lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 662 of 1285

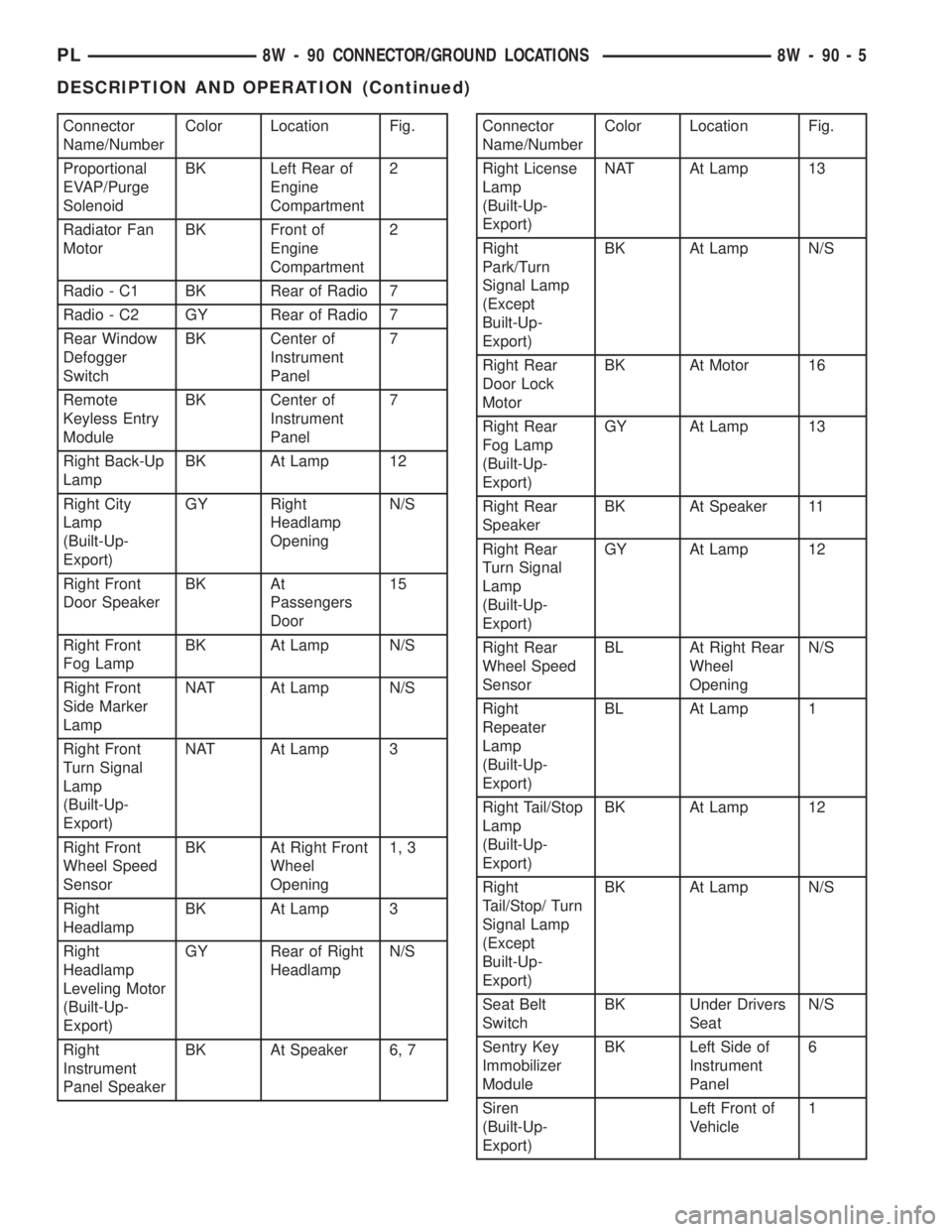

Connector

Name/NumberColor Location Fig.

Proportional

EVAP/Purge

SolenoidBK Left Rear of

Engine

Compartment2

Radiator Fan

MotorBK Front of

Engine

Compartment2

Radio - C1 BK Rear of Radio 7

Radio - C2 GY Rear of Radio 7

Rear Window

Defogger

SwitchBK Center of

Instrument

Panel7

Remote

Keyless Entry

ModuleBK Center of

Instrument

Panel7

Right Back-Up

LampBK At Lamp 12

Right City

Lamp

(Built-Up-

Export)GY Right

Headlamp

OpeningN/S

Right Front

Door SpeakerBK At

Passengers

Door15

Right Front

Fog LampBK At Lamp N/S

Right Front

Side Marker

LampNAT At Lamp N/S

Right Front

Turn Signal

Lamp

(Built-Up-

Export)NAT At Lamp 3

Right Front

Wheel Speed

SensorBK At Right Front

Wheel

Opening1, 3

Right

HeadlampBK At Lamp 3

Right

Headlamp

Leveling Motor

(Built-Up-

Export)GY Rear of Right

HeadlampN/S

Right

Instrument

Panel SpeakerBK At Speaker 6, 7Connector

Name/NumberColor Location Fig.

Right License

Lamp

(Built-Up-

Export)NAT At Lamp 13

Right

Park/Turn

Signal Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Right Rear

Door Lock

MotorBK At Motor 16

Right Rear

Fog Lamp

(Built-Up-

Export)GY At Lamp 13

Right Rear

SpeakerBK At Speaker 11

Right Rear

Turn Signal

Lamp

(Built-Up-

Export)GY At Lamp 12

Right Rear

Wheel Speed

SensorBL At Right Rear

Wheel

OpeningN/S

Right

Repeater

Lamp

(Built-Up-

Export)BL At Lamp 1

Right Tail/Stop

Lamp

(Built-Up-

Export)BK At Lamp 12

Right

Tail/Stop/ Turn

Signal Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Seat Belt

SwitchBK Under Drivers

SeatN/S

Sentry Key

Immobilizer

ModuleBK Left Side of

Instrument

Panel6

Siren

(Built-Up-

Export)Left Front of

Vehicle1

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 5

DESCRIPTION AND OPERATION (Continued)

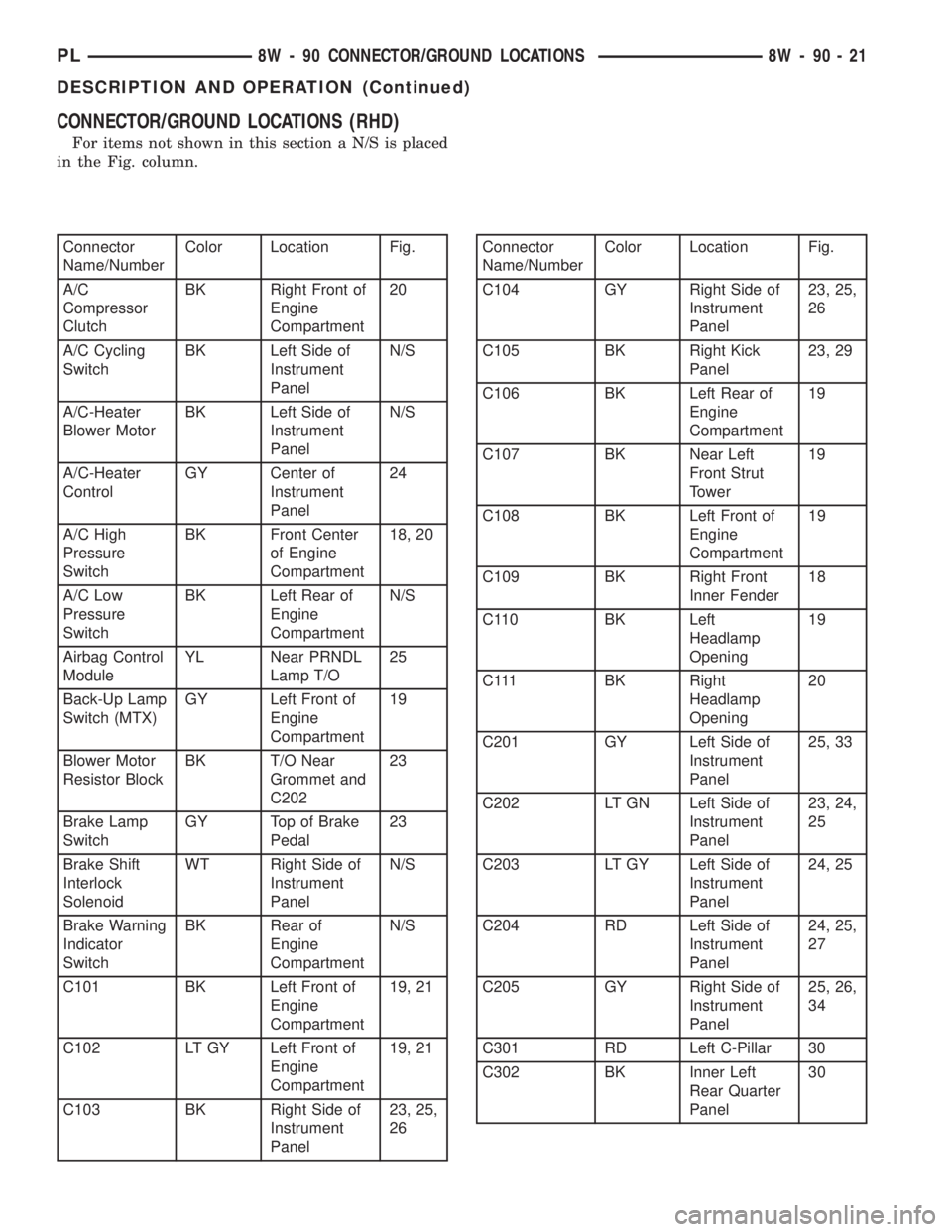

Page 678 of 1285

CONNECTOR/GROUND LOCATIONS (RHD)

For items not shown in this section a N/S is placed

in the Fig. column.

Connector

Name/NumberColor Location Fig.

A/C

Compressor

ClutchBK Right Front of

Engine

Compartment20

A/C Cycling

SwitchBK Left Side of

Instrument

PanelN/S

A/C-Heater

Blower MotorBK Left Side of

Instrument

PanelN/S

A/C-Heater

ControlGY Center of

Instrument

Panel24

A/C High

Pressure

SwitchBK Front Center

of Engine

Compartment18, 20

A/C Low

Pressure

SwitchBK Left Rear of

Engine

CompartmentN/S

Airbag Control

ModuleYL Near PRNDL

Lamp T/O25

Back-Up Lamp

Switch (MTX)GY Left Front of

Engine

Compartment19

Blower Motor

Resistor BlockBK T/O Near

Grommet and

C20223

Brake Lamp

SwitchGY Top of Brake

Pedal23

Brake Shift

Interlock

SolenoidWT Right Side of

Instrument

PanelN/S

Brake Warning

Indicator

SwitchBK Rear of

Engine

CompartmentN/S

C101 BK Left Front of

Engine

Compartment19, 21

C102 LT GY Left Front of

Engine

Compartment19, 21

C103 BK Right Side of

Instrument

Panel23, 25,

26Connector

Name/NumberColor Location Fig.

C104 GY Right Side of

Instrument

Panel23, 25,

26

C105 BK Right Kick

Panel23, 29

C106 BK Left Rear of

Engine

Compartment19

C107 BK Near Left

Front Strut

Tower19

C108 BK Left Front of

Engine

Compartment19

C109 BK Right Front

Inner Fender18

C110 BK Left

Headlamp

Opening19

C111 BK Right

Headlamp

Opening20

C201 GY Left Side of

Instrument

Panel25, 33

C202 LT GN Left Side of

Instrument

Panel23, 24,

25

C203 LT GY Left Side of

Instrument

Panel24, 25

C204 RD Left Side of

Instrument

Panel24, 25,

27

C205 GY Right Side of

Instrument

Panel25, 26,

34

C301 RD Left C-Pillar 30

C302 BK Inner Left

Rear Quarter

Panel30

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 21

DESCRIPTION AND OPERATION (Continued)

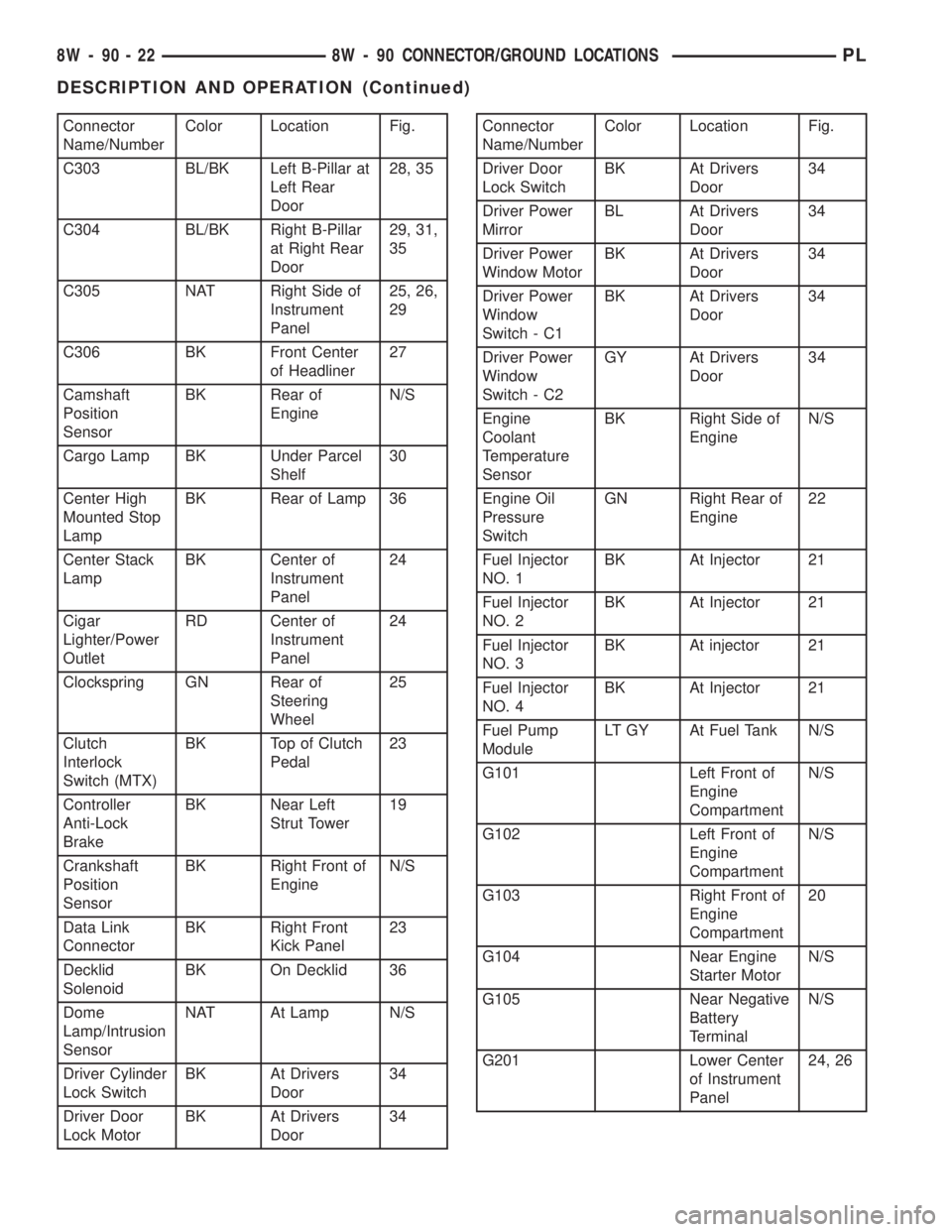

Page 679 of 1285

Connector

Name/NumberColor Location Fig.

C303 BL/BK Left B-Pillar at

Left Rear

Door28, 35

C304 BL/BK Right B-Pillar

at Right Rear

Door29, 31,

35

C305 NAT Right Side of

Instrument

Panel25, 26,

29

C306 BK Front Center

of Headliner27

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf30

Center High

Mounted Stop

LampBK Rear of Lamp 36

Center Stack

LampBK Center of

Instrument

Panel24

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel24

Clockspring GN Rear of

Steering

Wheel25

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal23

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower19

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK Right Front

Kick Panel23

Decklid

SolenoidBK On Decklid 36

Dome

Lamp/Intrusion

SensorNAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door34

Driver Door

Lock MotorBK At Drivers

Door34Connector

Name/NumberColor Location Fig.

Driver Door

Lock SwitchBK At Drivers

Door34

Driver Power

MirrorBL At Drivers

Door34

Driver Power

Window MotorBK At Drivers

Door34

Driver Power

Window

Switch - C1BK At Drivers

Door34

Driver Power

Window

Switch - C2GY At Drivers

Door34

Engine

Coolant

Temperature

SensorBK Right Side of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine22

Fuel Injector

NO. 1BK At Injector 21

Fuel Injector

NO. 2BK At Injector 21

Fuel Injector

NO. 3BK At injector 21

Fuel Injector

NO. 4BK At Injector 21

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

G102 Left Front of

Engine

CompartmentN/S

G103 Right Front of

Engine

Compartment20

G104 Near Engine

Starter MotorN/S

G105 Near Negative

Battery

TerminalN/S

G201 Lower Center

of Instrument

Panel24, 26

8W - 90 - 22 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

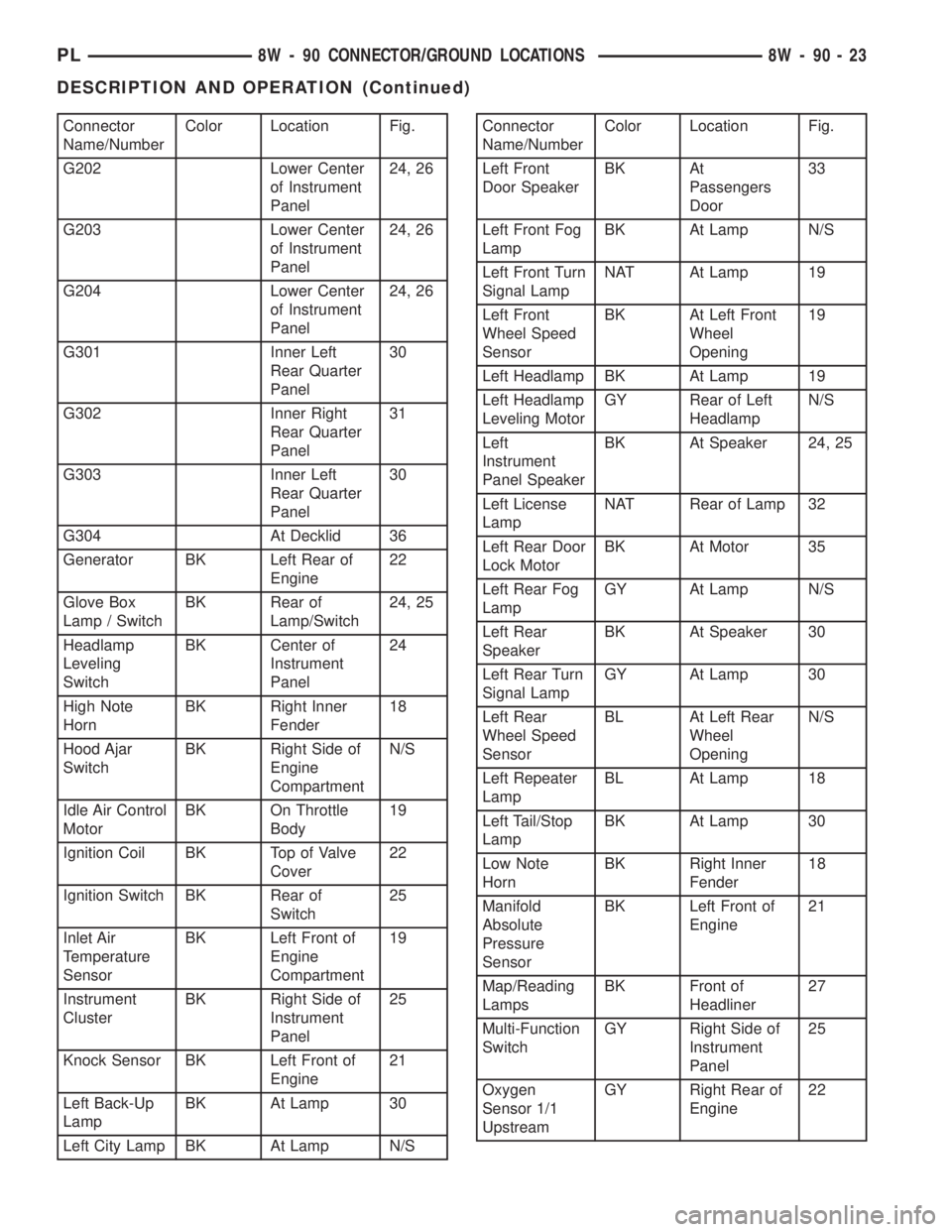

Page 680 of 1285

Connector

Name/NumberColor Location Fig.

G202 Lower Center

of Instrument

Panel24, 26

G203 Lower Center

of Instrument

Panel24, 26

G204 Lower Center

of Instrument

Panel24, 26

G301 Inner Left

Rear Quarter

Panel30

G302 Inner Right

Rear Quarter

Panel31

G303 Inner Left

Rear Quarter

Panel30

G304 At Decklid 36

Generator BK Left Rear of

Engine22

Glove Box

Lamp / SwitchBK Rear of

Lamp/Switch24, 25

Headlamp

Leveling

SwitchBK Center of

Instrument

Panel24

High Note

HornBK Right Inner

Fender18

Hood Ajar

SwitchBK Right Side of

Engine

CompartmentN/S

Idle Air Control

MotorBK On Throttle

Body19

Ignition Coil BK Top of Valve

Cover22

Ignition Switch BK Rear of

Switch25

Inlet Air

Temperature

SensorBK Left Front of

Engine

Compartment19

Instrument

ClusterBK Right Side of

Instrument

Panel25

Knock Sensor BK Left Front of

Engine21

Left Back-Up

LampBK At Lamp 30

Left City Lamp BK At Lamp N/SConnector

Name/NumberColor Location Fig.

Left Front

Door SpeakerBK At

Passengers

Door33

Left Front Fog

LampBK At Lamp N/S

Left Front Turn

Signal LampNAT At Lamp 19

Left Front

Wheel Speed

SensorBK At Left Front

Wheel

Opening19

Left Headlamp BK At Lamp 19

Left Headlamp

Leveling MotorGY Rear of Left

HeadlampN/S

Left

Instrument

Panel SpeakerBK At Speaker 24, 25

Left License

LampNAT Rear of Lamp 32

Left Rear Door

Lock MotorBK At Motor 35

Left Rear Fog

LampGY At Lamp N/S

Left Rear

SpeakerBK At Speaker 30

Left Rear Turn

Signal LampGY At Lamp 30

Left Rear

Wheel Speed

SensorBL At Left Rear

Wheel

OpeningN/S

Left Repeater

LampBL At Lamp 18

Left Tail/Stop

LampBK At Lamp 30

Low Note

HornBK Right Inner

Fender18

Manifold

Absolute

Pressure

SensorBK Left Front of

Engine21

Map/Reading

LampsBK Front of

Headliner27

Multi-Function

SwitchGY Right Side of

Instrument

Panel25

Oxygen

Sensor 1/1

UpstreamGY Right Rear of

Engine22

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 23

DESCRIPTION AND OPERATION (Continued)

Page 681 of 1285

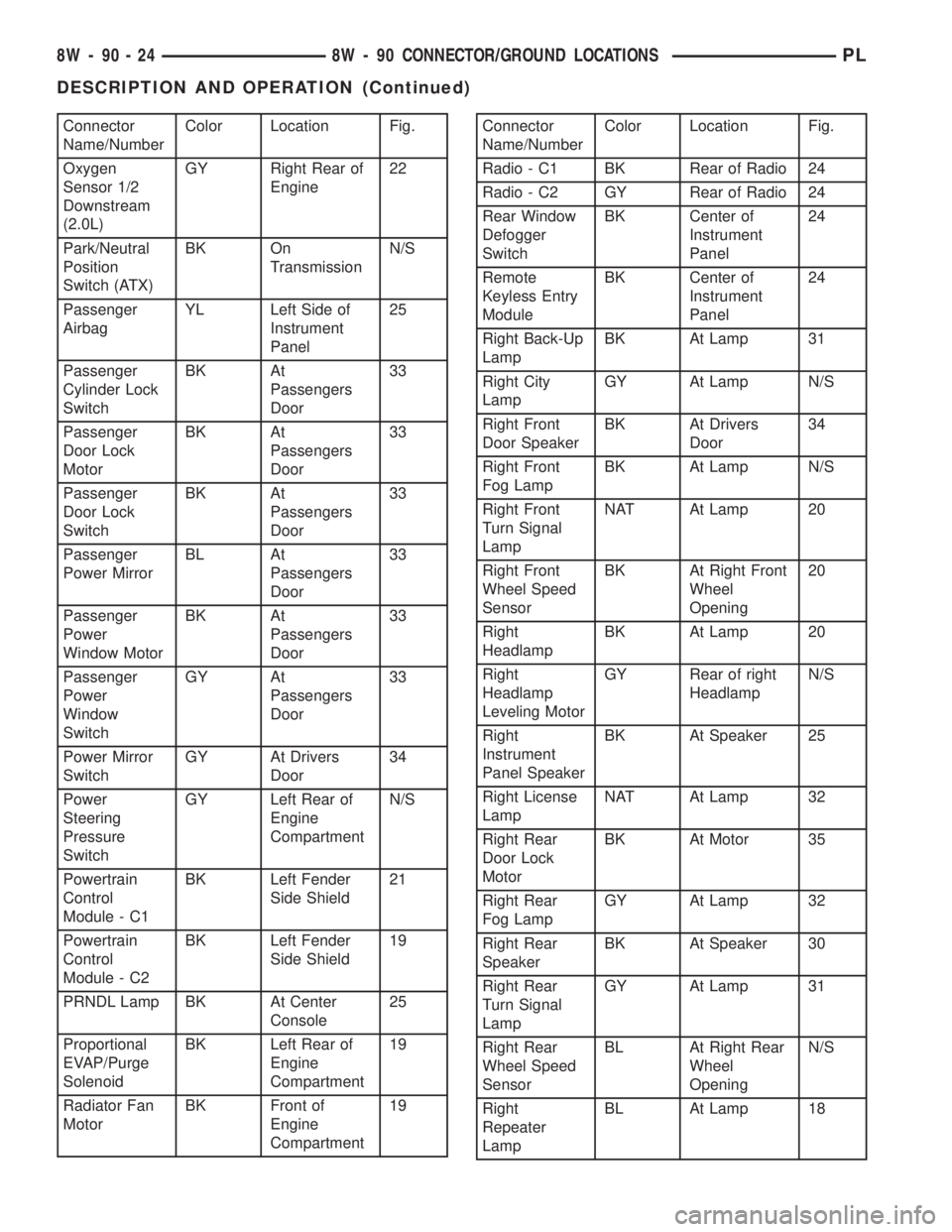

Connector

Name/NumberColor Location Fig.

Oxygen

Sensor 1/2

Downstream

(2.0L)GY Right Rear of

Engine22

Park/Neutral

Position

Switch (ATX)BK On

TransmissionN/S

Passenger

AirbagYL Left Side of

Instrument

Panel25

Passenger

Cylinder Lock

SwitchBK At

Passengers

Door33

Passenger

Door Lock

MotorBK At

Passengers

Door33

Passenger

Door Lock

SwitchBK At

Passengers

Door33

Passenger

Power MirrorBL At

Passengers

Door33

Passenger

Power

Window MotorBK At

Passengers

Door33

Passenger

Power

Window

SwitchGY At

Passengers

Door33

Power Mirror

SwitchGY At Drivers

Door34

Power

Steering

Pressure

SwitchGY Left Rear of

Engine

CompartmentN/S

Powertrain

Control

Module - C1BK Left Fender

Side Shield21

Powertrain

Control

Module - C2BK Left Fender

Side Shield19

PRNDL Lamp BK At Center

Console25

Proportional

EVAP/Purge

SolenoidBK Left Rear of

Engine

Compartment19

Radiator Fan

MotorBK Front of

Engine

Compartment19Connector

Name/NumberColor Location Fig.

Radio - C1 BK Rear of Radio 24

Radio - C2 GY Rear of Radio 24

Rear Window

Defogger

SwitchBK Center of

Instrument

Panel24

Remote

Keyless Entry

ModuleBK Center of

Instrument

Panel24

Right Back-Up

LampBK At Lamp 31

Right City

LampGY At Lamp N/S

Right Front

Door SpeakerBK At Drivers

Door34

Right Front

Fog LampBK At Lamp N/S

Right Front

Turn Signal

LampNAT At Lamp 20

Right Front

Wheel Speed

SensorBK At Right Front

Wheel

Opening20

Right

HeadlampBK At Lamp 20

Right

Headlamp

Leveling MotorGY Rear of right

HeadlampN/S

Right

Instrument

Panel SpeakerBK At Speaker 25

Right License

LampNAT At Lamp 32

Right Rear

Door Lock

MotorBK At Motor 35

Right Rear

Fog LampGY At Lamp 32

Right Rear

SpeakerBK At Speaker 30

Right Rear

Turn Signal

LampGY At Lamp 31

Right Rear

Wheel Speed

SensorBL At Right Rear

Wheel

OpeningN/S

Right

Repeater

LampBL At Lamp 18

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 698 of 1285

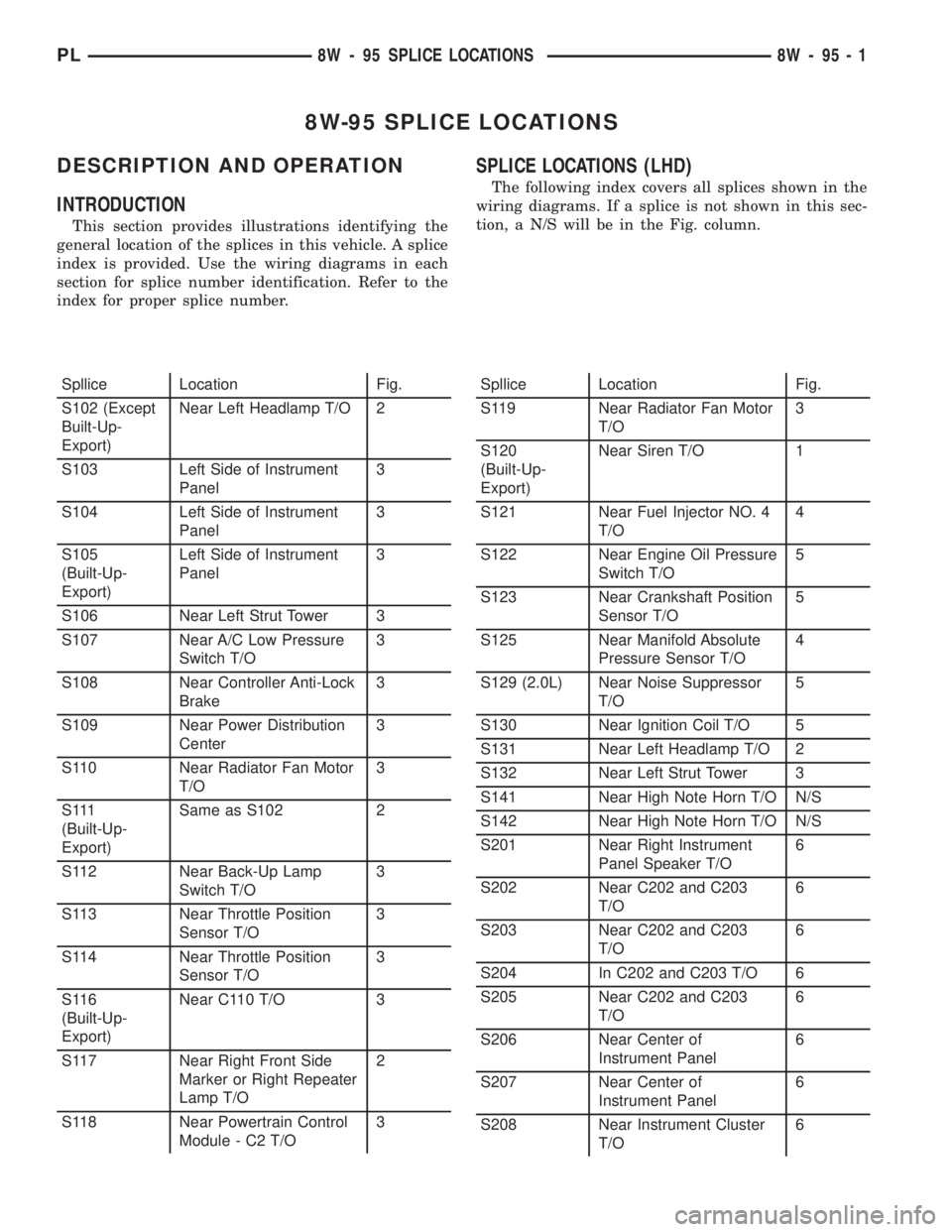

8W-95 SPLICE LOCATIONS

DESCRIPTION AND OPERATION

INTRODUCTION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for proper splice number.

SPLICE LOCATIONS (LHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S102 (Except

Built-Up-

Export)Near Left Headlamp T/O 2

S103 Left Side of Instrument

Panel3

S104 Left Side of Instrument

Panel3

S105

(Built-Up-

Export)Left Side of Instrument

Panel3

S106 Near Left Strut Tower 3

S107 Near A/C Low Pressure

Switch T/O3

S108 Near Controller Anti-Lock

Brake3

S109 Near Power Distribution

Center3

S110 Near Radiator Fan Motor

T/O3

S 111

(Built-Up-

Export)Same as S102 2

S112 Near Back-Up Lamp

Switch T/O3

S113 Near Throttle Position

Sensor T/O3

S114 Near Throttle Position

Sensor T/O3

S116

(Built-Up-

Export)Near C110 T/O 3

S117 Near Right Front Side

Marker or Right Repeater

Lamp T/O2

S118 Near Powertrain Control

Module - C2 T/O3Spllice Location Fig.

S119 Near Radiator Fan Motor

T/O3

S120

(Built-Up-

Export)Near Siren T/O 1

S121 Near Fuel Injector NO. 4

T/O4

S122 Near Engine Oil Pressure

Switch T/O5

S123 Near Crankshaft Position

Sensor T/O5

S125 Near Manifold Absolute

Pressure Sensor T/O4

S129 (2.0L) Near Noise Suppressor

T/O5

S130 Near Ignition Coil T/O 5

S131 Near Left Headlamp T/O 2

S132 Near Left Strut Tower 3

S141 Near High Note Horn T/O N/S

S142 Near High Note Horn T/O N/S

S201 Near Right Instrument

Panel Speaker T/O6

S202 Near C202 and C203

T/O6

S203 Near C202 and C203

T/O6

S204 In C202 and C203 T/O 6

S205 Near C202 and C203

T/O6

S206 Near Center of

Instrument Panel6

S207 Near Center of

Instrument Panel6

S208 Near Instrument Cluster

T/O6

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 1

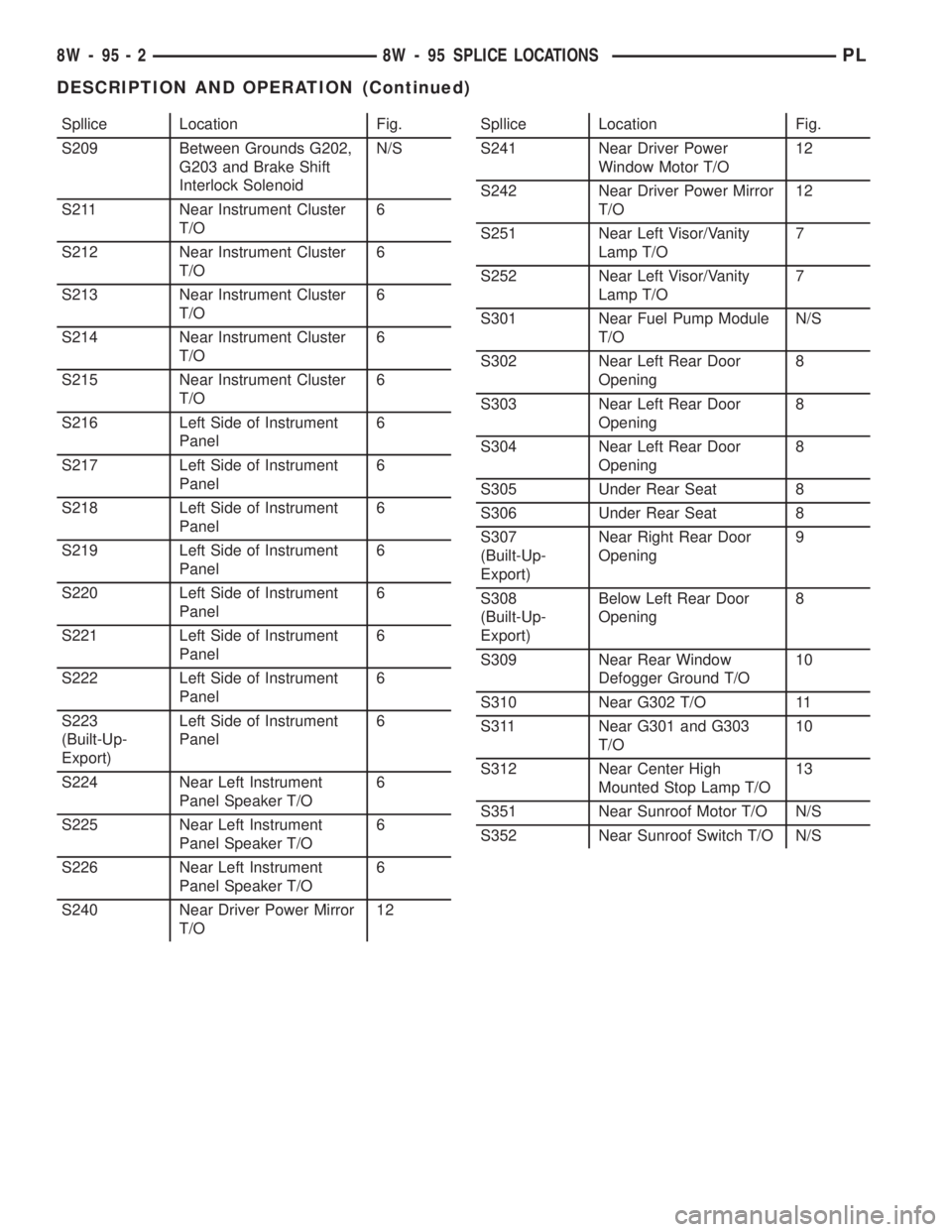

Page 699 of 1285

Spllice Location Fig.

S209 Between Grounds G202,

G203 and Brake Shift

Interlock SolenoidN/S

S211 Near Instrument Cluster

T/O6

S212 Near Instrument Cluster

T/O6

S213 Near Instrument Cluster

T/O6

S214 Near Instrument Cluster

T/O6

S215 Near Instrument Cluster

T/O6

S216 Left Side of Instrument

Panel6

S217 Left Side of Instrument

Panel6

S218 Left Side of Instrument

Panel6

S219 Left Side of Instrument

Panel6

S220 Left Side of Instrument

Panel6

S221 Left Side of Instrument

Panel6

S222 Left Side of Instrument

Panel6

S223

(Built-Up-

Export)Left Side of Instrument

Panel6

S224 Near Left Instrument

Panel Speaker T/O6

S225 Near Left Instrument

Panel Speaker T/O6

S226 Near Left Instrument

Panel Speaker T/O6

S240 Near Driver Power Mirror

T/O12Spllice Location Fig.

S241 Near Driver Power

Window Motor T/O12

S242 Near Driver Power Mirror

T/O12

S251 Near Left Visor/Vanity

Lamp T/O7

S252 Near Left Visor/Vanity

Lamp T/O7

S301 Near Fuel Pump Module

T/ON/S

S302 Near Left Rear Door

Opening8

S303 Near Left Rear Door

Opening8

S304 Near Left Rear Door

Opening8

S305 Under Rear Seat 8

S306 Under Rear Seat 8

S307

(Built-Up-

Export)Near Right Rear Door

Opening9

S308

(Built-Up-

Export)Below Left Rear Door

Opening8

S309 Near Rear Window

Defogger Ground T/O10

S310 Near G302 T/O 11

S311 Near G301 and G303

T/O10

S312 Near Center High

Mounted Stop Lamp T/O13

S351 Near Sunroof Motor T/O N/S

S352 Near Sunroof Switch T/O N/S

8W - 95 - 2 8W - 95 SPLICE LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 710 of 1285

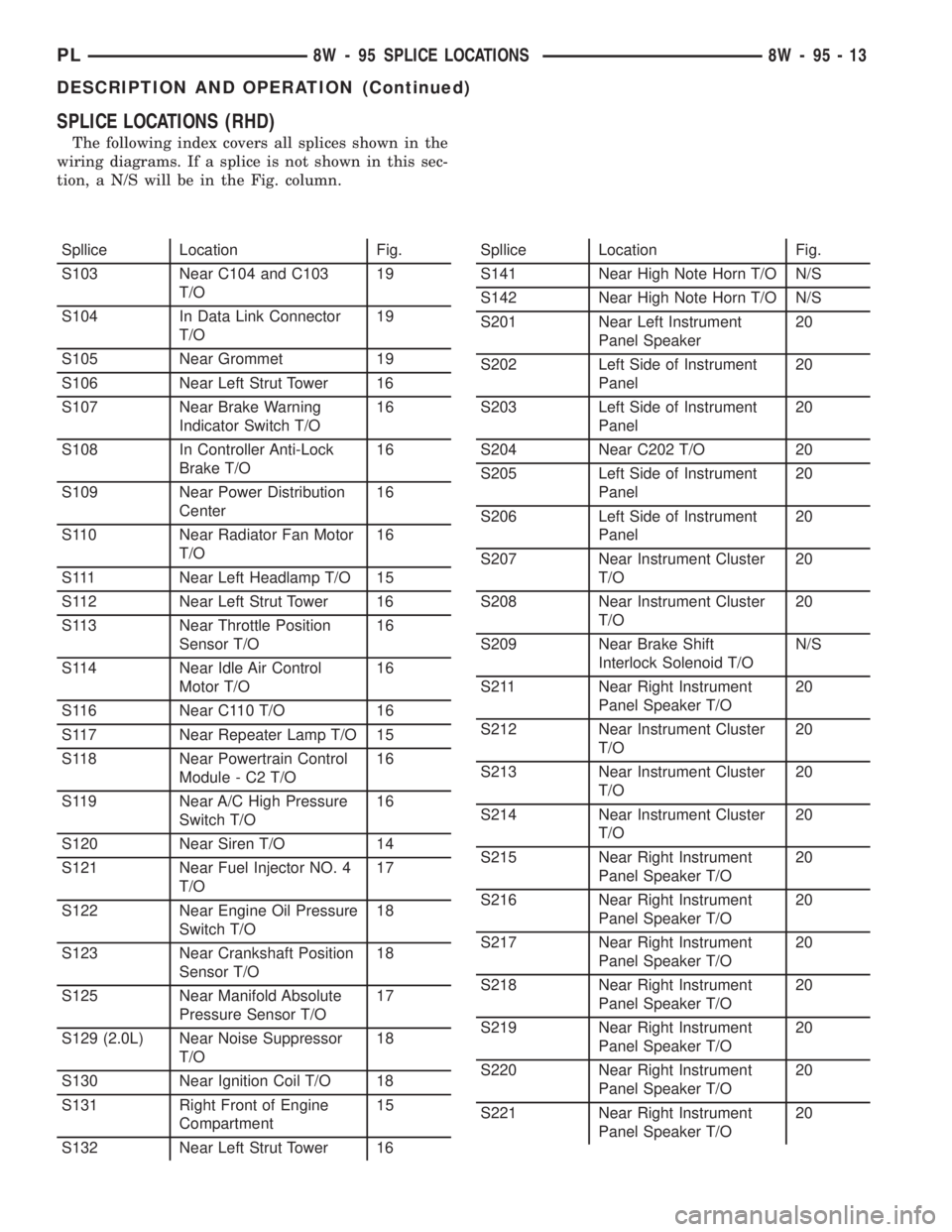

SPLICE LOCATIONS (RHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S103 Near C104 and C103

T/O19

S104 In Data Link Connector

T/O19

S105 Near Grommet 19

S106 Near Left Strut Tower 16

S107 Near Brake Warning

Indicator Switch T/O16

S108 In Controller Anti-Lock

Brake T/O16

S109 Near Power Distribution

Center16

S110 Near Radiator Fan Motor

T/O16

S111 Near Left Headlamp T/O 15

S112 Near Left Strut Tower 16

S113 Near Throttle Position

Sensor T/O16

S114 Near Idle Air Control

Motor T/O16

S116 Near C110 T/O 16

S117 Near Repeater Lamp T/O 15

S118 Near Powertrain Control

Module - C2 T/O16

S119 Near A/C High Pressure

Switch T/O16

S120 Near Siren T/O 14

S121 Near Fuel Injector NO. 4

T/O17

S122 Near Engine Oil Pressure

Switch T/O18

S123 Near Crankshaft Position

Sensor T/O18

S125 Near Manifold Absolute

Pressure Sensor T/O17

S129 (2.0L) Near Noise Suppressor

T/O18

S130 Near Ignition Coil T/O 18

S131 Right Front of Engine

Compartment15

S132 Near Left Strut Tower 16Spllice Location Fig.

S141 Near High Note Horn T/O N/S

S142 Near High Note Horn T/O N/S

S201 Near Left Instrument

Panel Speaker20

S202 Left Side of Instrument

Panel20

S203 Left Side of Instrument

Panel20

S204 Near C202 T/O 20

S205 Left Side of Instrument

Panel20

S206 Left Side of Instrument

Panel20

S207 Near Instrument Cluster

T/O20

S208 Near Instrument Cluster

T/O20

S209 Near Brake Shift

Interlock Solenoid T/ON/S

S211 Near Right Instrument

Panel Speaker T/O20

S212 Near Instrument Cluster

T/O20

S213 Near Instrument Cluster

T/O20

S214 Near Instrument Cluster

T/O20

S215 Near Right Instrument

Panel Speaker T/O20

S216 Near Right Instrument

Panel Speaker T/O20

S217 Near Right Instrument

Panel Speaker T/O20

S218 Near Right Instrument

Panel Speaker T/O20

S219 Near Right Instrument

Panel Speaker T/O20

S220 Near Right Instrument

Panel Speaker T/O20

S221 Near Right Instrument

Panel Speaker T/O20

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 13

DESCRIPTION AND OPERATION (Continued)

Page 724 of 1285

ENGINE

TABLE OF CONTENTS

page page

STANDARD SERVICE PROCEDURES........... 1

ENGINE DIAGNOSIS........................ 82.0L SOHC ENGINE....................... 15

STANDARD SERVICE PROCEDURES

TABLE OF CONTENTS

page page

GENERAL INFORMATION

FORM-IN-PLACE GASKETS & SEALERS........1

ENGINE GASKET SURFACE PREPARATION.....2

CRANKSHAFT DAMPER BOLT ACCESS PLUG . . . 2

ENGINE CORE PLUGS.....................2

ENGINE PERFORMANCE...................3HONING CYLINDER BORES.................3

MEASURING WITH PLASTIGAGE.............4

REPAIR OF DAMAGED OR WORN THREADS....5

HYDROSTATIC LOCKED ENGINE.............5

CHECKING ENGINE OIL LEVEL..............6

ENGINE OIL SERVICE......................7

GENERAL INFORMATION

FORM-IN-PLACE GASKETS & SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Alwaysinspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANT

MopartBed Plate Sealant is a unique (green-in-

color) anaerobic type gasket material that is specially

made to seal the area between the bedplate and cyl-

inder block without disturbing the bearing clearance

or alignment of these components. The material

cures slowly in the absence of air when torqued

between two metallic surfaces, and will rapidly cure

when heat is applied.

PLENGINE 9 - 1

Page 725 of 1285

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4 oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

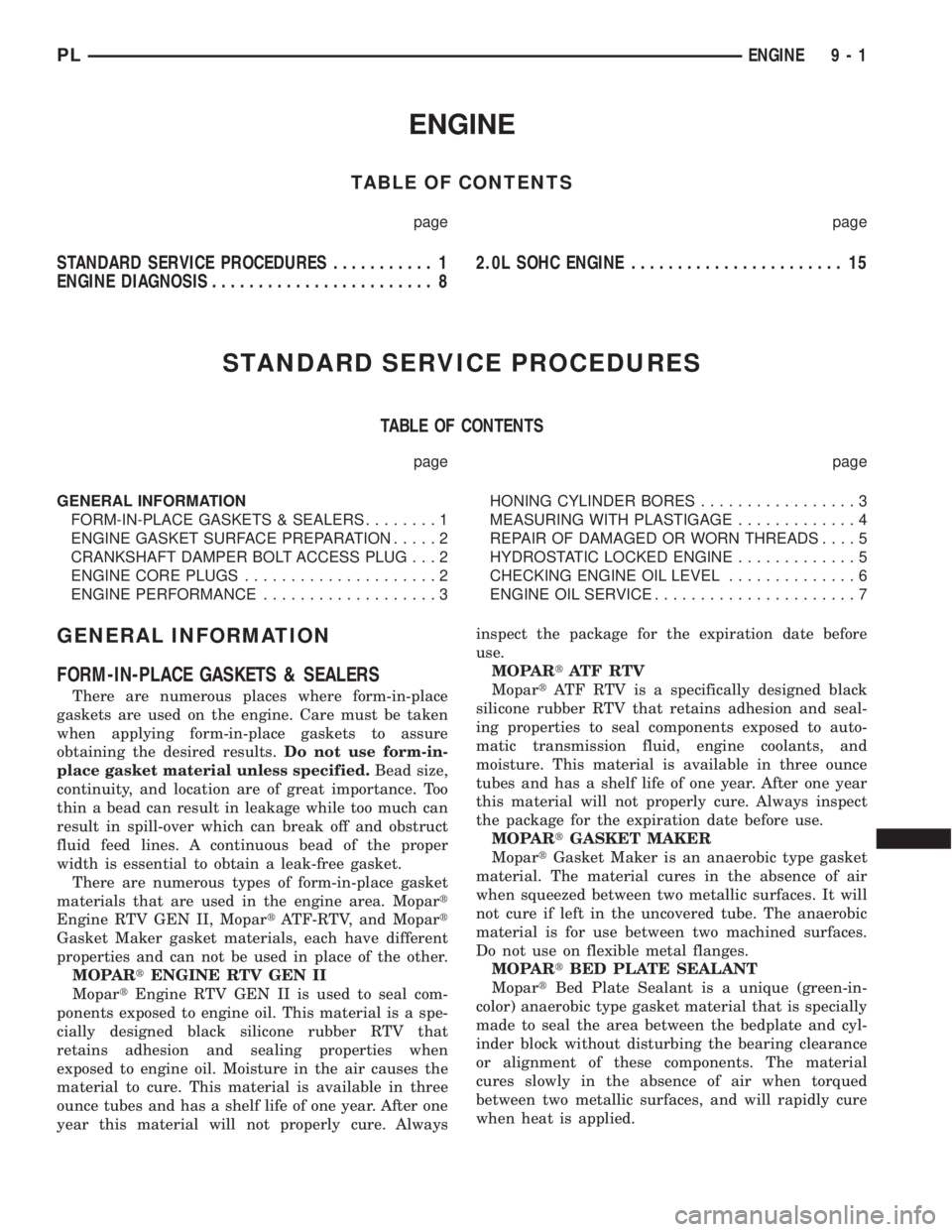

ENGINE GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 1)NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 1)

²Drill motor with 3M RolocyBristle Disc (white

or yellow) (Fig. 1)

CAUTION: Excessive pressure or high RPM can

damage the sealing surfaces. The mild (white, 120

grit) bristle disc is recommended. If necessary, the

medium (yellow, 80 grit) bristle disc may be used

on cast iron surfaces with care.

CRANKSHAFT DAMPER BOLT ACCESS PLUG

An access plug is located in the right splash shield

(Fig. 2). Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 3). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 3).

Fig. 1 Proper Tool Usage For Surface Preparation

1 ± ABRASIVE PAD

2 ± 3M ROLOCYBRISTLE DISC

3 ± PLASTIC/WOOD SCRAPER

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)