pcm DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2571 of 2627

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

DESCRIPTION - EVAP SYSTEM............10

SPECIFICATIONS

TORQUE - EVAP SYSTEM...............11

CCV HOSE

DESCRIPTION - 8.0L V-10................12

OPERATION - 8.0L V-10..................12

EVAP/PURGE SOLENOID

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................12

FUEL FILLER CAP

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL

REMOVAL/INSTALLATION...............13

LEAK DETECTION PUMP

DESCRIPTION.........................13

OPERATION...........................14

REMOVAL.............................16

INSTALLATION.........................16ORVR

DESCRIPTION.........................17

OPERATION...........................17

P C V VA LV E

DESCRIPTION.........................17

OPERATION...........................19

DIAGNOSIS AND TESTING - PCV VALVE -

3.7L V-6/ 4.7L V-8......................20

REMOVAL.............................21

INSTALLATION.........................21

VACUUM LINES

DESCRIPTION.........................22

VAPOR CANISTER

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

NATURAL VAC LEAK DETECTION ASSY

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24

INSTALLATION.........................25

EVAPORATIVE EMISSIONS

DESCRIPTION - EVAP SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through vent hoses or tubes into the two charcoal

filled evaporative canisters. The canisters tempo-

rarily hold the vapors. The Powertrain Control Mod-

ule (PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions.

All gasoline powered engines use a duty cycle

purge system. The PCM controls vapor flow by oper-

ating the duty cycle EVAP purge solenoid. Refer to

Duty Cycle EVAP Canister Purge Solenoid for addi-

tional information.When equipped with certain emissions packages, a

Leak Detection Pump (LDP) will be used as part of

the evaporative system. This pump is used as a part

of OBD II requirements. Refer to Leak Detection

Pump for additional information. Other emissions

packages will use a Natural Vacuum Leak Detection

(NVLD) system in place of the LDP. Refer to NVLD

for additional information.

NOTE: The hoses used in this system are specially

manufactured. If replacement becomes necessary, it

is important to use only fuel resistant hose.

Certain EVAP system components can be found in

(Fig. 1).

25 - 10 EVAPORATIVE EMISSIONSDR

Page 2573 of 2627

CCV HOSE

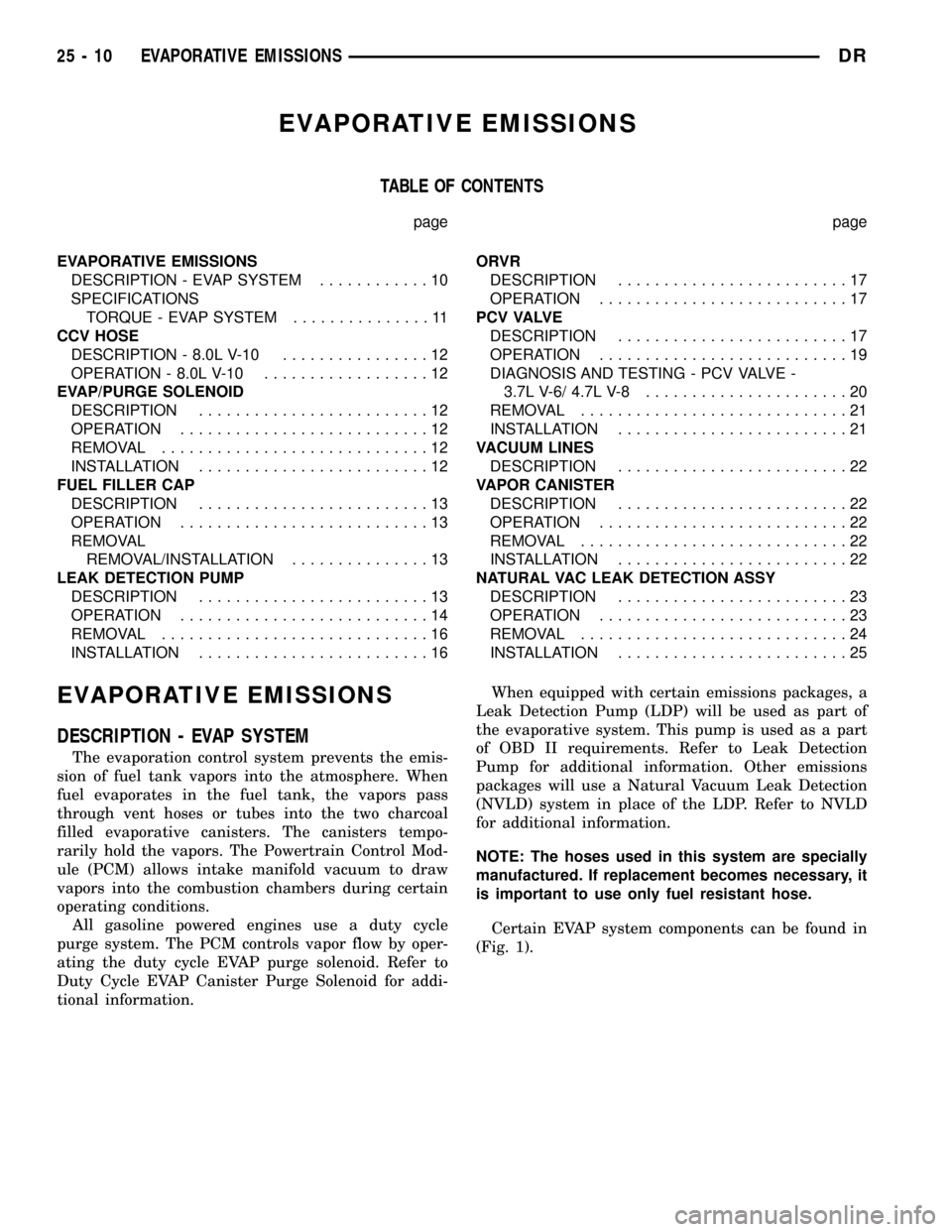

DESCRIPTION - 8.0L V-10

The 8.0L V-10 engine is equipped with a Crankcase

Ventilation (CCV) system. The CCV system performs

the same function as a conventional PCV system, but

does not use a vacuum controlled valve (PCV valve).

A molded vacuum tube connects manifold vacuum

to the top of the right cylinder head (valve) cover.

The vacuum tube connects to a fixed orifice fitting

(Fig. 2) of a calibrated size 2.6 mm (0.10 inches).

OPERATION - 8.0L V-10

A molded vacuum tube connects manifold vacuum

to the top of the right cylinder head (valve) cover.

The vacuum tube connects to a fixed orifice fitting

(Fig. 2) of a calibrated size 2.6 mm (0.10 inches). The

fitting meters the amount of crankcase vapors drawn

out of the engine.The fixed orifice fitting is grey

in color.A similar fitting (but does not contain a

fixed orifice) is used on the left cylinder head (valve)

cover. This fitting is black in color. Do not inter-

change these two fittings.

When the engine is operating, fresh air enters the

engine and mixes with crankcase vapors. Manifold

vacuum draws the vapor/air mixture through the

fixed orifice and into the intake manifold. The vapors

are then consumed during engine combustion.

EVAP/PURGE SOLENOID

DESCRIPTION

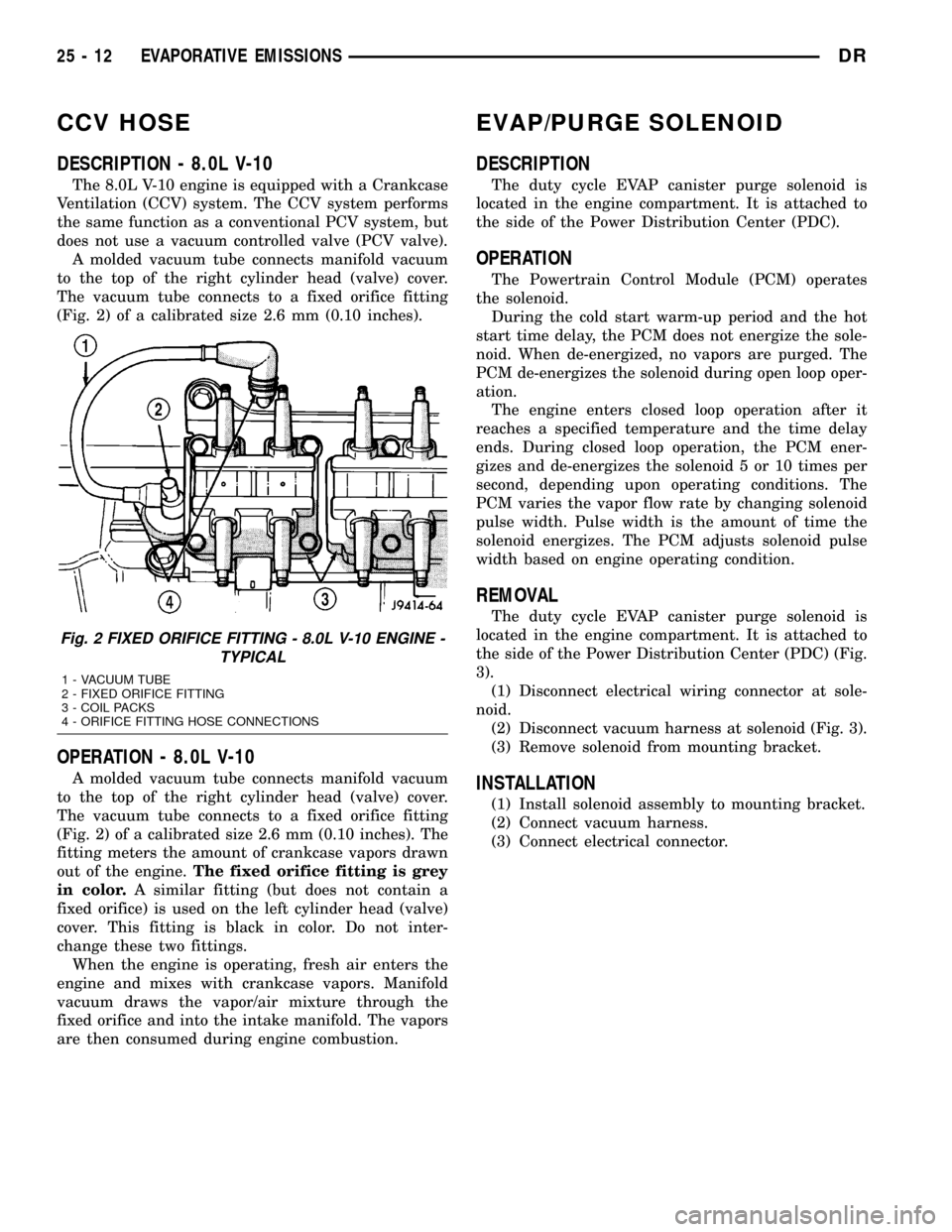

The duty cycle EVAP canister purge solenoid is

located in the engine compartment. It is attached to

the side of the Power Distribution Center (PDC).

OPERATION

The Powertrain Control Module (PCM) operates

the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid 5 or 10 times per

second, depending upon operating conditions. The

PCM varies the vapor flow rate by changing solenoid

pulse width. Pulse width is the amount of time the

solenoid energizes. The PCM adjusts solenoid pulse

width based on engine operating condition.

REMOVAL

The duty cycle EVAP canister purge solenoid is

located in the engine compartment. It is attached to

the side of the Power Distribution Center (PDC) (Fig.

3).

(1) Disconnect electrical wiring connector at sole-

noid.

(2) Disconnect vacuum harness at solenoid (Fig. 3).

(3) Remove solenoid from mounting bracket.

INSTALLATION

(1) Install solenoid assembly to mounting bracket.

(2) Connect vacuum harness.

(3) Connect electrical connector.

Fig. 2 FIXED ORIFICE FITTING - 8.0L V-10 ENGINE -

TYPICAL

1 - VACUUM TUBE

2 - FIXED ORIFICE FITTING

3 - COIL PACKS

4 - ORIFICE FITTING HOSE CONNECTIONS

25 - 12 EVAPORATIVE EMISSIONSDR

Page 2574 of 2627

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a Leak Detection Pump (LDP), or

NVLD system, the cap must be tightened securely.

If cap is left loose, a Diagnostic Trouble Code (DTC)

may be set.

REMOVAL

REMOVAL/INSTALLATION

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

CAUTION: Remove the fuel tank filler tube cap to

relieve fuel tank pressure. The cap must be

removed prior to disconnecting any fuel system

component or before draining the fuel tank.

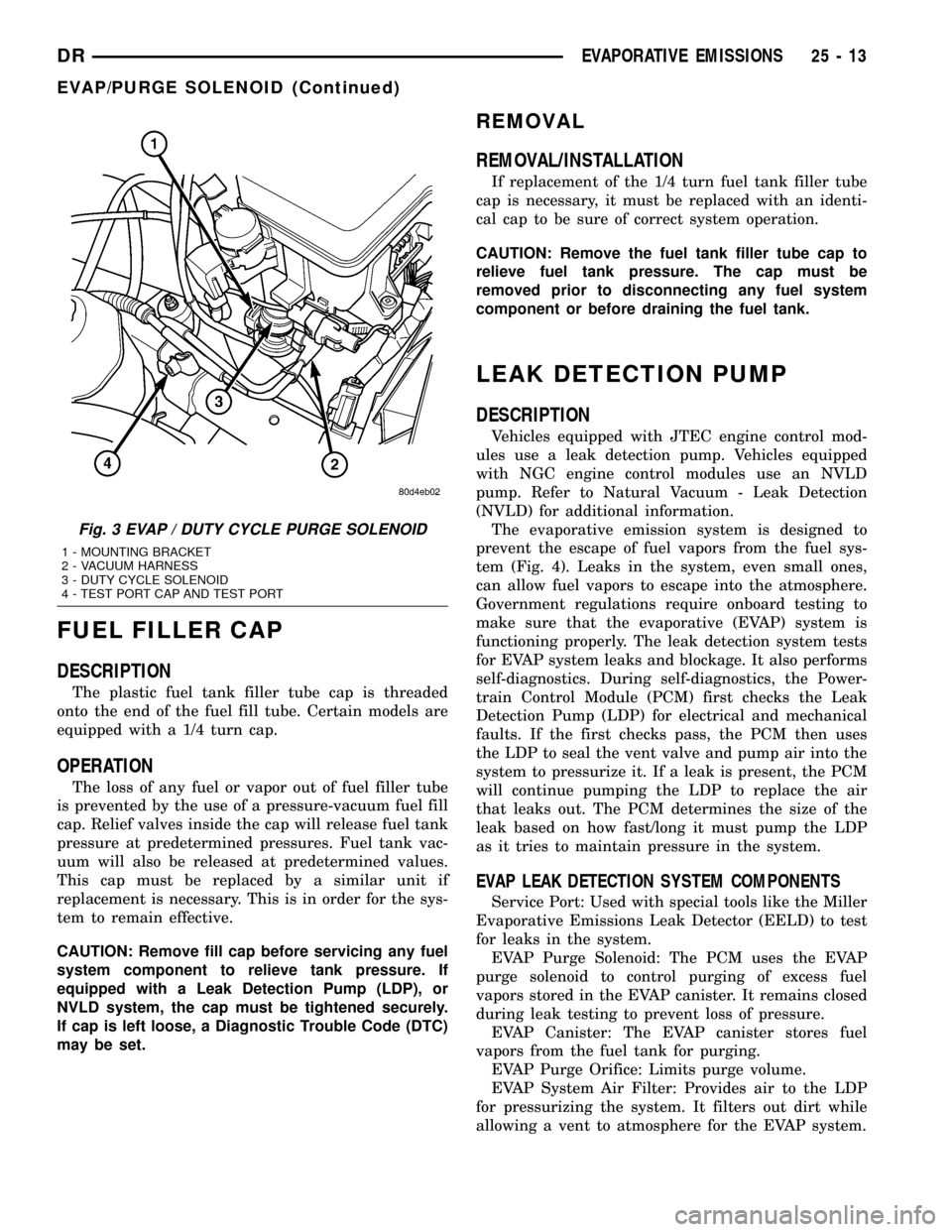

LEAK DETECTION PUMP

DESCRIPTION

Vehicles equipped with JTEC engine control mod-

ules use a leak detection pump. Vehicles equipped

with NGC engine control modules use an NVLD

pump. Refer to Natural Vacuum - Leak Detection

(NVLD) for additional information.

The evaporative emission system is designed to

prevent the escape of fuel vapors from the fuel sys-

tem (Fig. 4). Leaks in the system, even small ones,

can allow fuel vapors to escape into the atmosphere.

Government regulations require onboard testing to

make sure that the evaporative (EVAP) system is

functioning properly. The leak detection system tests

for EVAP system leaks and blockage. It also performs

self-diagnostics. During self-diagnostics, the Power-

train Control Module (PCM) first checks the Leak

Detection Pump (LDP) for electrical and mechanical

faults. If the first checks pass, the PCM then uses

the LDP to seal the vent valve and pump air into the

system to pressurize it. If a leak is present, the PCM

will continue pumping the LDP to replace the air

that leaks out. The PCM determines the size of the

leak based on how fast/long it must pump the LDP

as it tries to maintain pressure in the system.

EVAP LEAK DETECTION SYSTEM COMPONENTS

Service Port: Used with special tools like the Miller

Evaporative Emissions Leak Detector (EELD) to test

for leaks in the system.

EVAP Purge Solenoid: The PCM uses the EVAP

purge solenoid to control purging of excess fuel

vapors stored in the EVAP canister. It remains closed

during leak testing to prevent loss of pressure.

EVAP Canister: The EVAP canister stores fuel

vapors from the fuel tank for purging.

EVAP Purge Orifice: Limits purge volume.

EVAP System Air Filter: Provides air to the LDP

for pressurizing the system. It filters out dirt while

allowing a vent to atmosphere for the EVAP system.

Fig. 3 EVAP / DUTY CYCLE PURGE SOLENOID

1 - MOUNTING BRACKET

2 - VACUUM HARNESS

3 - DUTY CYCLE SOLENOID

4 - TEST PORT CAP AND TEST PORT

DREVAPORATIVE EMISSIONS 25 - 13

EVAP/PURGE SOLENOID (Continued)

Page 2575 of 2627

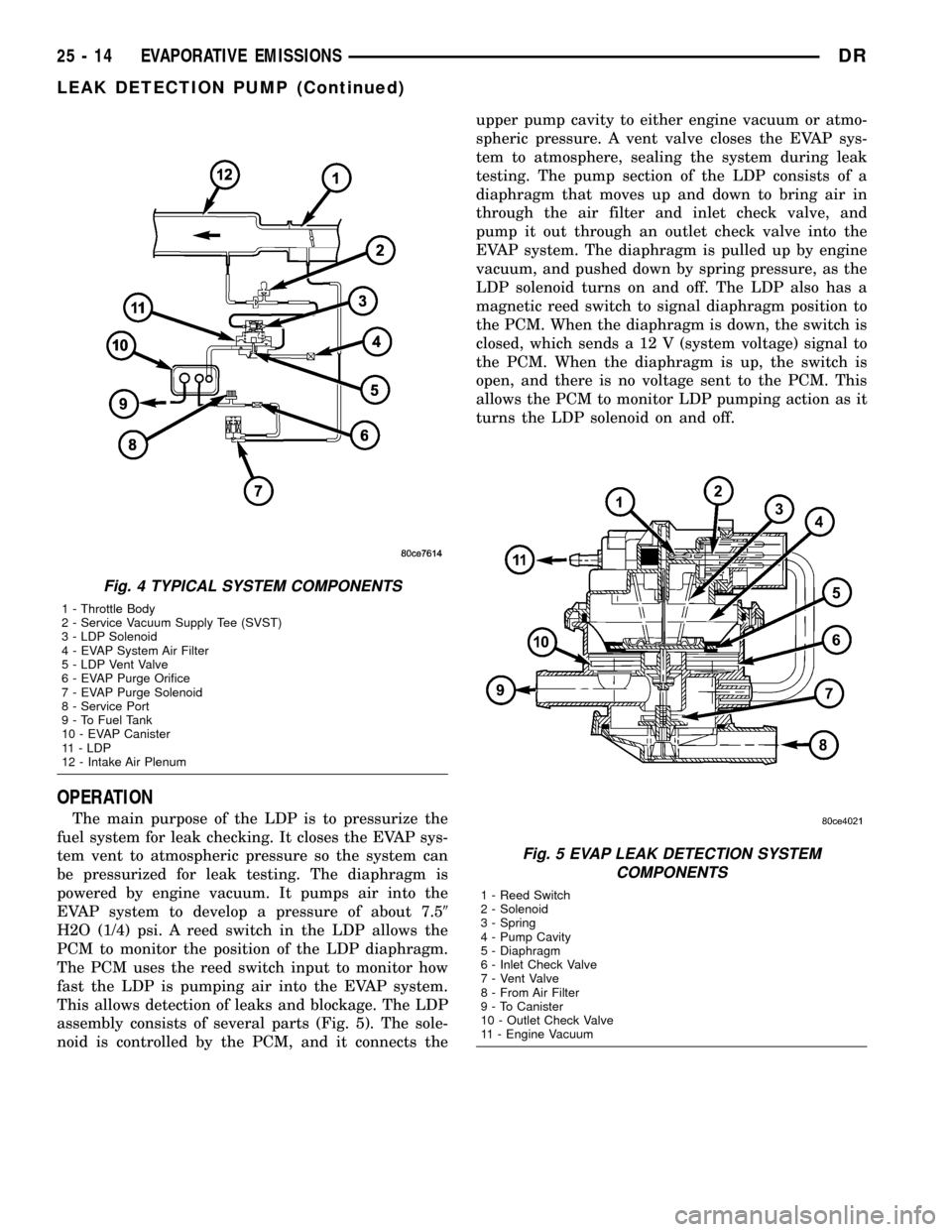

OPERATION

The main purpose of the LDP is to pressurize the

fuel system for leak checking. It closes the EVAP sys-

tem vent to atmospheric pressure so the system can

be pressurized for leak testing. The diaphragm is

powered by engine vacuum. It pumps air into the

EVAP system to develop a pressure of about 7.59

H2O (1/4) psi. A reed switch in the LDP allows the

PCM to monitor the position of the LDP diaphragm.

The PCM uses the reed switch input to monitor how

fast the LDP is pumping air into the EVAP system.

This allows detection of leaks and blockage. The LDP

assembly consists of several parts (Fig. 5). The sole-

noid is controlled by the PCM, and it connects theupper pump cavity to either engine vacuum or atmo-

spheric pressure. A vent valve closes the EVAP sys-

tem to atmosphere, sealing the system during leak

testing. The pump section of the LDP consists of a

diaphragm that moves up and down to bring air in

through the air filter and inlet check valve, and

pump it out through an outlet check valve into the

EVAP system. The diaphragm is pulled up by engine

vacuum, and pushed down by spring pressure, as the

LDP solenoid turns on and off. The LDP also has a

magnetic reed switch to signal diaphragm position to

the PCM. When the diaphragm is down, the switch is

closed, which sends a 12 V (system voltage) signal to

the PCM. When the diaphragm is up, the switch is

open, and there is no voltage sent to the PCM. This

allows the PCM to monitor LDP pumping action as it

turns the LDP solenoid on and off.

Fig. 4 TYPICAL SYSTEM COMPONENTS

1 - Throttle Body

2 - Service Vacuum Supply Tee (SVST)

3 - LDP Solenoid

4 - EVAP System Air Filter

5 - LDP Vent Valve

6 - EVAP Purge Orifice

7 - EVAP Purge Solenoid

8 - Service Port

9 - To Fuel Tank

10 - EVAP Canister

11 - LDP

12 - Intake Air Plenum

Fig. 5 EVAP LEAK DETECTION SYSTEM

COMPONENTS

1 - Reed Switch

2 - Solenoid

3 - Spring

4 - Pump Cavity

5 - Diaphragm

6 - Inlet Check Valve

7 - Vent Valve

8 - From Air Filter

9 - To Canister

10 - Outlet Check Valve

11 - Engine Vacuum

25 - 14 EVAPORATIVE EMISSIONSDR

LEAK DETECTION PUMP (Continued)

Page 2576 of 2627

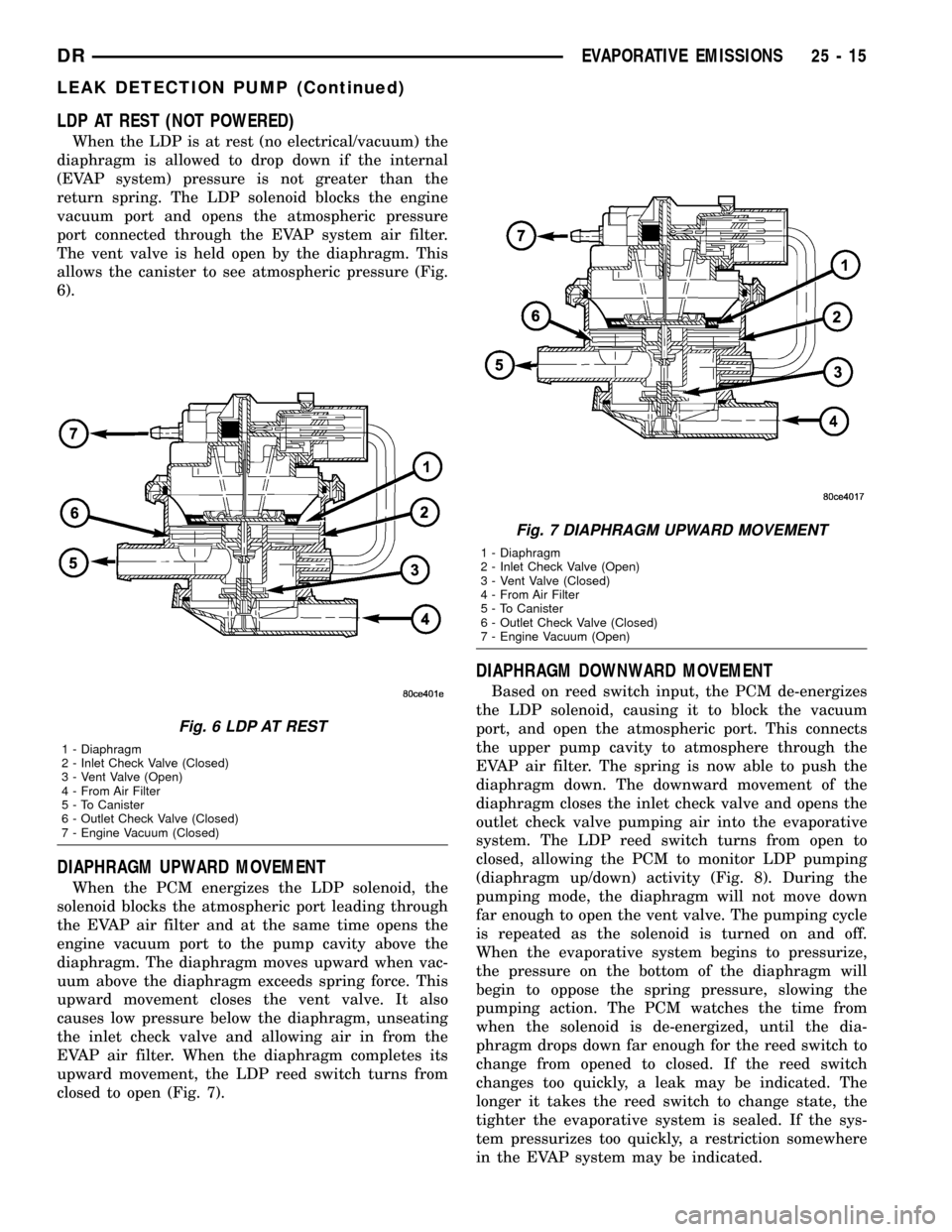

LDP AT REST (NOT POWERED)

When the LDP is at rest (no electrical/vacuum) the

diaphragm is allowed to drop down if the internal

(EVAP system) pressure is not greater than the

return spring. The LDP solenoid blocks the engine

vacuum port and opens the atmospheric pressure

port connected through the EVAP system air filter.

The vent valve is held open by the diaphragm. This

allows the canister to see atmospheric pressure (Fig.

6).

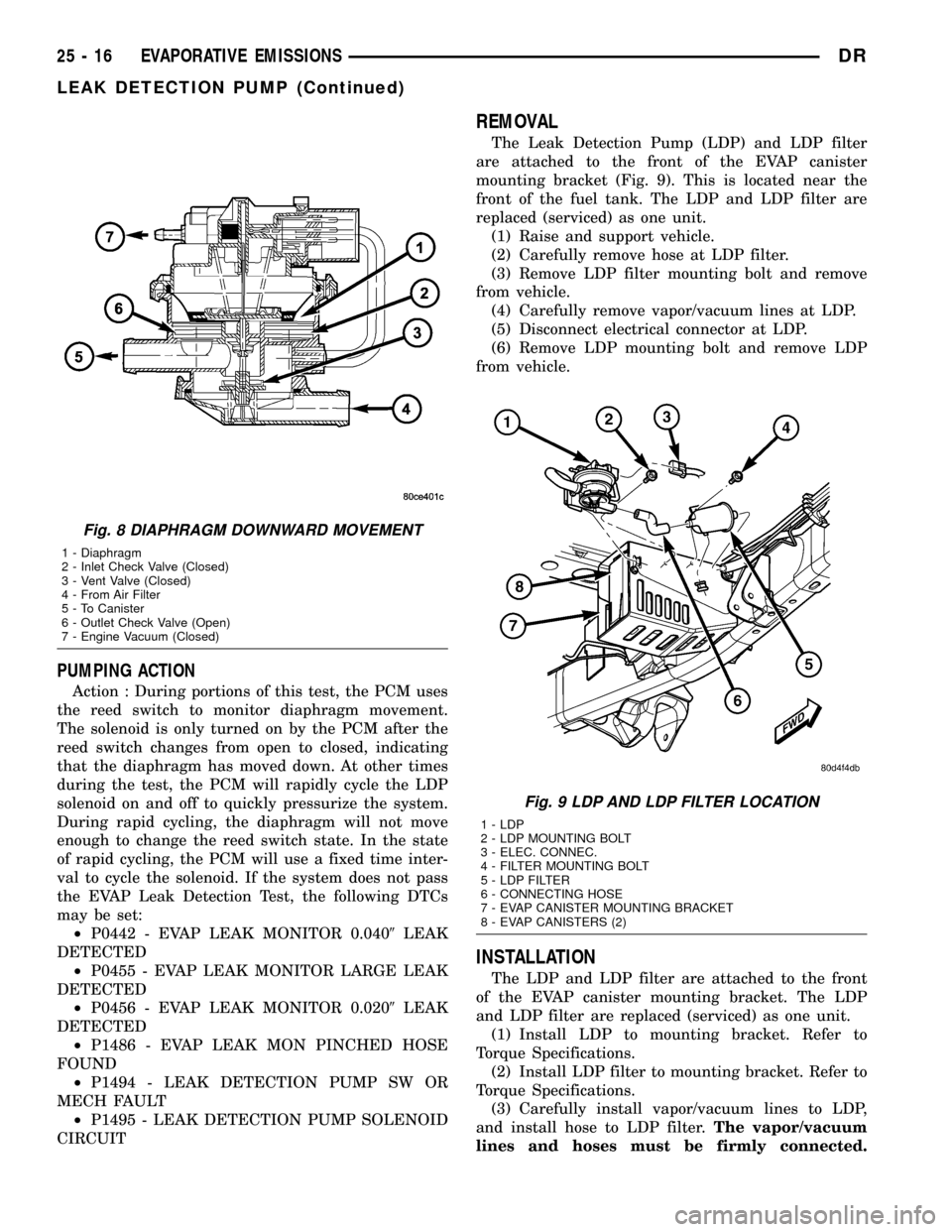

DIAPHRAGM UPWARD MOVEMENT

When the PCM energizes the LDP solenoid, the

solenoid blocks the atmospheric port leading through

the EVAP air filter and at the same time opens the

engine vacuum port to the pump cavity above the

diaphragm. The diaphragm moves upward when vac-

uum above the diaphragm exceeds spring force. This

upward movement closes the vent valve. It also

causes low pressure below the diaphragm, unseating

the inlet check valve and allowing air in from the

EVAP air filter. When the diaphragm completes its

upward movement, the LDP reed switch turns from

closed to open (Fig. 7).

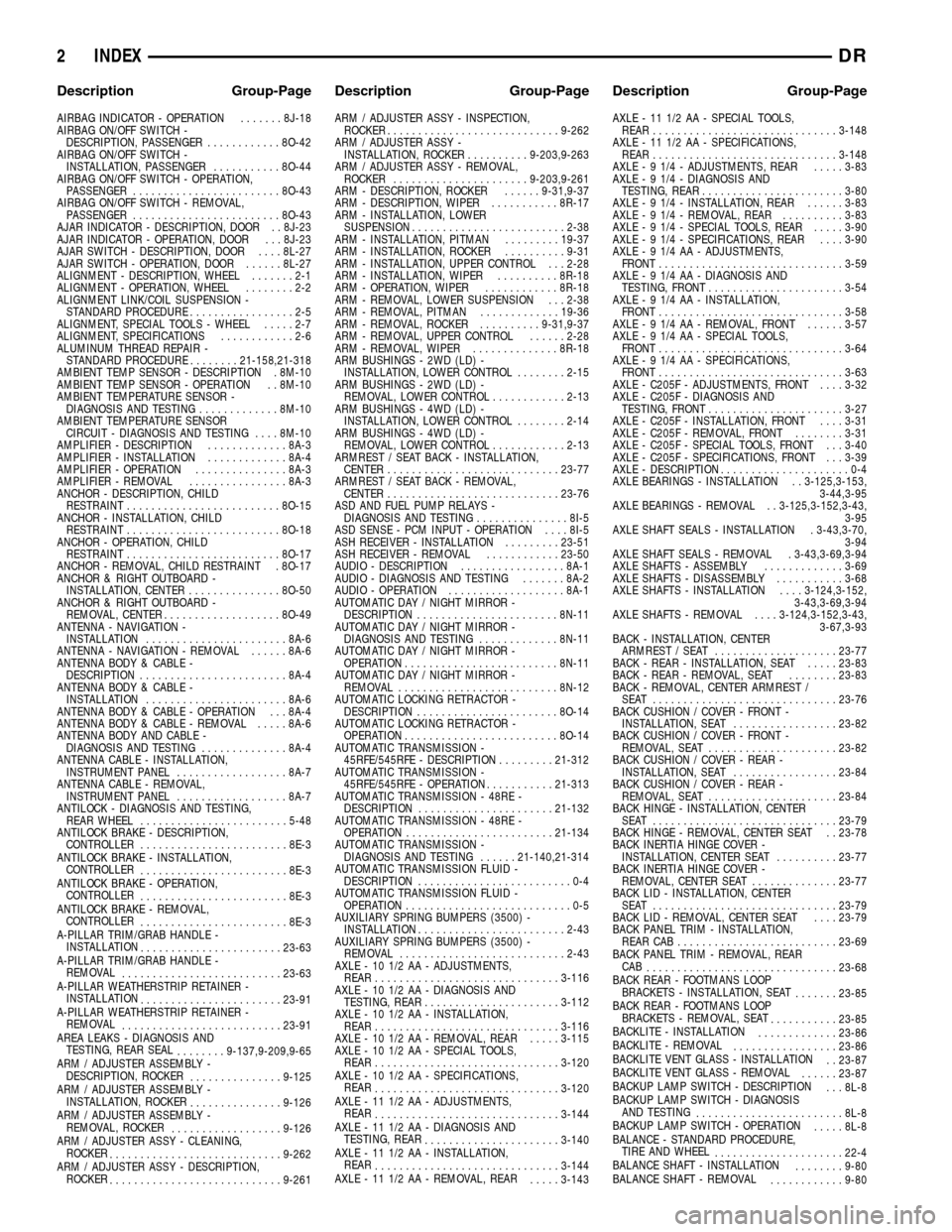

DIAPHRAGM DOWNWARD MOVEMENT

Based on reed switch input, the PCM de-energizes

the LDP solenoid, causing it to block the vacuum

port, and open the atmospheric port. This connects

the upper pump cavity to atmosphere through the

EVAP air filter. The spring is now able to push the

diaphragm down. The downward movement of the

diaphragm closes the inlet check valve and opens the

outlet check valve pumping air into the evaporative

system. The LDP reed switch turns from open to

closed, allowing the PCM to monitor LDP pumping

(diaphragm up/down) activity (Fig. 8). During the

pumping mode, the diaphragm will not move down

far enough to open the vent valve. The pumping cycle

is repeated as the solenoid is turned on and off.

When the evaporative system begins to pressurize,

the pressure on the bottom of the diaphragm will

begin to oppose the spring pressure, slowing the

pumping action. The PCM watches the time from

when the solenoid is de-energized, until the dia-

phragm drops down far enough for the reed switch to

change from opened to closed. If the reed switch

changes too quickly, a leak may be indicated. The

longer it takes the reed switch to change state, the

tighter the evaporative system is sealed. If the sys-

tem pressurizes too quickly, a restriction somewhere

in the EVAP system may be indicated.

Fig. 6 LDP AT REST

1 - Diaphragm

2 - Inlet Check Valve (Closed)

3 - Vent Valve (Open)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Closed)

7 - Engine Vacuum (Closed)

Fig. 7 DIAPHRAGM UPWARD MOVEMENT

1 - Diaphragm

2 - Inlet Check Valve (Open)

3 - Vent Valve (Closed)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Closed)

7 - Engine Vacuum (Open)

DREVAPORATIVE EMISSIONS 25 - 15

LEAK DETECTION PUMP (Continued)

Page 2577 of 2627

PUMPING ACTION

Action : During portions of this test, the PCM uses

the reed switch to monitor diaphragm movement.

The solenoid is only turned on by the PCM after the

reed switch changes from open to closed, indicating

that the diaphragm has moved down. At other times

during the test, the PCM will rapidly cycle the LDP

solenoid on and off to quickly pressurize the system.

During rapid cycling, the diaphragm will not move

enough to change the reed switch state. In the state

of rapid cycling, the PCM will use a fixed time inter-

val to cycle the solenoid. If the system does not pass

the EVAP Leak Detection Test, the following DTCs

may be set:

²P0442 - EVAP LEAK MONITOR 0.0409LEAK

DETECTED

²P0455 - EVAP LEAK MONITOR LARGE LEAK

DETECTED

²P0456 - EVAP LEAK MONITOR 0.0209LEAK

DETECTED

²P1486 - EVAP LEAK MON PINCHED HOSE

FOUND

²P1494 - LEAK DETECTION PUMP SW OR

MECH FAULT

²P1495 - LEAK DETECTION PUMP SOLENOID

CIRCUIT

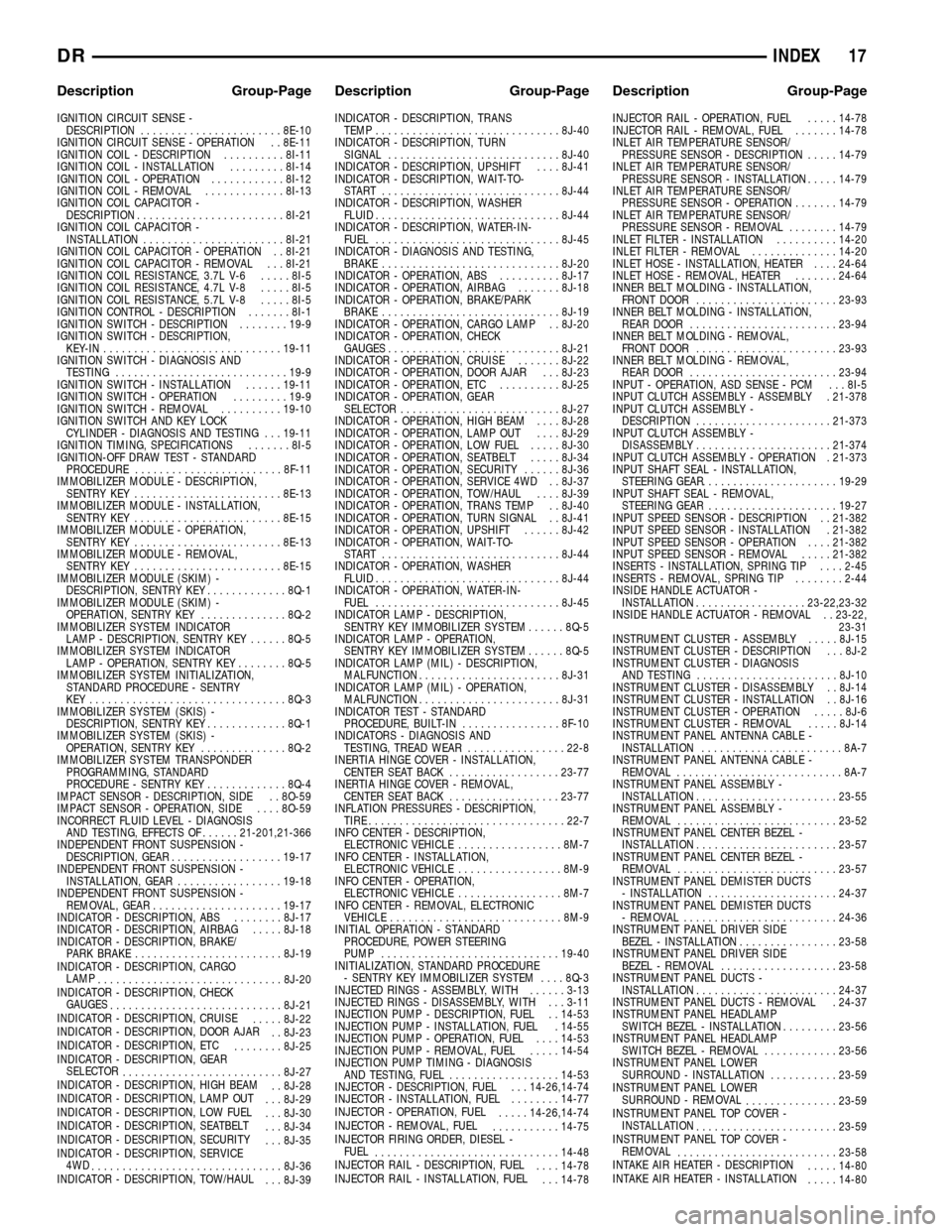

REMOVAL

The Leak Detection Pump (LDP) and LDP filter

are attached to the front of the EVAP canister

mounting bracket (Fig. 9). This is located near the

front of the fuel tank. The LDP and LDP filter are

replaced (serviced) as one unit.

(1) Raise and support vehicle.

(2) Carefully remove hose at LDP filter.

(3) Remove LDP filter mounting bolt and remove

from vehicle.

(4) Carefully remove vapor/vacuum lines at LDP.

(5) Disconnect electrical connector at LDP.

(6) Remove LDP mounting bolt and remove LDP

from vehicle.

INSTALLATION

The LDP and LDP filter are attached to the front

of the EVAP canister mounting bracket. The LDP

and LDP filter are replaced (serviced) as one unit.

(1) Install LDP to mounting bracket. Refer to

Torque Specifications.

(2) Install LDP filter to mounting bracket. Refer to

Torque Specifications.

(3) Carefully install vapor/vacuum lines to LDP,

and install hose to LDP filter.The vapor/vacuum

lines and hoses must be firmly connected.

Fig. 8 DIAPHRAGM DOWNWARD MOVEMENT

1 - Diaphragm

2 - Inlet Check Valve (Closed)

3 - Vent Valve (Closed)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Open)

7 - Engine Vacuum (Closed)

Fig. 9 LDP AND LDP FILTER LOCATION

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 16 EVAPORATIVE EMISSIONSDR

LEAK DETECTION PUMP (Continued)

Page 2589 of 2627

AIRBAG INDICATOR - OPERATION.......8J-18

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-42

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-44

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-43

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-43

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-23

AJAR INDICATOR - OPERATION, DOOR . . . 8J-23

AJAR SWITCH - DESCRIPTION, DOOR....8L-27

AJAR SWITCH - OPERATION, DOOR......8L-27

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS - WHEEL.....2-7

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE........21-158,21-318

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-10

AMBIENT TEMP SENSOR - OPERATION . . 8M-10

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING.............8M-10

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING....8M-10

AMPLIFIER - DESCRIPTION.............8A-3

AMPLIFIER - INSTALLATION.............8A-4

AMPLIFIER - OPERATION...............8A-3

AMPLIFIER - REMOVAL................8A-3

ANCHOR - DESCRIPTION, CHILD

RESTRAINT.........................8O-15

ANCHOR - INSTALLATION, CHILD

RESTRAINT.........................8O-18

ANCHOR - OPERATION, CHILD

RESTRAINT.........................8O-17

ANCHOR - REMOVAL, CHILD RESTRAINT . 8O-17

ANCHOR & RIGHT OUTBOARD -

INSTALLATION, CENTER...............8O-50

ANCHOR & RIGHT OUTBOARD -

REMOVAL, CENTER...................8O-49

ANTENNA - NAVIGATION -

INSTALLATION.......................8A-6

ANTENNA - NAVIGATION - REMOVAL......8A-6

ANTENNA BODY & CABLE -

DESCRIPTION........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION.......................8A-6

ANTENNA BODY & CABLE - OPERATION . . . 8A-4

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-7

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-7

ANTILOCK - DIAGNOSIS AND TESTING,

REAR WHEEL........................5-48

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - OPERATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - REMOVAL,

CONTROLLER

........................8E-3

A-PILLAR TRIM/GRAB HANDLE -

INSTALLATION

.......................23-63

A-PILLAR TRIM/GRAB HANDLE -

REMOVAL

..........................23-63

A-PILLAR WEATHERSTRIP RETAINER -

INSTALLATION

.......................23-91

A-PILLAR WEATHERSTRIP RETAINER -

REMOVAL

..........................23-91

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL

........9-137,9-209,9-65

ARM / ADJUSTER ASSEMBLY -

DESCRIPTION, ROCKER

...............9-125

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER

...............9-126

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER

..................9-126

ARM / ADJUSTER ASSY - CLEANING,

ROCKER

............................9-262

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER

............................9-261ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-262

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER..........9-203,9-263

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER......................9-203,9-261

ARM - DESCRIPTION, ROCKER......9-31,9-37

ARM - DESCRIPTION, WIPER...........8R-17

ARM - INSTALLATION, LOWER

SUSPENSION.........................2-38

ARM - INSTALLATION, PITMAN.........19-37

ARM - INSTALLATION, ROCKER..........9-31

ARM - INSTALLATION, UPPER CONTROL . . . 2-28

ARM - INSTALLATION, WIPER..........8R-18

ARM - OPERATION, WIPER............8R-18

ARM - REMOVAL, LOWER SUSPENSION . . . 2-38

ARM - REMOVAL, PITMAN.............19-36

ARM - REMOVAL, ROCKER..........9-31,9-37

ARM - REMOVAL, UPPER CONTROL......2-28

ARM - REMOVAL, WIPER..............8R-18

ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER CONTROL........2-15

ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER CONTROL........2-14

ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARMREST / SEAT BACK - INSTALLATION,

CENTER.............................23-77

ARMREST / SEAT BACK - REMOVAL,

CENTER............................23-76

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-5

ASD SENSE - PCM INPUT - OPERATION....8I-5

ASH RECEIVER - INSTALLATION.........23-51

ASH RECEIVER - REMOVAL............23-50

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-11

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-12

AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION.......................8O-14

AUTOMATIC LOCKING RETRACTOR -

OPERATION.........................8O-14

AUTOMATIC TRANSMISSION -

45RFE/545RFE - DESCRIPTION.........21-312

AUTOMATIC TRANSMISSION -

45RFE/545RFE - OPERATION...........21-313

AUTOMATIC TRANSMISSION - 48RE -

DESCRIPTION......................21-132

AUTOMATIC TRANSMISSION - 48RE -

OPERATION........................21-134

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-140,21-314

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-4

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AUXILIARY SPRING BUMPERS (3500) -

INSTALLATION........................2-43

AUXILIARY SPRING BUMPERS (3500) -

REMOVAL...........................2-43

AXLE - 10 1/2 AA - ADJUSTMENTS,

REAR..............................3-116

AXLE - 10 1/2 AA - DIAGNOSIS AND

TESTING, REAR......................3-112

AXLE - 10 1/2 AA - INSTALLATION,

REAR..............................3-116

AXLE - 10 1/2 AA - REMOVAL, REAR.....3-115

AXLE - 10 1/2 AA - SPECIAL TOOLS,

REAR..............................3-120

AXLE - 10 1/2 AA - SPECIFICATIONS,

REAR

..............................3-120

AXLE - 11 1/2 AA - ADJUSTMENTS,

REAR

..............................3-144

AXLE - 11 1/2 AA - DIAGNOSIS AND

TESTING, REAR

......................3-140

AXLE - 11 1/2 AA - INSTALLATION,

REAR

..............................3-144

AXLE - 11 1/2 AA - REMOVAL, REAR

.....3-143AXLE - 11 1/2 AA - SPECIAL TOOLS,

REAR..............................3-148

AXLE - 11 1/2 AA - SPECIFICATIONS,

REAR..............................3-148

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-83

AXLE - 9 1/4 - DIAGNOSIS AND

TESTING, REAR.......................3-80

AXLE - 9 1/4 - INSTALLATION, REAR......3-83

AXLE - 9 1/4 - REMOVAL, REAR..........3-83

AXLE - 9 1/4 - SPECIAL TOOLS, REAR.....3-90

AXLE - 9 1/4 - SPECIFICATIONS, REAR....3-90

AXLE - 9 1/4 AA - ADJUSTMENTS,

FRONT..............................3-59

AXLE - 9 1/4 AA - DIAGNOSIS AND

TESTING, FRONT......................3-54

AXLE - 9 1/4 AA - INSTALLATION,

FRONT..............................3-58

AXLE - 9 1/4 AA - REMOVAL, FRONT......3-57

AXLE - 9 1/4 AA - SPECIAL TOOLS,

FRONT..............................3-64

AXLE - 9 1/4 AA - SPECIFICATIONS,

FRONT..............................3-63

AXLE - C205F - ADJUSTMENTS, FRONT....3-32

AXLE - C205F - DIAGNOSIS AND

TESTING, FRONT......................3-27

AXLE - C205F - INSTALLATION, FRONT....3-31

AXLE - C205F - REMOVAL, FRONT........3-31

AXLE - C205F - SPECIAL TOOLS, FRONT . . . 3-40

AXLE - C205F - SPECIFICATIONS, FRONT . . . 3-39

AXLE - DESCRIPTION.....................0-4

AXLE BEARINGS - INSTALLATION . . 3-125,3-153,

3-44,3-95

AXLE BEARINGS - REMOVAL . . 3-125,3-152,3-43,

3-95

AXLE SHAFT SEALS - INSTALLATION . 3-43,3-70,

3-94

AXLE SHAFT SEALS - REMOVAL . 3-43,3-69,3-94

AXLE SHAFTS - ASSEMBLY.............3-69

AXLE SHAFTS - DISASSEMBLY...........3-68

AXLE SHAFTS - INSTALLATION....3-124,3-152,

3-43,3-69,3-94

AXLE SHAFTS - REMOVAL....3-124,3-152,3-43,

3-67,3-93

BACK - INSTALLATION, CENTER

ARMREST / SEAT....................23-77

BACK - REAR - INSTALLATION, SEAT.....23-83

BACK - REAR - REMOVAL, SEAT........23-83

BACK - REMOVAL, CENTER ARMREST /

SEAT ..............................23-76

BACK CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-82

BACK CUSHION / COVER - FRONT -

REMOVAL, SEAT.....................23-82

BACK CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-84

BACK CUSHION / COVER - REAR -

REMOVAL, SEAT.....................23-84

BACK HINGE - INSTALLATION, CENTER

SEAT ..............................23-79

BACK HINGE - REMOVAL, CENTER SEAT . . 23-78

BACK INERTIA HINGE COVER -

INSTALLATION, CENTER SEAT..........23-77

BACK INERTIA HINGE COVER -

REMOVAL, CENTER SEAT..............23-77

BACK LID - INSTALLATION, CENTER

SEAT ..............................23-79

BACK LID - REMOVAL, CENTER SEAT....23-79

BACK PANEL TRIM - INSTALLATION,

REAR CAB..........................23-69

BACK PANEL TRIM - REMOVAL, REAR

CAB

...............................23-68

BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION, SEAT

.......23-85

BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL, SEAT

...........23-85

BACKLITE - INSTALLATION

.............23-86

BACKLITE - REMOVAL

.................23-86

BACKLITE VENT GLASS - INSTALLATION

. . 23-87

BACKLITE VENT GLASS - REMOVAL

......23-87

BACKUP LAMP SWITCH - DESCRIPTION

. . . 8L-8

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING

........................8L-8

BACKUP LAMP SWITCH - OPERATION

.....8L-8

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL

.....................22-4

BALANCE SHAFT - INSTALLATION

........9-80

BALANCE SHAFT - REMOVAL

............9-80

2 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2604 of 2627

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-10

IGNITION CIRCUIT SENSE - OPERATION . . 8E-11

IGNITION COIL - DESCRIPTION..........8I-11

IGNITION COIL - INSTALLATION.........8I-14

IGNITION COIL - OPERATION............8I-12

IGNITION COIL - REMOVAL.............8I-13

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-21

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-21

IGNITION COIL CAPACITOR - OPERATION . . 8I-21

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-21

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-5

IGNITION COIL RESISTANCE, 4.7L V-8.....8I-5

IGNITION COIL RESISTANCE, 5.7L V-8.....8I-5

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION SWITCH - DESCRIPTION........19-9

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-11

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-9

IGNITION SWITCH - INSTALLATION......19-11

IGNITION SWITCH - OPERATION.........19-9

IGNITION SWITCH - REMOVAL..........19-10

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-11

IGNITION TIMING, SPECIFICATIONS.......8I-5

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-11

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE (SKIM) -

DESCRIPTION, SENTRY KEY.............8Q-1

IMMOBILIZER MODULE (SKIM) -

OPERATION, SENTRY KEY..............8Q-2

IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY KEY......8Q-5

IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY KEY........8Q-5

IMMOBILIZER SYSTEM INITIALIZATION,

STANDARD PROCEDURE - SENTRY

KEY................................8Q-3

IMMOBILIZER SYSTEM (SKIS) -

DESCRIPTION, SENTRY KEY.............8Q-1

IMMOBILIZER SYSTEM (SKIS) -

OPERATION, SENTRY KEY..............8Q-2

IMMOBILIZER SYSTEM TRANSPONDER

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY.............8Q-4

IMPACT SENSOR - DESCRIPTION, SIDE . . 8O-59

IMPACT SENSOR - OPERATION, SIDE....8O-59

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF......21-201,21-366

INDEPENDENT FRONT SUSPENSION -

DESCRIPTION, GEAR..................19-17

INDEPENDENT FRONT SUSPENSION -

INSTALLATION, GEAR.................19-18

INDEPENDENT FRONT SUSPENSION -

REMOVAL, GEAR.....................19-17

INDICATOR - DESCRIPTION, ABS........8J-17

INDICATOR - DESCRIPTION, AIRBAG.....8J-18

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-19

INDICATOR - DESCRIPTION, CARGO

LAMP

..............................8J-20

INDICATOR - DESCRIPTION, CHECK

GAUGES

............................8J-21

INDICATOR - DESCRIPTION, CRUISE

.....8J-22

INDICATOR - DESCRIPTION, DOOR AJAR

. . 8J-23

INDICATOR - DESCRIPTION, ETC

........8J-25

INDICATOR - DESCRIPTION, GEAR

SELECTOR

..........................8J-27

INDICATOR - DESCRIPTION, HIGH BEAM

. . 8J-28

INDICATOR - DESCRIPTION, LAMP OUT

. . . 8J-29

INDICATOR - DESCRIPTION, LOW FUEL

. . . 8J-30

INDICATOR - DESCRIPTION, SEATBELT

. . . 8J-34

INDICATOR - DESCRIPTION, SECURITY

. . . 8J-35

INDICATOR - DESCRIPTION, SERVICE

4WD

...............................8J-36

INDICATOR - DESCRIPTION, TOW/HAUL

. . . 8J-39INDICATOR - DESCRIPTION, TRANS

TEMP..............................8J-40

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-40

INDICATOR - DESCRIPTION, UPSHIFT....8J-41

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-44

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-44

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-45

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-20

INDICATOR - OPERATION, ABS..........8J-17

INDICATOR - OPERATION, AIRBAG.......8J-18

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-19

INDICATOR - OPERATION, CARGO LAMP . . 8J-20

INDICATOR - OPERATION, CHECK

GAUGES............................8J-21

INDICATOR - OPERATION, CRUISE.......8J-22

INDICATOR - OPERATION, DOOR AJAR . . . 8J-23

INDICATOR - OPERATION, ETC..........8J-25

INDICATOR - OPERATION, GEAR

SELECTOR..........................8J-27

INDICATOR - OPERATION, HIGH BEAM....8J-28

INDICATOR - OPERATION, LAMP OUT....8J-29

INDICATOR - OPERATION, LOW FUEL.....8J-30

INDICATOR - OPERATION, SEATBELT.....8J-34

INDICATOR - OPERATION, SECURITY......8J-36

INDICATOR - OPERATION, SERVICE 4WD . . 8J-37

INDICATOR - OPERATION, TOW/HAUL....8J-39

INDICATOR - OPERATION, TRANS TEMP . . 8J-40

INDICATOR - OPERATION, TURN SIGNAL . . 8J-41

INDICATOR - OPERATION, UPSHIFT......8J-42

INDICATOR - OPERATION, WAIT-TO-

START .............................8J-44

INDICATOR - OPERATION, WASHER

FLUID..............................8J-44

INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-45

INDICATOR LAMP - DESCRIPTION,

SENTRY KEY IMMOBILIZER SYSTEM......8Q-5

INDICATOR LAMP - OPERATION,

SENTRY KEY IMMOBILIZER SYSTEM......8Q-5

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-31

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-31

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-10

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-8

INERTIA HINGE COVER - INSTALLATION,

CENTER SEAT BACK..................23-77

INERTIA HINGE COVER - REMOVAL,

CENTER SEAT BACK..................23-77

INFLATION PRESSURES - DESCRIPTION,

TIRE................................22-7

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-40

INITIALIZATION, STANDARD PROCEDURE

- SENTRY KEY IMMOBILIZER SYSTEM....8Q-3

INJECTED RINGS - ASSEMBLY, WITH......3-13

INJECTED RINGS - DISASSEMBLY, WITH . . . 3-11

INJECTION PUMP - DESCRIPTION, FUEL . . 14-53

INJECTION PUMP - INSTALLATION, FUEL . 14-55

INJECTION PUMP - OPERATION, FUEL....14-53

INJECTION PUMP - REMOVAL, FUEL.....14-54

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-53

INJECTOR - DESCRIPTION, FUEL . . . 14-26,14-74

INJECTOR - INSTALLATION, FUEL........14-77

INJECTOR - OPERATION, FUEL

.....14-26,14-74

INJECTOR - REMOVAL, FUEL

...........14-75

INJECTOR FIRING ORDER, DIESEL -

FUEL

..............................14-48

INJECTOR RAIL - DESCRIPTION, FUEL

....14-78

INJECTOR RAIL - INSTALLATION, FUEL

. . . 14-78INJECTOR RAIL - OPERATION, FUEL.....14-78

INJECTOR RAIL - REMOVAL, FUEL.......14-78

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - DESCRIPTION.....14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - INSTALLATION.....14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - OPERATION.......14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - REMOVAL........14-79

INLET FILTER - INSTALLATION..........14-20

INLET FILTER - REMOVAL..............14-20

INLET HOSE - INSTALLATION, HEATER....24-64

INLET HOSE - REMOVAL, HEATER.......24-64

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR.......................23-93

INNER BELT MOLDING - INSTALLATION,

REAR DOOR........................23-94

INNER BELT MOLDING - REMOVAL,

FRONT DOOR.......................23-93

INNER BELT MOLDING - REMOVAL,

REAR DOOR........................23-94

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-5

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-378

INPUT CLUTCH ASSEMBLY -

DESCRIPTION......................21-373

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY......................21-374

INPUT CLUTCH ASSEMBLY - OPERATION . 21-373

INPUT SHAFT SEAL - INSTALLATION,

STEERING GEAR.......................19-29

INPUT SHAFT SEAL - REMOVAL,

STEERING GEAR.....................19-27

INPUT SPEED SENSOR - DESCRIPTION . . 21-382

INPUT SPEED SENSOR - INSTALLATION . 21-382

INPUT SPEED SENSOR - OPERATION....21-382

INPUT SPEED SENSOR - REMOVAL.....21-382

INSERTS - INSTALLATION, SPRING TIP....2-45

INSERTS - REMOVAL, SPRING TIP........2-44

INSIDE HANDLE ACTUATOR -

INSTALLATION..................23-22,23-32

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-22,

23-31

INSTRUMENT CLUSTER - ASSEMBLY.....8J-15

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING.......................8J-10

INSTRUMENT CLUSTER - DISASSEMBLY . . 8J-14

INSTRUMENT CLUSTER - INSTALLATION . . 8J-16

INSTRUMENT CLUSTER - OPERATION.....8J-6

INSTRUMENT CLUSTER - REMOVAL.....8J-14

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-7

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-7

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION.......................23-55

INSTRUMENT PANEL ASSEMBLY -

REMOVAL..........................23-52

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION.......................23-57

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL..........................23-57

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-37

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-36

INSTRUMENT PANEL DRIVER SIDE

BEZEL - INSTALLATION................23-58

INSTRUMENT PANEL DRIVER SIDE

BEZEL - REMOVAL...................23-58

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL HEADLAMP

SWITCH BEZEL - INSTALLATION.........23-56

INSTRUMENT PANEL HEADLAMP

SWITCH BEZEL - REMOVAL............23-56

INSTRUMENT PANEL LOWER

SURROUND - INSTALLATION...........23-59

INSTRUMENT PANEL LOWER

SURROUND - REMOVAL

...............23-59

INSTRUMENT PANEL TOP COVER -

INSTALLATION

.......................23-59

INSTRUMENT PANEL TOP COVER -

REMOVAL

..........................23-58

INTAKE AIR HEATER - DESCRIPTION

.....14-80

INTAKE AIR HEATER - INSTALLATION

.....14-80

DRINDEX 17

Description Group-Page Description Group-Page Description Group-Page

Page 2610 of 2627

OUTER TIE ROD END - REMOVAL.......19-32

OUTLET - DESCRIPTION, CIGAR

LIGHTER.........................8W-97-2

OUTLET - DESCRIPTION, POWER......8W-97-7

OUTLET - DIAGNOSIS AND TESTING,

CIGAR LIGHTER...................8W-97-2

OUTLET - DIAGNOSIS AND TESTING,

POWER..........................8W-97-7

OUTLET - INSTALLATION, POWER.....8W-97-8

OUTLET - OPERATION, CIGAR LIGHTER . 8W-97-2

OUTLET - OPERATION, POWER.......8W-97-7

OUTLET - REMOVAL, POWER.........8W-97-8

OUTLETS - DESCRIPTION, AIR..........24-26

OUTLETS - INSTALLATION, AIR.........24-27

OUTLETS - REMOVAL, AIR.............24-26

OUTPUT - DESCRIPTION, PCM...........8I-5

OUTPUT - OPERATION, PCM............14-27

OUTPUT - OPERATION, PCM.............8I-5

OUTPUT SHAFT FRONT BEARING -

INSTALLATION......................21-216

OUTPUT SHAFT FRONT BEARING -

REMOVAL.........................21-216

OUTPUT SHAFT REAR BEARING -

INSTALLATION......................21-217

OUTPUT SHAFT REAR BEARING -

REMOVAL.........................21-216

OUTPUT SHAFT SEAL - INSTALLATION,

FRONT....21-442,21-477,21-508,21-538,21-572

OUTPUT SHAFT SEAL - REMOVAL,

FRONT.....21-441,21-477,21-507,21-537,21-572

OUTPUT SPEED SENSOR - DESCRIPTION . 21-391

OUTPUT SPEED SENSOR -

INSTALLATION......................21-392

OUTPUT SPEED SENSOR - OPERATION . . 21-391

OUTPUT SPEED SENSOR - REMOVAL . . . 21-391

OVERDRIVE CLUTCH - DESCRIPTION....21-217

OVERDRIVE CLUTCH - OPERATION.....21-217

OVERDRIVE ELECTRICAL CONTROLS -

DIAGNOSIS AND TESTING............21-262

OVERDRIVE SWITCH - DESCRIPTION,

TOW/HAUL..................21-261,21-392

OVERDRIVE SWITCH - INSTALLATION,

TOW/HAUL..................21-262,21-393

OVERDRIVE SWITCH - OPERATION,

TOW/HAUL..................21-262,21-392

OVERDRIVE SWITCH - REMOVAL,

TOW/HAUL..................21-262,21-392

OVERDRIVE UNIT - ASSEMBLY.........21-226

OVERDRIVE UNIT - CLEANING.........21-225

OVERDRIVE UNIT - DISASSEMBLY......21-218

OVERDRIVE UNIT - INSPECTION.......21-225

OVERDRIVE UNIT - INSTALLATION......21-235

OVERDRIVE UNIT - REMOVAL.........21-218

OVERFLOW VALVE - DESCRIPTION,

CASCADE...........................14-66

OVERFLOW VALVE - OPERATION,

CASCADE...........................14-66

OVERHEAD CONSOLE - DESCRIPTION....8M-1

OVERHEAD CONSOLE - DIAGNOSIS AND

TESTING............................8M-2

OVERHEAD CONSOLE - OPERATION......8M-2

OVERHEAD CONSOLE REMOVAL,

REMOVAL

...........................8M-6

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

ASSEMBLY

.........................21-237

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

CLEANING

.........................21-236

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

DESCRIPTION

......................21-236

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

DISASSEMBLY

......................21-236

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

INSPECTION

.......................21-237

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

OPERATION

........................21-236

OXYGEN SENSOR - DESCRIPTION

.......14-35

OXYGEN SENSOR - INSTALLATION

.......14-36

OXYGEN SENSOR - REMOVAL

..........14-35

PAINT CODE - DESCRIPTION

...........23-73

PAINT CODES - SPECIFICATIONS

........23-73

PAINT TOUCH-UP - DESCRIPTION

.......23-74PAINT TOUCH-UP - STANDARD

PROCEDURE........................23-74

PAN - CLEANING, OIL.............9-293,9-66

PAN - DESCRIPTION, OIL...............9-66

PAN - INSPECTION, OIL...........9-293,9-66

PAN - INSTALLATION, OIL . . . 9-155,9-224,9-293,

9-66

PAN - REMOVAL, OIL . . . 9-155,9-224,9-293,9-66

PANEL - INSTALLATION, TRIM.....23-24,23-33

PANEL - REMOVAL, TRIM.........23-24,23-33

PANEL ANTENNA CABLE -

INSTALLATION, INSTRUMENT............8A-7

PANEL ANTENNA CABLE - REMOVAL,

INSTRUMENT........................8A-7

PANEL ASSEMBLY - INSTALLATION,

INSTRUMENT.......................23-55

PANEL ASSEMBLY - REMOVAL,

INSTRUMENT.......................23-52

PANEL CENTER BEZEL - INSTALLATION,

INSTRUMENT.......................23-57

PANEL CENTER BEZEL - REMOVAL,

INSTRUMENT.......................23-57

PANEL DEMISTER DUCTS -

INSTALLATION, INSTRUMENT...........24-37

PANEL DEMISTER DUCTS - REMOVAL,

INSTRUMENT.......................24-36

PANEL DRIVER SIDE BEZEL -

INSTALLATION, INSTRUMENT...........23-58

PANEL DRIVER SIDE BEZEL - REMOVAL,

INSTRUMENT.......................23-58

PANEL DUCTS - INSTALLATION,

INSTRUMENT.........................24-37

PANEL DUCTS - REMOVAL,

INSTRUMENT.......................24-37

PANEL HEADLAMP SWITCH BEZEL -

INSTALLATION, INSTRUMENT...........23-56

PANEL HEADLAMP SWITCH BEZEL -

REMOVAL, INSTRUMENT..............23-56

PANEL LOWER SURROUND -

INSTALLATION, INSTRUMENT...........23-59

PANEL LOWER SURROUND - REMOVAL,

INSTRUMENT.......................23-59

PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC BODY............23-3

PANEL TOP COVER - INSTALLATION,

INSTRUMENT.......................23-59

PANEL TOP COVER - REMOVAL,

INSTRUMENT.......................23-58

PANEL TRIM - INSTALLATION, REAR

CAB BACK..........................23-69

PANEL TRIM - REMOVAL, REAR CAB

BACK..............................23-68

PARK BRAKE CABLE - INSTALLATION,

REAR...............................5-38

PARK BRAKE CABLE - REMOVAL, REAR . . . 5-37

PARK LAMP RELAY - DESCRIPTION......8L-20

PARK LAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-20

PARK LAMP RELAY - INSTALLATION.....8L-21

PARK LAMP RELAY - OPERATION.......8L-20

PARK LAMP RELAY - REMOVAL.........8L-21

PARKING BRAKE - DESCRIPTION.........5-36

PARKING BRAKE - OPERATION...........5-36

PARKING BRAKE CABLE -

INSTALLATION, FRONT.................5-38

PARKING BRAKE CABLE - REMOVAL,

FRONT..............................5-36

PARKING BRAKE SHOES - ADJUSTMENT

. . . 5-41

PARK/TURN SIGNAL LAMP -

INSTALLATION

.......................8L-21

PARK/TURN SIGNAL LAMP - REMOVAL

. . . 8L-21

PARTS - STANDARD PROCEDURES,

CLEANING FUEL SYSTEM

..............14-47

PASSENGER AIRBAG - DESCRIPTION

....8O-39

PASSENGER AIRBAG - INSTALLATION

....8O-41

PASSENGER AIRBAG - OPERATION

......8O-40

PASSENGER AIRBAG - REMOVAL

........8O-40

PASSENGER AIRBAG ON/OFF SWITCH -

DESCRIPTION

.......................8O-42

PASSENGER AIRBAG ON/OFF SWITCH -

INSTALLATION

......................8O-44

PASSENGER AIRBAG ON/OFF SWITCH -

OPERATION

.........................8O-43

PASSENGER AIRBAG ON/OFF SWITCH -

REMOVAL

..........................8O-43

PASSENGER SEAT SWITCH -

DESCRIPTION

.......................8N-15PASSENGER SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8N-16

PASSENGER SEAT SWITCH -

INSTALLATION......................8N-16

PASSENGER SEAT SWITCH - OPERATION . 8N-15

PASSENGER SEAT SWITCH - REMOVAL . . . 8N-16

PATTERNS - DIAGNOSIS AND TESTING,

TIRE WEAR..........................22-8

PCM - DESCRIPTION...................8E-7

PCM - OPERATION...................8E-10

PCM INPUT - OPERATION, ASD SENSE.....8I-5

PCM OUTPUT - DESCRIPTION............8I-5

PCM OUTPUT - OPERATION............14-27

PCM OUTPUT - OPERATION.............8I-5

PCM/SKIM PROGRAMMING - STANDARD

PROCEDURE........................8E-14

PCV VALVE - 3.7L V-6/ 4.7L V-8 -

DIAGNOSIS AND TESTING.............25-20

PCV VALVE - DESCRIPTION............25-17

PCV VALVE - INSTALLATION............25-21

PCV VALVE - OPERATION..............25-19

PCV VALVE - REMOVAL...............25-21

PEDAL - DESCRIPTION.................5-28

PEDAL - INSTALLATION............5-28,5-42

PEDAL - INSTALLATION, ACCELERATOR . . . 14-21

PEDAL - OPERATION...................5-28

PEDAL - REMOVAL................5-28,5-42

PEDAL - REMOVAL, ACCELERATOR........14-21

PEDAL MOTOR - DESCRIPTION,

ADJUSTABLE..........................5-6

PEDAL MOTOR - INSTALLATION,

ADJUSTABLE..........................5-7

PEDAL MOTOR - REMOVAL,

ADJUSTABLE..........................5-7

PEDAL POSITION SENSOR -

DESCRIPTION, ACCELERATOR.....14-22,14-68

PEDAL POSITION SENSOR -

INSTALLATION, ACCELERATOR.....14-22,14-71

PEDAL POSITION SENSOR - OPERATION,

ACCELERATOR.................14-22,14-68

PEDAL POSITION SENSOR - REMOVAL,

ACCELERATOR.................14-22,14-68

PEDAL POSITION SWITCH -

DESCRIPTION, CLUTCH.................6-13

PEDAL POSITION SWITCH - DIAGNOSIS

AND TESTING, CLUTCH.................6-13

PEDAL POSITION SWITCH - OPERATION,

CLUTCH.............................6-13

PEDAL SWITCH - INSTALLATION,

ADJUSTABLE..........................5-6

PEDAL SWITCH - REMOVAL,

ADJUSTABLE..........................5-6

PER MILE, SPECIFICATIONS - TIRE

REVOLUTIONS.......................22-10

PERFORMANCE - DIAGNOSIS AND

TESTING, A/C........................24-3

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS . . . 9-183,9-4,9-90

PERFORMANCE TEST - DIAGNOSIS AND

TESTING, HEATER.....................24-6

PILOT BEARING - INSTALLATION.........6-12

PILOT BEARING - REMOVAL.............6-11

PINION GEAR/RING GEAR -

INSTALLATION....................3-51,3-77

PINION GEAR/RING GEAR - REMOVAL . 3-49,3-75

PINION GEAR/RING GEAR/TONE RING -

INSTALLATION.............3-108,3-137,3-164

PINION GEAR/RING GEAR/TONE RING -

REMOVAL................3-106,3-134,3-162

PINION SEAL - INSTALLATION . 3-126,3-154,3-45,

3-71,3-96

PINION SEAL - REMOVAL....3-126,3-153,3-44,

3-70,3-95

PIPE - INSPECTION, EXHAUST.......11-7,11-8

PISTON & CONNECTING ROD -

CLEANING.....................9-140,9-212

PISTON & CONNECTING ROD -

DESCRIPTION.........9-139,9-211,9-281,9-48

PISTON & CONNECTING ROD -

INSPECTION

...................9-140,9-213

PISTON & CONNECTING ROD -

INSTALLATION

..................9-140,9-213

PISTON & CONNECTING ROD -

REMOVAL

................9-139,9-212,9-281

PISTON AND CONNECTING ROD -

CLEANING

..........................9-282

PISTON FITTING - STANDARD

PROCEDURE

...............9-139,9-211,9-51

DRINDEX 23

Description Group-Page Description Group-Page Description Group-Page

Page 2612 of 2627

PRESSURE HOSE - REMOVAL.....19-44,19-45

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION . . . 9-186,9-8,

9-93

PRESSURE LIMITING VALVE -

DESCRIPTION, FUEL..................14-61

PRESSURE LIMITING VALVE -

INSTALLATION, FUEL.................14-61

PRESSURE LIMITING VALVE -

OPERATION, FUEL....................14-61

PRESSURE LIMITING VALVE - REMOVAL,

FUEL..............................14-61

PRESSURE (LP) SENSOR -

DESCRIPTION, LINE.................21-382

PRESSURE (LP) SENSOR -

INSTALLATION, LINE.................21-383

PRESSURE (LP) SENSOR - OPERATION,

LINE..............................21-383

PRESSURE (LP) SENSOR - REMOVAL,

LINE..............................21-383

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-2

PRESSURE RELIEF VALVE - CLEANING,

OIL................................9-294

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH..................24-48

PRESSURE RELIEF VALVE - INSPECTION,

OIL................................9-294

PRESSURE RELIEF VALVE -

INSTALLATION, OIL...................9-294

PRESSURE RELIEF VALVE - OPERATION,

HIGH..............................24-48

PRESSURE RELIEF VALVE - REMOVAL,

OIL.................................9-294

PRESSURE SENSOR - DESCRIPTION,

FUEL..............................14-60

PRESSURE SENSOR - INSTALLATION,

FUEL..............................14-61

PRESSURE SENSOR - OPERATION, FUEL . . 14-60

PRESSURE SENSOR - REMOVAL, FUEL . . . 14-60

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-67

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL....................9-67

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-67

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL.......................9-67

PRESSURE, SPECIFICATIONS - FUEL

SYSTEM............................14-3

PRESSURE SWITCH - DESCRIPTION,

POWER STEERING...................19-46

PRESSURE SWITCH - INSTALLATION,

OIL................................9-294

PRESSURE SWITCH - OPERATION,

POWER STEERING...................19-46

PRESSURE SWITCH - REMOVAL, OIL.....9-294

PRESSURE TEST - DIAGNOSIS AND

TESTING, HYDRAULIC..........21-141,21-316

PRESSURE TRANSDUCER -

DESCRIPTION, A/C

...................24-15

PRESSURE TRANSDUCER - DIAGNOSIS

AND TESTING, A/C

...................24-16

PRESSURE TRANSDUCER -

INSTALLATION, A/C

...................24-16

PRESSURE TRANSDUCER - OPERATION,

A/C

................................24-16

PRESSURE TRANSDUCER - REMOVAL,

A/C

................................24-16

PRESSURES - DESCRIPTION, TIRE

INFLATION

...........................22-7

PRIMING - STANDARD PROCEDURE,

FUEL SYSTEM

.......................14-47

PROCESS - SPECIFICATIONS, WELD

.....13-15

PROGRAMING - STANDARD

PROCEDURE, RKE TRANSMITTER

........8N-9

PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC VEHICLE

INFORMATION CENTER

................8M-8

PROGRAMMING - STANDARD

PROCEDURE, ENHANCED SEATBELT

REMINDER

..........................8J-35

PROGRAMMING - STANDARD

PROCEDURE, PCM/SKIM

...............8E-14

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY

IMMOBILIZER SYSTEM TRANSPONDER

....8Q-4PROPELLER SHAFT - DIAGNOSIS AND

TESTING.............................3-1

PROPELLER SHAFT - HD FRONT -

INSTALLATION.........................3-7

PROPELLER SHAFT - HD FRONT -

REMOVAL............................3-7

PROPELLER SHAFT - INSTALLATION,

REAR................................3-8

PROPELLER SHAFT - REMOVAL, REAR.....3-8

PROPELLER SHAFT - SPECIAL TOOLS......3-6

PROPELLER SHAFT - SPECIFICATIONS......3-6

PROPELLER SHAFT - STANDARD

PROCEDURE..........................3-3

PROPELLER SHAFT- LD FRONT -

INSTALLATION.........................3-7

PROPELLER SHAFT- LD FRONT -

REMOVAL............................3-6

PROPORTIONING - DESCRIPTION,

ELECTRONIC VARIABLE BRAKE..........5-49

PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE BRAKE..........5-49

PTO SWITCH - DESCRIPTION......14-36,14-85

PTO SWITCH - OPERATION........14-36,14-85

PULLEY - INSTALLATION..............19-47

PULLEY - REMOVAL..................19-47

PUMP - 5.7L - INSTALLATION, WATER.....7-63

PUMP - 5.7L - REMOVAL, WATER........7-63

PUMP - 5.9L DIESEL - CLEANING,

WATER .............................7-62

PUMP - 5.9L DIESEL - DESCRIPTION,

WATER...............................7-62

PUMP - 5.9L DIESEL - INSPECTION,

WATER .............................7-62

PUMP - 5.9L DIESEL - INSTALLATION,

WATER .............................7-62

PUMP - 5.9L DIESEL - OPERATION,

WATER .............................7-62

PUMP - 5.9L DIESEL - REMOVAL,

WATER .............................7-62

PUMP - 8.0L - CLEANING, WATER........7-66

PUMP - 8.0L - INSPECTION, WATER......7-66

PUMP - 8.0L - INSTALLATION, WATER.....7-66

PUMP - 8.0L - REMOVAL, WATER........7-64

PUMP - ASSEMBLY, OIL...........9-158,9-69

PUMP - ASSEMBLY, OIL........21-214,21-390

PUMP - CLEANING, OIL.....9-157,9-224,9-295

PUMP - CLEANING, OIL........21-214,21-390

PUMP - DESCRIPTION................19-39

PUMP - DESCRIPTION, FUEL...........14-11

PUMP - DESCRIPTION, FUEL INJECTION . . 14-53

PUMP - DESCRIPTION, FUEL TRANSFER . . 14-64

PUMP - DESCRIPTION, LEAK DETECTION . 25-13

PUMP - DESCRIPTION, OIL......21-213,21-386

PUMP - DESCRIPTION, WATER..........7-59

PUMP - DIAGNOSIS AND TESTING,

WATER .........................7-62,7-63

PUMP - DISASSEMBLY, OIL........9-157,9-68

PUMP - DISASSEMBLY, OIL.....21-214,21-388

PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER

STEERING..........................19-40

PUMP - INSPECTION, OIL . . . 9-157,9-224,9-295,

9-68

PUMP - INSPECTION, OIL.......21-214,21-390

PUMP - INSTALLATION, FUEL INJECTION . 14-55

PUMP - INSTALLATION, FUEL TRANSFER . 14-65

PUMP - INSTALLATION, LEAK

DETECTION.........................25-16

PUMP - INSTALLATION, OIL . 9-159,9-225,9-296,

9-69

PUMP - OPERATION..................19-40

PUMP - OPERATION, FUEL.............14-11

PUMP - OPERATION, FUEL INJECTION....14-53

PUMP - OPERATION, FUEL TRANSFER....14-64

PUMP - OPERATION, LEAK DETECTION . . . 25-14

PUMP - OPERATION, OIL.......21-213,21-386

PUMP - OPERATION, WATER............7-60

PUMP - REMOVAL, FUEL INJECTION.....14-54

PUMP - REMOVAL, FUEL TRANSFER.....14-64

PUMP - REMOVAL, LEAK DETECTION....25-16

PUMP - REMOVAL, OIL . 9-156,9-224,9-294,9-67

PUMP BYPASS - DESCRIPTION, WATER

. . . 7-59

PUMP BYPASS - OPERATION, WATER

.....7-60

PUMP FRONT SEAL - INSTALLATION,

OIL

...............................21-391

PUMP FRONT SEAL - REMOVAL, OIL

....21-391

PUMP LEAKAGE - DIAGNOSIS AND

TESTING

...........................19-40PUMP MODULE - DESCRIPTION, FUEL....14-11

PUMP MODULE - INSTALLATION, FUEL . . . 14-12

PUMP MODULE - OPERATION, FUEL.....14-11

PUMP MODULE - REMOVAL, FUEL.......14-12

PUMP RELAY - DESCRIPTION, FUEL.....14-27

PUMP RELAY - INSTALLATION, FUEL.....14-28

PUMP RELAY - OPERATION, FUEL.......14-27

PUMP RELAY - REMOVAL, FUEL........14-28

PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD AND FUEL...............8I-5

PUMP TIMING - DIAGNOSIS AND

TESTING, FUEL INJECTION.............14-53

PUMP VOLUME CHECK - STANDARD

PROCEDURE, OIL...................21-387

PUMP/MOTOR - DESCRIPTION, WASHER . 8R-13

PUMP/MOTOR - INSTALLATION,

WASHER...........................8R-14

PUMP/MOTOR - OPERATION, WASHER . . . 8R-13

PUMP/MOTOR - REMOVAL, WASHER....8R-14

PUSHRODS - CLEANING...............9-252

PUSHRODS - INSPECTION.............9-253

QUAD CAB - INSTALLATION.......8O-36,8O-61

QUAD CAB - REMOVAL..........8O-33,8O-60

QUICK CONNECT FITTING -

DESCRIPTION........................14-8

QUICK LEARN - STANDARD

PROCEDURE, TCM...................8E-23

QUICK-CONNECT FITTINGS - STANDARD

PROCEDURE...........................14-8

RADIAL - PLY TIRES - DESCRIPTION......22-6

RADIATOR - 5.9L DIESEL - CLEANING.....7-56

RADIATOR - 5.9L DIESEL -

DESCRIPTION........................7-56

RADIATOR - 5.9L DIESEL - INSPECTION . . . 7-56

RADIATOR - 5.9L DIESEL -

INSTALLATION........................7-57

RADIATOR - 5.9L DIESEL - OPERATION....7-56

RADIATOR - 5.9L DIESEL - REMOVAL.....7-56

RADIATOR CAP - DIAGNOSIS AND

TESTING............................7-58

RADIATOR CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING..............7-58

RADIATOR COOLANT FLOW -

DIAGNOSIS AND TESTING..........7-54,7-56

RADIATOR CROSSMEMBER -

INSTALLATION, UPPER................23-42

RADIATOR CROSSMEMBER - REMOVAL,

UPPER.............................23-42

RADIATOR FAN - 5.9L DIESEL -

CLEANING...........................7-35

RADIATOR FAN - 5.9L DIESEL -

INSPECTION.........................7-35

RADIATOR FAN - 5.9L DIESEL -

INSTALLATION........................7-36

RADIATOR FAN - 5.9L DIESEL -

REMOVAL...........................7-35

RADIATOR FAN - GAS ENGINES -

CLEANING...........................7-34

RADIATOR FAN - GAS ENGINES -

INSPECTION.........................7-34

RADIATOR FAN - GAS ENGINES -

INSTALLATION........................7-34

RADIATOR FAN - GAS ENGINES -

REMOVAL...........................7-33

RADIATOR PRESSURE CAP -

DESCRIPTION........................7-57

RADIATOR PRESSURE CAP - OPERATION . . 7-58

RADIATOR-3.7L/4.7L/5.7L - CLEANING.....7-55

RADIATOR-3.7L/4.7L/5.7L -

DESCRIPTION........................7-54

RADIATOR-3.7L/4.7L/5.7L - INSPECTION . . . 7-55

RADIATOR-3.7L/4.7L/5.7L -

INSTALLATION........................7-55

RADIATOR-3.7L/4.7L/5.7L - OPERATION....7-54

RADIATOR-3.7L/4.7L/5.7L - REMOVAL.....7-54

RADIO - DESCRIPTION.................8A-8

RADIO - INSTALLATION................8A-8

RADIO - OPERATION...................8A-8

RADIO - REMOVAL....................8A-8

RADIO NOISE SUPPRESSION GROUND

STRAP - DESCRIPTION

.................8A-9

RADIO NOISE SUPPRESSION GROUND

STRAP - INSTALLATION

...............8A-10

RADIO NOISE SUPPRESSION GROUND

STRAP - OPERATION

..................8A-9

RADIO NOISE SUPPRESSION GROUND

STRAP - REMOVAL

....................8A-9

RAIL - DESCRIPTION, FUEL

............14-12

DRINDEX 25

Description Group-Page Description Group-Page Description Group-Page