clock DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 201 of 1285

(10) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

INSTALLATION

(1) Slide radiator down into position behind radia-

tor support (yoke).

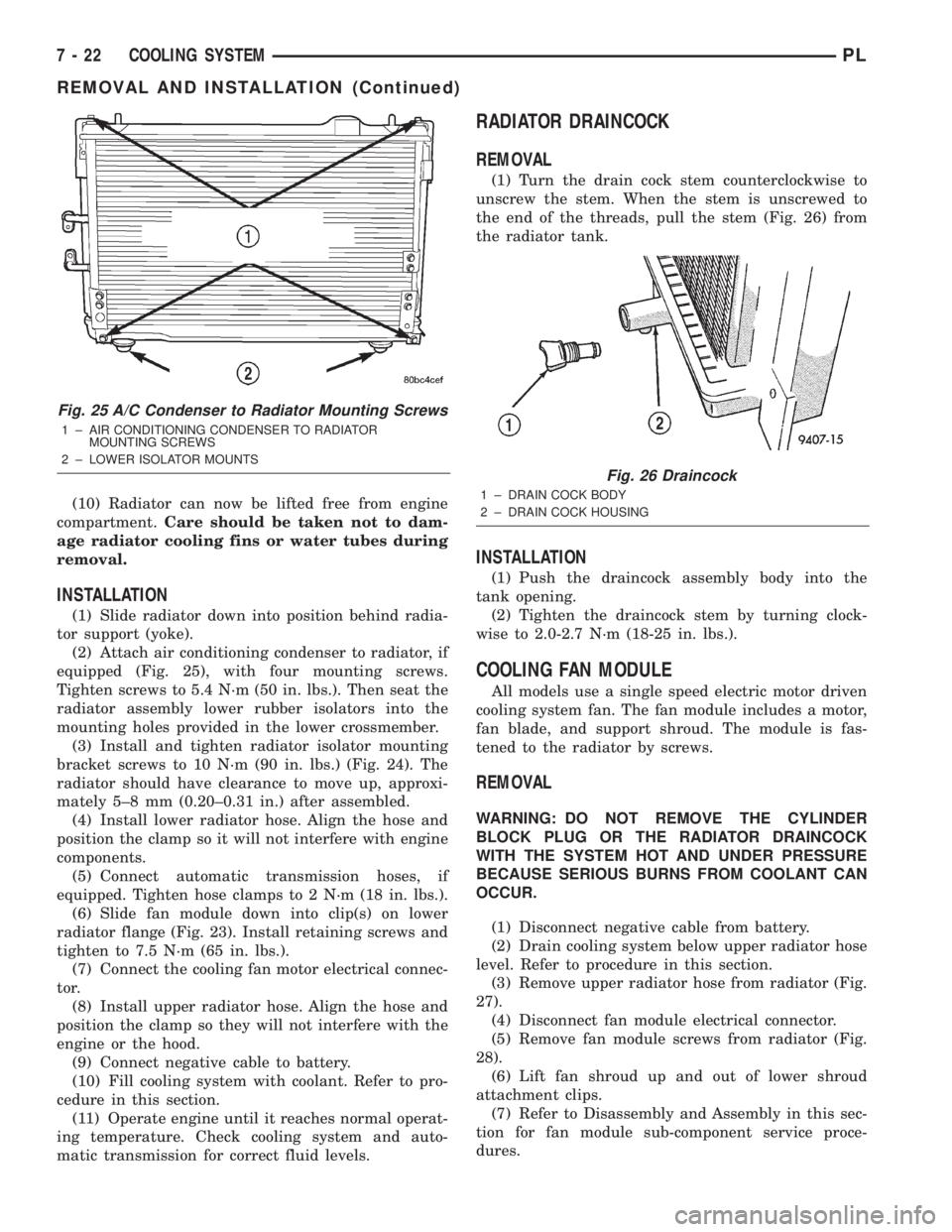

(2) Attach air conditioning condenser to radiator, if

equipped (Fig. 25), with four mounting screws.

Tighten screws to 5.4 N´m (50 in. lbs.). Then seat the

radiator assembly lower rubber isolators into the

mounting holes provided in the lower crossmember.

(3) Install and tighten radiator isolator mounting

bracket screws to 10 N´m (90 in. lbs.) (Fig. 24). The

radiator should have clearance to move up, approxi-

mately 5±8 mm (0.20±0.31 in.) after assembled.

(4) Install lower radiator hose. Align the hose and

position the clamp so it will not interfere with engine

components.

(5) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 2 N´m (18 in. lbs.).

(6) Slide fan module down into clip(s) on lower

radiator flange (Fig. 23). Install retaining screws and

tighten to 7.5 N´m (65 in. lbs.).

(7) Connect the cooling fan motor electrical connec-

tor.

(8) Install upper radiator hose. Align the hose and

position the clamp so they will not interfere with the

engine or the hood.

(9) Connect negative cable to battery.

(10) Fill cooling system with coolant. Refer to pro-

cedure in this section.

(11) Operate engine until it reaches normal operat-

ing temperature. Check cooling system and auto-

matic transmission for correct fluid levels.

RADIATOR DRAINCOCK

REMOVAL

(1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 26) from

the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening.

(2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N´m (18-25 in. lbs.).

COOLING FAN MODULE

All models use a single speed electric motor driven

cooling system fan. The fan module includes a motor,

fan blade, and support shroud. The module is fas-

tened to the radiator by screws.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain cooling system below upper radiator hose

level. Refer to procedure in this section.

(3) Remove upper radiator hose from radiator (Fig.

27).

(4) Disconnect fan module electrical connector.

(5) Remove fan module screws from radiator (Fig.

28).

(6) Lift fan shroud up and out of lower shroud

attachment clips.

(7) Refer to Disassembly and Assembly in this sec-

tion for fan module sub-component service proce-

dures.

Fig. 25 A/C Condenser to Radiator Mounting Screws

1 ± AIR CONDITIONING CONDENSER TO RADIATOR

MOUNTING SCREWS

2 ± LOWER ISOLATOR MOUNTS

Fig. 26 Draincock

1 ± DRAIN COCK BODY

2 ± DRAIN COCK HOUSING

7 - 22 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 203 of 1285

(2) Connect recovery hose to water outlet connec-

tor/thermostat housing (Fig. 29).

(3) Fill container to proper level. Refer to Cooling

System Refilling in this section.

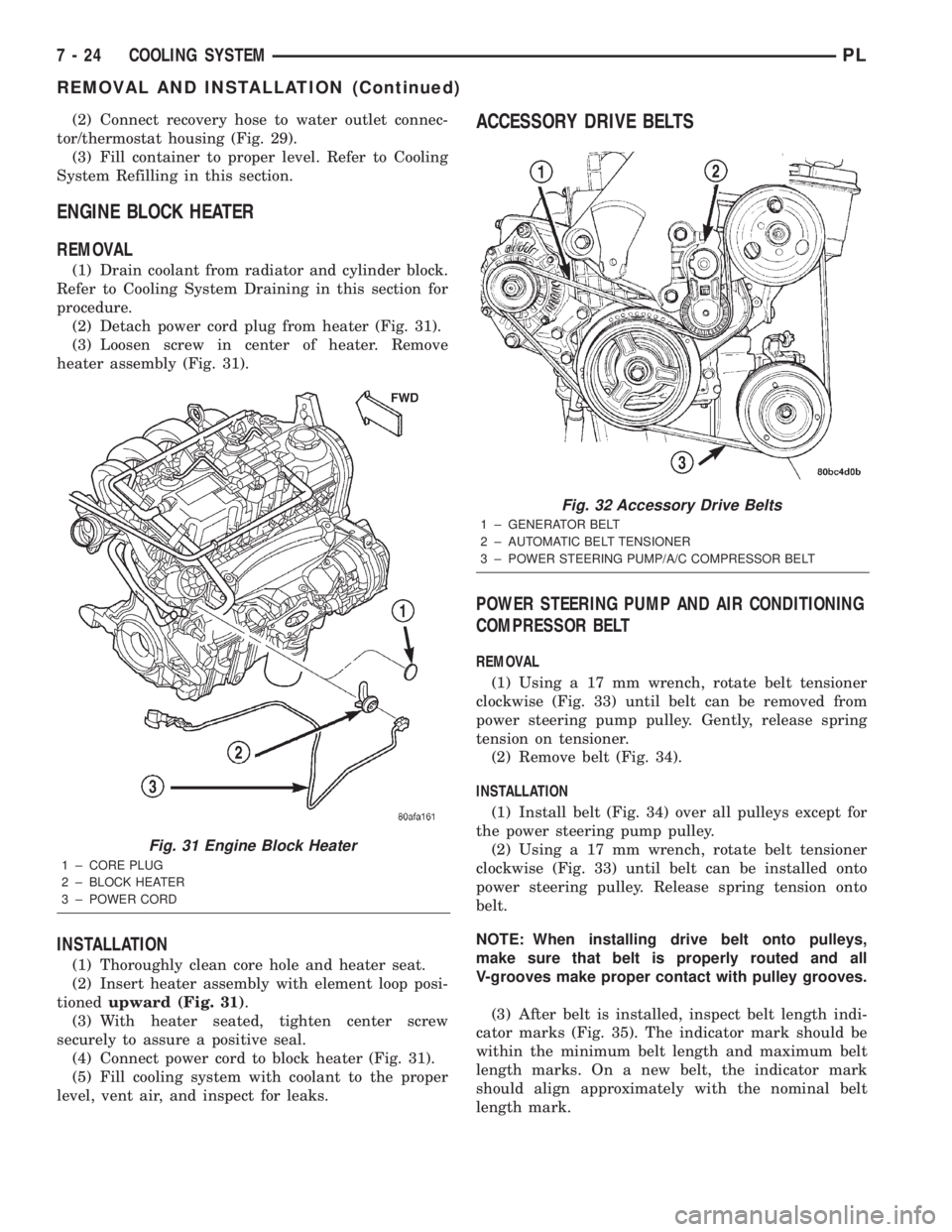

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Draining in this section for

procedure.

(2) Detach power cord plug from heater (Fig. 31).

(3) Loosen screw in center of heater. Remove

heater assembly (Fig. 31).

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward (Fig. 31).

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Connect power cord to block heater (Fig. 31).

(5) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks.

ACCESSORY DRIVE BELTS

POWER STEERING PUMP AND AIR CONDITIONING

COMPRESSOR BELT

REMOVAL

(1) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be removed from

power steering pump pulley. Gently, release spring

tension on tensioner.

(2) Remove belt (Fig. 34).

INSTALLATION

(1) Install belt (Fig. 34) over all pulleys except for

the power steering pump pulley.

(2) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be installed onto

power steering pulley. Release spring tension onto

belt.

NOTE: When installing drive belt onto pulleys,

make sure that belt is properly routed and all

V-grooves make proper contact with pulley grooves.

(3) After belt is installed, inspect belt length indi-

cator marks (Fig. 35). The indicator mark should be

within the minimum belt length and maximum belt

length marks. On a new belt, the indicator mark

should align approximately with the nominal belt

length mark.

Fig. 31 Engine Block Heater

1 ± CORE PLUG

2 ± BLOCK HEATER

3 ± POWER CORD

Fig. 32 Accessory Drive Belts

1 ± GENERATOR BELT

2 ± AUTOMATIC BELT TENSIONER

3 ± POWER STEERING PUMP/A/C COMPRESSOR BELT

7 - 24 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 253 of 1285

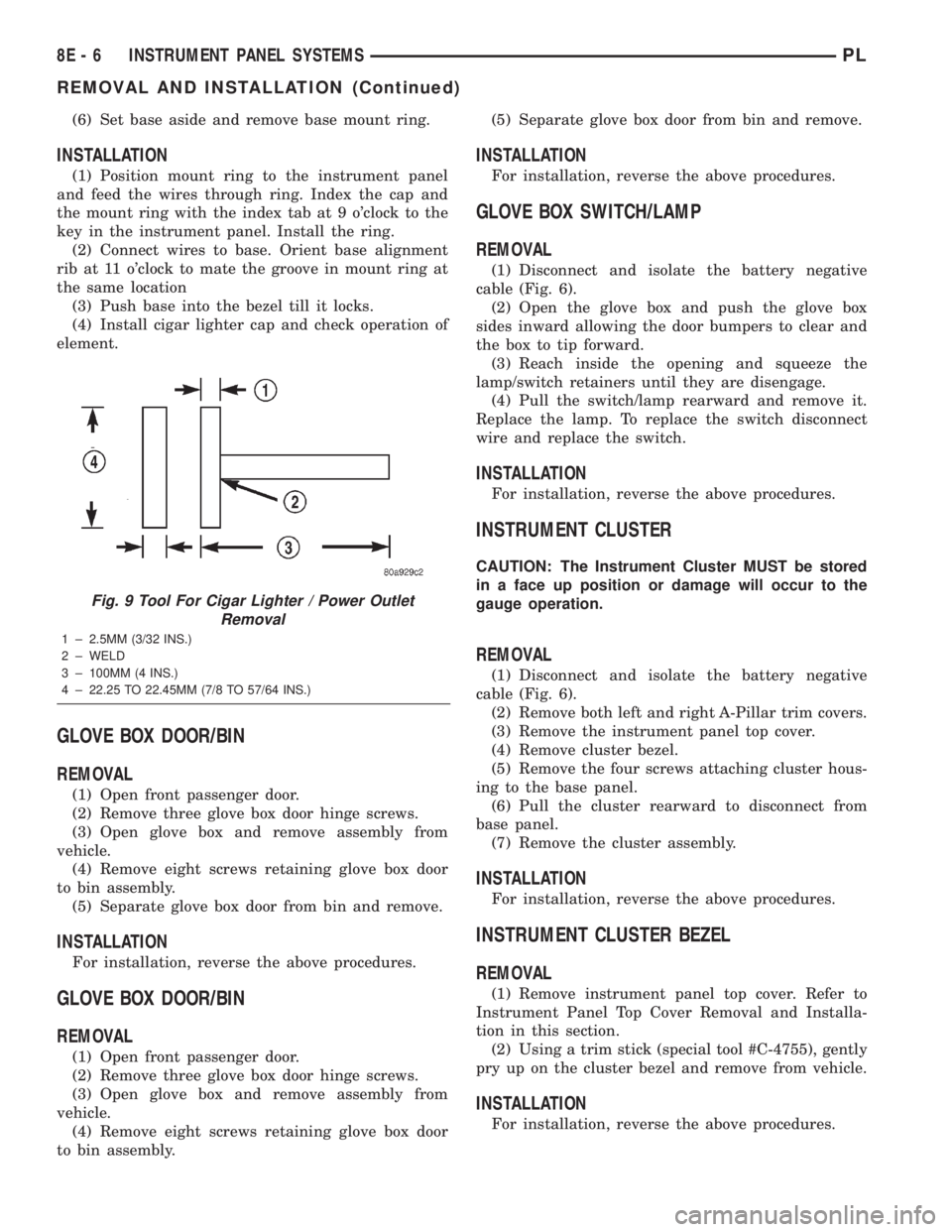

(6) Set base aside and remove base mount ring.

INSTALLATION

(1) Position mount ring to the instrument panel

and feed the wires through ring. Index the cap and

the mount ring with the index tab at 9 o'clock to the

key in the instrument panel. Install the ring.

(2) Connect wires to base. Orient base alignment

rib at 11 o'clock to mate the groove in mount ring at

the same location

(3) Push base into the bezel till it locks.

(4) Install cigar lighter cap and check operation of

element.

GLOVE BOX DOOR/BIN

REMOVAL

(1) Open front passenger door.

(2) Remove three glove box door hinge screws.

(3) Open glove box and remove assembly from

vehicle.

(4) Remove eight screws retaining glove box door

to bin assembly.

(5) Separate glove box door from bin and remove.

INSTALLATION

For installation, reverse the above procedures.

GLOVE BOX DOOR/BIN

REMOVAL

(1) Open front passenger door.

(2) Remove three glove box door hinge screws.

(3) Open glove box and remove assembly from

vehicle.

(4) Remove eight screws retaining glove box door

to bin assembly.(5) Separate glove box door from bin and remove.

INSTALLATION

For installation, reverse the above procedures.

GLOVE BOX SWITCH/LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 6).

(2) Open the glove box and push the glove box

sides inward allowing the door bumpers to clear and

the box to tip forward.

(3) Reach inside the opening and squeeze the

lamp/switch retainers until they are disengage.

(4) Pull the switch/lamp rearward and remove it.

Replace the lamp. To replace the switch disconnect

wire and replace the switch.

INSTALLATION

For installation, reverse the above procedures.

INSTRUMENT CLUSTER

CAUTION: The Instrument Cluster MUST be stored

in a face up position or damage will occur to the

gauge operation.

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 6).

(2) Remove both left and right A-Pillar trim covers.

(3) Remove the instrument panel top cover.

(4) Remove cluster bezel.

(5) Remove the four screws attaching cluster hous-

ing to the base panel.

(6) Pull the cluster rearward to disconnect from

base panel.

(7) Remove the cluster assembly.

INSTALLATION

For installation, reverse the above procedures.

INSTRUMENT CLUSTER BEZEL

REMOVAL

(1) Remove instrument panel top cover. Refer to

Instrument Panel Top Cover Removal and Installa-

tion in this section.

(2) Using a trim stick (special tool #C-4755), gently

pry up on the cluster bezel and remove from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Fig. 9 Tool For Cigar Lighter / Power Outlet

Removal

1 ± 2.5MM (3/32 INS.)

2 ± WELD

3 ± 100MM (4 INS.)

4 ± 22.25 TO 22.45MM (7/8 TO 57/64 INS.)

8E - 6 INSTRUMENT PANEL SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 254 of 1285

INSTRUMENT CLUSTER LAMPS

WARNINGS/INDICATORS

The instrument cluster warning/indicator lamps

are all serviceable Light Emitting Diodes (LED's).

The instrument cluster must first be removed, refer

to Instrument Cluster Removal and Installation in

this section, and then the defective LED just turns

out with needle nose pliers.

ILLUMINATION LAMPS

The high beam indicator, turn signals, and illumi-

nation bulbs are also serviceable. The instrument

cluster must first be removed, refer to Instrument

Cluster Removal and Installation in this section, and

then the defective bulb and socket turns out. The

bulb locations are printed on the back cover of the

instrument cluster.

INSTRUMENT PANEL ASSEMBLY

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 6).

(2) Push seats back to their full back position.

(3) Using a trim stick (special tool #C-4755), gently

pry out on left and right A-pillar trim moldings and

remove.

(4) Remove top cover. Refer to Top Cover Removal

and Installation in this section.

(5) Gently pull up on cluster bezel and remove

from vehicle.

(6) Gently pull rearward on left lower instrument

panel cover and remove from vehicle.

CAUTION: Lock the steering wheel in the straight

ahead position. This will prevent clockspring dam-

age when the steering wheel rotates freely.

(7) Remove steering column. Refer to Group 19

Steering, Steering Column Removal and Installation.

(8) Remove left and right instrument panel end-

caps.

(9) Remove left and right cowl side panels.

(10) Remove center console. Refer to Group 23

Body, Center Console Removal and Installation.

(11) Depress the sides of the Data Link Connector

(DLC) and remove from instrument panel reinforce-

ment.

(12) Remove four bulkhead instrument panel

retaining screws.

(13) Remove two bolts on top of the brake pedal

support bracket.

(14) Remove two center support mounting bolts.

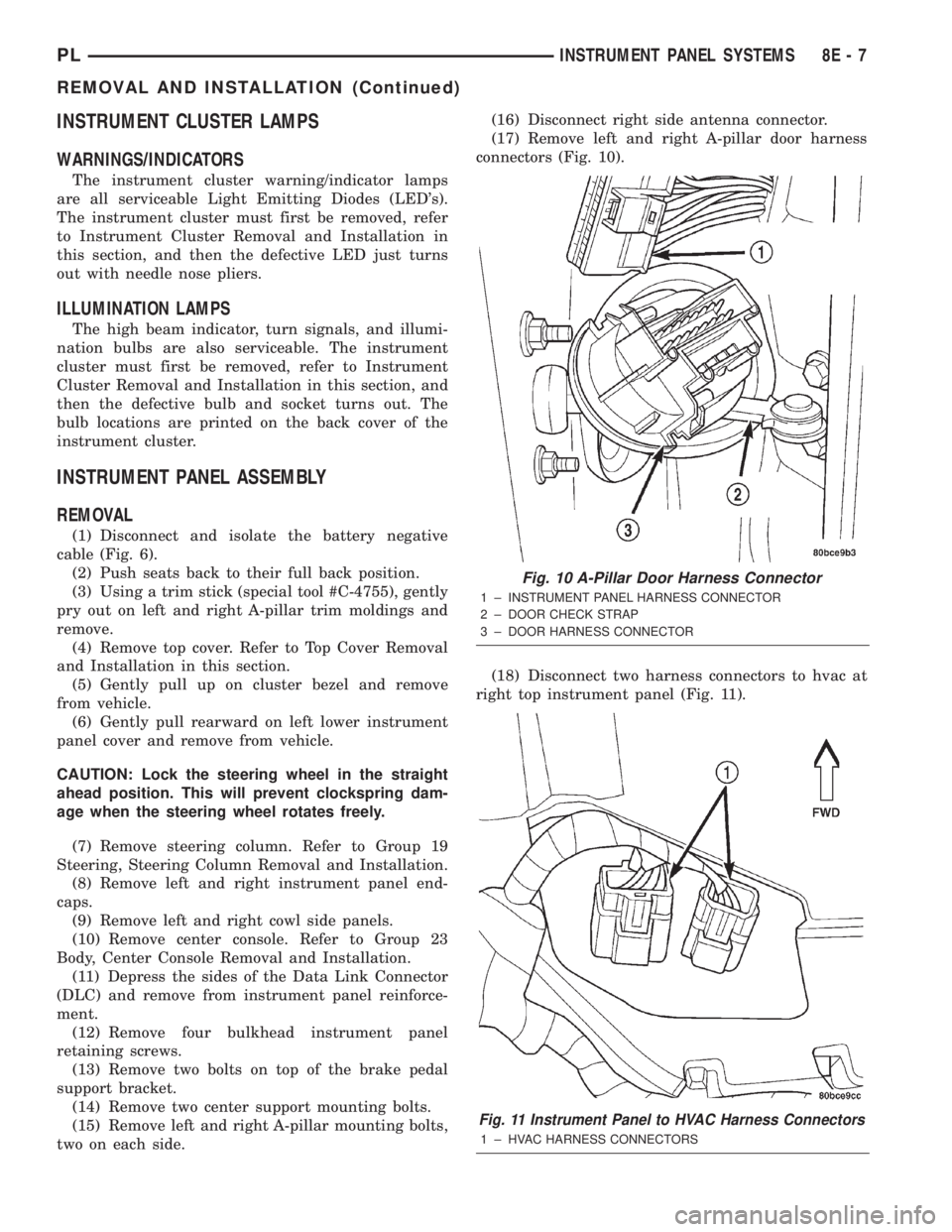

(15) Remove left and right A-pillar mounting bolts,

two on each side.(16) Disconnect right side antenna connector.

(17) Remove left and right A-pillar door harness

connectors (Fig. 10).

(18) Disconnect two harness connectors to hvac at

right top instrument panel (Fig. 11).

Fig. 10 A-Pillar Door Harness Connector

1 ± INSTRUMENT PANEL HARNESS CONNECTOR

2 ± DOOR CHECK STRAP

3 ± DOOR HARNESS CONNECTOR

Fig. 11 Instrument Panel to HVAC Harness Connectors

1 ± HVAC HARNESS CONNECTORS

PLINSTRUMENT PANEL SYSTEMS 8E - 7

REMOVAL AND INSTALLATION (Continued)

Page 262 of 1285

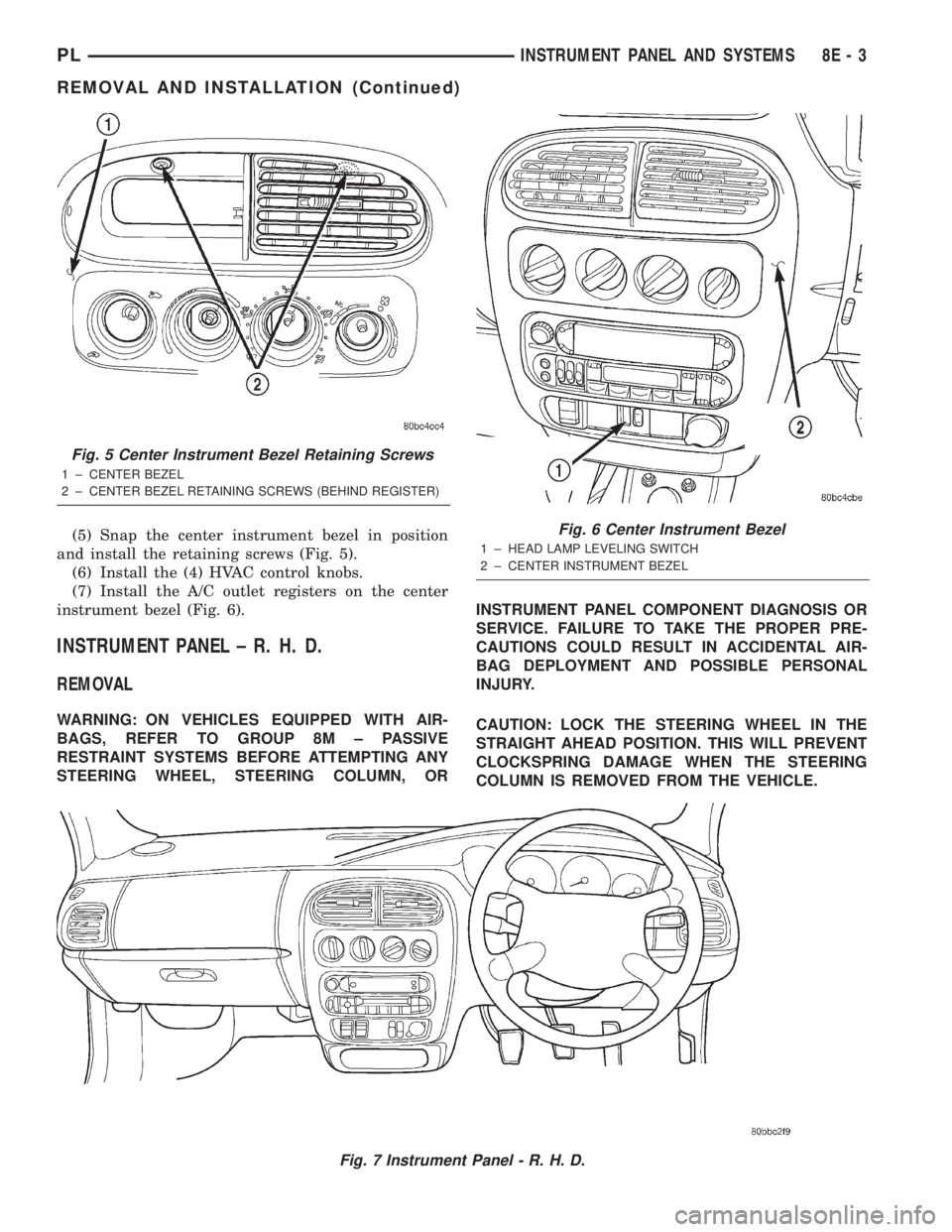

(5) Snap the center instrument bezel in position

and install the retaining screws (Fig. 5).

(6) Install the (4) HVAC control knobs.

(7) Install the A/C outlet registers on the center

instrument bezel (Fig. 6).

INSTRUMENT PANEL ± R. H. D.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M ± PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, ORINSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: LOCK THE STEERING WHEEL IN THE

STRAIGHT AHEAD POSITION. THIS WILL PREVENT

CLOCKSPRING DAMAGE WHEN THE STEERING

COLUMN IS REMOVED FROM THE VEHICLE.

Fig. 7 Instrument Panel - R. H. D.

Fig. 5 Center Instrument Bezel Retaining Screws

1 ± CENTER BEZEL

2 ± CENTER BEZEL RETAINING SCREWS (BEHIND REGISTER)

Fig. 6 Center Instrument Bezel

1 ± HEAD LAMP LEVELING SWITCH

2 ± CENTER INSTRUMENT BEZEL

PLINSTRUMENT PANEL AND SYSTEMS 8E - 3

REMOVAL AND INSTALLATION (Continued)

Page 263 of 1285

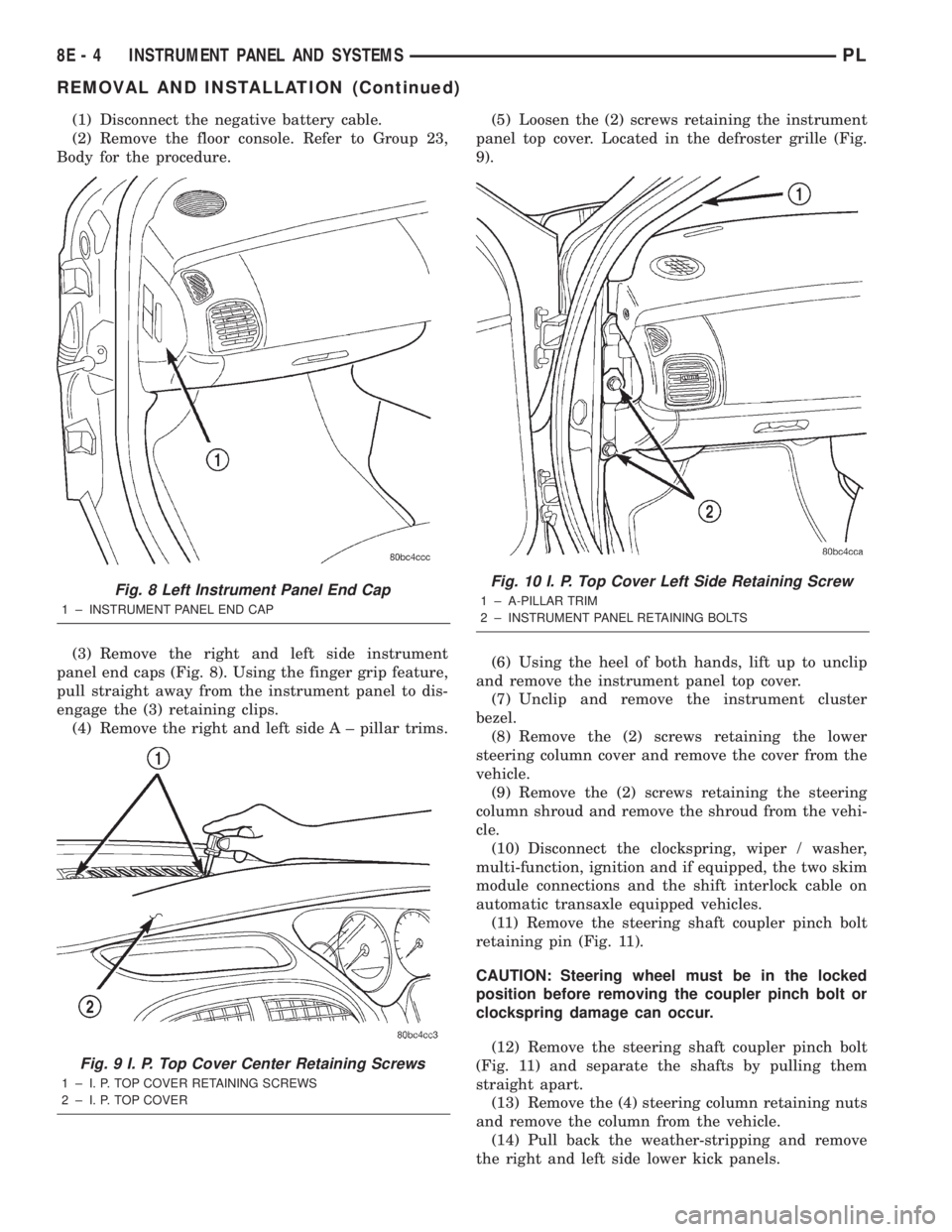

(1) Disconnect the negative battery cable.

(2) Remove the floor console. Refer to Group 23,

Body for the procedure.

(3) Remove the right and left side instrument

panel end caps (Fig. 8). Using the finger grip feature,

pull straight away from the instrument panel to dis-

engage the (3) retaining clips.

(4) Remove the right and left side A ± pillar trims.(5) Loosen the (2) screws retaining the instrument

panel top cover. Located in the defroster grille (Fig.

9).

(6) Using the heel of both hands, lift up to unclip

and remove the instrument panel top cover.

(7) Unclip and remove the instrument cluster

bezel.

(8) Remove the (2) screws retaining the lower

steering column cover and remove the cover from the

vehicle.

(9) Remove the (2) screws retaining the steering

column shroud and remove the shroud from the vehi-

cle.

(10) Disconnect the clockspring, wiper / washer,

multi-function, ignition and if equipped, the two skim

module connections and the shift interlock cable on

automatic transaxle equipped vehicles.

(11) Remove the steering shaft coupler pinch bolt

retaining pin (Fig. 11).

CAUTION: Steering wheel must be in the locked

position before removing the coupler pinch bolt or

clockspring damage can occur.

(12) Remove the steering shaft coupler pinch bolt

(Fig. 11) and separate the shafts by pulling them

straight apart.

(13) Remove the (4) steering column retaining nuts

and remove the column from the vehicle.

(14) Pull back the weather-stripping and remove

the right and left side lower kick panels.

Fig. 8 Left Instrument Panel End Cap

1 ± INSTRUMENT PANEL END CAP

Fig. 9 I. P. Top Cover Center Retaining Screws

1 ± I. P. TOP COVER RETAINING SCREWS

2 ± I. P. TOP COVER

Fig. 10 I. P. Top Cover Left Side Retaining Screw

1 ± A-PILLAR TRIM

2 ± INSTRUMENT PANEL RETAINING BOLTS

8E - 4 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 267 of 1285

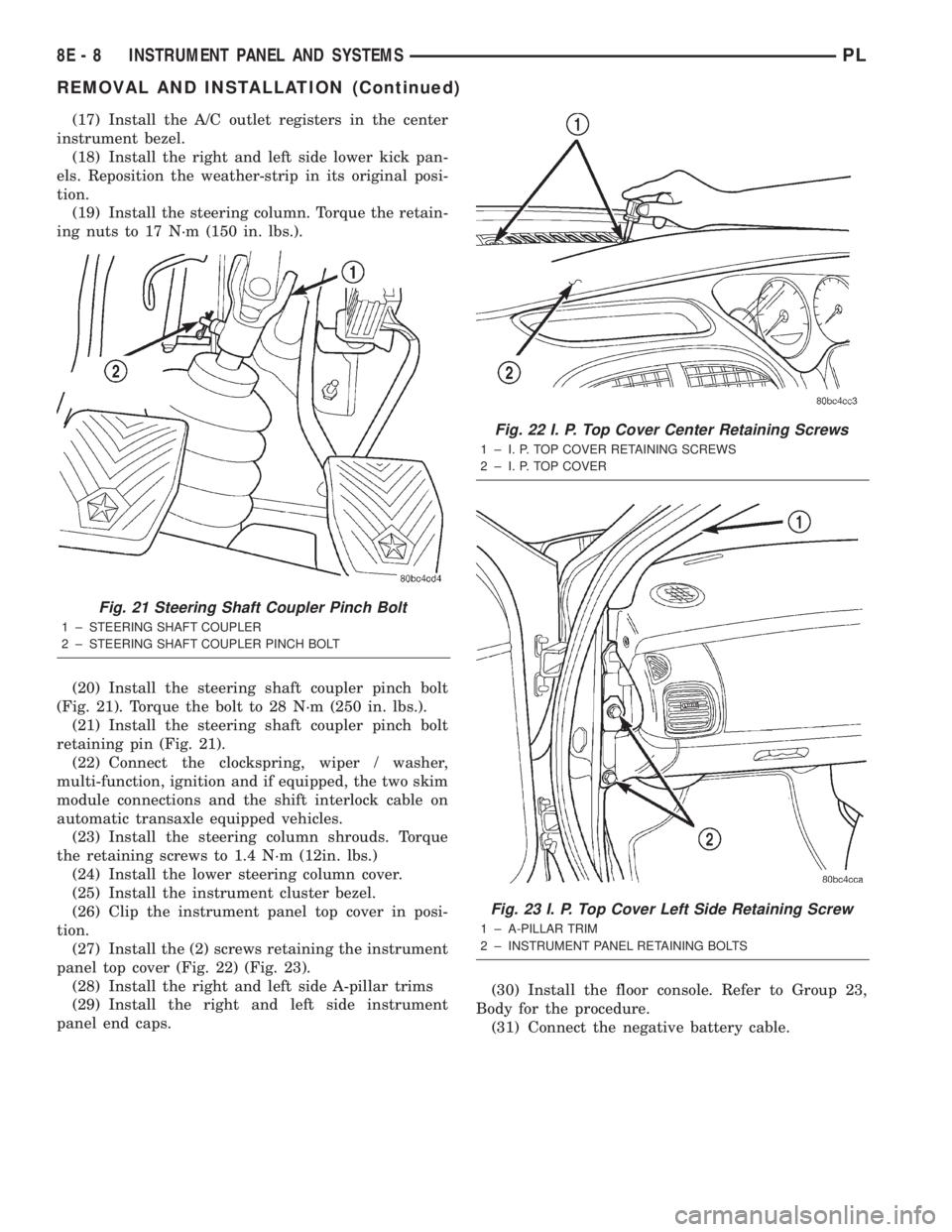

(17) Install the A/C outlet registers in the center

instrument bezel.

(18) Install the right and left side lower kick pan-

els. Reposition the weather-strip in its original posi-

tion.

(19) Install the steering column. Torque the retain-

ing nuts to 17 N´m (150 in. lbs.).

(20) Install the steering shaft coupler pinch bolt

(Fig. 21). Torque the bolt to 28 N´m (250 in. lbs.).

(21) Install the steering shaft coupler pinch bolt

retaining pin (Fig. 21).

(22) Connect the clockspring, wiper / washer,

multi-function, ignition and if equipped, the two skim

module connections and the shift interlock cable on

automatic transaxle equipped vehicles.

(23) Install the steering column shrouds. Torque

the retaining screws to 1.4 N´m (12in. lbs.)

(24) Install the lower steering column cover.

(25) Install the instrument cluster bezel.

(26) Clip the instrument panel top cover in posi-

tion.

(27) Install the (2) screws retaining the instrument

panel top cover (Fig. 22) (Fig. 23).

(28) Install the right and left side A-pillar trims

(29) Install the right and left side instrument

panel end caps.(30) Install the floor console. Refer to Group 23,

Body for the procedure.

(31) Connect the negative battery cable.

Fig. 21 Steering Shaft Coupler Pinch Bolt

1 ± STEERING SHAFT COUPLER

2 ± STEERING SHAFT COUPLER PINCH BOLT

Fig. 22 I. P. Top Cover Center Retaining Screws

1 ± I. P. TOP COVER RETAINING SCREWS

2 ± I. P. TOP COVER

Fig. 23 I. P. Top Cover Left Side Retaining Screw

1 ± A-PILLAR TRIM

2 ± INSTRUMENT PANEL RETAINING BOLTS

8E - 8 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 270 of 1285

AUDIO SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION...............1

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES......1

TESTING................................1

BENCH TEST FOR ANTENNA MALFUNCTION...7REMOVAL AND INSTALLATION

CD CHANGER............................7

FRONT DOOR SPEAKER....................8

INSTRUMENT PANEL SPEAKER(S)...........8

MAST and ANTENNA ASSEMBLY.............8

RADIO..................................9

REAR SHELF SPEAKER(S).................10

GENERAL INFORMATION

INTRODUCTION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with the vehicle.

The vehicles are equipped with an Interior (Igni-

tion Off Draw) fuse in the Power Distribution Center

located in the engine compartment. After the Interior

(IOD) fuse or battery has been disconnected the clock

will require resetting. The radio station presets have

a nonvolatile memory and will retain the preset sta-

tions after a battery disconnect.

The available radio options are:

²AM/FM Stereo Cassette w/Clock

²AM/FM/CD

²AM/FM Cassette w/CD Changer Controls and

Display

²CD/4 Disc Changer - In-Dash (used w/Radio CD

Changer Controls)

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION

The radio utilizes a ground wire plugged on to a

blade terminal and is bolted to the radio chassis.

Both connector and terminal should be securely

attached. The engine has two separate ground straps

to suppress ignition noise which may interfere with

radio reception.

²Left engine mount clip on strap

²Engine to shock tower reinforcement

Inductive type spark plug cables in the high ten-

sion circuit of the ignition system complete the inter-

ference suppression. Faulty or deteriorated spark

plug wires should be replaced.

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES

CAUTION: The CD player will only operate between

approximate temperatures of -23ÉC and +65ÉC (-10ÉF

and +145ÉF).

Whenever a radio malfunction occurs;

(1) First check FUSES:

(a) Power Distribution Center (PDC), Interior

lamp fuse, M1 - Radio Memory Feed

(b) Fuse Block:

(I) Fuse 12, Illumination in the fuse block

(II) Fuse 16, Ignition feed in the fuse block

NOTE: The vehicles are shipped with the INTERIOR

LAMP fuse disconnected.

(2) Verify, the radio wire harness are properly con-

nected before starting normal diagnosis and repair

procedures. Refer to Audio Diagnostic Charts and/or

Group 8W, Wiring Diagrams, Radio Section.

TESTING

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

PLAUDIO SYSTEM 8F - 1

Page 280 of 1285

HORNS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

HORN..................................2

HORN RELAY............................2

HORN SWITCH...........................2HORN SYSTEM TEST......................2

REMOVAL AND INSTALLATION

HORN..................................4

HORN RELAY............................4

HORN SWITCH...........................5

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, PASSIVE RESTRAINT SYS-

TEMS FOR STEERING WHEEL REMOVAL.

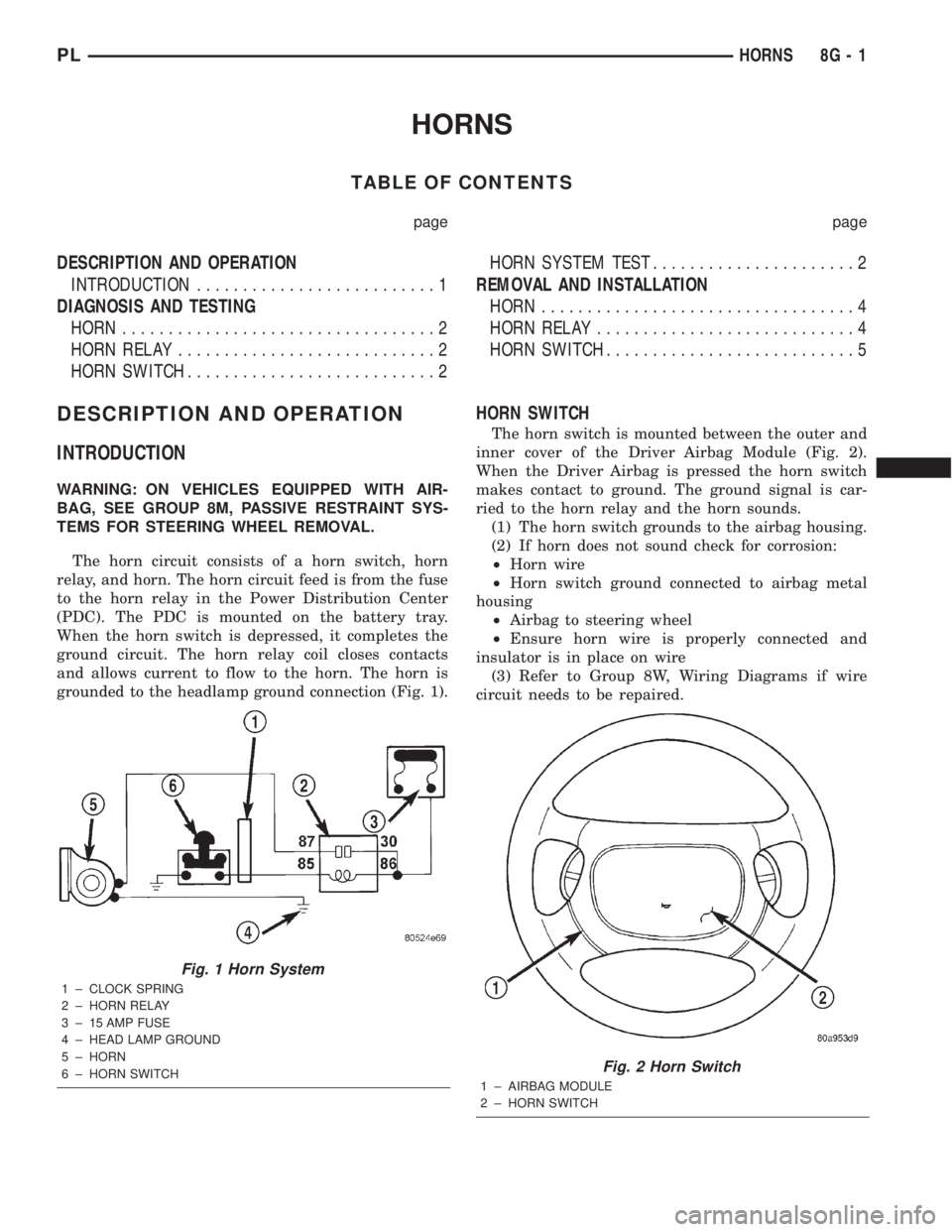

The horn circuit consists of a horn switch, horn

relay, and horn. The horn circuit feed is from the fuse

to the horn relay in the Power Distribution Center

(PDC). The PDC is mounted on the battery tray.

When the horn switch is depressed, it completes the

ground circuit. The horn relay coil closes contacts

and allows current to flow to the horn. The horn is

grounded to the headlamp ground connection (Fig. 1).

HORN SWITCH

The horn switch is mounted between the outer and

inner cover of the Driver Airbag Module (Fig. 2).

When the Driver Airbag is pressed the horn switch

makes contact to ground. The ground signal is car-

ried to the horn relay and the horn sounds.

(1) The horn switch grounds to the airbag housing.

(2) If horn does not sound check for corrosion:

²Horn wire

²Horn switch ground connected to airbag metal

housing

²Airbag to steering wheel

²Ensure horn wire is properly connected and

insulator is in place on wire

(3) Refer to Group 8W, Wiring Diagrams if wire

circuit needs to be repaired.

Fig. 1 Horn System

1 ± CLOCK SPRING

2 ± HORN RELAY

3 ± 15 AMP FUSE

4 ± HEAD LAMP GROUND

5 ± HORN

6 ± HORN SWITCH

Fig. 2 Horn Switch

1 ± AIRBAG MODULE

2 ± HORN SWITCH

PLHORNS 8G - 1

Page 289 of 1285

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(3) Connect electrical connector to servo.

(4) Connect vacuum hose to servo

SPEED CONTROL SWITCH

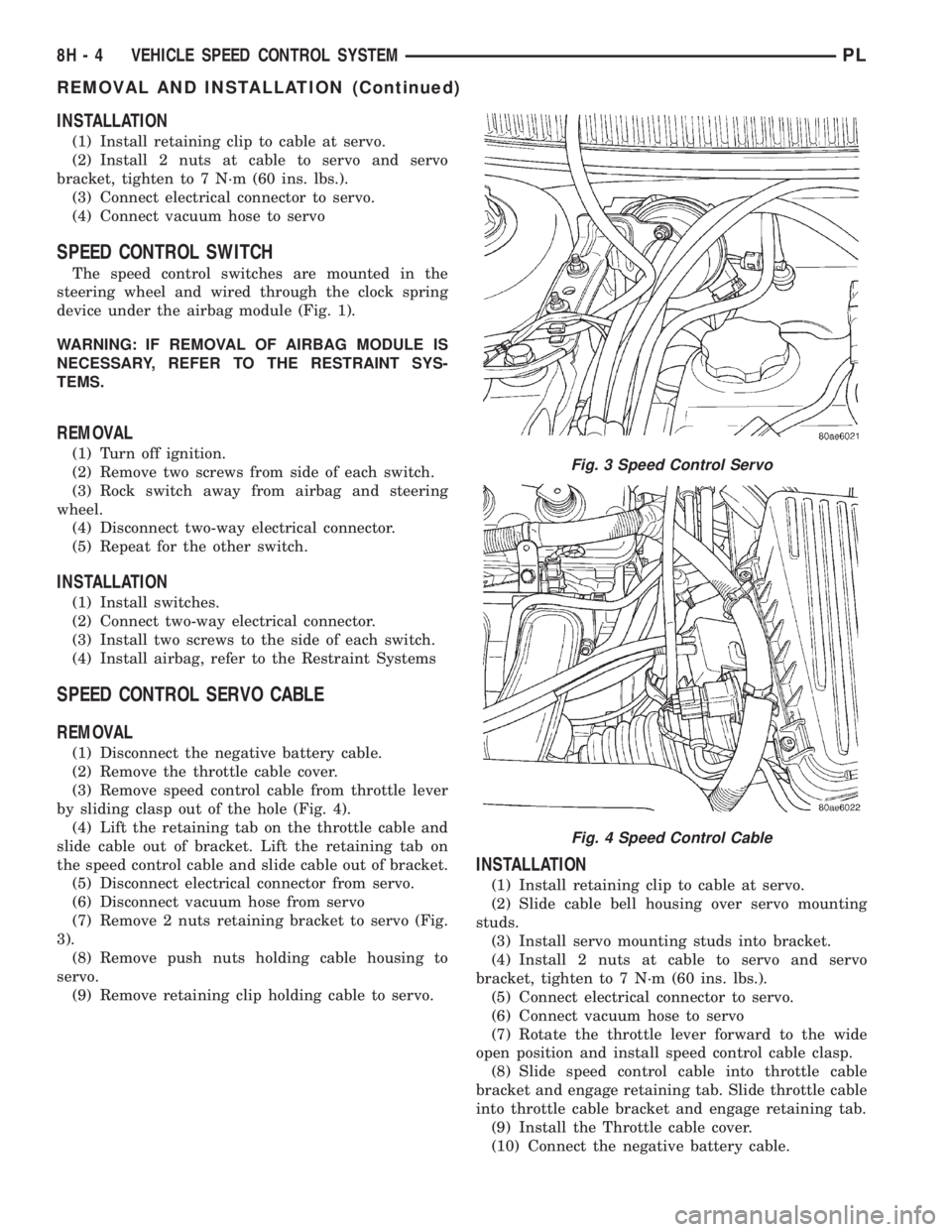

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module (Fig. 1).

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS.

REMOVAL

(1) Turn off ignition.

(2) Remove two screws from side of each switch.

(3) Rock switch away from airbag and steering

wheel.

(4) Disconnect two-way electrical connector.

(5) Repeat for the other switch.

INSTALLATION

(1) Install switches.

(2) Connect two-way electrical connector.

(3) Install two screws to the side of each switch.

(4) Install airbag, refer to the Restraint Systems

SPEED CONTROL SERVO CABLE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the throttle cable cover.

(3) Remove speed control cable from throttle lever

by sliding clasp out of the hole (Fig. 4).

(4) Lift the retaining tab on the throttle cable and

slide cable out of bracket. Lift the retaining tab on

the speed control cable and slide cable out of bracket.

(5) Disconnect electrical connector from servo.

(6) Disconnect vacuum hose from servo

(7) Remove 2 nuts retaining bracket to servo (Fig.

3).

(8) Remove push nuts holding cable housing to

servo.

(9) Remove retaining clip holding cable to servo.

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Slide cable bell housing over servo mounting

studs.

(3) Install servo mounting studs into bracket.

(4) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(5) Connect electrical connector to servo.

(6) Connect vacuum hose to servo

(7) Rotate the throttle lever forward to the wide

open position and install speed control cable clasp.

(8) Slide speed control cable into throttle cable

bracket and engage retaining tab. Slide throttle cable

into throttle cable bracket and engage retaining tab.

(9) Install the Throttle cable cover.

(10) Connect the negative battery cable.

Fig. 3 Speed Control Servo

Fig. 4 Speed Control Cable

8H - 4 VEHICLE SPEED CONTROL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)