boot DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 134 of 513

CHASSIS

Fig

BR

19

Greasing

points

on

brake

disc

3

Tighten

the

brake

disc

installation

bolt

to

2

7

to

3

7

kg

m

19

5

to

26

7

ft

lb

4

Adjust

brake

shoe

clearance

and

perform

air

bleeding

on

the

hydraulic

system

FRONT

DISC

BRAKE

Floating

type

disc

brake

Model

ANNET

12

14A

is

used

for

some

territories

as

a

standard

Rigidity

of

the

caliper

is

high

brake

pedal

feeling

is

adequate

and

the

pad

dragging

is

minimized

The

pad

is

returned

by

elasticity

of

the

piston

seal

When

the

pad

is

worn

the

piston

operating

stroke

increases

slipping

occurs

on

the

piston

seal

surface

and

thus

clearance

is

adjusted

automatically

Moreover

in

order

to

prevent

brake

squealing

a

shim

is

inserted

behind

the

pad

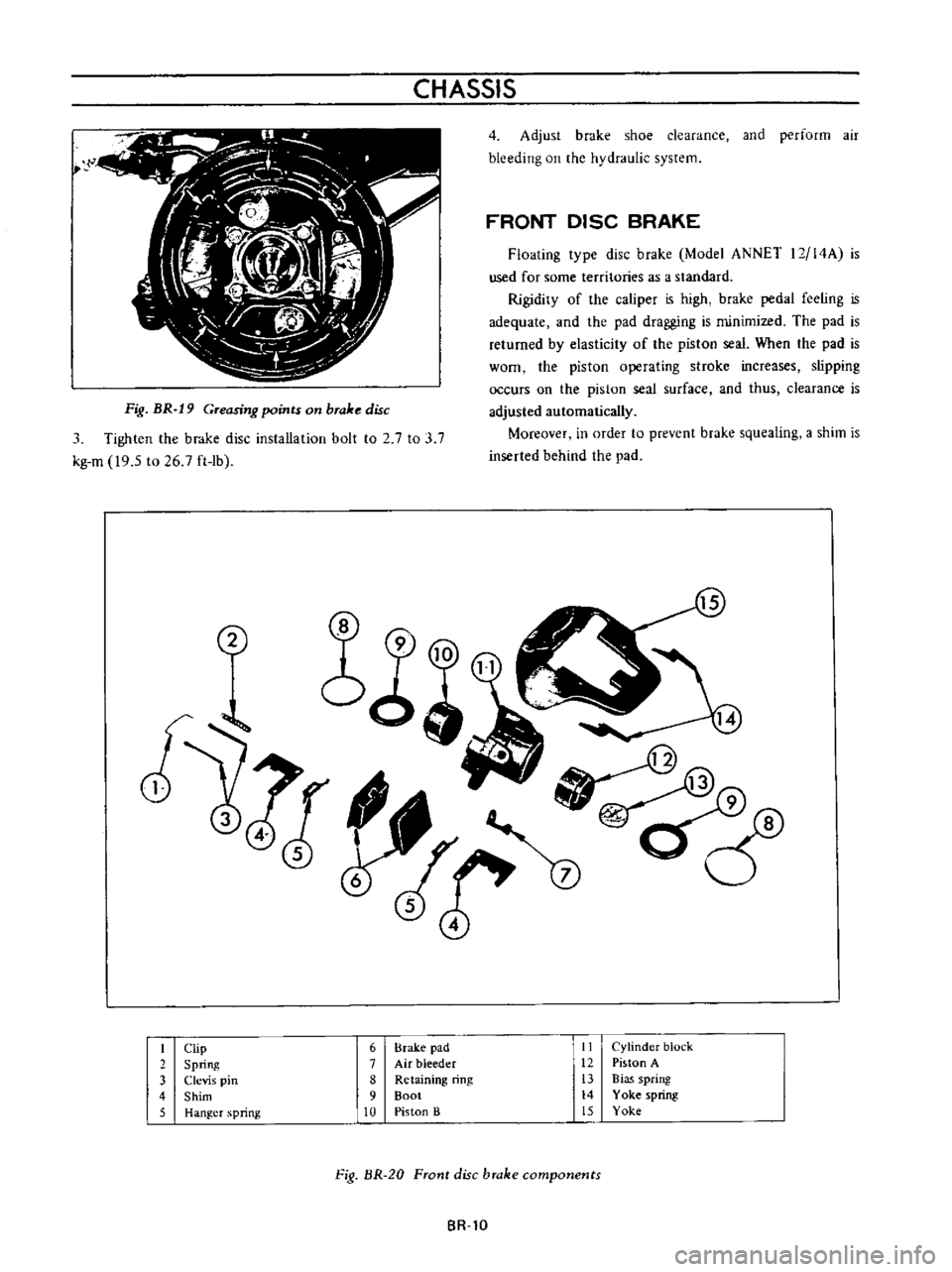

2

I

Clip

6

Brake

pad

II

Cylinder

block

2

Spring

7

Air

bleeder

12

Piston

A

3

Clevis

pin

8

Retaining

ring

13

Bias

spring

4

Shim

9

Boot

14

Yoke

spring

5

Hanger

spring

10

Piston

B

15

Yoke

Fig

BR

20

Front

disc

brake

components

BR

lO

Page 137 of 513

BRAKE

Fig

BR

27

Removing

strut

assembly

and

knuckle

arm

installation

bolt

4

Remove

the

caliper

assembly

installation

bolt

and

separate

it

from

the

strut

assembly

Fig

BR

28

Removing

caliper

assembly

instaUation

bolt

Disassembly

I

Remove

mud

and

other

contaminations

from

the

caliper

assembly

before

disassembly

2

Drain

brake

fluid

from

the

wheel

cylinder

3

Loosen

the

air

bleeder

and

depress

tha

pistons

A

and

B

into

the

cylinder

Refer

to

Pad

replacement

4

Secure

the

yoke

in

a

vise

and

tap

the

yoke

head

with

a

hammer

The

cylinder

body

can

then

be

removed

from

the

yoke

When

removing

the

cylinder

body

be

careful

not

to

allow

the

piston

A

coming

out

from

the

cylinder

BR

13

i

c

J

l

l

7

I

0

I

I

i

I

f

1

1

J

t

1

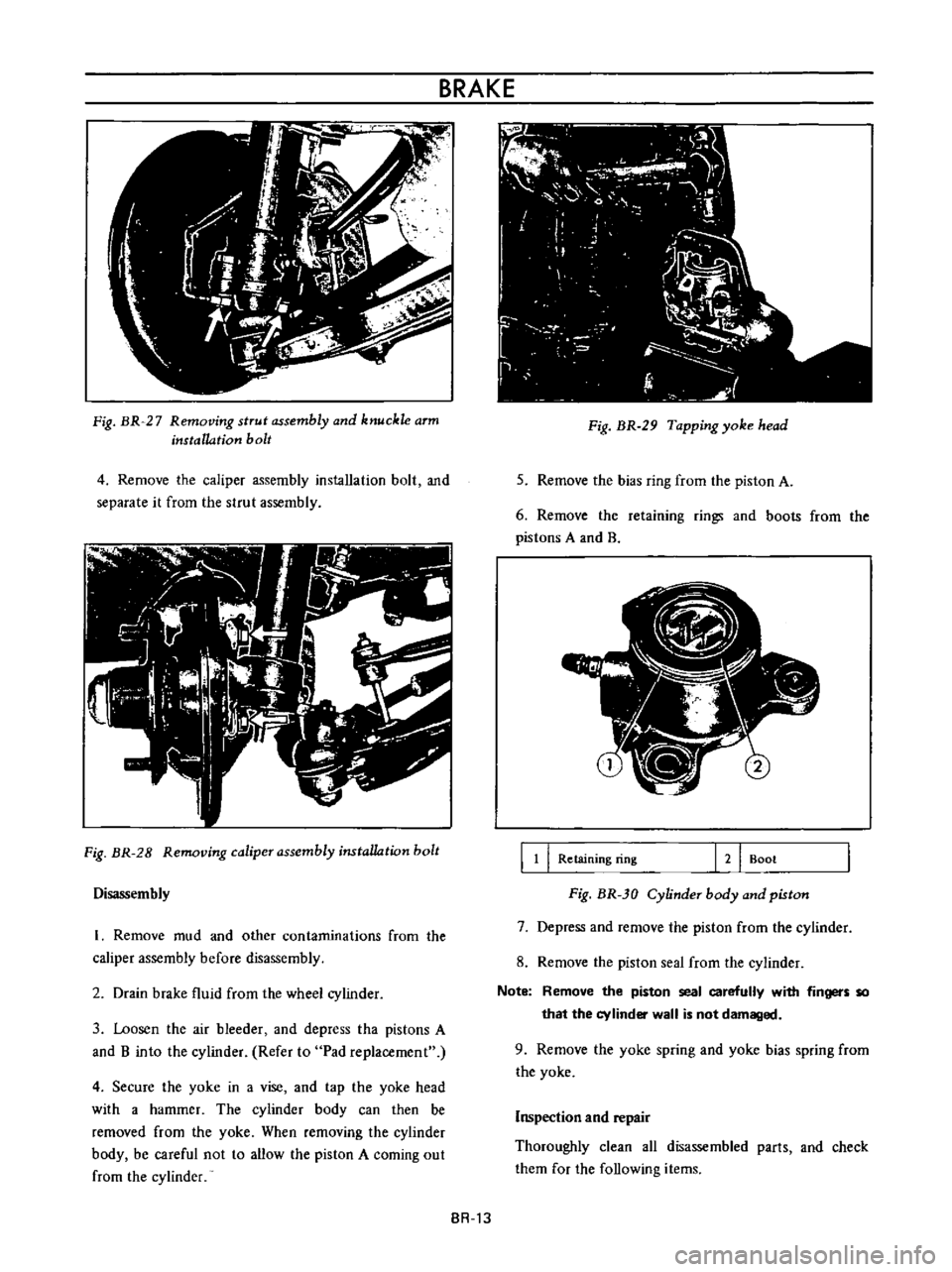

Fig

BR

29

Tapping

yoke

head

5

Remove

the

bias

ring

from

the

piston

A

6

Remove

the

retaining

rings

and

boots

from

the

pistons

A

and

B

J

l

lj

7

fI

II

l

j

B

11

I

Retaining

ring

121

Boot

Fig

BR

30

Cylinder

body

and

piston

7

Depress

and

remove

the

piston

from

the

cylinder

8

Remove

the

pislon

seal

from

the

cylinder

Note

Remove

the

piston

seal

carefully

with

fingers

so

that

the

cylinder

wall

is

not

damaged

9

Remove

the

yoke

spring

and

yoke

bias

spring

from

the

yoke

Inspection

and

repair

Thoroughly

clean

all

disassembled

parIs

and

check

them

for

the

following

items

Page 139 of 513

BRAKE

i

f

F

PISTON

A

PISTON

S

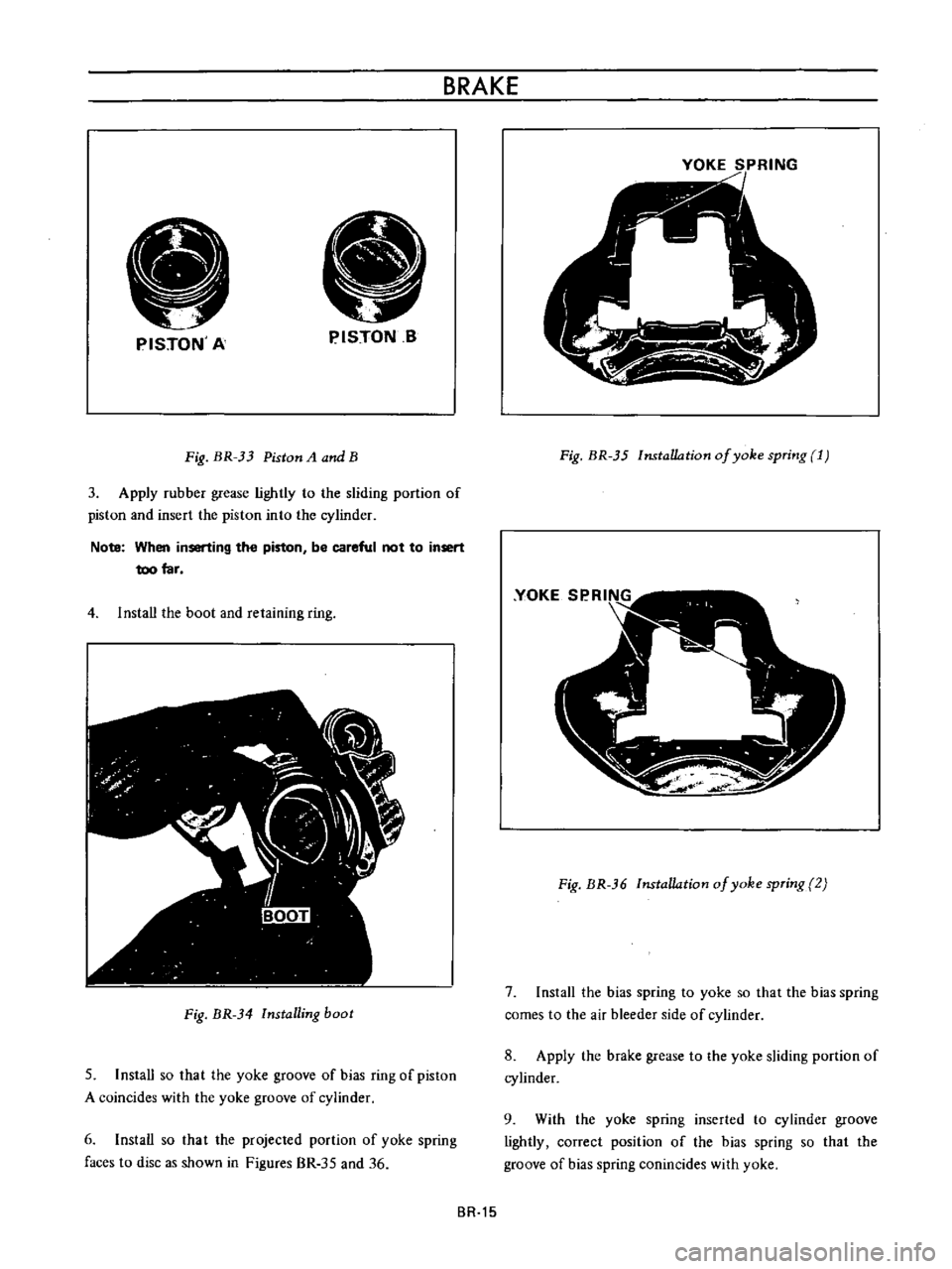

Fig

BR

33

Piston

A

and

B

3

Apply

rubber

grease

lightly

to

the

sliding

portion

of

piston

and

insert

the

piston

into

the

cylinder

Note

When

inserting

the

piston

be

careful

not

to

insert

too

far

4

1

nstaU

the

boot

and

retaining

ring

Fig

BR

34

Installing

boot

5

Install

so

that

the

yoke

groove

of

bias

ring

of

piston

A

coincides

with

the

yoke

groove

of

cylinder

6

Install

so

that

the

projected

portion

of

yoke

spring

faces

to

disc

as

shown

in

Figures

BR

35

and

36

BR

15

YOKE

SPRING

Fig

BR

35

Installation

of

yoke

spring

1

Fig

BR

36

Installation

of

yoke

spring

2

7

Install

the

bias

spring

to

yoke

so

that

the

bias

spring

comes

to

the

air

bleeder

side

of

cylinder

8

Apply

the

brake

grease

to

the

yoke

sliding

portion

of

cylinder

9

With

the

yoke

spring

inserted

to

cylinder

groove

lightly

correct

position

of

the

bias

spring

so

that

the

groove

of

bias

spring

conincides

with

yoke

Page 457 of 513

ENGINE

ElECTRICAL

SYSTEM

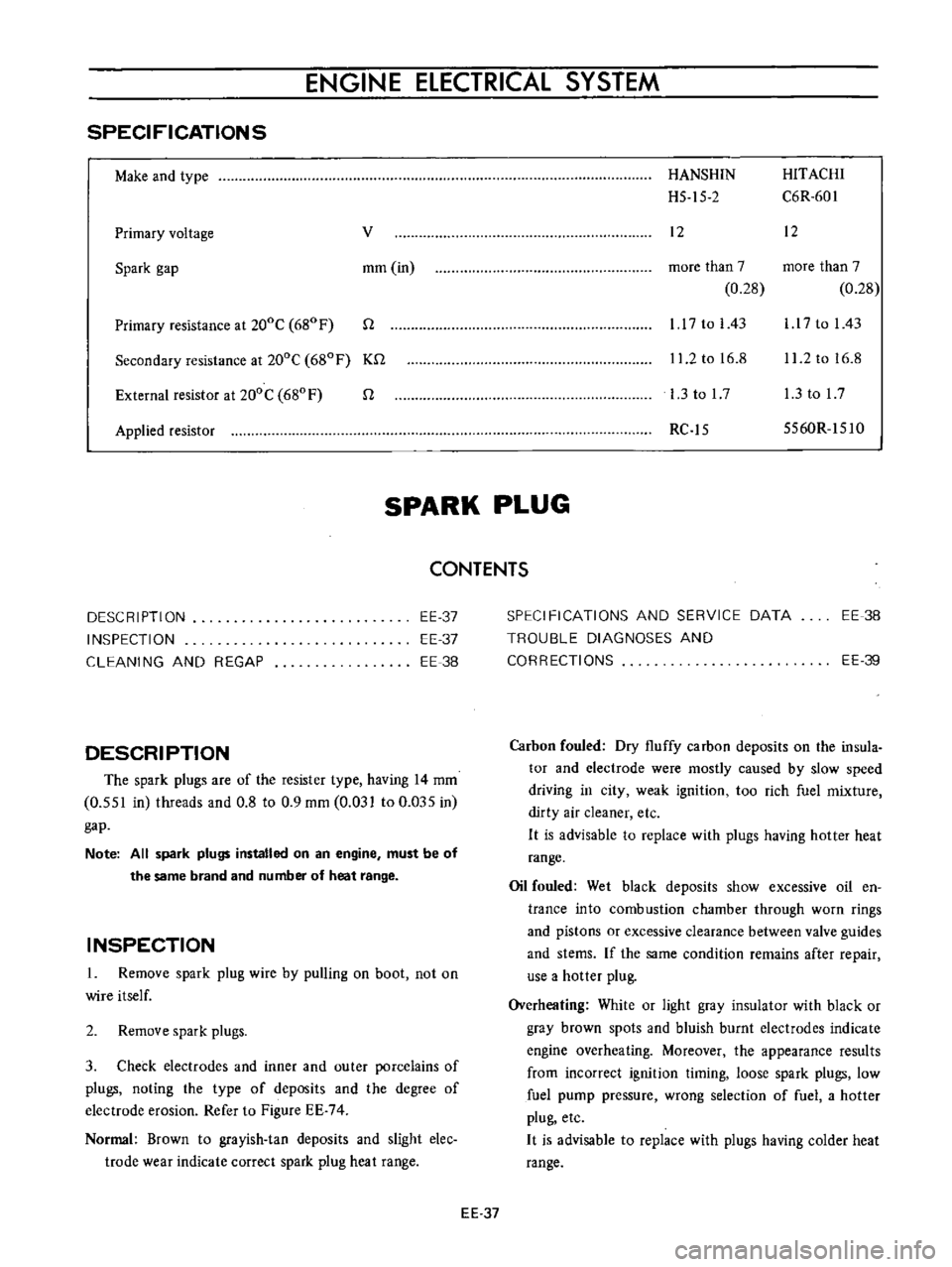

SPECIFICATIONS

Make

and

type

Primary

voltage

v

Spark

gap

mm

in

Primary

resistance

at

200C

680

F

n

Secondary

resistance

at

200C

680F

Kn

External

resistor

at

200C

680

F

n

Applied

resistor

HANSHIN

HITACHI

H5

15

2

C6R

601

12

12

more

than

7

more

than

7

0

28

0

28

1

17

to

I

43

l

l

7

to

I

43

11

2

to

16

8

11

2

to

16

8

l

3tol7

l

3tol7

RC

15

5560R

151O

SPARK

PLUG

CONTENTS

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

EE

37

EE

37

EE

38

DESCRIPTION

The

spark

plugs

are

of

the

resister

type

having

14

mm

0

551

in

threads

and

0

8

to

0

9

mm

0

031

to

0

Q35

in

gap

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

number

of

heat

range

INSPECTION

1

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

74

Normal

Brown

to

grayish

tan

deposits

and

slight

elec

trode

wear

indicate

correct

spark

plug

heat

range

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

38

EE

39

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insula

tor

and

electrode

were

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

en

trance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

Moreover

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pressure

wrong

selection

of

fuel

a

hotter

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

EE

37

Page 468 of 513

ENGINE

REMOVAL

INSTAllATION

5

Disconnecting

clutch

wire

on

right

hand

drive

model

On

left

hand

drive

model

disconnect

hydraulic

line

from

the

clutch

slave

cylinder

Disconnect

the

clutch

wire

at

the

portion

of

the

withdrawal

lever

See

the

section

covering

the

clutch

6

Remove

the

exhaust

front

tube

ij

f

I

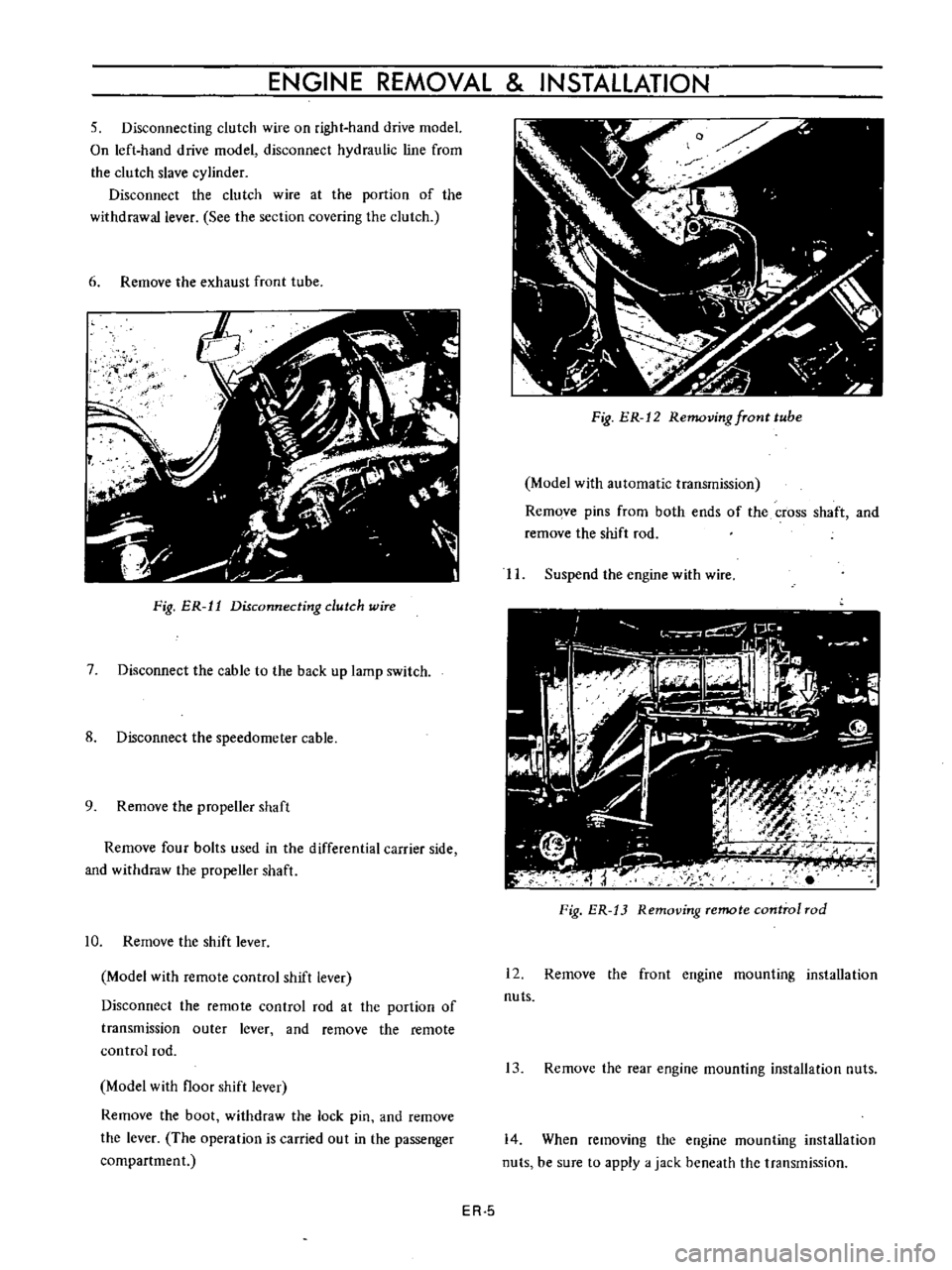

Fig

ER

11

Disconnecting

dutch

wire

7

Disconnect

the

cable

to

the

back

up

lamp

switch

8

Disconnect

the

speedometer

cable

9

Remove

the

propeller

shaft

Remove

four

bolts

used

in

the

differential

carrier

side

and

withdraw

the

propeller

shaft

10

Remove

the

shift

lever

Model

with

remote

control

shift

lever

Disconnect

the

remote

control

rod

at

the

portion

of

transmission

outer

lever

and

remove

the

remote

control

rod

Model

with

floor

shift

lever

Remove

the

boot

withdraw

the

lock

pin

and

remove

the

lever

The

operation

is

carried

out

in

the

passenger

compartment

Fig

ER

12

Removing

fTont

tube

Model

with

automatic

transmission

Remove

pins

from

both

ends

of

the

cross

shaft

and

remove

the

shift

rod

II

Suspend

the

engine

with

wire

Fig

ER

13

Removing

remote

control

rod

12

Remove

the

front

engine

mounting

installation

nuts

13

Remove

the

rear

engine

mounting

installation

nuts

14

When

removing

the

engine

mounting

installation

nuts

be

sure

to

apply

a

jack

beneath

the

transmission

ER

5