tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 888 of 1285

reduces the power required to drive the pump and

holds down temperature build-up.

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops, the pressure built up in the

steering gear exerts pressure on the spring end of the

flow control valve. The high pressure lifts the relief

valve ball from its seat and allows oil to flow through

a trigger orifice located in the outlet fitting. This

reduces pressure on the spring end of the flow con-

trol valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level.

Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to

remain closed.

POWER STEERING FLUID RESERVOIR

The power steering fluid reservoir is mounted on

the power steering pump using 3 bolts (Fig. 1). It

stores fluid for the power steering system.

The power steering fluid reservoir is considered an

integral part of the power steering pump and is not

serviced separately.

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe the filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature, approximately 21ÉC to 27ÉC

(70ÉF to 80ÉF).

(1) Fill the power steering fluid reservoir to the

proper level and let the fluid settle for at least two

minutes.

(2) Start the engine and let run for a few seconds,

then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING PUMP

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Remove battery cable from the negative post on

the battery.

(2) Siphon as much fluid as possible from the

power steering fluid reservoir.

(3) Remove the power steering pump drive belt

from the power steering pump pulley. Refer to

ACCESSORY DRIVE BELTS in the COOLING SYS-

TEM service manual group for the required removal

and installation procedure.

(4) Remove the hose clamp securing the return

hose to the power steering fluid reservoir. Slide the

hose off the end of the reservoir fitting. (Fig. 2).

(5) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 2).

PLSTEERING 19 - 17

DESCRIPTION AND OPERATION (Continued)

Page 892 of 1285

STEERING GEAR

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER STEERING GEAR..................21

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........22

POWER STEERING GEAR..................22

OUTER TIE ROD.........................26SPECIFICATIONS

POWER STEERING GEAR FASTENER

TORQUE SPECIFICATIONS...............28

SPECIAL TOOLS

POWER STEERING GEAR..................28

DESCRIPTION AND OPERATION

POWER STEERING GEAR

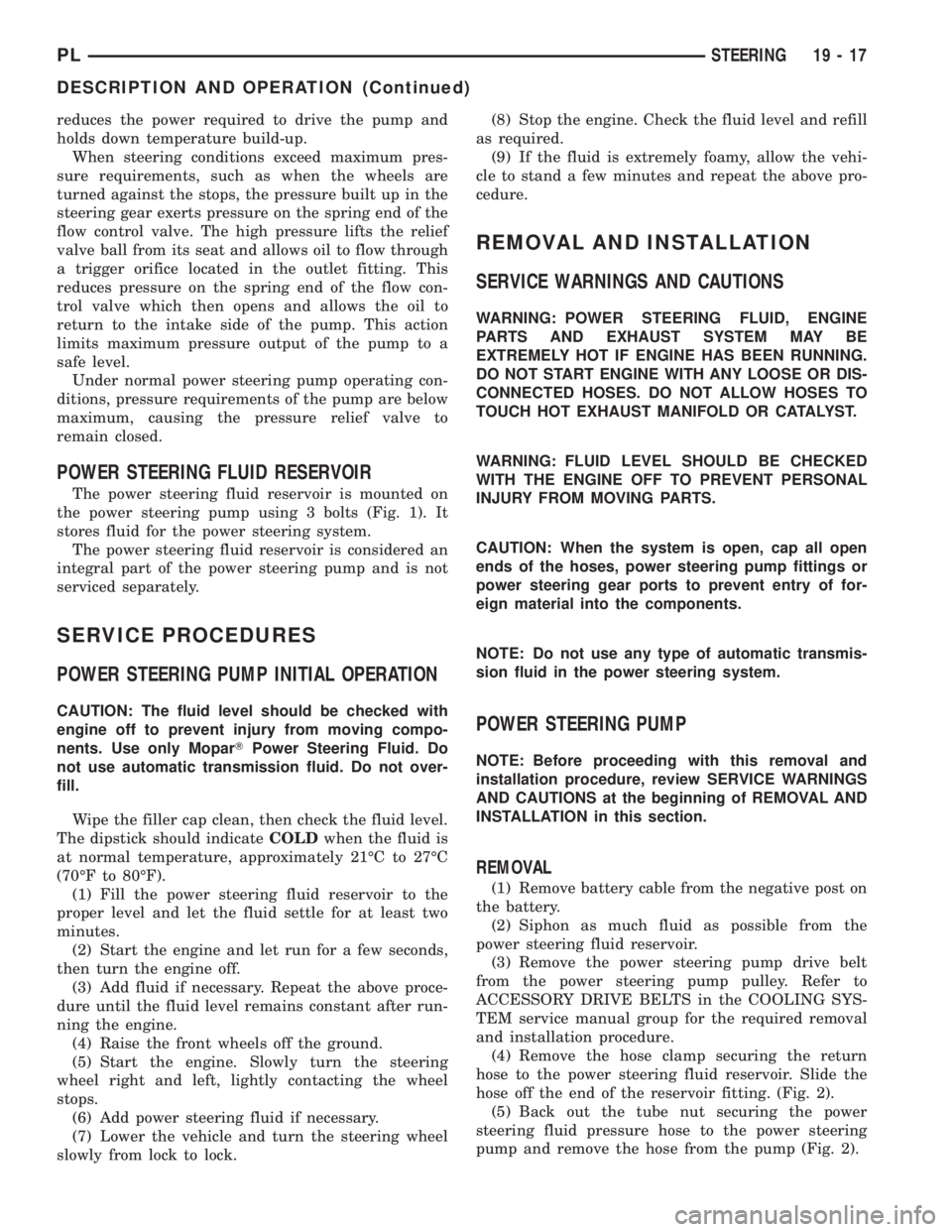

The power steering gear is mounted on the front

suspension crossmember (Fig. 1). The outer ends of

the outer tie rods attach to the steering knuckles.

The power steering gear operates as follows: Turn-

ing of the steering wheel is converted into linear

travel through the meshing of the helical pinion

teeth with the rack teeth of the gear. Power assist

steering is provided by a pump supplying fluid to

either side of the integral rack piston.Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. This movement

directs oil behind the integral rack piston, which, in

turn, builds up hydraulic pressure and assists in the

turning effort.

The drive tangs on the pinion of the power steering

gear mate loosely with a stub shaft. This is to permit

manual steering control to be maintained if the drive

belt on the power steering pump should break. How-

ever, under these conditions, steering effort will be

increased.

Fig. 1 Power Steering Gear

1 ± OUTER TIE ROD

2 ± JAM NUT3 ± STEERING GEAR

4 ± FRONT SUSPENSION CROSSMEMBER

PLSTEERING 19 - 21

Page 893 of 1285

NOTE: The power steering gear should not be ser-

viced or adjusted. If a malfunction or oil leak occurs

with the steering gear, the complete steering gear

needs to be replaced.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING GEAR

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

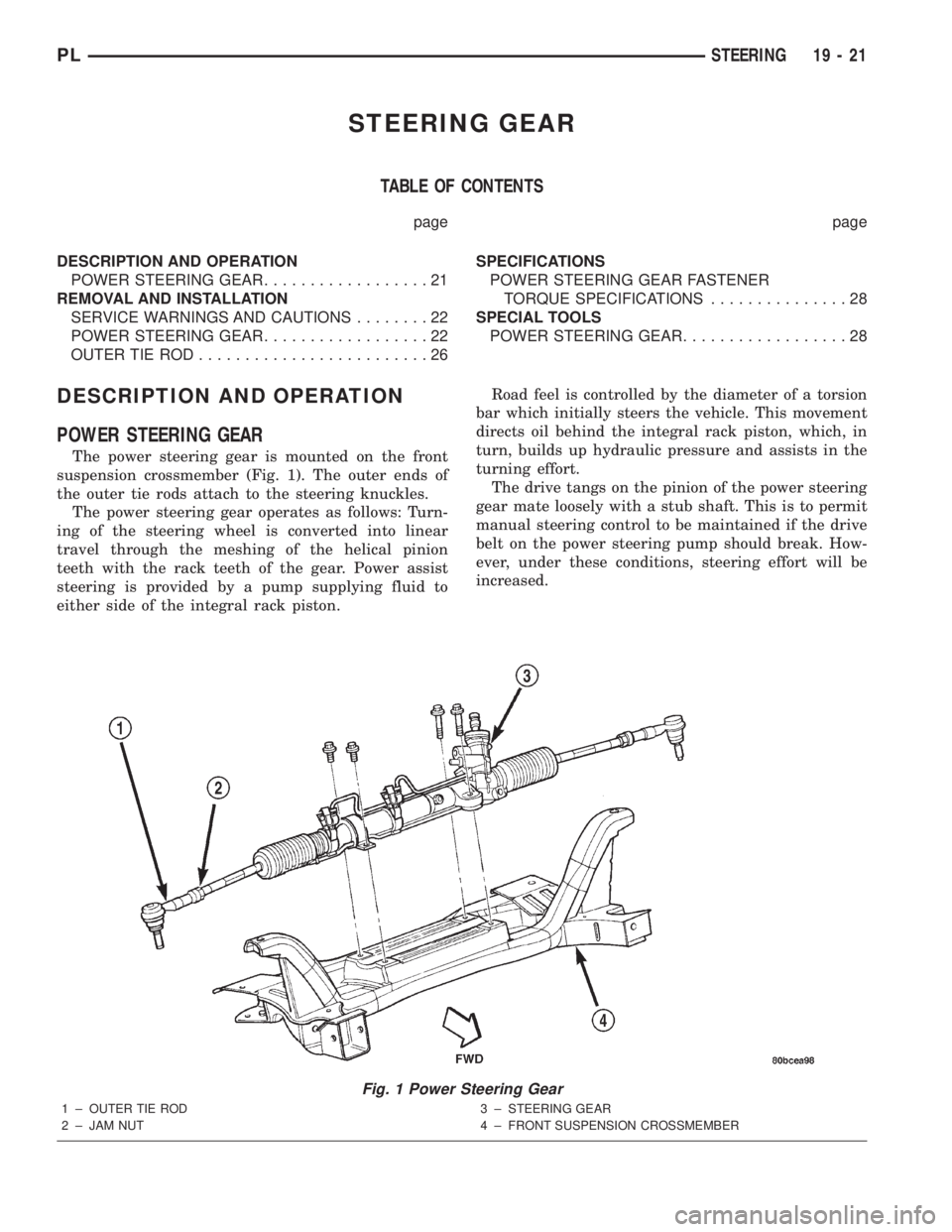

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 2). This keeps the clockspring in the proper ori-

entation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 3) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Remove both front tire and wheel assemblies

from the vehicle.

(5) Remove nuts attaching both outer tie rods to

the steering knuckles (Fig. 4). Remove each nut by

holding the tie rod stud stationary while loosening

and removing the nut with a wrench.

(6) Remove the outer tie rod from the steering

knuckles using Remover, Special Tool MB991113

(Fig. 5).

(7) Remove the tie rod heat shield.

Fig. 2 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 3 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

19 - 22 STEERINGPL

DESCRIPTION AND OPERATION (Continued)

Page 895 of 1285

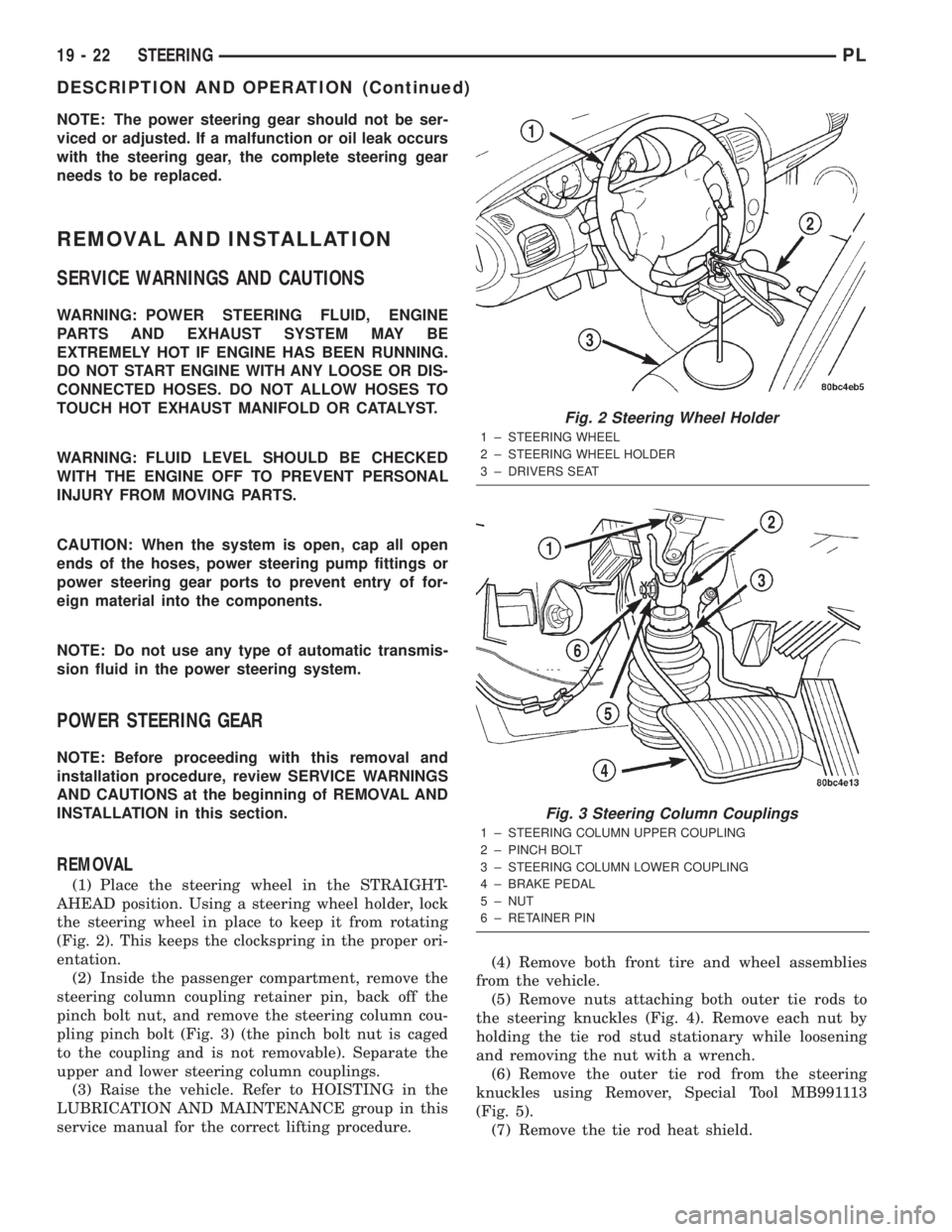

(13) If the vehicle is equipped with a power steer-

ing fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

(14) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 8).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

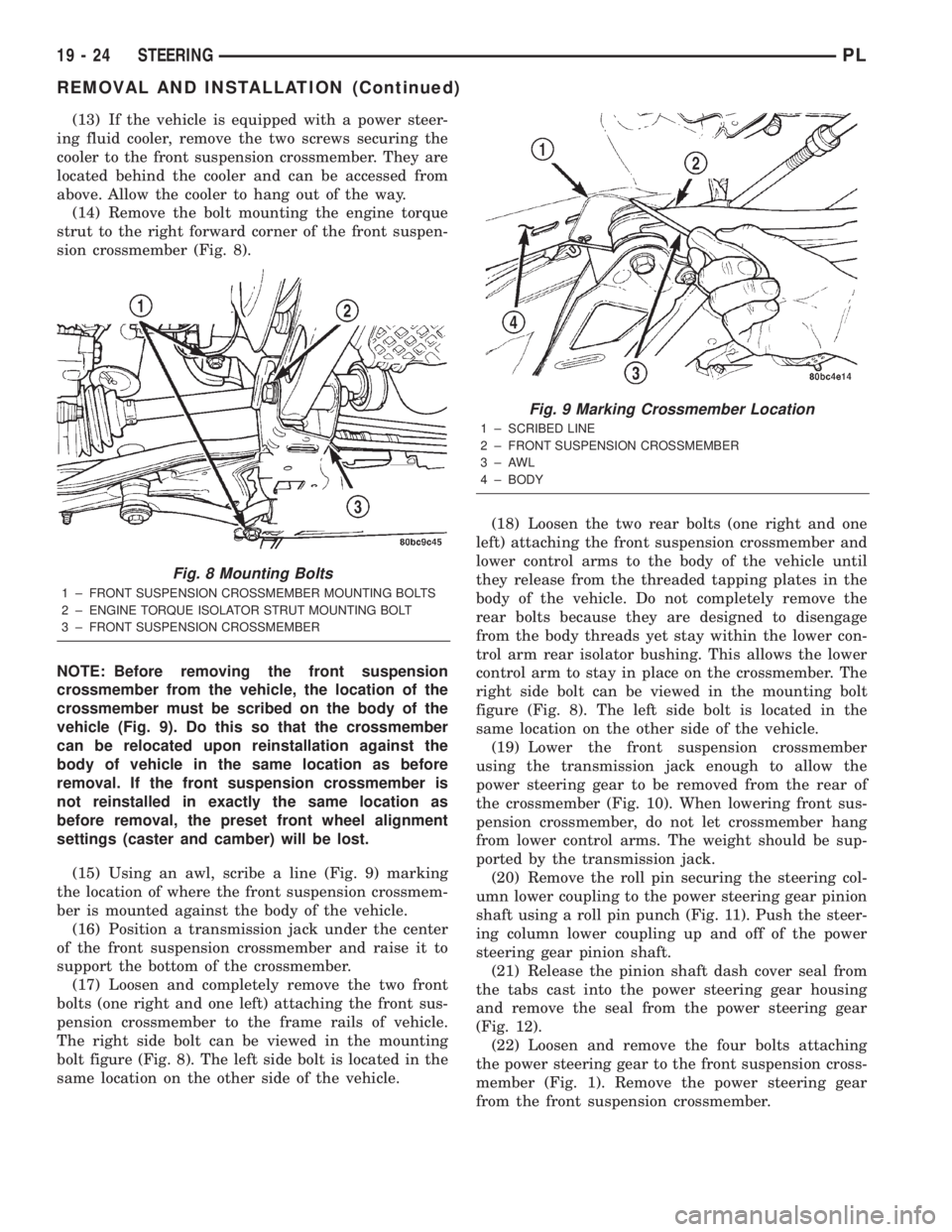

(15) Using an awl, scribe a line (Fig. 9) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(16) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(17) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.(18) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.

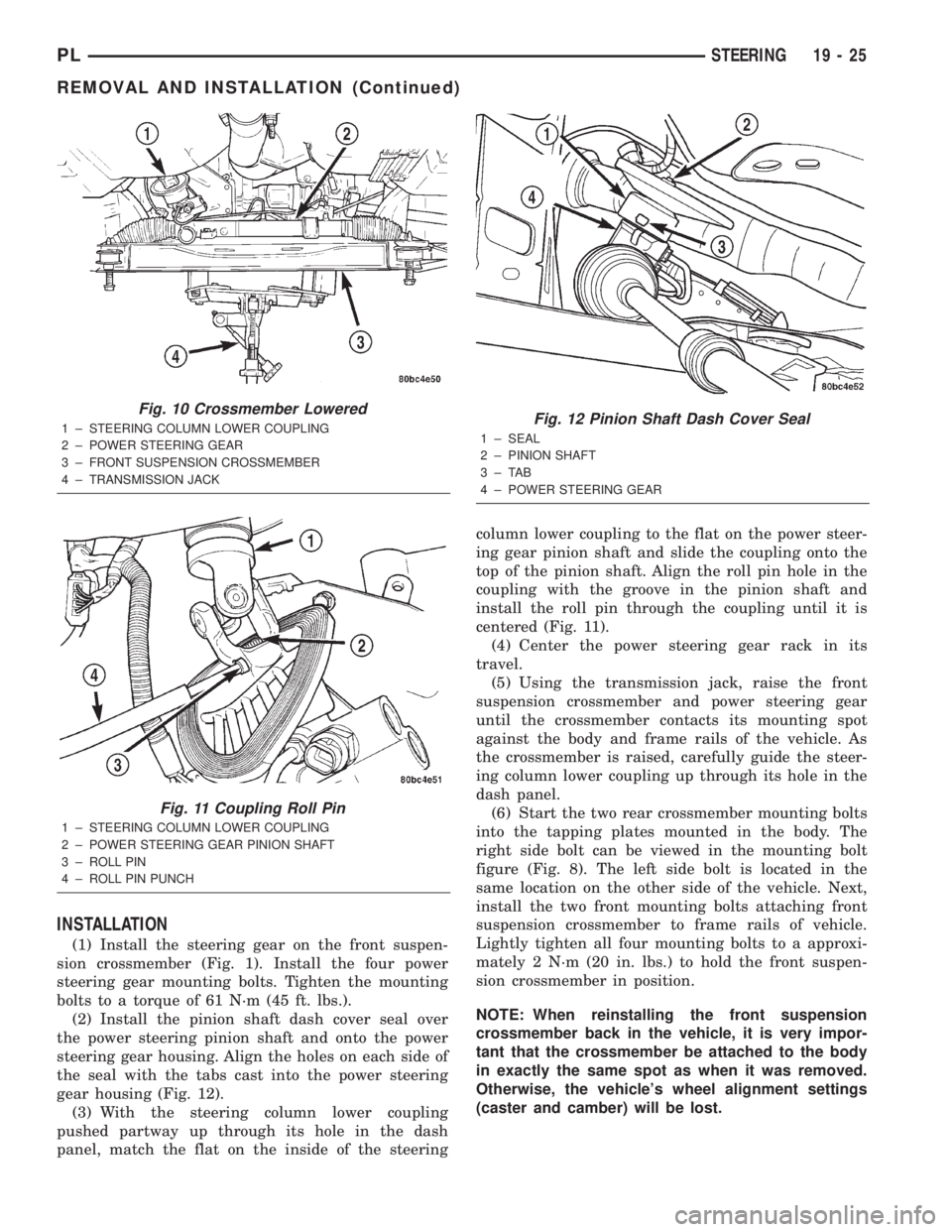

(19) Lower the front suspension crossmember

using the transmission jack enough to allow the

power steering gear to be removed from the rear of

the crossmember (Fig. 10). When lowering front sus-

pension crossmember, do not let crossmember hang

from lower control arms. The weight should be sup-

ported by the transmission jack.

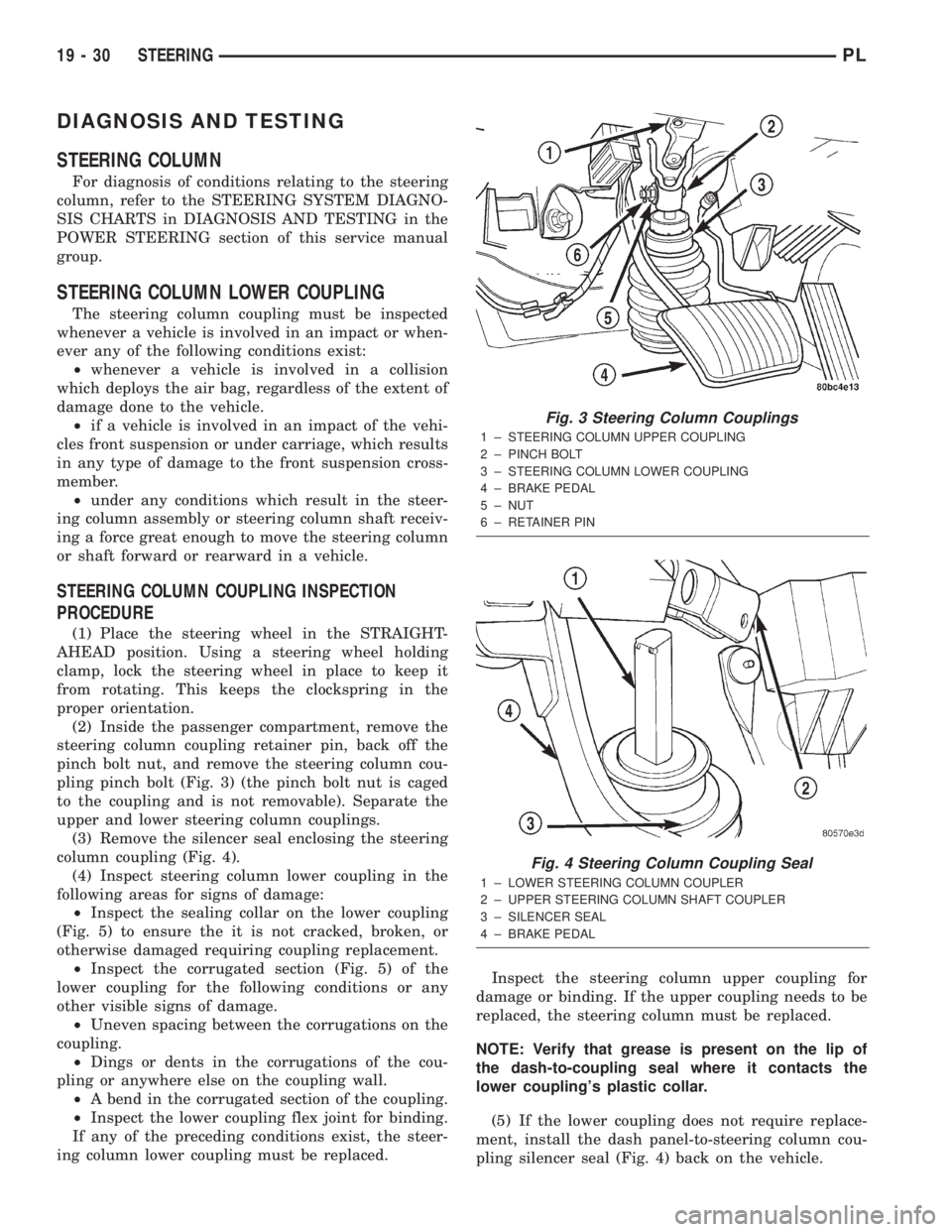

(20) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 11). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

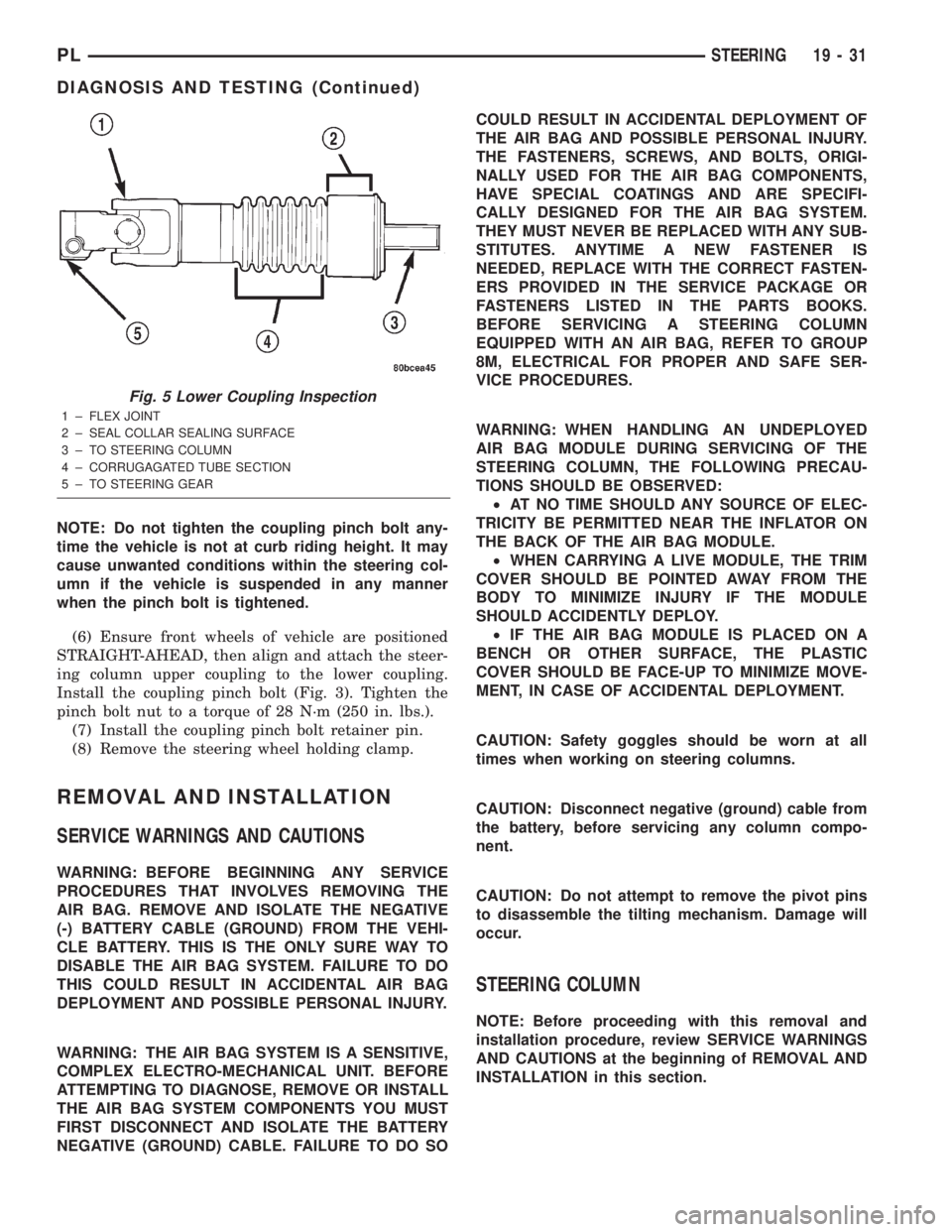

(21) Release the pinion shaft dash cover seal from

the tabs cast into the power steering gear housing

and remove the seal from the power steering gear

(Fig. 12).

(22) Loosen and remove the four bolts attaching

the power steering gear to the front suspension cross-

member (Fig. 1). Remove the power steering gear

from the front suspension crossmember.

Fig. 8 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 9 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

19 - 24 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 896 of 1285

INSTALLATION

(1) Install the steering gear on the front suspen-

sion crossmember (Fig. 1). Install the four power

steering gear mounting bolts. Tighten the mounting

bolts to a torque of 61 N´m (45 ft. lbs.).

(2) Install the pinion shaft dash cover seal over

the power steering pinion shaft and onto the power

steering gear housing. Align the holes on each side of

the seal with the tabs cast into the power steering

gear housing (Fig. 12).

(3) With the steering column lower coupling

pushed partway up through its hole in the dash

panel, match the flat on the inside of the steeringcolumn lower coupling to the flat on the power steer-

ing gear pinion shaft and slide the coupling onto the

top of the pinion shaft. Align the roll pin hole in the

coupling with the groove in the pinion shaft and

install the roll pin through the coupling until it is

centered (Fig. 11).

(4) Center the power steering gear rack in its

travel.

(5) Using the transmission jack, raise the front

suspension crossmember and power steering gear

until the crossmember contacts its mounting spot

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(6) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-

mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

Fig. 10 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

Fig. 11 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

Fig. 12 Pinion Shaft Dash Cover Seal

1 ± SEAL

2 ± PINION SHAFT

3±TAB

4 ± POWER STEERING GEAR

PLSTEERING 19 - 25

REMOVAL AND INSTALLATION (Continued)

Page 901 of 1285

DIAGNOSIS AND TESTING

STEERING COLUMN

For diagnosis of conditions relating to the steering

column, refer to the STEERING SYSTEM DIAGNO-

SIS CHARTS in DIAGNOSIS AND TESTING in the

POWER STEERING section of this service manual

group.

STEERING COLUMN LOWER COUPLING

The steering column coupling must be inspected

whenever a vehicle is involved in an impact or when-

ever any of the following conditions exist:

²whenever a vehicle is involved in a collision

which deploys the air bag, regardless of the extent of

damage done to the vehicle.

²if a vehicle is involved in an impact of the vehi-

cles front suspension or under carriage, which results

in any type of damage to the front suspension cross-

member.

²under any conditions which result in the steer-

ing column assembly or steering column shaft receiv-

ing a force great enough to move the steering column

or shaft forward or rearward in a vehicle.

STEERING COLUMN COUPLING INSPECTION

PROCEDURE

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holding

clamp, lock the steering wheel in place to keep it

from rotating. This keeps the clockspring in the

proper orientation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 3) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Remove the silencer seal enclosing the steering

column coupling (Fig. 4).

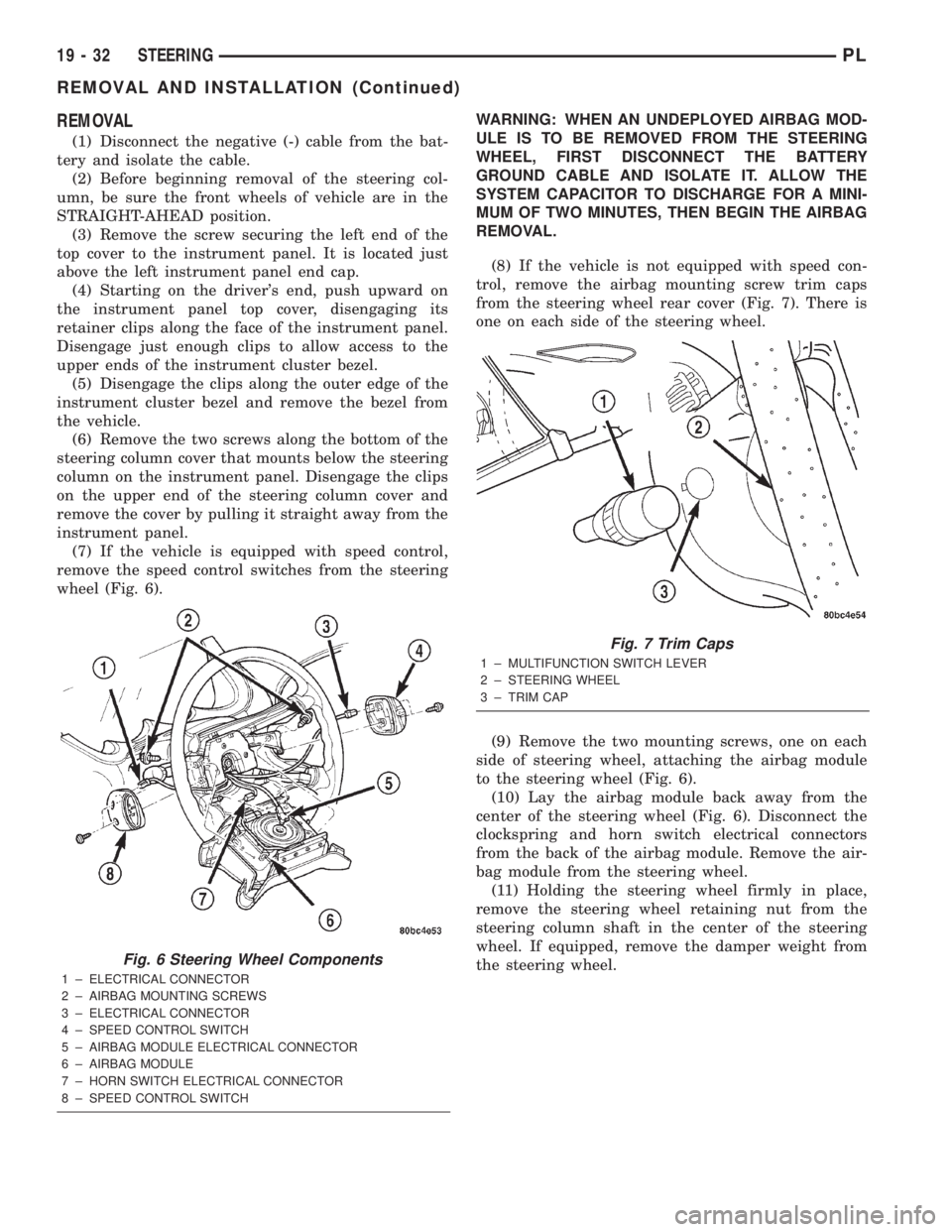

(4) Inspect steering column lower coupling in the

following areas for signs of damage:

²Inspect the sealing collar on the lower coupling

(Fig. 5) to ensure the it is not cracked, broken, or

otherwise damaged requiring coupling replacement.

²Inspect the corrugated section (Fig. 5) of the

lower coupling for the following conditions or any

other visible signs of damage.

²Uneven spacing between the corrugations on the

coupling.

²Dings or dents in the corrugations of the cou-

pling or anywhere else on the coupling wall.

²A bend in the corrugated section of the coupling.

²Inspect the lower coupling flex joint for binding.

If any of the preceding conditions exist, the steer-

ing column lower coupling must be replaced.Inspect the steering column upper coupling for

damage or binding. If the upper coupling needs to be

replaced, the steering column must be replaced.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the

lower coupling's plastic collar.

(5) If the lower coupling does not require replace-

ment, install the dash panel-to-steering column cou-

pling silencer seal (Fig. 4) back on the vehicle.

Fig. 3 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 4 Steering Column Coupling Seal

1 ± LOWER STEERING COLUMN COUPLER

2 ± UPPER STEERING COLUMN SHAFT COUPLER

3 ± SILENCER SEAL

4 ± BRAKE PEDAL

19 - 30 STEERINGPL

Page 902 of 1285

NOTE: Do not tighten the coupling pinch bolt any-

time the vehicle is not at curb riding height. It may

cause unwanted conditions within the steering col-

umn if the vehicle is suspended in any manner

when the pinch bolt is tightened.

(6) Ensure front wheels of vehicle are positioned

STRAIGHT-AHEAD, then align and attach the steer-

ing column upper coupling to the lower coupling.

Install the coupling pinch bolt (Fig. 3). Tighten the

pinch bolt nut to a torque of 28 N´m (250 in. lbs.).

(7) Install the coupling pinch bolt retainer pin.

(8) Remove the steering wheel holding clamp.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. FAILURE TO DO SOCOULD RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIR BAG AND POSSIBLE PERSONAL INJURY.

THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI-

CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY SUB-

STITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS.

BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

WARNING: WHEN HANDLING AN UNDEPLOYED

AIR BAG MODULE DURING SERVICING OF THE

STEERING COLUMN, THE FOLLOWING PRECAU-

TIONS SHOULD BE OBSERVED:

²AT NO TIME SHOULD ANY SOURCE OF ELEC-

TRICITY BE PERMITTED NEAR THE INFLATOR ON

THE BACK OF THE AIR BAG MODULE.

²WHEN CARRYING A LIVE MODULE, THE TRIM

COVER SHOULD BE POINTED AWAY FROM THE

BODY TO MINIMIZE INJURY IF THE MODULE

SHOULD ACCIDENTLY DEPLOY.

²IF THE AIR BAG MODULE IS PLACED ON A

BENCH OR OTHER SURFACE, THE PLASTIC

COVER SHOULD BE FACE-UP TO MINIMIZE MOVE-

MENT, IN CASE OF ACCIDENTAL DEPLOYMENT.

CAUTION: Safety goggles should be worn at all

times when working on steering columns.

CAUTION: Disconnect negative (ground) cable from

the battery, before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

STEERING COLUMN

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

Fig. 5 Lower Coupling Inspection

1 ± FLEX JOINT

2 ± SEAL COLLAR SEALING SURFACE

3 ± TO STEERING COLUMN

4 ± CORRUGAGATED TUBE SECTION

5 ± TO STEERING GEAR

PLSTEERING 19 - 31

DIAGNOSIS AND TESTING (Continued)

Page 903 of 1285

REMOVAL

(1) Disconnect the negative (-) cable from the bat-

tery and isolate the cable.

(2) Before beginning removal of the steering col-

umn, be sure the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

(3) Remove the screw securing the left end of the

top cover to the instrument panel. It is located just

above the left instrument panel end cap.

(4) Starting on the driver's end, push upward on

the instrument panel top cover, disengaging its

retainer clips along the face of the instrument panel.

Disengage just enough clips to allow access to the

upper ends of the instrument cluster bezel.

(5) Disengage the clips along the outer edge of the

instrument cluster bezel and remove the bezel from

the vehicle.

(6) Remove the two screws along the bottom of the

steering column cover that mounts below the steering

column on the instrument panel. Disengage the clips

on the upper end of the steering column cover and

remove the cover by pulling it straight away from the

instrument panel.

(7) If the vehicle is equipped with speed control,

remove the speed control switches from the steering

wheel (Fig. 6).WARNING: WHEN AN UNDEPLOYED AIRBAG MOD-

ULE IS TO BE REMOVED FROM THE STEERING

WHEEL, FIRST DISCONNECT THE BATTERY

GROUND CABLE AND ISOLATE IT. ALLOW THE

SYSTEM CAPACITOR TO DISCHARGE FOR A MINI-

MUM OF TWO MINUTES, THEN BEGIN THE AIRBAG

REMOVAL.

(8) If the vehicle is not equipped with speed con-

trol, remove the airbag mounting screw trim caps

from the steering wheel rear cover (Fig. 7). There is

one on each side of the steering wheel.

(9) Remove the two mounting screws, one on each

side of steering wheel, attaching the airbag module

to the steering wheel (Fig. 6).

(10) Lay the airbag module back away from the

center of the steering wheel (Fig. 6). Disconnect the

clockspring and horn switch electrical connectors

from the back of the airbag module. Remove the air-

bag module from the steering wheel.

(11) Holding the steering wheel firmly in place,

remove the steering wheel retaining nut from the

steering column shaft in the center of the steering

wheel. If equipped, remove the damper weight from

the steering wheel.

Fig. 6 Steering Wheel Components

1 ± ELECTRICAL CONNECTOR

2 ± AIRBAG MOUNTING SCREWS

3 ± ELECTRICAL CONNECTOR

4 ± SPEED CONTROL SWITCH

5 ± AIRBAG MODULE ELECTRICAL CONNECTOR

6 ± AIRBAG MODULE

7 ± HORN SWITCH ELECTRICAL CONNECTOR

8 ± SPEED CONTROL SWITCH

Fig. 7 Trim Caps

1 ± MULTIFUNCTION SWITCH LEVER

2 ± STEERING WHEEL

3 ± TRIM CAP

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 904 of 1285

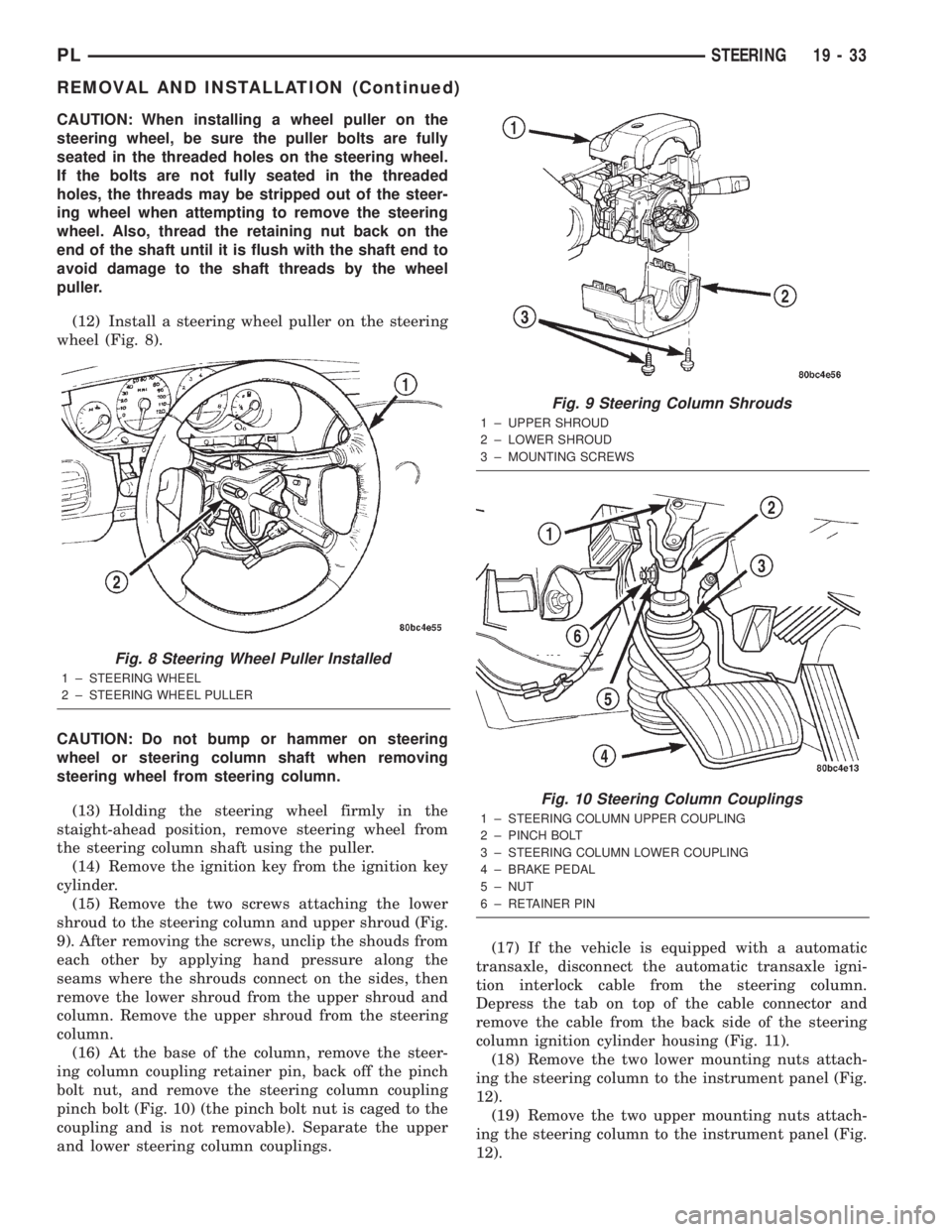

CAUTION: When installing a wheel puller on the

steering wheel, be sure the puller bolts are fully

seated in the threaded holes on the steering wheel.

If the bolts are not fully seated in the threaded

holes, the threads may be stripped out of the steer-

ing wheel when attempting to remove the steering

wheel. Also, thread the retaining nut back on the

end of the shaft until it is flush with the shaft end to

avoid damage to the shaft threads by the wheel

puller.

(12) Install a steering wheel puller on the steering

wheel (Fig. 8).

CAUTION: Do not bump or hammer on steering

wheel or steering column shaft when removing

steering wheel from steering column.

(13) Holding the steering wheel firmly in the

staight-ahead position, remove steering wheel from

the steering column shaft using the puller.

(14) Remove the ignition key from the ignition key

cylinder.

(15) Remove the two screws attaching the lower

shroud to the steering column and upper shroud (Fig.

9). After removing the screws, unclip the shouds from

each other by applying hand pressure along the

seams where the shrouds connect on the sides, then

remove the lower shroud from the upper shroud and

column. Remove the upper shroud from the steering

column.

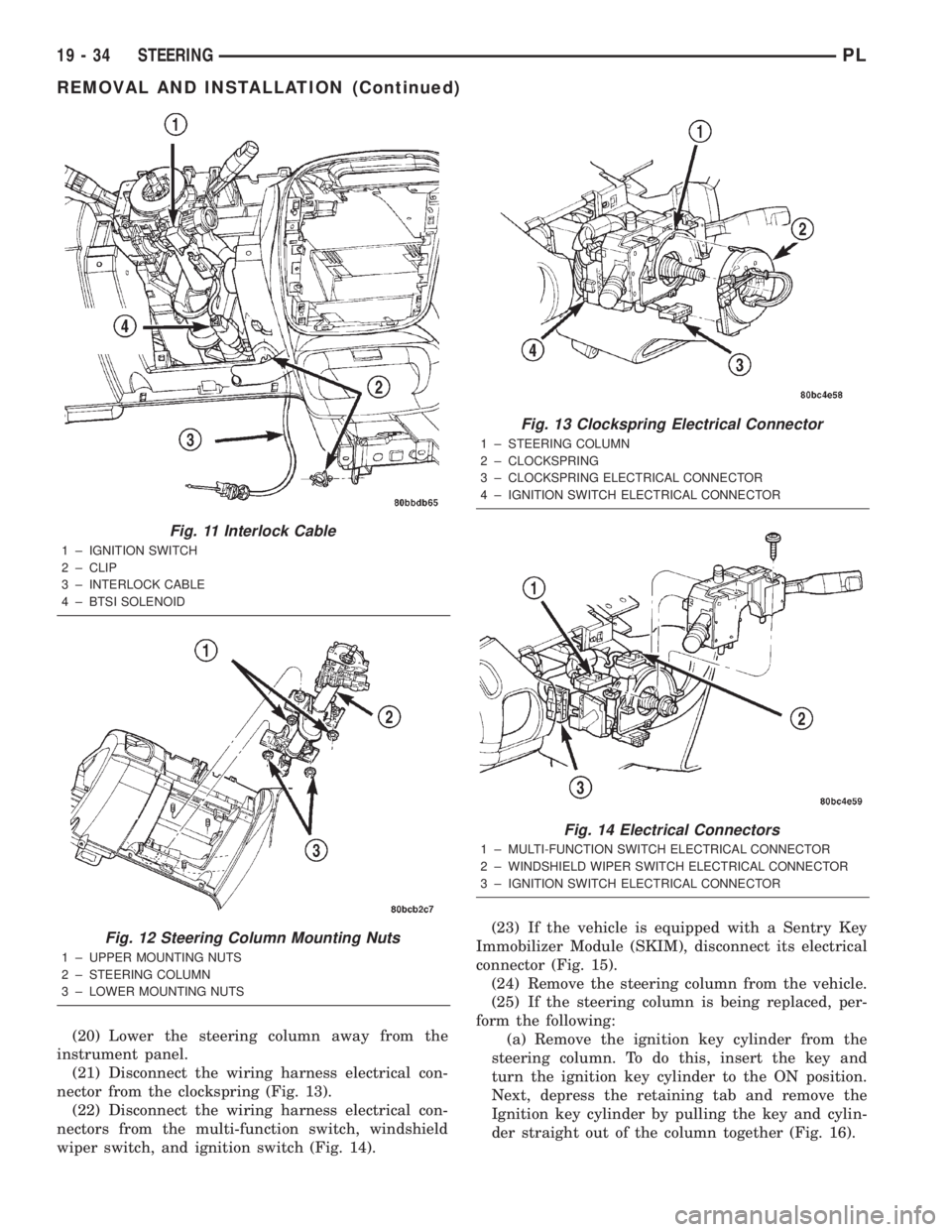

(16) At the base of the column, remove the steer-

ing column coupling retainer pin, back off the pinch

bolt nut, and remove the steering column coupling

pinch bolt (Fig. 10) (the pinch bolt nut is caged to the

coupling and is not removable). Separate the upper

and lower steering column couplings.(17) If the vehicle is equipped with a automatic

transaxle, disconnect the automatic transaxle igni-

tion interlock cable from the steering column.

Depress the tab on top of the cable connector and

remove the cable from the back side of the steering

column ignition cylinder housing (Fig. 11).

(18) Remove the two lower mounting nuts attach-

ing the steering column to the instrument panel (Fig.

12).

(19) Remove the two upper mounting nuts attach-

ing the steering column to the instrument panel (Fig.

12).

Fig. 8 Steering Wheel Puller Installed

1 ± STEERING WHEEL

2 ± STEERING WHEEL PULLER

Fig. 9 Steering Column Shrouds

1 ± UPPER SHROUD

2 ± LOWER SHROUD

3 ± MOUNTING SCREWS

Fig. 10 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

PLSTEERING 19 - 33

REMOVAL AND INSTALLATION (Continued)

Page 905 of 1285

(20) Lower the steering column away from the

instrument panel.

(21) Disconnect the wiring harness electrical con-

nector from the clockspring (Fig. 13).

(22) Disconnect the wiring harness electrical con-

nectors from the multi-function switch, windshield

wiper switch, and ignition switch (Fig. 14).(23) If the vehicle is equipped with a Sentry Key

Immobilizer Module (SKIM), disconnect its electrical

connector (Fig. 15).

(24) Remove the steering column from the vehicle.

(25) If the steering column is being replaced, per-

form the following:

(a) Remove the ignition key cylinder from the

steering column. To do this, insert the key and

turn the ignition key cylinder to the ON position.

Next, depress the retaining tab and remove the

Ignition key cylinder by pulling the key and cylin-

der straight out of the column together (Fig. 16).

Fig. 11 Interlock Cable

1 ± IGNITION SWITCH

2 ± CLIP

3 ± INTERLOCK CABLE

4 ± BTSI SOLENOID

Fig. 12 Steering Column Mounting Nuts

1 ± UPPER MOUNTING NUTS

2 ± STEERING COLUMN

3 ± LOWER MOUNTING NUTS

Fig. 13 Clockspring Electrical Connector

1 ± STEERING COLUMN

2 ± CLOCKSPRING

3 ± CLOCKSPRING ELECTRICAL CONNECTOR

4 ± IGNITION SWITCH ELECTRICAL CONNECTOR

Fig. 14 Electrical Connectors

1 ± MULTI-FUNCTION SWITCH ELECTRICAL CONNECTOR

2 ± WINDSHIELD WIPER SWITCH ELECTRICAL CONNECTOR

3 ± IGNITION SWITCH ELECTRICAL CONNECTOR

19 - 34 STEERINGPL

REMOVAL AND INSTALLATION (Continued)