lock DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 54 of 1200

Inspect the tension strut for signs of contact with

the ground or road debris which has bent or caused

other damage to the tension strut. If the tension

strut is bent or damaged the tension strut will

require replacement.Do not attempt to repair or

straighten a tension strut.

STABILIZER BAR AND BUSHINGS

Inspect the stabilizer bar for damage or bending.

Inspect for broken or distorted stabilizer bar bush-

ings, bushing retainers, and worn or damaged stabi-

lizer bar to strut attaching links. If stabiizer bar to

rear frame rail bushing replacement is required,

bushings can be removed from sway bar by opening

slit and peeling bushing off sway bar.

STABILIZER BAR ATTACHING LINKS

Inspect the bushings and sleeves in the stabilizer

bar attaching links for damage or deterioration.

Inspect the stabilizer bar attaching link to ensure it

is not bent or broken. If any of these conditions are

present when inspecting the attaching links, replace-

ment of the attaching link is required.

SERVICE PROCEDURES

REAR WHEEL ALIGNMENT

Refer to Front And Rear Wheel Toe Setting Proce-

dures in the Wheel Alignment Check And Adjustment

section in this group of the service manual for the

required rear wheel Toe setting procedure.

REMOVAL AND INSTALLATION

STRUT ASSEMBLY

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly from

the vehicle.

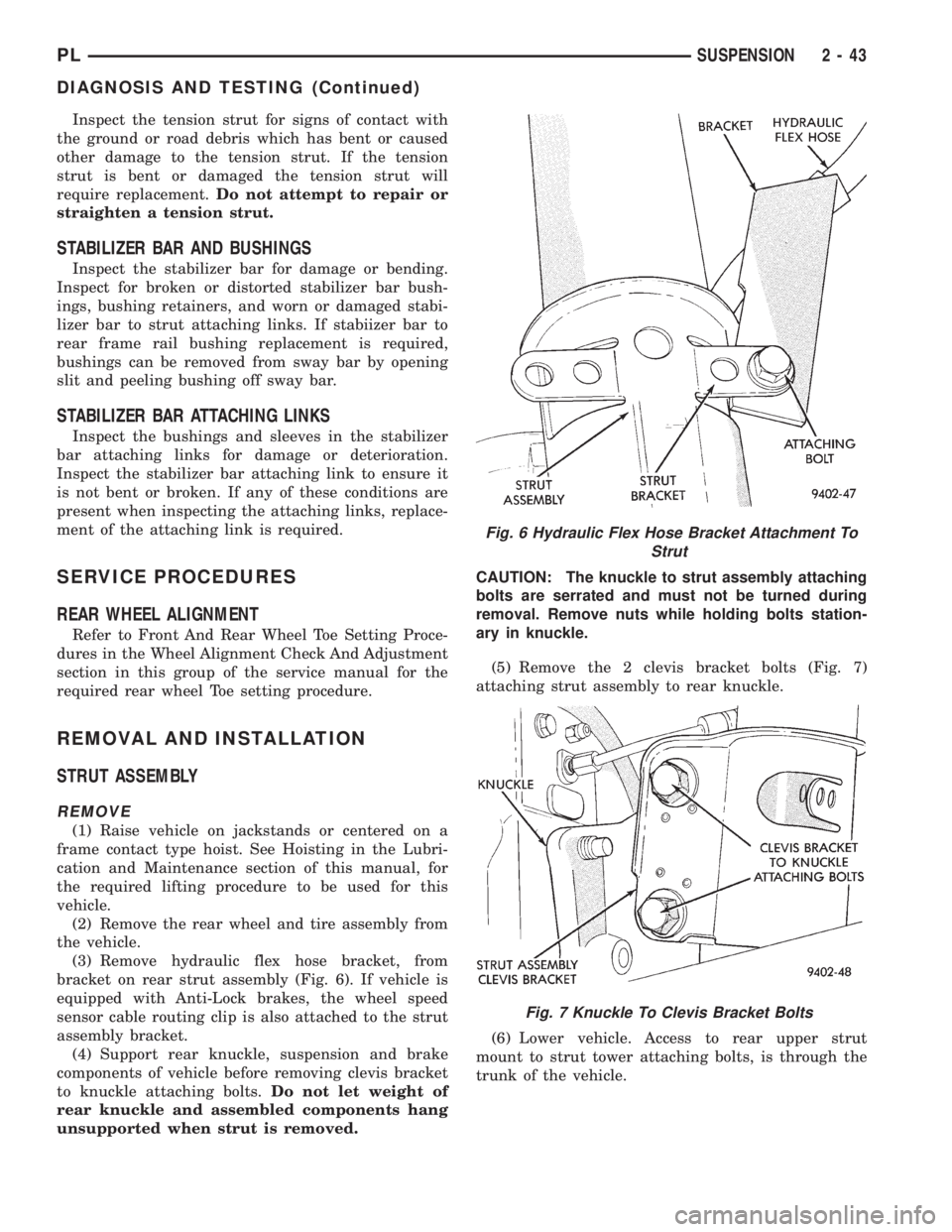

(3) Remove hydraulic flex hose bracket, from

bracket on rear strut assembly (Fig. 6). If vehicle is

equipped with Anti-Lock brakes, the wheel speed

sensor cable routing clip is also attached to the strut

assembly bracket.

(4) Support rear knuckle, suspension and brake

components of vehicle before removing clevis bracket

to knuckle attaching bolts.Do not let weight of

rear knuckle and assembled components hang

unsupported when strut is removed.CAUTION: The knuckle to strut assembly attaching

bolts are serrated and must not be turned during

removal. Remove nuts while holding bolts station-

ary in knuckle.

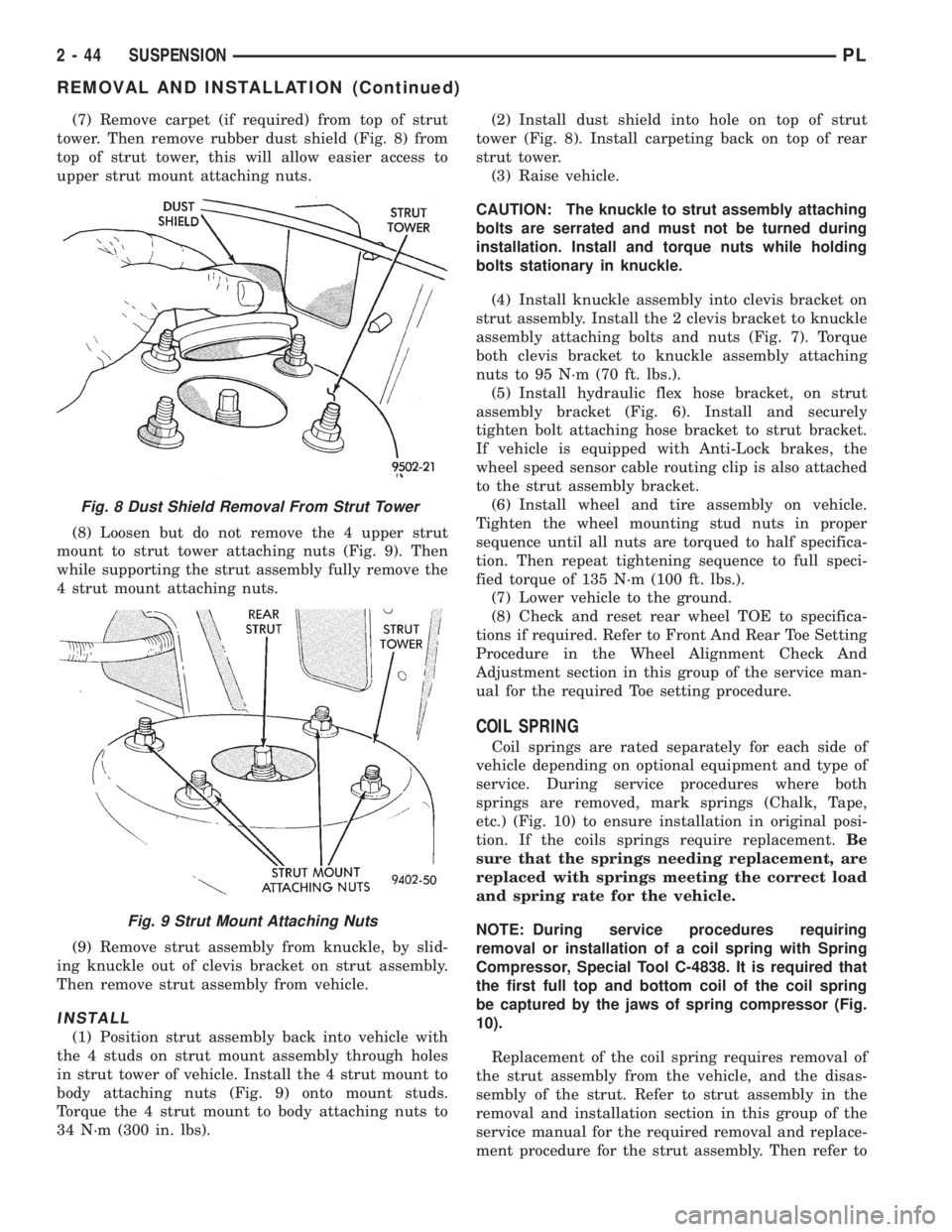

(5) Remove the 2 clevis bracket bolts (Fig. 7)

attaching strut assembly to rear knuckle.

(6) Lower vehicle. Access to rear upper strut

mount to strut tower attaching bolts, is through the

trunk of the vehicle.

Fig. 6 Hydraulic Flex Hose Bracket Attachment To

Strut

Fig. 7 Knuckle To Clevis Bracket Bolts

PLSUSPENSION 2 - 43

DIAGNOSIS AND TESTING (Continued)

Page 55 of 1200

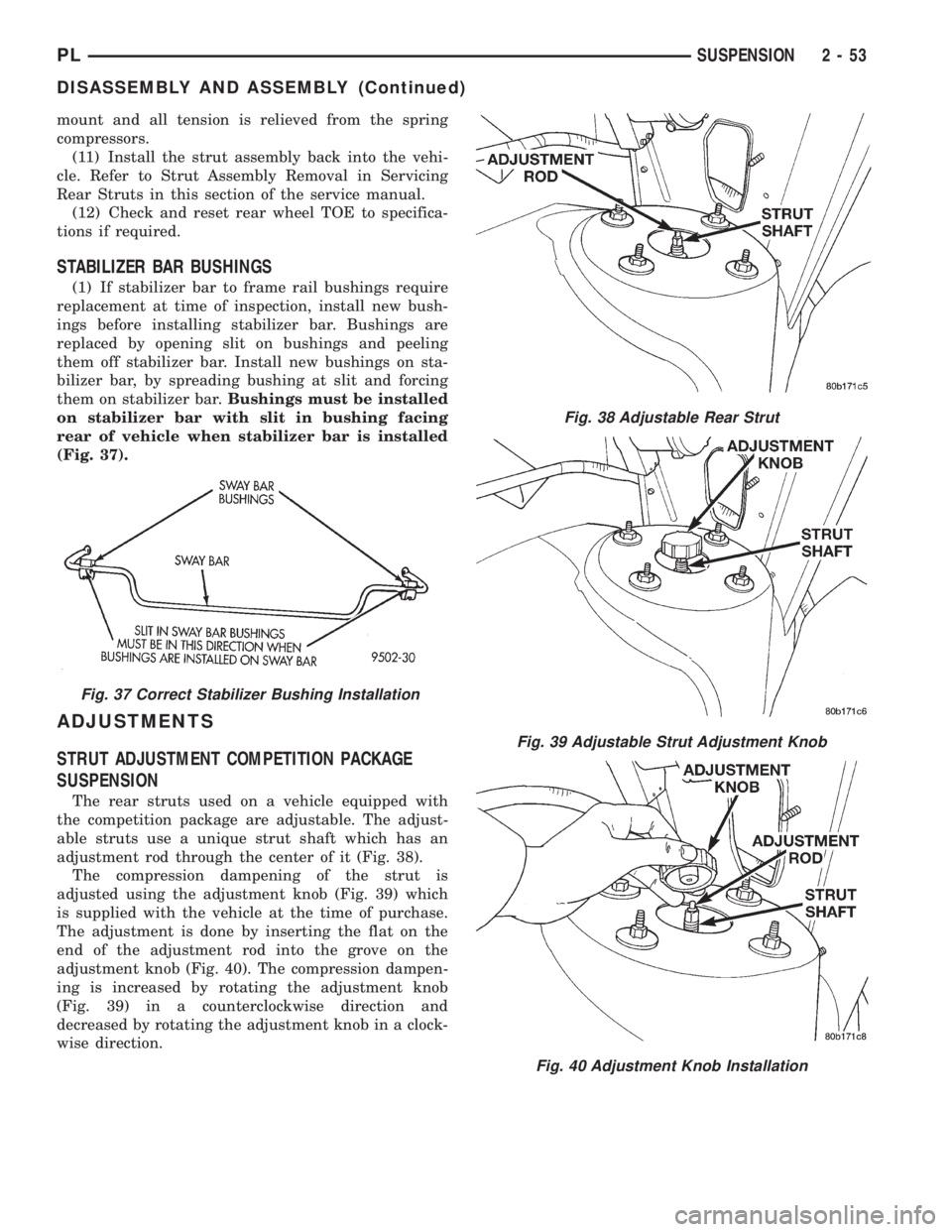

(7) Remove carpet (if required) from top of strut

tower. Then remove rubber dust shield (Fig. 8) from

top of strut tower, this will allow easier access to

upper strut mount attaching nuts.

(8) Loosen but do not remove the 4 upper strut

mount to strut tower attaching nuts (Fig. 9). Then

while supporting the strut assembly fully remove the

4 strut mount attaching nuts.

(9) Remove strut assembly from knuckle, by slid-

ing knuckle out of clevis bracket on strut assembly.

Then remove strut assembly from vehicle.

INSTALL

(1) Position strut assembly back into vehicle with

the 4 studs on strut mount assembly through holes

in strut tower of vehicle. Install the 4 strut mount to

body attaching nuts (Fig. 9) onto mount studs.

Torque the 4 strut mount to body attaching nuts to

34 N´m (300 in. lbs).(2) Install dust shield into hole on top of strut

tower (Fig. 8). Install carpeting back on top of rear

strut tower.

(3) Raise vehicle.

CAUTION: The knuckle to strut assembly attaching

bolts are serrated and must not be turned during

installation. Install and torque nuts while holding

bolts stationary in knuckle.

(4) Install knuckle assembly into clevis bracket on

strut assembly. Install the 2 clevis bracket to knuckle

assembly attaching bolts and nuts (Fig. 7). Torque

both clevis bracket to knuckle assembly attaching

nuts to 95 N´m (70 ft. lbs.).

(5) Install hydraulic flex hose bracket, on strut

assembly bracket (Fig. 6). Install and securely

tighten bolt attaching hose bracket to strut bracket.

If vehicle is equipped with Anti-Lock brakes, the

wheel speed sensor cable routing clip is also attached

to the strut assembly bracket.

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat tightening sequence to full speci-

fied torque of 135 N´m (100 ft. lbs.).

(7) Lower vehicle to the ground.

(8) Check and reset rear wheel TOE to specifica-

tions if required. Refer to Front And Rear Toe Setting

Procedure in the Wheel Alignment Check And

Adjustment section in this group of the service man-

ual for the required Toe setting procedure.

COIL SPRING

Coil springs are rated separately for each side of

vehicle depending on optional equipment and type of

service. During service procedures where both

springs are removed, mark springs (Chalk, Tape,

etc.) (Fig. 10) to ensure installation in original posi-

tion. If the coils springs require replacement.Be

sure that the springs needing replacement, are

replaced with springs meeting the correct load

and spring rate for the vehicle.

NOTE: During service procedures requiring

removal or installation of a coil spring with Spring

Compressor, Special Tool C-4838. It is required that

the first full top and bottom coil of the coil spring

be captured by the jaws of spring compressor (Fig.

10).

Replacement of the coil spring requires removal of

the strut assembly from the vehicle, and the disas-

sembly of the strut. Refer to strut assembly in the

removal and installation section in this group of the

service manual for the required removal and replace-

ment procedure for the strut assembly. Then refer to

Fig. 8 Dust Shield Removal From Strut Tower

Fig. 9 Strut Mount Attaching Nuts

2 - 44 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 64 of 1200

mount and all tension is relieved from the spring

compressors.

(11) Install the strut assembly back into the vehi-

cle. Refer to Strut Assembly Removal in Servicing

Rear Struts in this section of the service manual.

(12) Check and reset rear wheel TOE to specifica-

tions if required.

STABILIZER BAR BUSHINGS

(1) If stabilizer bar to frame rail bushings require

replacement at time of inspection, install new bush-

ings before installing stabilizer bar. Bushings are

replaced by opening slit on bushings and peeling

them off stabilizer bar. Install new bushings on sta-

bilizer bar, by spreading bushing at slit and forcing

them on stabilizer bar.Bushings must be installed

on stabilizer bar with slit in bushing facing

rear of vehicle when stabilizer bar is installed

(Fig. 37).

ADJUSTMENTS

STRUT ADJUSTMENT COMPETITION PACKAGE

SUSPENSION

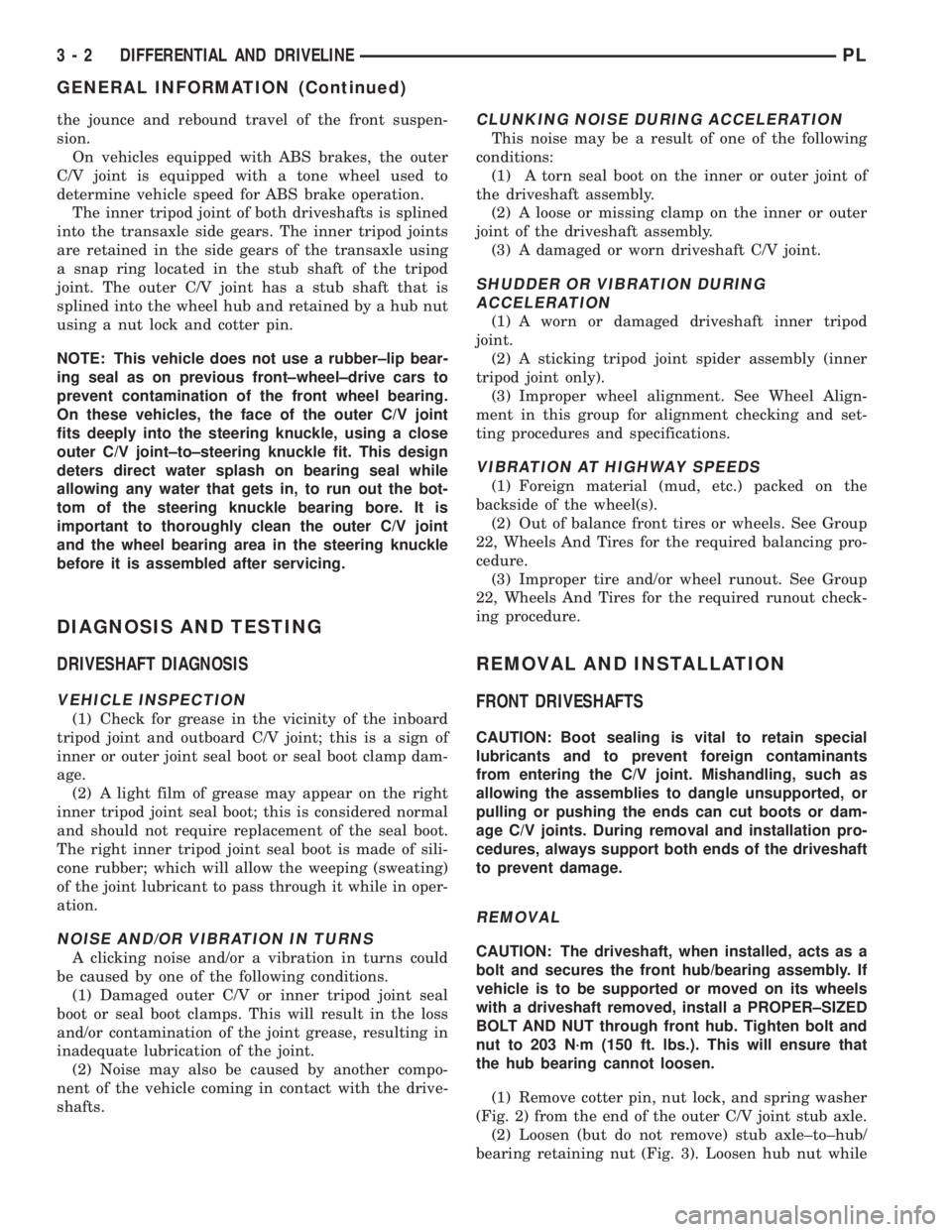

The rear struts used on a vehicle equipped with

the competition package are adjustable. The adjust-

able struts use a unique strut shaft which has an

adjustment rod through the center of it (Fig. 38).

The compression dampening of the strut is

adjusted using the adjustment knob (Fig. 39) which

is supplied with the vehicle at the time of purchase.

The adjustment is done by inserting the flat on the

end of the adjustment rod into the grove on the

adjustment knob (Fig. 40). The compression dampen-

ing is increased by rotating the adjustment knob

(Fig. 39) in a counterclockwise direction and

decreased by rotating the adjustment knob in a clock-

wise direction.

Fig. 37 Correct Stabilizer Bushing Installation

Fig. 38 Adjustable Rear Strut

Fig. 39 Adjustable Strut Adjustment Knob

Fig. 40 Adjustment Knob Installation

PLSUSPENSION 2 - 53

DISASSEMBLY AND ASSEMBLY (Continued)

Page 67 of 1200

the jounce and rebound travel of the front suspen-

sion.

On vehicles equipped with ABS brakes, the outer

C/V joint is equipped with a tone wheel used to

determine vehicle speed for ABS brake operation.

The inner tripod joint of both driveshafts is splined

into the transaxle side gears. The inner tripod joints

are retained in the side gears of the transaxle using

a snap ring located in the stub shaft of the tripod

joint. The outer C/V joint has a stub shaft that is

splined into the wheel hub and retained by a hub nut

using a nut lock and cotter pin.

NOTE: This vehicle does not use a rubber±lip bear-

ing seal as on previous front±wheel±drive cars to

prevent contamination of the front wheel bearing.

On these vehicles, the face of the outer C/V joint

fits deeply into the steering knuckle, using a close

outer C/V joint±to±steering knuckle fit. This design

deters direct water splash on bearing seal while

allowing any water that gets in, to run out the bot-

tom of the steering knuckle bearing bore. It is

important to thoroughly clean the outer C/V joint

and the wheel bearing area in the steering knuckle

before it is assembled after servicing.

DIAGNOSIS AND TESTING

DRIVESHAFT DIAGNOSIS

VEHICLE INSPECTION

(1) Check for grease in the vicinity of the inboard

tripod joint and outboard C/V joint; this is a sign of

inner or outer joint seal boot or seal boot clamp dam-

age.

(2) A light film of grease may appear on the right

inner tripod joint seal boot; this is considered normal

and should not require replacement of the seal boot.

The right inner tripod joint seal boot is made of sili-

cone rubber; which will allow the weeping (sweating)

of the joint lubricant to pass through it while in oper-

ation.

NOISE AND/OR VIBRATION IN TURNS

A clicking noise and/or a vibration in turns could

be caused by one of the following conditions.

(1) Damaged outer C/V or inner tripod joint seal

boot or seal boot clamps. This will result in the loss

and/or contamination of the joint grease, resulting in

inadequate lubrication of the joint.

(2) Noise may also be caused by another compo-

nent of the vehicle coming in contact with the drive-

shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of one of the following

conditions:

(1) A torn seal boot on the inner or outer joint of

the driveshaft assembly.

(2) A loose or missing clamp on the inner or outer

joint of the driveshaft assembly.

(3) A damaged or worn driveshaft C/V joint.

SHUDDER OR VIBRATION DURING

ACCELERATION

(1) A worn or damaged driveshaft inner tripod

joint.

(2) A sticking tripod joint spider assembly (inner

tripod joint only).

(3) Improper wheel alignment. See Wheel Align-

ment in this group for alignment checking and set-

ting procedures and specifications.

VIBRATION AT HIGHWAY SPEEDS

(1) Foreign material (mud, etc.) packed on the

backside of the wheel(s).

(2) Out of balance front tires or wheels. See Group

22, Wheels And Tires for the required balancing pro-

cedure.

(3) Improper tire and/or wheel runout. See Group

22, Wheels And Tires for the required runout check-

ing procedure.

REMOVAL AND INSTALLATION

FRONT DRIVESHAFTS

CAUTION: Boot sealing is vital to retain special

lubricants and to prevent foreign contaminants

from entering the C/V joint. Mishandling, such as

allowing the assemblies to dangle unsupported, or

pulling or pushing the ends can cut boots or dam-

age C/V joints. During removal and installation pro-

cedures, always support both ends of the driveshaft

to prevent damage.

REMOVAL

CAUTION: The driveshaft, when installed, acts as a

bolt and secures the front hub/bearing assembly. If

vehicle is to be supported or moved on its wheels

with a driveshaft removed, install a PROPER±SIZED

BOLT AND NUT through front hub. Tighten bolt and

nut to 203 N´m (150 ft. lbs.). This will ensure that

the hub bearing cannot loosen.

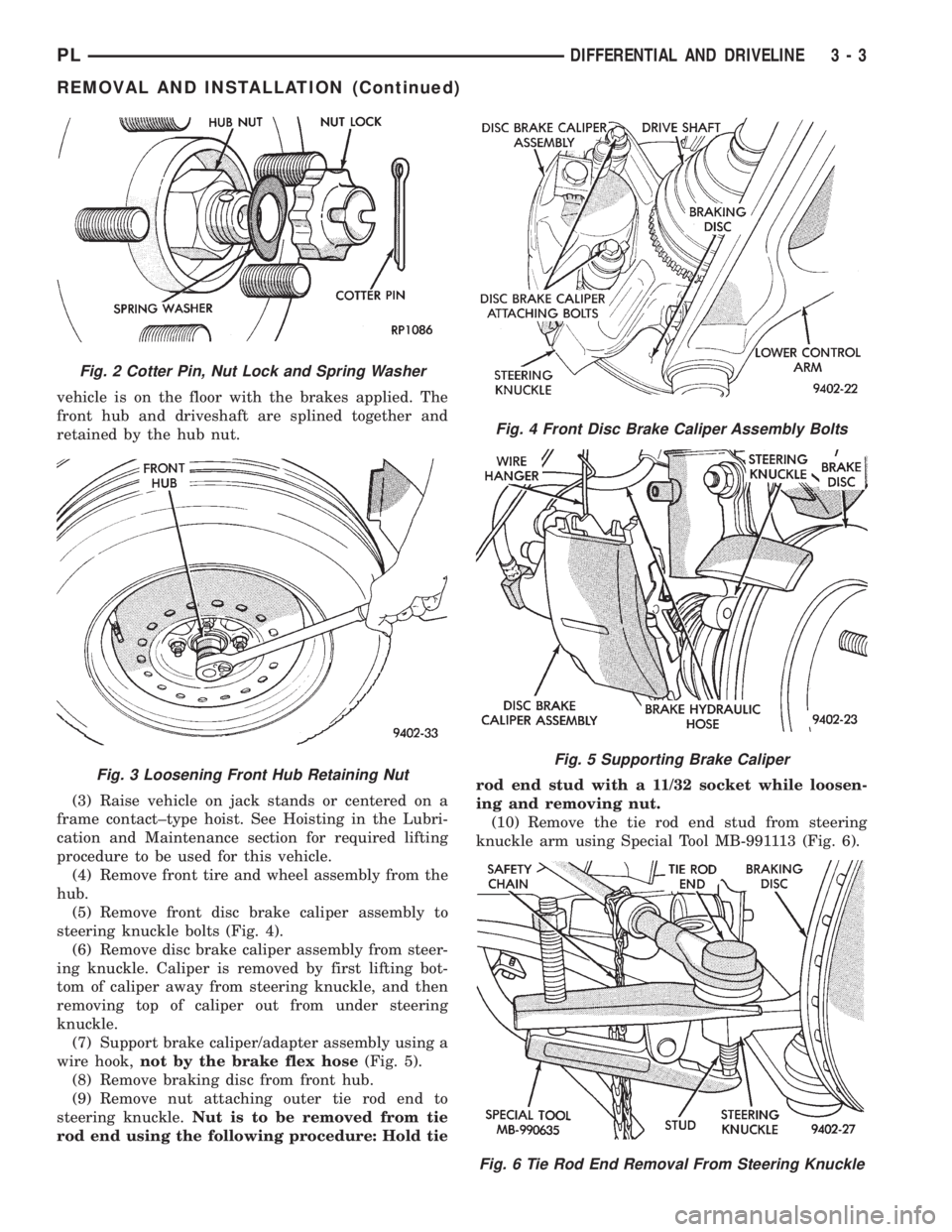

(1) Remove cotter pin, nut lock, and spring washer

(Fig. 2) from the end of the outer C/V joint stub axle.

(2) Loosen (but do not remove) stub axle±to±hub/

bearing retaining nut (Fig. 3). Loosen hub nut while

3 - 2 DIFFERENTIAL AND DRIVELINEPL

GENERAL INFORMATION (Continued)

Page 68 of 1200

vehicle is on the floor with the brakes applied. The

front hub and driveshaft are splined together and

retained by the hub nut.

(3) Raise vehicle on jack stands or centered on a

frame contact±type hoist. See Hoisting in the Lubri-

cation and Maintenance section for required lifting

procedure to be used for this vehicle.

(4) Remove front tire and wheel assembly from the

hub.

(5) Remove front disc brake caliper assembly to

steering knuckle bolts (Fig. 4).

(6) Remove disc brake caliper assembly from steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle.

(7) Support brake caliper/adapter assembly using a

wire hook,not by the brake flex hose(Fig. 5).

(8) Remove braking disc from front hub.

(9) Remove nut attaching outer tie rod end to

steering knuckle.Nut is to be removed from tie

rod end using the following procedure: Hold tierod end stud with a 11/32 socket while loosen-

ing and removing nut.

(10) Remove the tie rod end stud from steering

knuckle arm using Special Tool MB-991113 (Fig. 6).

Fig. 2 Cotter Pin, Nut Lock and Spring Washer

Fig. 3 Loosening Front Hub Retaining Nut

Fig. 4 Front Disc Brake Caliper Assembly Bolts

Fig. 5 Supporting Brake Caliper

Fig. 6 Tie Rod End Removal From Steering Knuckle

PLDIFFERENTIAL AND DRIVELINE 3 - 3

REMOVAL AND INSTALLATION (Continued)

Page 71 of 1200

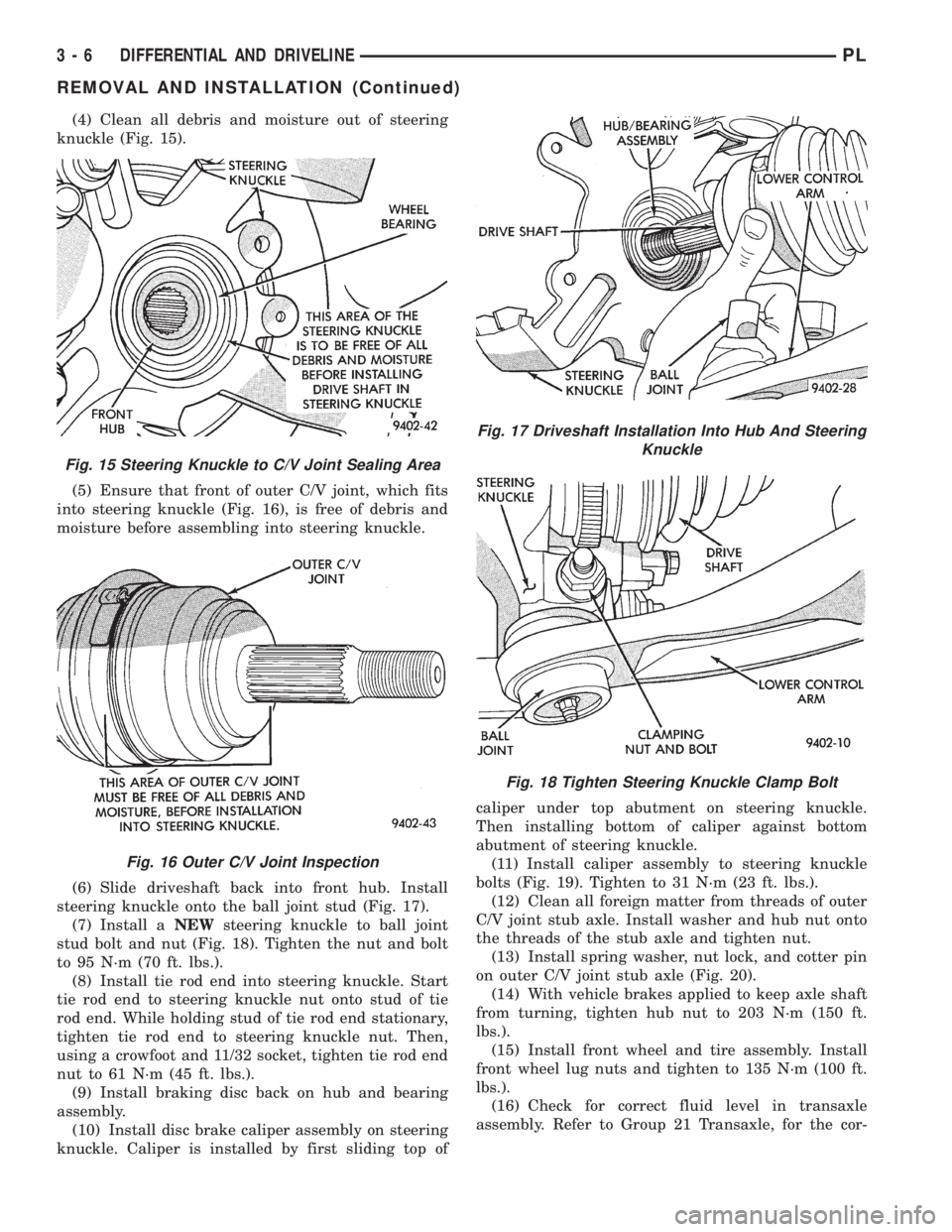

(4) Clean all debris and moisture out of steering

knuckle (Fig. 15).

(5) Ensure that front of outer C/V joint, which fits

into steering knuckle (Fig. 16), is free of debris and

moisture before assembling into steering knuckle.

(6) Slide driveshaft back into front hub. Install

steering knuckle onto the ball joint stud (Fig. 17).

(7) Install aNEWsteering knuckle to ball joint

stud bolt and nut (Fig. 18). Tighten the nut and bolt

to 95 N´m (70 ft. lbs.).

(8) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle nut onto stud of tie

rod end. While holding stud of tie rod end stationary,

tighten tie rod end to steering knuckle nut. Then,

using a crowfoot and 11/32 socket, tighten tie rod end

nut to 61 N´m (45 ft. lbs.).

(9) Install braking disc back on hub and bearing

assembly.

(10) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding top ofcaliper under top abutment on steering knuckle.

Then installing bottom of caliper against bottom

abutment of steering knuckle.

(11) Install caliper assembly to steering knuckle

bolts (Fig. 19). Tighten to 31 N´m (23 ft. lbs.).

(12) Clean all foreign matter from threads of outer

C/V joint stub axle. Install washer and hub nut onto

the threads of the stub axle and tighten nut.

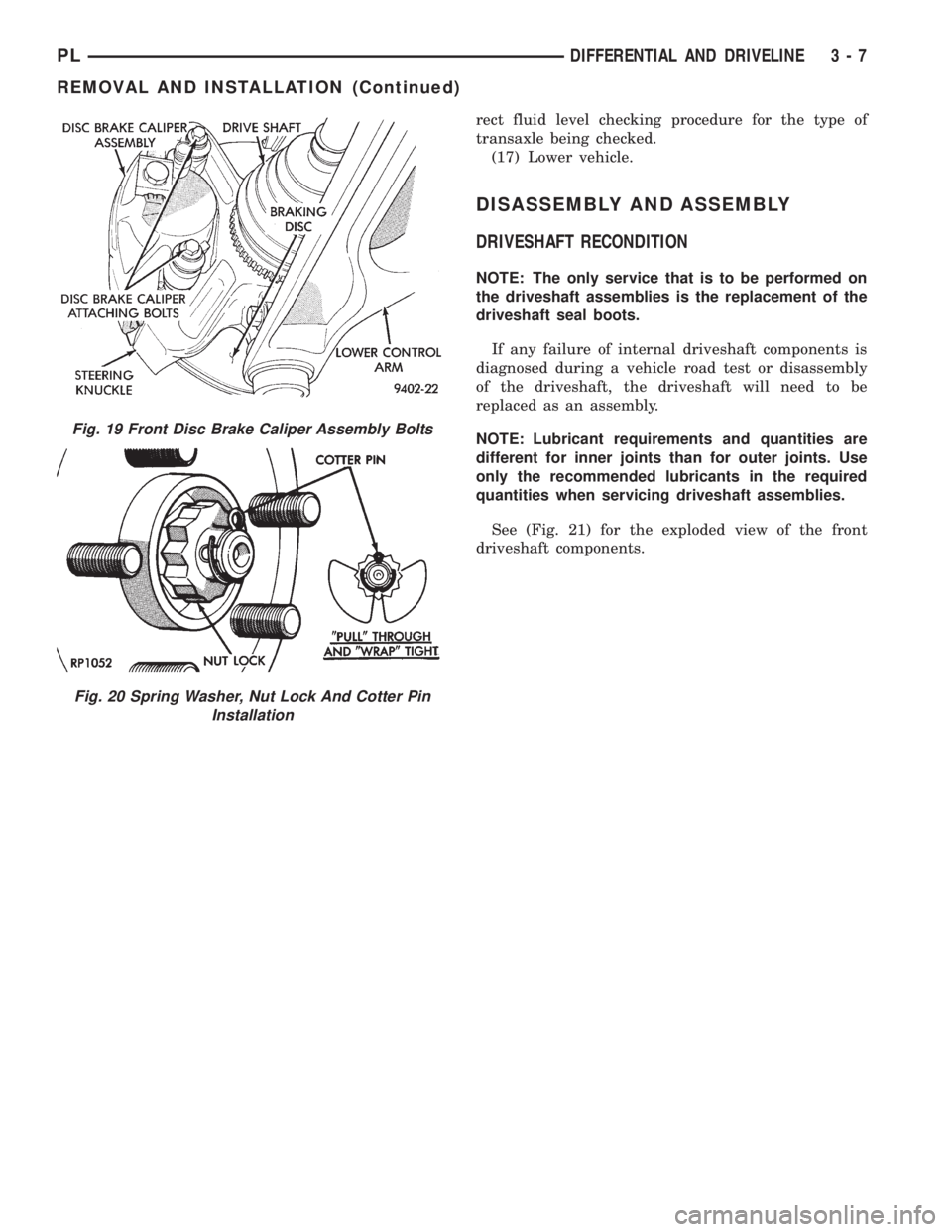

(13) Install spring washer, nut lock, and cotter pin

on outer C/V joint stub axle (Fig. 20).

(14) With vehicle brakes applied to keep axle shaft

from turning, tighten hub nut to 203 N´m (150 ft.

lbs.).

(15) Install front wheel and tire assembly. Install

front wheel lug nuts and tighten to 135 N´m (100 ft.

lbs.).

(16) Check for correct fluid level in transaxle

assembly. Refer to Group 21 Transaxle, for the cor-

Fig. 15 Steering Knuckle to C/V Joint Sealing Area

Fig. 16 Outer C/V Joint Inspection

Fig. 17 Driveshaft Installation Into Hub And Steering

Knuckle

Fig. 18 Tighten Steering Knuckle Clamp Bolt

3 - 6 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 72 of 1200

rect fluid level checking procedure for the type of

transaxle being checked.

(17) Lower vehicle.

DISASSEMBLY AND ASSEMBLY

DRIVESHAFT RECONDITION

NOTE: The only service that is to be performed on

the driveshaft assemblies is the replacement of the

driveshaft seal boots.

If any failure of internal driveshaft components is

diagnosed during a vehicle road test or disassembly

of the driveshaft, the driveshaft will need to be

replaced as an assembly.

NOTE: Lubricant requirements and quantities are

different for inner joints than for outer joints. Use

only the recommended lubricants in the required

quantities when servicing driveshaft assemblies.

See (Fig. 21) for the exploded view of the front

driveshaft components.

Fig. 19 Front Disc Brake Caliper Assembly Bolts

Fig. 20 Spring Washer, Nut Lock And Cotter Pin

Installation

PLDIFFERENTIAL AND DRIVELINE 3 - 7

REMOVAL AND INSTALLATION (Continued)

Page 77 of 1200

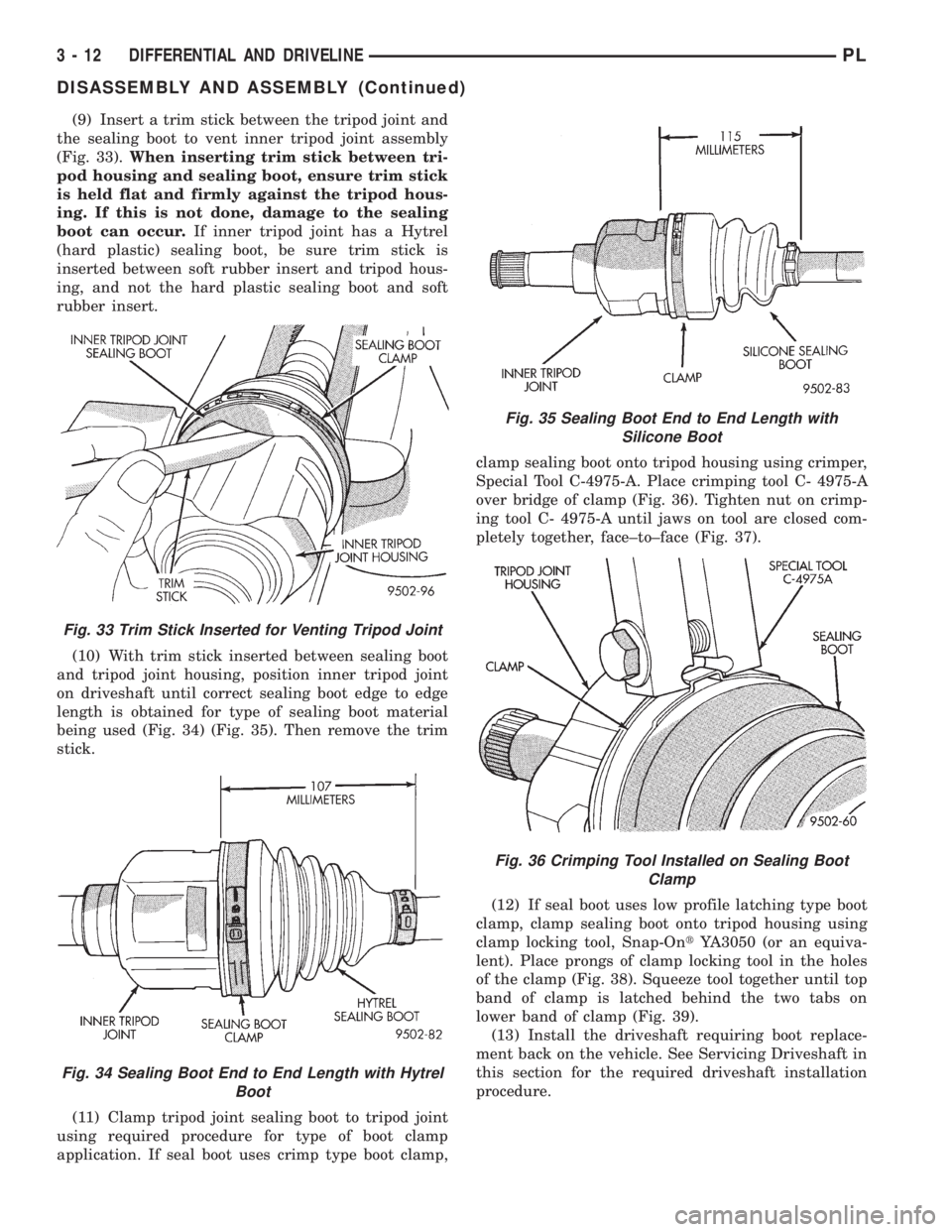

(9) Insert a trim stick between the tripod joint and

the sealing boot to vent inner tripod joint assembly

(Fig. 33).When inserting trim stick between tri-

pod housing and sealing boot, ensure trim stick

is held flat and firmly against the tripod hous-

ing. If this is not done, damage to the sealing

boot can occur.If inner tripod joint has a Hytrel

(hard plastic) sealing boot, be sure trim stick is

inserted between soft rubber insert and tripod hous-

ing, and not the hard plastic sealing boot and soft

rubber insert.

(10) With trim stick inserted between sealing boot

and tripod joint housing, position inner tripod joint

on driveshaft until correct sealing boot edge to edge

length is obtained for type of sealing boot material

being used (Fig. 34) (Fig. 35). Then remove the trim

stick.

(11) Clamp tripod joint sealing boot to tripod joint

using required procedure for type of boot clamp

application. If seal boot uses crimp type boot clamp,clamp sealing boot onto tripod housing using crimper,

Special Tool C-4975-A. Place crimping tool C- 4975-A

over bridge of clamp (Fig. 36). Tighten nut on crimp-

ing tool C- 4975-A until jaws on tool are closed com-

pletely together, face±to±face (Fig. 37).

(12) If seal boot uses low profile latching type boot

clamp, clamp sealing boot onto tripod housing using

clamp locking tool, Snap-OntYA3050 (or an equiva-

lent). Place prongs of clamp locking tool in the holes

of the clamp (Fig. 38). Squeeze tool together until top

band of clamp is latched behind the two tabs on

lower band of clamp (Fig. 39).

(13) Install the driveshaft requiring boot replace-

ment back on the vehicle. See Servicing Driveshaft in

this section for the required driveshaft installation

procedure.

Fig. 33 Trim Stick Inserted for Venting Tripod Joint

Fig. 34 Sealing Boot End to End Length with Hytrel

Boot

Fig. 35 Sealing Boot End to End Length with

Silicone Boot

Fig. 36 Crimping Tool Installed on Sealing Boot

Clamp

3 - 12 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 82 of 1200

BRAKES

CONTENTS

page page

ANTILOCK BRAKE SYSTEM±TEVES MARK 20 . 69

BASE BRAKE SYSTEM..................... 2GENERAL INFORMATION................... 1

GENERAL INFORMATION

INDEX

page

GENERAL INFORMATION

BASE BRAKE SYSTEM DESCRIPTION........ 1

GENERAL INFORMATION

BASE BRAKE SYSTEM DESCRIPTION

Typical brake equipment consists of:

²Double pin floating caliper disc front brakes.

²Rear automatic adjusting drum brakes.

²Brake Fluid Level Switch.

²Master cylinder.

²Vacuum power booster.

²Double pin floating caliper rear disc brakes are

available on some models.

²Hand operated auto adjust park brake lever.

²Front disc brake pads are semi-metallic.

Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20 and

is supplied by Teves. This system shares the base

brake hardware with vehicles not equipped withABS. A vehicle equipped with ABS does however use

a different vacuum booster, master cylinder and

brake tubes. Also included in the ABS system is an

integrated control unit (ICU), four wheel speed sen-

sors, and an electronic controller referred to as the

controller antilock brakes (CAB). These components

will be described in detail in the Teves Mark 20 ABS

brake section in this group of the service manual.

The hydraulic brake system is diagonally split on

both the Non-ABS and ABS braking system. With the

left front and right rear brakes on one hydraulic sys-

tem and the right front and left rear on the other.

The master cylinder is anodized, lightweight alu-

minum. On vehicles equipped with front disc brakes

and rear drum brakes, the master cylinder bore is

21.0 mm. On vehicles equipped with four wheel disc

brakes, the master cylinder bore is 22.2 mm.

PLBRAKES 5 - 1

Page 86 of 1200

operating cable configuration as the drum brake

equipped vehicles, but different cables.

PROPORTIONING VALVES

NON-ANTILOCK BRAKES

Proportioning valves balance front to rear braking

by controlling at a given ratio, the increase in rear

brake system hydraulic pressure above a preset level

(split point). Under light pedal application, the pro-portioning valve allows full hydraulic pressure to be

applied to the rear brakes.

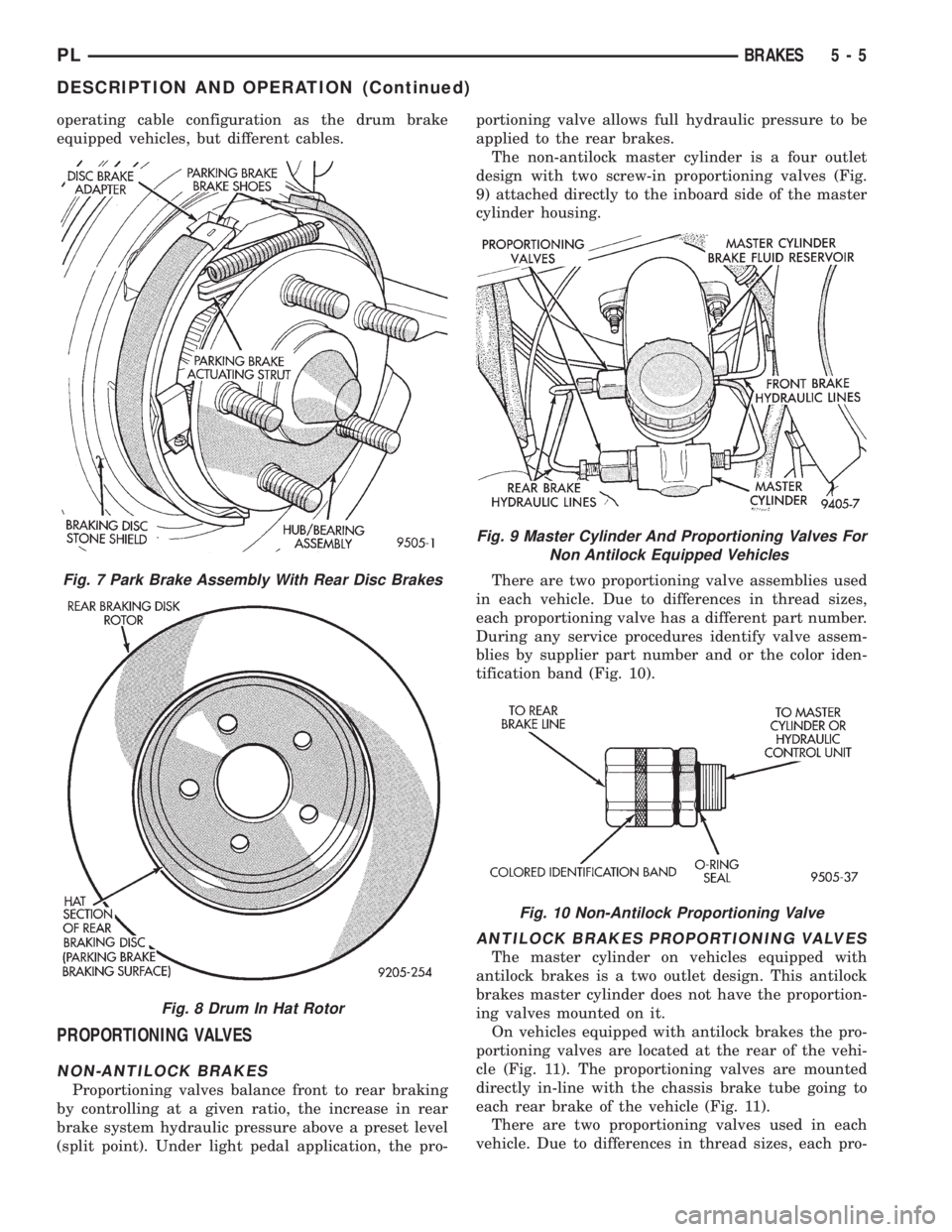

The non-antilock master cylinder is a four outlet

design with two screw-in proportioning valves (Fig.

9) attached directly to the inboard side of the master

cylinder housing.

There are two proportioning valve assemblies used

in each vehicle. Due to differences in thread sizes,

each proportioning valve has a different part number.

During any service procedures identify valve assem-

blies by supplier part number and or the color iden-

tification band (Fig. 10).

ANTILOCK BRAKES PROPORTIONING VALVES

The master cylinder on vehicles equipped with

antilock brakes is a two outlet design. This antilock

brakes master cylinder does not have the proportion-

ing valves mounted on it.

On vehicles equipped with antilock brakes the pro-

portioning valves are located at the rear of the vehi-

cle (Fig. 11). The proportioning valves are mounted

directly in-line with the chassis brake tube going to

each rear brake of the vehicle (Fig. 11).

There are two proportioning valves used in each

vehicle. Due to differences in thread sizes, each pro-

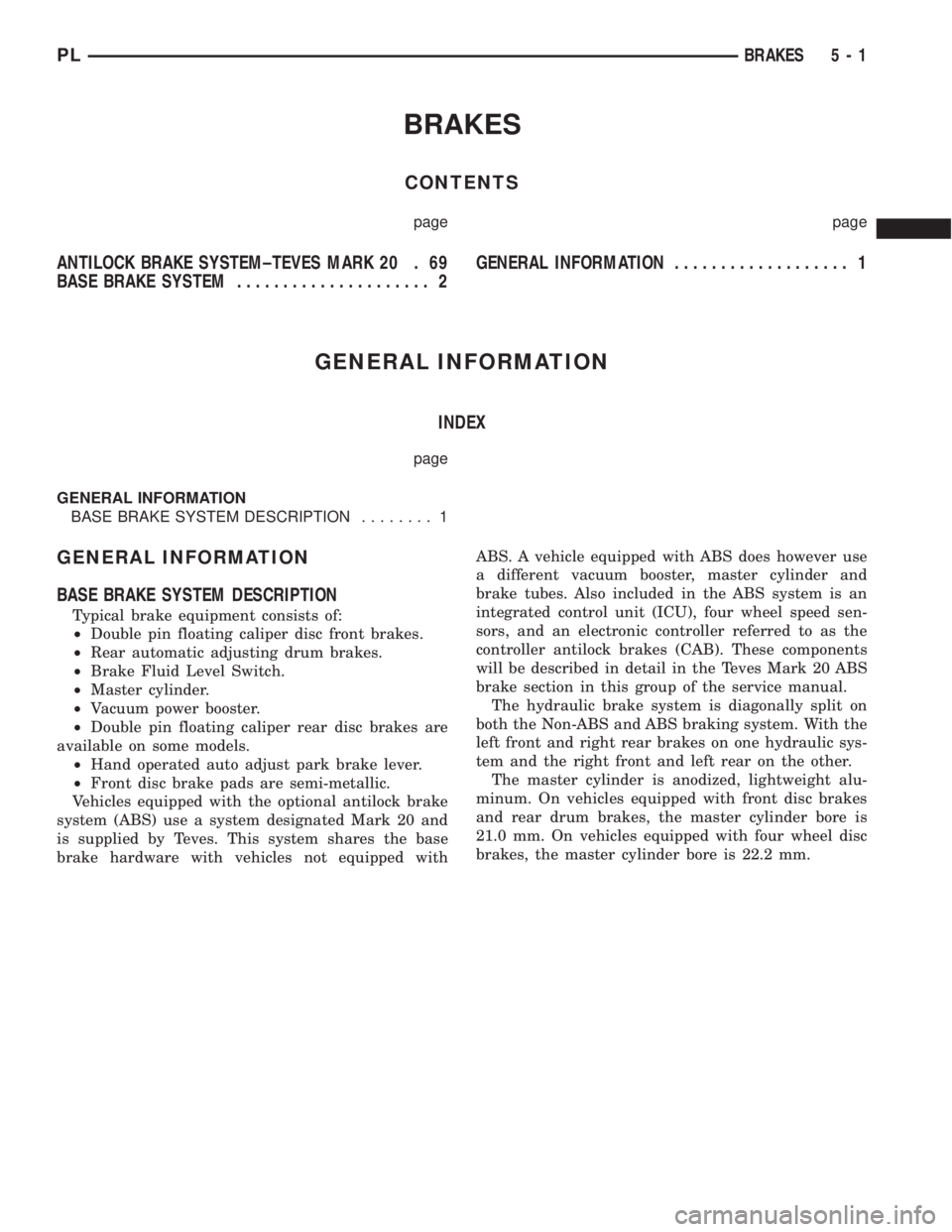

Fig. 7 Park Brake Assembly With Rear Disc Brakes

Fig. 8 Drum In Hat Rotor

Fig. 9 Master Cylinder And Proportioning Valves For

Non Antilock Equipped Vehicles

Fig. 10 Non-Antilock Proportioning Valve

PLBRAKES 5 - 5

DESCRIPTION AND OPERATION (Continued)