brake DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1146 of 2627

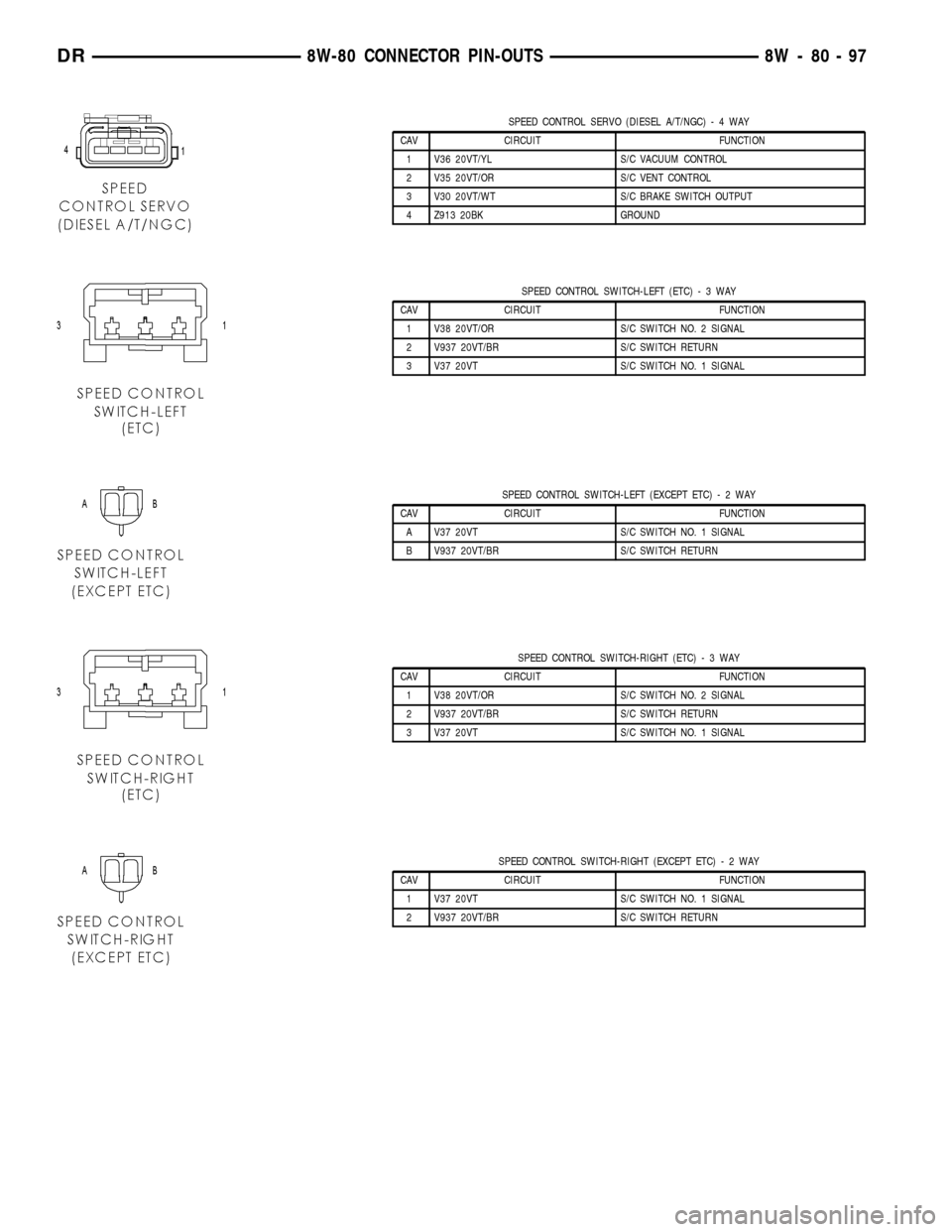

SPEED CONTROL SERVO (DIESEL A/T/NGC)-4WAY

CAV CIRCUIT FUNCTION

1 V36 20VT/YL S/C VACUUM CONTROL

2 V35 20VT/OR S/C VENT CONTROL

3 V30 20VT/WT S/C BRAKE SWITCH OUTPUT

4 Z913 20BK GROUND

SPEED CONTROL SWITCH-LEFT (ETC)-3WAY

CAV CIRCUIT FUNCTION

1 V38 20VT/OR S/C SWITCH NO. 2 SIGNAL

2 V937 20VT/BR S/C SWITCH RETURN

3 V37 20VT S/C SWITCH NO. 1 SIGNAL

SPEED CONTROL SWITCH-LEFT (EXCEPT ETC)-2WAY

CAV CIRCUIT FUNCTION

A V37 20VT S/C SWITCH NO. 1 SIGNAL

B V937 20VT/BR S/C SWITCH RETURN

SPEED CONTROL SWITCH-RIGHT (ETC)-3WAY

CAV CIRCUIT FUNCTION

1 V38 20VT/OR S/C SWITCH NO. 2 SIGNAL

2 V937 20VT/BR S/C SWITCH RETURN

3 V37 20VT S/C SWITCH NO. 1 SIGNAL

SPEED CONTROL SWITCH-RIGHT (EXCEPT ETC)-2WAY

CAV CIRCUIT FUNCTION

1 V37 20VT S/C SWITCH NO. 1 SIGNAL

2 V937 20VT/BR S/C SWITCH RETURN

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 97

Page 1148 of 2627

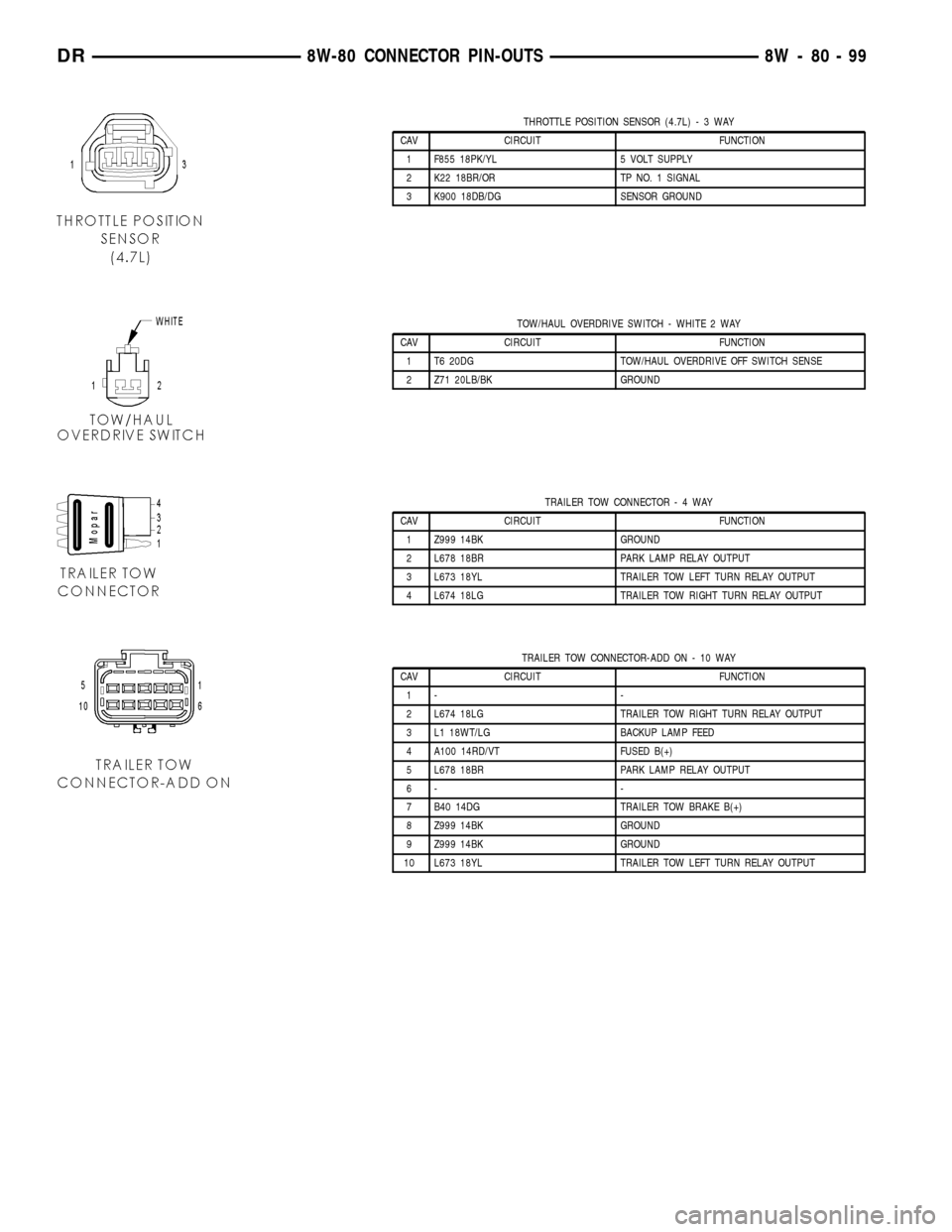

THROTTLE POSITION SENSOR (4.7L)-3WAY

CAV CIRCUIT FUNCTION

1 F855 18PK/YL 5 VOLT SUPPLY

2 K22 18BR/OR TP NO. 1 SIGNAL

3 K900 18DB/DG SENSOR GROUND

TOW/HAUL OVERDRIVE SWITCH - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 T6 20DG TOW/HAUL OVERDRIVE OFF SWITCH SENSE

2 Z71 20LB/BK GROUND

TRAILER TOW CONNECTOR-4WAY

CAV CIRCUIT FUNCTION

1 Z999 14BK GROUND

2 L678 18BR PARK LAMP RELAY OUTPUT

3 L673 18YL TRAILER TOW LEFT TURN RELAY OUTPUT

4 L674 18LG TRAILER TOW RIGHT TURN RELAY OUTPUT

TRAILER TOW CONNECTOR-ADD ON - 10 WAY

CAV CIRCUIT FUNCTION

1- -

2 L674 18LG TRAILER TOW RIGHT TURN RELAY OUTPUT

3 L1 18WT/LG BACKUP LAMP FEED

4 A100 14RD/VT FUSED B(+)

5 L678 18BR PARK LAMP RELAY OUTPUT

6- -

7 B40 14DG TRAILER TOW BRAKE B(+)

8 Z999 14BK GROUND

9 Z999 14BK GROUND

10 L673 18YL TRAILER TOW LEFT TURN RELAY OUTPUT

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 99

Page 1155 of 2627

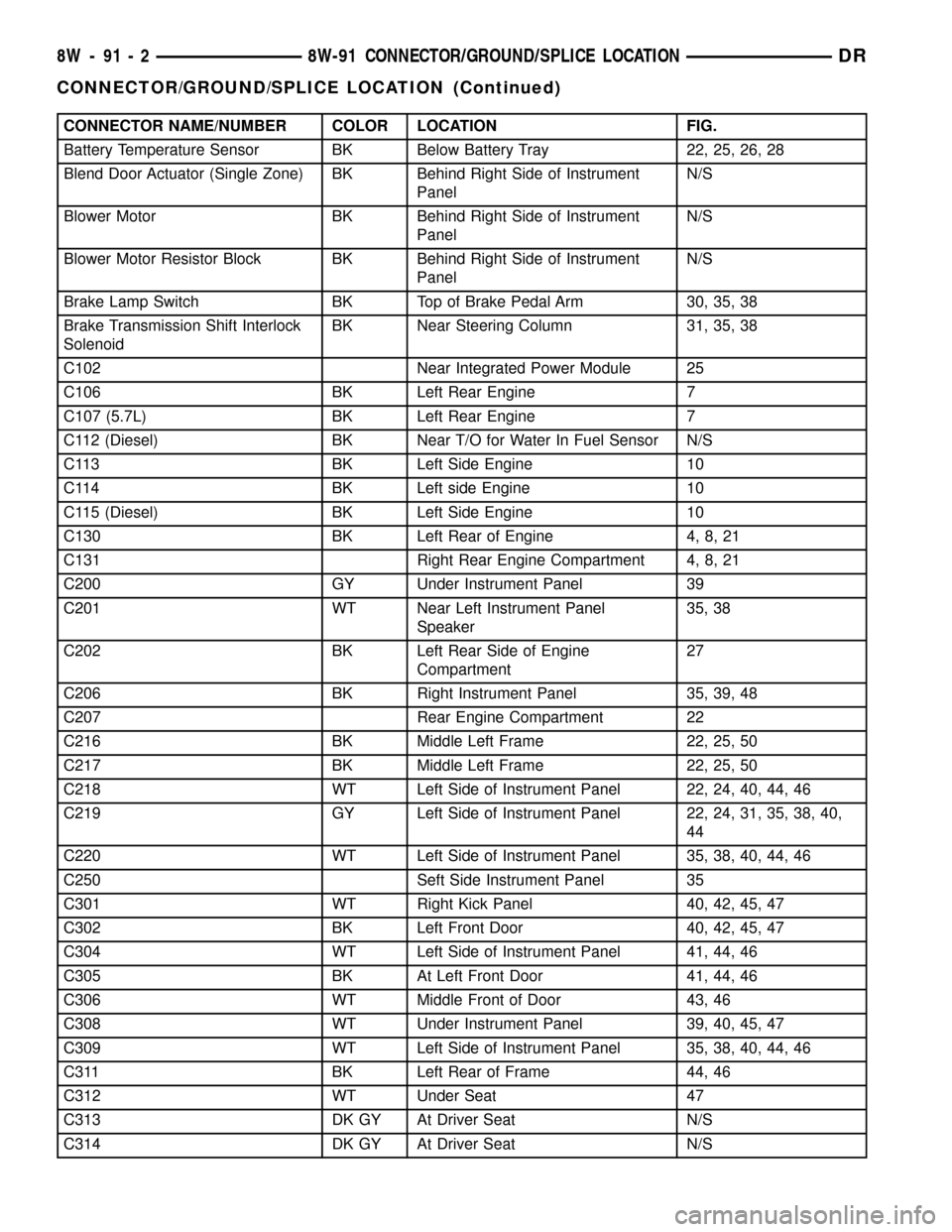

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Battery Temperature Sensor BK Below Battery Tray 22, 25, 26, 28

Blend Door Actuator (Single Zone) BK Behind Right Side of Instrument

PanelN/S

Blower Motor BK Behind Right Side of Instrument

PanelN/S

Blower Motor Resistor Block BK Behind Right Side of Instrument

PanelN/S

Brake Lamp Switch BK Top of Brake Pedal Arm 30, 35, 38

Brake Transmission Shift Interlock

SolenoidBK Near Steering Column 31, 35, 38

C102 Near Integrated Power Module 25

C106 BK Left Rear Engine 7

C107 (5.7L) BK Left Rear Engine 7

C112 (Diesel) BK Near T/O for Water In Fuel Sensor N/S

C113 BK Left Side Engine 10

C114 BK Left side Engine 10

C115 (Diesel) BK Left Side Engine 10

C130 BK Left Rear of Engine 4, 8, 21

C131 Right Rear Engine Compartment 4, 8, 21

C200 GY Under Instrument Panel 39

C201 WT Near Left Instrument Panel

Speaker35, 38

C202 BK Left Rear Side of Engine

Compartment27

C206 BK Right Instrument Panel 35, 39, 48

C207 Rear Engine Compartment 22

C216 BK Middle Left Frame 22, 25, 50

C217 BK Middle Left Frame 22, 25, 50

C218 WT Left Side of Instrument Panel 22, 24, 40, 44, 46

C219 GY Left Side of Instrument Panel 22, 24, 31, 35, 38, 40,

44

C220 WT Left Side of Instrument Panel 35, 38, 40, 44, 46

C250 Seft Side Instrument Panel 35

C301 WT Right Kick Panel 40, 42, 45, 47

C302 BK Left Front Door 40, 42, 45, 47

C304 WT Left Side of Instrument Panel 41, 44, 46

C305 BK At Left Front Door 41, 44, 46

C306 WT Middle Front of Door 43, 46

C308 WT Under Instrument Panel 39, 40, 45, 47

C309 WT Left Side of Instrument Panel 35, 38, 40, 44, 46

C311 BK Left Rear of Frame 44, 46

C312 WT Under Seat 47

C313 DK GY At Driver Seat N/S

C314 DK GY At Driver Seat N/S

8W - 91 - 2 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1156 of 2627

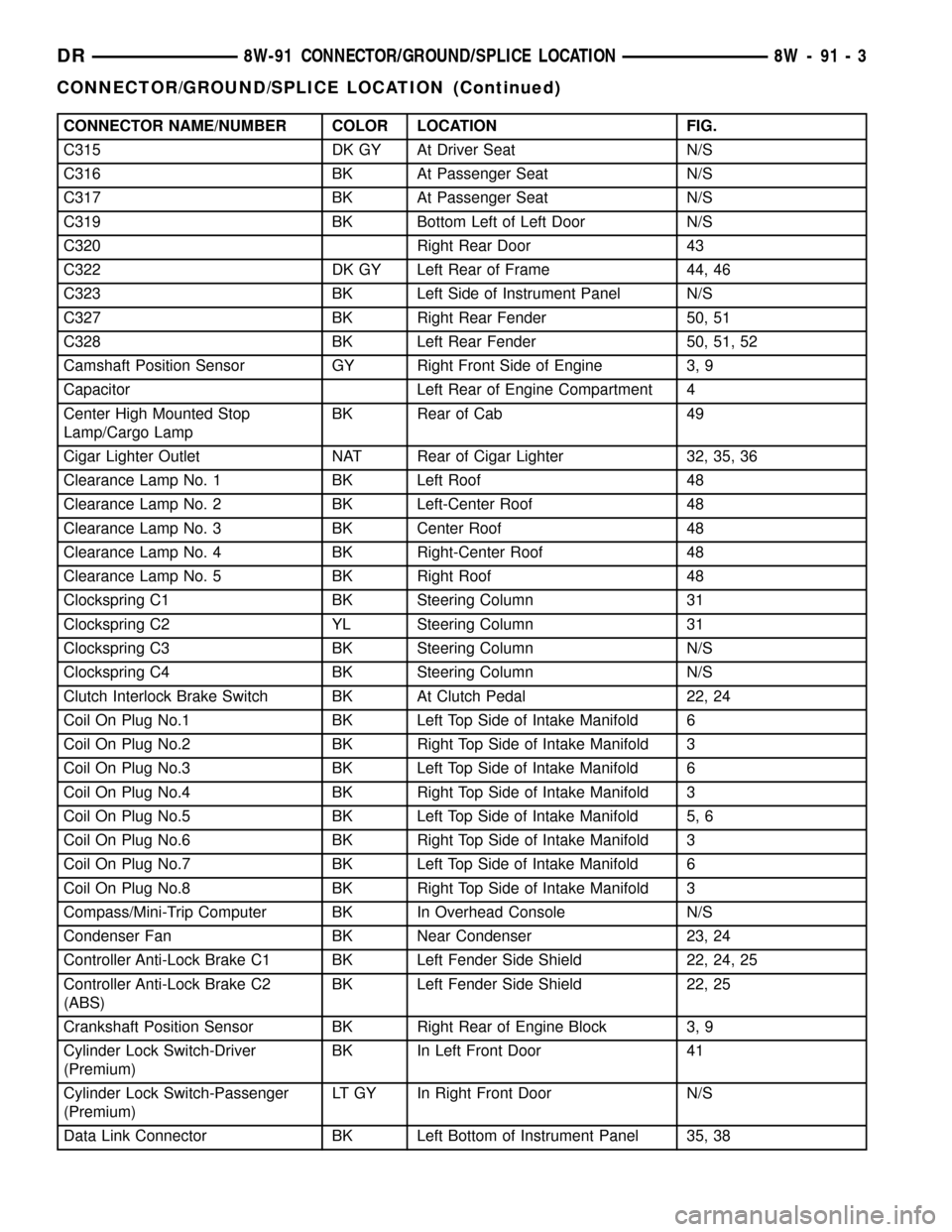

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C315 DK GY At Driver Seat N/S

C316 BK At Passenger Seat N/S

C317 BK At Passenger Seat N/S

C319 BK Bottom Left of Left Door N/S

C320 Right Rear Door 43

C322 DK GY Left Rear of Frame 44, 46

C323 BK Left Side of Instrument Panel N/S

C327 BK Right Rear Fender 50, 51

C328 BK Left Rear Fender 50, 51, 52

Camshaft Position Sensor GY Right Front Side of Engine 3, 9

Capacitor Left Rear of Engine Compartment 4

Center High Mounted Stop

Lamp/Cargo LampBK Rear of Cab 49

Cigar Lighter Outlet NAT Rear of Cigar Lighter 32, 35, 36

Clearance Lamp No. 1 BK Left Roof 48

Clearance Lamp No. 2 BK Left-Center Roof 48

Clearance Lamp No. 3 BK Center Roof 48

Clearance Lamp No. 4 BK Right-Center Roof 48

Clearance Lamp No. 5 BK Right Roof 48

Clockspring C1 BK Steering Column 31

Clockspring C2 YL Steering Column 31

Clockspring C3 BK Steering Column N/S

Clockspring C4 BK Steering Column N/S

Clutch Interlock Brake Switch BK At Clutch Pedal 22, 24

Coil On Plug No.1 BK Left Top Side of Intake Manifold 6

Coil On Plug No.2 BK Right Top Side of Intake Manifold 3

Coil On Plug No.3 BK Left Top Side of Intake Manifold 6

Coil On Plug No.4 BK Right Top Side of Intake Manifold 3

Coil On Plug No.5 BK Left Top Side of Intake Manifold 5, 6

Coil On Plug No.6 BK Right Top Side of Intake Manifold 3

Coil On Plug No.7 BK Left Top Side of Intake Manifold 6

Coil On Plug No.8 BK Right Top Side of Intake Manifold 3

Compass/Mini-Trip Computer BK In Overhead Console N/S

Condenser Fan BK Near Condenser 23, 24

Controller Anti-Lock Brake C1 BK Left Fender Side Shield 22, 24, 25

Controller Anti-Lock Brake C2

(ABS)BK Left Fender Side Shield 22, 25

Crankshaft Position Sensor BK Right Rear of Engine Block 3, 9

Cylinder Lock Switch-Driver

(Premium)BK In Left Front Door 41

Cylinder Lock Switch-Passenger

(Premium)LT GY In Right Front Door N/S

Data Link Connector BK Left Bottom of Instrument Panel 35, 38

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1157 of 2627

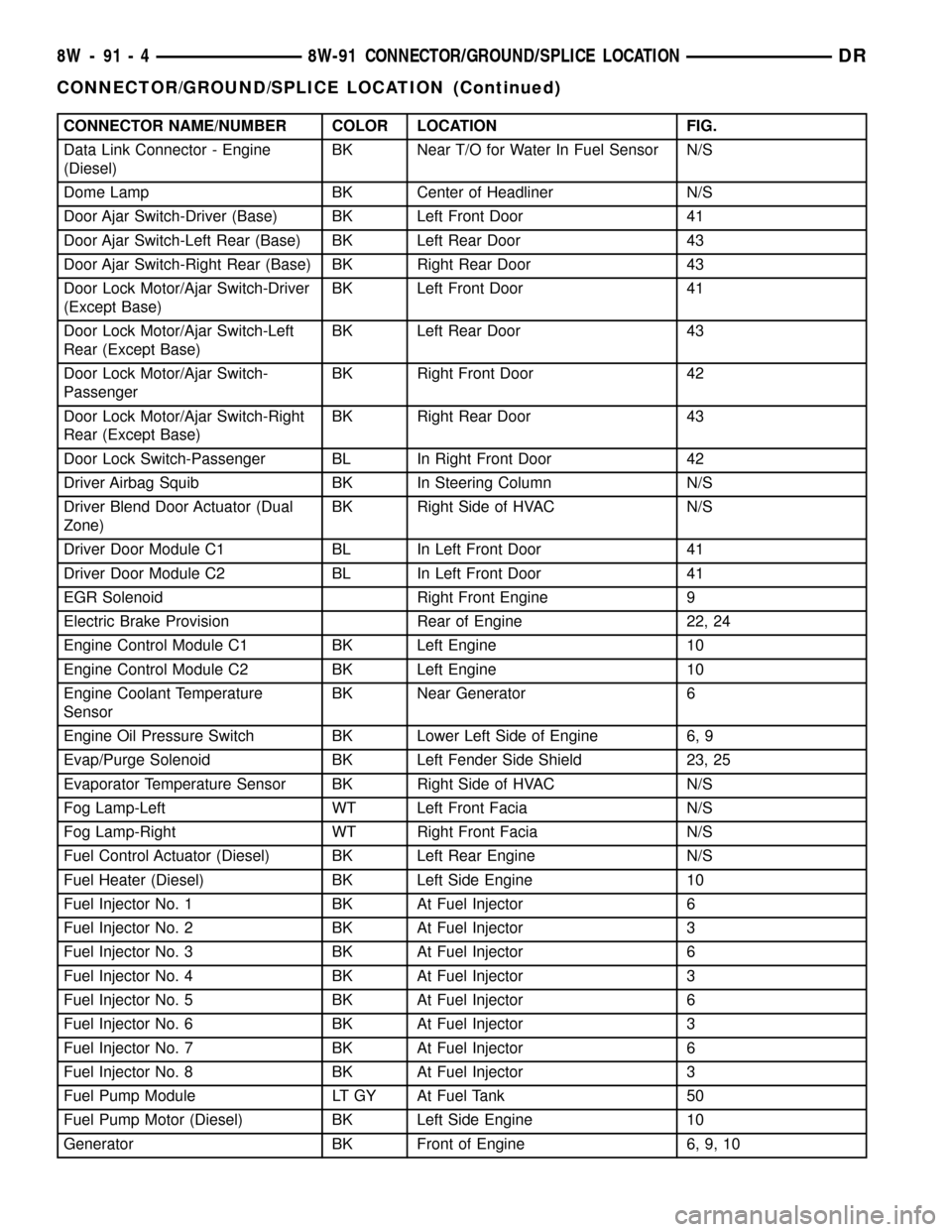

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Data Link Connector - Engine

(Diesel)BK Near T/O for Water In Fuel Sensor N/S

Dome Lamp BK Center of Headliner N/S

Door Ajar Switch-Driver (Base) BK Left Front Door 41

Door Ajar Switch-Left Rear (Base) BK Left Rear Door 43

Door Ajar Switch-Right Rear (Base) BK Right Rear Door 43

Door Lock Motor/Ajar Switch-Driver

(Except Base)BK Left Front Door 41

Door Lock Motor/Ajar Switch-Left

Rear (Except Base)BK Left Rear Door 43

Door Lock Motor/Ajar Switch-

PassengerBK Right Front Door 42

Door Lock Motor/Ajar Switch-Right

Rear (Except Base)BK Right Rear Door 43

Door Lock Switch-Passenger BL In Right Front Door 42

Driver Airbag Squib BK In Steering Column N/S

Driver Blend Door Actuator (Dual

Zone)BK Right Side of HVAC N/S

Driver Door Module C1 BL In Left Front Door 41

Driver Door Module C2 BL In Left Front Door 41

EGR Solenoid Right Front Engine 9

Electric Brake Provision Rear of Engine 22, 24

Engine Control Module C1 BK Left Engine 10

Engine Control Module C2 BK Left Engine 10

Engine Coolant Temperature

SensorBK Near Generator 6

Engine Oil Pressure Switch BK Lower Left Side of Engine 6, 9

Evap/Purge Solenoid BK Left Fender Side Shield 23, 25

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Fog Lamp-Left WT Left Front Facia N/S

Fog Lamp-Right WT Right Front Facia N/S

Fuel Control Actuator (Diesel) BK Left Rear Engine N/S

Fuel Heater (Diesel) BK Left Side Engine 10

Fuel Injector No. 1 BK At Fuel Injector 6

Fuel Injector No. 2 BK At Fuel Injector 3

Fuel Injector No. 3 BK At Fuel Injector 6

Fuel Injector No. 4 BK At Fuel Injector 3

Fuel Injector No. 5 BK At Fuel Injector 6

Fuel Injector No. 6 BK At Fuel Injector 3

Fuel Injector No. 7 BK At Fuel Injector 6

Fuel Injector No. 8 BK At Fuel Injector 3

Fuel Pump Module LT GY At Fuel Tank 50

Fuel Pump Motor (Diesel) BK Left Side Engine 10

Generator BK Front of Engine 6, 9, 10

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1159 of 2627

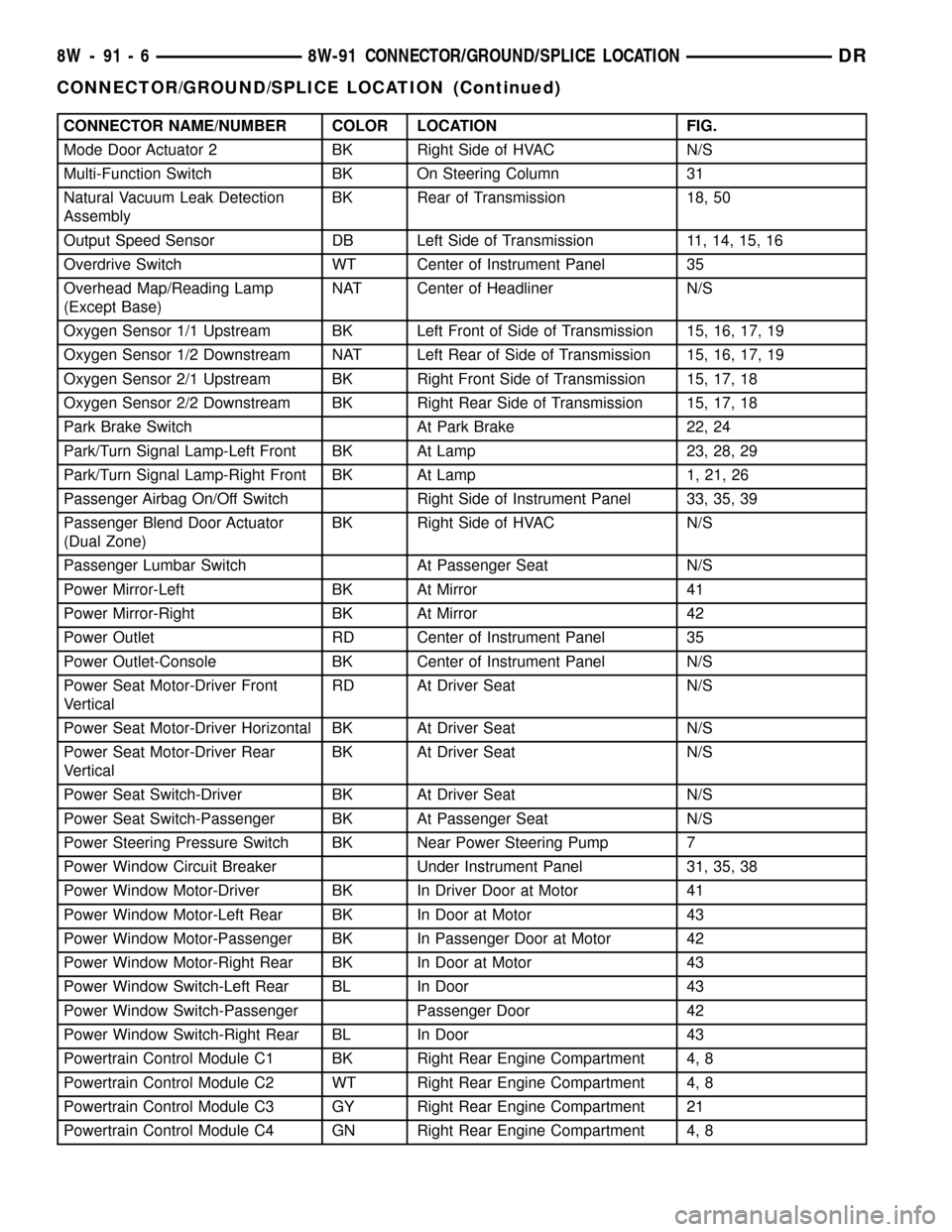

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column 31

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 50

Output Speed Sensor DB Left Side of Transmission 11, 14, 15, 16

Overdrive Switch WT Center of Instrument Panel 35

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 15, 16, 17, 19

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 15, 16, 17, 19

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 15, 17, 18

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 15, 17, 18

Park Brake Switch At Park Brake 22, 24

Park/Turn Signal Lamp-Left Front BK At Lamp 23, 28, 29

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 21, 26

Passenger Airbag On/Off Switch Right Side of Instrument Panel 33, 35, 39

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 41

Power Mirror-Right BK At Mirror 42

Power Outlet RD Center of Instrument Panel 35

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 7

Power Window Circuit Breaker Under Instrument Panel 31, 35, 38

Power Window Motor-Driver BK In Driver Door at Motor 41

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor 42

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Passenger Passenger Door 42

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 4, 8

Powertrain Control Module C2 WT Right Rear Engine Compartment 4, 8

Powertrain Control Module C3 GY Right Rear Engine Compartment 21

Powertrain Control Module C4 GN Right Rear Engine Compartment 4, 8

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1160 of 2627

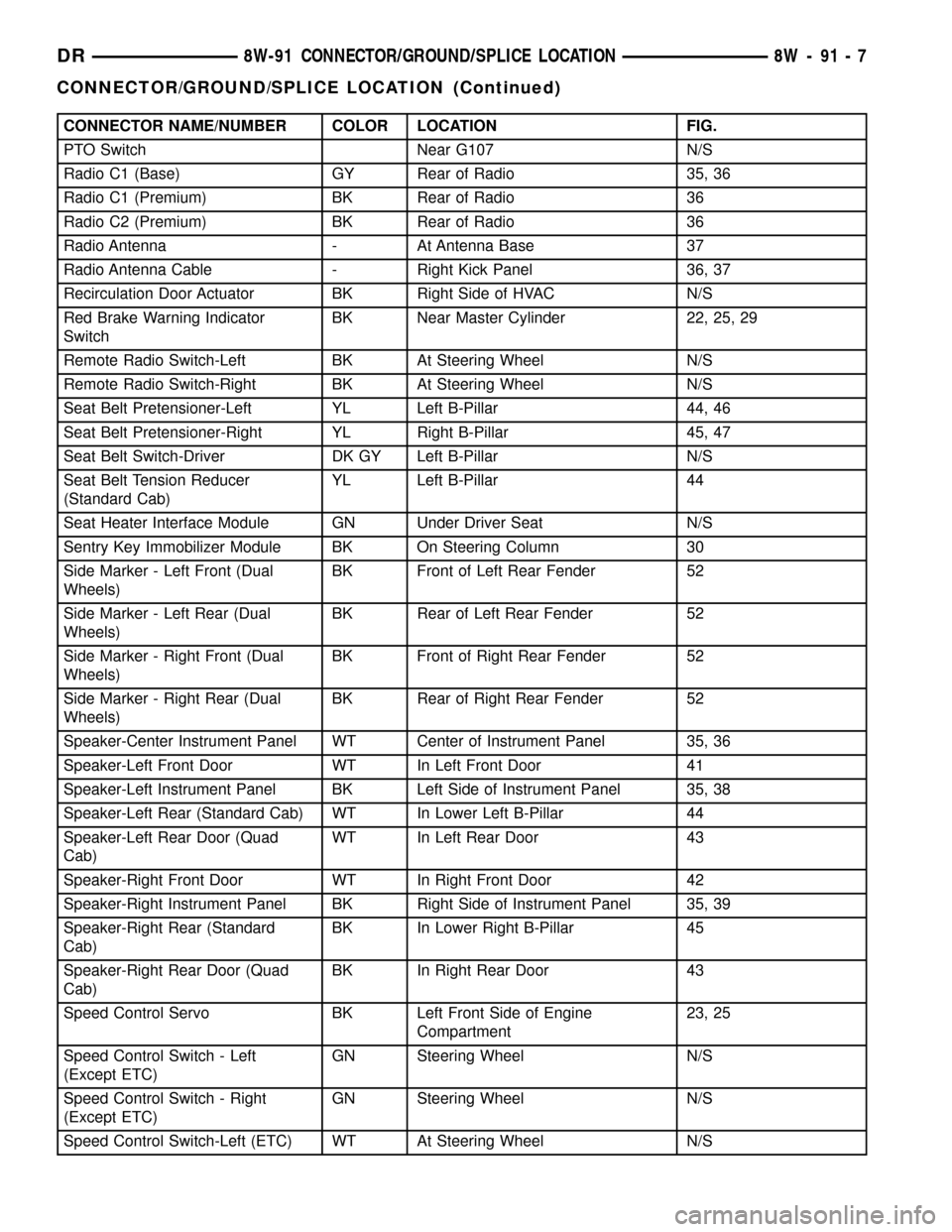

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

PTO Switch Near G107 N/S

Radio C1 (Base) GY Rear of Radio 35, 36

Radio C1 (Premium) BK Rear of Radio 36

Radio C2 (Premium) BK Rear of Radio 36

Radio Antenna - At Antenna Base 37

Radio Antenna Cable - Right Kick Panel 36, 37

Recirculation Door Actuator BK Right Side of HVAC N/S

Red Brake Warning Indicator

SwitchBK Near Master Cylinder 22, 25, 29

Remote Radio Switch-Left BK At Steering Wheel N/S

Remote Radio Switch-Right BK At Steering Wheel N/S

Seat Belt Pretensioner-Left YL Left B-Pillar 44, 46

Seat Belt Pretensioner-Right YL Right B-Pillar 45, 47

Seat Belt Switch-Driver DK GY Left B-Pillar N/S

Seat Belt Tension Reducer

(Standard Cab)YL Left B-Pillar 44

Seat Heater Interface Module GN Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 30

Side Marker - Left Front (Dual

Wheels)BK Front of Left Rear Fender 52

Side Marker - Left Rear (Dual

Wheels)BK Rear of Left Rear Fender 52

Side Marker - Right Front (Dual

Wheels)BK Front of Right Rear Fender 52

Side Marker - Right Rear (Dual

Wheels)BK Rear of Right Rear Fender 52

Speaker-Center Instrument Panel WT Center of Instrument Panel 35, 36

Speaker-Left Front Door WT In Left Front Door 41

Speaker-Left Instrument Panel BK Left Side of Instrument Panel 35, 38

Speaker-Left Rear (Standard Cab) WT In Lower Left B-Pillar 44

Speaker-Left Rear Door (Quad

Cab)WT In Left Rear Door 43

Speaker-Right Front Door WT In Right Front Door 42

Speaker-Right Instrument Panel BK Right Side of Instrument Panel 35, 39

Speaker-Right Rear (Standard

Cab)BK In Lower Right B-Pillar 45

Speaker-Right Rear Door (Quad

Cab)BK In Right Rear Door 43

Speed Control Servo BK Left Front Side of Engine

Compartment23, 25

Speed Control Switch - Left

(Except ETC)GN Steering Wheel N/S

Speed Control Switch - Right

(Except ETC)GN Steering Wheel N/S

Speed Control Switch-Left (ETC) WT At Steering Wheel N/S

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1234 of 2627

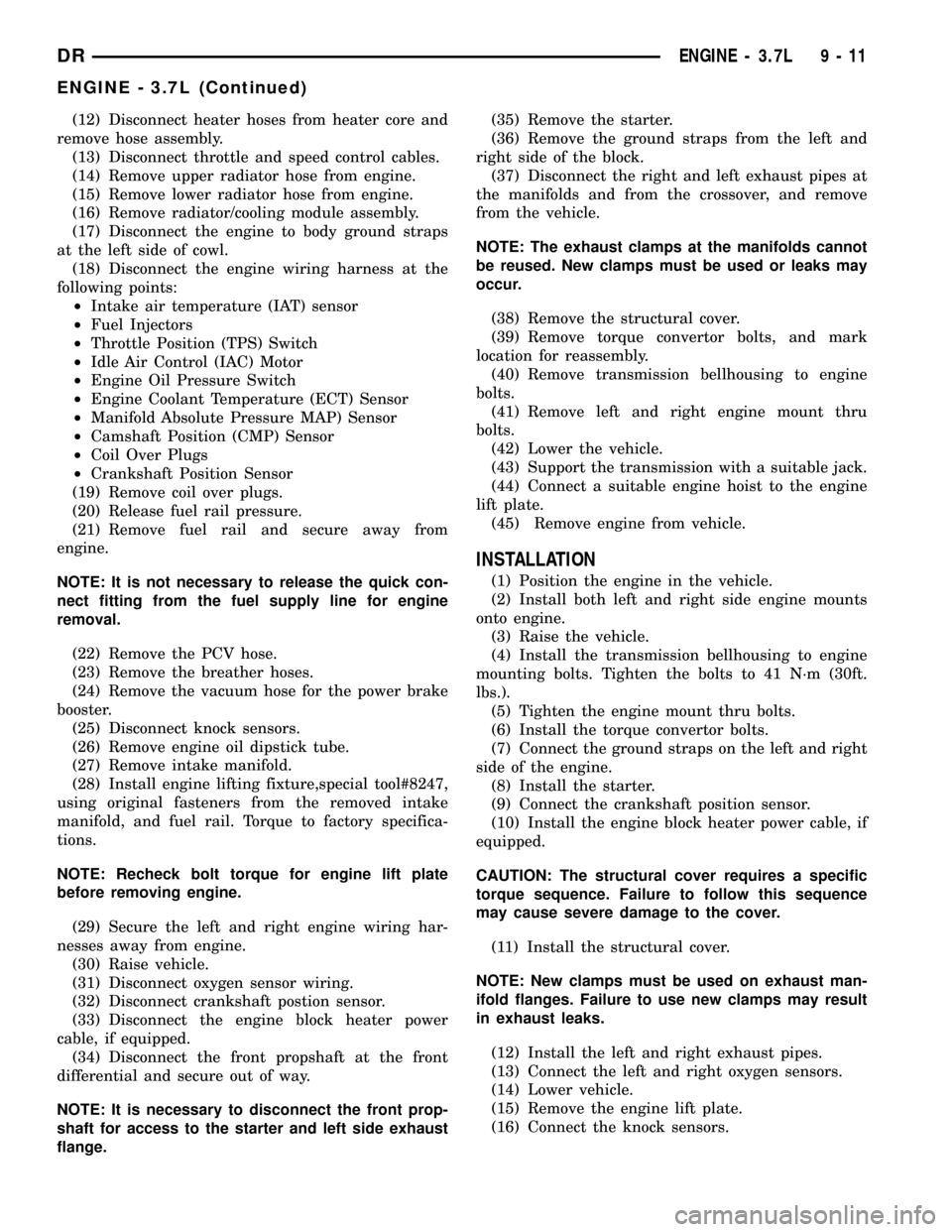

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1235 of 2627

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

(44) Start the engine and check for leaks.SPECIFICATIONS

SPECIFICATIONS - 3.7L ENGINE

GENERAL SPECIFICATIONS

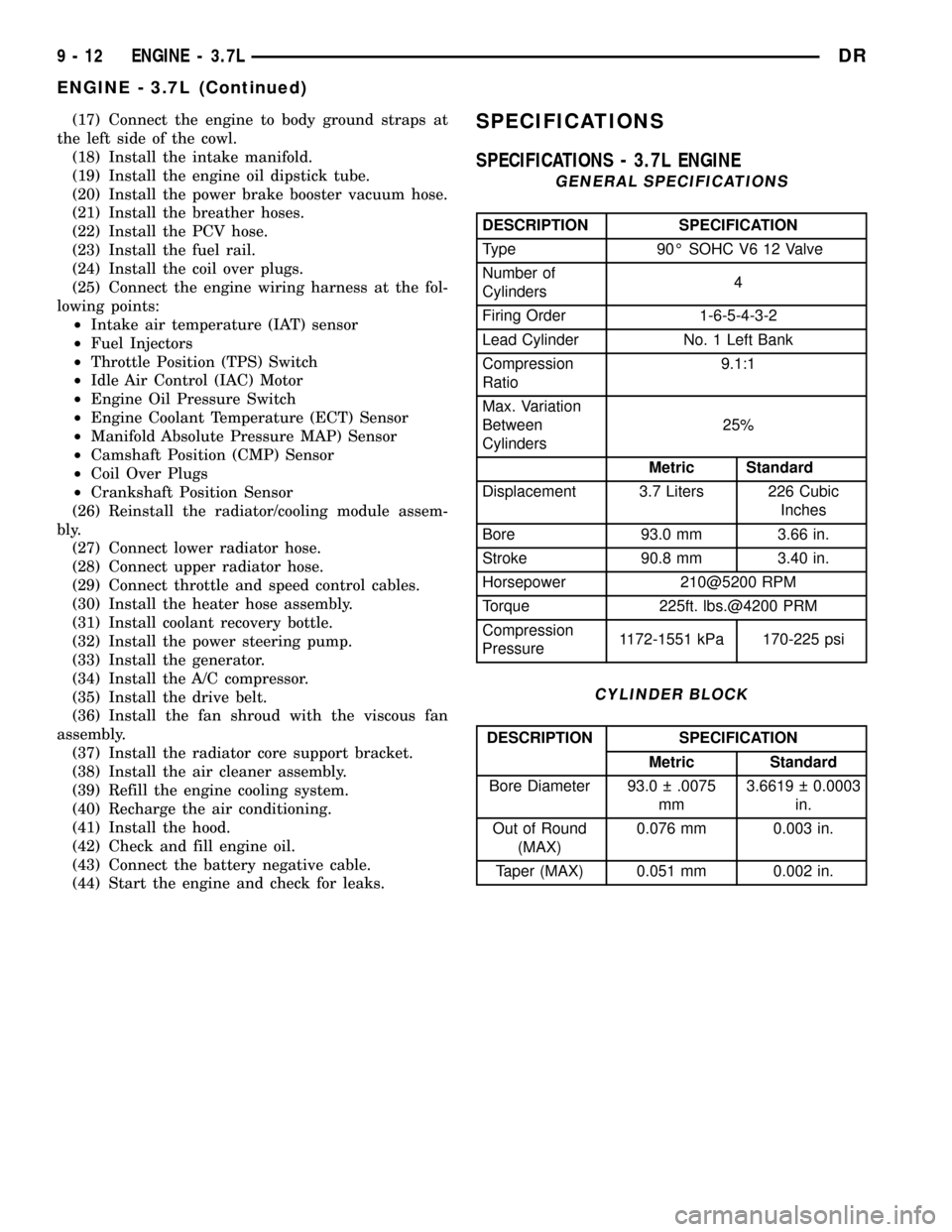

DESCRIPTION SPECIFICATION

Type 90É SOHC V6 12 Valve

Number of

Cylinders4

Firing Order 1-6-5-4-3-2

Lead Cylinder No. 1 Left Bank

Compression

Ratio9.1:1

Max. Variation

Between

Cylinders25%

Metric Standard

Displacement 3.7 Liters 226 Cubic

Inches

Bore 93.0 mm 3.66 in.

Stroke 90.8 mm 3.40 in.

Horsepower 210@5200 RPM

Torque 225ft. lbs.@4200 PRM

Compression

Pressure1172-1551 kPa 170-225 psi

CYLINDER BLOCK

DESCRIPTION SPECIFICATION

Metric Standard

Bore Diameter 93.0 .0075

mm3.6619 0.0003

in.

Out of Round

(MAX)0.076 mm 0.003 in.

Taper (MAX) 0.051 mm 0.002 in.

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1245 of 2627

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50 - 70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the master cylinder and booster assem-

bly(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/POWER BRAKE BOOSTER - REMOVAL).

(8) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(9) Remove the fan shroud and fan blade assem-

bly(Refer to 7 - COOLING/ENGINE/RADIATOR FAN

- REMOVAL).

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the power steering pump and set

aside.

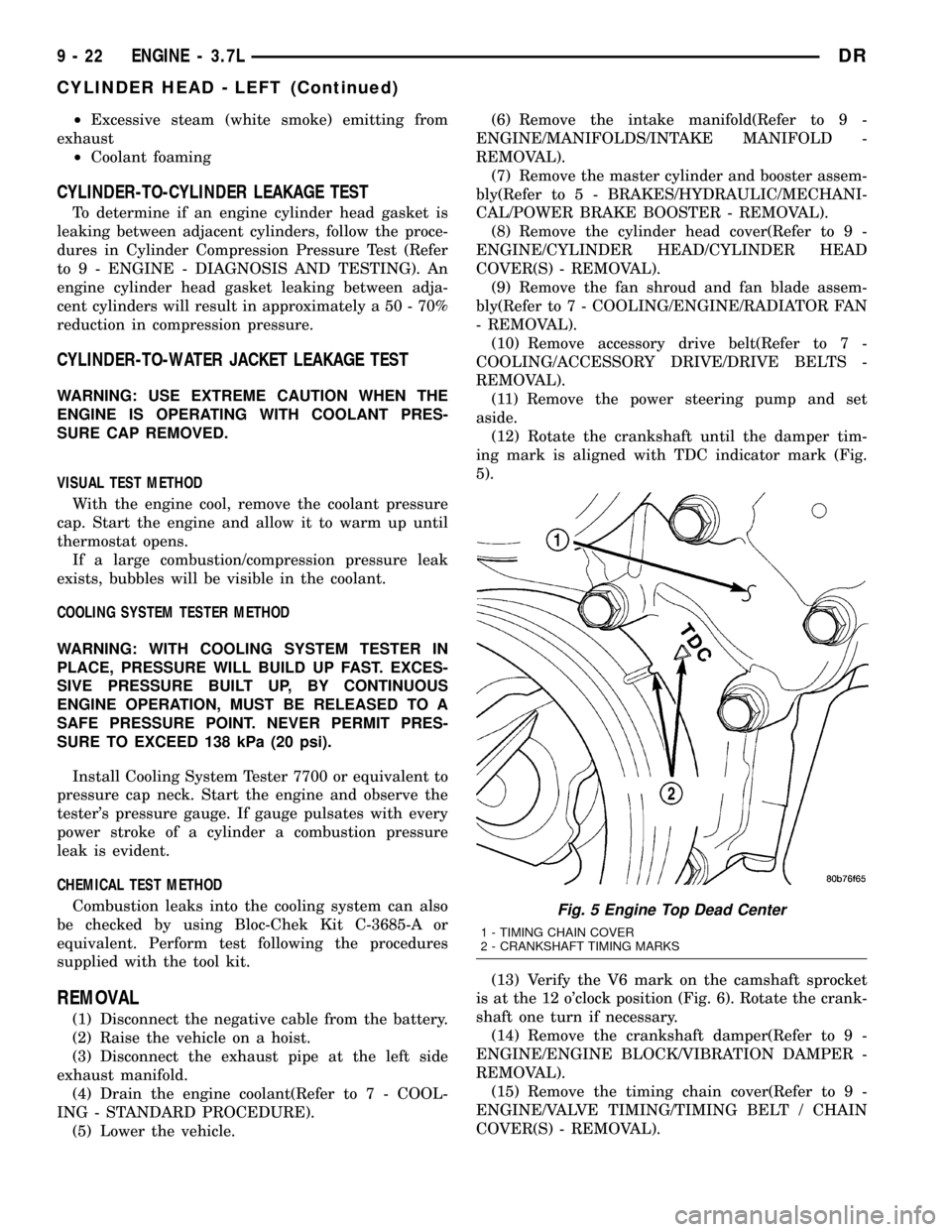

(12) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

5).

(13) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 6). Rotate the crank-

shaft one turn if necessary.

(14) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(15) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 5 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 22 ENGINE - 3.7LDR

CYLINDER HEAD - LEFT (Continued)