tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 771 of 1285

(2) Apply MopartSilicone Rubber Adhesive Seal-

ant at the oil pump to engine block parting line (Fig.

83).

(3) Position a new oil pan gasket onto pan.

(4) Install oil pan and tighten screws to 12 N´m

(105 in. lbs.).

(5) Install transaxle dust cover (Fig. 82).

(6) Install lateral bending brace (Fig. 82).(7) Install structural collar. Refer to procedure in

this section.

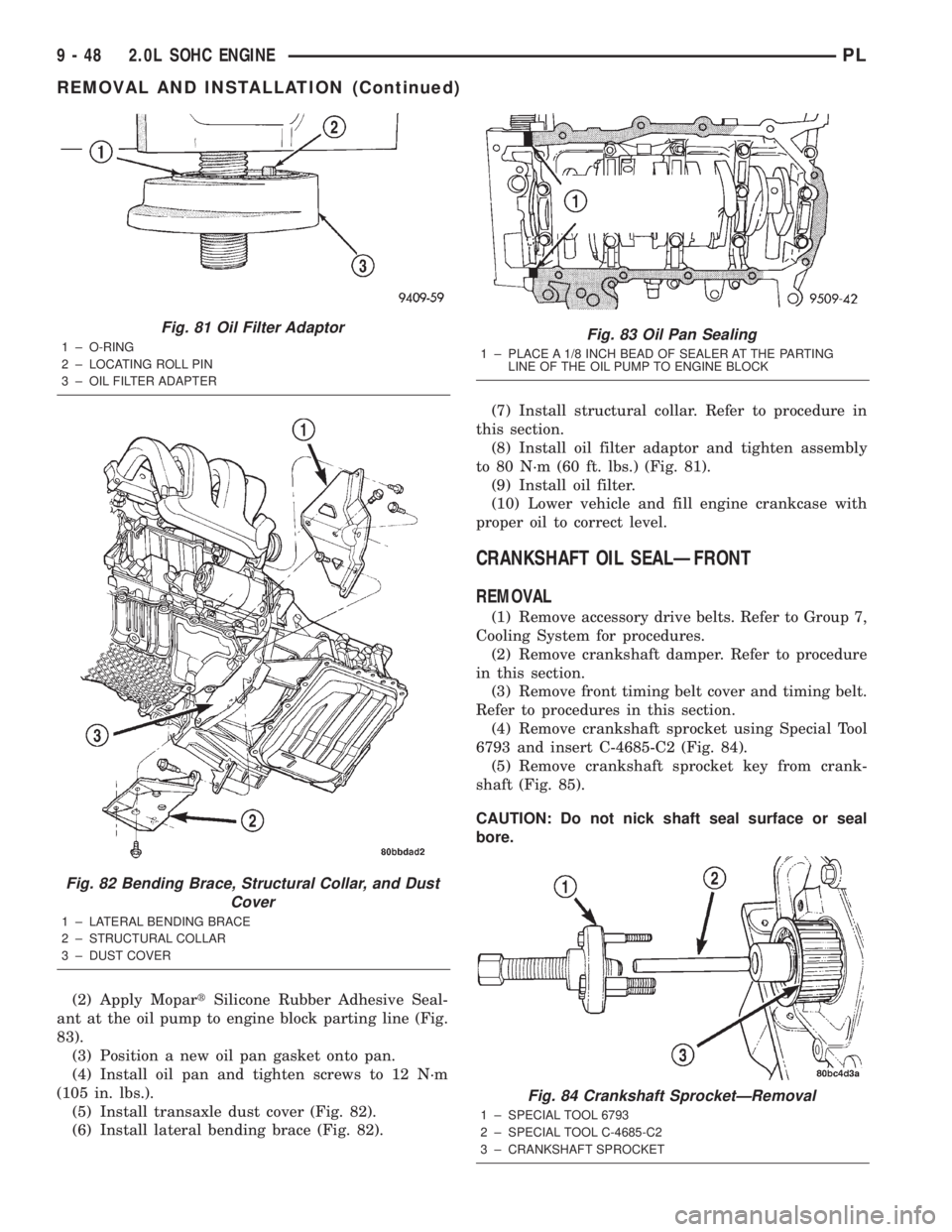

(8) Install oil filter adaptor and tighten assembly

to 80 N´m (60 ft. lbs.) (Fig. 81).

(9) Install oil filter.

(10) Lower vehicle and fill engine crankcase with

proper oil to correct level.

CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedures.

(2) Remove crankshaft damper. Refer to procedure

in this section.

(3) Remove front timing belt cover and timing belt.

Refer to procedures in this section.

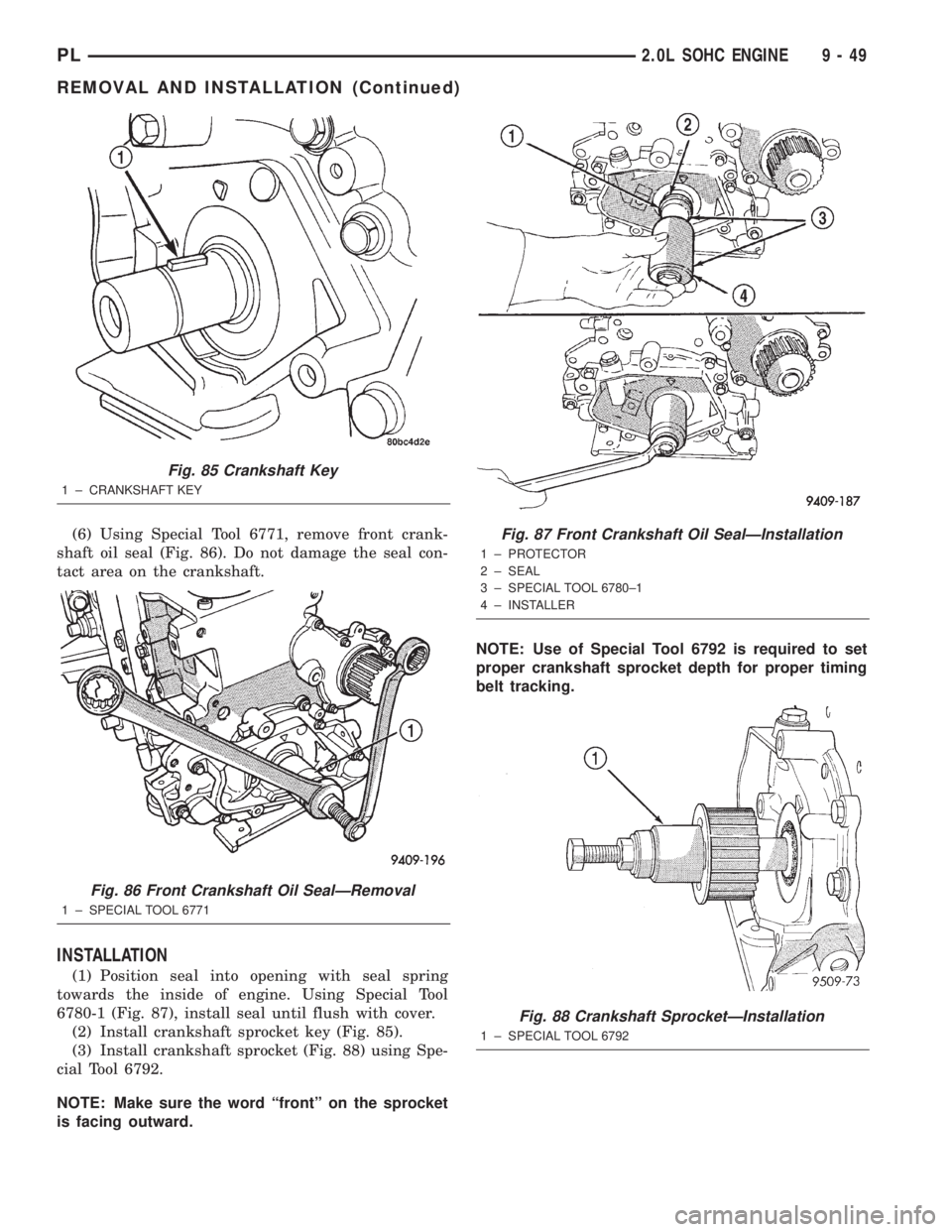

(4) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 84).

(5) Remove crankshaft sprocket key from crank-

shaft (Fig. 85).

CAUTION: Do not nick shaft seal surface or seal

bore.

Fig. 81 Oil Filter Adaptor

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 82 Bending Brace, Structural Collar, and Dust

Cover

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 83 Oil Pan Sealing

1 ± PLACE A 1/8 INCH BEAD OF SEALER AT THE PARTING

LINE OF THE OIL PUMP TO ENGINE BLOCK

Fig. 84 Crankshaft SprocketÐRemoval

1 ± SPECIAL TOOL 6793

2 ± SPECIAL TOOL C-4685-C2

3 ± CRANKSHAFT SPROCKET

9 - 48 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 772 of 1285

(6) Using Special Tool 6771, remove front crank-

shaft oil seal (Fig. 86). Do not damage the seal con-

tact area on the crankshaft.

INSTALLATION

(1) Position seal into opening with seal spring

towards the inside of engine. Using Special Tool

6780-1 (Fig. 87), install seal until flush with cover.

(2) Install crankshaft sprocket key (Fig. 85).

(3) Install crankshaft sprocket (Fig. 88) using Spe-

cial Tool 6792.

NOTE: Make sure the word ªfrontº on the sprocket

is facing outward.NOTE: Use of Special Tool 6792 is required to set

proper crankshaft sprocket depth for proper timing

belt tracking.

Fig. 85 Crankshaft Key

1 ± CRANKSHAFT KEY

Fig. 86 Front Crankshaft Oil SealÐRemoval

1 ± SPECIAL TOOL 6771

Fig. 87 Front Crankshaft Oil SealÐInstallation

1 ± PROTECTOR

2 ± SEAL

3 ± SPECIAL TOOL 6780±1

4 ± INSTALLER

Fig. 88 Crankshaft SprocketÐInstallation

1 ± SPECIAL TOOL 6792

PL2.0L SOHC ENGINE 9 - 49

REMOVAL AND INSTALLATION (Continued)

Page 773 of 1285

(4) Install timing belt and cover. Refer to proce-

dures in this section.

(5) Install crankshaft damper. Refer to procedure

in this section.

(6) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

CRANKSHAFT OIL SEALÐREAR

REMOVAL

(1) Remove transaxle. Refer to Group 21, Tran-

saxle for procedure.

(2) Remove drive plate. Refer to procedure in this

section.

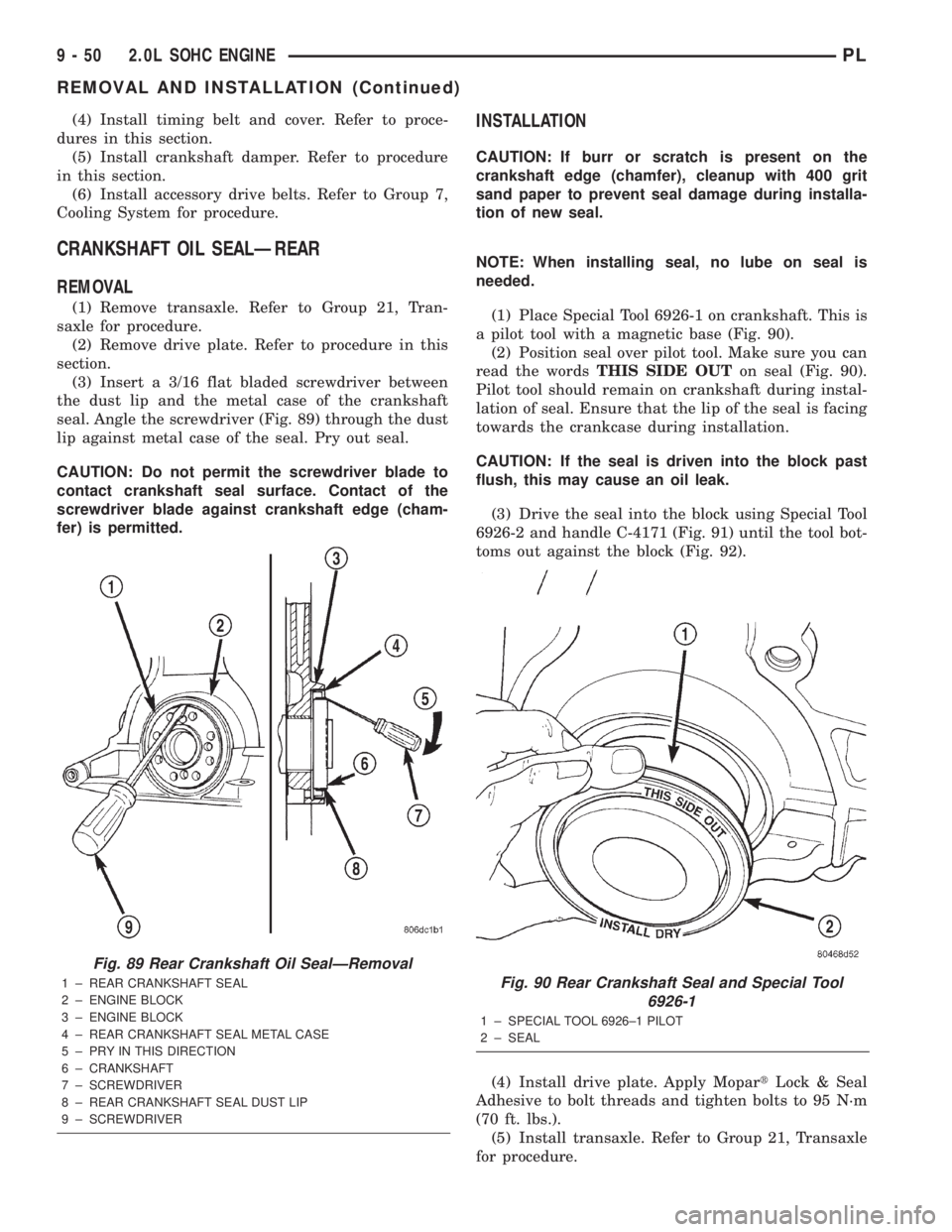

(3) Insert a 3/16 flat bladed screwdriver between

the dust lip and the metal case of the crankshaft

seal. Angle the screwdriver (Fig. 89) through the dust

lip against metal case of the seal. Pry out seal.

CAUTION: Do not permit the screwdriver blade to

contact crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

NOTE: When installing seal, no lube on seal is

needed.

(1) Place Special Tool 6926-1 on crankshaft. This is

a pilot tool with a magnetic base (Fig. 90).

(2) Position seal over pilot tool. Make sure you can

read the wordsTHIS SIDE OUTon seal (Fig. 90).

Pilot tool should remain on crankshaft during instal-

lation of seal. Ensure that the lip of the seal is facing

towards the crankcase during installation.

CAUTION: If the seal is driven into the block past

flush, this may cause an oil leak.

(3) Drive the seal into the block using Special Tool

6926-2 and handle C-4171 (Fig. 91) until the tool bot-

toms out against the block (Fig. 92).

(4) Install drive plate. Apply MopartLock & Seal

Adhesive to bolt threads and tighten bolts to 95 N´m

(70 ft. lbs.).

(5) Install transaxle. Refer to Group 21, Transaxle

for procedure.

Fig. 89 Rear Crankshaft Oil SealÐRemoval

1 ± REAR CRANKSHAFT SEAL

2 ± ENGINE BLOCK

3 ± ENGINE BLOCK

4 ± REAR CRANKSHAFT SEAL METAL CASE

5 ± PRY IN THIS DIRECTION

6 ± CRANKSHAFT

7 ± SCREWDRIVER

8 ± REAR CRANKSHAFT SEAL DUST LIP

9 ± SCREWDRIVERFig. 90 Rear Crankshaft Seal and Special Tool

6926-1

1 ± SPECIAL TOOL 6926±1 PILOT

2 ± SEAL

9 - 50 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 774 of 1285

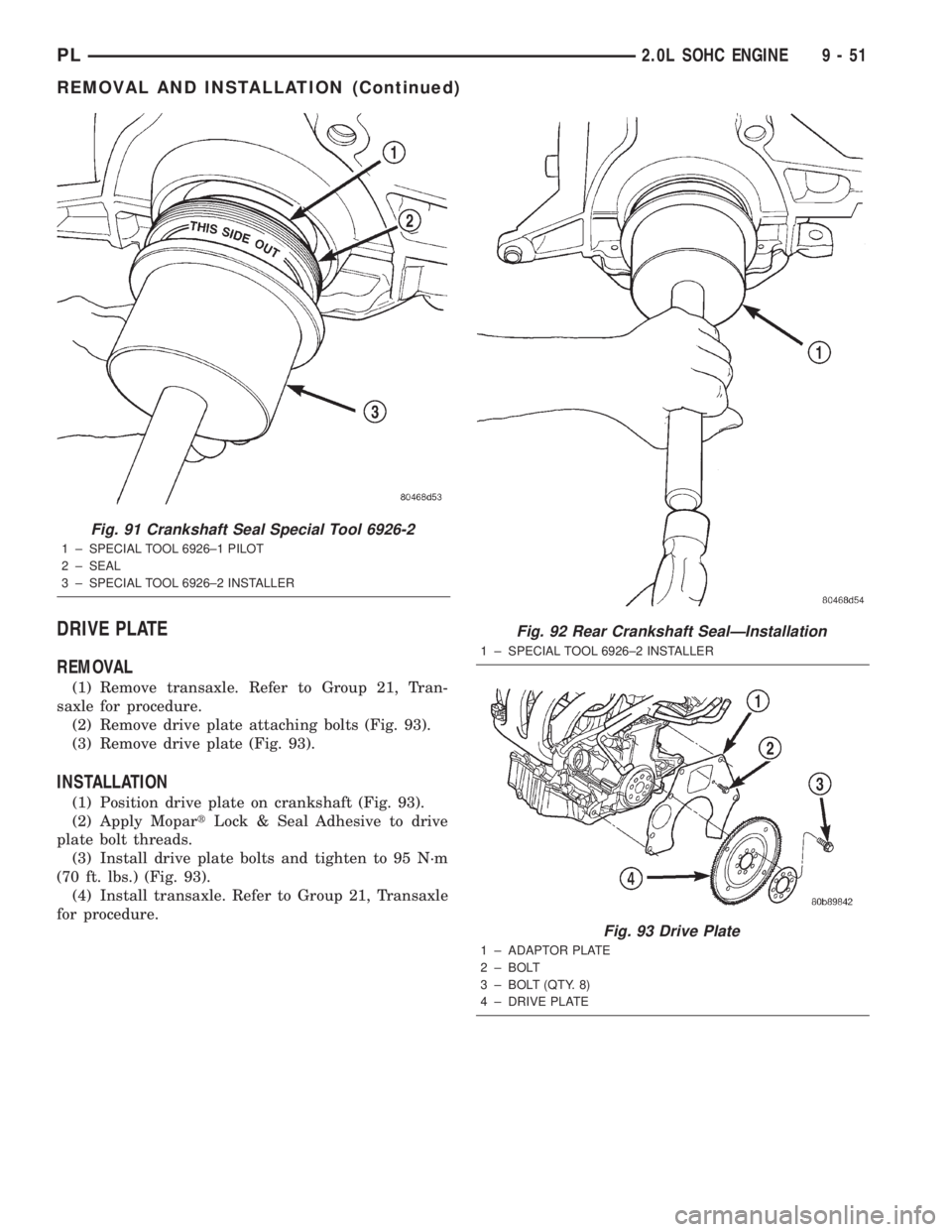

DRIVE PLATE

REMOVAL

(1) Remove transaxle. Refer to Group 21, Tran-

saxle for procedure.

(2) Remove drive plate attaching bolts (Fig. 93).

(3) Remove drive plate (Fig. 93).

INSTALLATION

(1) Position drive plate on crankshaft (Fig. 93).

(2) Apply MopartLock & Seal Adhesive to drive

plate bolt threads.

(3) Install drive plate bolts and tighten to 95 N´m

(70 ft. lbs.) (Fig. 93).

(4) Install transaxle. Refer to Group 21, Transaxle

for procedure.

Fig. 91 Crankshaft Seal Special Tool 6926-2

1 ± SPECIAL TOOL 6926±1 PILOT

2 ± SEAL

3 ± SPECIAL TOOL 6926±2 INSTALLER

Fig. 92 Rear Crankshaft SealÐInstallation

1 ± SPECIAL TOOL 6926±2 INSTALLER

Fig. 93 Drive Plate

1 ± ADAPTOR PLATE

2 ± BOLT

3 ± BOLT (QTY. 8)

4 ± DRIVE PLATE

PL2.0L SOHC ENGINE 9 - 51

REMOVAL AND INSTALLATION (Continued)

Page 775 of 1285

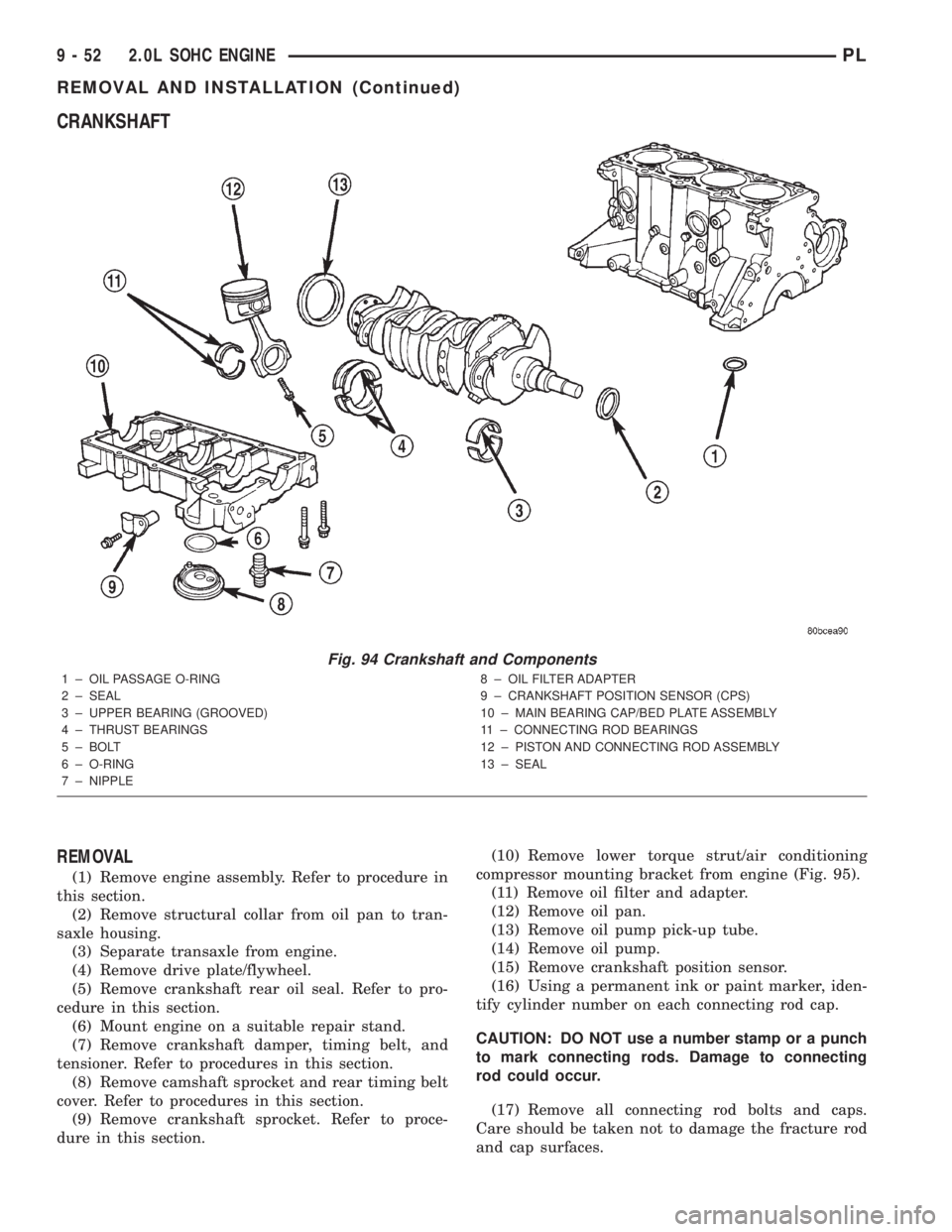

CRANKSHAFT

REMOVAL

(1) Remove engine assembly. Refer to procedure in

this section.

(2) Remove structural collar from oil pan to tran-

saxle housing.

(3) Separate transaxle from engine.

(4) Remove drive plate/flywheel.

(5) Remove crankshaft rear oil seal. Refer to pro-

cedure in this section.

(6) Mount engine on a suitable repair stand.

(7) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(8) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(9) Remove crankshaft sprocket. Refer to proce-

dure in this section.(10) Remove lower torque strut/air conditioning

compressor mounting bracket from engine (Fig. 95).

(11) Remove oil filter and adapter.

(12) Remove oil pan.

(13) Remove oil pump pick-up tube.

(14) Remove oil pump.

(15) Remove crankshaft position sensor.

(16) Using a permanent ink or paint marker, iden-

tify cylinder number on each connecting rod cap.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(17) Remove all connecting rod bolts and caps.

Care should be taken not to damage the fracture rod

and cap surfaces.

Fig. 94 Crankshaft and Components

1 ± OIL PASSAGE O-RING

2 ± SEAL

3 ± UPPER BEARING (GROOVED)

4 ± THRUST BEARINGS

5 ± BOLT

6 ± O-RING

7 ± NIPPLE8 ± OIL FILTER ADAPTER

9 ± CRANKSHAFT POSITION SENSOR (CPS)

10 ± MAIN BEARING CAP/BED PLATE ASSEMBLY

11 ± CONNECTING ROD BEARINGS

12 ± PISTON AND CONNECTING ROD ASSEMBLY

13 ± SEAL

9 - 52 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 778 of 1285

(17) Install rear timing belt cover and camshaft

sprocket.

(18) Install crankshaft sprocket, timing belt ten-

sioner, timing belt, and cover.

(19) Install front engine mount bracket.

(20) Remove engine from repair stand and position

on Special Tools 6135 and 6710 Engine Dolly and

Cradle. Install safety straps around the engine to

cradle and tighten and lock them into position.

(21) Install crankshaft rear oil seal. Refer to proce-

dure in this section.

(22) Install drive plate/flywheel. Apply Mopart

Lock & Seal Adhesive to bolt threads and tighten to

95 N´m (70 ft. lbs.).

(23) Install transaxle to engine.

(24) Install structural collar. Refer to procedure in

this section.

(25) Install engine assembly. Refer to procedure in

this section.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

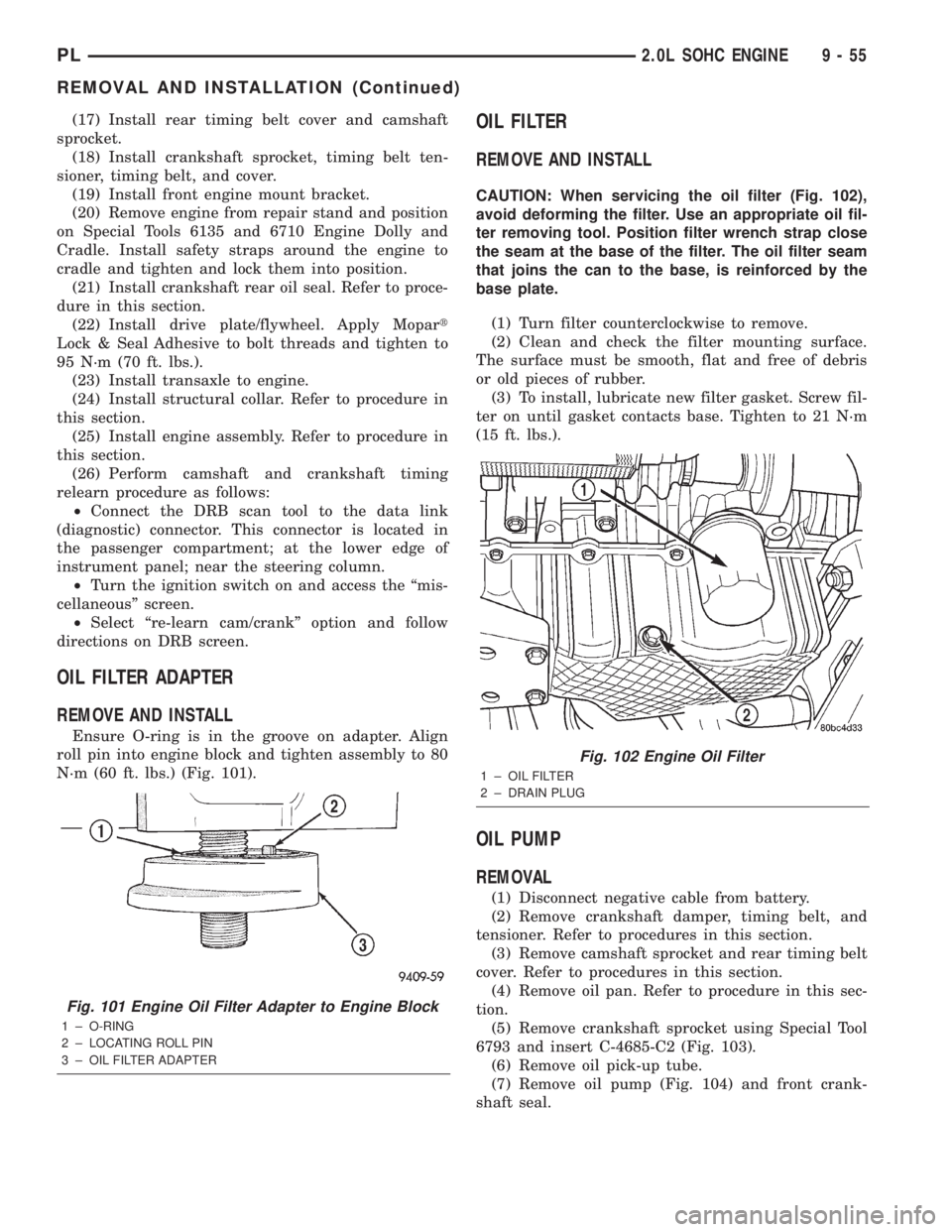

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 101).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 102),

avoid deforming the filter. Use an appropriate oil fil-

ter removing tool. Position filter wrench strap close

the seam at the base of the filter. The oil filter seam

that joins the can to the base, is reinforced by the

base plate.

(1) Turn filter counterclockwise to remove.

(2) Clean and check the filter mounting surface.

The surface must be smooth, flat and free of debris

or old pieces of rubber.

(3) To install, lubricate new filter gasket. Screw fil-

ter on until gasket contacts base. Tighten to 21 N´m

(15 ft. lbs.).

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(3) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(4) Remove oil pan. Refer to procedure in this sec-

tion.

(5) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 103).

(6) Remove oil pick-up tube.

(7) Remove oil pump (Fig. 104) and front crank-

shaft seal.

Fig. 101 Engine Oil Filter Adapter to Engine Block

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 102 Engine Oil Filter

1 ± OIL FILTER

2 ± DRAIN PLUG

PL2.0L SOHC ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 785 of 1285

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. The intake valve seat must be ser-

viced when the valve seat width is 2.0 mm (0.079 in.)

or greater. The exhaust valve seat must be serviced

when the valve seat width is 2.5 mm (0.098 in.) or

greater. Otherwise the cylinder head must be

replaced.

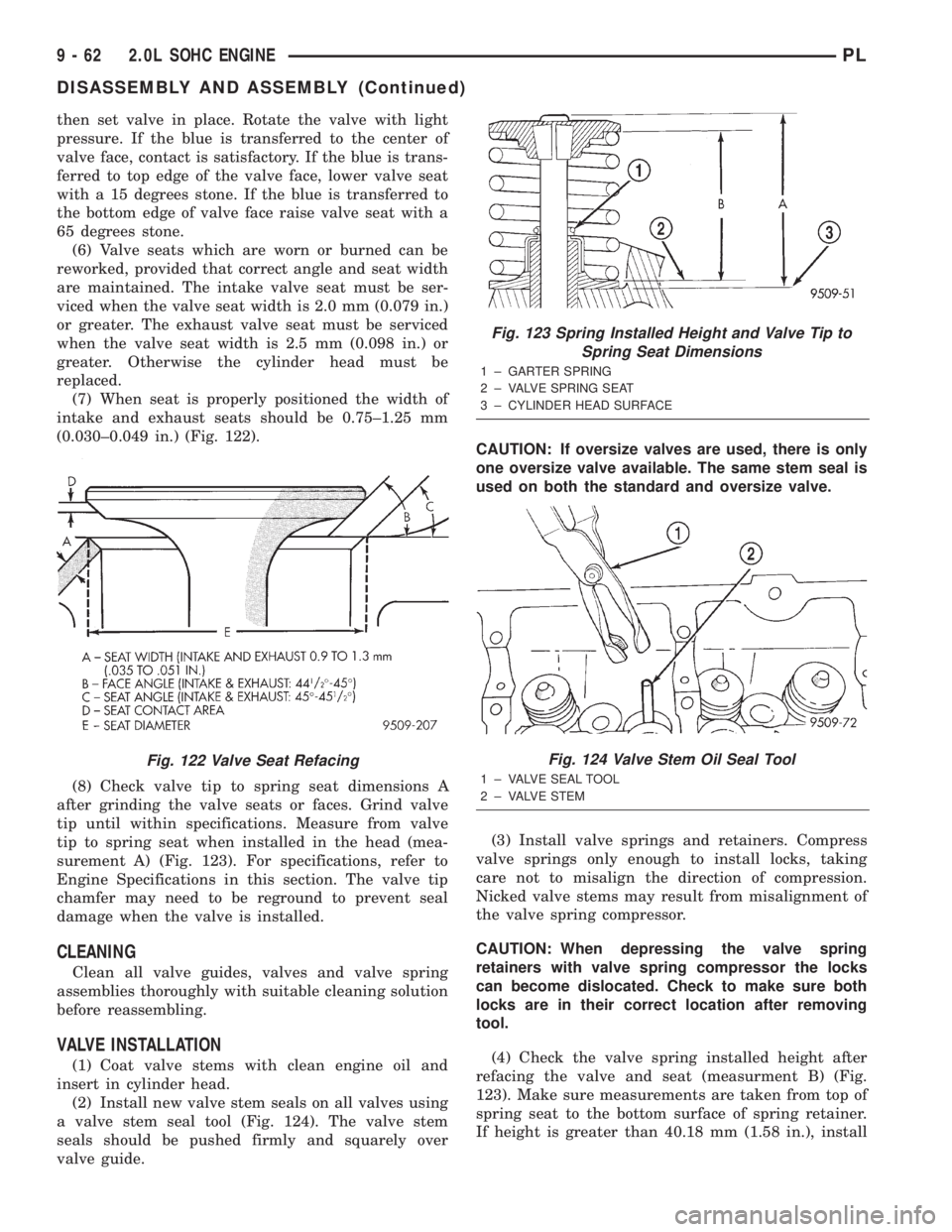

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.75±1.25 mm

(0.030±0.049 in.) (Fig. 122).

(8) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip until within specifications. Measure from valve

tip to spring seat when installed in the head (mea-

surement A) (Fig. 123). For specifications, refer to

Engine Specifications in this section. The valve tip

chamfer may need to be reground to prevent seal

damage when the valve is installed.

CLEANING

Clean all valve guides, valves and valve spring

assemblies thoroughly with suitable cleaning solution

before reassembling.

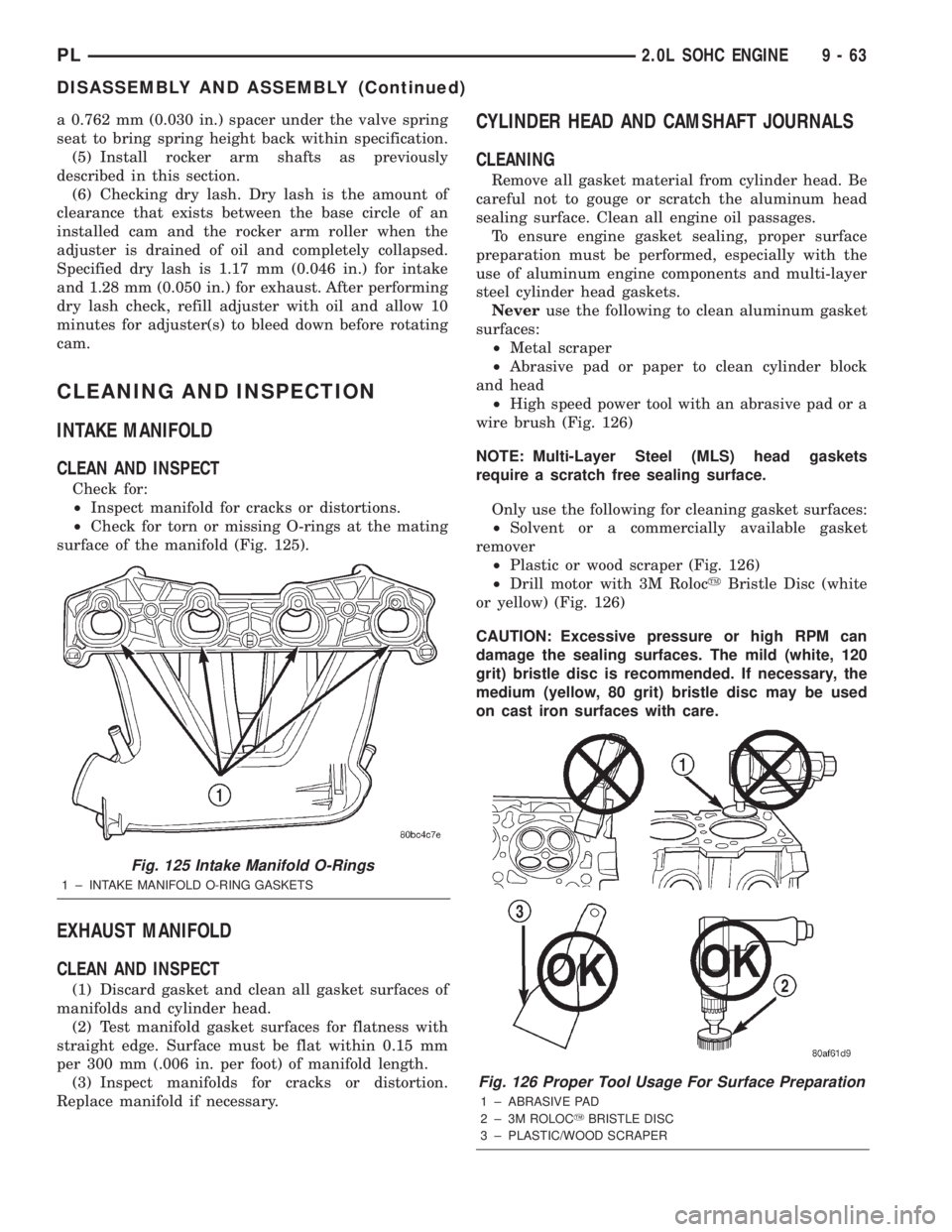

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 124). The valve stem

seals should be pushed firmly and squarely over

valve guide.CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height after

refacing the valve and seat (measurment B) (Fig.

123). Make sure measurements are taken from top of

spring seat to the bottom surface of spring retainer.

If height is greater than 40.18 mm (1.58 in.), install

Fig. 122 Valve Seat Refacing

Fig. 123 Spring Installed Height and Valve Tip to

Spring Seat Dimensions

1 ± GARTER SPRING

2 ± VALVE SPRING SEAT

3 ± CYLINDER HEAD SURFACE

Fig. 124 Valve Stem Oil Seal Tool

1 ± VALVE SEAL TOOL

2 ± VALVE STEM

9 - 62 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 786 of 1285

a 0.762 mm (0.030 in.) spacer under the valve spring

seat to bring spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster(s) to bleed down before rotating

cam.

CLEANING AND INSPECTION

INTAKE MANIFOLD

CLEAN AND INSPECT

Check for:

²Inspect manifold for cracks or distortions.

²Check for torn or missing O-rings at the mating

surface of the manifold (Fig. 125).

EXHAUST MANIFOLD

CLEAN AND INSPECT

(1) Discard gasket and clean all gasket surfaces of

manifolds and cylinder head.

(2) Test manifold gasket surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (.006 in. per foot) of manifold length.

(3) Inspect manifolds for cracks or distortion.

Replace manifold if necessary.

CYLINDER HEAD AND CAMSHAFT JOURNALS

CLEANING

Remove all gasket material from cylinder head. Be

careful not to gouge or scratch the aluminum head

sealing surface. Clean all engine oil passages.

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean aluminum gasket

surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 126)

NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 126)

²Drill motor with 3M RolocyBristle Disc (white

or yellow) (Fig. 126)

CAUTION: Excessive pressure or high RPM can

damage the sealing surfaces. The mild (white, 120

grit) bristle disc is recommended. If necessary, the

medium (yellow, 80 grit) bristle disc may be used

on cast iron surfaces with care.

Fig. 125 Intake Manifold O-Rings

1 ± INTAKE MANIFOLD O-RING GASKETS

Fig. 126 Proper Tool Usage For Surface Preparation

1 ± ABRASIVE PAD

2 ± 3M ROLOCYBRISTLE DISC

3 ± PLASTIC/WOOD SCRAPER

PL2.0L SOHC ENGINE 9 - 63

DISASSEMBLY AND ASSEMBLY (Continued)

Page 787 of 1285

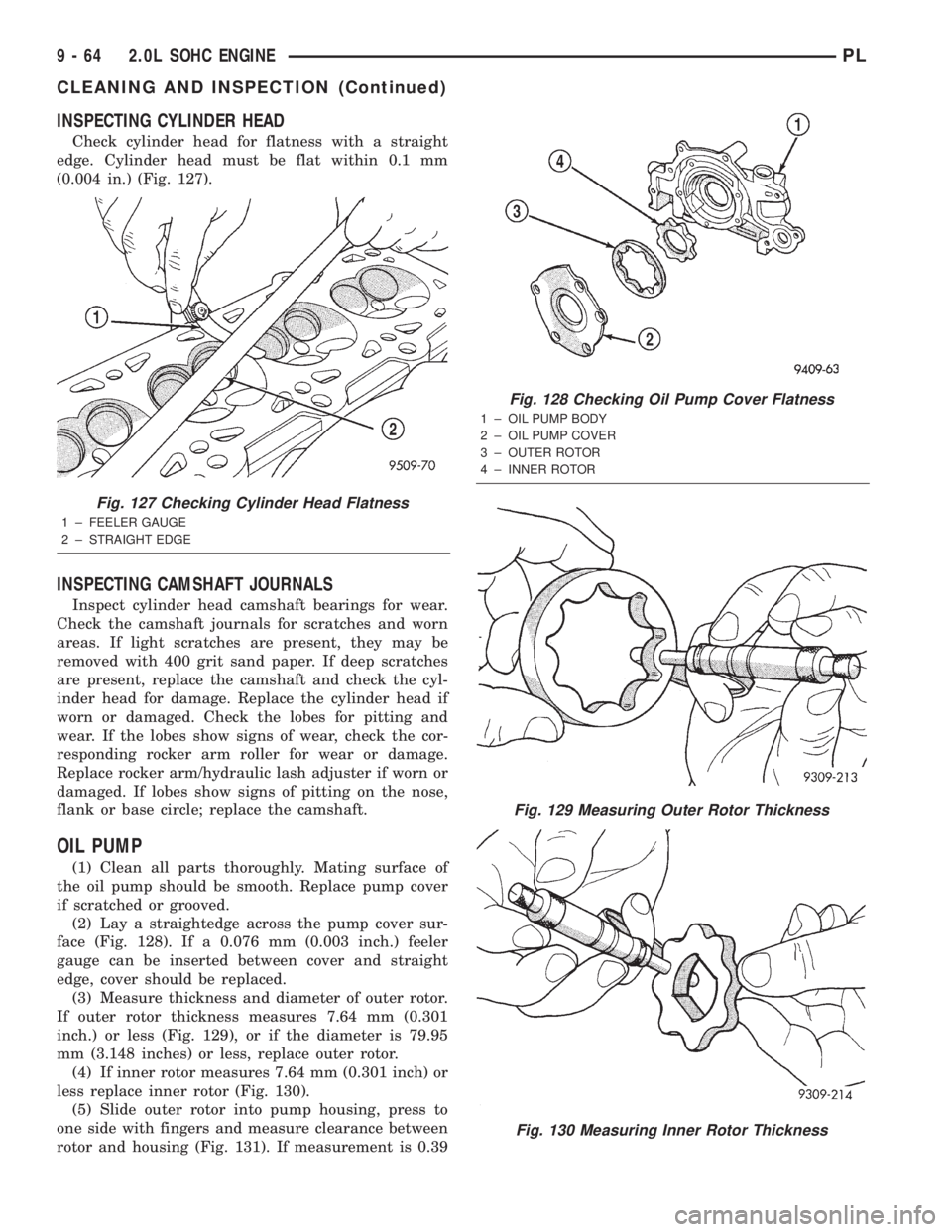

INSPECTING CYLINDER HEAD

Check cylinder head for flatness with a straight

edge. Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 127).

INSPECTING CAMSHAFT JOURNALS

Inspect cylinder head camshaft bearings for wear.

Check the camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head if

worn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 128). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 129), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (0.301 inch) or

less replace inner rotor (Fig. 130).

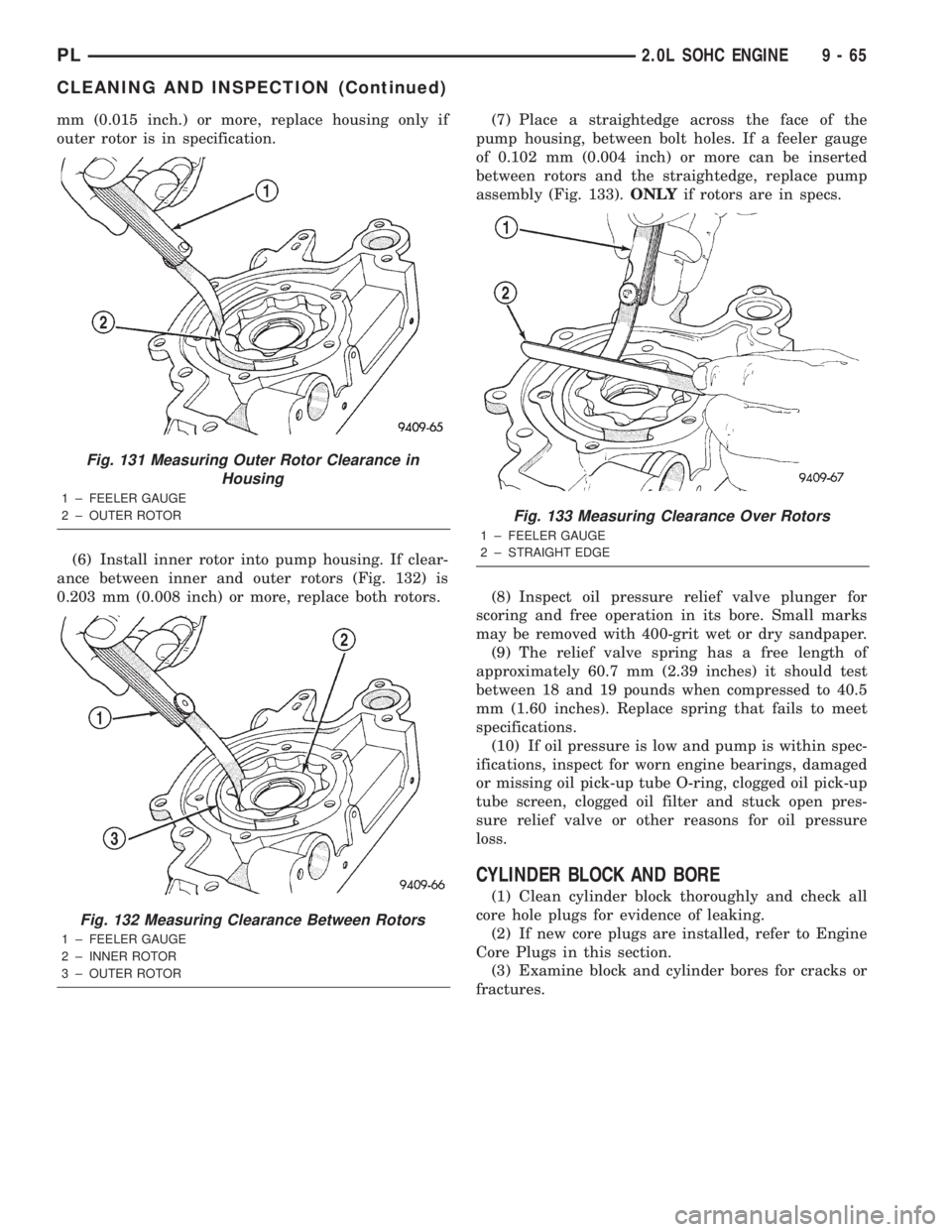

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 131). If measurement is 0.39

Fig. 127 Checking Cylinder Head Flatness

1 ± FEELER GAUGE

2 ± STRAIGHT EDGE

Fig. 128 Checking Oil Pump Cover Flatness

1 ± OIL PUMP BODY

2 ± OIL PUMP COVER

3 ± OUTER ROTOR

4 ± INNER ROTOR

Fig. 129 Measuring Outer Rotor Thickness

Fig. 130 Measuring Inner Rotor Thickness

9 - 64 2.0L SOHC ENGINEPL

CLEANING AND INSPECTION (Continued)

Page 788 of 1285

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

(6) Install inner rotor into pump housing. If clear-

ance between inner and outer rotors (Fig. 132) is

0.203 mm (0.008 inch) or more, replace both rotors.(7) Place a straightedge across the face of the

pump housing, between bolt holes. If a feeler gauge

of 0.102 mm (0.004 inch) or more can be inserted

between rotors and the straightedge, replace pump

assembly (Fig. 133).ONLYif rotors are in specs.

(8) Inspect oil pressure relief valve plunger for

scoring and free operation in its bore. Small marks

may be removed with 400-grit wet or dry sandpaper.

(9) The relief valve spring has a free length of

approximately 60.7 mm (2.39 inches) it should test

between 18 and 19 pounds when compressed to 40.5

mm (1.60 inches). Replace spring that fails to meet

specifications.

(10) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings, damaged

or missing oil pick-up tube O-ring, clogged oil pick-up

tube screen, clogged oil filter and stuck open pres-

sure relief valve or other reasons for oil pressure

loss.

CYLINDER BLOCK AND BORE

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, refer to Engine

Core Plugs in this section.

(3) Examine block and cylinder bores for cracks or

fractures.

Fig. 131 Measuring Outer Rotor Clearance in

Housing

1 ± FEELER GAUGE

2 ± OUTER ROTOR

Fig. 132 Measuring Clearance Between Rotors

1 ± FEELER GAUGE

2 ± INNER ROTOR

3 ± OUTER ROTOR

Fig. 133 Measuring Clearance Over Rotors

1 ± FEELER GAUGE

2 ± STRAIGHT EDGE

PL2.0L SOHC ENGINE 9 - 65

CLEANING AND INSPECTION (Continued)