lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 841 of 1285

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Accelerator Pedal to Dash Nuts......... 12N´m

(105 in. lbs.)

Fuel Pump Module Locknut . . . 55 N´m (40 ft. lbs.)

Fuel Tank Strap Bolts.....22.5 N´m (200 in. lbs.)

Fuel Rail Bolts............ 23N´m(195 in. lbs.)

Ignition Coil Mounting Bolts . . 11 N´m (95 in. lbs.)

Fig. 39 Retainer Clip

14 - 20 FUEL SYSTEMPL

SPECIFICATIONS (Continued)

Page 842 of 1285

FUEL INJECTION SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INJECTION SYSTEM......................22

MODES OF OPERATION...................22

SYSTEM DIAGNOSIS......................24

POWER DISTRIBUTION CENTER............24

POWERTRAIN CONTROL MODULE...........24

PCM GROUND...........................26

5 VOLT SUPPLYÐPCM OUTPUT.............26

8-VOLT SUPPLYÐPCM OUTPUT.............26

FUEL CORRECTION or ADAPTIVE MEMORIES . . 26

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS...................27

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT..............27

AUTOMATIC SHUTDOWN (ASD) SENSEÐ

PCM INPUT...........................27

BATTERY VOLTAGEÐPCM INPUT............28

BRAKE SWITCHÐPCM INPUT...............28

CAMSHAFT POSITION SENSORÐPCM INPUT . . 28

CLUTCH INTERLOCK/UPSTOP SWITCH.......29

CRANKSHAFT POSITION SENSORÐPCM

INPUT................................30

ENGINE COOLANT TEMPERATURE

SENSORÐPCM INPUT...................30

FUEL LEVEL SENSORÐPCM INPUT..........31

HEATED OXYGEN SENSOR (O2 SENSOR)Ð

PCM INPUT...........................32

IGNITION CIRCUIT SENSEÐPCM INPUT......34

INLET AIR TEMPERATURE SENSORÐPCM

INPUT................................34

KNOCK SENSORÐPCM INPUT..............34

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT...................35

POWER STEERING PRESSURE SWITCHÐ

PCM INPUT...........................35

SENSOR RETURNÐPCM INPUT.............35

SPEED CONTROLÐPCM INPUT.............36

SCI RECEIVEÐPCM INPUT.................36

PARK/NEUTRAL POSITION SWITCHÐPCM

INPUT................................36

THROTTLE POSITION SENSORÐPCM INPUT . . 36VEHICLE SPEED SIGNAL (VSS)ÐPCM INPUT . . 37

AIR CONDITIONING CLUTCH RELAYÐPCM

OUTPUT..............................38

AUTOMATIC SHUTDOWN RELAYÐPCM

OUTPUT..............................38

CHARGING SYSTEM INDICATOR LAMPÐPCM

OUTPUT..............................38

FUEL PUMP RELAYÐPCM OUTPUT..........38

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT..............................39

GENERATOR FIELDÐPCM OUTPUT..........39

IDLE AIR CONTROL MOTORÐPCM OUTPUT . . . 39

DATA LINK CONNECTOR...................40

FUEL INJECTORSÐPCM OUTPUT...........40

IGNITION COILÐPCM OUTPUT..............40

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT...................41

SPEED CONTROLÐPCM INPUT.............41

SCI RECEIVEÐPCM OUTPUT...............41

TACHOMETERÐPCM OUTPUT..............42

TORQUE CONVERTOR CLUTCH SOLENOIDÐ

PCM OUTPUT..........................42

REMOVAL AND INSTALLATION

THROTTLE BODY........................42

THROTTLE POSITION SENSOR.............43

IDLE AIR CONTROL MOTOR................43

MAP SENSOR...........................44

POWERTRAIN CONTROL MODULE (PCM).....44

UPSTREAM HEATED OXYGEN SENSOR......45

DOWNSTREAM HEATED OXYGEN SENSOR

1/2 ..................................46

AIR CLEANER BOX.......................46

AIR CLEANER ELEMENT...................47

ENGINE COOLANT TEMPERATURE SENSOR . . . 47

VEHICLE SPEED SENSOR.................47

KNOCK SENSOR.........................48

SPECIFICATIONS

VECI LABEL.............................49

TORQUE...............................49

SPECIAL TOOLS

FUEL..................................49

PLFUEL SYSTEM 14 - 21

Page 850 of 1285

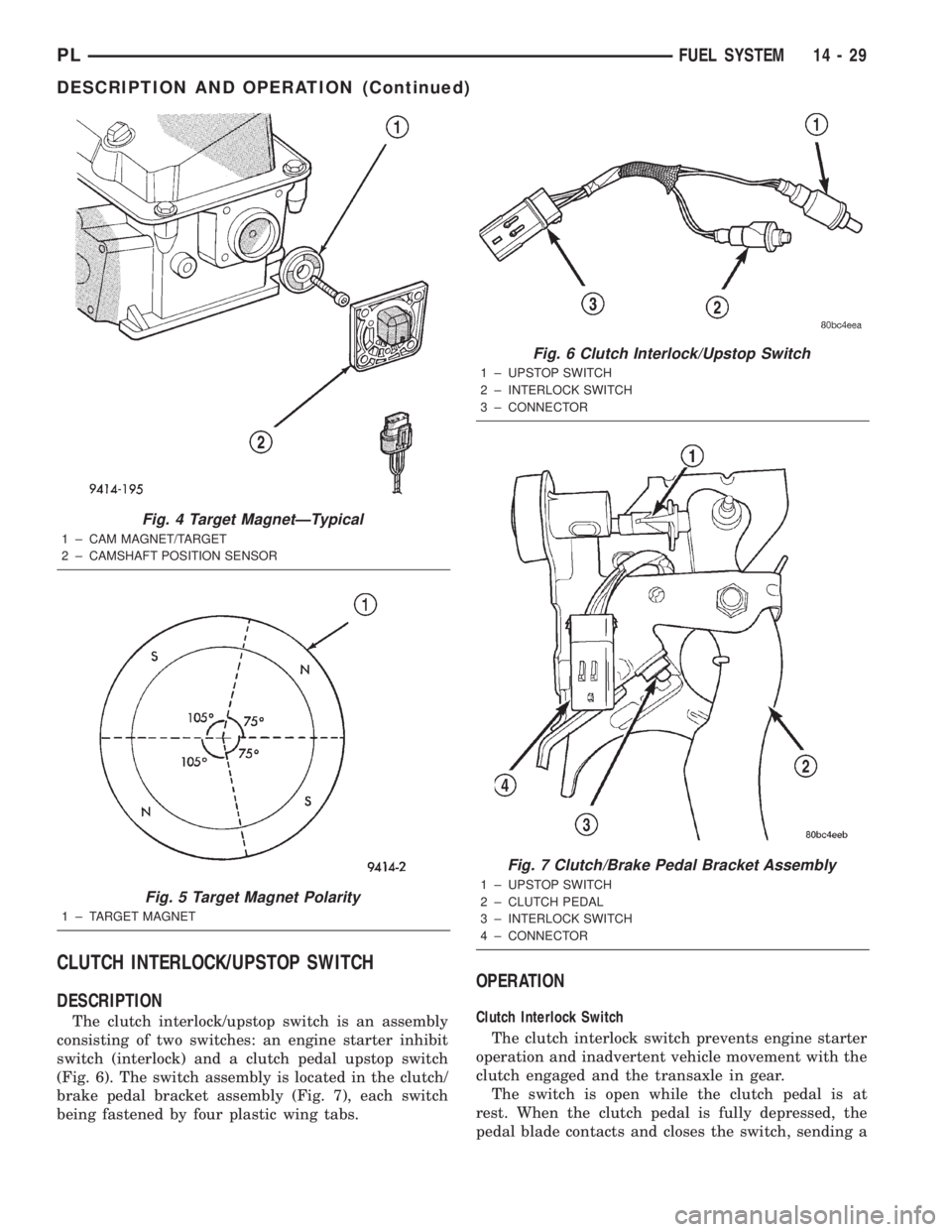

CLUTCH INTERLOCK/UPSTOP SWITCH

DESCRIPTION

The clutch interlock/upstop switch is an assembly

consisting of two switches: an engine starter inhibit

switch (interlock) and a clutch pedal upstop switch

(Fig. 6). The switch assembly is located in the clutch/

brake pedal bracket assembly (Fig. 7), each switch

being fastened by four plastic wing tabs.

OPERATION

Clutch Interlock Switch

The clutch interlock switch prevents engine starter

operation and inadvertent vehicle movement with the

clutch engaged and the transaxle in gear.

The switch is open while the clutch pedal is at

rest. When the clutch pedal is fully depressed, the

pedal blade contacts and closes the switch, sending a

Fig. 4 Target MagnetÐTypical

1 ± CAM MAGNET/TARGET

2 ± CAMSHAFT POSITION SENSOR

Fig. 5 Target Magnet Polarity

1 ± TARGET MAGNET

Fig. 6 Clutch Interlock/Upstop Switch

1 ± UPSTOP SWITCH

2 ± INTERLOCK SWITCH

3 ± CONNECTOR

Fig. 7 Clutch/Brake Pedal Bracket Assembly

1 ± UPSTOP SWITCH

2 ± CLUTCH PEDAL

3 ± INTERLOCK SWITCH

4 ± CONNECTOR

PLFUEL SYSTEM 14 - 29

DESCRIPTION AND OPERATION (Continued)

Page 851 of 1285

signal to the PCM, allowing engine starter operation.

The interlock switch is not adjustable.

Clutch Pedal Upstop Switch

With the clutch pedal at rest, the clutch pedal

upstop switch is closed, allowing speed control oper-

ation. When the clutch pedal is depressed, the upstop

switch opens and signals the PCM to cancel speed

control operation, and enter a modified engine cali-

bration schedule to improve driveability during gear-

to-gear shifts. The upstop switch is not adjustable.

CRANKSHAFT POSITION SENSORÐPCM

INPUT

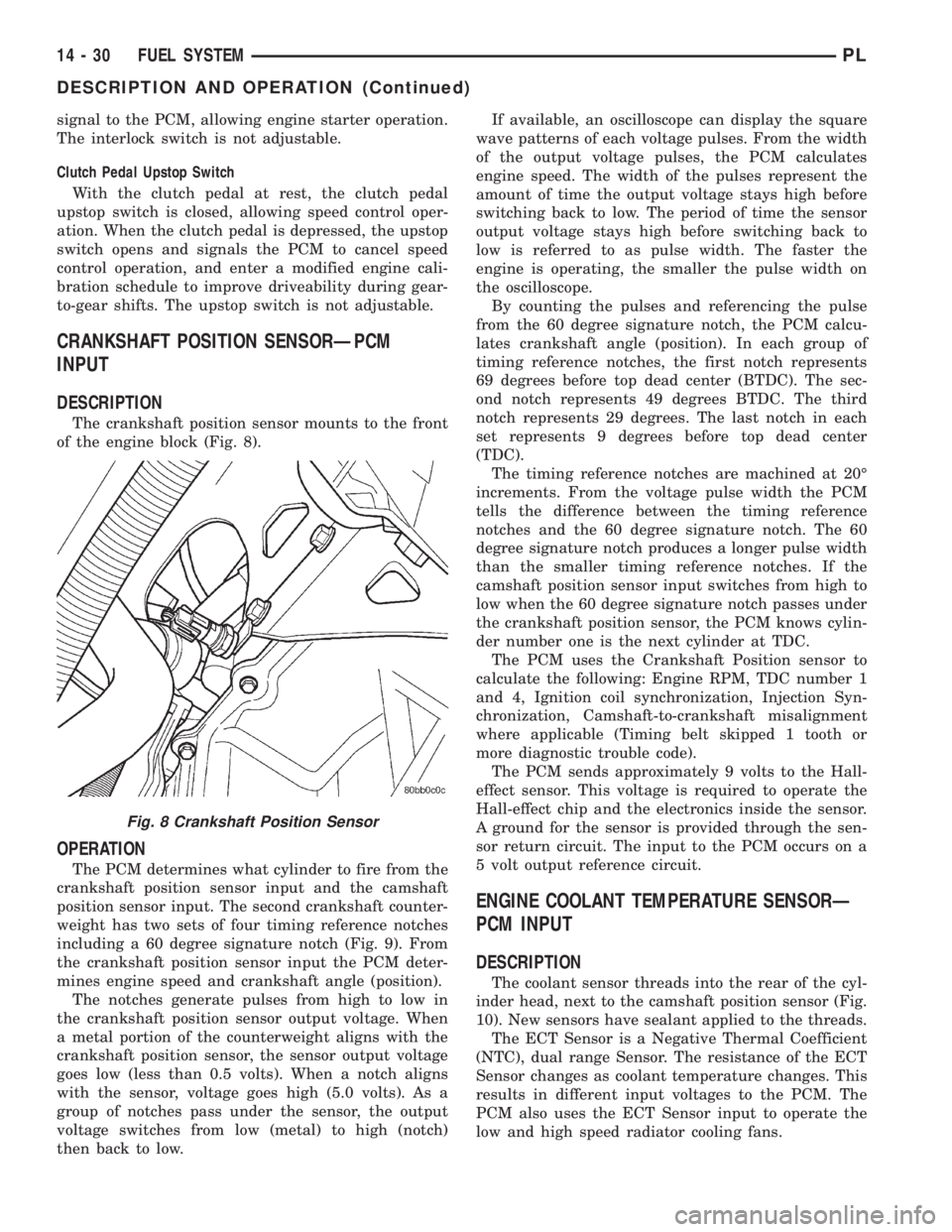

DESCRIPTION

The crankshaft position sensor mounts to the front

of the engine block (Fig. 8).

OPERATION

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 9). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The PCM uses the Crankshaft Position sensor to

calculate the following: Engine RPM, TDC number 1

and 4, Ignition coil synchronization, Injection Syn-

chronization, Camshaft-to-crankshaft misalignment

where applicable (Timing belt skipped 1 tooth or

more diagnostic trouble code).

The PCM sends approximately 9 volts to the Hall-

effect sensor. This voltage is required to operate the

Hall-effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT

DESCRIPTION

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

10). New sensors have sealant applied to the threads.

The ECT Sensor is a Negative Thermal Coefficient

(NTC), dual range Sensor. The resistance of the ECT

Sensor changes as coolant temperature changes. This

results in different input voltages to the PCM. The

PCM also uses the ECT Sensor input to operate the

low and high speed radiator cooling fans.

Fig. 8 Crankshaft Position Sensor

14 - 30 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 855 of 1285

IGNITION CIRCUIT SENSEÐPCM INPUT

OPERATION

The ignition circuit sense input tells the Power-

train Control Module (PCM) the ignition switch has

energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the Ignition Switch when the ignition is in

the RUN or START position. This is called the9igni-

tion senseº circuit and is used to ªwake upº the PCM.

Voltage on the ignition input can be as low as 6 volts

and the PCM will still function. Voltage is supplied to

this circuit to power the 8-volt regulator and to allow

the PCM to perform fuel, ignition and emissions con-

trol functions. The battery voltage on this line is sup-

plied to the 8-volt regulator which then passes on a

power-up supply to the 5-volt regulator.

INLET AIR TEMPERATURE SENSORÐPCM

INPUT

DESCRIPTION

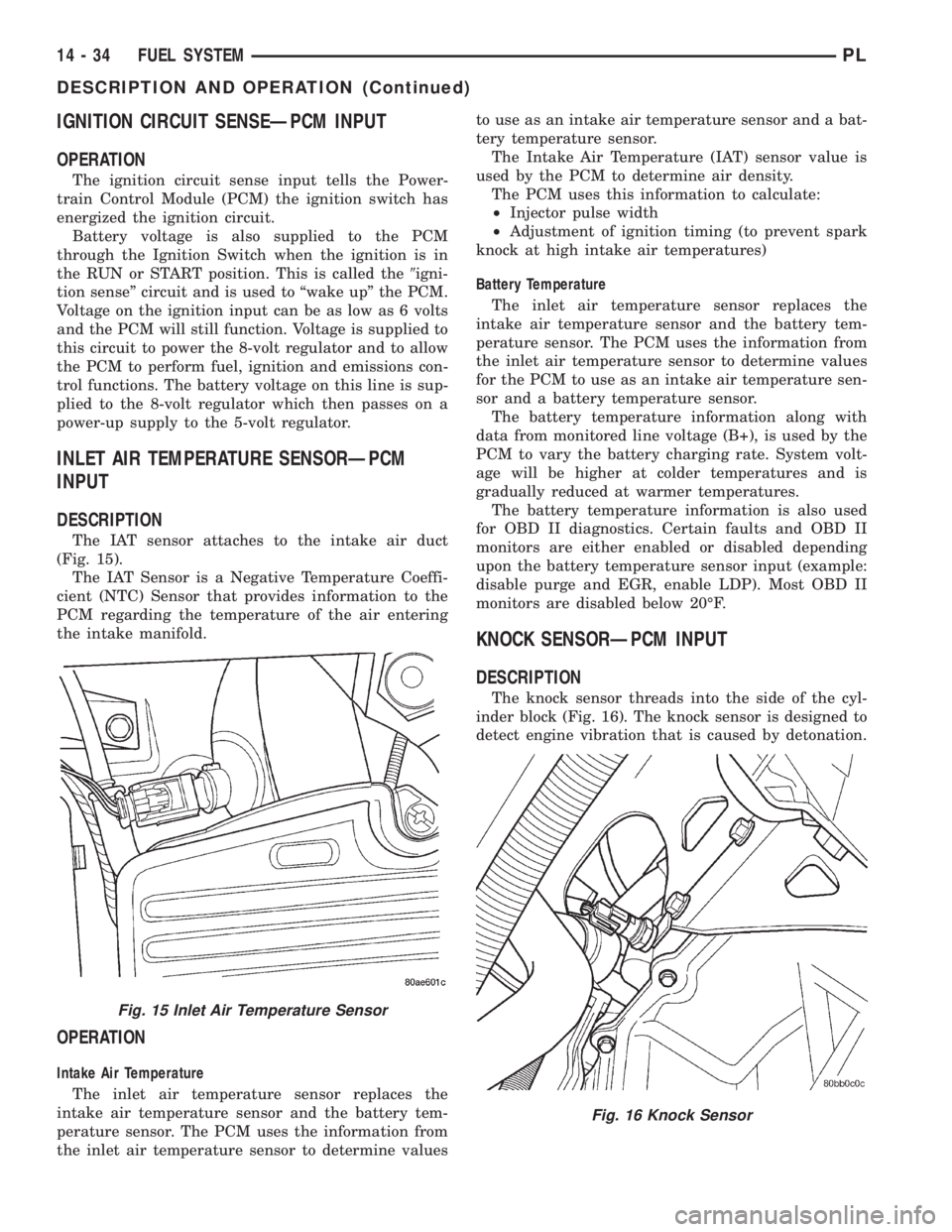

The IAT sensor attaches to the intake air duct

(Fig. 15).

The IAT Sensor is a Negative Temperature Coeffi-

cient (NTC) Sensor that provides information to the

PCM regarding the temperature of the air entering

the intake manifold.

OPERATION

Intake Air Temperature

The inlet air temperature sensor replaces the

intake air temperature sensor and the battery tem-

perature sensor. The PCM uses the information from

the inlet air temperature sensor to determine valuesto use as an intake air temperature sensor and a bat-

tery temperature sensor.

The Intake Air Temperature (IAT) sensor value is

used by the PCM to determine air density.

The PCM uses this information to calculate:

²Injector pulse width

²Adjustment of ignition timing (to prevent spark

knock at high intake air temperatures)

Battery Temperature

The inlet air temperature sensor replaces the

intake air temperature sensor and the battery tem-

perature sensor. The PCM uses the information from

the inlet air temperature sensor to determine values

for the PCM to use as an intake air temperature sen-

sor and a battery temperature sensor.

The battery temperature information along with

data from monitored line voltage (B+), is used by the

PCM to vary the battery charging rate. System volt-

age will be higher at colder temperatures and is

gradually reduced at warmer temperatures.

The battery temperature information is also used

for OBD II diagnostics. Certain faults and OBD II

monitors are either enabled or disabled depending

upon the battery temperature sensor input (example:

disable purge and EGR, enable LDP). Most OBD II

monitors are disabled below 20ÉF.

KNOCK SENSORÐPCM INPUT

DESCRIPTION

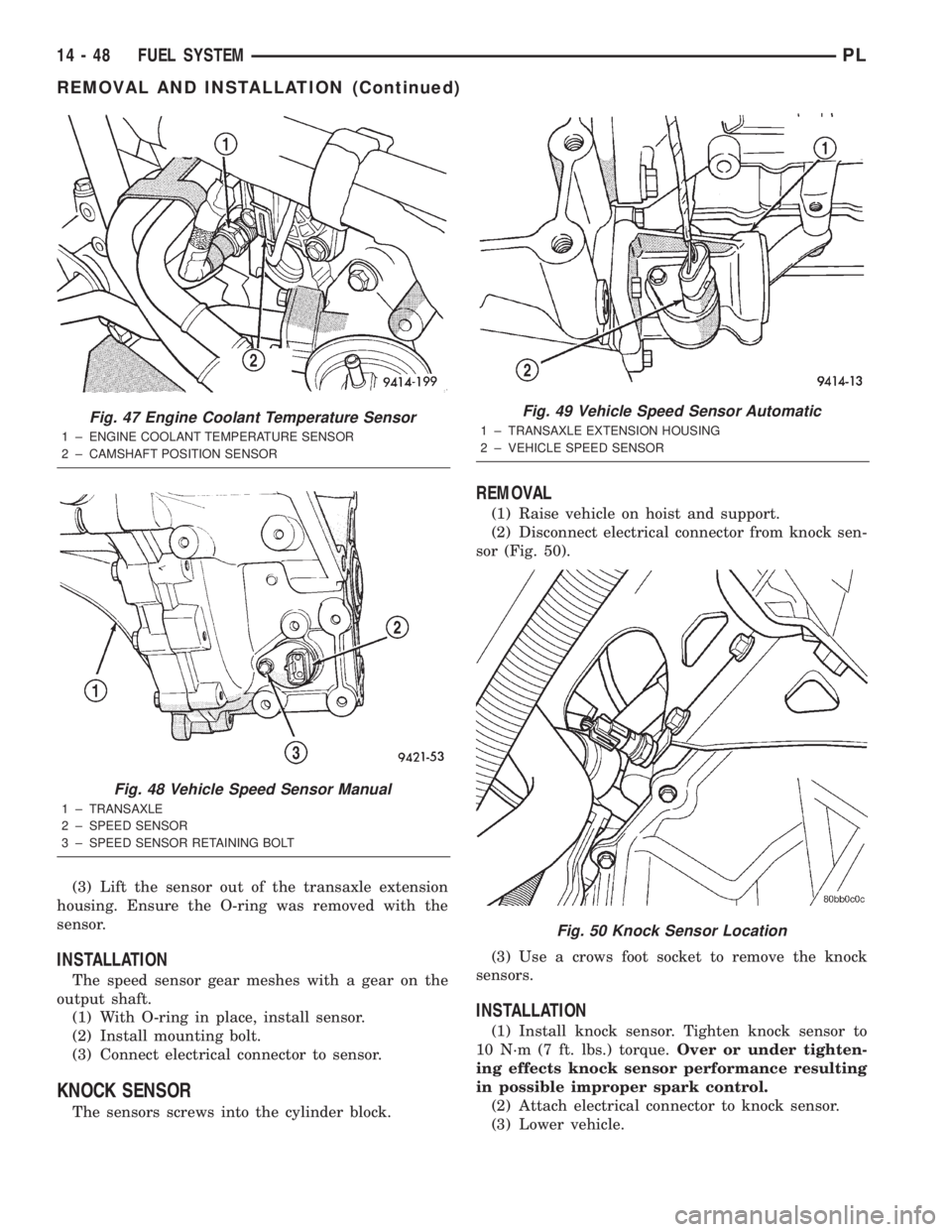

The knock sensor threads into the side of the cyl-

inder block (Fig. 16). The knock sensor is designed to

detect engine vibration that is caused by detonation.

Fig. 15 Inlet Air Temperature Sensor

Fig. 16 Knock Sensor

14 - 34 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 869 of 1285

(3) Lift the sensor out of the transaxle extension

housing. Ensure the O-ring was removed with the

sensor.

INSTALLATION

The speed sensor gear meshes with a gear on the

output shaft.

(1) With O-ring in place, install sensor.

(2) Install mounting bolt.

(3) Connect electrical connector to sensor.

KNOCK SENSOR

The sensors screws into the cylinder block.

REMOVAL

(1) Raise vehicle on hoist and support.

(2) Disconnect electrical connector from knock sen-

sor (Fig. 50).

(3) Use a crows foot socket to remove the knock

sensors.

INSTALLATION

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance resulting

in possible improper spark control.

(2) Attach electrical connector to knock sensor.

(3) Lower vehicle.

Fig. 47 Engine Coolant Temperature Sensor

1 ± ENGINE COOLANT TEMPERATURE SENSOR

2 ± CAMSHAFT POSITION SENSOR

Fig. 48 Vehicle Speed Sensor Manual

1 ± TRANSAXLE

2 ± SPEED SENSOR

3 ± SPEED SENSOR RETAINING BOLT

Fig. 49 Vehicle Speed Sensor Automatic

1 ± TRANSAXLE EXTENSION HOUSING

2 ± VEHICLE SPEED SENSOR

Fig. 50 Knock Sensor Location

14 - 48 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 879 of 1285

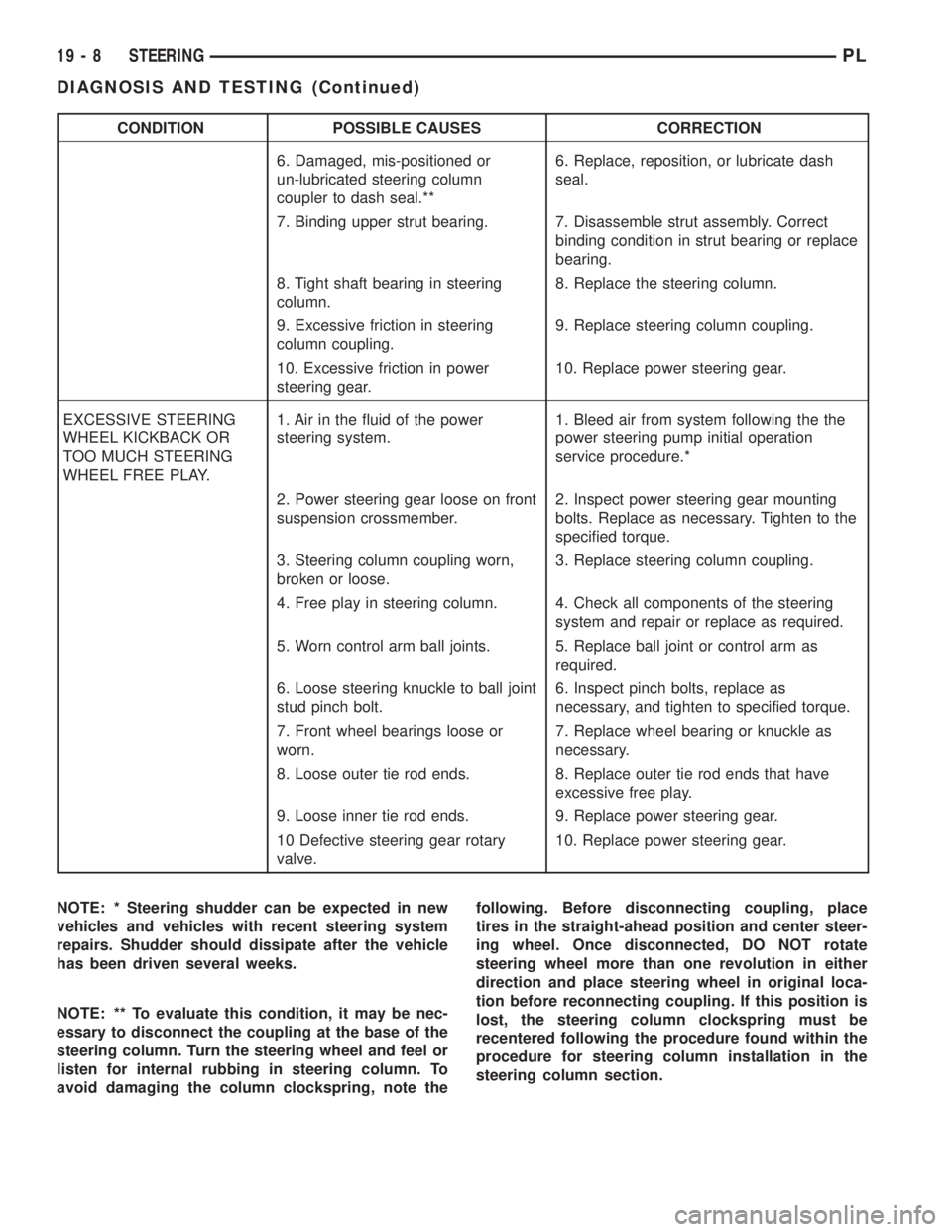

CONDITION POSSIBLE CAUSES CORRECTION

6. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding upper strut bearing. 7. Disassemble strut assembly. Correct

binding condition in strut bearing or replace

bearing.

8. Tight shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on front

suspension crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling worn,

broken or loose.3. Replace steering column coupling.

4. Free play in steering column. 4. Check all components of the steering

system and repair or replace as required.

5. Worn control arm ball joints. 5. Replace ball joint or control arm as

required.

6. Loose steering knuckle to ball joint

stud pinch bolt.6. Inspect pinch bolts, replace as

necessary, and tighten to specified torque.

7. Front wheel bearings loose or

worn.7. Replace wheel bearing or knuckle as

necessary.

8. Loose outer tie rod ends. 8. Replace outer tie rod ends that have

excessive free play.

9. Loose inner tie rod ends. 9. Replace power steering gear.

10 Defective steering gear rotary

valve.10. Replace power steering gear.

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering system

repairs. Shudder should dissipate after the vehicle

has been driven several weeks.

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note thefollowing. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotate

steering wheel more than one revolution in either

direction and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

19 - 8 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 885 of 1285

(3) Install the hose clamp on the power steering

cooler fluid hose past the bead formed into the steel

fitting and secure in place.

(4) Install the two screws attaching the cooler to

the front suspension crossmember. Tighten the cooler

attaching screws to a torque of 10 N´m (90 in. lbs.).

(5) Install the power steering fluid return hose on

the power steering fluid cooler tube. Install the hose

clamp on the power steering return hose securing it

to the power steering cooler. Be sure the hose clamp

is installed on the return hose past the bead on the

end of the cooler tube.

(6) Lower the vehicle.

(7) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(8) Check for leaks at all connections.

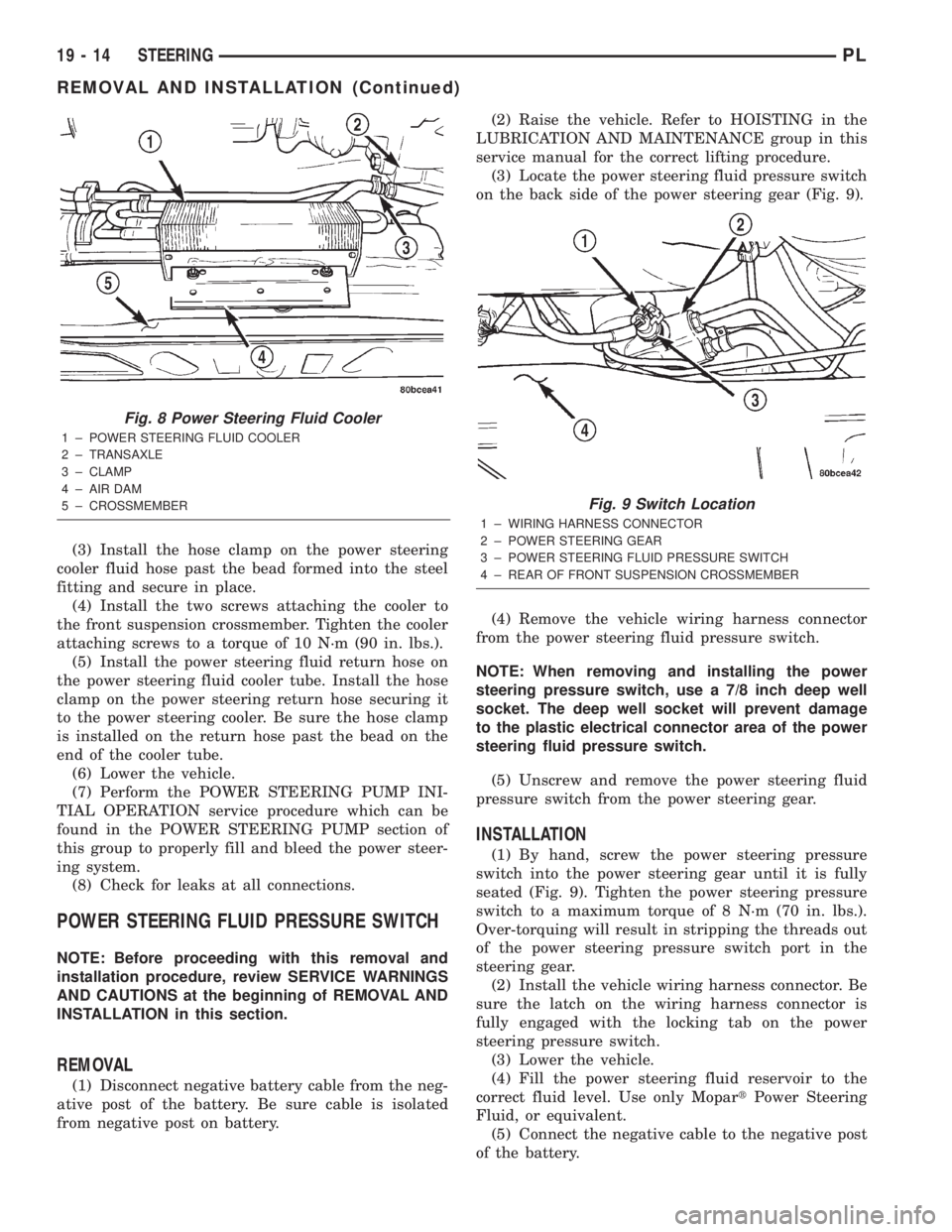

POWER STEERING FLUID PRESSURE SWITCH

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Disconnect negative battery cable from the neg-

ative post of the battery. Be sure cable is isolated

from negative post on battery.(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Locate the power steering fluid pressure switch

on the back side of the power steering gear (Fig. 9).

(4) Remove the vehicle wiring harness connector

from the power steering fluid pressure switch.

NOTE: When removing and installing the power

steering pressure switch, use a 7/8 inch deep well

socket. The deep well socket will prevent damage

to the plastic electrical connector area of the power

steering fluid pressure switch.

(5) Unscrew and remove the power steering fluid

pressure switch from the power steering gear.

INSTALLATION

(1) By hand, screw the power steering pressure

switch into the power steering gear until it is fully

seated (Fig. 9). Tighten the power steering pressure

switch to a maximum torque of 8 N´m (70 in. lbs.).

Over-torquing will result in stripping the threads out

of the power steering pressure switch port in the

steering gear.

(2) Install the vehicle wiring harness connector. Be

sure the latch on the wiring harness connector is

fully engaged with the locking tab on the power

steering pressure switch.

(3) Lower the vehicle.

(4) Fill the power steering fluid reservoir to the

correct fluid level. Use only MopartPower Steering

Fluid, or equivalent.

(5) Connect the negative cable to the negative post

of the battery.

Fig. 8 Power Steering Fluid Cooler

1 ± POWER STEERING FLUID COOLER

2 ± TRANSAXLE

3 ± CLAMP

4 ± AIR DAM

5 ± CROSSMEMBER

Fig. 9 Switch Location

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 14 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 888 of 1285

reduces the power required to drive the pump and

holds down temperature build-up.

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops, the pressure built up in the

steering gear exerts pressure on the spring end of the

flow control valve. The high pressure lifts the relief

valve ball from its seat and allows oil to flow through

a trigger orifice located in the outlet fitting. This

reduces pressure on the spring end of the flow con-

trol valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level.

Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to

remain closed.

POWER STEERING FLUID RESERVOIR

The power steering fluid reservoir is mounted on

the power steering pump using 3 bolts (Fig. 1). It

stores fluid for the power steering system.

The power steering fluid reservoir is considered an

integral part of the power steering pump and is not

serviced separately.

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe the filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature, approximately 21ÉC to 27ÉC

(70ÉF to 80ÉF).

(1) Fill the power steering fluid reservoir to the

proper level and let the fluid settle for at least two

minutes.

(2) Start the engine and let run for a few seconds,

then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING PUMP

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Remove battery cable from the negative post on

the battery.

(2) Siphon as much fluid as possible from the

power steering fluid reservoir.

(3) Remove the power steering pump drive belt

from the power steering pump pulley. Refer to

ACCESSORY DRIVE BELTS in the COOLING SYS-

TEM service manual group for the required removal

and installation procedure.

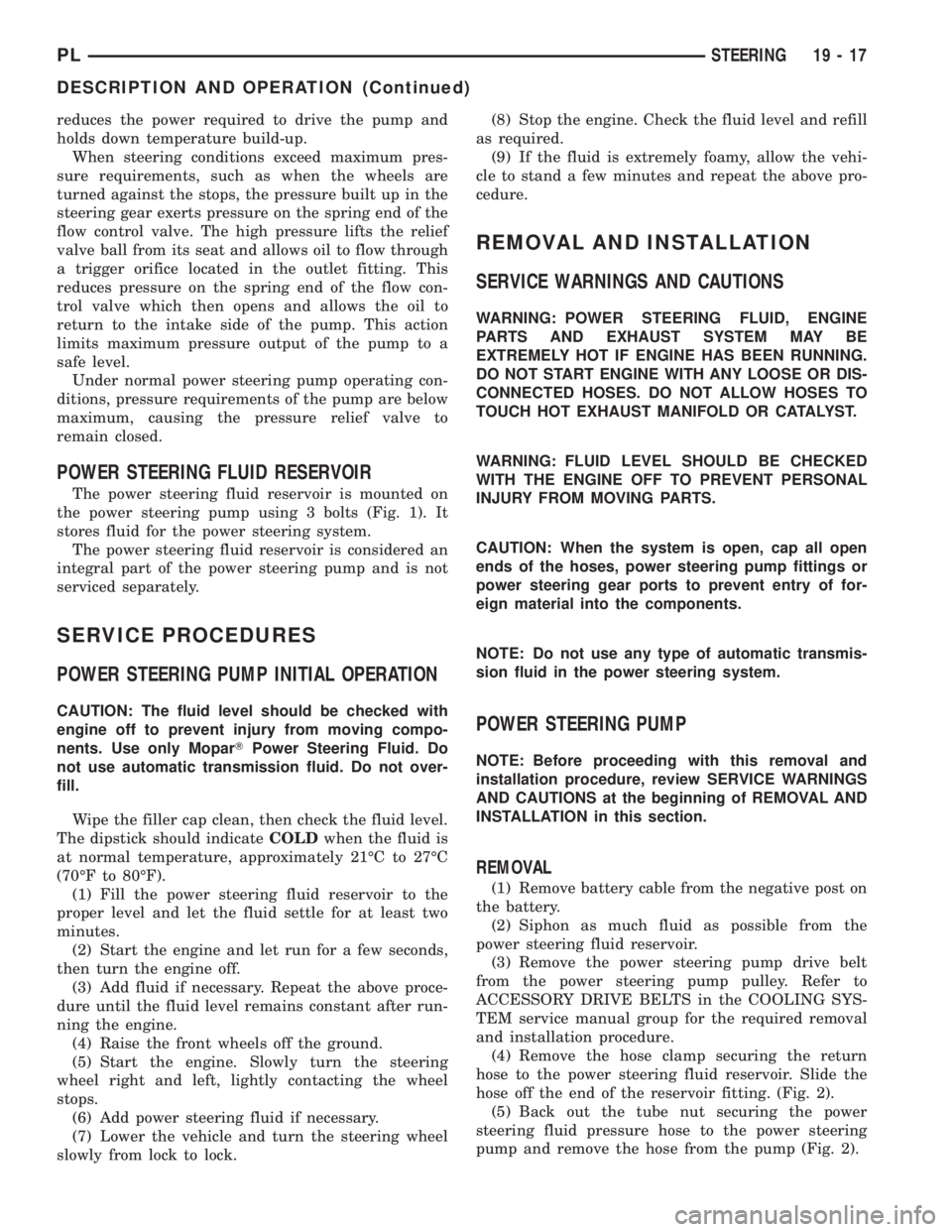

(4) Remove the hose clamp securing the return

hose to the power steering fluid reservoir. Slide the

hose off the end of the reservoir fitting. (Fig. 2).

(5) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 2).

PLSTEERING 19 - 17

DESCRIPTION AND OPERATION (Continued)

Page 889 of 1285

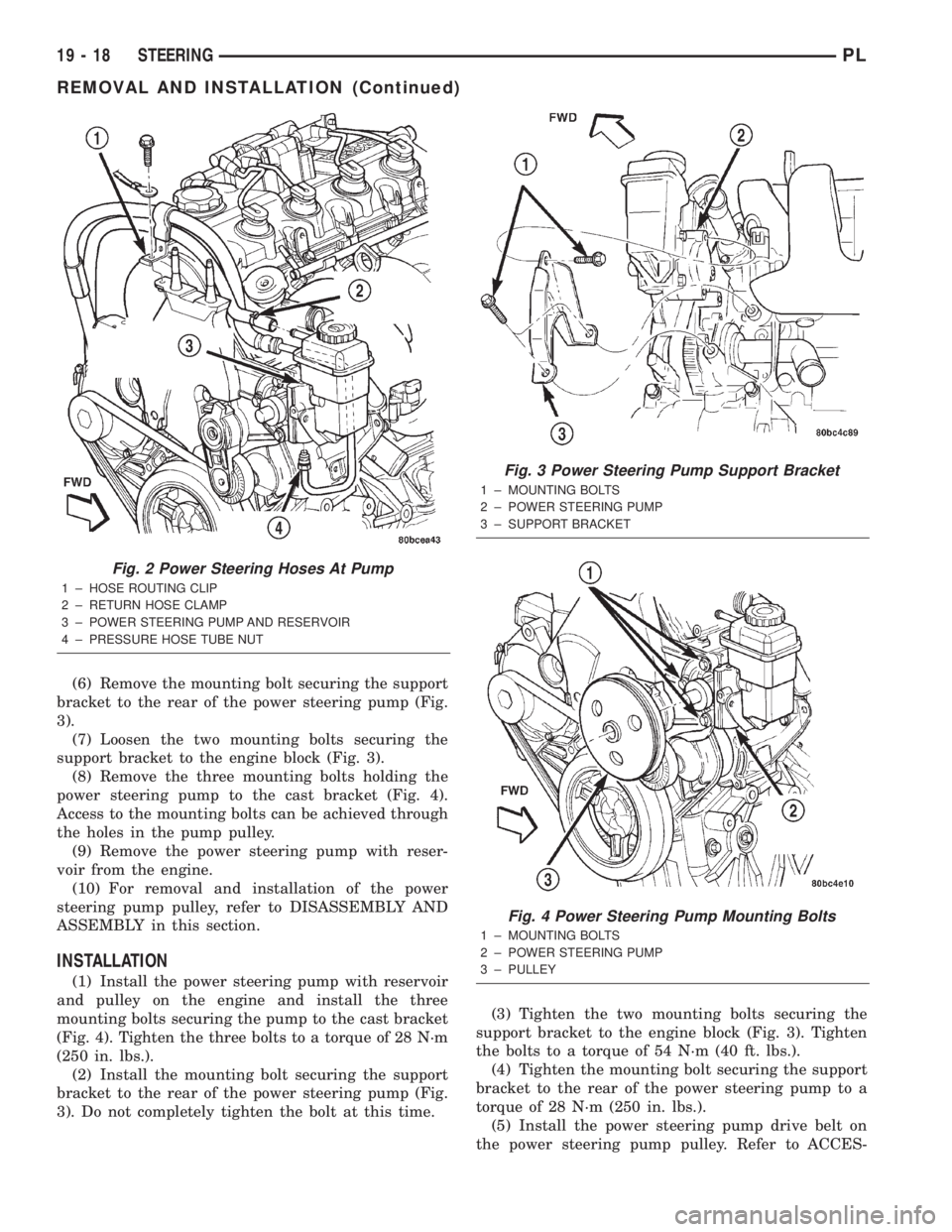

(6) Remove the mounting bolt securing the support

bracket to the rear of the power steering pump (Fig.

3).

(7) Loosen the two mounting bolts securing the

support bracket to the engine block (Fig. 3).

(8) Remove the three mounting bolts holding the

power steering pump to the cast bracket (Fig. 4).

Access to the mounting bolts can be achieved through

the holes in the pump pulley.

(9) Remove the power steering pump with reser-

voir from the engine.

(10) For removal and installation of the power

steering pump pulley, refer to DISASSEMBLY AND

ASSEMBLY in this section.

INSTALLATION

(1) Install the power steering pump with reservoir

and pulley on the engine and install the three

mounting bolts securing the pump to the cast bracket

(Fig. 4). Tighten the three bolts to a torque of 28 N´m

(250 in. lbs.).

(2) Install the mounting bolt securing the support

bracket to the rear of the power steering pump (Fig.

3). Do not completely tighten the bolt at this time.(3) Tighten the two mounting bolts securing the

support bracket to the engine block (Fig. 3). Tighten

the bolts to a torque of 54 N´m (40 ft. lbs.).

(4) Tighten the mounting bolt securing the support

bracket to the rear of the power steering pump to a

torque of 28 N´m (250 in. lbs.).

(5) Install the power steering pump drive belt on

the power steering pump pulley. Refer to ACCES-

Fig. 2 Power Steering Hoses At Pump

1 ± HOSE ROUTING CLIP

2 ± RETURN HOSE CLAMP

3 ± POWER STEERING PUMP AND RESERVOIR

4 ± PRESSURE HOSE TUBE NUT

Fig. 3 Power Steering Pump Support Bracket

1 ± MOUNTING BOLTS

2 ± POWER STEERING PUMP

3 ± SUPPORT BRACKET

Fig. 4 Power Steering Pump Mounting Bolts

1 ± MOUNTING BOLTS

2 ± POWER STEERING PUMP

3 ± PULLEY

19 - 18 STEERINGPL

REMOVAL AND INSTALLATION (Continued)