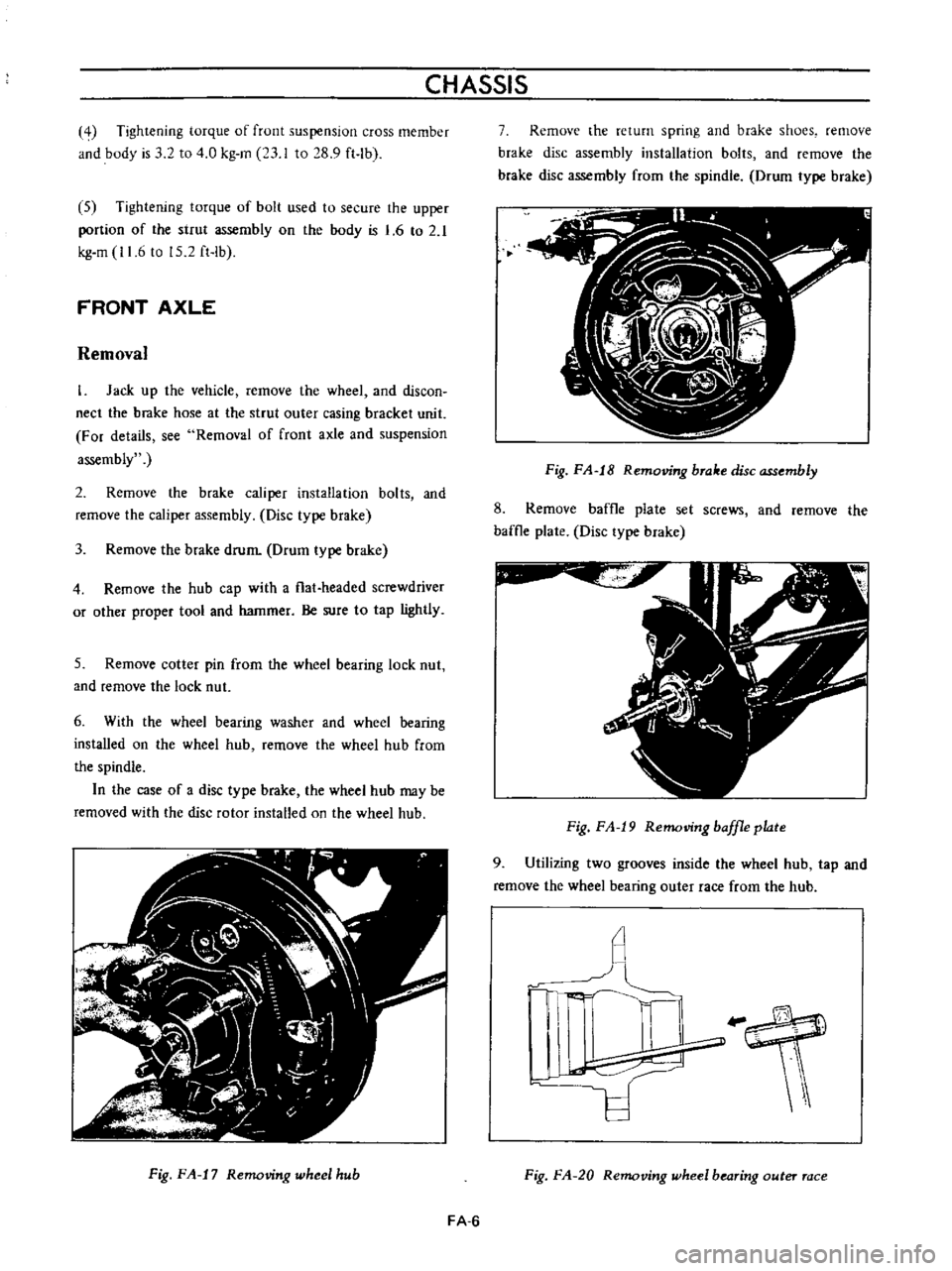

Fig

FA

17

Removing

wheel

hub

7

Remove

the

return

spring

and

brake

shoes

remove

brake

disc

assembly

installation

bolts

and

remove

the

brake

disc

assembly

from

the

spindle

Drum

type

brake

Fig

FA

IS

Removing

brake

disc

a

ssembly

8

Remove

baffle

plate

set

screws

and

remove

the

baffle

plate

Disc

type

brake

Fig

FA

19

Removingbaffleplate

9

Utilizing

two

grooves

inside

the

wheel

hub

tap

and

remove

the

wheel

bearing

outer

race

from

the

hub

Fig

FA

20

Removing

wheel

bearing

outer

race

FA

6

Page 97 of 513

FRONT

AXLE

FRONT

SUSPENSION

t

t

Fig

FA

26

Returning

wheel

bearing

lock

nut

4

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

again

to

allow

the

bearing

breaking

in

measure

bearing

rotation

starting

torque

apply

a

cotter

pin

to

secure

the

nut

if

the

measured

starting

torque

is

within

the

rated

value

and

install

the

hub

cap

hub

cap

Wheel

bearing

rotation

starting

torque

9

0

kg

cm

7

8

in

1b

4

0

kg

cm

3

4

7

in

1b

At

the

hub

bolt

1

57

kg

3

461b

New

bearing

0

7

kg

1

54lb

Used

bearing

No

slackness

should

exist

toward

the

axis

direction

New

bearing

Used

bearing

J

o

i

@

j

Be

sure

to

remove

the

brake

pad

Disc

type

brake

Correctly

measure

starting

force

toward

tangential

direction

against

the

hub

bolt

Fig

FA

27

Measuring

wheel

bearing

ro

ation

starting

torque

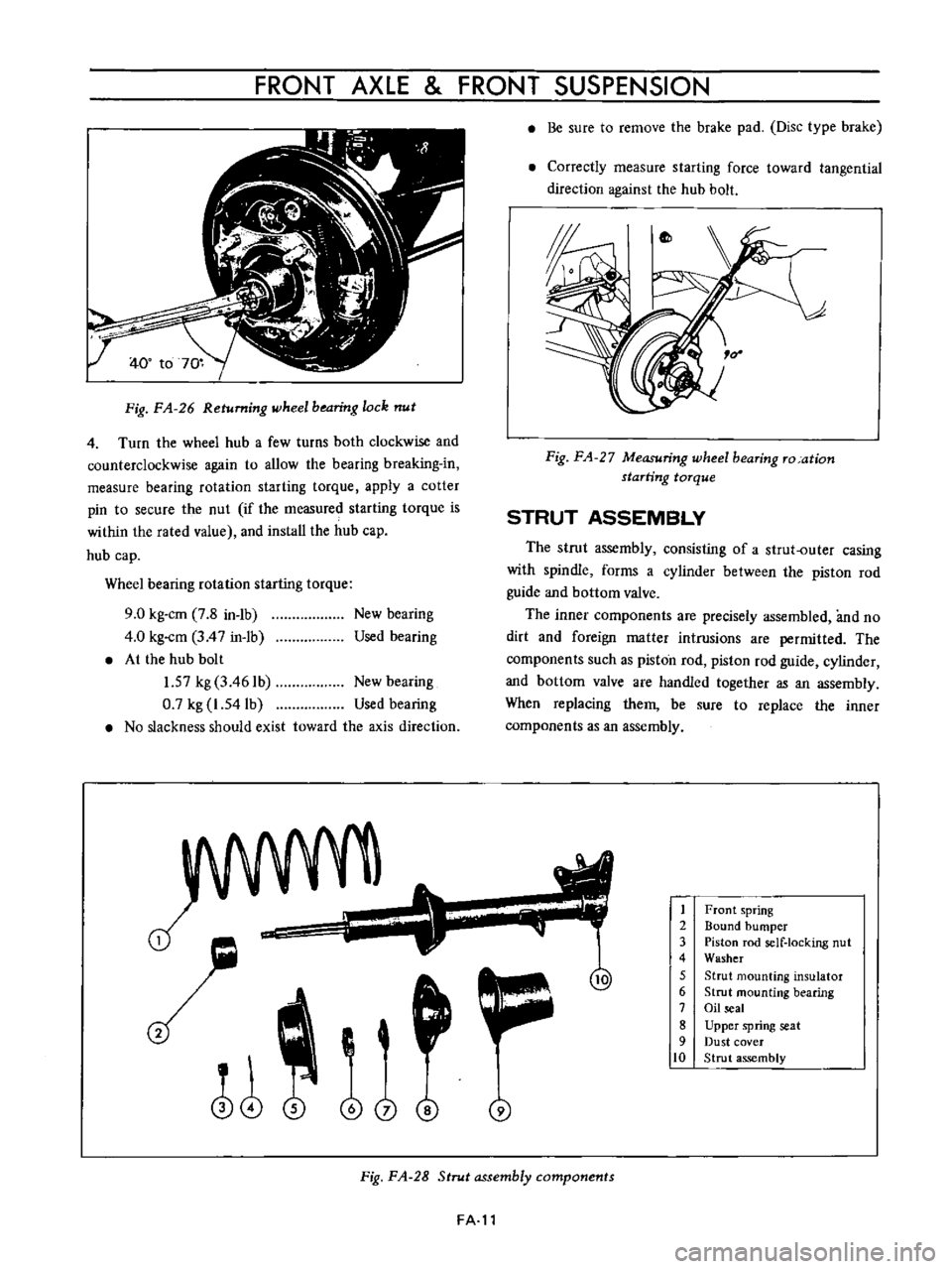

STRUT

ASSEMBLY

The

strut

assembly

consisting

of

a

strut

outer

casing

with

spindle

forms

a

cylinder

between

the

piston

rod

guide

and

bottom

valve

The

inner

components

are

precisely

assembled

and

no

dirt

and

foreign

matter

intrusions

are

permitted

The

components

such

as

piston

rod

piston

rod

guide

cylinder

and

bottom

valve

are

handled

together

as

an

assembly

When

replacing

them

be

sure

to

replace

the

inner

components

as

an

assembly

1

2

3

4

5

6

7

8

9

10

Front

spring

Bound

bumper

Piston

rod

self

locking

nut

Washer

Strut

mounting

insulator

Strut

mounting

bearing

Oil

seal

Upper

spring

seat

Dust

cover

Strut

assembly

Fig

FA

28

Strut

assembly

components

FA

l1

Page 99 of 513

FRONT

AXLE

FRONT

SUSPENSION

Fig

FA

31

Removing

front

strut

assembly

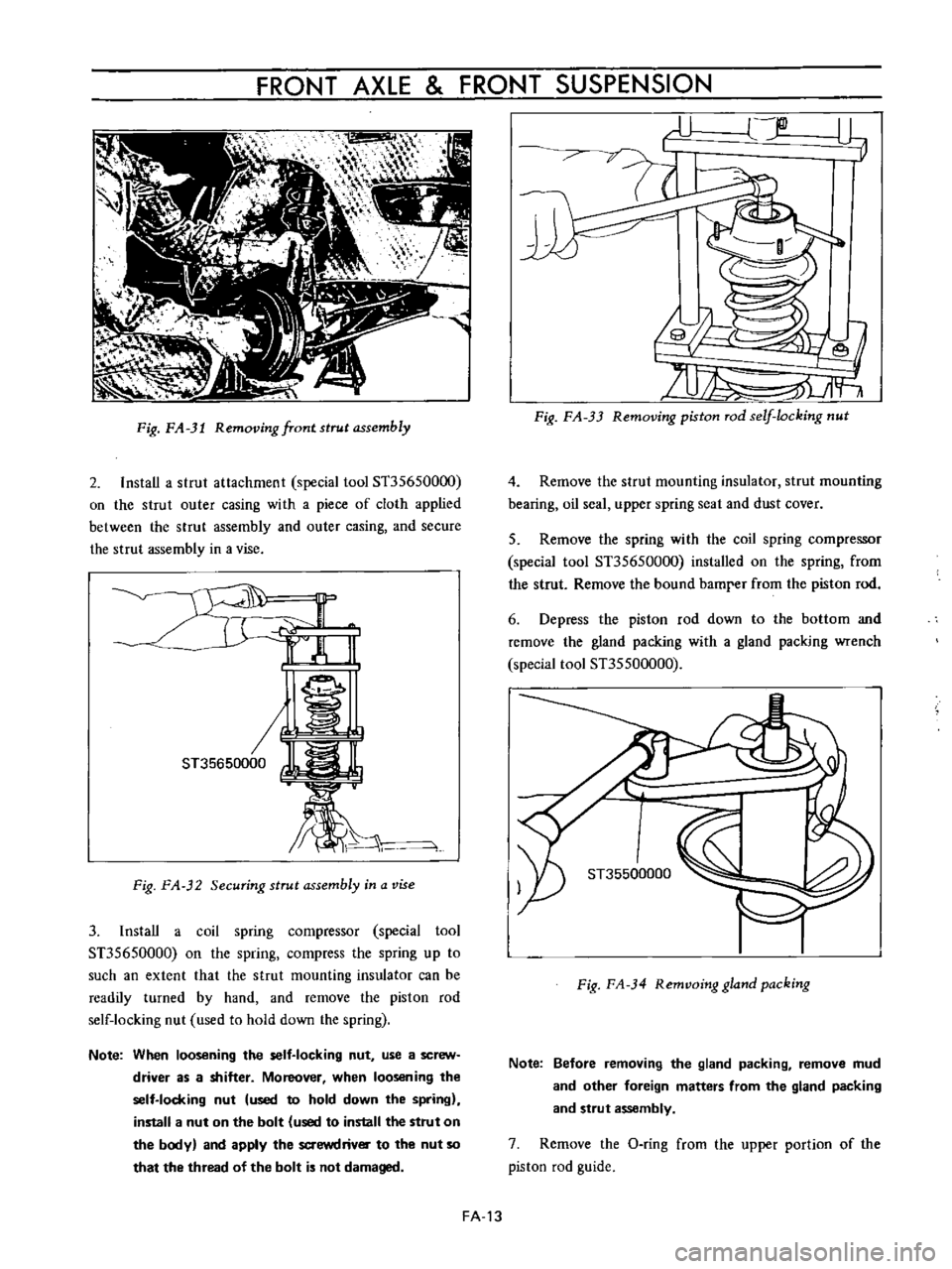

2

InstaU

a

strut

attachment

special

tool

ST35650000

00

the

strut

outer

casing

with

a

piece

of

cloth

applied

between

the

strut

assembly

and

outer

casing

and

secure

the

strut

assembly

in

a

vise

J

1

i

kj

ST35650000

W

lL

bi

Fig

FA

32

Securing

strut

assembly

in

a

vise

3

1nstaU

a

coil

spring

compressor

special

tool

ST35650000

on

the

spring

compress

the

spring

up

to

such

an

extent

that

the

strut

mounting

insulator

can

be

readily

turned

by

hand

and

remove

the

piston

rod

self

locking

nut

used

to

hold

down

the

spring

Note

When

loosening

the

self

locking

nut

use

a

screw

driver

as

a

shitter

Moreover

when

loosening

the

self

locking

nut

used

to

hold

down

the

spring

install

a

nut

on

the

bolt

used

to

install

the

strut

on

the

body

and

apply

the

saewdrivOI

to

the

nut

so

that

the

thread

of

the

bolt

is

not

damaged

r

U

jlD

L1

19

71

it

fr

Fig

FA

33

Removing

piston

rod

self

locking

nut

4

Remove

the

strut

mounting

insulator

strut

mounting

bearing

oil

seal

upper

spring

seat

and

dust

cover

5

Remove

the

spring

with

the

coil

spring

compressor

special

tool

ST35650000

installed

on

the

spring

from

the

strut

Remove

the

bound

bamrer

from

the

piston

rod

6

Depress

the

piston

rod

down

to

the

bottom

and

remove

the

gland

packing

with

a

gland

packing

wrench

special

tool

ST35500000

I

ST35500000

Fig

FA

34

Remvoing

gland

packing

Note

Before

removing

the

gland

packing

remove

mud

and

other

foreign

matters

from

the

gland

packing

and

strut

assembly

7

Remove

the

O

ring

from

the

upper

portion

of

the

piston

rod

guide

FA

13

Page 101 of 513

FRONT

AXLE

FRONT

SUSPENSION

I

f

f

ij

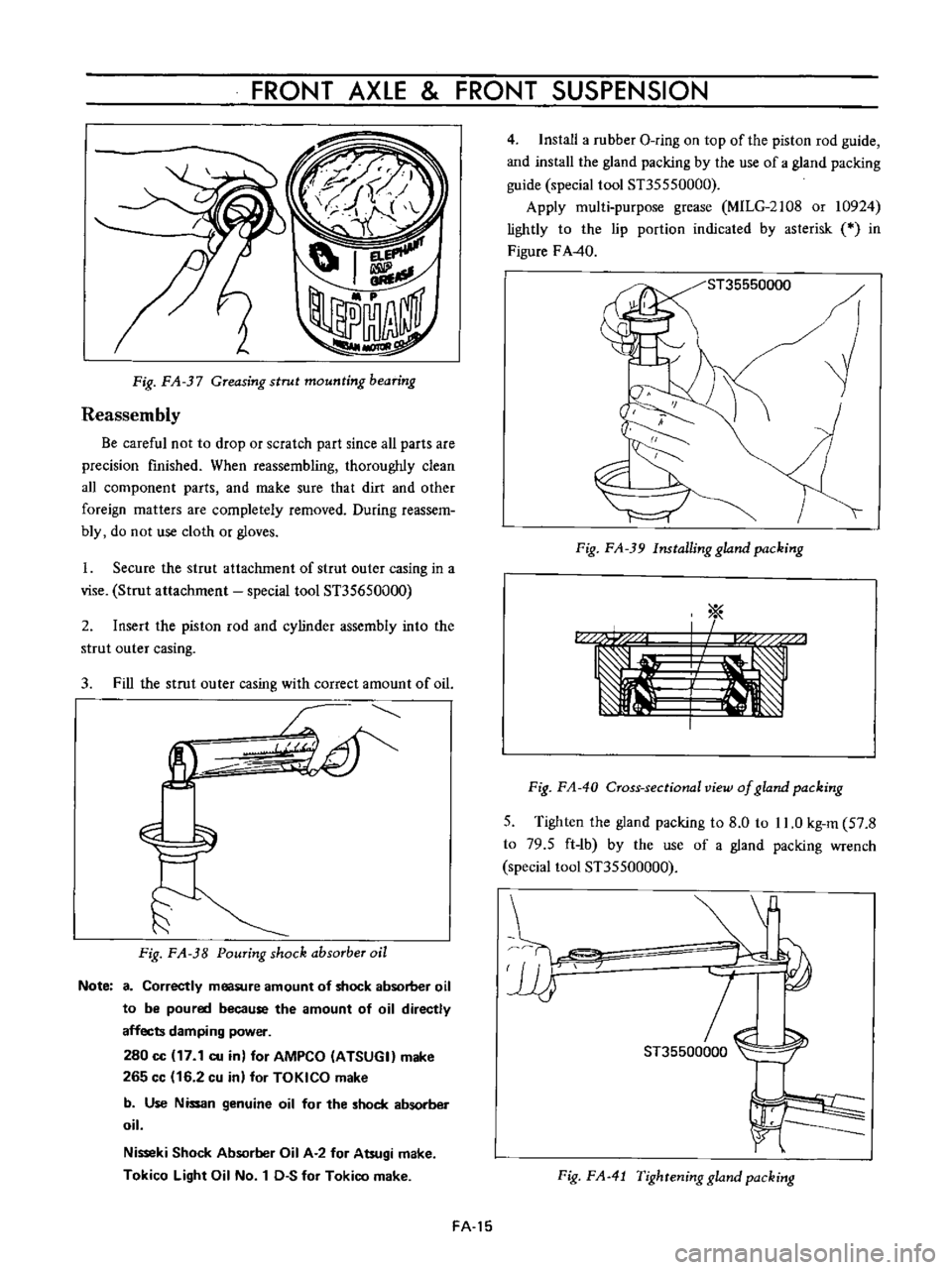

Reassembly

Fig

FA

37

Greasing

strut

mounting

bearing

Be

careful

not

to

drop

or

scratch

part

since

all

parts

are

precision

finished

When

reassembling

thoroughly

clean

all

component

parts

and

make

sure

that

dirt

and

other

foreign

matters

are

completely

removed

During

reassem

bly

do

not

use

cloth

or

gloves

I

Secure

the

strut

attachment

of

strut

Quter

casing

in

a

vise

Strut

attachment

special

tool

ST35650000

2

Insert

the

piston

rod

and

cylinder

assembly

into

the

strut

outer

casing

3

Fill

the

strut

outer

casing

with

correct

amount

of

oil

1

Fig

FA

38

Pouring

shock

absorber

oil

Note

a

Correctly

measure

amount

of

shock

absorber

oil

to

be

poured

because

the

amount

of

oil

directly

affects

damping

power

280

cc

17

1

cu

in

for

AMPCO

ATSUGI

make

265

cc

16

2

cu

in

for

TOKICO

make

b

Use

Nissan

genuine

oil

for

the

shock

absorber

oil

Nisseki

Shock

Absorber

Oil

A

2

for

Atsugi

make

Tokico

light

Oil

No

1

D

S

for

Tokico

make

FA

15

4

Install

a

rubber

O

ring

on

top

of

the

piston

rod

guide

and

install

the

gland

packing

by

the

use

of

a

gland

packing

guide

special

tool

ST35550000

Apply

multi

purpose

grease

MILG

2108

or

10924

lightly

to

the

lip

portion

indicated

by

asterisk

0

in

Figure

F

A40

ST35550000

1

Fig

FA

39

Installing

gland

packing

a

1

c

I

Fig

FA

40

Cross

sectional

view

of

gland

packing

5

Tighten

the

gland

packing

to

8

0

to

11

0

kg

m

57

8

to

79

5

ft

1b

by

the

use

of

a

gland

packing

wrench

special

tool

ST35500000

ST35500000

Fig

FA

41

Tighrening

gland

packing

Page 102 of 513

CHASSIS

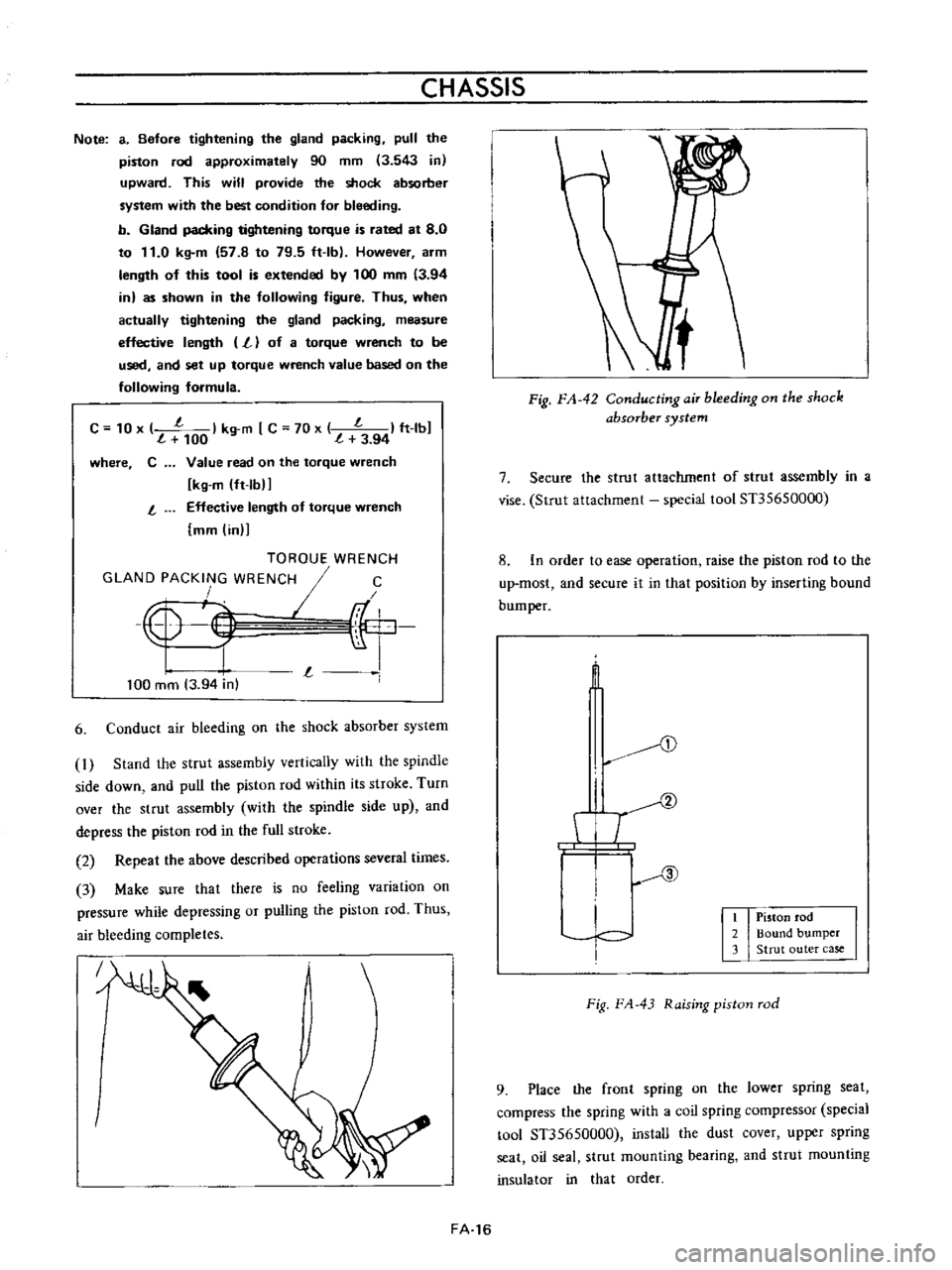

Note

a

Before

tightening

the

gland

packing

pull

the

piston

rod

approximately

90

mm

3

543

in

upward

This

will

provide

the

shock

absorber

system

with

the

best

condition

for

bleeding

b

Gland

packing

tightening

torque

is

rated

at

8

0

to

11

0

kg

m

57

8

to

79

5

ft

Ib

However

arm

length

of

this

tool

is

extended

by

100

mm

3

94

in

as

shown

in

the

following

figure

Thus

when

actually

tightening

the

gland

packing

measure

effective

length

L

of

a

torque

wrench

to

be

used

and

set

up

torque

wrench

value

based

on

the

following

formula

C

10

x

l

I

kg

m

C

70

x

l

I

ft

lbJ

100

l

3

94

where

C

Value

read

on

the

torque

wrench

kg

m

ft

lbIJ

Effective

length

of

torque

wrench

mm

in

l

TOROUE

WRENCH

GLAND

PACKING

WRENCH

I

C

4

F

r

I

L

I

100

mm

3

94

in

6

Conduct

air

bleeding

on

the

shock

absorber

system

1

Stand

the

strut

assembly

vertically

with

the

spindle

side

down

and

pull

the

piston

rod

within

its

stroke

Turn

over

the

strut

assembly

with

the

spindle

side

up

and

depress

the

piston

rod

in

the

full

stroke

2

Repeat

the

above

described

operations

several

times

3

Make

sure

that

there

is

no

feeling

variation

on

pressure

while

depressing

or

pulling

the

piston

rod

Thus

air

bleeding

completes

J

FA

16

Fig

FA

42

ConductingaiT

bleeding

on

the

shock

absorber

system

7

Secure

the

strut

attachment

of

strut

assembly

in

a

vise

Strut

attachment

special

tool

Sn5650000

8

In

order

to

ease

operation

raise

the

piston

rod

to

the

up

most

and

secure

it

in

that

position

by

inserting

bound

bum

per

t

D

I

T

I

c

I

Piston

rod

2

Bound

bumper

3

Strut

outer

case

Fig

FA

43

Raising

piston

rod

9

Place

the

front

spring

on

the

lower

spring

seat

compress

the

spring

with

a

coil

spring

compressor

special

tool

Sn5650000

install

the

dust

cover

upper

spring

seat

oil

seal

strut

mounting

bearing

and

strut

mounting

insulator

in

that

order

Page 117 of 513

CHASSIS

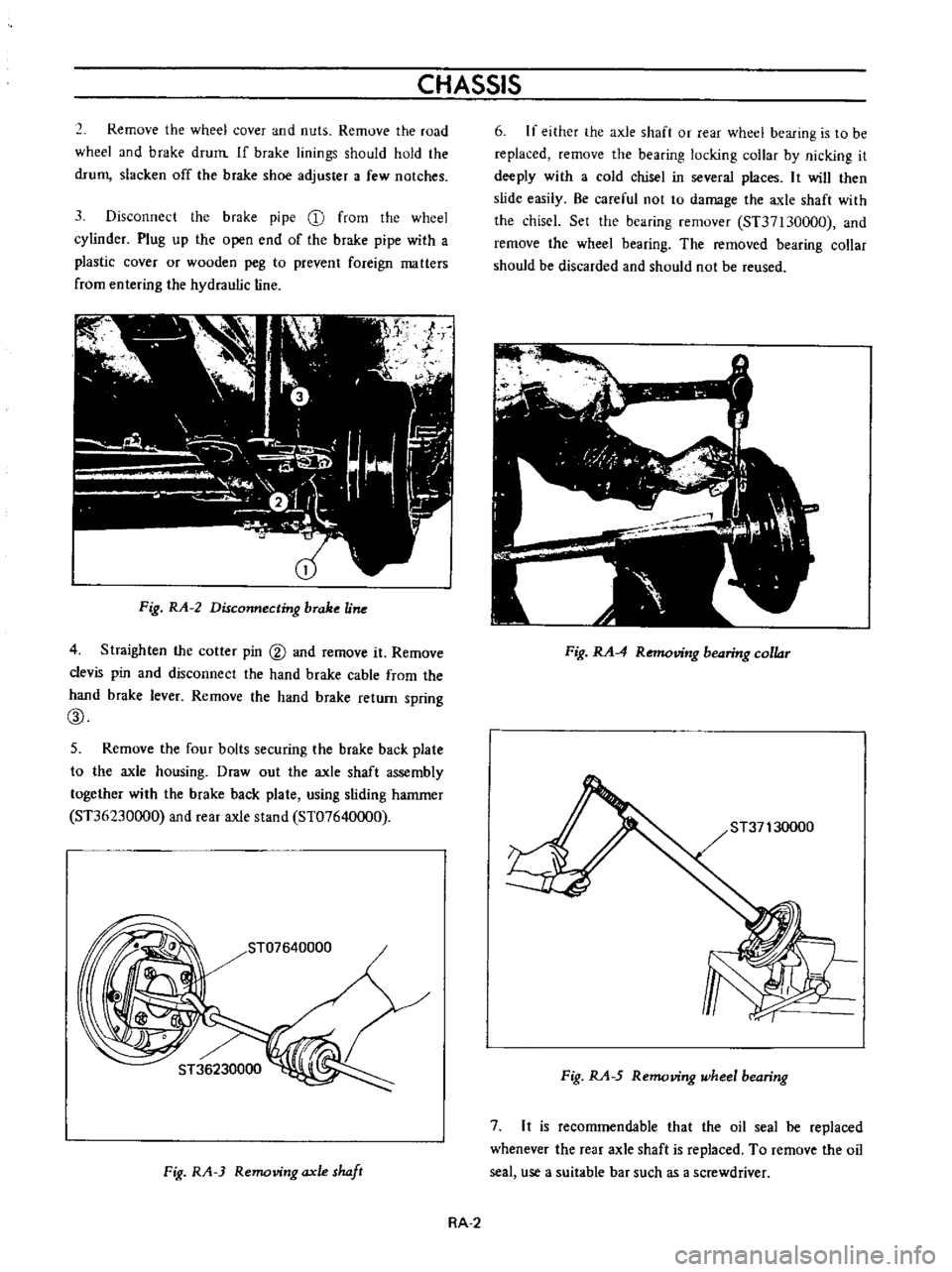

2

Remove

the

wheel

cover

and

nuts

Remove

the

road

wheel

and

b

rake

drum

If

brake

linings

should

hold

the

drum

slacken

off

the

brake

shoe

adjuster

a

few

notches

3

Disconnect

the

brake

pipe

CD

from

the

wheel

cylinder

Plug

up

the

open

end

of

the

brake

pipe

with

a

plastic

cover

or

wooden

peg

to

prevent

foreign

matters

from

entering

the

hydraulic

line

Fig

RA

2

Disconnecting

brake

Une

4

Straighten

the

cotler

pin

@

and

remove

it

Remove

clevis

pin

and

disconnect

the

hand

brake

cable

from

the

hand

brake

lever

Remove

the

hand

brake

return

spring

CID

5

Remove

the

four

bolts

securing

the

brake

back

plate

to

the

axle

housing

Draw

out

the

axle

shaft

assembly

together

with

the

brake

back

plate

using

sliding

hammer

ST36230000

and

rear

axle

stand

ST07640000

ST07640000

I

Fig

RA

3

Removing

axle

shaft

6

If

either

the

axle

shaft

or

rear

wheel

bearing

is

to

be

replaced

remove

the

bearing

locking

collar

by

nicking

it

deeply

with

a

cold

chisel

in

several

places

It

will

then

slide

easily

Be

careful

not

to

damage

the

axle

shaft

with

the

chiscl

Set

the

bearing

remover

ST37130000

and

remove

the

wheel

bearing

The

removed

bearing

collar

should

be

discarded

and

should

not

be

reused

Fig

RA

4

Removing

bearing

collar

Fig

RA

5

Removing

wheel

bearing

7

It

is

recommendable

that

the

oil

seal

be

replaced

whenever

the

rear

axle

shaft

is

replaced

To

remove

the

oil

seal

use

a

suitable

bar

such

as

a

screwdriver

RA

2