Ball joint DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 58 of 2627

(7) Remove the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - REMOVAL).

(8) Remove the lower ball joint nut at the steering

knuckle.

(9) Install Ball Joint Remover tool 8677 on the

lower ball joint and separate the ball joint from the

knuckle.

(10)

NOTE: Do not allow the upper control arm and

steering knuckle to rebound downwards they must

be supported.Support the upper control arm and

steering knuckle out of the way.

(11) Remove the lower control arm support.

(12) Tighten the spring compressor tool to allow

clearance for the lower ball joint to be removed out of

the knuckle.

NOTE: It may necessary to loosen the control arm

pivot bolt to allow downward swing.

(13) Loosen the tension on the spring compressor

tool slowly allowing the lower suspension arm to

pivot downward.

(14) Remove the spring compressor tool.

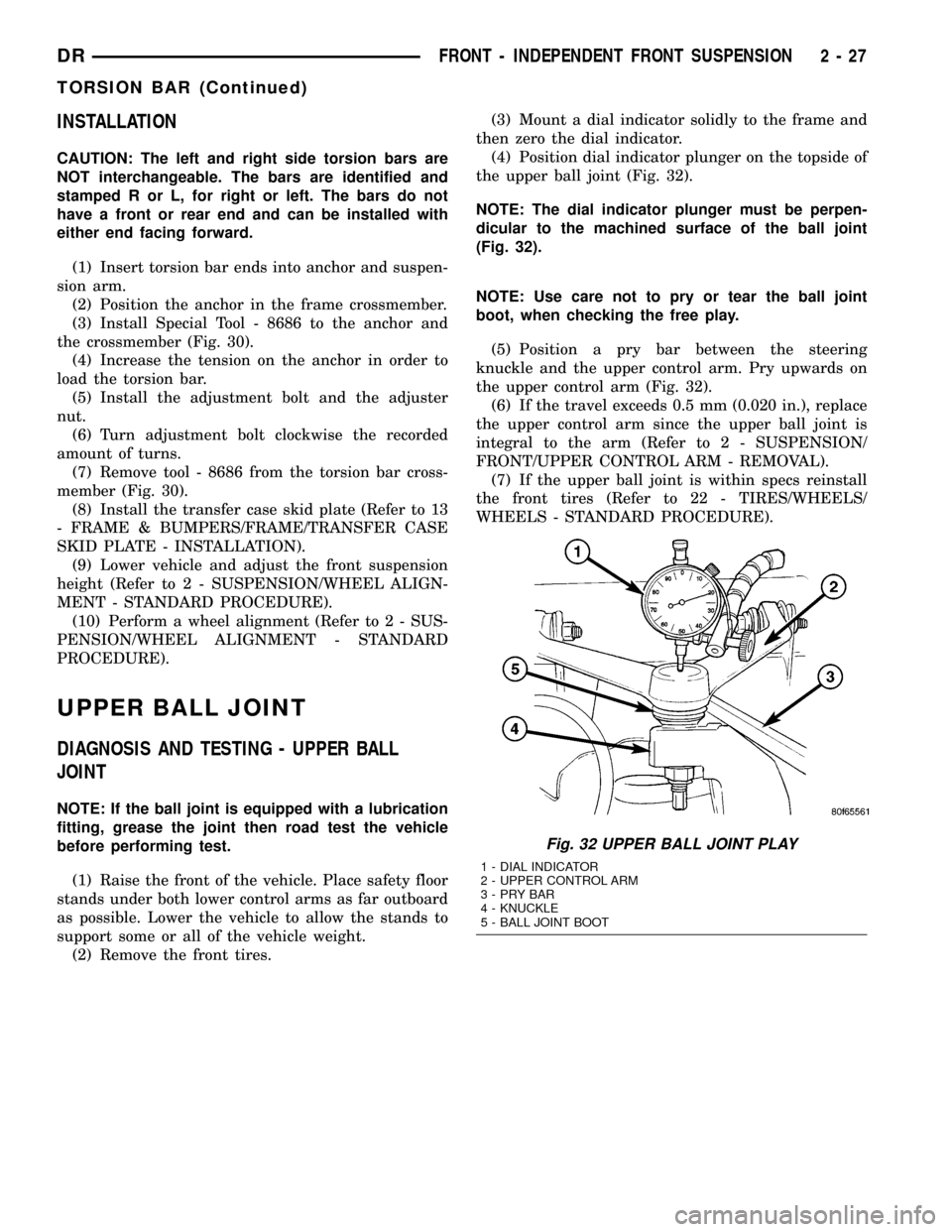

(15) Remove coil spring and isolator pad from the

vehicle (Fig. 26).

INSTALLATION

(1) Tape the isolator pad to the top of the coil

spring. Position the spring in the lower suspension

arm well. Be sure that the coil spring is seated in the

well.

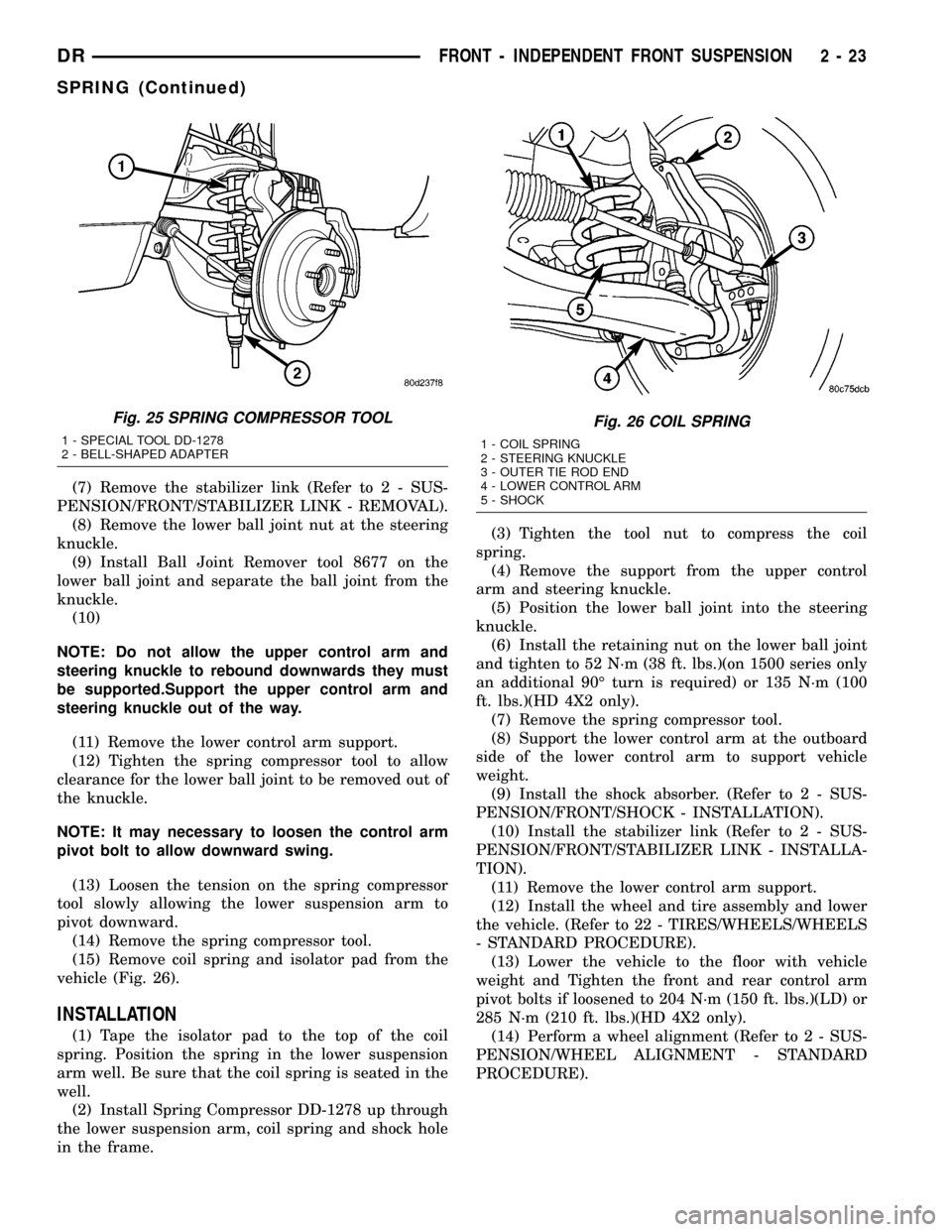

(2) Install Spring Compressor DD-1278 up through

the lower suspension arm, coil spring and shock hole

in the frame.(3) Tighten the tool nut to compress the coil

spring.

(4) Remove the support from the upper control

arm and steering knuckle.

(5) Position the lower ball joint into the steering

knuckle.

(6) Install the retaining nut on the lower ball joint

and tighten to 52 N´m (38 ft. lbs.)(on 1500 series only

an additional 90É turn is required) or 135 N´m (100

ft. lbs.)(HD 4X2 only).

(7) Remove the spring compressor tool.

(8) Support the lower control arm at the outboard

side of the lower control arm to support vehicle

weight.

(9) Install the shock absorber. (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - INSTALLATION).

(10) Install the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(11) Remove the lower control arm support.

(12) Install the wheel and tire assembly and lower

the vehicle. (Refer to 22 - TIRES/WHEELS/WHEELS

- STANDARD PROCEDURE).

(13) Lower the vehicle to the floor with vehicle

weight and Tighten the front and rear control arm

pivot bolts if loosened to 204 N´m (150 ft. lbs.)(LD) or

285 N´m (210 ft. lbs.)(HD 4X2 only).

(14) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 25 SPRING COMPRESSOR TOOL

1 - SPECIAL TOOL DD-1278

2 - BELL-SHAPED ADAPTER

Fig. 26 COIL SPRING

1 - COIL SPRING

2 - STEERING KNUCKLE

3 - OUTER TIE ROD END

4 - LOWER CONTROL ARM

5 - SHOCK

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 23

SPRING (Continued)

Page 62 of 2627

INSTALLATION

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Insert torsion bar ends into anchor and suspen-

sion arm.

(2) Position the anchor in the frame crossmember.

(3) Install Special Tool - 8686 to the anchor and

the crossmember (Fig. 30).

(4) Increase the tension on the anchor in order to

load the torsion bar.

(5) Install the adjustment bolt and the adjuster

nut.

(6) Turn adjustment bolt clockwise the recorded

amount of turns.

(7) Remove tool - 8686 from the torsion bar cross-

member (Fig. 30).

(8) Install the transfer case skid plate (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION).

(9) Lower vehicle and adjust the front suspension

height (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

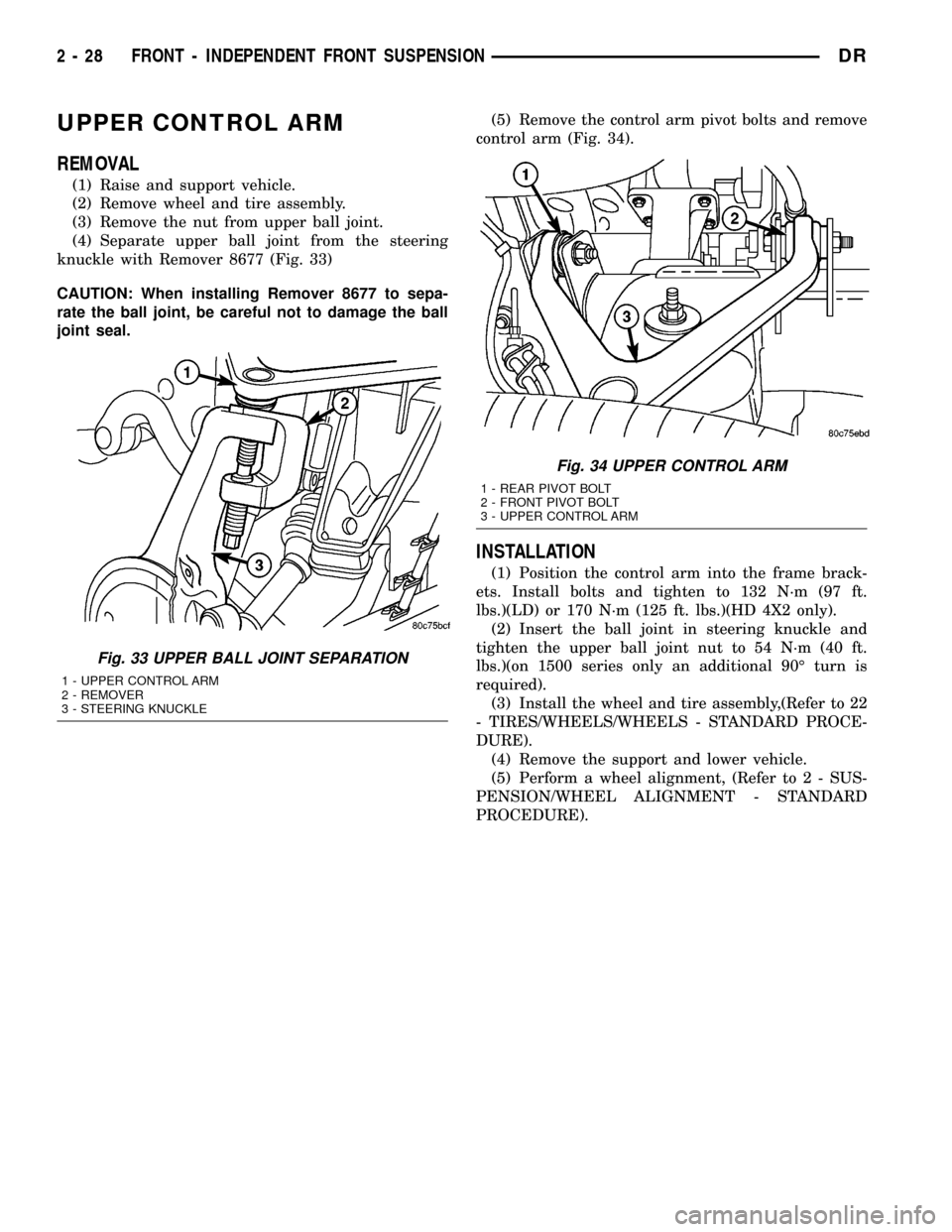

(2) Remove the front tires.(3) Mount a dial indicator solidly to the frame and

then zero the dial indicator.

(4) Position dial indicator plunger on the topside of

the upper ball joint (Fig. 32).

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the ball joint

(Fig. 32).

NOTE: Use care not to pry or tear the ball joint

boot, when checking the free play.

(5) Position a pry bar between the steering

knuckle and the upper control arm. Pry upwards on

the upper control arm (Fig. 32).

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the upper control arm since the upper ball joint is

integral to the arm (Refer to 2 - SUSPENSION/

FRONT/UPPER CONTROL ARM - REMOVAL).

(7) If the upper ball joint is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 32 UPPER BALL JOINT PLAY

1 - DIAL INDICATOR

2 - UPPER CONTROL ARM

3-PRYBAR

4 - KNUCKLE

5 - BALL JOINT BOOT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 27

TORSION BAR (Continued)

Page 63 of 2627

UPPER CONTROL ARM

REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove the nut from upper ball joint.

(4) Separate upper ball joint from the steering

knuckle with Remover 8677 (Fig. 33)

CAUTION: When installing Remover 8677 to sepa-

rate the ball joint, be careful not to damage the ball

joint seal.(5) Remove the control arm pivot bolts and remove

control arm (Fig. 34).

INSTALLATION

(1) Position the control arm into the frame brack-

ets. Install bolts and tighten to 132 N´m (97 ft.

lbs.)(LD) or 170 N´m (125 ft. lbs.)(HD 4X2 only).

(2) Insert the ball joint in steering knuckle and

tighten the upper ball joint nut to 54 N´m (40 ft.

lbs.)(on 1500 series only an additional 90É turn is

required).

(3) Install the wheel and tire assembly,(Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(4) Remove the support and lower vehicle.

(5) Perform a wheel alignment, (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 33 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

Fig. 34 UPPER CONTROL ARM

1 - REAR PIVOT BOLT

2 - FRONT PIVOT BOLT

3 - UPPER CONTROL ARM

2 - 28 FRONT - INDEPENDENT FRONT SUSPENSIONDR

Page 64 of 2627

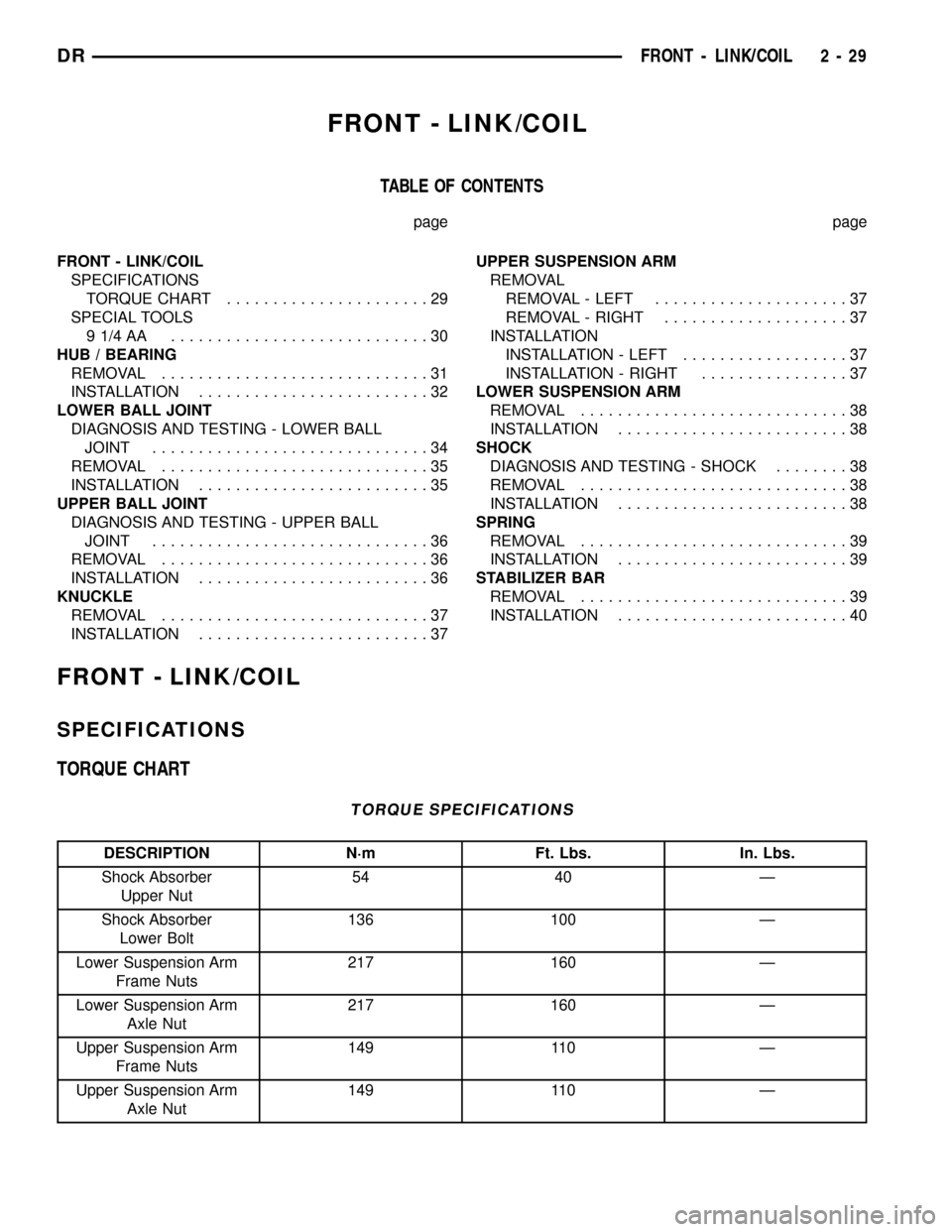

FRONT - LINK/COIL

TABLE OF CONTENTS

page page

FRONT - LINK/COIL

SPECIFICATIONS

TORQUE CHART......................29

SPECIAL TOOLS

91/4AA ............................30

HUB / BEARING

REMOVAL.............................31

INSTALLATION.........................32

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT..............................34

REMOVAL.............................35

INSTALLATION.........................35

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT..............................36

REMOVAL.............................36

INSTALLATION.........................36

KNUCKLE

REMOVAL.............................37

INSTALLATION.........................37UPPER SUSPENSION ARM

REMOVAL

REMOVAL - LEFT.....................37

REMOVAL - RIGHT....................37

INSTALLATION

INSTALLATION - LEFT..................37

INSTALLATION - RIGHT................37

LOWER SUSPENSION ARM

REMOVAL.............................38

INSTALLATION.........................38

SHOCK

DIAGNOSIS AND TESTING - SHOCK........38

REMOVAL.............................38

INSTALLATION.........................38

SPRING

REMOVAL.............................39

INSTALLATION.........................39

STABILIZER BAR

REMOVAL.............................39

INSTALLATION.........................40

FRONT - LINK/COIL

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber

Upper Nut54 40 Ð

Shock Absorber

Lower Bolt136 100 Ð

Lower Suspension Arm

Frame Nuts217 160 Ð

Lower Suspension Arm

Axle Nut217 160 Ð

Upper Suspension Arm

Frame Nuts149 110 Ð

Upper Suspension Arm

Axle Nut149 110 Ð

DRFRONT - LINK/COIL 2 - 29

Page 65 of 2627

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Stabilizer Bar

Frame Bolt61 45 Ð

Stabilizer Link

Lower Control Arm Nut102 75 Ð

Stabilizer Link

Axle Bracket71 52 Ð

Stabilizer Link

Stabilizer Bar Nut38 27 Ð

Hub/Bearing

Bolts202 149 Ð

Axle Nut 179 Beginning Torque,

Then Rotate 5 to 10

Times With a Final Torque

of 356132 Beginning Torque,

Then Rotate 5 to 10

Times With a Final Torque

of 263Ð

Tie Rod End

Nut75 55 Ð

NOTE: Suspension components with rubber/urethane bushings should be tightened with the vehicle at nor-

mal ride height. It is important to have the springs supporting the weight of the vehicle when the fasteners

are torqued. If springs are not at their normal ride position, vehicle ride comfort could be affected and pre-

mature bushing wear may occur.

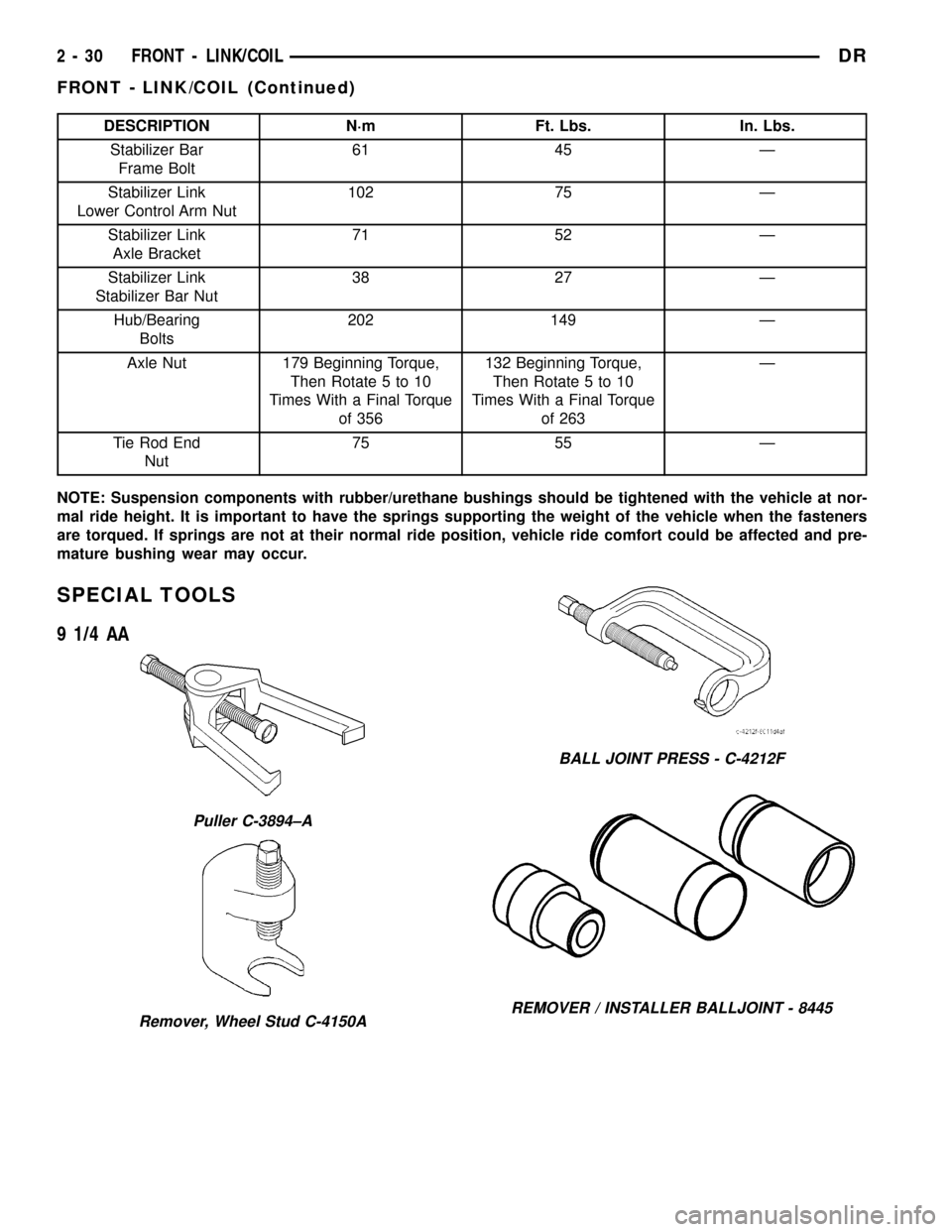

SPECIAL TOOLS

9 1/4 AA

Puller C-3894±A

Remover, Wheel Stud C-4150A

BALL JOINT PRESS - C-4212F

REMOVER / INSTALLER BALLJOINT - 8445

2 - 30 FRONT - LINK/COILDR

FRONT - LINK/COIL (Continued)

Page 66 of 2627

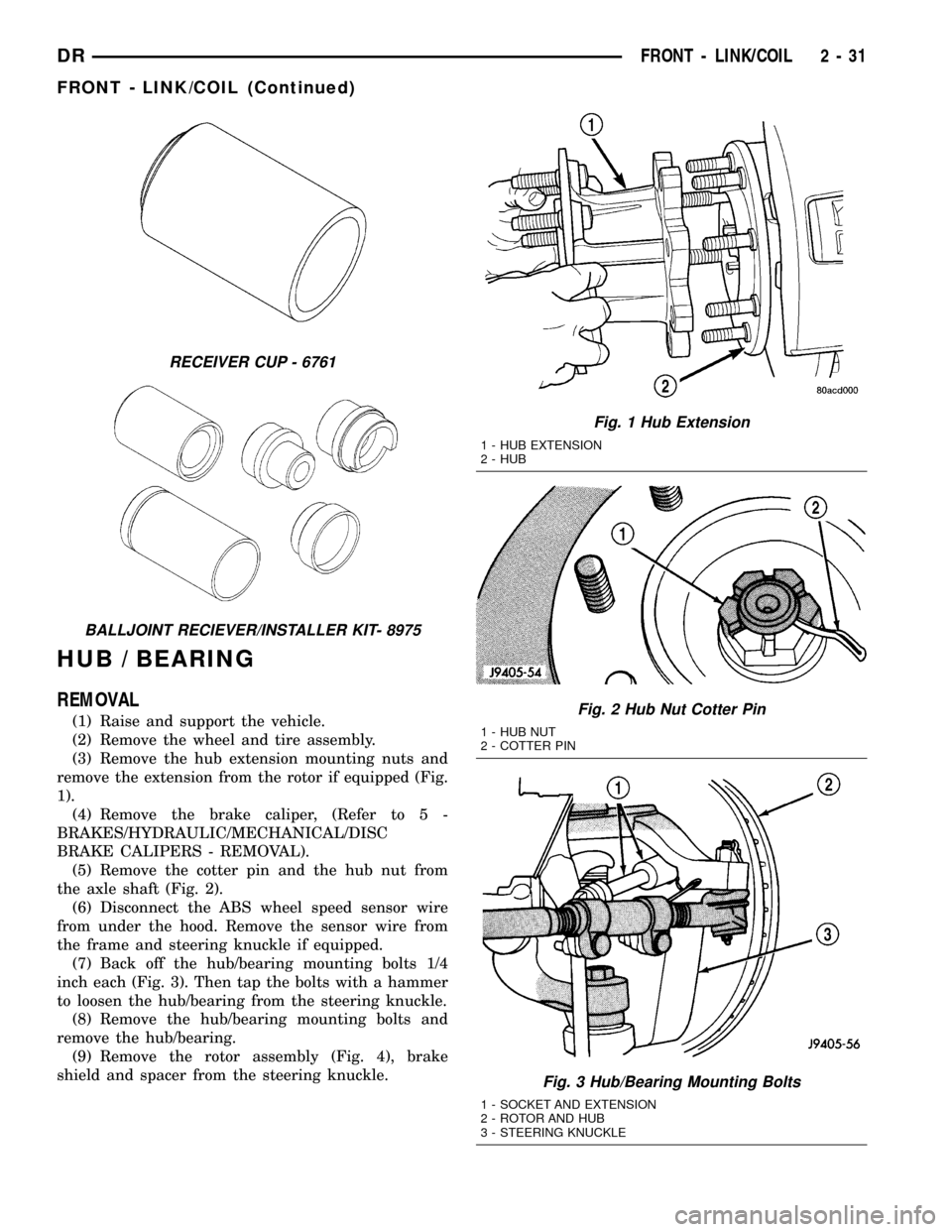

HUB / BEARING

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the hub extension mounting nuts and

remove the extension from the rotor if equipped (Fig.

1).

(4) Remove the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(5) Remove the cotter pin and the hub nut from

the axle shaft (Fig. 2).

(6) Disconnect the ABS wheel speed sensor wire

from under the hood. Remove the sensor wire from

the frame and steering knuckle if equipped.

(7) Back off the hub/bearing mounting bolts 1/4

inch each (Fig. 3). Then tap the bolts with a hammer

to loosen the hub/bearing from the steering knuckle.

(8) Remove the hub/bearing mounting bolts and

remove the hub/bearing.

(9) Remove the rotor assembly (Fig. 4), brake

shield and spacer from the steering knuckle.

RECEIVER CUP - 6761

BALLJOINT RECIEVER/INSTALLER KIT- 8975

Fig. 1 Hub Extension

1 - HUB EXTENSION

2 - HUB

Fig. 2 Hub Nut Cotter Pin

1 - HUB NUT

2 - COTTER PIN

Fig. 3 Hub/Bearing Mounting Bolts

1 - SOCKET AND EXTENSION

2 - ROTOR AND HUB

3 - STEERING KNUCKLE

DRFRONT - LINK/COIL 2 - 31

FRONT - LINK/COIL (Continued)

Page 69 of 2627

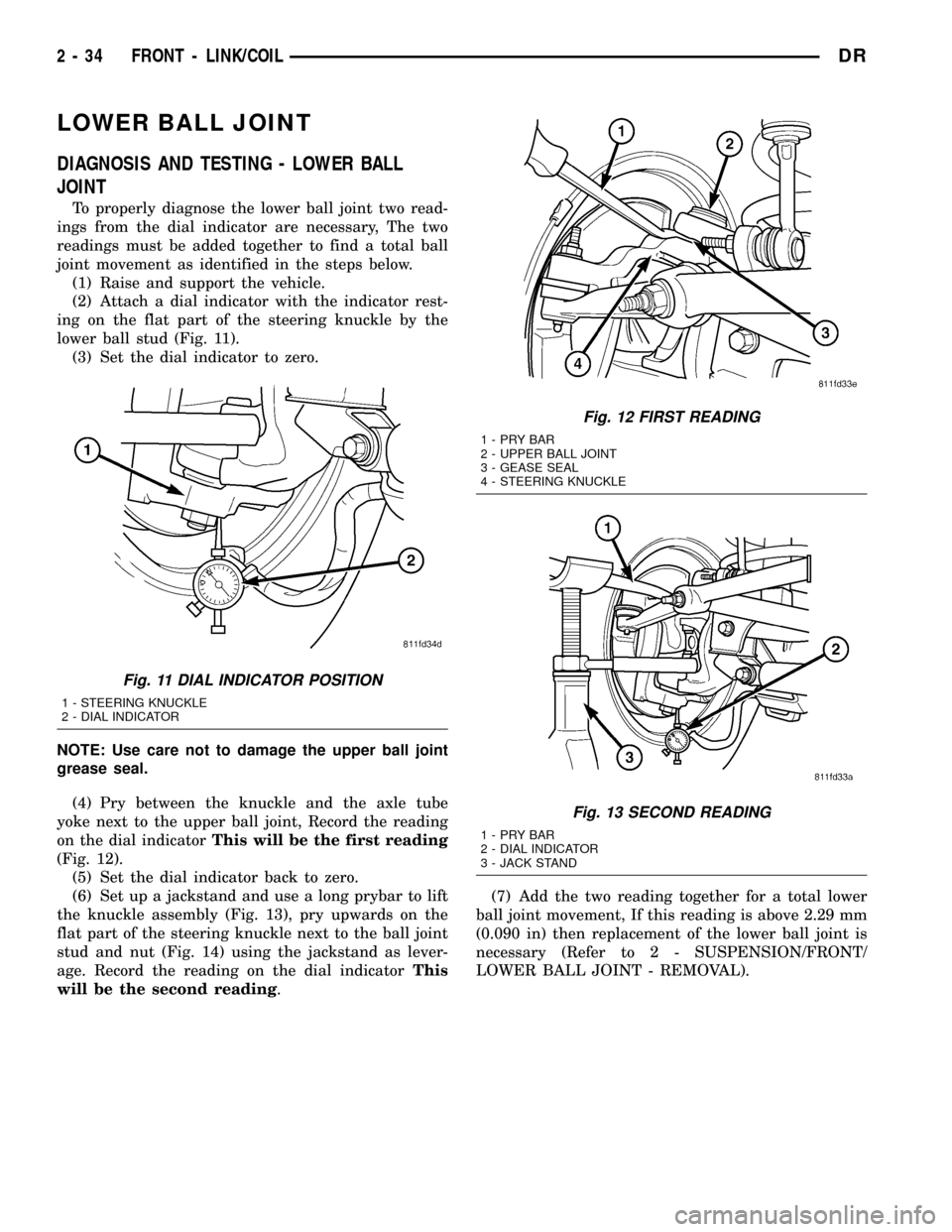

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT

To properly diagnose the lower ball joint two read-

ings from the dial indicator are necessary, The two

readings must be added together to find a total ball

joint movement as identified in the steps below.

(1) Raise and support the vehicle.

(2) Attach a dial indicator with the indicator rest-

ing on the flat part of the steering knuckle by the

lower ball stud (Fig. 11).

(3) Set the dial indicator to zero.

NOTE: Use care not to damage the upper ball joint

grease seal.

(4) Pry between the knuckle and the axle tube

yoke next to the upper ball joint, Record the reading

on the dial indicatorThis will be the first reading

(Fig. 12).

(5) Set the dial indicator back to zero.

(6) Set up a jackstand and use a long prybar to lift

the knuckle assembly (Fig. 13), pry upwards on the

flat part of the steering knuckle next to the ball joint

stud and nut (Fig. 14) using the jackstand as lever-

age. Record the reading on the dial indicatorThis

will be the second reading.(7) Add the two reading together for a total lower

ball joint movement, If this reading is above 2.29 mm

(0.090 in) then replacement of the lower ball joint is

necessary (Refer to 2 - SUSPENSION/FRONT/

LOWER BALL JOINT - REMOVAL).

Fig. 11 DIAL INDICATOR POSITION

1 - STEERING KNUCKLE

2 - DIAL INDICATOR

Fig. 12 FIRST READING

1-PRYBAR

2 - UPPER BALL JOINT

3 - GEASE SEAL

4 - STEERING KNUCKLE

Fig. 13 SECOND READING

1-PRYBAR

2 - DIAL INDICATOR

3 - JACK STAND

2 - 34 FRONT - LINK/COILDR

Page 70 of 2627

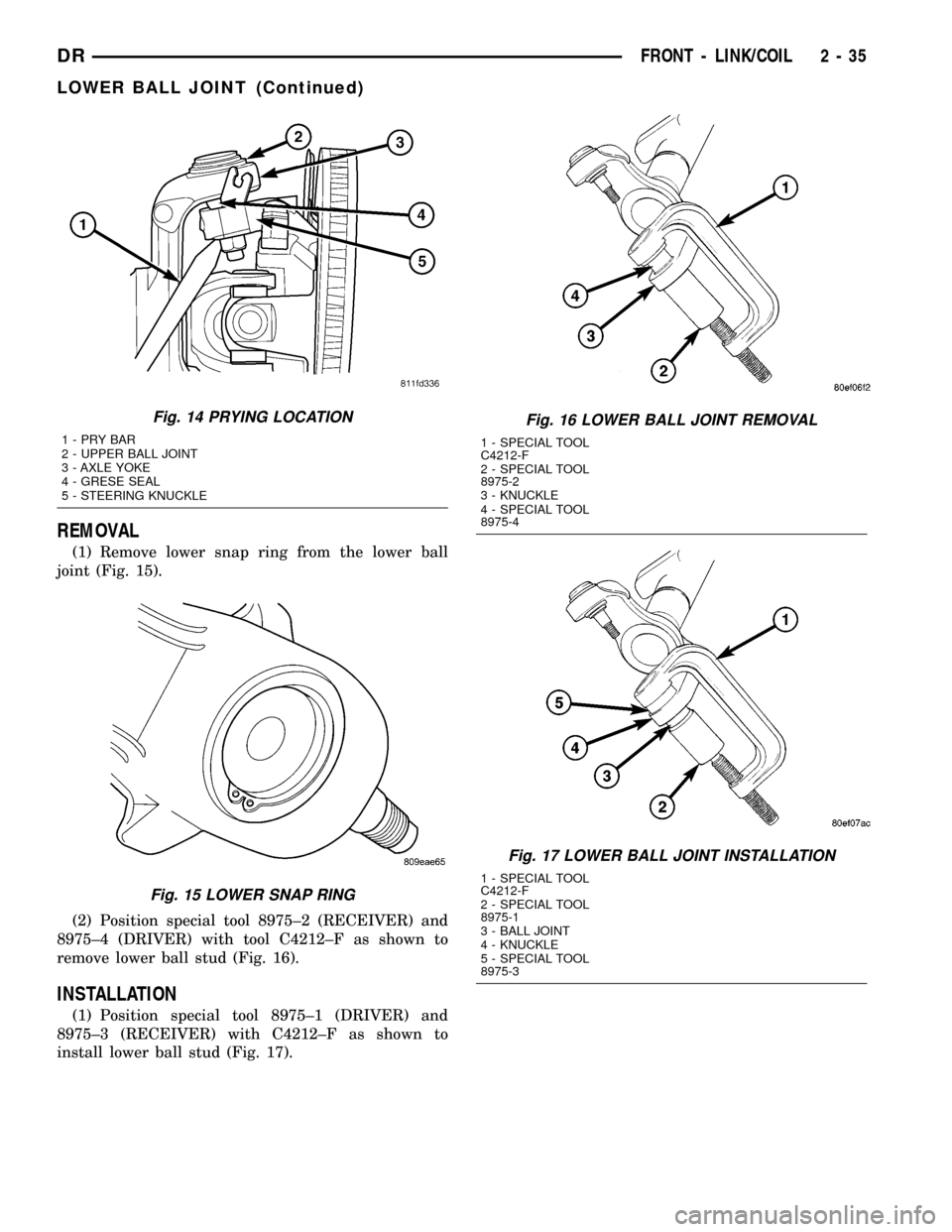

REMOVAL

(1) Remove lower snap ring from the lower ball

joint (Fig. 15).

(2) Position special tool 8975±2 (RECEIVER) and

8975±4 (DRIVER) with tool C4212±F as shown to

remove lower ball stud (Fig. 16).

INSTALLATION

(1) Position special tool 8975±1 (DRIVER) and

8975±3 (RECEIVER) with C4212±F as shown to

install lower ball stud (Fig. 17).

Fig. 14 PRYING LOCATION

1-PRYBAR

2 - UPPER BALL JOINT

3 - AXLE YOKE

4 - GRESE SEAL

5 - STEERING KNUCKLE

Fig. 15 LOWER SNAP RING

Fig. 16 LOWER BALL JOINT REMOVAL

1 - SPECIAL TOOL

C4212-F

2 - SPECIAL TOOL

8975-2

3 - KNUCKLE

4 - SPECIAL TOOL

8975-4

Fig. 17 LOWER BALL JOINT INSTALLATION

1 - SPECIAL TOOL

C4212-F

2 - SPECIAL TOOL

8975-1

3 - BALL JOINT

4 - KNUCKLE

5 - SPECIAL TOOL

8975-3

DRFRONT - LINK/COIL 2 - 35

LOWER BALL JOINT (Continued)

Page 71 of 2627

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

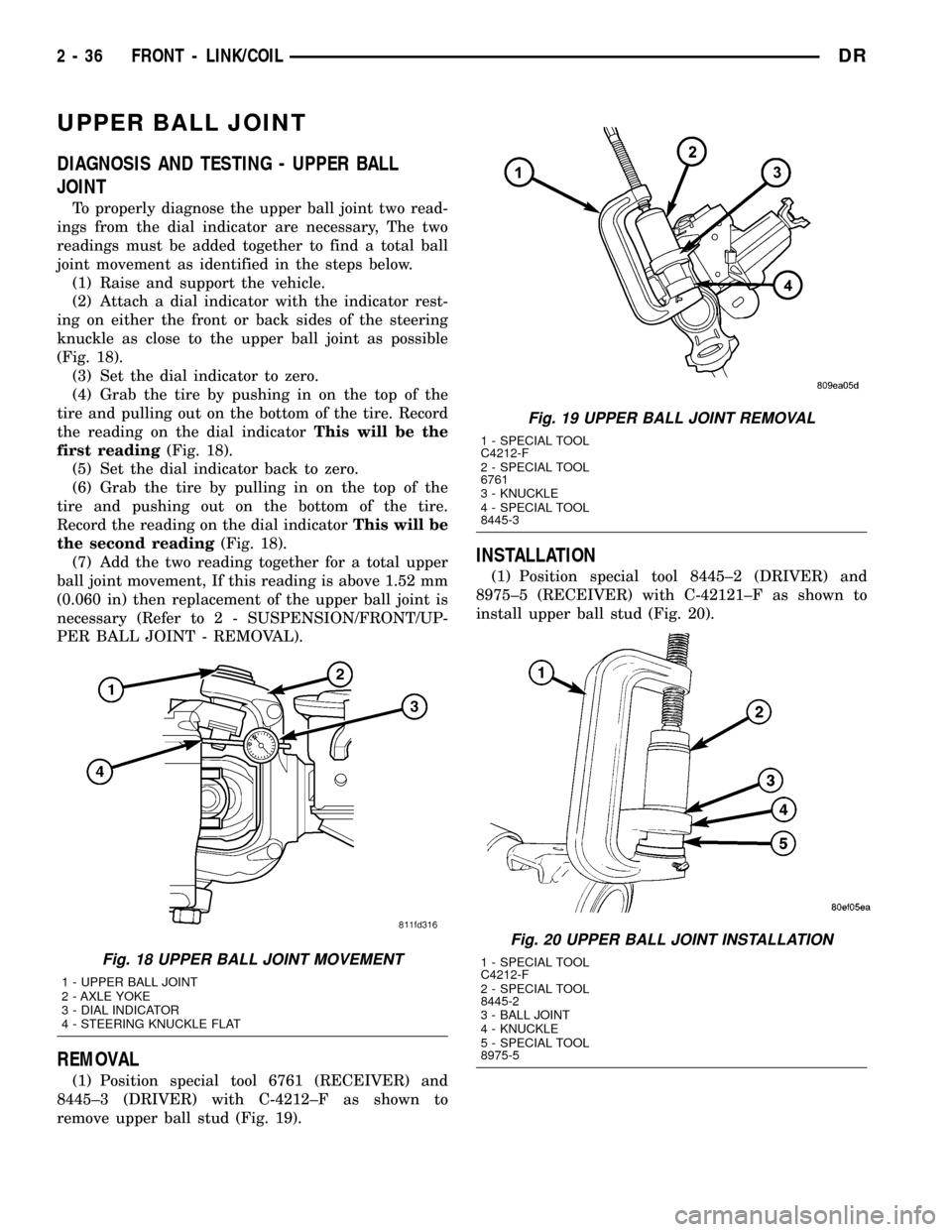

To properly diagnose the upper ball joint two read-

ings from the dial indicator are necessary, The two

readings must be added together to find a total ball

joint movement as identified in the steps below.

(1) Raise and support the vehicle.

(2) Attach a dial indicator with the indicator rest-

ing on either the front or back sides of the steering

knuckle as close to the upper ball joint as possible

(Fig. 18).

(3) Set the dial indicator to zero.

(4) Grab the tire by pushing in on the top of the

tire and pulling out on the bottom of the tire. Record

the reading on the dial indicatorThis will be the

first reading(Fig. 18).

(5) Set the dial indicator back to zero.

(6) Grab the tire by pulling in on the top of the

tire and pushing out on the bottom of the tire.

Record the reading on the dial indicatorThis will be

the second reading(Fig. 18).

(7) Add the two reading together for a total upper

ball joint movement, If this reading is above 1.52 mm

(0.060 in) then replacement of the upper ball joint is

necessary (Refer to 2 - SUSPENSION/FRONT/UP-

PER BALL JOINT - REMOVAL).

REMOVAL

(1) Position special tool 6761 (RECEIVER) and

8445±3 (DRIVER) with C-4212±F as shown to

remove upper ball stud (Fig. 19).

INSTALLATION

(1) Position special tool 8445±2 (DRIVER) and

8975±5 (RECEIVER) with C-42121±F as shown to

install upper ball stud (Fig. 20).

Fig. 18 UPPER BALL JOINT MOVEMENT

1 - UPPER BALL JOINT

2 - AXLE YOKE

3 - DIAL INDICATOR

4 - STEERING KNUCKLE FLAT

Fig. 19 UPPER BALL JOINT REMOVAL

1 - SPECIAL TOOL

C4212-F

2 - SPECIAL TOOL

6761

3 - KNUCKLE

4 - SPECIAL TOOL

8445-3

Fig. 20 UPPER BALL JOINT INSTALLATION

1 - SPECIAL TOOL

C4212-F

2 - SPECIAL TOOL

8445-2

3 - BALL JOINT

4 - KNUCKLE

5 - SPECIAL TOOL

8975-5

2 - 36 FRONT - LINK/COILDR

Page 101 of 2627

HALF SHAFT

TABLE OF CONTENTS

page page

HALF SHAFT

CAUTION.............................20

DIAGNOSIS AND TESTING................20

REMOVAL.............................20

INSTALLATION.........................21

SPECIFICATIONS.......................21

SPECIAL TOOLS.......................21CV JOINT-OUTER

REMOVAL.............................22

INSTALLATION.........................23

CV JOINT-INNER

REMOVAL.............................25

INSTALLATION.........................25

HALF SHAFT

CAUTION

CAUTION:: Never grasp half shaft assembly by the

boots. This may cause the boot to pucker or crease

and reduce the service life of the boot.

Avoid over angulating or stroking the C/V joints

when handling the half shaft.

Half shafts exposed to battery acid, transmission

fluid, brake fluid, differential fluid or gasoline may

cause the boots to deteriorate. Failure to heed cau-

tion may result in damage.

DIAGNOSIS AND TESTING

Check inboard and outboard C/V joint for leaking

grease. This is a sign of boot or boot clamp damage.

NOISE/VIBRATION IN TURNS

A clicking noise or vibration in turns could be

caused by a damaged outer C/V or inner tripod joint

seal boot or seal boot clamps. This will result in the

loss/contamination of the joint grease, resulting in

inadequate lubrication of the joint. Noise could also

be caused by another component of the vehicle com-

ing in contact with the half shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a damaged or worn C/V joint. A

torn boot or loose/missing clamp on the inner/outer

joint which has allowed the grease to be lost will

damage the C/V joint.

SHUDDER/VIBRATION DURING ACCELERATION

This could be a worn/damaged inner tripod joint or

a sticking tripod joint. Improper wheel alignment

may also cause a shudder or vibration.

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of out of balance

front tires or tire/wheel runout. Foreign material

(mud, etc.) packed on the backside of the wheel(s)

will also cause a vibration.

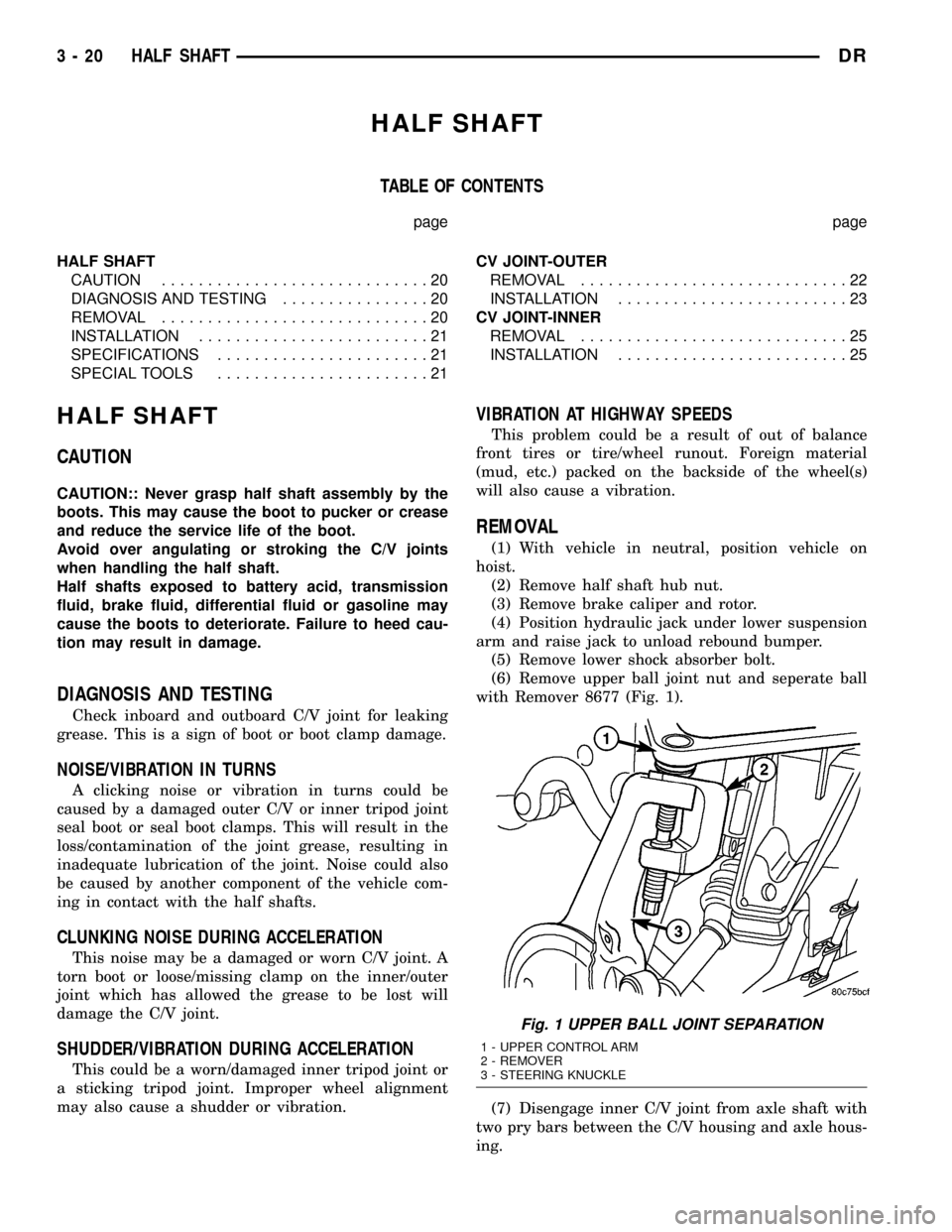

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove half shaft hub nut.

(3) Remove brake caliper and rotor.

(4) Position hydraulic jack under lower suspension

arm and raise jack to unload rebound bumper.

(5) Remove lower shock absorber bolt.

(6) Remove upper ball joint nut and seperate ball

with Remover 8677 (Fig. 1).

(7) Disengage inner C/V joint from axle shaft with

two pry bars between the C/V housing and axle hous-

ing.

Fig. 1 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

3 - 20 HALF SHAFTDR