tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1109 of 1285

Pending ConditionsÐThere are not conditions

or situations that prompt conflict or suspension of

testing. The oxygen sensor heater test is not run

pending resolution of MIL illumination due to oxygen

sensor failure.

SuspendÐThere are no conditions which exist for

suspending the Heater Monitor.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For atotally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL (check

engine lamp) will be illuminated.

Monitor OperationÐTo monitor catalyst effi-

ciency, the PCM expands the rich and lean switch

points of the heated oxygen sensor. With extended

switch points, the air/fuel mixture runs richer and

leaner to overburden the catalytic converter. Once

the test is started, the air/fuel mixture runs rich and

lean and the O2 switches are counted. A switch is

counted when an oxygen sensor signal goes from

below the lean threshold to above the rich threshold.

The number of Rear O2 sensor switches is divided by

the number of Front O2 sensor switches to determine

the switching ratio.

The test runs for 20 seconds. As catalyst efficiency

deteriorated over the life of the vehicle, the switch

rate at the downstream sensor approaches that of the

upstream sensor. If at any point during the test

period the switch ratio reaches a predetermined

value, a counter is incremented by one. The monitor

is enabled to run another test during that trip. When

the test fails three times, the counter increments to

three, a malfunction is entered, and a Freeze Frame

is stored. When the counter increments to three dur-

ing the next trip, the code is matured and the MIL is

illuminated. If the test passes the first, no further

testing is conducted during that trip.

The MIL is extinguished after three consecutive

good trips. The good trip criteria for the catalyst

monitor is more stringent than the failure criteria. In

order to pass the test and increment one good trip,

the downstream sensor switch rate must be less than

80% of the upstream rate (60% for manual transmis-

sions). The failure percentages are 90% and 70%

respectively.

Enabling ConditionsÐThe following conditions

must typically be met before the PCM runs the cat-

alyst monitor. Specific times for each parameter may

be different from engine to engine.

²Accumulated drive time

²Enable time

²Ambient air temperature

²Barometric pressure

²Catalyst warm-up counter

²Engine coolant temperature

²Accumulated throttle position sensor

²Vehicle speed

²MAP

²RPM

²Engine in closed loop

²Fuel level

25 - 22 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1111 of 1285

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

HIGH AND LOW LIMITS

OPERATION

The PCM compares input signal voltages from each

input device with established high and low limits forthe device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

LOAD VALUE

ENGINE IDLE/NEUTRAL 2500 RPM/NEUTRAL

2.0L 2% to 8% of Maximum Load 8% to 15% of Maximum Load

25 - 24 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1112 of 1285

EVAPORATIVE EMISSION CONTROLS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

EVAPORATION CONTROL SYSTEM..........25

EVAP CANISTER.........................25

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT..............................25

LEAK DETECTION PUMP..................26

LEAK DETECTION PUMP PRESSURE

SWITCH..............................27

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS.............................28POSITIVE CRANKCASE VENTILATION VALVE. . . 28

VEHICLE EMISSION CONTROL

INFORMATION LABEL...................29

REMOVAL AND INSTALLATION

EVAP CANISTER.........................29

LEAK DETECTION PUMP..................30

PROPORTIONAL PURGE SOLENOID VALVE....30

DESCRIPTION AND OPERATION

EVAPORATION CONTROL SYSTEM

OPERATION

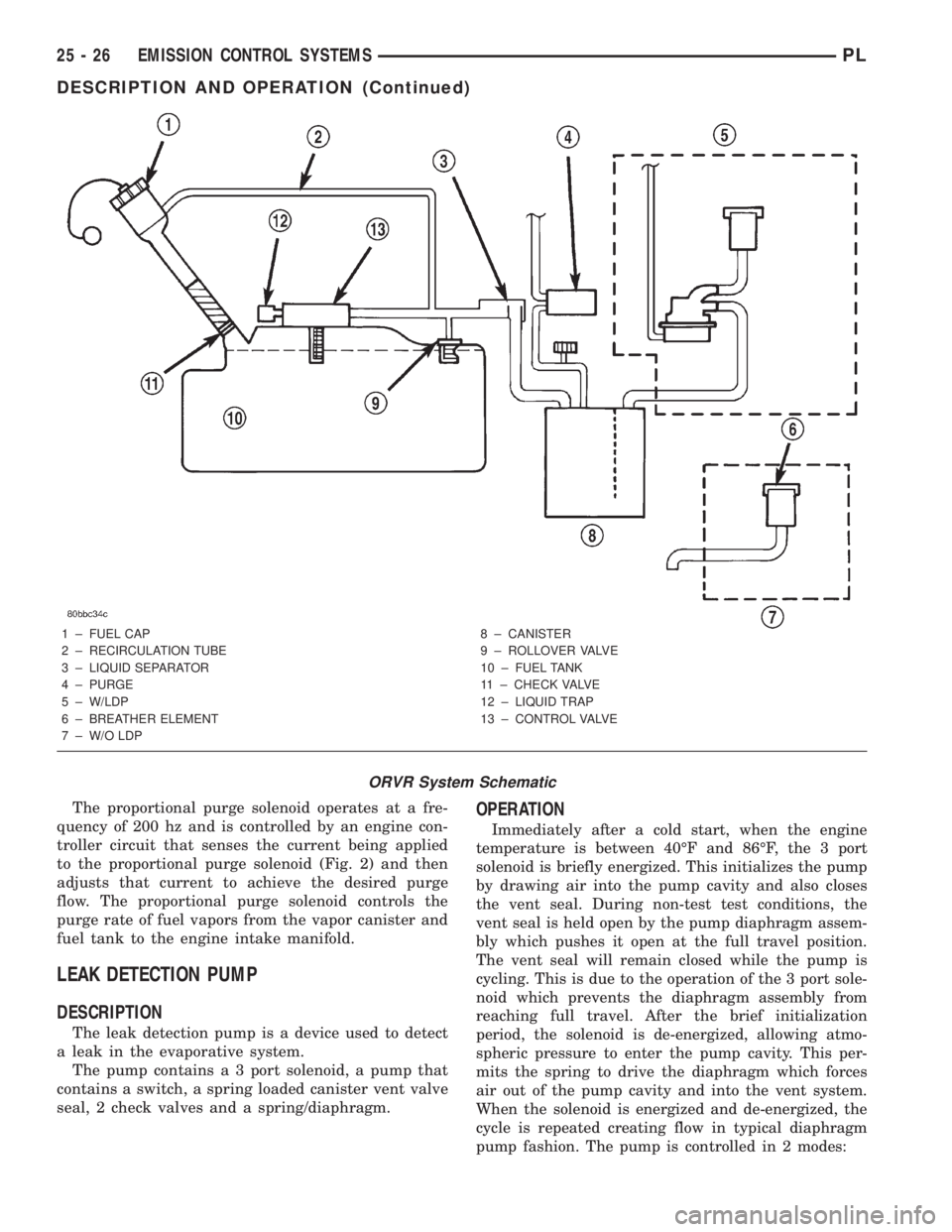

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through vent hoses or tubes to an activated carbon

filled evaporative canister. The canister temporarily

holds the vapors. The Powertrain Control Module

(PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions.

All engines use a proportional purge solenoid sys-

tem. The PCM controls vapor flow by operating the

purge solenoid. Refer to Proportional Purge Solenoid

in this section.

NOTE: The evaporative system uses specially man-

ufactured hoses. If they need replacement, only use

fuel resistant hose. Also the hoses must be able to

pass an Ozone compliance test.

NOTE: For more information on Onboard Refueling

Vapor Recovery (ORVR), refer to the Fuel Delivery

section.

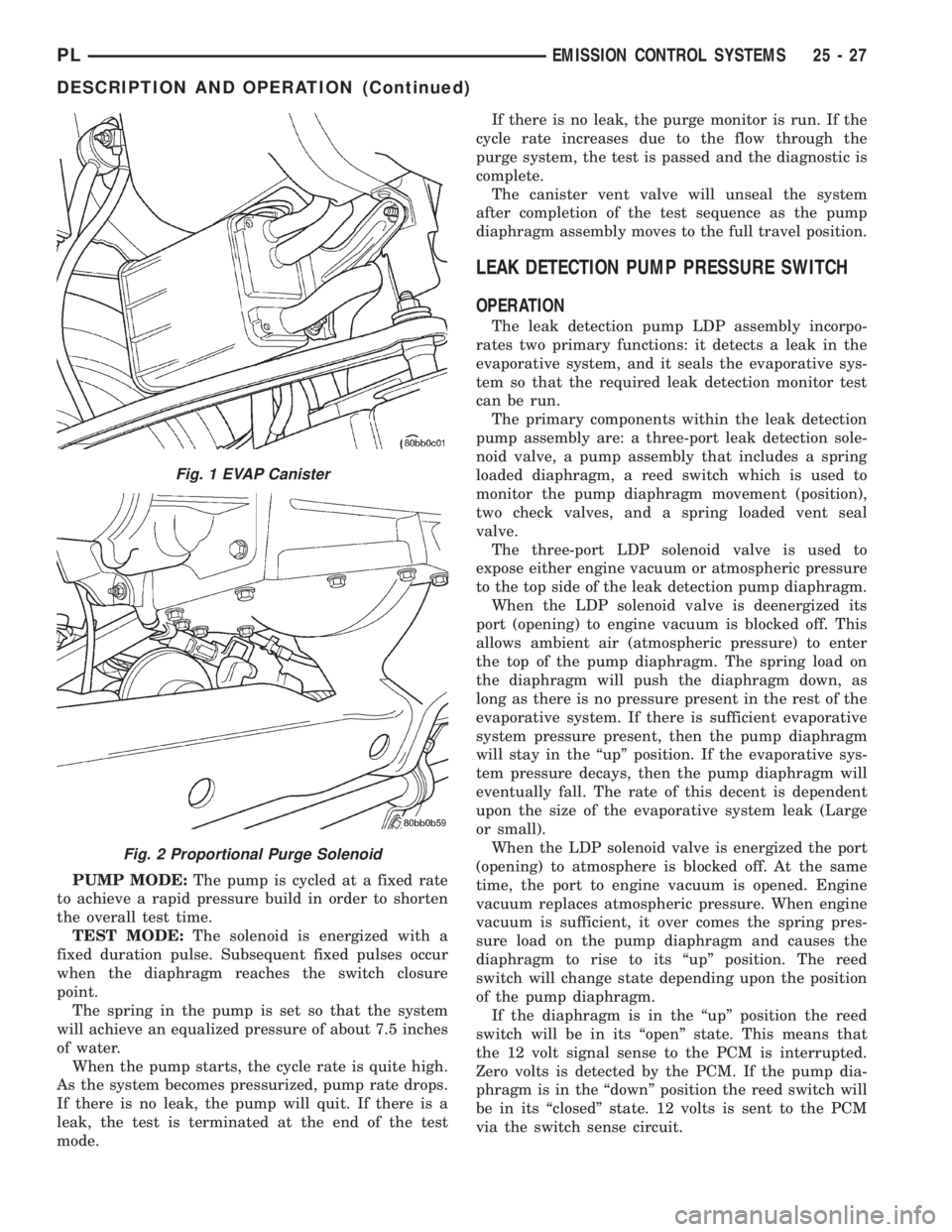

EVAP CANISTER

DESCRIPTION

The vacuum and vapor tubes connect to the top of

the canister (Fig. 1).

OPERATION

All vehicles use a, maintenance free, evaporative

(EVAP) canister. Fuel tank vapors vent into the can-

ister. The canister temporarily holds the fuel vapors

until intake manifold vacuum draws them into the

combustion chamber. The Powertrain Control Module

(PCM) purges the canister through the proportional

purge solenoid. The PCM purges the canister at pre-

determined intervals and engine conditions.

Purge Free Cells

Purge-free memory cells are used to identify the

fuel vapor content of the evaporative canister. Since

the evaporative canister is not purged 100% of the

time, the PCM stores information about the evapora-

tive canister's vapor content in a memory cell.

The purge-free cells are constructed similar to cer-

tain purge-normal cells. The purge-free cells can be

monitored by the DRB III Scan Tool. The only differ-

ence between the purge-free cells and normal adap-

tive cells is that in purge-free, the purge is

completely turned off. This gives the PCM the ability

to compare purge and purge-free operation.

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT

DESCRIPTION

OPERATION

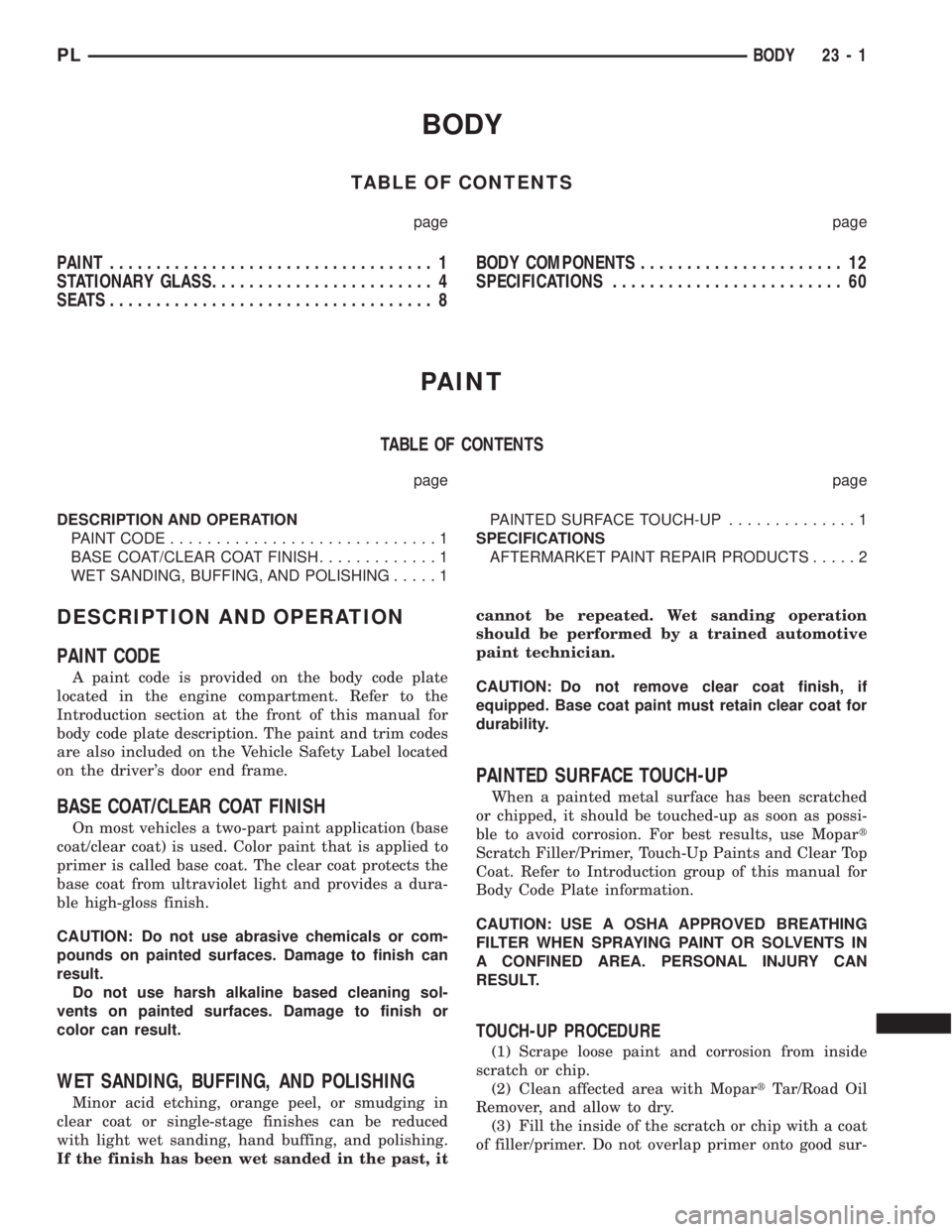

All vehicles use a proportional purge solenoid. The

solenoid regulates the rate of vapor flow from the

EVAP canister to the throttle body. The PCM oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

PLEMISSION CONTROL SYSTEMS 25 - 25

Page 1113 of 1285

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid (Fig. 2) and then

adjusts that current to achieve the desired purge

flow. The proportional purge solenoid controls the

purge rate of fuel vapors from the vapor canister and

fuel tank to the engine intake manifold.

LEAK DETECTION PUMP

DESCRIPTION

The leak detection pump is a device used to detect

a leak in the evaporative system.

The pump contains a 3 port solenoid, a pump that

contains a switch, a spring loaded canister vent valve

seal, 2 check valves and a spring/diaphragm.

OPERATION

Immediately after a cold start, when the engine

temperature is between 40ÉF and 86ÉF, the 3 port

solenoid is briefly energized. This initializes the pump

by drawing air into the pump cavity and also closes

the vent seal. During non-test test conditions, the

vent seal is held open by the pump diaphragm assem-

bly which pushes it open at the full travel position.

The vent seal will remain closed while the pump is

cycling. This is due to the operation of the 3 port sole-

noid which prevents the diaphragm assembly from

reaching full travel. After the brief initialization

period, the solenoid is de-energized, allowing atmo-

spheric pressure to enter the pump cavity. This per-

mits the spring to drive the diaphragm which forces

air out of the pump cavity and into the vent system.

When the solenoid is energized and de-energized, the

cycle is repeated creating flow in typical diaphragm

pump fashion. The pump is controlled in 2 modes:

1 ± FUEL CAP

2 ± RECIRCULATION TUBE

3 ± LIQUID SEPARATOR

4 ± PURGE

5 ± W/LDP

6 ± BREATHER ELEMENT

7 ± W/O LDP8 ± CANISTER

9 ± ROLLOVER VALVE

10 ± FUEL TANK

11 ± CHECK VALVE

12 ± LIQUID TRAP

13 ± CONTROL VALVE

ORVR System Schematic

25 - 26 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1114 of 1285

PUMP MODE:The pump is cycled at a fixed rate

to achieve a rapid pressure build in order to shorten

the overall test time.

TEST MODE:The solenoid is energized with a

fixed duration pulse. Subsequent fixed pulses occur

when the diaphragm reaches the switch closure

point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5 inches

of water.

When the pump starts, the cycle rate is quite high.

As the system becomes pressurized, pump rate drops.

If there is no leak, the pump will quit. If there is a

leak, the test is terminated at the end of the test

mode.If there is no leak, the purge monitor is run. If the

cycle rate increases due to the flow through the

purge system, the test is passed and the diagnostic is

complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

LEAK DETECTION PUMP PRESSURE SWITCH

OPERATION

The leak detection pump LDP assembly incorpo-

rates two primary functions: it detects a leak in the

evaporative system, and it seals the evaporative sys-

tem so that the required leak detection monitor test

can be run.

The primary components within the leak detection

pump assembly are: a three-port leak detection sole-

noid valve, a pump assembly that includes a spring

loaded diaphragm, a reed switch which is used to

monitor the pump diaphragm movement (position),

two check valves, and a spring loaded vent seal

valve.

The three-port LDP solenoid valve is used to

expose either engine vacuum or atmospheric pressure

to the top side of the leak detection pump diaphragm.

When the LDP solenoid valve is deenergized its

port (opening) to engine vacuum is blocked off. This

allows ambient air (atmospheric pressure) to enter

the top of the pump diaphragm. The spring load on

the diaphragm will push the diaphragm down, as

long as there is no pressure present in the rest of the

evaporative system. If there is sufficient evaporative

system pressure present, then the pump diaphragm

will stay in the ªupº position. If the evaporative sys-

tem pressure decays, then the pump diaphragm will

eventually fall. The rate of this decent is dependent

upon the size of the evaporative system leak (Large

or small).

When the LDP solenoid valve is energized the port

(opening) to atmosphere is blocked off. At the same

time, the port to engine vacuum is opened. Engine

vacuum replaces atmospheric pressure. When engine

vacuum is sufficient, it over comes the spring pres-

sure load on the pump diaphragm and causes the

diaphragm to rise to its ªupº position. The reed

switch will change state depending upon the position

of the pump diaphragm.

If the diaphragm is in the ªupº position the reed

switch will be in its ªopenº state. This means that

the 12 volt signal sense to the PCM is interrupted.

Zero volts is detected by the PCM. If the pump dia-

phragm is in the ªdownº position the reed switch will

be in its ªclosedº state. 12 volts is sent to the PCM

via the switch sense circuit.

Fig. 1 EVAP Canister

Fig. 2 Proportional Purge Solenoid

PLEMISSION CONTROL SYSTEMS 25 - 27

DESCRIPTION AND OPERATION (Continued)

Page 1118 of 1285

BODY

TABLE OF CONTENTS

page page

PAINT................................... 1

STATIONARY GLASS........................ 4

SEATS ................................... 8BODY COMPONENTS...................... 12

SPECIFICATIONS......................... 60

PAINT

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

PAINT CODE.............................1

BASE COAT/CLEAR COAT FINISH.............1

WET SANDING, BUFFING, AND POLISHING.....1PAINTED SURFACE TOUCH-UP..............1

SPECIFICATIONS

AFTERMARKET PAINT REPAIR PRODUCTS.....2

DESCRIPTION AND OPERATION

PAINT CODE

A paint code is provided on the body code plate

located in the engine compartment. Refer to the

Introduction section at the front of this manual for

body code plate description. The paint and trim codes

are also included on the Vehicle Safety Label located

on the driver's door end frame.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning sol-

vents on painted surfaces. Damage to finish or

color can result.

WET SANDING, BUFFING, AND POLISHING

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light wet sanding, hand buffing, and polishing.

If the finish has been wet sanded in the past, itcannot be repeated. Wet sanding operation

should be performed by a trained automotive

paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

CAUTION: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

PLBODY 23 - 1

Page 1125 of 1285

SEATS

TABLE OF CONTENTS

page page

REMOVAL AND INSTALLATION

FRONT SEAT.............................8

FRONT SEAT BACK........................8

FRONT SEAT BACK COVER.................9FRONT SEAT CUSHION COVER..............9

FRONT SEAT CUSHION....................9

REAR SEAT BACK........................10

REAR SEAT CUSHION.....................11

REMOVAL AND INSTALLATION

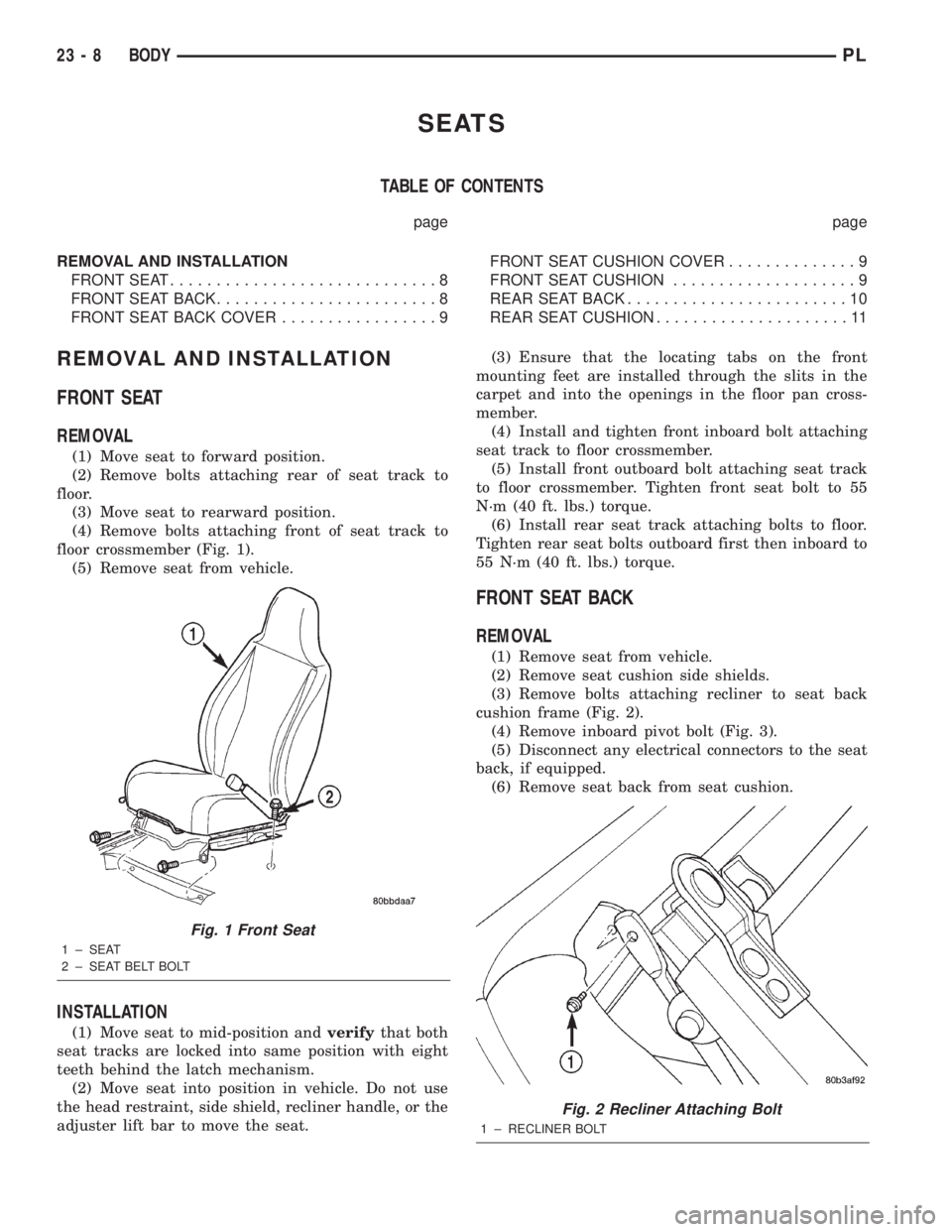

FRONT SEAT

REMOVAL

(1) Move seat to forward position.

(2) Remove bolts attaching rear of seat track to

floor.

(3) Move seat to rearward position.

(4) Remove bolts attaching front of seat track to

floor crossmember (Fig. 1).

(5) Remove seat from vehicle.

INSTALLATION

(1) Move seat to mid-position andverifythat both

seat tracks are locked into same position with eight

teeth behind the latch mechanism.

(2) Move seat into position in vehicle. Do not use

the head restraint, side shield, recliner handle, or the

adjuster lift bar to move the seat.(3) Ensure that the locating tabs on the front

mounting feet are installed through the slits in the

carpet and into the openings in the floor pan cross-

member.

(4) Install and tighten front inboard bolt attaching

seat track to floor crossmember.

(5) Install front outboard bolt attaching seat track

to floor crossmember. Tighten front seat bolt to 55

N´m (40 ft. lbs.) torque.

(6) Install rear seat track attaching bolts to floor.

Tighten rear seat bolts outboard first then inboard to

55 N´m (40 ft. lbs.) torque.

FRONT SEAT BACK

REMOVAL

(1) Remove seat from vehicle.

(2) Remove seat cushion side shields.

(3) Remove bolts attaching recliner to seat back

cushion frame (Fig. 2).

(4) Remove inboard pivot bolt (Fig. 3).

(5) Disconnect any electrical connectors to the seat

back, if equipped.

(6) Remove seat back from seat cushion.

Fig. 1 Front Seat

1 ± SEAT

2 ± SEAT BELT BOLT

Fig. 2 Recliner Attaching Bolt

1 ± RECLINER BOLT

23 - 8 BODYPL

Page 1126 of 1285

INSTALLATION

(1) Position seat back on cushion.

(2) Connect electrical connectors to the seat back,

if equipped.

(3) Install inboard pivot bolt. Tighten bolt to 40

N´m (30 ft. lbs.) torque.

(4) Install bolts attaching recliner to seat cushion

frame. Tighten bolts to 12 N´m (9 ft. lbs.) torque.

(5) Install seat cushion side shields.

(6) Install seat in vehicle.

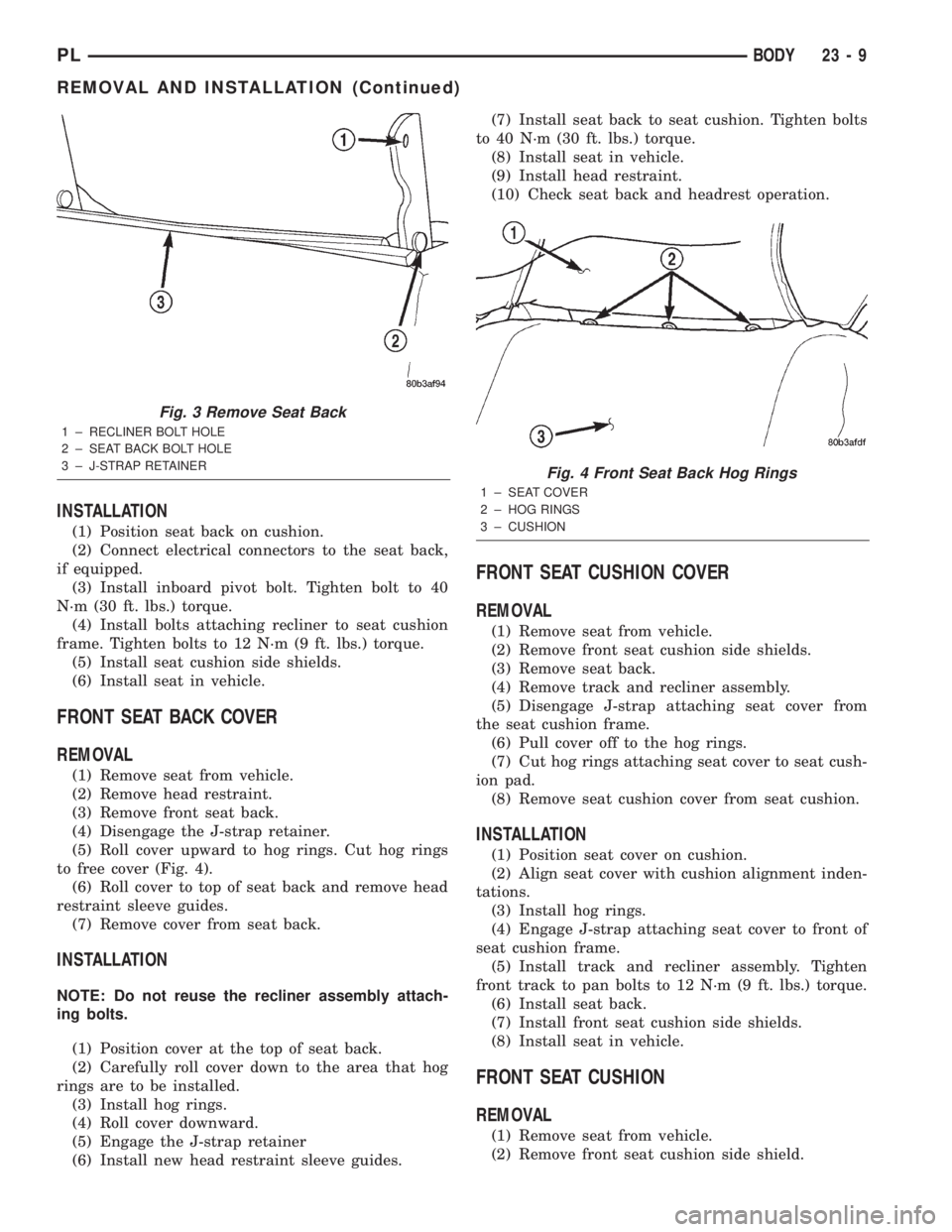

FRONT SEAT BACK COVER

REMOVAL

(1) Remove seat from vehicle.

(2) Remove head restraint.

(3) Remove front seat back.

(4) Disengage the J-strap retainer.

(5) Roll cover upward to hog rings. Cut hog rings

to free cover (Fig. 4).

(6) Roll cover to top of seat back and remove head

restraint sleeve guides.

(7) Remove cover from seat back.

INSTALLATION

NOTE: Do not reuse the recliner assembly attach-

ing bolts.

(1) Position cover at the top of seat back.

(2) Carefully roll cover down to the area that hog

rings are to be installed.

(3) Install hog rings.

(4) Roll cover downward.

(5) Engage the J-strap retainer

(6) Install new head restraint sleeve guides.(7) Install seat back to seat cushion. Tighten bolts

to 40 N´m (30 ft. lbs.) torque.

(8) Install seat in vehicle.

(9) Install head restraint.

(10) Check seat back and headrest operation.

FRONT SEAT CUSHION COVER

REMOVAL

(1) Remove seat from vehicle.

(2) Remove front seat cushion side shields.

(3) Remove seat back.

(4) Remove track and recliner assembly.

(5) Disengage J-strap attaching seat cover from

the seat cushion frame.

(6) Pull cover off to the hog rings.

(7) Cut hog rings attaching seat cover to seat cush-

ion pad.

(8) Remove seat cushion cover from seat cushion.

INSTALLATION

(1) Position seat cover on cushion.

(2) Align seat cover with cushion alignment inden-

tations.

(3) Install hog rings.

(4) Engage J-strap attaching seat cover to front of

seat cushion frame.

(5) Install track and recliner assembly. Tighten

front track to pan bolts to 12 N´m (9 ft. lbs.) torque.

(6) Install seat back.

(7) Install front seat cushion side shields.

(8) Install seat in vehicle.

FRONT SEAT CUSHION

REMOVAL

(1) Remove seat from vehicle.

(2) Remove front seat cushion side shield.

Fig. 3 Remove Seat Back

1 ± RECLINER BOLT HOLE

2 ± SEAT BACK BOLT HOLE

3 ± J-STRAP RETAINER

Fig. 4 Front Seat Back Hog Rings

1 ± SEAT COVER

2 ± HOG RINGS

3 ± CUSHION

PLBODY 23 - 9

REMOVAL AND INSTALLATION (Continued)

Page 1127 of 1285

(3) Remove seat back.

(4) Remove track and recliner assembly.

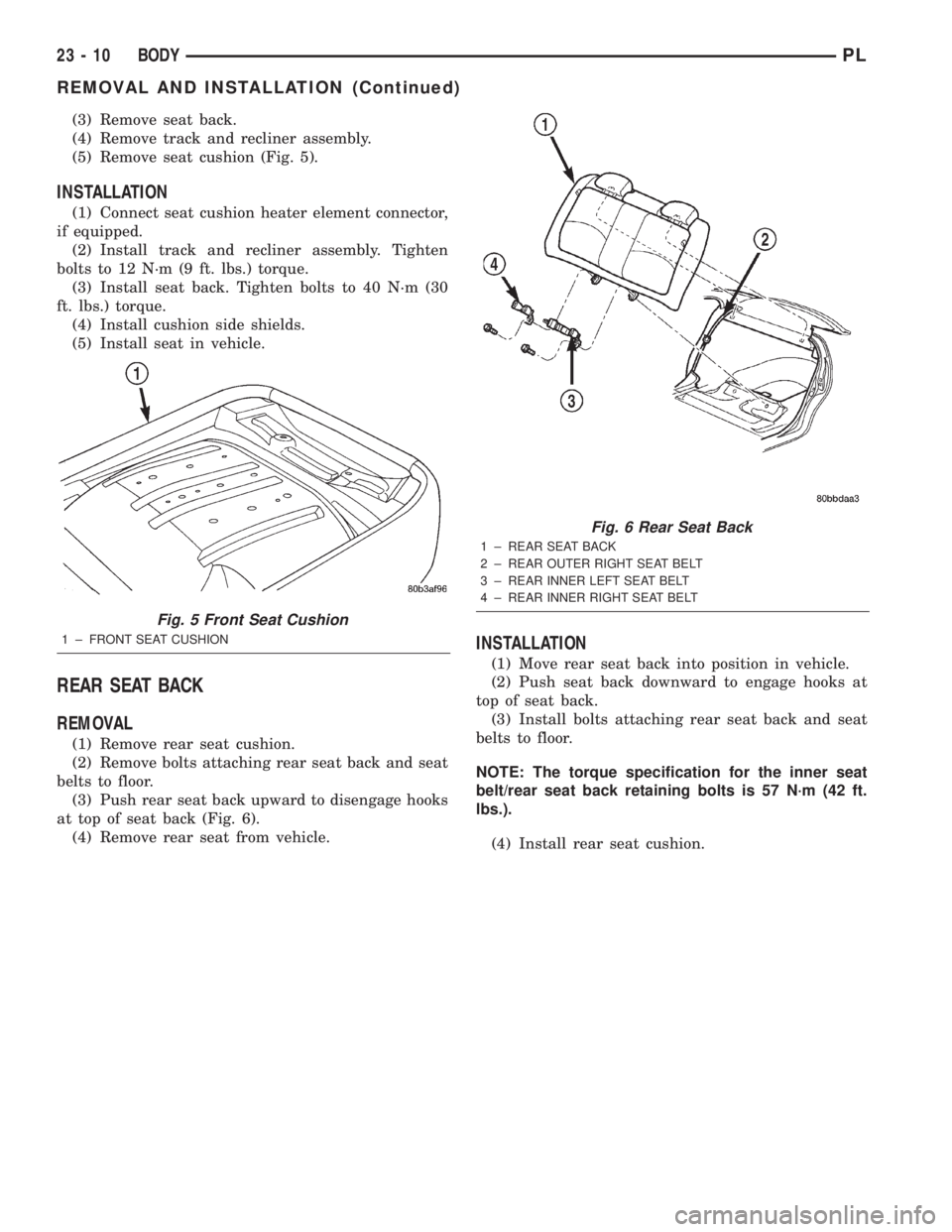

(5) Remove seat cushion (Fig. 5).

INSTALLATION

(1) Connect seat cushion heater element connector,

if equipped.

(2) Install track and recliner assembly. Tighten

bolts to 12 N´m (9 ft. lbs.) torque.

(3) Install seat back. Tighten bolts to 40 N´m (30

ft. lbs.) torque.

(4) Install cushion side shields.

(5) Install seat in vehicle.

REAR SEAT BACK

REMOVAL

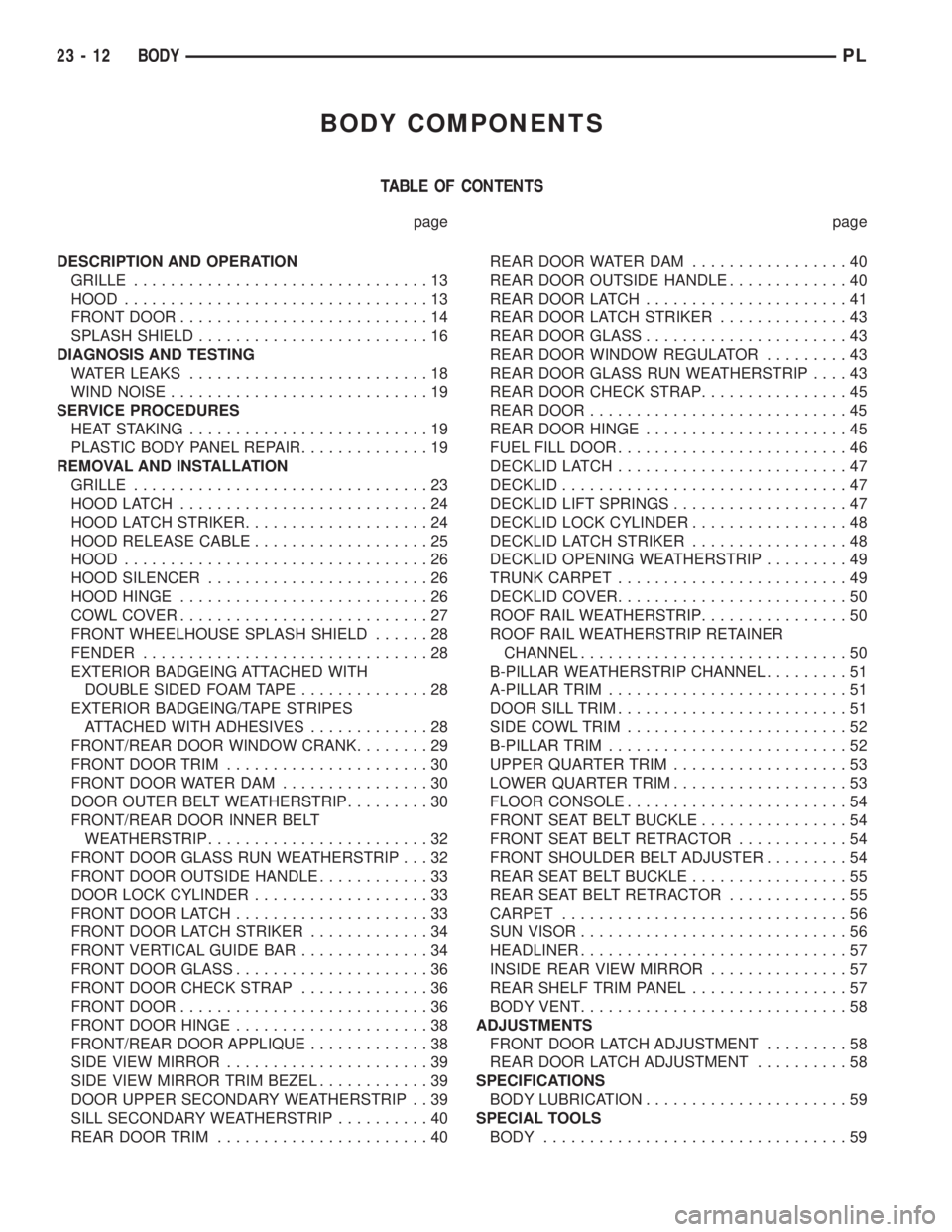

(1) Remove rear seat cushion.

(2) Remove bolts attaching rear seat back and seat

belts to floor.

(3) Push rear seat back upward to disengage hooks

at top of seat back (Fig. 6).

(4) Remove rear seat from vehicle.

INSTALLATION

(1) Move rear seat back into position in vehicle.

(2) Push seat back downward to engage hooks at

top of seat back.

(3) Install bolts attaching rear seat back and seat

belts to floor.

NOTE: The torque specification for the inner seat

belt/rear seat back retaining bolts is 57 N´m (42 ft.

lbs.).

(4) Install rear seat cushion.

Fig. 5 Front Seat Cushion

1 ± FRONT SEAT CUSHION

Fig. 6 Rear Seat Back

1 ± REAR SEAT BACK

2 ± REAR OUTER RIGHT SEAT BELT

3 ± REAR INNER LEFT SEAT BELT

4 ± REAR INNER RIGHT SEAT BELT

23 - 10 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1129 of 1285

BODY COMPONENTS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

GRILLE................................13

HOOD.................................13

FRONT DOOR...........................14

SPLASH SHIELD.........................16

DIAGNOSIS AND TESTING

WATER LEAKS..........................18

WIND NOISE............................19

SERVICE PROCEDURES

HEAT STAKING..........................19

PLASTIC BODY PANEL REPAIR..............19

REMOVAL AND INSTALLATION

GRILLE................................23

HOOD LATCH...........................24

HOOD LATCH STRIKER....................24

HOOD RELEASE CABLE...................25

HOOD.................................26

HOOD SILENCER........................26

HOOD HINGE...........................26

COWL COVER...........................27

FRONT WHEELHOUSE SPLASH SHIELD......28

FENDER...............................28

EXTERIOR BADGEING ATTACHED WITH

DOUBLE SIDED FOAM TAPE..............28

EXTERIOR BADGEING/TAPE STRIPES

ATTACHED WITH ADHESIVES.............28

FRONT/REAR DOOR WINDOW CRANK........29

FRONT DOOR TRIM......................30

FRONT DOOR WATER DAM................30

DOOR OUTER BELT WEATHERSTRIP.........30

FRONT/REAR DOOR INNER BELT

WEATHERSTRIP........................32

FRONT DOOR GLASS RUN WEATHERSTRIP . . . 32

FRONT DOOR OUTSIDE HANDLE............33

DOOR LOCK CYLINDER...................33

FRONT DOOR LATCH.....................33

FRONT DOOR LATCH STRIKER.............34

FRONT VERTICAL GUIDE BAR..............34

FRONT DOOR GLASS.....................36

FRONT DOOR CHECK STRAP..............36

FRONT DOOR...........................36

FRONT DOOR HINGE.....................38

FRONT/REAR DOOR APPLIQUE.............38

SIDE VIEW MIRROR......................39

SIDE VIEW MIRROR TRIM BEZEL............39

DOOR UPPER SECONDARY WEATHERSTRIP . . 39

SILL SECONDARY WEATHERSTRIP..........40

REAR DOOR TRIM.......................40REAR DOOR WATER DAM.................40

REAR DOOR OUTSIDE HANDLE.............40

REAR DOOR LATCH......................41

REAR DOOR LATCH STRIKER..............43

REAR DOOR GLASS......................43

REAR DOOR WINDOW REGULATOR.........43

REAR DOOR GLASS RUN WEATHERSTRIP....43

REAR DOOR CHECK STRAP................45

REAR DOOR............................45

REAR DOOR HINGE......................45

FUEL FILL DOOR.........................46

DECKLID LATCH.........................47

DECKLID...............................47

DECKLID LIFT SPRINGS...................47

DECKLID LOCK CYLINDER.................48

DECKLID LATCH STRIKER.................48

DECKLID OPENING WEATHERSTRIP.........49

TRUNK CARPET.........................49

DECKLID COVER.........................50

ROOF RAIL WEATHERSTRIP................50

ROOF RAIL WEATHERSTRIP RETAINER

CHANNEL.............................50

B-PILLAR WEATHERSTRIP CHANNEL.........51

A-PILLAR TRIM..........................51

DOOR SILL TRIM.........................51

SIDE COWL TRIM........................52

B-PILLAR TRIM..........................52

UPPER QUARTER TRIM...................53

LOWER QUARTER TRIM...................53

FLOOR CONSOLE........................54

FRONT SEAT BELT BUCKLE................54

FRONT SEAT BELT RETRACTOR............54

FRONT SHOULDER BELT ADJUSTER.........54

REAR SEAT BELT BUCKLE.................55

REAR SEAT BELT RETRACTOR.............55

CARPET...............................56

SUN VISOR.............................56

HEADLINER.............................57

INSIDE REAR VIEW MIRROR...............57

REAR SHELF TRIM PANEL.................57

BODY VENT.............................58

ADJUSTMENTS

FRONT DOOR LATCH ADJUSTMENT.........58

REAR DOOR LATCH ADJUSTMENT..........58

SPECIFICATIONS

BODY LUBRICATION......................59

SPECIAL TOOLS

BODY.................................59

23 - 12 BODYPL